pan TOYOTA RAV4 2006 Service Manual PDF

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 985 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–191

AX

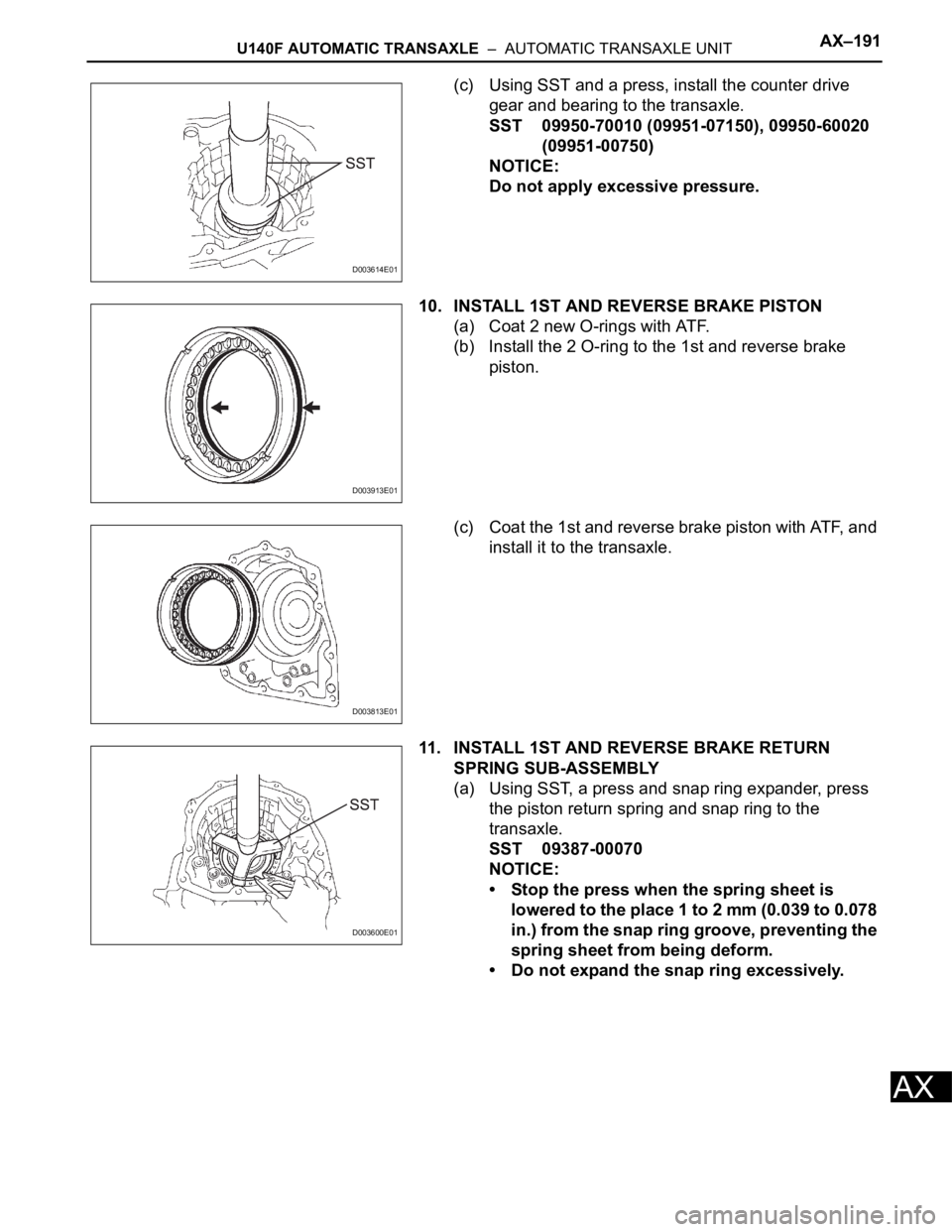

(c) Using SST and a press, install the counter drive

gear and bearing to the transaxle.

SST 09950-70010 (09951-07150), 09950-60020

(09951-00750)

NOTICE:

Do not apply excessive pressure.

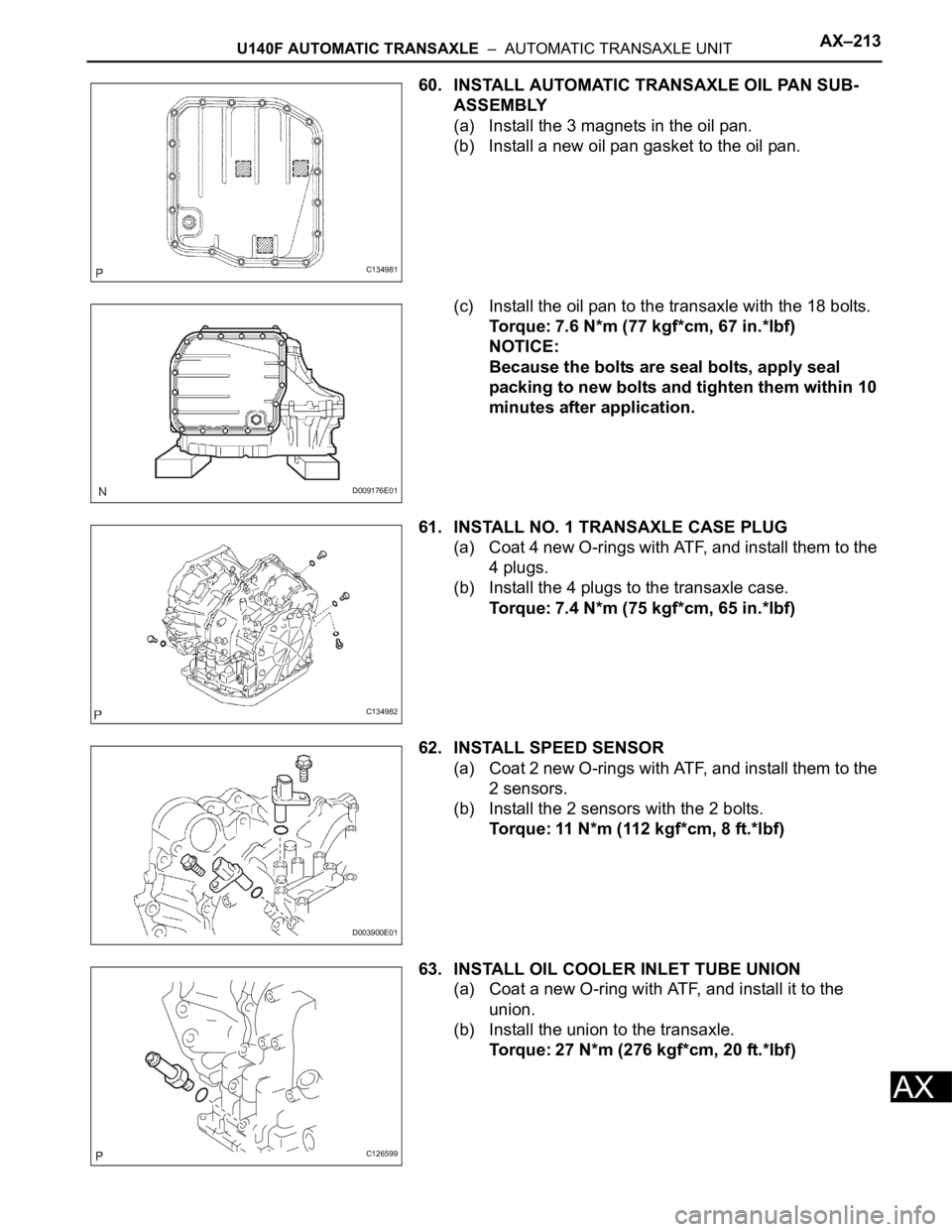

10. INSTALL 1ST AND REVERSE BRAKE PISTON

(a) Coat 2 new O-rings with ATF.

(b) Install the 2 O-ring to the 1st and reverse brake

piston.

(c) Coat the 1st and reverse brake piston with ATF, and

install it to the transaxle.

11. INSTALL 1ST AND REVERSE BRAKE RETURN

SPRING SUB-ASSEMBLY

(a) Using SST, a press and snap ring expander, press

the piston return spring and snap ring to the

transaxle.

SST 09387-00070

NOTICE:

• Stop the press when the spring sheet is

lowered to the place 1 to 2 mm (0.039 to 0.078

in.) from the snap ring groove, preventing the

spring sheet from being deform.

• Do not expand the snap ring excessively.

D003614E01

D003913E01

D003813E01

D003600E01

Page 1007 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–213

AX

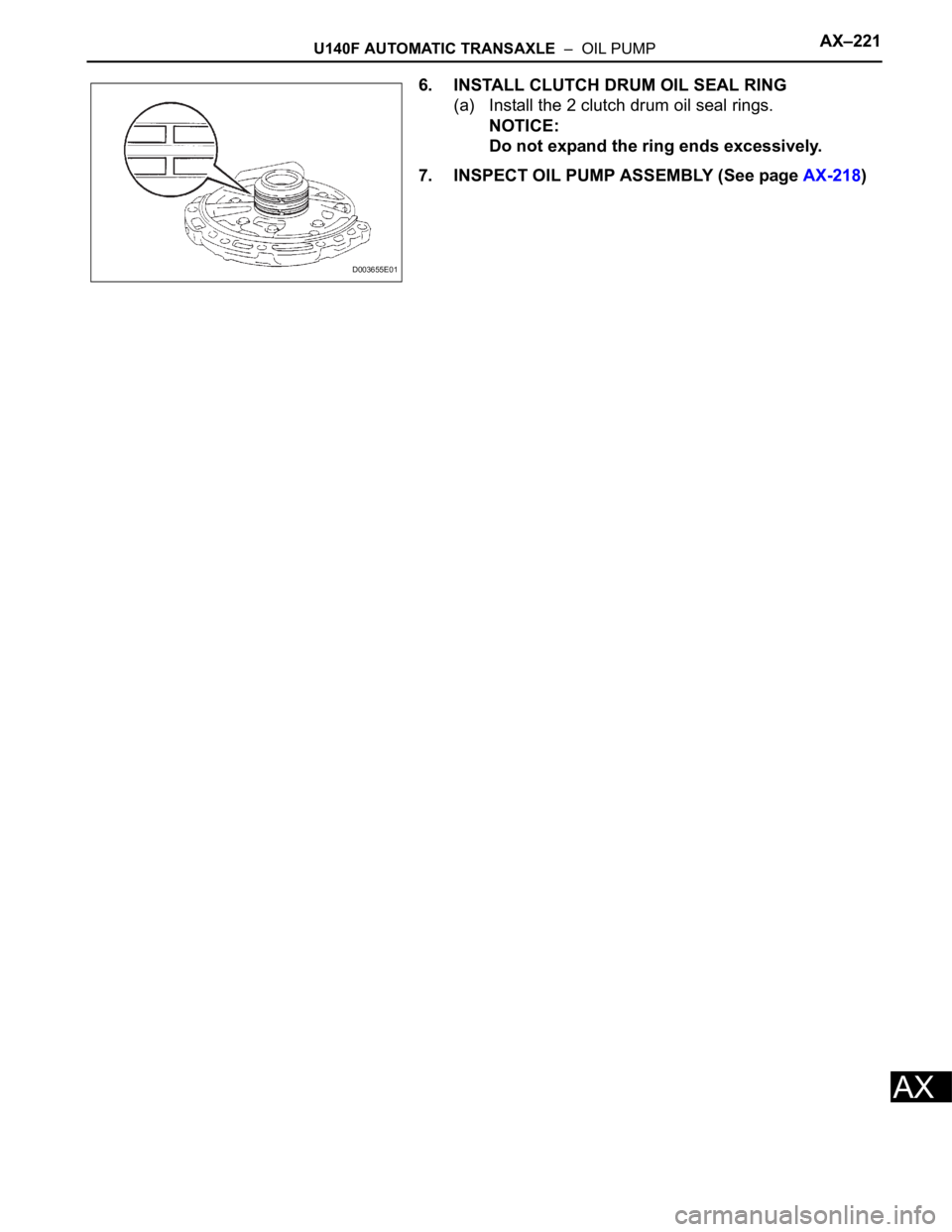

60. INSTALL AUTOMATIC TRANSAXLE OIL PAN SUB-

ASSEMBLY

(a) Install the 3 magnets in the oil pan.

(b) Install a new oil pan gasket to the oil pan.

(c) Install the oil pan to the transaxle with the 18 bolts.

Torque: 7.6 N*m (77 kgf*cm, 67 in.*lbf)

NOTICE:

Because the bolts are seal bolts, apply seal

packing to new bolts and tighten them within 10

minutes after application.

61. INSTALL NO. 1 TRANSAXLE CASE PLUG

(a) Coat 4 new O-rings with ATF, and install them to the

4 plugs.

(b) Install the 4 plugs to the transaxle case.

Torque: 7.4 N*m (75 kgf*cm, 65 in.*lbf)

62. INSTALL SPEED SENSOR

(a) Coat 2 new O-rings with ATF, and install them to the

2 sensors.

(b) Install the 2 sensors with the 2 bolts.

Torque: 11 N*m (112 kgf*cm, 8 ft.*lbf)

63. INSTALL OIL COOLER INLET TUBE UNION

(a) Coat a new O-ring with ATF, and install it to the

union.

(b) Install the union to the transaxle.

Torque: 27 N*m (276 kgf*cm, 20 ft.*lbf)

C134981

D009176E01

C134982

D003900E01

C126599

Page 1011 of 2000

U140F AUTOMATIC TRANSAXLE – OIL PUMPAX–221

AX

6. INSTALL CLUTCH DRUM OIL SEAL RING

(a) Install the 2 clutch drum oil seal rings.

NOTICE:

Do not expand the ring ends excessively.

7. INSPECT OIL PUMP ASSEMBLY (See page AX-218)

D003655E01

Page 1014 of 2000

U140F AUTOMATIC TRANSAXLE – DIRECT CLUTCHAX–235

AX

3. INSPECT DIRECT CLUTCH RETURN SPRING SUB-

ASSEMBLY

(a) Using a vernier caliper, measure the free length of

the spring together with the spring seat.

Standard free length:

22.58 mm (0.8898 in.)

REASSEMBLY

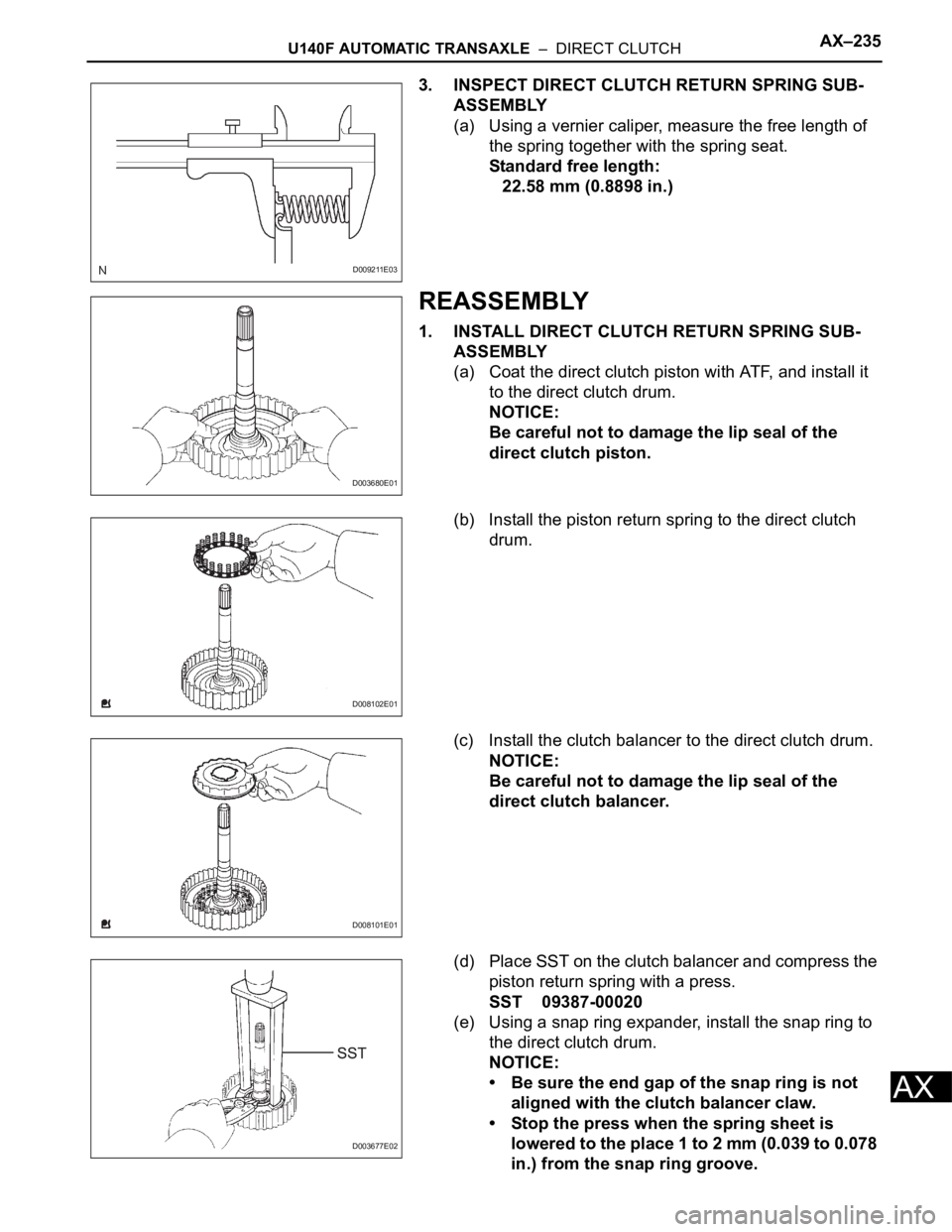

1. INSTALL DIRECT CLUTCH RETURN SPRING SUB-

ASSEMBLY

(a) Coat the direct clutch piston with ATF, and install it

to the direct clutch drum.

NOTICE:

Be careful not to damage the lip seal of the

direct clutch piston.

(b) Install the piston return spring to the direct clutch

drum.

(c) Install the clutch balancer to the direct clutch drum.

NOTICE:

Be careful not to damage the lip seal of the

direct clutch balancer.

(d) Place SST on the clutch balancer and compress the

piston return spring with a press.

SST 09387-00020

(e) Using a snap ring expander, install the snap ring to

the direct clutch drum.

NOTICE:

• Be sure the end gap of the snap ring is not

aligned with the clutch balancer claw.

• Stop the press when the spring sheet is

lowered to the place 1 to 2 mm (0.039 to 0.078

in.) from the snap ring groove.

D009211E03

D003680E01

D008102E01

D008101E01

D003677E02

Page 1015 of 2000

AX–236U140F AUTOMATIC TRANSAXLE – DIRECT CLUTCH

AX

• This prevents the spring sheet from being

deformed.

• Do not expand the snap ring excessively.

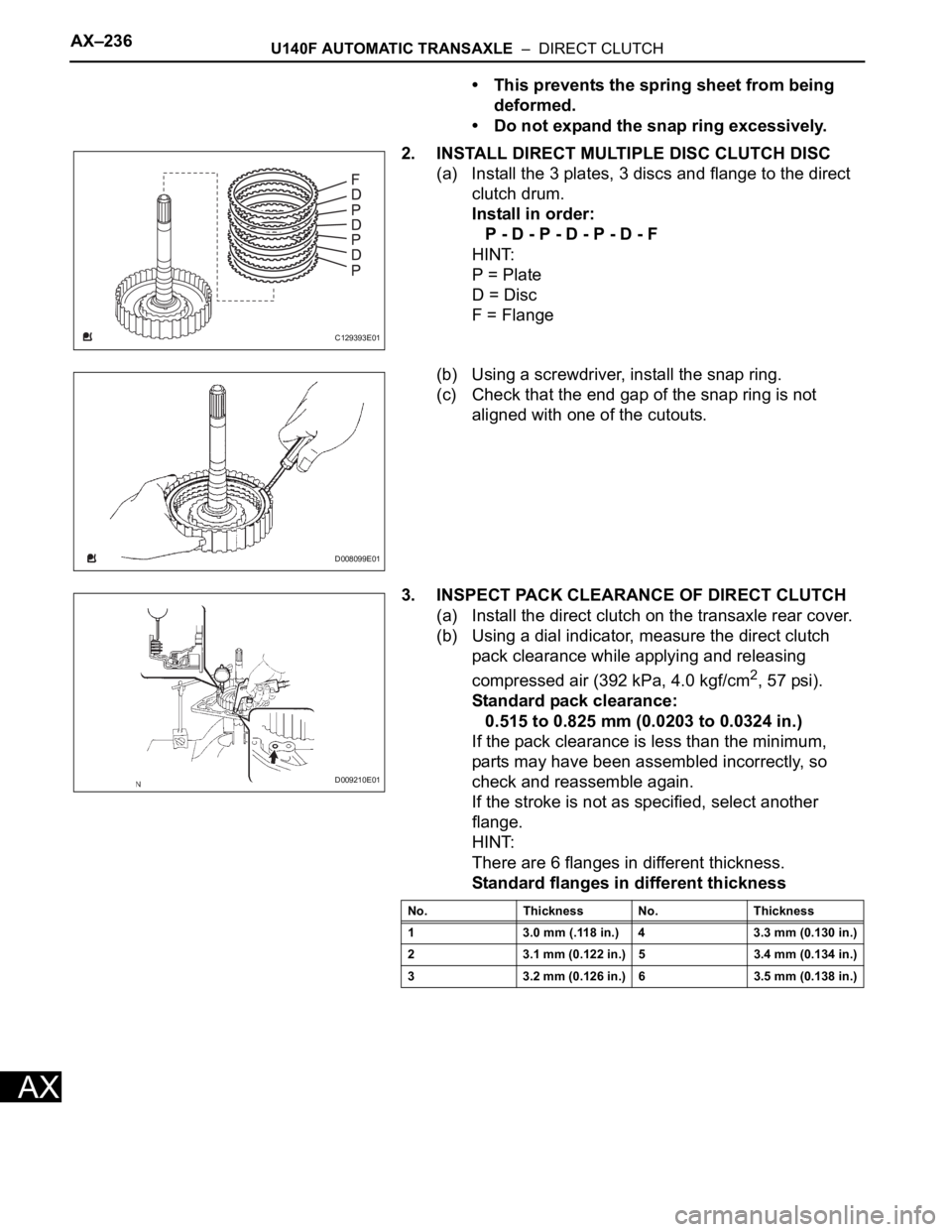

2. INSTALL DIRECT MULTIPLE DISC CLUTCH DISC

(a) Install the 3 plates, 3 discs and flange to the direct

clutch drum.

Install in order:

P - D - P - D - P - D - F

HINT:

P = Plate

D = Disc

F = Flange

(b) Using a screwdriver, install the snap ring.

(c) Check that the end gap of the snap ring is not

aligned with one of the cutouts.

3. INSPECT PACK CLEARANCE OF DIRECT CLUTCH

(a) Install the direct clutch on the transaxle rear cover.

(b) Using a dial indicator, measure the direct clutch

pack clearance while applying and releasing

compressed air (392 kPa, 4.0 kgf/cm

2, 57 psi).

Standard pack clearance:

0.515 to 0.825 mm (0.0203 to 0.0324 in.)

If the pack clearance is less than the minimum,

parts may have been assembled incorrectly, so

check and reassemble again.

If the stroke is not as specified, select another

flange.

HINT:

There are 6 flanges in different thickness.

Standard flanges in different thickness

C129393E01

D008099E01

D009210E01

No. Thickness No. Thickness

1 3.0 mm (.118 in.) 4 3.3 mm (0.130 in.)

2 3.1 mm (0.122 in.) 5 3.4 mm (0.134 in.)

3 3.2 mm (0.126 in.) 6 3.5 mm (0.138 in.)

Page 1050 of 2000

AX–34U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) When troubleshooting On-Board Diagnostic (OBD

II) vehicles, the vehicle must be connected to the

OBD II scan tool (complying with SAE J1987).

Various data output from the vehicle's ECM can

then be read.

(b) OBD II regulations require that the vehicle's on-

board computer illuminates the Malfunction

Indicator Lamp (MIL) on the instrument panel when

the computer detects a malfunction in:

(1) The emission control system/components

(2) The powertrain control components (which affect

vehicle emissions)

(3) The computer

In addition, the applicable Diagnostic Trouble

Codes (DTCs) prescribed by SAE J2012 are

recorded in the ECM memory.

When the malfunction does not reoccur, the MIL

stays illuminated until the ignition switch is

turned OFF, and the MIL turns OFF when the

engine is started. However, the DTCs remain

recorded in the ECM memory.

(c) To check DTCs, connect the intelligent tester to the

Data Link Connector 3 (DLC3) of the vehicle. The

tester displays DTCs, the freeze frame data and a

variety of the engine data.

The DTCs and freeze frame data can be erased

with the tester (see page AX-40).

2. NORMAL MODE AND CHECK MODE

(a) The diagnosis system operates in "normal mode"

during normal vehicle use. In normal mode, "2 trip

detection logic" is used to ensure accurate detection

of malfunctions. "Check mode" is also available to

technicians as an option. In check mode, "1 trip

detection logic" is used for simulating malfunction

symptoms and increasing the system's ability to

detect malfunctions, including intermittent

malfunctions.

3. 2 TRIP DETECTION LOGIC

(a) When a malfunction is first detected, the

malfunction is temporarily stored in the ECM

memory (1st trip). If the same malfunction is

detected during the next drive cycle, the MIL is

illuminated (2nd trip).

C140856

B127989E02

Page 1064 of 2000

AX–190U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

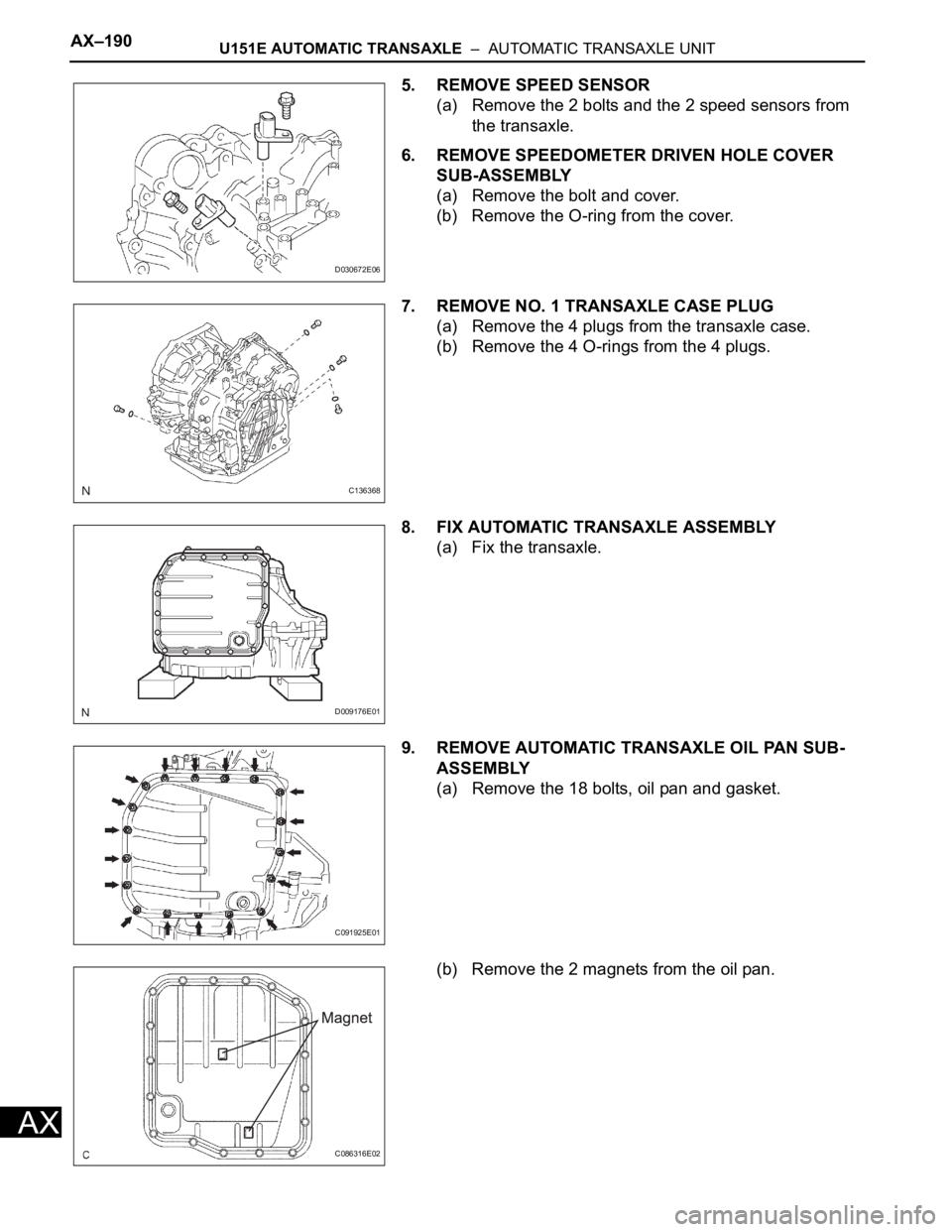

5. REMOVE SPEED SENSOR

(a) Remove the 2 bolts and the 2 speed sensors from

the transaxle.

6. REMOVE SPEEDOMETER DRIVEN HOLE COVER

SUB-ASSEMBLY

(a) Remove the bolt and cover.

(b) Remove the O-ring from the cover.

7. REMOVE NO. 1 TRANSAXLE CASE PLUG

(a) Remove the 4 plugs from the transaxle case.

(b) Remove the 4 O-rings from the 4 plugs.

8. FIX AUTOMATIC TRANSAXLE ASSEMBLY

(a) Fix the transaxle.

9. REMOVE AUTOMATIC TRANSAXLE OIL PAN SUB-

ASSEMBLY

(a) Remove the 18 bolts, oil pan and gasket.

(b) Remove the 2 magnets from the oil pan.

D030672E06

C136368

D009176E01

C091925E01

C086316E02

Page 1065 of 2000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–191

AX

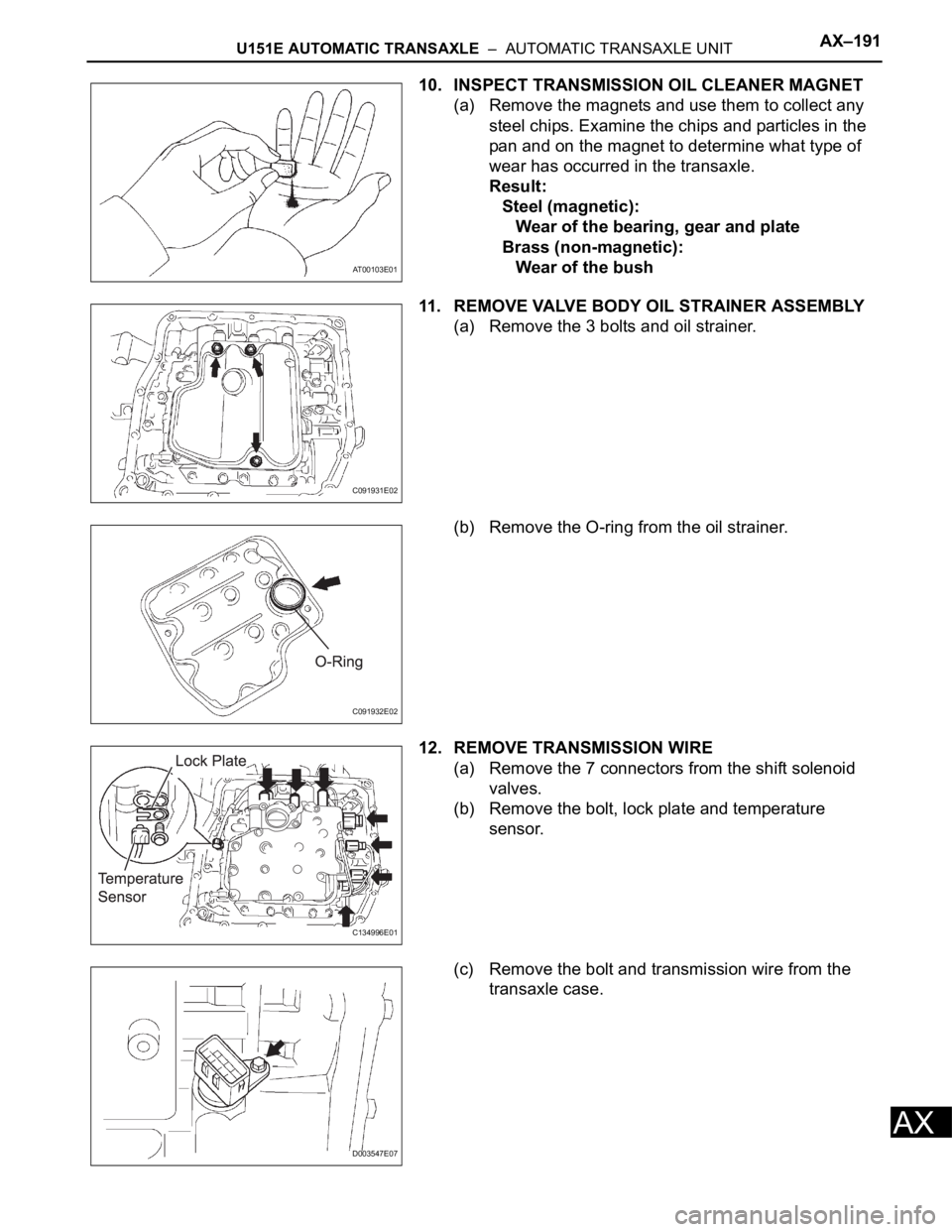

10. INSPECT TRANSMISSION OIL CLEANER MAGNET

(a) Remove the magnets and use them to collect any

steel chips. Examine the chips and particles in the

pan and on the magnet to determine what type of

wear has occurred in the transaxle.

Result:

Steel (magnetic):

Wear of the bearing, gear and plate

Brass (non-magnetic):

Wear of the bush

11. REMOVE VALVE BODY OIL STRAINER ASSEMBLY

(a) Remove the 3 bolts and oil strainer.

(b) Remove the O-ring from the oil strainer.

12. REMOVE TRANSMISSION WIRE

(a) Remove the 7 connectors from the shift solenoid

valves.

(b) Remove the bolt, lock plate and temperature

sensor.

(c) Remove the bolt and transmission wire from the

transaxle case.

AT00103E01

C091931E02

C091932E02

C134996E01

D003547E07

Page 1079 of 2000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–205

AX

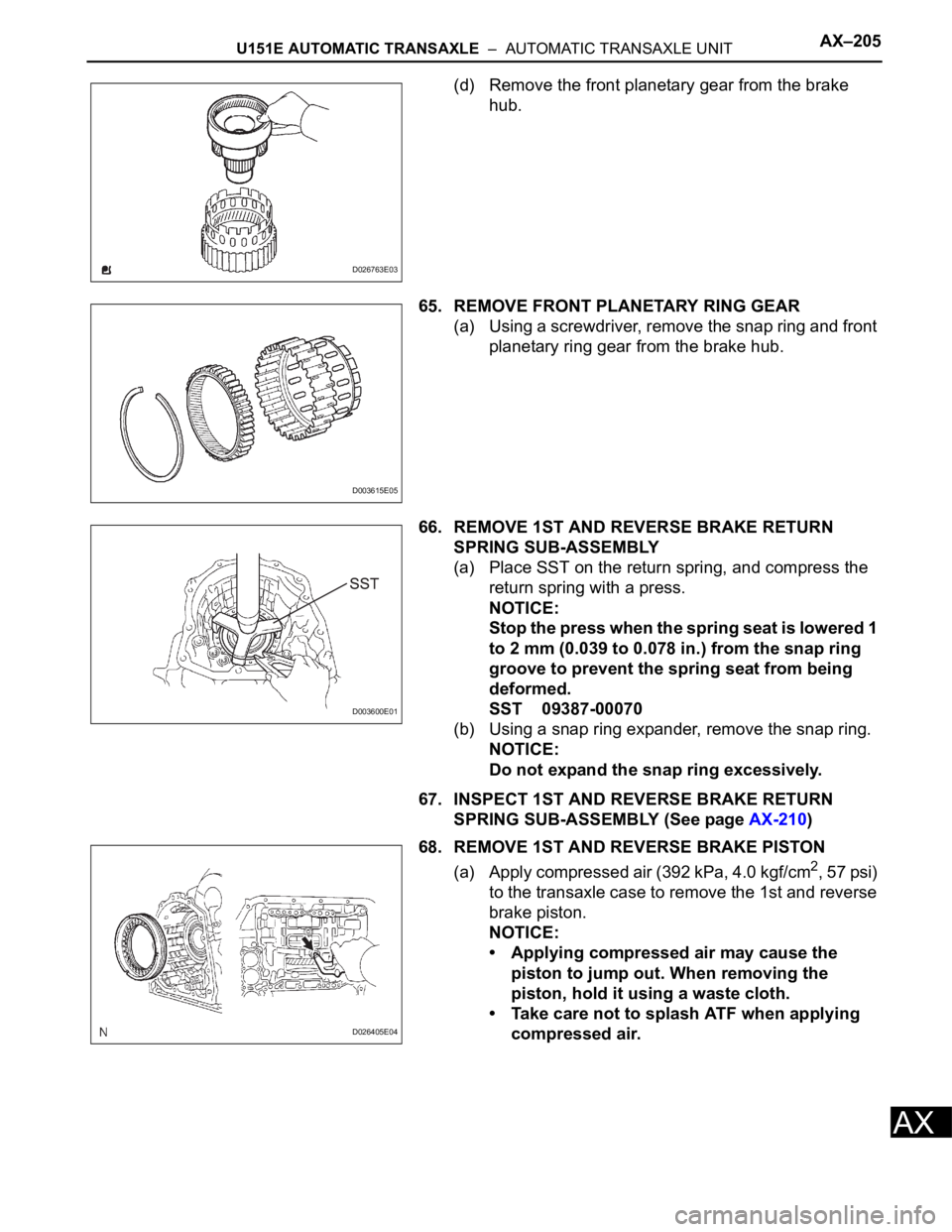

(d) Remove the front planetary gear from the brake

hub.

65. REMOVE FRONT PLANETARY RING GEAR

(a) Using a screwdriver, remove the snap ring and front

planetary ring gear from the brake hub.

66. REMOVE 1ST AND REVERSE BRAKE RETURN

SPRING SUB-ASSEMBLY

(a) Place SST on the return spring, and compress the

return spring with a press.

NOTICE:

Stop the press when the spring seat is lowered 1

to 2 mm (0.039 to 0.078 in.) from the snap ring

groove to prevent the spring seat from being

deformed.

SST 09387-00070

(b) Using a snap ring expander, remove the snap ring.

NOTICE:

Do not expand the snap ring excessively.

67. INSPECT 1ST AND REVERSE BRAKE RETURN

SPRING SUB-ASSEMBLY (See page AX-210)

68. REMOVE 1ST AND REVERSE BRAKE PISTON

(a) Apply compressed air (392 kPa, 4.0 kgf/cm

2, 57 psi)

to the transaxle case to remove the 1st and reverse

brake piston.

NOTICE:

• Applying compressed air may cause the

piston to jump out. When removing the

piston, hold it using a waste cloth.

• Take care not to splash ATF when applying

compressed air.

D026763E03

D003615E05

D003600E01

D026405E04

Page 1080 of 2000

AX–206U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

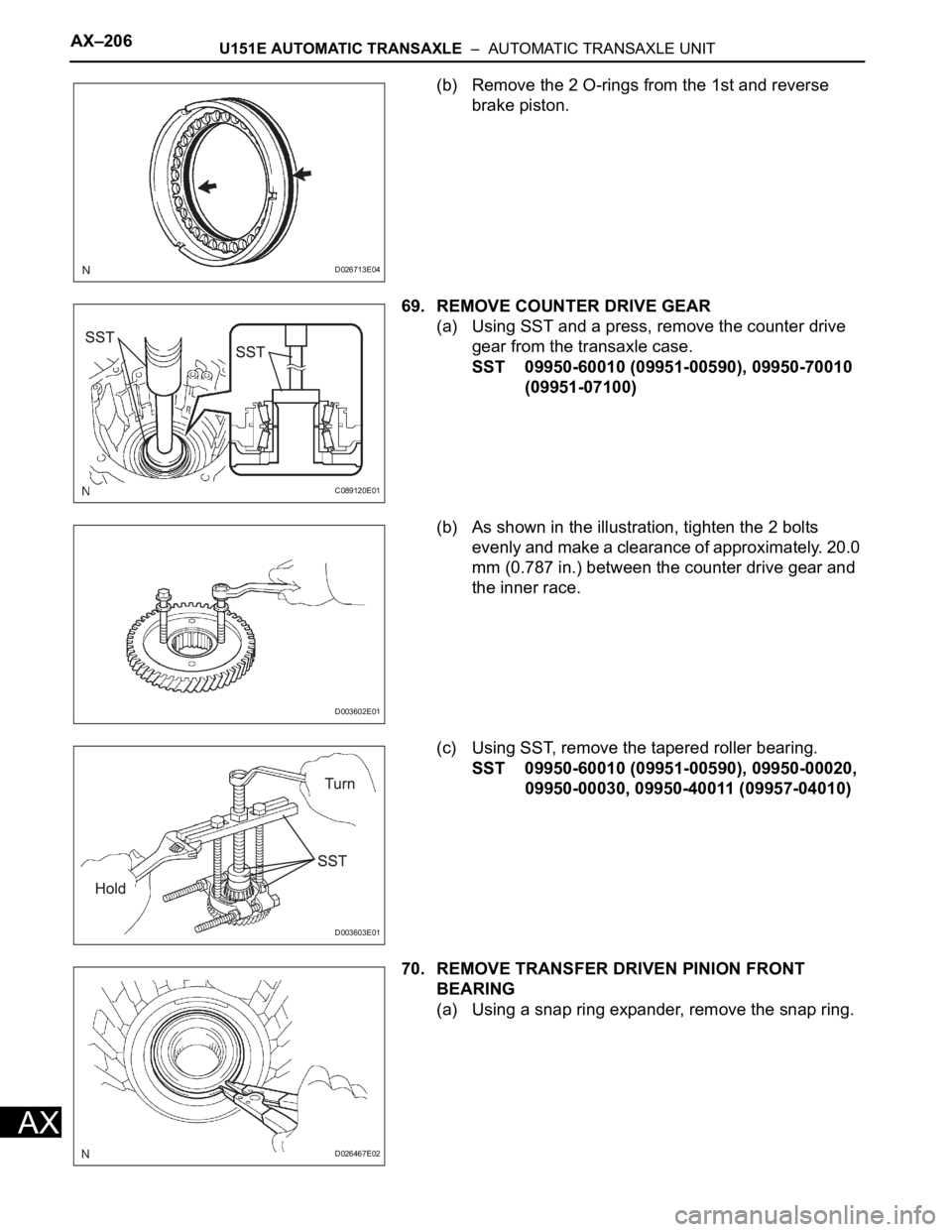

(b) Remove the 2 O-rings from the 1st and reverse

brake piston.

69. REMOVE COUNTER DRIVE GEAR

(a) Using SST and a press, remove the counter drive

gear from the transaxle case.

SST 09950-60010 (09951-00590), 09950-70010

(09951-07100)

(b) As shown in the illustration, tighten the 2 bolts

evenly and make a clearance of approximately. 20.0

mm (0.787 in.) between the counter drive gear and

the inner race.

(c) Using SST, remove the tapered roller bearing.

SST 09950-60010 (09951-00590), 09950-00020,

09950-00030, 09950-40011 (09957-04010)

70. REMOVE TRANSFER DRIVEN PINION FRONT

BEARING

(a) Using a snap ring expander, remove the snap ring.

D026713E04

C089120E01

D003602E01

D003603E01

D026467E02