engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1354 of 2000

TF–26GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

OK

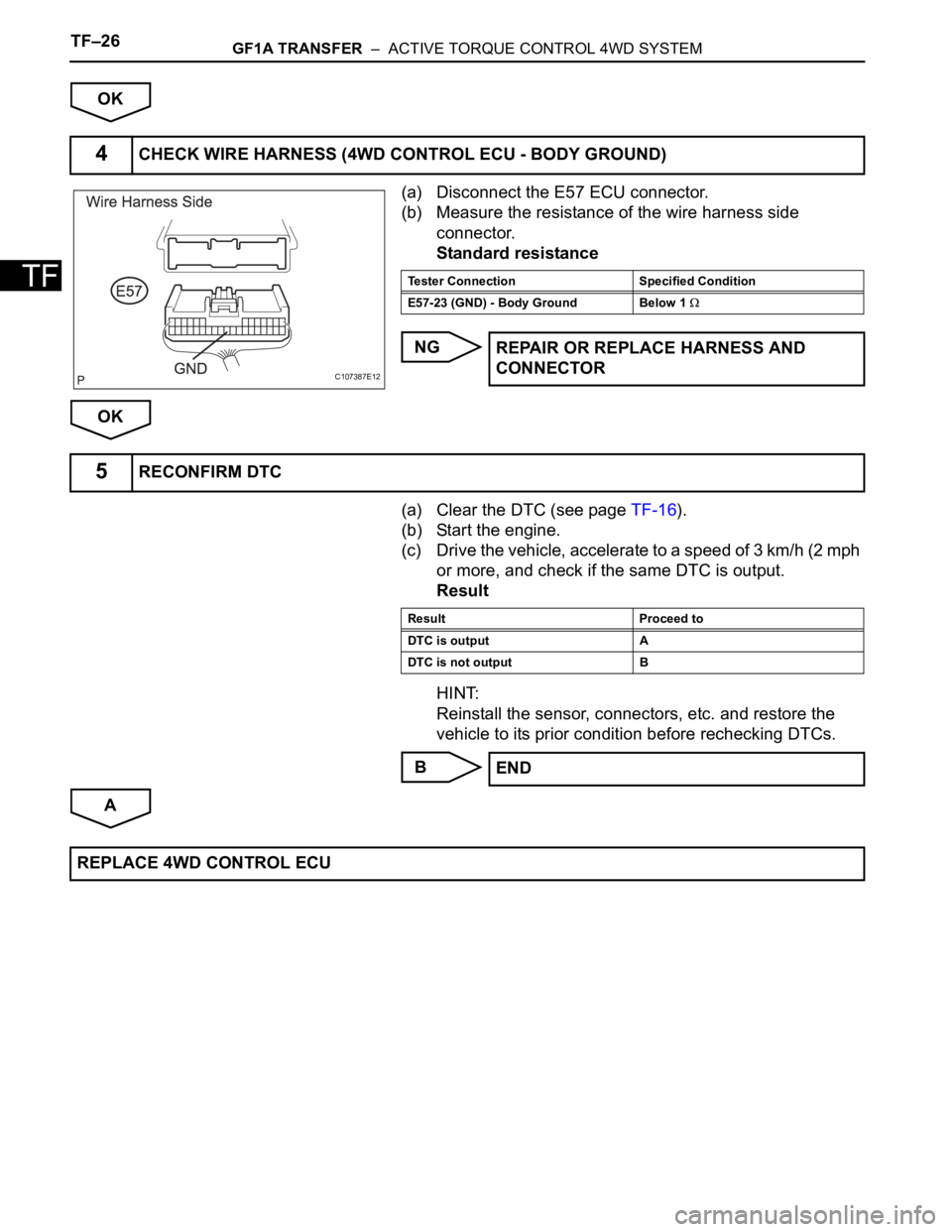

(a) Disconnect the E57 ECU connector.

(b) Measure the resistance of the wire harness side

connector.

Standard resistance

NG

OK

(a) Clear the DTC (see page TF-16).

(b) Start the engine.

(c) Drive the vehicle, accelerate to a speed of 3 km/h (2 mph

or more, and check if the same DTC is output.

Result

HINT:

Reinstall the sensor, connectors, etc. and restore the

vehicle to its prior condition before rechecking DTCs.

B

A

4CHECK WIRE HARNESS (4WD CONTROL ECU - BODY GROUND)

C107387E12

Tester Connection Specified Condition

E57-23 (GND) - Body Ground Below 1

REPAIR OR REPLACE HARNESS AND

CONNECTOR

5RECONFIRM DTC

Result Proceed to

DTC is output A

DTC is not output B

END

REPLACE 4WD CONTROL ECU

Page 1355 of 2000

GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEMTF–27

TF

DESCRIPTION

If a malfunction in the engine control ECU circuit occurs, the 4WD control ECU will output this DTC.

INSPECTION PROCEDURE

HINT:

Check the condition of each related circuit connector before troubleshooting (see page IN-37).

(a) Clear the DTC (see page TF-16).

(b) Turn the ignition switch OFF.

(c) Turn the ignition switch ON and check that can

communication system DTC is not output.

Result

B

A

DTC C1280/82 Engine Circuit Malfunction

DTC No. DTC Detection Condition Trouble Area

C1280/82 When the following continues for 5 seconds

or more:

- Communication with engine control ECU is

operating normally, but throttle position

sensor is malfunctioning.• Throttle position sensor

• Throttle position sensor wire harness and

connector

• CAN communication system

1CHECK FOR DTC

Result Proceed to

CAN communication system DTC is

outputA

Engine control DTC is output B

GO TO ENGINE CONTROL SYSTEM

GO TO CAN COMMUNICATION SYSTEM

Page 1358 of 2000

TF–30GF1A TRANSFER – ACTIVE TORQUE CONTROL 4WD SYSTEM

TF

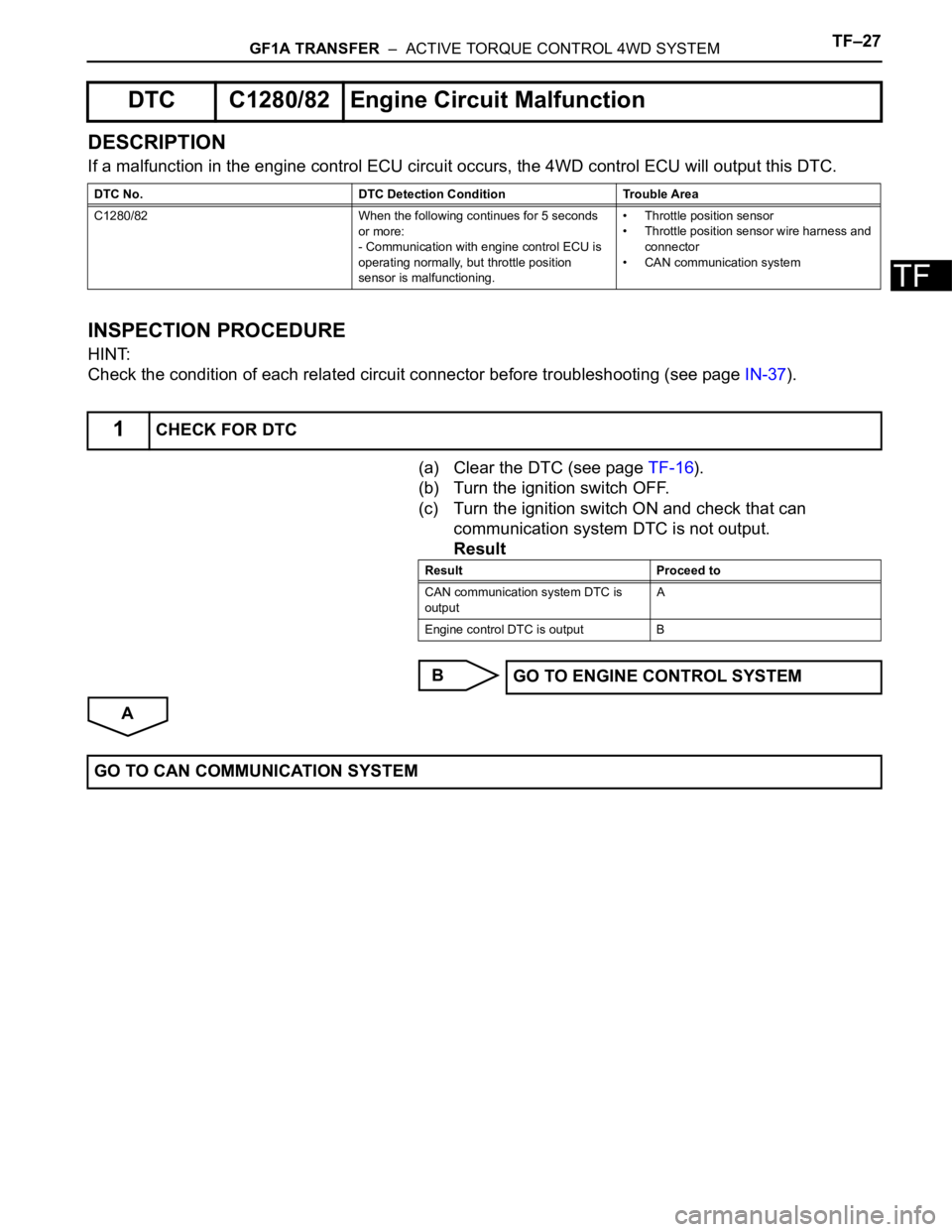

DESCRIPTION

• The 4WD control ECU determines that the vehicle is turning based on the signals sent from the

steering angle sensor.

• The steering angle sensor signal is sent to the 4WD control ECU via the CAN communication system.

• The 4WD control ECU detects the amount of steering wheel movement and performs "slip control at

vehicle start up", according to the amount of movement, and "slip control" to secure high turning

performance.

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

Check the condition of each related circuit connector before troubleshooting (see page IN-37).

(a) Clear the DTC (see page TF-16).

(b) Turn the ignition switch OFF.

(c) Turn the ignition switch ON again and check that no CAN

communication system DTC(s) is output.

(d) Start the engine.

DTC C1297/97 Steering Angle Sensor

DTC No. DTC Detection Condition Trouble Area

C1297/97 When voltage of 4WD control ECU IG1

terminal is 9.5 V or more, and steering angle

sensor malfunction signal is received.• Steering angle sensor

• CAN communication

• 4WD control ECU

• Wire harness

1CHECK FOR DTC

C128601E02

Page 1467 of 2000

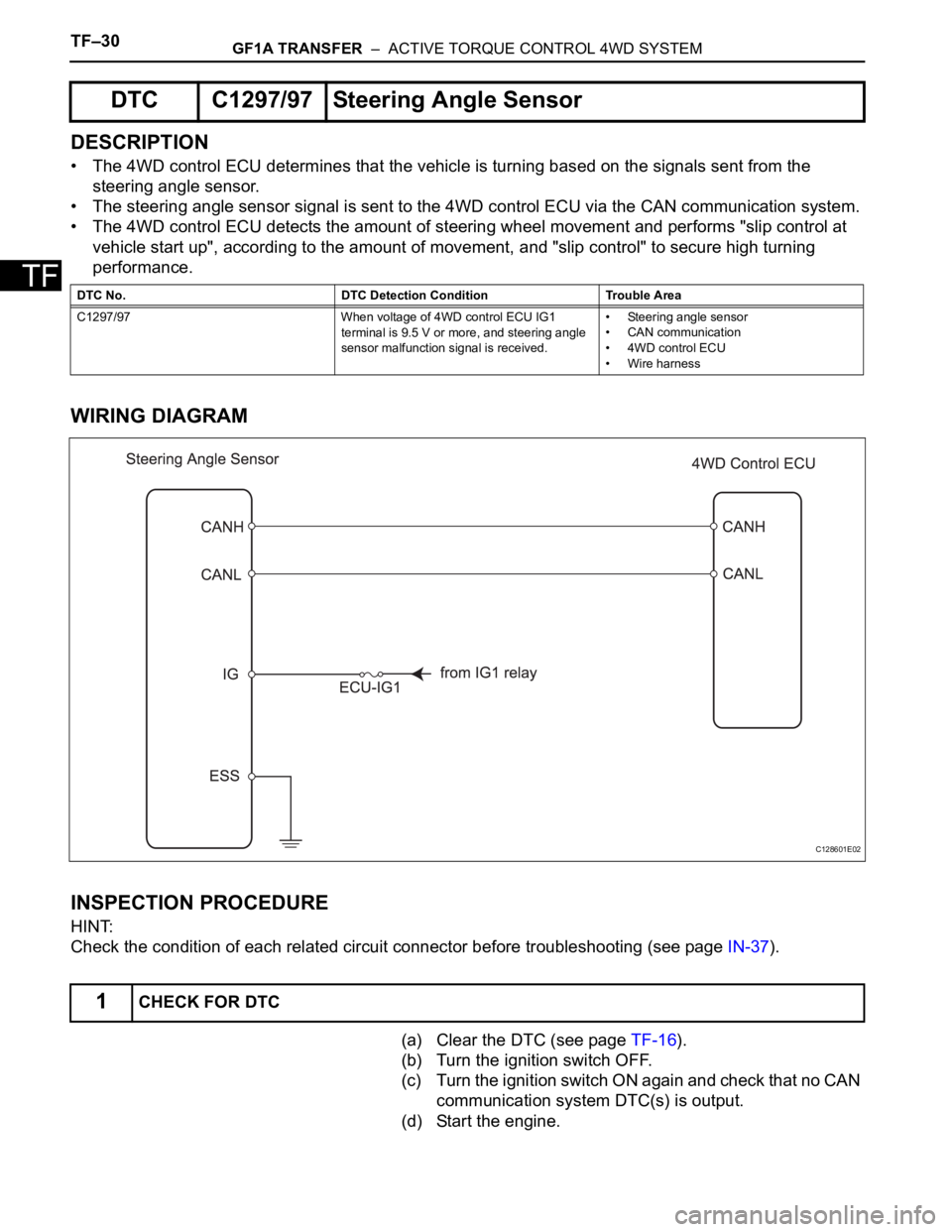

SP–24SUSPENSION – FRONT SUSPENSION LOWER NO. 1 ARM

SP

(f) Install the suspension member with the bolt to the

body.

(g) Perform the procedure above on the other side.

(h) Install the engine mounting insulator rear with the 2

nuts and 2 bolts.

4. INSTALL FRONT STABILIZER LINK ASSEMBLY LH

(See page SP-30)

5. CONNECT FRONT SUSPENSION LOWER NO. 1 ARM

SUB-ASSEMBLY LH

(a) Connect the lower arm with the 2 bolts and nut to

the ball joint.

Torque: 92 N*m (938 kgf*cm, 68 ft.*lbf)

6. INSTALL FRONT WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

7. STABILIZE SUSPENSION (See page SP-12)

8. TIGHTEN FRONT CROSS MEMBER SUB-ASSEMBLY

(a) Tighten the bolts and nuts.

Torque: 87 N*m (887 kgf*cm, 64 ft.*lbf) for bolt A

93 N*m (948 kgf*cm, 69 ft.*lbf) for bolt B

145 N*m (1,479 kgf*cm, 107 ft.*lbf) for

body

95 N*m (969 kgf*cm, 70 ft.*lbf) for

engine mounting insulator

9. TIGHTEN FRONT SUSPENSION LOWER NO. 1 ARM

SUB-ASSEMBLY LH

(a) Using SST, and tighten the bolt on the front side.

SST 09961-01270

Torque: 223 N*m (2,376 kgf*cm, 172 ft.*lbf) for

use without SST

175 N*m (1,785 kgf*cm, 129 ft.*lbf) for

use with SST

NOTICE:

Do not tighten the nut.

(b) Fix the nut in place and tighten the bolt on the rear

side.

Torque: 223 N*m (2,376 kgf*cm, 172 ft.*lbf)

NOTICE:

Do not tighten the nut.

10. TIGHTEN FRONT SUSPENSION LOWER NO. 1 ARM

SUB-ASSEMBLY RH

HINT:

Use the same procedures described for the LH side.

11. INSTALL HOOD SUB-ASSEMBLY (See page ED-7)

C131836

A124842

C117420E01

Page 1513 of 2000

BC–10BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

(1) Operation description:

The skid control ECU detects the vehicle's slip

condition by receiving signals from each speed

sensor and the ECM via CAN communication.

The skid control ECU controls engine torque

with the ECM via CAN communication and

brake fluid pressure through the pump and

solenoid valve. The slip indicator light blinks

when the system is operating.

for 4WD: The VSC warning light comes on when

the TRC system malfunctions.

for 2WD: The VSC warning light and SLIP

indicator light comes on when the TRC system

malfunctions.

Page 1515 of 2000

BC–12BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

(1) Operation description:

The skid control ECU determines the vehicle

condition by receiving signals from the speed

sensor, the yaw rate and deceleration sensor

and the steering sensor. The skid control ECU

controls engine torque with the ECM via CAN

communication and brake fluid pressure through

the pump and solenoid valve. The slip indicator

light blinks and the skid control buzzer sounds

when the system is operating.

for 4WD: The VSC warning light comes on when

the TRC system malfunctions.

for 2WD: The VSC warning light and slip

indicator light come on when the TRC system

malfunctions.

(f) Downhill Assist Control:

When the downhill assist control switch is pressed

with the shift lever on L or R range and the

accelerator and brake pedals not depressed,

downhill assist control is activated. When activated,

4-wheel hydraulic pressure control occurs in order

to maintain a constant low vehicle speed without

causing the wheels to become locked. Thus, the

vehicle can descend a steep hill in a stable manner.

HINT:

• Depressing the accelerator and brake pedal

cancels control of the downhill assist control.

• Downhill assist control begins operating when

driving down on a slope at a speed of 25 km/h

(16 mph) or less with the engine brake applied.

Page 1518 of 2000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–15

BC

(1) Operation description:

When the system is in operation, the following

occurs: 1) the slip indicator light blinks; 2) the

VSC light comes on; and 3) when hill-start assist

control operation starts, the skid control buzzer

sounds once; when hill-start assist control

operation ends, the skid control buzzer sounds

twice.

The VSC warning light comes on when the hill-

start assist control is malfunctioning.

(h) AUTO LSD (Auto Limited Slip Differential) for 2WD:

The AUTO LSD achieves the equivalent functions of

an LSD (Limited Slip Differential) through the use of

a traction control system. When the driver presses

the AUTO LSD switch, this system achieves the

LSD effect by regulating the hydraulic pressure that

acts on the drive wheels and controlling the engine

output in accordance with the amount of pedal effort

applied on the accelerator. The AUTO LSD

operates with the AUTO LSD switch on and the

accelerator pedal depressed.

Auto LSD restrains brake pressure and reduces

differential movement, thus transmitting the drive

torque to the other drive wheel to ensure stability

under the following conditions:

• Wheels run off the road.

• Drive wheels spin in place when starting on a

slope with one wheel on snow/ice.

HINT:

Releasing the accelerator pedal cancels control of

the AUTO LSD system.

Page 1520 of 2000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–17

BC

(1) Operation description:

The skid control ECU determines that the

vehicle is in a state in which the AUTO LSD can

operate by using various sensors and switches

to detect the operating conditions of the AUTO

LSD switch, shift position, accelerator pedal, and

brake pedal. When the vehicle is in a state in

which the AUTO LSD can operate, the skid

control ECU effects hydraulic pressure control of

the wheel cylinder at the wheel with the faster

wheel speed so that the wheel speeds of the

right and left drive wheels will become equal.

The slip indicator light blinks and the AUTO LSD

indicator light comes on when the system is

operating. Both the VSC warning light and SLIP

indicator light come on when the AUTO LSD

system malfunctions.

2. COOPERATIVE CONTROL FUNCTION

(a) Description

(1) Braking when Surface Resistance Differs

Between Left and Right Wheels

If the driver suddenly applies the brakes on a

road surface with a considerable difference in

friction coefficient between the right and left

wheels, the difference in the brake force

between the right and left wheels will cause the

vehicle posture to become unstable and create a

yaw movement. In this state, the skid control

ECU controls the VSC to stabilize the vehicle

posture. At the same time, it effects cooperative

control with the EPS to provide steering torque

assist, which facilitates the driver's steering

maneuvers to stabilize the vehicle posture.

(2) Accelerating when Surface Resistance Differs

Between Left and Right Wheels

If the driver suddenly starts off or accelerates on

a road surface with a considerable difference in

friction coefficient between the right and left

wheels, the slippage of a drive wheel will cause

the vehicle posture to become unstable and

negatively affect its acceleration performance. In

this state, the skid control ECU causes the TRC

to control the hydraulic brake of the slipping

drive wheel, and requests the engine ECU to

effect engine output control. At the same time, it

effects cooperative control with the EPS to

provide steering torque assist, which facilitates

the driver's steering maneuvers to stabilize the

vehicle posture.

Page 1521 of 2000

BC–18BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEM

BC

(3) Front Wheel Skid Tendency

When the skid control ECU determines that

there is a front wheel skid tendency, it controls

the VSC to dampen the front wheel skid. At the

same time, it effects cooperative control with the

EPS to provide steering torque assist, which

facilitates the driver's steering maneuvers to

stabilize the vehicle posture. To prevent

excessive steering maneuvers, it provides a

steering torque assist. This assist increases the

resistance to counter the driver's steering effort,

if the driver turns the steering wheel excessively.

(4) Rear Wheel Skid Tendency

When the skid control ECU determines that

there is a rear wheel skid tendency, it controls

the VSC to dampen the rear wheel skid. At the

same time, it effects cooperative control with the

EPS to provide steering torque assist, which

facilitates the driver's steering maneuvers in the

direction to correct the rear wheel skid.

(5) Acceleration During Cornering

A sudden acceleration of the vehicle during

cornering may cause a drive wheel to freewheel,

which could cause the front wheels or rear

wheels to skid. If the skid control ECU

determines that there is freewheeling of a drive

wheel, a front wheel skid tendency, or a rear

wheel skid tendency, it effects cooperative

control with the 4WD system to optimally control

the drive torque distribution to the front and rear

wheels. Furthermore, it controls the TRC and

the VSC as needed to ensure driving stability

and acceleration performance.

(b) Operation

The operation of the solenoid valves under the

cooperative control is the same as the TRC or VSC

operation.

3. ABS WITH EBD, BA, TRC AND VSC OPERATION

(a) The skid control ECU calculates vehicle stability

tendency based on the signals from the 4 wheel

speed sensors, the yaw rate and deceleration

sensor and the steering sensor. In addition, it

evaluates the results of the calculations to

determine whether any control actions (control of

the engine output torque by electronic throttle

control and of the brake fluid pressure by the ABS

and TRACTION actuator) should be implemented.

(b) The slip indicator blinks and the skid control buzzer

sounds to inform the driver that the VSC system is

operating. The slip indicator also blinks when

traction control is operating, and the operation being

performed is displayed.

Page 1522 of 2000

BRAKE CONTROL – VEHICLE STABILITY CONTROL SYSTEMBC–19

BC

4. FAIL SAFE FUNCTION

(a) When a failure occurs in the ABS with BA, TRC and

VSC systems, the ABS and VSC warning lights

illuminate, the slip indicator light comes on*1 or

remains off*2, and the operations of those systems

are prohibited. In addition to this, when a failure

which disables the EBD operation occurs, the brake

warning light comes on and its operation is

prohibited.

HINT:

*1: for 2WD

*2: for 4WD

(b) If control is prohibited due to a malfunction during

operation, control is disabled gradually to avoid

sudden vehicle instability.

5. INITIAL CHECK

(a) When the vehicle speed first reaches approximately

6 km/h (4 mph) or more after the ignition switch is

turned ON, each solenoid valve and the motor of the

ABS and TRACTION actuator are sequentially

activated to perform electrical checks. During the

initial check, the operating sound of the solenoid

valve and motor can be heard from the engine

compartment, but this does not indicate a

malfunction.

6. SERVICE MODE

(a) VSC operation can be disabled by operating the

intelligent tester.

HINT:

Refer to the intelligent tester operator's manual for

further details.

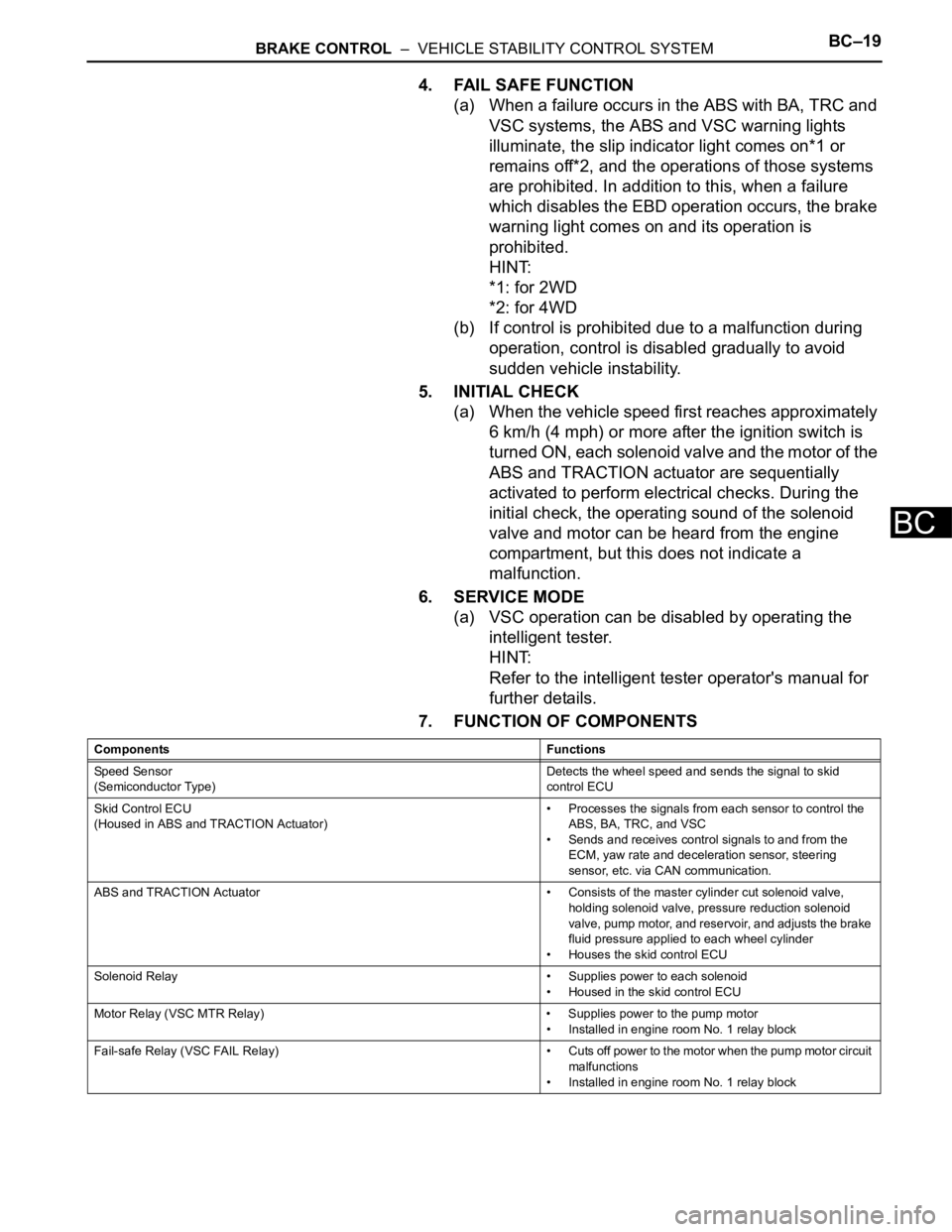

7. FUNCTION OF COMPONENTS

Components Functions

Speed Sensor

(Semiconductor Type)Detects the wheel speed and sends the signal to skid

control ECU

Skid Control ECU

(Housed in ABS and TRACTION Actuator)• Processes the signals from each sensor to control the

ABS, BA, TRC, and VSC

• Sends and receives control signals to and from the

ECM, yaw rate and deceleration sensor, steering

sensor, etc. via CAN communication.

ABS and TRACTION Actuator • Consists of the master cylinder cut solenoid valve,

holding solenoid valve, pressure reduction solenoid

valve, pump motor, and reservoir, and adjusts the brake

fluid pressure applied to each wheel cylinder

• Houses the skid control ECU

Solenoid Relay • Supplies power to each solenoid

• Housed in the skid control ECU

Motor Relay (VSC MTR Relay) • Supplies power to the pump motor

• Installed in engine room No. 1 relay block

Fail-safe Relay (VSC FAIL Relay) • Cuts off power to the motor when the pump motor circuit

malfunctions

• Installed in engine room No. 1 relay block