engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1653 of 2000

AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)AC–25

AC

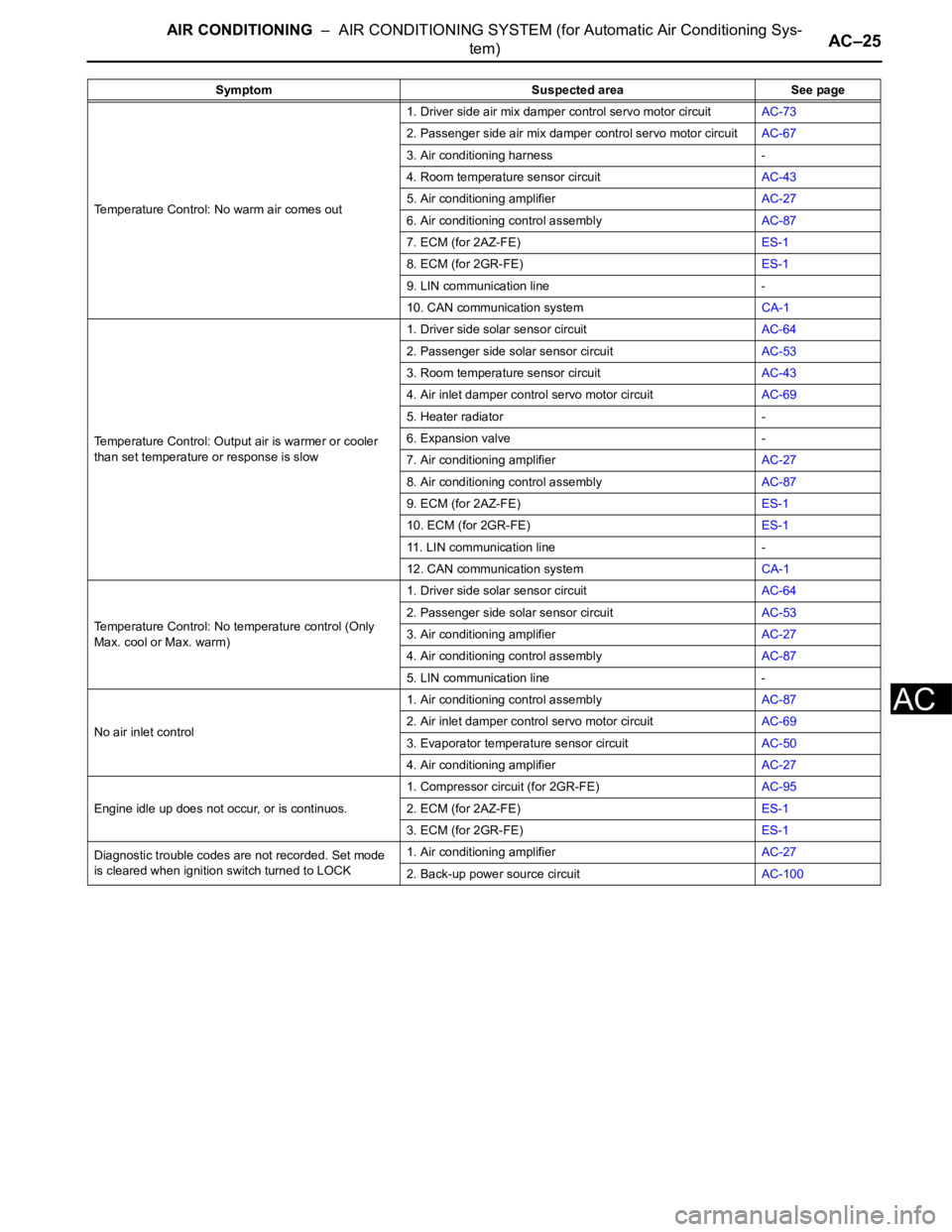

Temperature Control: No warm air comes out1. Driver side air mix damper control servo motor circuitAC-73

2. Passenger side air mix damper control servo motor circuitAC-67

3. Air conditioning harness -

4. Room temperature sensor circuitAC-43

5. Air conditioning amplifierAC-27

6. Air conditioning control assemblyAC-87

7. ECM (for 2AZ-FE)ES-1

8. ECM (for 2GR-FE)ES-1

9. LIN communication line -

10. CAN communication systemCA-1

Temperature Control: Output air is warmer or cooler

than set temperature or response is slow1. Driver side solar sensor circuitAC-64

2. Passenger side solar sensor circuitAC-53

3. Room temperature sensor circuitAC-43

4. Air inlet damper control servo motor circuitAC-69

5. Heater radiator -

6. Expansion valve -

7. Air conditioning amplifierAC-27

8. Air conditioning control assemblyAC-87

9. ECM (for 2AZ-FE)ES-1

10. ECM (for 2GR-FE)ES-1

11. LIN communication line -

12. CAN communication systemCA-1

Temperature Control: No temperature control (Only

Max. cool or Max. warm)1. Driver side solar sensor circuitAC-64

2. Passenger side solar sensor circuitAC-53

3. Air conditioning amplifierAC-27

4. Air conditioning control assemblyAC-87

5. LIN communication line -

No air inlet control1. Air conditioning control assemblyAC-87

2. Air inlet damper control servo motor circuitAC-69

3. Evaporator temperature sensor circuitAC-50

4. Air conditioning amplifierAC-27

Engine idle up does not occur, or is continuos.1. Compressor circuit (for 2GR-FE)AC-95

2. ECM (for 2AZ-FE)ES-1

3. ECM (for 2GR-FE)ES-1

Diagnostic trouble codes are not recorded. Set mode

is cleared when ignition switch turned to LOCK1. Air conditioning amplifierAC-27

2. Back-up power source circuitAC-100 Symptom Suspected area See page

Page 1654 of 2000

AC–26AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

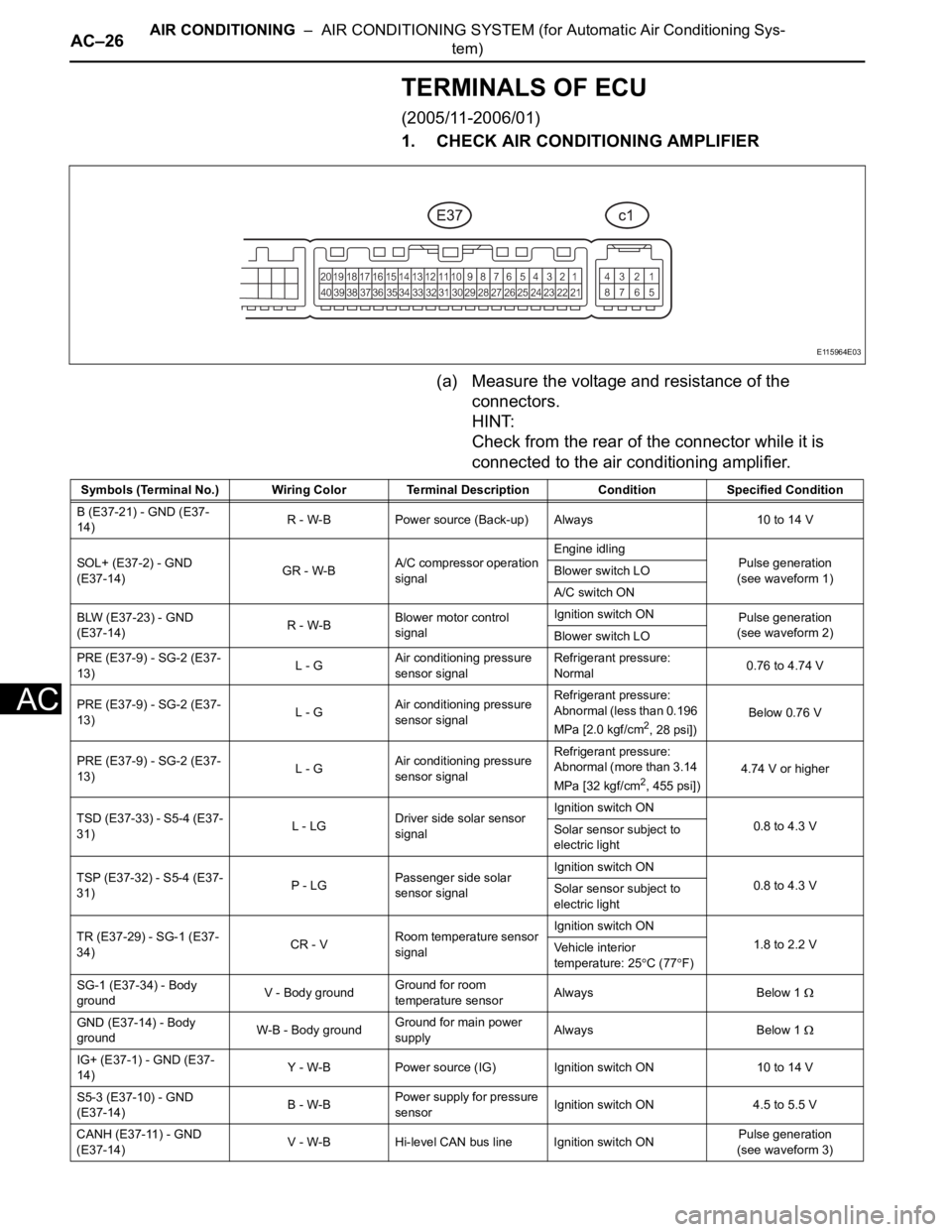

TERMINALS OF ECU

(2005/11-2006/01)

1. CHECK AIR CONDITIONING AMPLIFIER

(a) Measure the voltage and resistance of the

connectors.

HINT:

Check from the rear of the connector while it is

connected to the air conditioning amplifier.

E115964E03

Symbols (Terminal No.) Wiring Color Terminal Description ConditionSpecified Condition

B (E37-21) - GND (E37-

14)R - W-B Power source (Back-up) Always 10 to 14 V

SOL+ (E37-2) - GND

(E37-14)GR - W-BA/C compressor operation

signalEngine idling

Pulse generation

(see waveform 1) Blower switch LO

A/C switch ON

BLW (E37-23) - GND

(E37-14)R - W-BBlower motor control

signalIgnition switch ON

Pulse generation

(see waveform 2)

Blower switch LO

PRE (E37-9) - SG-2 (E37-

13)L - GAir conditioning pressure

sensor signalRefrigerant pressure:

Normal0.76 to 4.74 V

PRE (E37-9) - SG-2 (E37-

13)L - GAir conditioning pressure

sensor signalRefrigerant pressure:

Abnormal (less than 0.196

MPa [2.0 kgf/cm

2, 28 psi]) Below 0.76 V

PRE (E37-9) - SG-2 (E37-

13)L - GAir conditioning pressure

sensor signalRefrigerant pressure:

Abnormal (more than 3.14

MPa [32 kgf/cm

2, 455 psi])4.74 V or higher

TSD (E37-33) - S5-4 (E37-

31)L - LGDriver side solar sensor

signalIgnition switch ON

0.8 to 4.3 V

Solar sensor subject to

electric light

TSP (E37-32) - S5-4 (E37-

31)P - LGPassenger side solar

sensor signalIgnition switch ON

0.8 to 4.3 V

Solar sensor subject to

electric light

TR (E37-29) - SG-1 (E37-

34)CR - VRoom temperature sensor

signalIgnition switch ON

1.8 to 2.2 V

Vehicle interior

temperature: 25

C (77F)

SG-1 (E37-34) - Body

groundV - Body groundGround for room

temperature sensorAlways Below 1

GND (E37-14) - Body

groundW-B - Body groundGround for main power

supplyAlways Below 1

IG+ (E37-1) - GND (E37-

14)Y - W-B Power source (IG) Ignition switch ON 10 to 14 V

S5-3 (E37-10) - GND

(E37-14)B - W-BPower supply for pressure

sensorIgnition switch ON 4.5 to 5.5 V

CANH (E37-11) - GND

(E37-14)V - W-B Hi-level CAN bus line Ignition switch ONPulse generation

(see waveform 3)

Page 1655 of 2000

AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)AC–27

AC

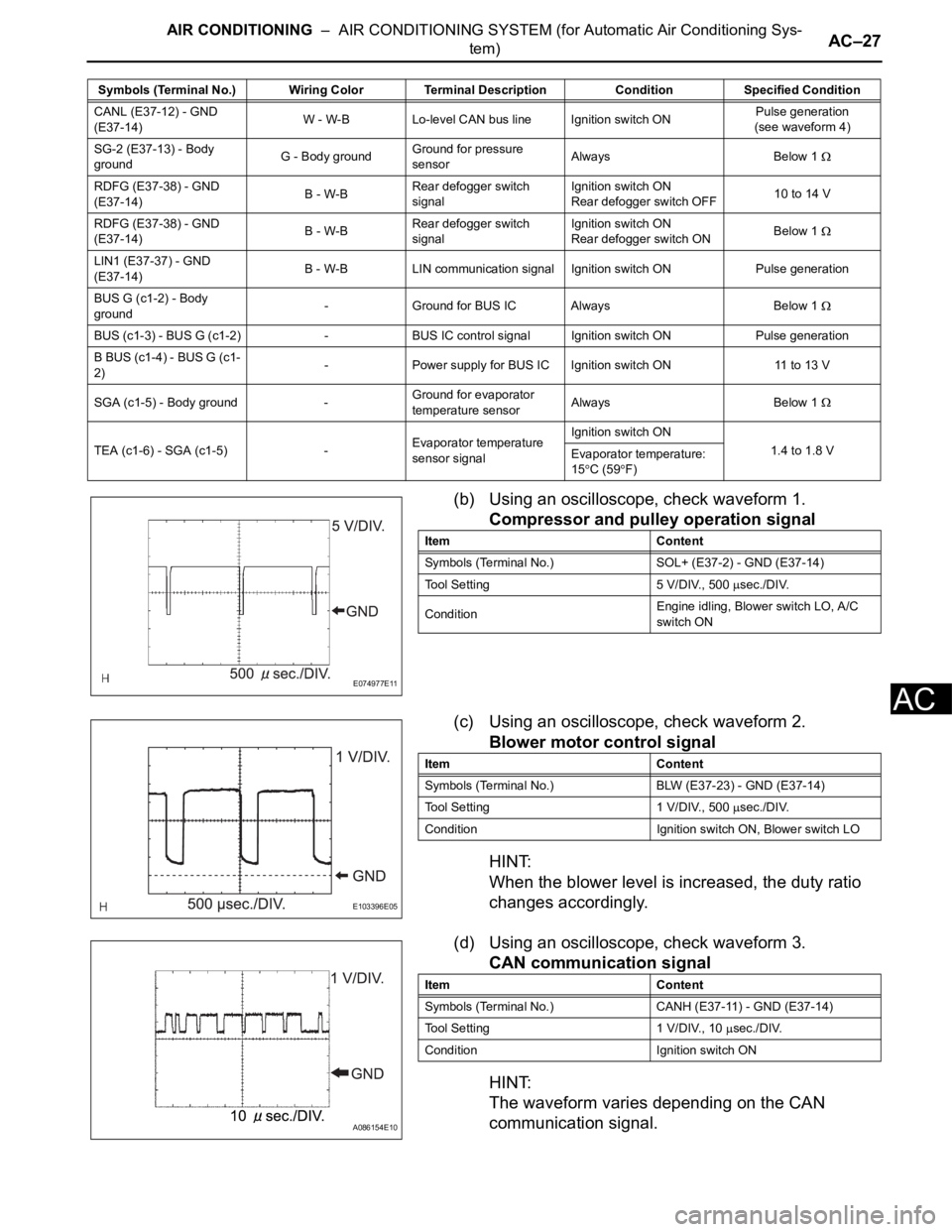

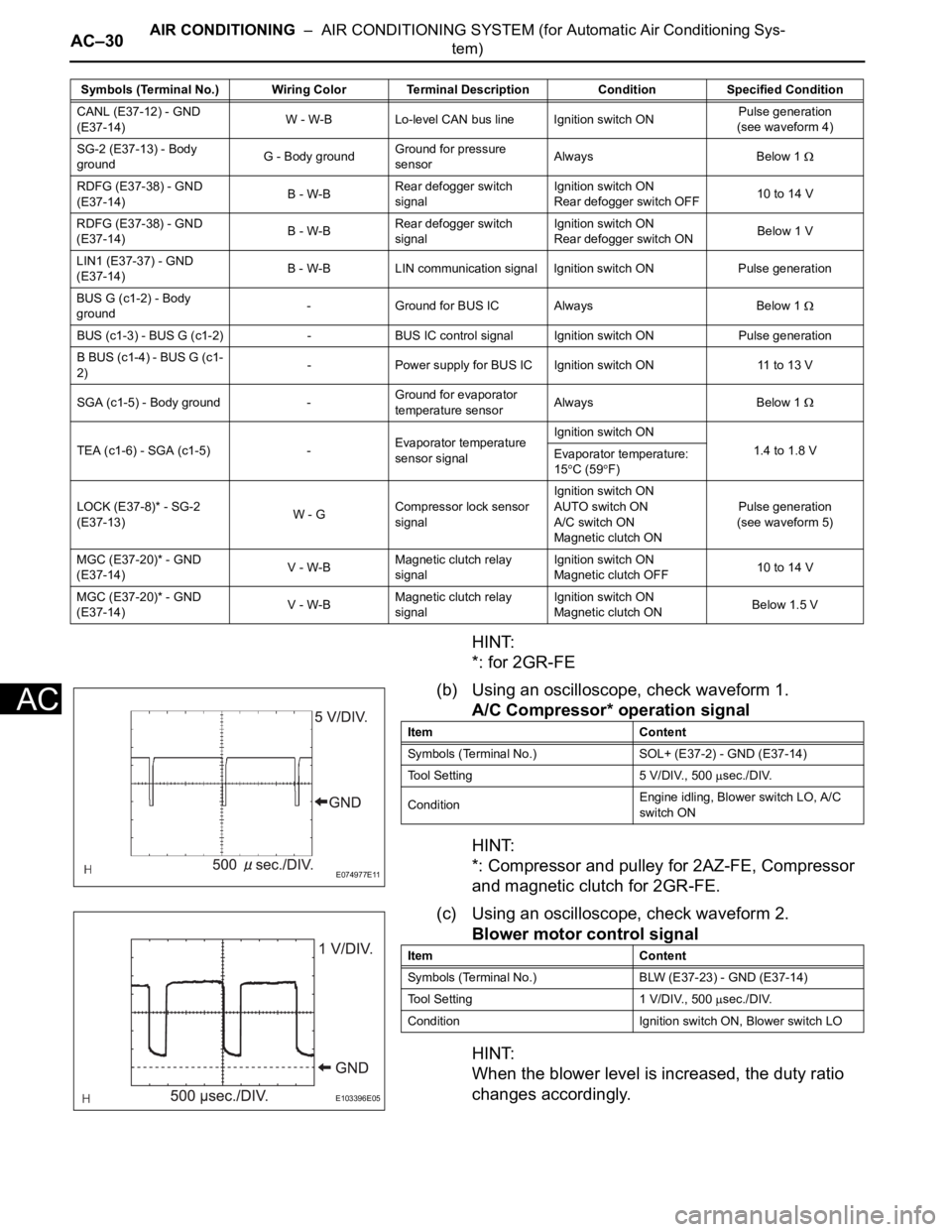

(b) Using an oscilloscope, check waveform 1.

Compressor and pulley operation signal

(c) Using an oscilloscope, check waveform 2.

Blower motor control signal

HINT:

When the blower level is increased, the duty ratio

changes accordingly.

(d) Using an oscilloscope, check waveform 3.

CAN communication signal

HINT:

The waveform varies depending on the CAN

communication signal.

CANL (E37-12) - GND

(E37-14)W - W-B Lo-level CAN bus line Ignition switch ONPulse generation

(see waveform 4)

SG-2 (E37-13) - Body

groundG - Body groundGround for pressure

sensorAlways Below 1

RDFG (E37-38) - GND

(E37-14)B - W-BRear defogger switch

signalIgnition switch ON

Rear defogger switch OFF10 to 14 V

RDFG (E37-38) - GND

(E37-14)B - W-BRear defogger switch

signalIgnition switch ON

Rear defogger switch ONBelow 1

LIN1 (E37-37) - GND

(E37-14)B - W-B LIN communication signalIgnition switch ON Pulse generation

BUS G (c1-2) - Body

ground- Ground for BUS IC Always Below 1

BUS (c1-3) - BUS G (c1-2) - BUS IC control signal Ignition switch ON Pulse generation

B BUS (c1-4) - BUS G (c1-

2)- Power supply for BUS IC Ignition switch ON 11 to 13 V

SGA (c1-5) - Body ground -Ground for evaporator

temperature sensorAlways Below 1

TEA (c1-6) - SGA (c1-5) -Evaporator temperature

sensor signalIgnition switch ON

1.4 to 1.8 V

Evaporator temperature:

15

C (59F) Symbols (Terminal No.) Wiring Color Terminal Description ConditionSpecified Condition

E074977E11

Item Content

Symbols (Terminal No.) SOL+ (E37-2) - GND (E37-14)

Tool Setting 5 V/DIV., 500

sec./DIV.

ConditionEngine idling, Blower switch LO, A/C

switch ON

E103396E05

Item Content

Symbols (Terminal No.) BLW (E37-23) - GND (E37-14)

Tool Setting 1 V/DIV., 500

sec./DIV.

Condition Ignition switch ON, Blower switch LO

A086154E10

Item Content

Symbols (Terminal No.) CANH (E37-11) - GND (E37-14)

Tool Setting 1 V/DIV., 10

sec./DIV.

Condition Ignition switch ON

Page 1657 of 2000

AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)AC–29

AC

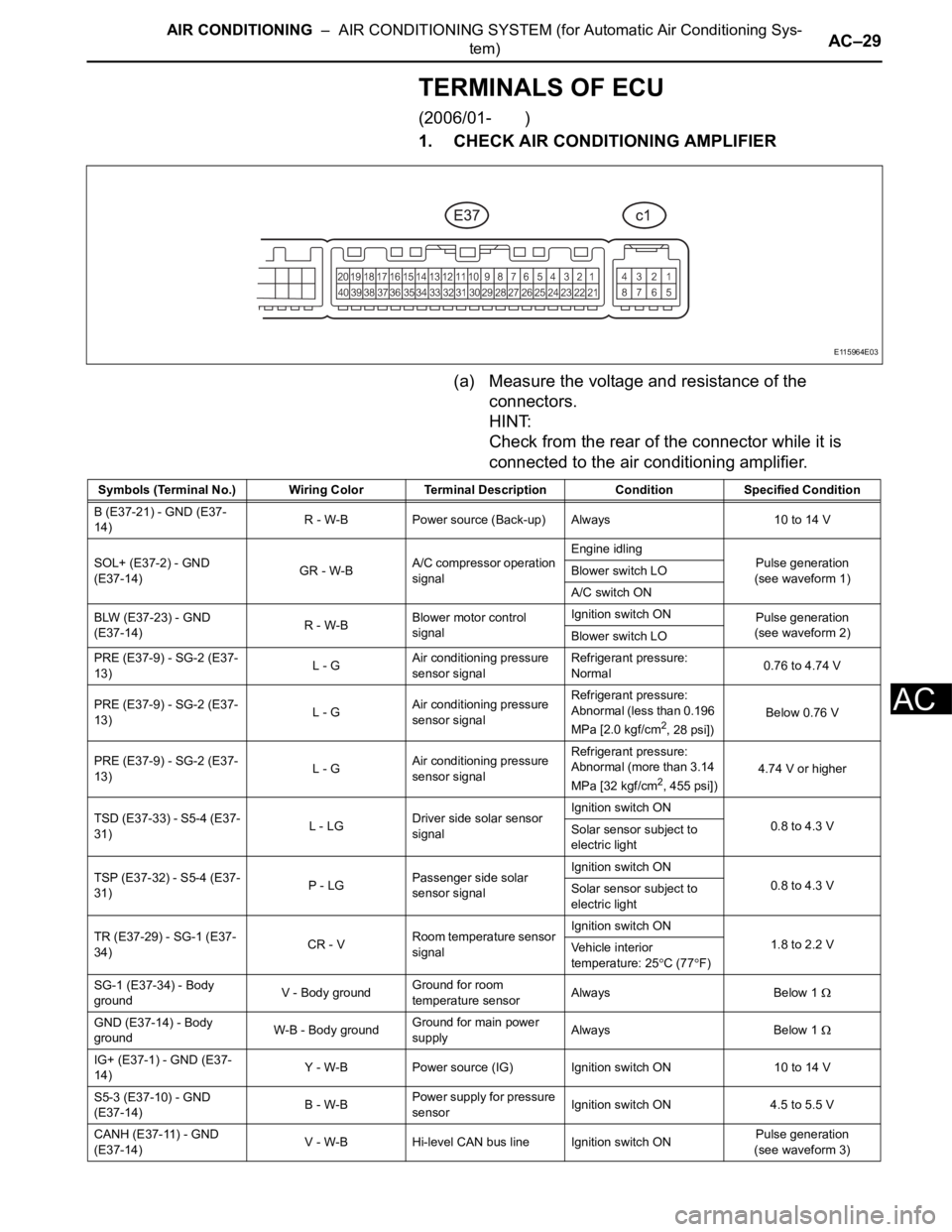

TERMINALS OF ECU

(2006/01- )

1. CHECK AIR CONDITIONING AMPLIFIER

(a) Measure the voltage and resistance of the

connectors.

HINT:

Check from the rear of the connector while it is

connected to the air conditioning amplifier.

E115964E03

Symbols (Terminal No.) Wiring Color Terminal Description ConditionSpecified Condition

B (E37-21) - GND (E37-

14)R - W-B Power source (Back-up) Always 10 to 14 V

SOL+ (E37-2) - GND

(E37-14)GR - W-BA/C compressor operation

signalEngine idling

Pulse generation

(see waveform 1) Blower switch LO

A/C switch ON

BLW (E37-23) - GND

(E37-14)R - W-BBlower motor control

signalIgnition switch ON

Pulse generation

(see waveform 2)

Blower switch LO

PRE (E37-9) - SG-2 (E37-

13)L - GAir conditioning pressure

sensor signalRefrigerant pressure:

Normal0.76 to 4.74 V

PRE (E37-9) - SG-2 (E37-

13)L - GAir conditioning pressure

sensor signalRefrigerant pressure:

Abnormal (less than 0.196

MPa [2.0 kgf/cm

2, 28 psi]) Below 0.76 V

PRE (E37-9) - SG-2 (E37-

13)L - GAir conditioning pressure

sensor signalRefrigerant pressure:

Abnormal (more than 3.14

MPa [32 kgf/cm

2, 455 psi])4.74 V or higher

TSD (E37-33) - S5-4 (E37-

31)L - LGDriver side solar sensor

signalIgnition switch ON

0.8 to 4.3 V

Solar sensor subject to

electric light

TSP (E37-32) - S5-4 (E37-

31)P - LGPassenger side solar

sensor signalIgnition switch ON

0.8 to 4.3 V

Solar sensor subject to

electric light

TR (E37-29) - SG-1 (E37-

34)CR - VRoom temperature sensor

signalIgnition switch ON

1.8 to 2.2 V

Vehicle interior

temperature: 25

C (77F)

SG-1 (E37-34) - Body

groundV - Body groundGround for room

temperature sensorAlways Below 1

GND (E37-14) - Body

groundW-B - Body groundGround for main power

supplyAlways Below 1

IG+ (E37-1) - GND (E37-

14)Y - W-B Power source (IG) Ignition switch ON 10 to 14 V

S5-3 (E37-10) - GND

(E37-14)B - W-BPower supply for pressure

sensorIgnition switch ON 4.5 to 5.5 V

CANH (E37-11) - GND

(E37-14)V - W-B Hi-level CAN bus line Ignition switch ONPulse generation

(see waveform 3)

Page 1658 of 2000

AC–30AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

HINT:

*: for 2GR-FE

(b) Using an oscilloscope, check waveform 1.

A/C Compressor* operation signal

HINT:

*: Compressor and pulley for 2AZ-FE, Compressor

and magnetic clutch for 2GR-FE.

(c) Using an oscilloscope, check waveform 2.

Blower motor control signal

HINT:

When the blower level is increased, the duty ratio

changes accordingly.

CANL (E37-12) - GND

(E37-14)W - W-B Lo-level CAN bus line Ignition switch ONPulse generation

(see waveform 4)

SG-2 (E37-13) - Body

groundG - Body groundGround for pressure

sensorAlways Below 1

RDFG (E37-38) - GND

(E37-14)B - W-BRear defogger switch

signalIgnition switch ON

Rear defogger switch OFF10 to 14 V

RDFG (E37-38) - GND

(E37-14)B - W-BRear defogger switch

signalIgnition switch ON

Rear defogger switch ONBelow 1 V

LIN1 (E37-37) - GND

(E37-14)B - W-B LIN communication signal Ignition switch ON Pulse generation

BUS G (c1-2) - Body

ground- Ground for BUS IC Always Below 1

BUS (c1-3) - BUS G (c1-2) - BUS IC control signal Ignition switch ON Pulse generation

B BUS (c1-4) - BUS G (c1-

2)- Power supply for BUS IC Ignition switch ON 11 to 13 V

SGA (c1-5) - Body ground -Ground for evaporator

temperature sensorAlways Below 1

TEA (c1-6) - SGA (c1-5) -Evaporator temperature

sensor signalIgnition switch ON

1.4 to 1.8 V

Evaporator temperature:

15

C (59F)

LOCK (E37-8)* - SG-2

(E37-13)W - GCompressor lock sensor

signalIgnition switch ON

AUTO switch ON

A/C switch ON

Magnetic clutch ONPulse generation

(see waveform 5)

MGC (E37-20)* - GND

(E37-14)V - W-BMagnetic clutch relay

signalIgnition switch ON

Magnetic clutch OFF10 to 14 V

MGC (E37-20)* - GND

(E37-14)V - W-BMagnetic clutch relay

signalIgnition switch ON

Magnetic clutch ONBelow 1.5 V Symbols (Terminal No.) Wiring Color Terminal Description ConditionSpecified Condition

E074977E11

Item Content

Symbols (Terminal No.) SOL+ (E37-2) - GND (E37-14)

Tool Setting 5 V/DIV., 500

sec./DIV.

ConditionEngine idling, Blower switch LO, A/C

switch ON

E103396E05

Item Content

Symbols (Terminal No.) BLW (E37-23) - GND (E37-14)

Tool Setting 1 V/DIV., 500

sec./DIV.

Condition Ignition switch ON, Blower switch LO

Page 1663 of 2000

AC–218AIR CONDITIONING – COMPRESSOR AND PULLEY (for 2AZ-FE)

AC

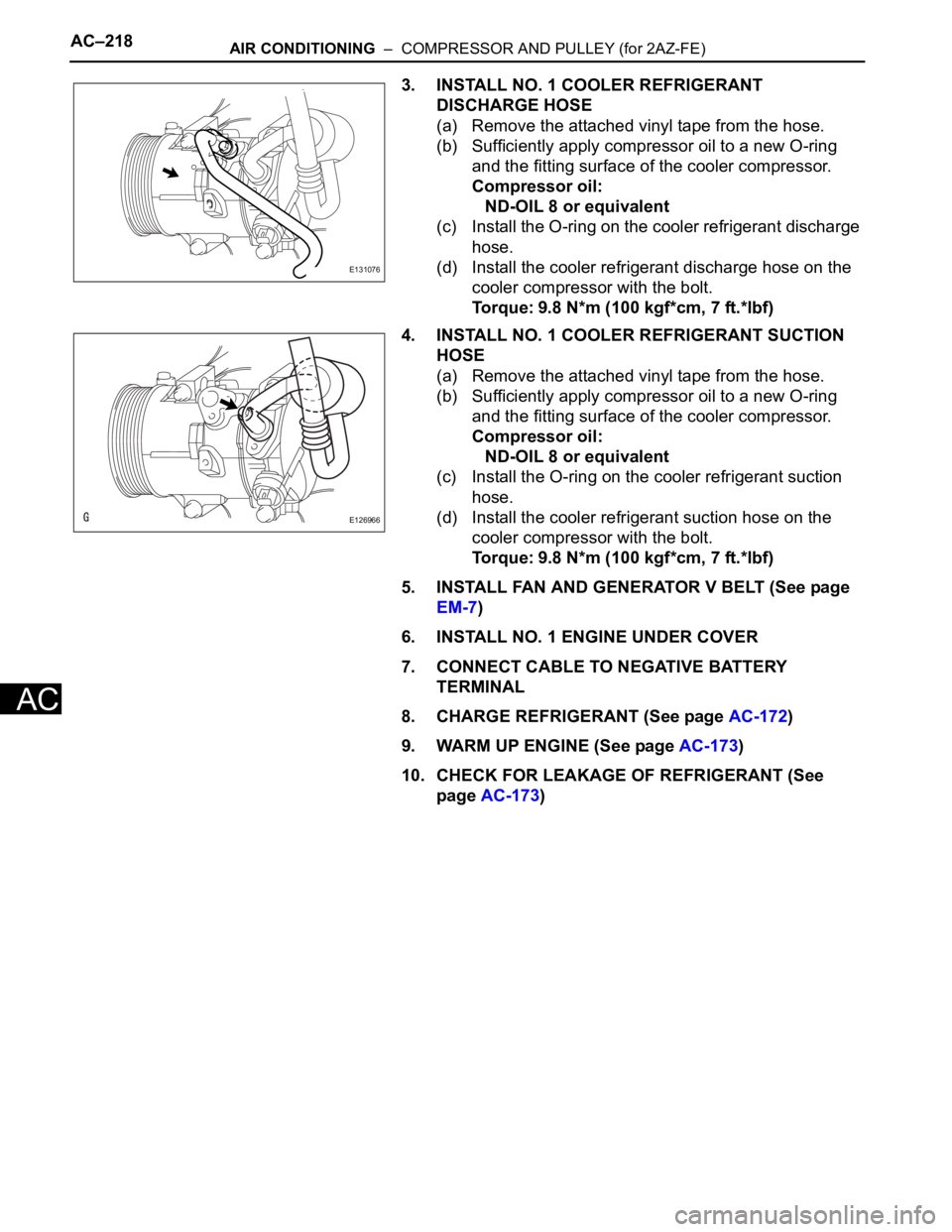

3. INSTALL NO. 1 COOLER REFRIGERANT

DISCHARGE HOSE

(a) Remove the attached vinyl tape from the hose.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the cooler compressor.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring on the cooler refrigerant discharge

hose.

(d) Install the cooler refrigerant discharge hose on the

cooler compressor with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

4. INSTALL NO. 1 COOLER REFRIGERANT SUCTION

HOSE

(a) Remove the attached vinyl tape from the hose.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the cooler compressor.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring on the cooler refrigerant suction

hose.

(d) Install the cooler refrigerant suction hose on the

cooler compressor with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

5. INSTALL FAN AND GENERATOR V BELT (See page

EM-7)

6. INSTALL NO. 1 ENGINE UNDER COVER

7. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

8. CHARGE REFRIGERANT (See page AC-172)

9. WARM UP ENGINE (See page AC-173)

10. CHECK FOR LEAKAGE OF REFRIGERANT (See

page AC-173)

E131076

E126966

Page 1664 of 2000

AIR CONDITIONING – COMPRESSOR AND PULLEY (for 2GR-FE)AC–221

AC

INSTALLATION

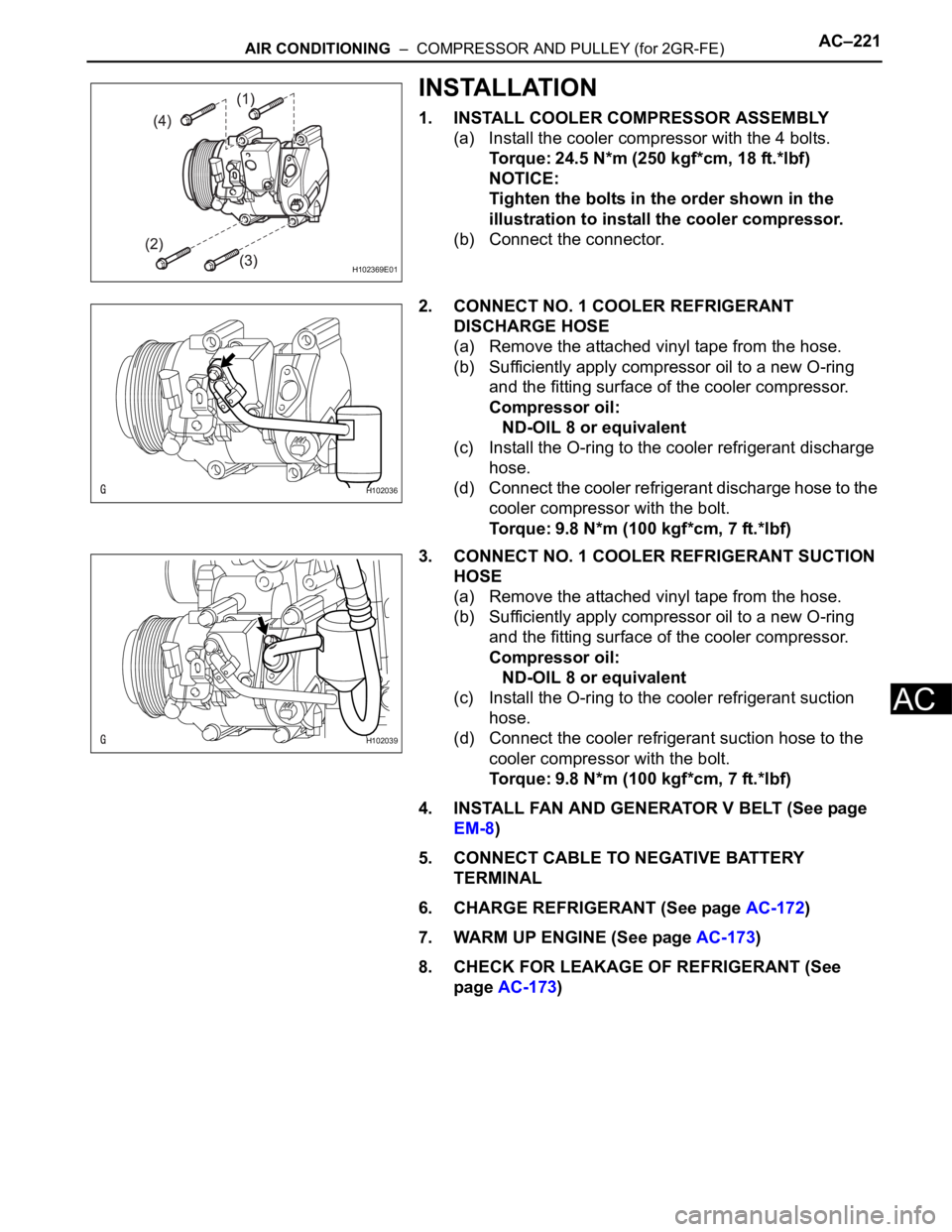

1. INSTALL COOLER COMPRESSOR ASSEMBLY

(a) Install the cooler compressor with the 4 bolts.

Torque: 24.5 N*m (250 kgf*cm, 18 ft.*lbf)

NOTICE:

Tighten the bolts in the order shown in the

illustration to install the cooler compressor.

(b) Connect the connector.

2. CONNECT NO. 1 COOLER REFRIGERANT

DISCHARGE HOSE

(a) Remove the attached vinyl tape from the hose.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the cooler compressor.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring to the cooler refrigerant discharge

hose.

(d) Connect the cooler refrigerant discharge hose to the

cooler compressor with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

3. CONNECT NO. 1 COOLER REFRIGERANT SUCTION

HOSE

(a) Remove the attached vinyl tape from the hose.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the cooler compressor.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring to the cooler refrigerant suction

hose.

(d) Connect the cooler refrigerant suction hose to the

cooler compressor with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

4. INSTALL FAN AND GENERATOR V BELT (See page

EM-8)

5. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

6. CHARGE REFRIGERANT (See page AC-172)

7. WARM UP ENGINE (See page AC-173)

8. CHECK FOR LEAKAGE OF REFRIGERANT (See

page AC-173)

H102369E01

H102036

H102039

Page 1669 of 2000

AC–228AIR CONDITIONING – CONDENSER

AC

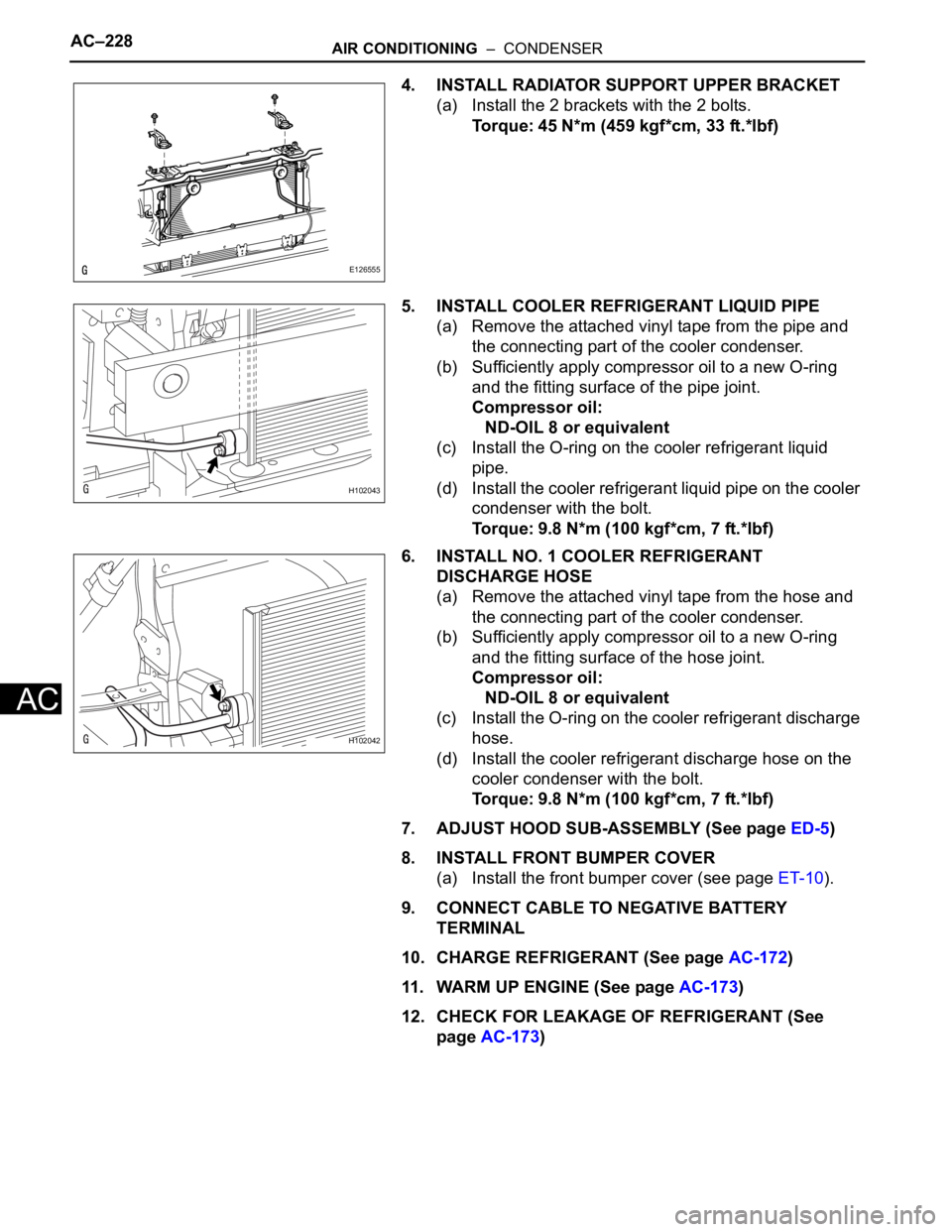

4. INSTALL RADIATOR SUPPORT UPPER BRACKET

(a) Install the 2 brackets with the 2 bolts.

Torque: 45 N*m (459 kgf*cm, 33 ft.*lbf)

5. INSTALL COOLER REFRIGERANT LIQUID PIPE

(a) Remove the attached vinyl tape from the pipe and

the connecting part of the cooler condenser.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the pipe joint.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring on the cooler refrigerant liquid

pipe.

(d) Install the cooler refrigerant liquid pipe on the cooler

condenser with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

6. INSTALL NO. 1 COOLER REFRIGERANT

DISCHARGE HOSE

(a) Remove the attached vinyl tape from the hose and

the connecting part of the cooler condenser.

(b) Sufficiently apply compressor oil to a new O-ring

and the fitting surface of the hose joint.

Compressor oil:

ND-OIL 8 or equivalent

(c) Install the O-ring on the cooler refrigerant discharge

hose.

(d) Install the cooler refrigerant discharge hose on the

cooler condenser with the bolt.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf)

7. ADJUST HOOD SUB-ASSEMBLY (See page ED-5)

8. INSTALL FRONT BUMPER COVER

(a) Install the front bumper cover (see page ET-10).

9. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

10. CHARGE REFRIGERANT (See page AC-172)

11. WARM UP ENGINE (See page AC-173)

12. CHECK FOR LEAKAGE OF REFRIGERANT (See

page AC-173)

E126555

H102043

H102042

Page 1709 of 2000

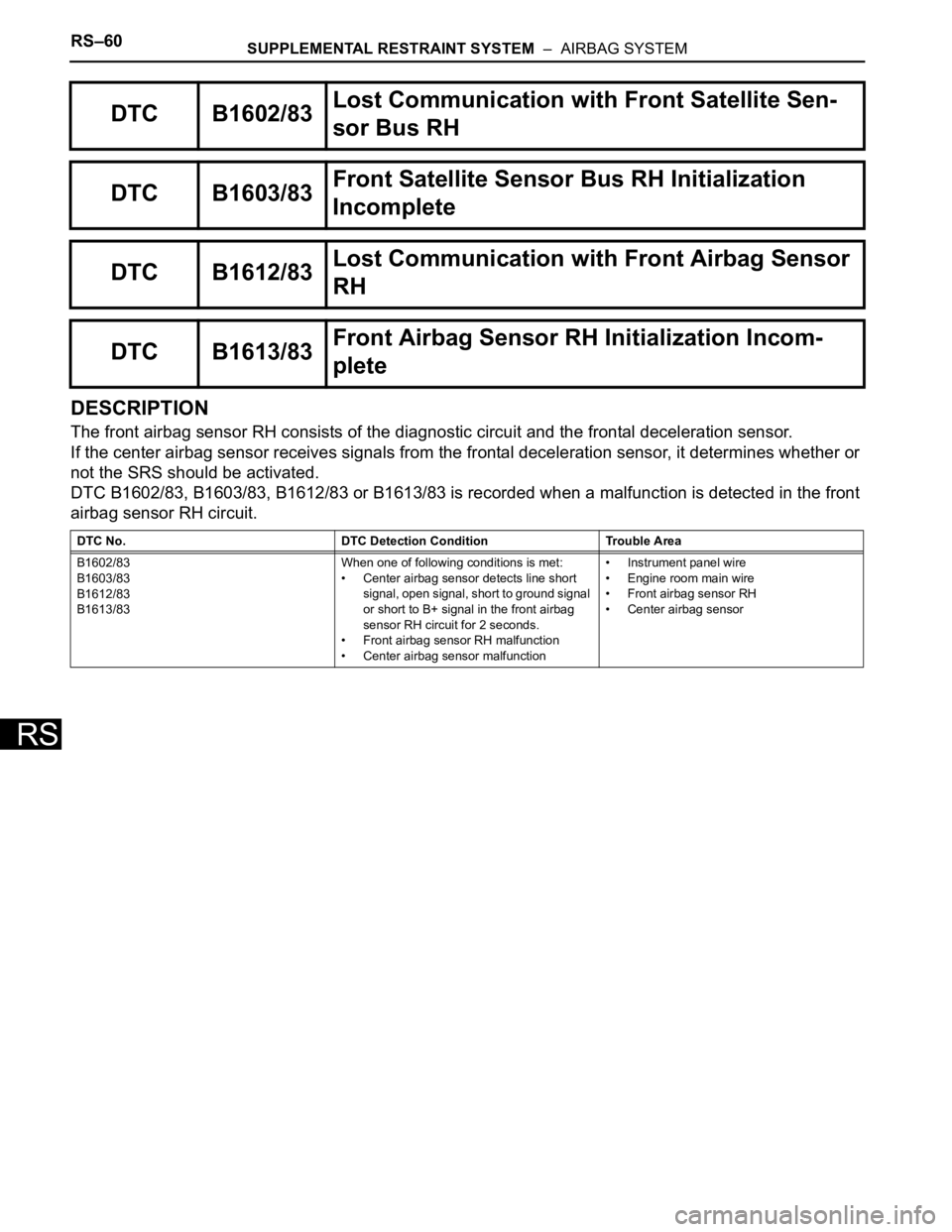

RS–60SUPPLEMENTAL RESTRAINT SYSTEM – AIRBAG SYSTEM

RS

DESCRIPTION

The front airbag sensor RH consists of the diagnostic circuit and the frontal deceleration sensor.

If the center airbag sensor receives signals from the frontal deceleration sensor, it determines whether or

not the SRS should be activated.

DTC B1602/83, B1603/83, B1612/83 or B1613/83 is recorded when a malfunction is detected in the front

airbag sensor RH circuit.

DTC B1602/83Lost Communication with Front Satellite Sen-

sor Bus RH

DTC B1603/83Front Satellite Sensor Bus RH Initialization

Incomplete

DTC B1612/83Lost Communication with Front Airbag Sensor

RH

DTC B1613/83Front Airbag Sensor RH Initialization Incom-

plete

DTC No. DTC Detection Condition Trouble Area

B1602/83

B1603/83

B1612/83

B1613/83When one of following conditions is met:

• Center airbag sensor detects line short

signal, open signal, short to ground signal

or short to B+ signal in the front airbag

sensor RH circuit for 2 seconds.

• Front airbag sensor RH malfunction

• Center airbag sensor malfunction• Instrument panel wire

• Engine room main wire

• Front airbag sensor RH

• Center airbag sensor

Page 1716 of 2000

SUPPLEMENTAL RESTRAINT SYSTEM – AIRBAG SYSTEMRS–67

RS

(a) Disconnect the service wire from connector E.

(b) Disconnect the engine room main wire connector from

the instrument panel wire.

(c) Using a service wire, connect AE9-2 (+SR) and AE9-1 (-

SR) of connector D.

NOTICE:

Do not forcibly insert a service wire into the

terminals of the connector when connecting.

(d) Measure the resistance of the wire harness side

connector.

Standard resistance

NG

OK

7CHECK ENGINE ROOM MAIN WIRE (OPEN)

C128665E01

Tester Connection Specified Condition

A29-2 (+SR) - A29-1 (-SR) Below 1

REPAIR OR REPLACE ENGINE ROOM MAIN

WIRE

REPAIR OR REPLACE INSTRUMENT PANEL WIRE