pan TOYOTA RAV4 2006 Service Owner's Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 391 of 2000

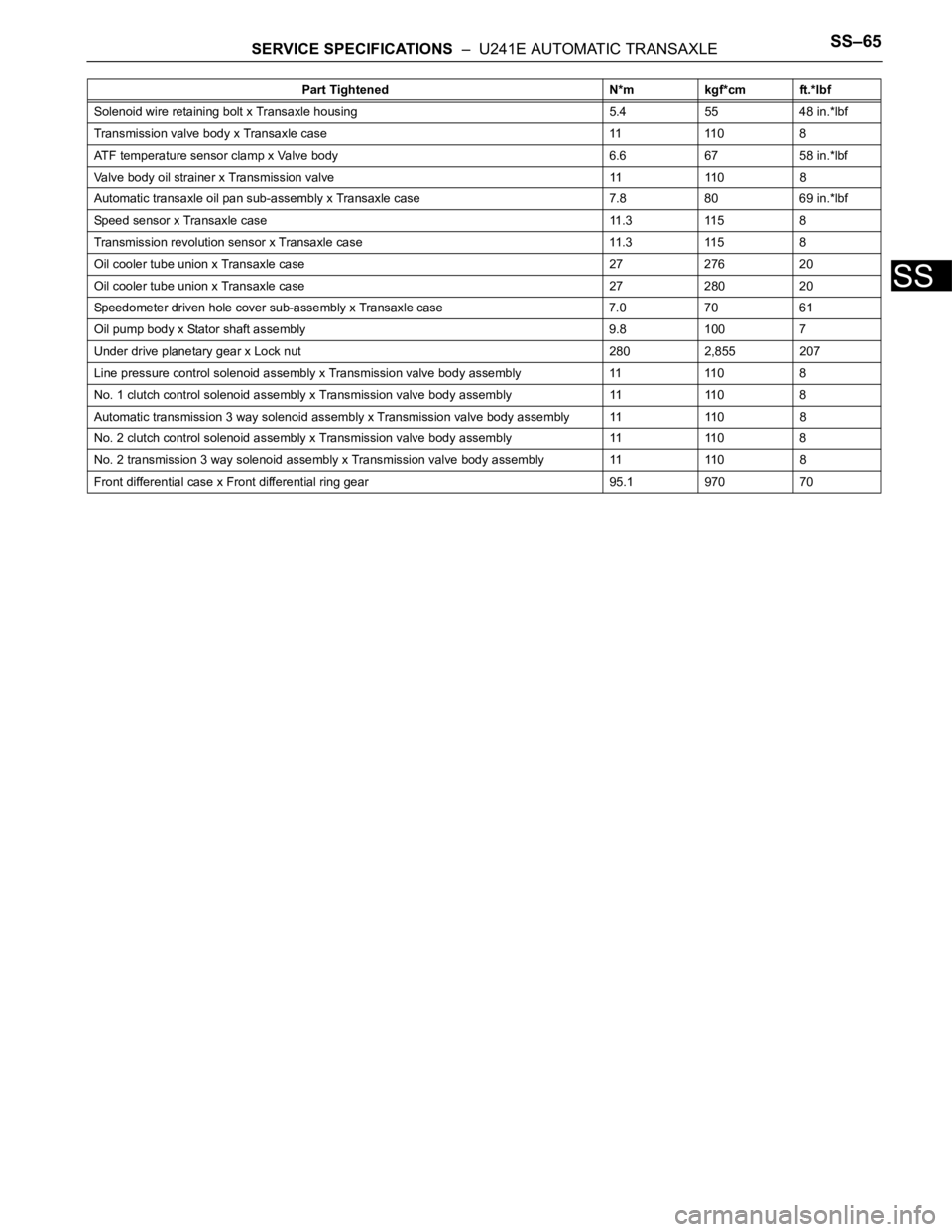

SERVICE SPECIFICATIONS – U241E AUTOMATIC TRANSAXLESS–65

SS

Solenoid wire retaining bolt x Transaxle housing 5.4 55 48 in.*lbf

Transmission valve body x Transaxle case 11 110 8

ATF temperature sensor clamp x Valve body 6.6 67 58 in.*lbf

Valve body oil strainer x Transmission valve 11 110 8

Automatic transaxle oil pan sub-assembly x Transaxle case 7.8 80 69 in.*lbf

Speed sensor x Transaxle case 11.3 115 8

Transmission revolution sensor x Transaxle case 11.3 115 8

Oil cooler tube union x Transaxle case 27 276 20

Oil cooler tube union x Transaxle case 27 280 20

Speedometer driven hole cover sub-assembly x Transaxle case 7.0 7061

Oil pump body x Stator shaft assembly 9.8 100 7

Under drive planetary gear x Lock nut 280 2,855 207

Line pressure control solenoid assembly x Transmission valve body assembly 11 110 8

No. 1 clutch control solenoid assembly x Transmission valve body assembly 11 110 8

Automatic transmission 3 way solenoid assembly x Transmission valve body assembly 11 110 8

No. 2 clutch control solenoid assembly x Transmission valve body assembly 11 110 8

No. 2 transmission 3 way solenoid assembly x Transmission valve body assembly 11 110 8

Front differential case x Front differential ring gear 95.1 970 70Part Tightened N*m kgf*cm ft.*lbf

Page 395 of 2000

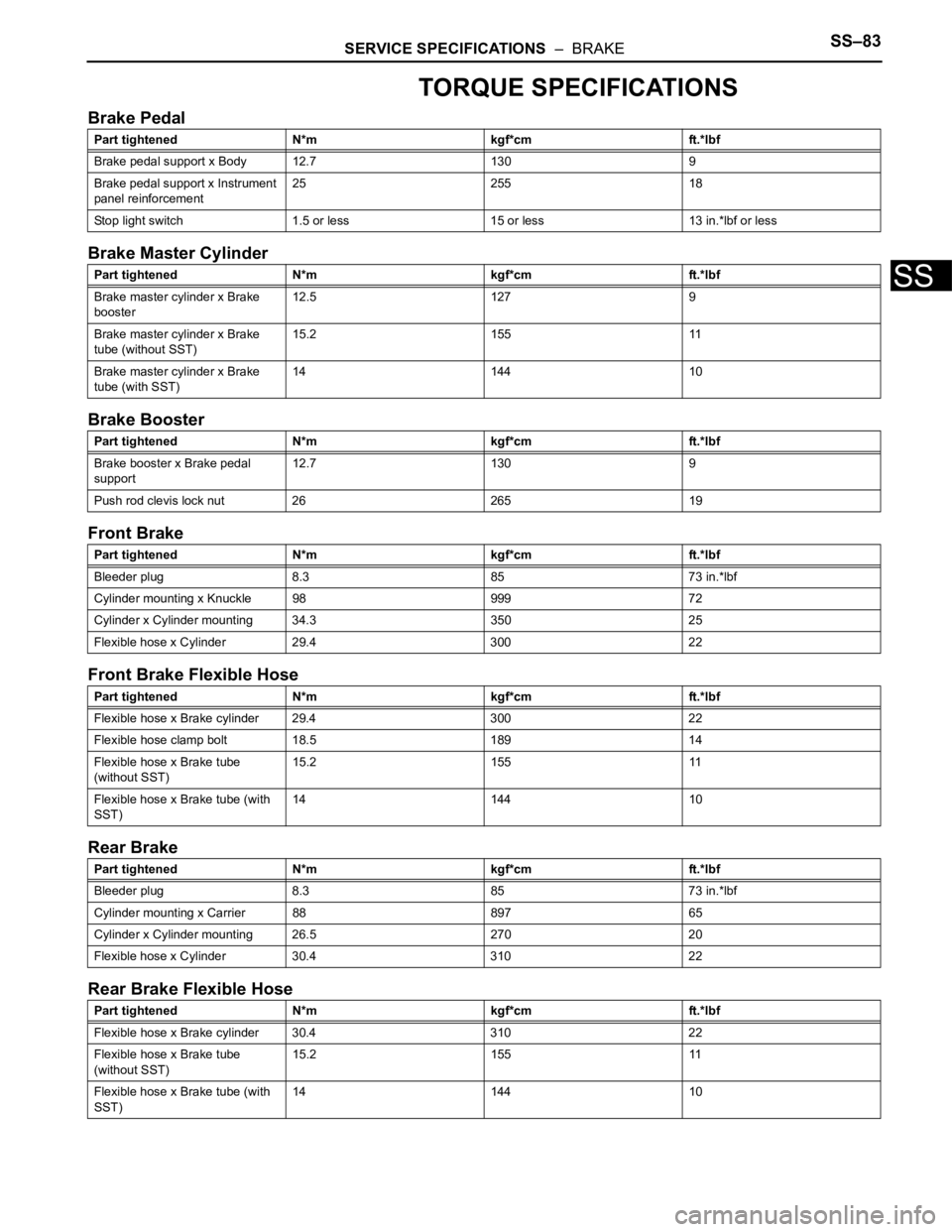

SERVICE SPECIFICATIONS – BRAKESS–83

SS

TORQUE SPECIFICATIONS

Brake Pedal

Brake Master Cylinder

Brake Booster

Front Brake

Front Brake Flexible Hose

Rear Brake

Rear Brake Flexible Hose

Part tightened N*m kgf*cm ft.*lbf

Brake pedal support x Body 12.7 130 9

Brake pedal support x Instrument

panel reinforcement25 255 18

Stop light switch 1.5 or less 15 or less 13 in.*lbf or less

Part tightened N*m kgf*cm ft.*lbf

Brake master cylinder x Brake

booster12.5 127 9

Brake master cylinder x Brake

tube (without SST)15.2 155 11

Brake master cylinder x Brake

tube (with SST)14 144 10

Part tightened N*m kgf*cm ft.*lbf

Brake booster x Brake pedal

support12.7 130 9

Push rod clevis lock nut 26 265 19

Part tightened N*m kgf*cm ft.*lbf

Bleeder plug 8.3 85 73 in.*lbf

Cylinder mounting x Knuckle 98 999 72

Cylinder x Cylinder mounting 34.3 350 25

Flexible hose x Cylinder 29.4 300 22

Part tightened N*m kgf*cm ft.*lbf

Flexible hose x Brake cylinder 29.4 300 22

Flexible hose clamp bolt 18.5 189 14

Flexible hose x Brake tube

(without SST)15.2 155 11

Flexible hose x Brake tube (with

SST)14 144 10

Part tightened N*m kgf*cm ft.*lbf

Bleeder plug 8.3 85 73 in.*lbf

Cylinder mounting x Carrier 88 897 65

Cylinder x Cylinder mounting 26.5 270 20

Flexible hose x Cylinder 30.4 310 22

Part tightened N*m kgf*cm ft.*lbf

Flexible hose x Brake cylinder 30.4 310 22

Flexible hose x Brake tube

(without SST)15.2 155 11

Flexible hose x Brake tube (with

SST)14 144 10

Page 417 of 2000

PARKING BRAKE – PARKING BRAKE LEVERPB–5

PB

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

2. REMOVE REAR CONSOLE BOX SUB-ASSEMBLY

(a) Remove the rear console box (see page IP-16).

HINT:

Refer to the procedures from the removal of the No.

1 console upper panel garnish up until the removal

of the rear console box sub-assembly.

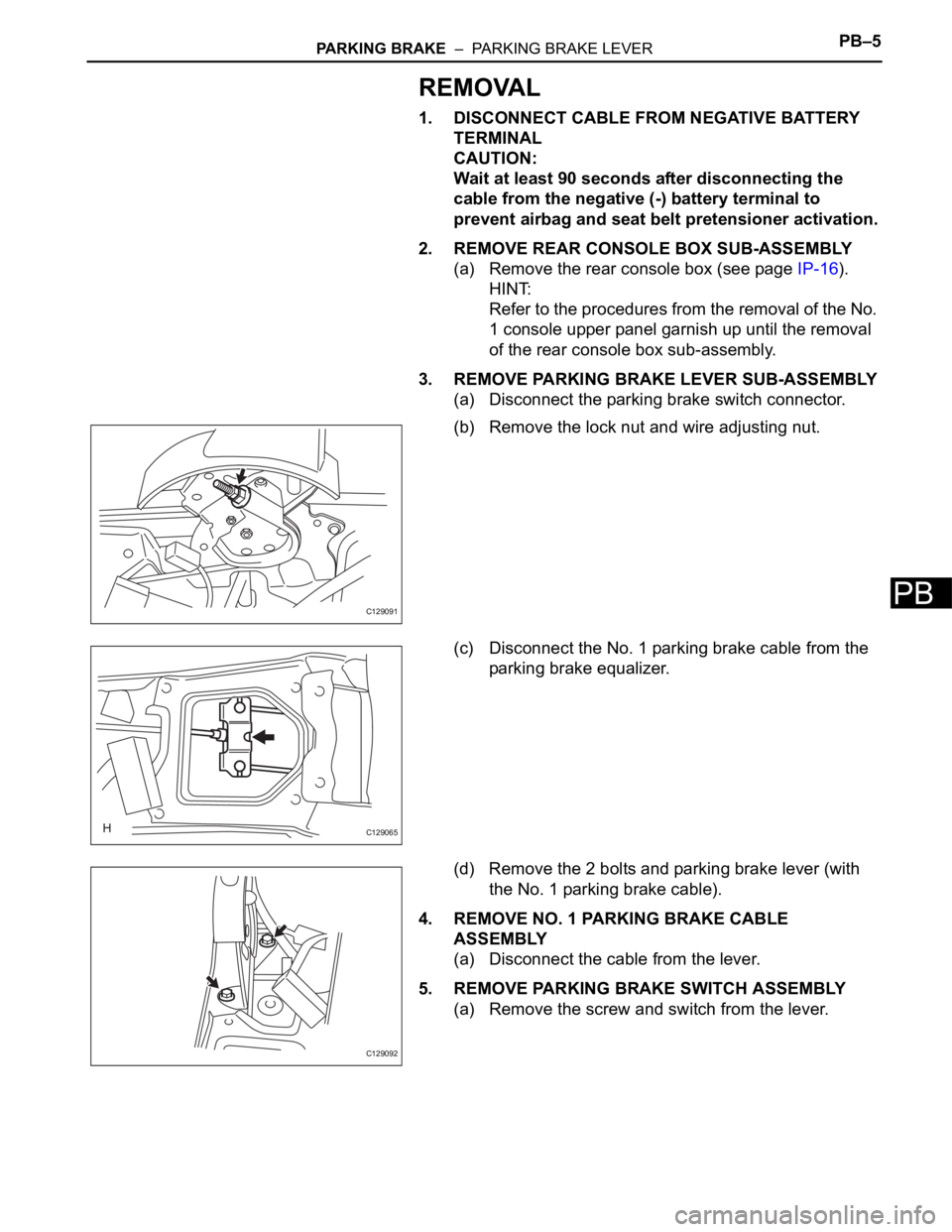

3. REMOVE PARKING BRAKE LEVER SUB-ASSEMBLY

(a) Disconnect the parking brake switch connector.

(b) Remove the lock nut and wire adjusting nut.

(c) Disconnect the No. 1 parking brake cable from the

parking brake equalizer.

(d) Remove the 2 bolts and parking brake lever (with

the No. 1 parking brake cable).

4. REMOVE NO. 1 PARKING BRAKE CABLE

ASSEMBLY

(a) Disconnect the cable from the lever.

5. REMOVE PARKING BRAKE SWITCH ASSEMBLY

(a) Remove the screw and switch from the lever.

C129091

C129065

C129092

Page 418 of 2000

PB–6PARKING BRAKE – PARKING BRAKE LEVER

PB

INSTALLATION

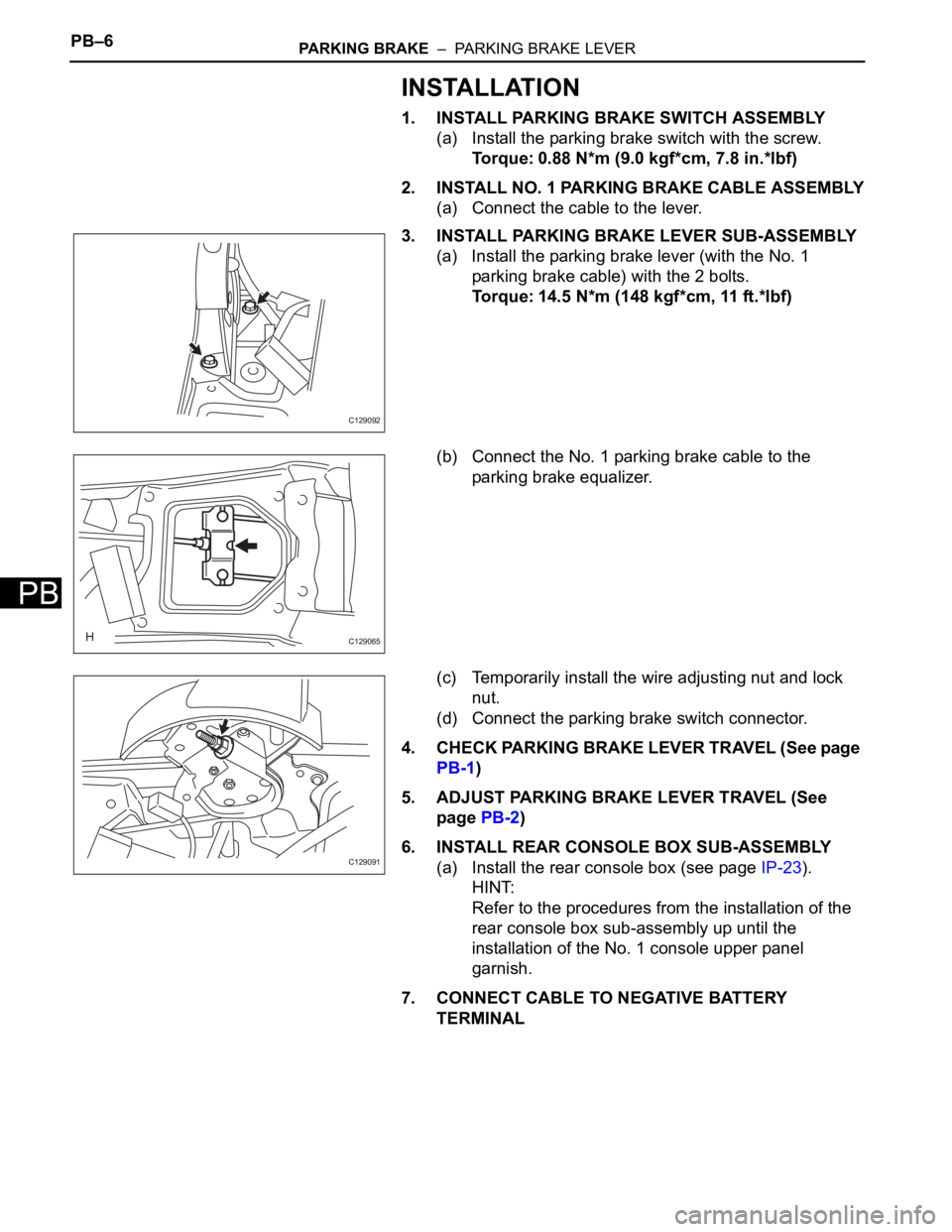

1. INSTALL PARKING BRAKE SWITCH ASSEMBLY

(a) Install the parking brake switch with the screw.

Torque: 0.88 N*m (9.0 kgf*cm, 7.8 in.*lbf)

2. INSTALL NO. 1 PARKING BRAKE CABLE ASSEMBLY

(a) Connect the cable to the lever.

3. INSTALL PARKING BRAKE LEVER SUB-ASSEMBLY

(a) Install the parking brake lever (with the No. 1

parking brake cable) with the 2 bolts.

Torque: 14.5 N*m (148 kgf*cm, 11 ft.*lbf)

(b) Connect the No. 1 parking brake cable to the

parking brake equalizer.

(c) Temporarily install the wire adjusting nut and lock

nut.

(d) Connect the parking brake switch connector.

4. CHECK PARKING BRAKE LEVER TRAVEL (See page

PB-1)

5. ADJUST PARKING BRAKE LEVER TRAVEL (See

page PB-2)

6. INSTALL REAR CONSOLE BOX SUB-ASSEMBLY

(a) Install the rear console box (see page IP-23).

HINT:

Refer to the procedures from the installation of the

rear console box sub-assembly up until the

installation of the No. 1 console upper panel

garnish.

7. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

C129092

C129065

C129091

Page 430 of 2000

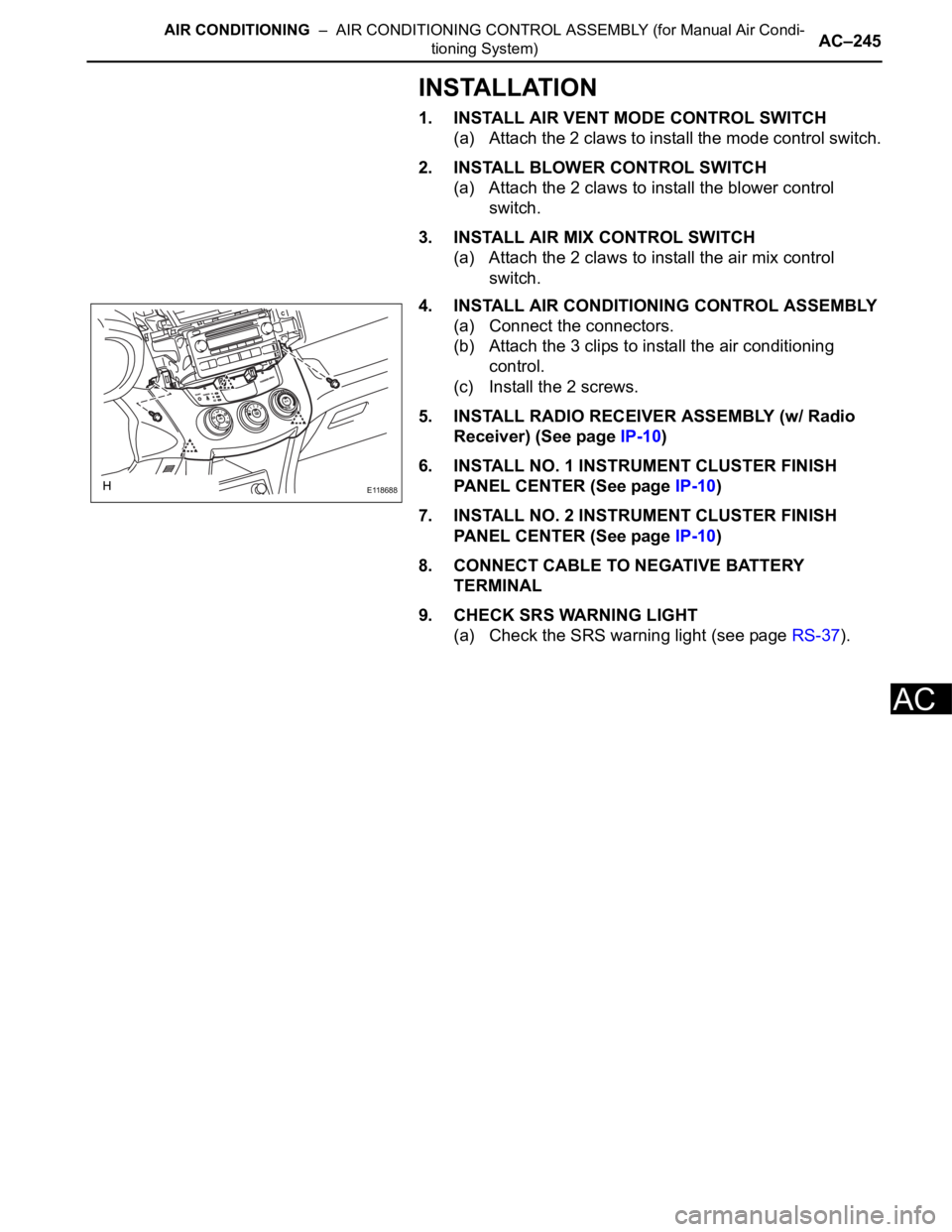

AIR CONDITIONING – AIR CONDITIONING CONTROL ASSEMBLY (for Manual Air Condi-

tioning System)AC–245

AC

INSTALLATION

1. INSTALL AIR VENT MODE CONTROL SWITCH

(a) Attach the 2 claws to install the mode control switch.

2. INSTALL BLOWER CONTROL SWITCH

(a) Attach the 2 claws to install the blower control

switch.

3. INSTALL AIR MIX CONTROL SWITCH

(a) Attach the 2 claws to install the air mix control

switch.

4. INSTALL AIR CONDITIONING CONTROL ASSEMBLY

(a) Connect the connectors.

(b) Attach the 3 clips to install the air conditioning

control.

(c) Install the 2 screws.

5. INSTALL RADIO RECEIVER ASSEMBLY (w/ Radio

Receiver) (See page IP-10)

6. INSTALL NO. 1 INSTRUMENT CLUSTER FINISH

PANEL CENTER (See page IP-10)

7. INSTALL NO. 2 INSTRUMENT CLUSTER FINISH

PANEL CENTER (See page IP-10)

8. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

9. CHECK SRS WARNING LIGHT

(a) Check the SRS warning light (see page RS-37).

E118688

Page 436 of 2000

SEAT BELT – SEAT BELT WARNING SYSTEMSB–3

SB

SYSTEM DESCRIPTION

1. DRIVER SEAT BELT WARNING LIGHT

(a) When the driver seat belt is not fastened with the

ignition switch ON, the driver seat belt warning light

on the combination meter comes on to inform the

driver. The center airbag sensor detects the driver

seat belt status and sends signals to the

combination meter through the CAN bus line.

2. PASSENGER SEAT BELT WARNING LIGHT

(a) for Automatic air conditioning system:

When the passenger seat belt is not fastened with

the ignition switch ON and the passenger seat

occupied, check that the passenger seat belt

warning light on the heater control panel display

blinks. The combination meter detects the

passenger seat belt status and whether the

passenger seat is occupied.

(b) for Manual air conditioning system:

When the passenger seat belt is not fastened with

the ignition switch ON and the passenger seat

occupied, check that the passenger seat belt

warning light on the clock panel blinks. The

combination meter detects the passenger seat belt

status and whether the passenger seat is occupied.

Page 437 of 2000

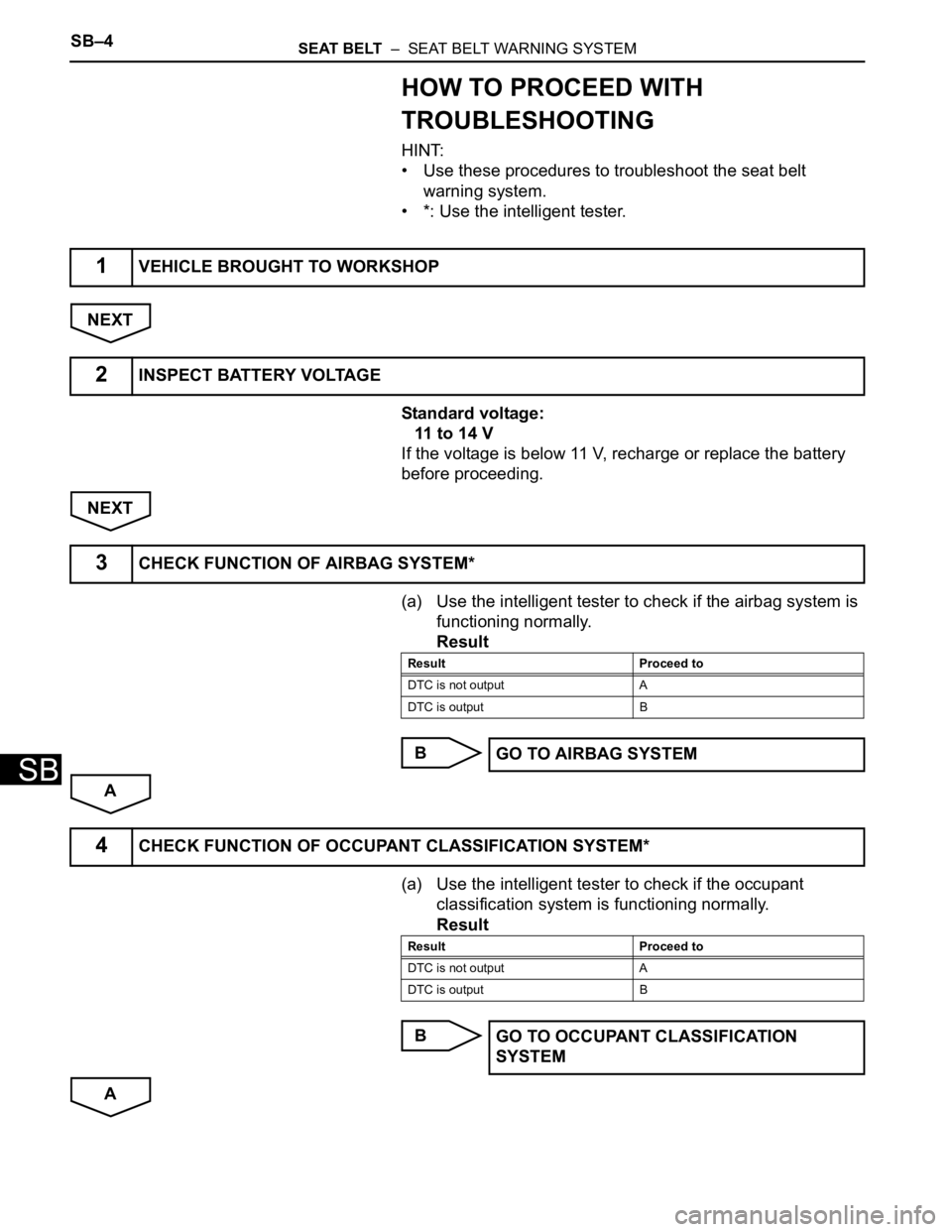

SB–4SEAT BELT – SEAT BELT WARNING SYSTEM

SB

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

• Use these procedures to troubleshoot the seat belt

warning system.

• *: Use the intelligent tester.

NEXT

Standard voltage:

11 to 14 V

If the voltage is below 11 V, recharge or replace the battery

before proceeding.

NEXT

(a) Use the intelligent tester to check if the airbag system is

functioning normally.

Result

B

A

(a) Use the intelligent tester to check if the occupant

classification system is functioning normally.

Result

B

A

1VEHICLE BROUGHT TO WORKSHOP

2INSPECT BATTERY VOLTAGE

3CHECK FUNCTION OF AIRBAG SYSTEM*

Result Proceed to

DTC is not output A

DTC is output B

GO TO AIRBAG SYSTEM

4CHECK FUNCTION OF OCCUPANT CLASSIFICATION SYSTEM*

Result Proceed to

DTC is not output A

DTC is output B

GO TO OCCUPANT CLASSIFICATION

SYSTEM

Page 457 of 2000

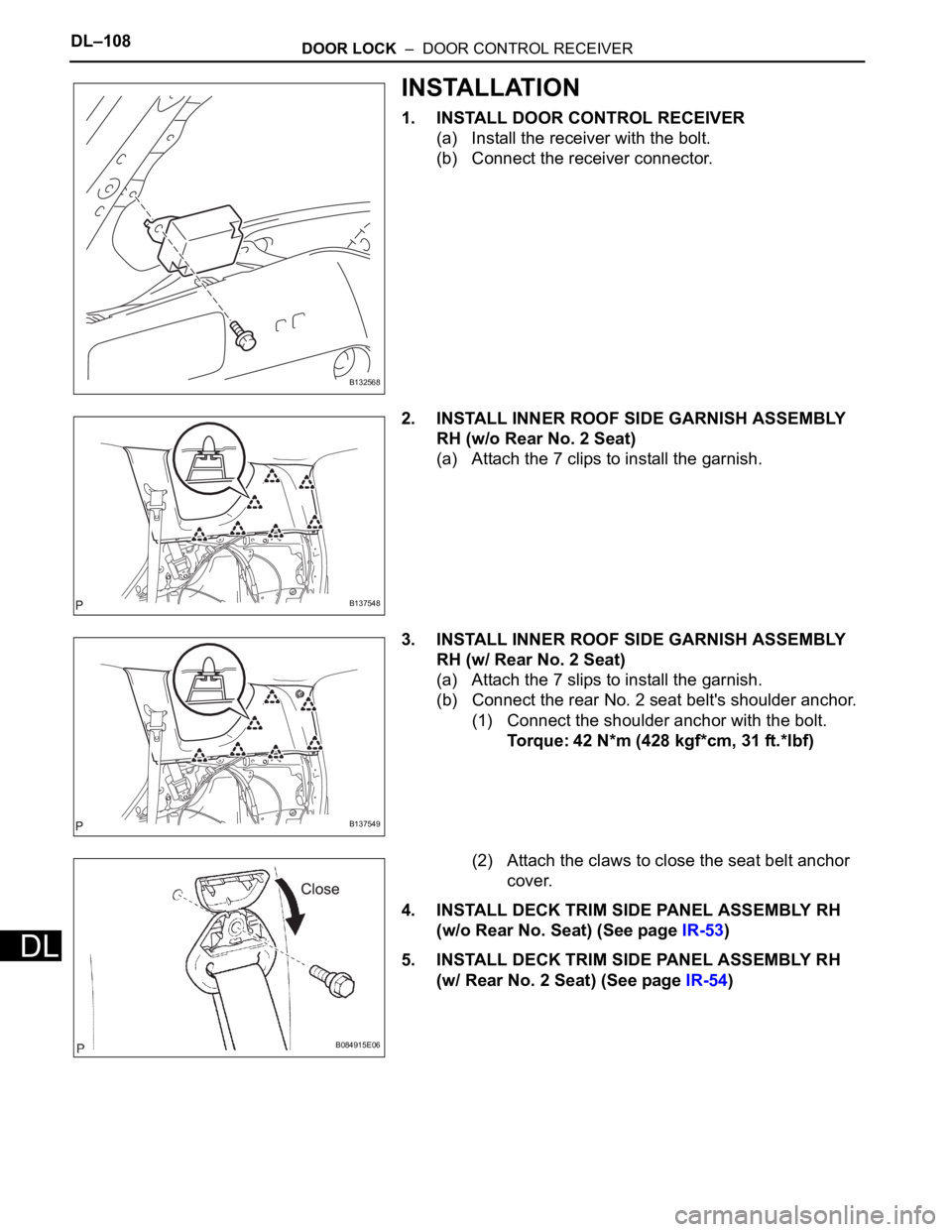

DL–108DOOR LOCK – DOOR CONTROL RECEIVER

DL

INSTALLATION

1. INSTALL DOOR CONTROL RECEIVER

(a) Install the receiver with the bolt.

(b) Connect the receiver connector.

2. INSTALL INNER ROOF SIDE GARNISH ASSEMBLY

RH (w/o Rear No. 2 Seat)

(a) Attach the 7 clips to install the garnish.

3. INSTALL INNER ROOF SIDE GARNISH ASSEMBLY

RH (w/ Rear No. 2 Seat)

(a) Attach the 7 slips to install the garnish.

(b) Connect the rear No. 2 seat belt's shoulder anchor.

(1) Connect the shoulder anchor with the bolt.

Torque: 42 N*m (428 kgf*cm, 31 ft.*lbf)

(2) Attach the claws to close the seat belt anchor

cover.

4. INSTALL DECK TRIM SIDE PANEL ASSEMBLY RH

(w/o Rear No. Seat) (See page IR-53)

5. INSTALL DECK TRIM SIDE PANEL ASSEMBLY RH

(w/ Rear No. 2 Seat) (See page IR-54)

B132568

B137548

B137549

B084915E06

Page 492 of 2000

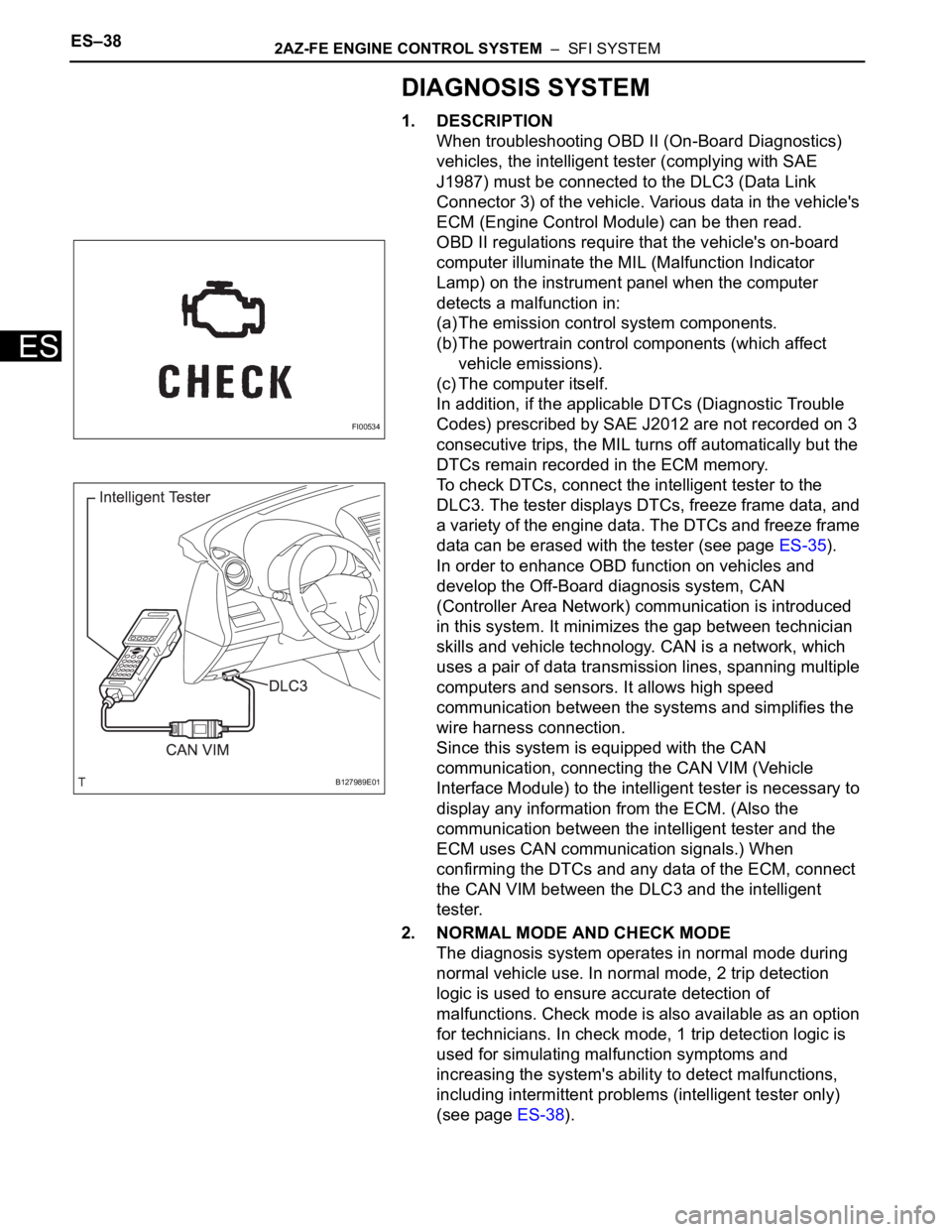

ES–382AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

DIAGNOSIS SYSTEM

1. DESCRIPTION

When troubleshooting OBD II (On-Board Diagnostics)

vehicles, the intelligent tester (complying with SAE

J1987) must be connected to the DLC3 (Data Link

Connector 3) of the vehicle. Various data in the vehicle's

ECM (Engine Control Module) can be then read.

OBD II regulations require that the vehicle's on-board

computer illuminate the MIL (Malfunction Indicator

Lamp) on the instrument panel when the computer

detects a malfunction in:

(a) The emission control system components.

(b) The powertrain control components (which affect

vehicle emissions).

(c) The computer itself.

In addition, if the applicable DTCs (Diagnostic Trouble

Codes) prescribed by SAE J2012 are not recorded on 3

consecutive trips, the MIL turns off automatically but the

DTCs remain recorded in the ECM memory.

To check DTCs, connect the intelligent tester to the

DLC3. The tester displays DTCs, freeze frame data, and

a variety of the engine data. The DTCs and freeze frame

data can be erased with the tester (see page ES-35).

In order to enhance OBD function on vehicles and

develop the Off-Board diagnosis system, CAN

(Controller Area Network) communication is introduced

in this system. It minimizes the gap between technician

skills and vehicle technology. CAN is a network, which

uses a pair of data transmission lines, spanning multiple

computers and sensors. It allows high speed

communication between the systems and simplifies the

wire harness connection.

Since this system is equipped with the CAN

communication, connecting the CAN VIM (Vehicle

Interface Module) to the intelligent tester is necessary to

display any information from the ECM. (Also the

communication between the intelligent tester and the

ECM uses CAN communication signals.) When

confirming the DTCs and any data of the ECM, connect

the CAN VIM between the DLC3 and the intelligent

tester.

2. NORMAL MODE AND CHECK MODE

The diagnosis system operates in normal mode during

normal vehicle use. In normal mode, 2 trip detection

logic is used to ensure accurate detection of

malfunctions. Check mode is also available as an option

for technicians. In check mode, 1 trip detection logic is

used for simulating malfunction symptoms and

increasing the system's ability to detect malfunctions,

including intermittent problems (intelligent tester only)

(see page ES-38).

FI00534

B127989E01

Page 502 of 2000

OTHER SYSTEM – CENTER POWER OUTLET SOCKETOT–5

OT

INSTALLATION

1. INSTALL CENTER POWER OUTLET SOCKET

ASSEMBLY

(a) Align the protrusion on the backside of the socket

with the groove of the cover. Then push the socket

into the cover.

2. INSTALL UPPER REAR CONSOLE PANEL SUB-

ASSEMBLY (See page IP-27)

3. INSTALL UPPER CONSOLE PANEL SUB-ASSEMBLY

(See page IP-27)

4. INSTALL SHIFT LEVER KNOB SUB-ASSEMBLY

5. INSTALL NO. 2 CONSOLE UPPER PANEL GARNISH

(See page IP-28)

6. INSTALL NO. 1 CONSOLE UPPER PANEL GARNISH

(See page IP-28)

7. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

B110252