engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1570 of 2000

BRAKE – BRAKE PEDALBR–15

BR

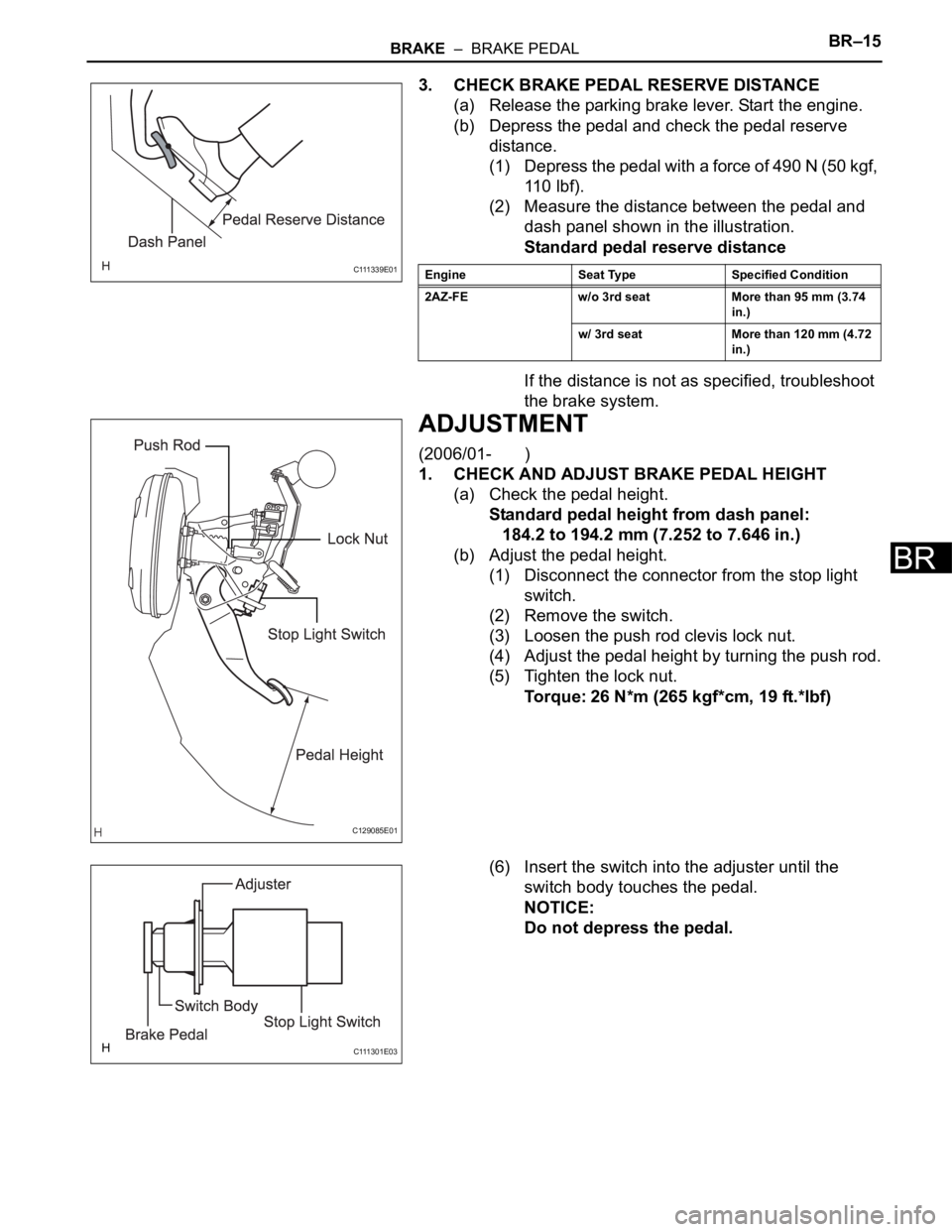

3. CHECK BRAKE PEDAL RESERVE DISTANCE

(a) Release the parking brake lever. Start the engine.

(b) Depress the pedal and check the pedal reserve

distance.

(1) Depress the pedal with a force of 490 N (50 kgf,

11 0 l b f ) .

(2) Measure the distance between the pedal and

dash panel shown in the illustration.

Standard pedal reserve distance

If the distance is not as specified, troubleshoot

the brake system.

ADJUSTMENT

(2006/01- )

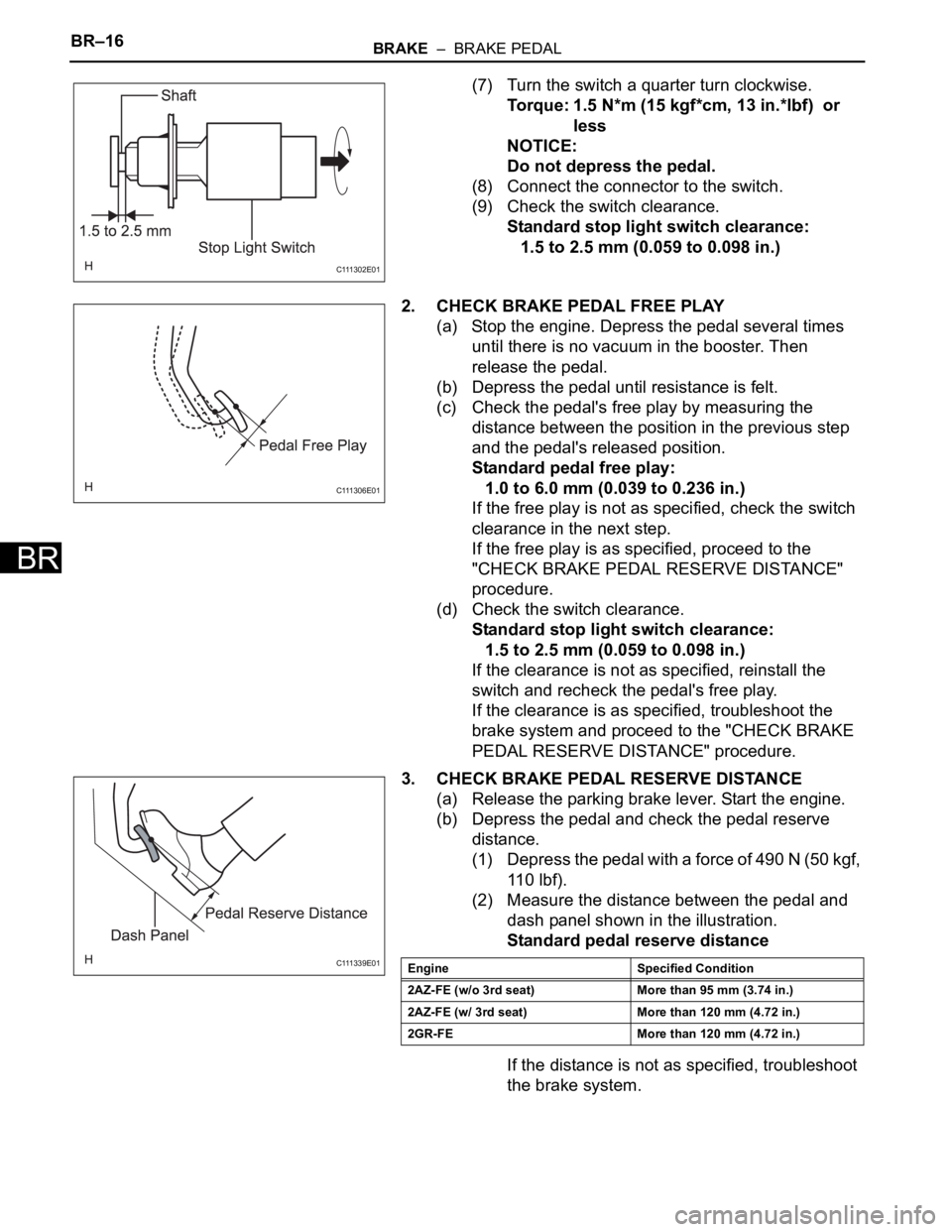

1. CHECK AND ADJUST BRAKE PEDAL HEIGHT

(a) Check the pedal height.

Standard pedal height from dash panel:

184.2 to 194.2 mm (7.252 to 7.646 in.)

(b) Adjust the pedal height.

(1) Disconnect the connector from the stop light

switch.

(2) Remove the switch.

(3) Loosen the push rod clevis lock nut.

(4) Adjust the pedal height by turning the push rod.

(5) Tighten the lock nut.

Torque: 26 N*m (265 kgf*cm, 19 ft.*lbf)

(6) Insert the switch into the adjuster until the

switch body touches the pedal.

NOTICE:

Do not depress the pedal.

C 111 3 3 9 E 0 1Engine Seat Type Specified Condition

2AZ-FE w/o 3rd seat More than 95 mm (3.74

in.)

w/ 3rd seat More than 120 mm (4.72

in.)

C129085E01

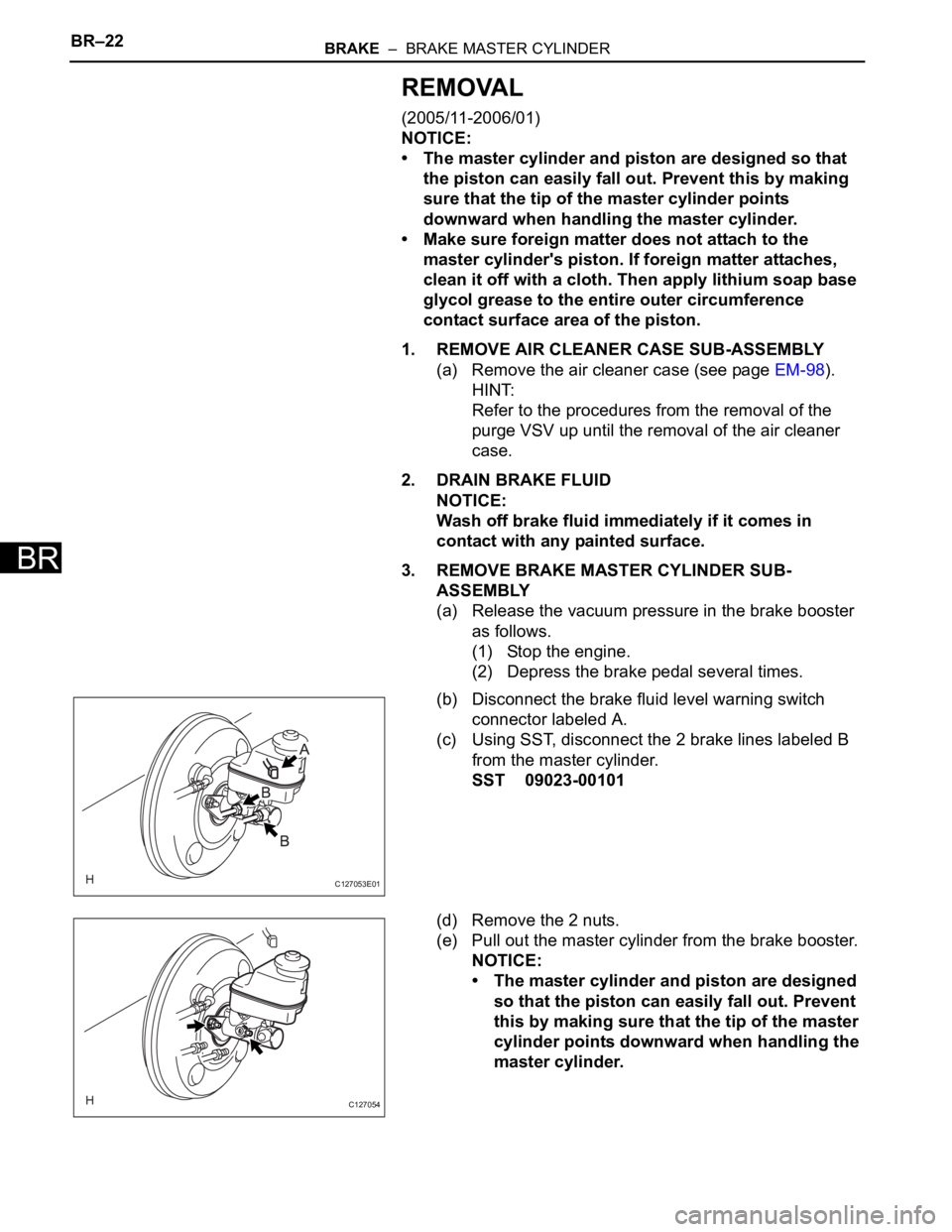

C 111 3 0 1 E 0 3

Page 1571 of 2000

BR–16BRAKE – BRAKE PEDAL

BR

(7) Turn the switch a quarter turn clockwise.

Torque: 1.5 N*m (15 kgf*cm, 13 in.*lbf) or

less

NOTICE:

Do not depress the pedal.

(8) Connect the connector to the switch.

(9) Check the switch clearance.

Standard stop light switch clearance:

1.5 to 2.5 mm (0.059 to 0.098 in.)

2. CHECK BRAKE PEDAL FREE PLAY

(a) Stop the engine. Depress the pedal several times

until there is no vacuum in the booster. Then

release the pedal.

(b) Depress the pedal until resistance is felt.

(c) Check the pedal's free play by measuring the

distance between the position in the previous step

and the pedal's released position.

Standard pedal free play:

1.0 to 6.0 mm (0.039 to 0.236 in.)

If the free play is not as specified, check the switch

clearance in the next step.

If the free play is as specified, proceed to the

"CHECK BRAKE PEDAL RESERVE DISTANCE"

procedure.

(d) Check the switch clearance.

Standard stop light switch clearance:

1.5 to 2.5 mm (0.059 to 0.098 in.)

If the clearance is not as specified, reinstall the

switch and recheck the pedal's free play.

If the clearance is as specified, troubleshoot the

brake system and proceed to the "CHECK BRAKE

PEDAL RESERVE DISTANCE" procedure.

3. CHECK BRAKE PEDAL RESERVE DISTANCE

(a) Release the parking brake lever. Start the engine.

(b) Depress the pedal and check the pedal reserve

distance.

(1) Depress the pedal with a force of 490 N (50 kgf,

11 0 l b f ) .

(2) Measure the distance between the pedal and

dash panel shown in the illustration.

Standard pedal reserve distance

If the distance is not as specified, troubleshoot

the brake system.

C 111 3 0 2 E 0 1

C 111 3 0 6 E 0 1

C 111 3 3 9 E 0 1Engine Specified Condition

2AZ-FE (w/o 3rd seat) More than 95 mm (3.74 in.)

2AZ-FE (w/ 3rd seat) More than 120 mm (4.72 in.)

2GR-FE More than 120 mm (4.72 in.)

Page 1575 of 2000

BR–22BRAKE – BRAKE MASTER CYLINDER

BR

REMOVAL

(2005/11-2006/01)

NOTICE:

• The master cylinder and piston are designed so that

the piston can easily fall out. Prevent this by making

sure that the tip of the master cylinder points

downward when handling the master cylinder.

• Make sure foreign matter does not attach to the

master cylinder's piston. If foreign matter attaches,

clean it off with a cloth. Then apply lithium soap base

glycol grease to the entire outer circumference

contact surface area of the piston.

1. REMOVE AIR CLEANER CASE SUB-ASSEMBLY

(a) Remove the air cleaner case (see page EM-98).

HINT:

Refer to the procedures from the removal of the

purge VSV up until the removal of the air cleaner

case.

2. DRAIN BRAKE FLUID

NOTICE:

Wash off brake fluid immediately if it comes in

contact with any painted surface.

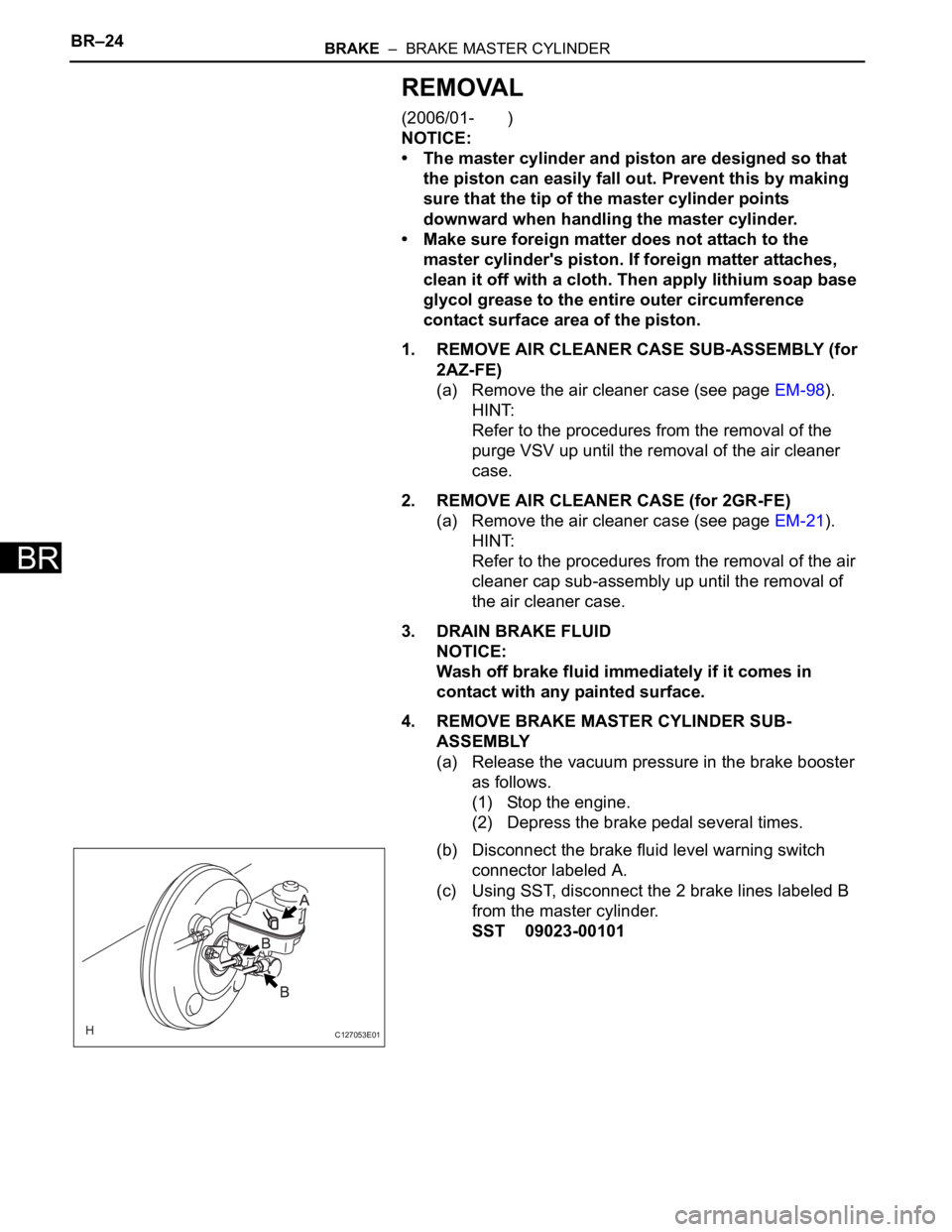

3. REMOVE BRAKE MASTER CYLINDER SUB-

ASSEMBLY

(a) Release the vacuum pressure in the brake booster

as follows.

(1) Stop the engine.

(2) Depress the brake pedal several times.

(b) Disconnect the brake fluid level warning switch

connector labeled A.

(c) Using SST, disconnect the 2 brake lines labeled B

from the master cylinder.

SST 09023-00101

(d) Remove the 2 nuts.

(e) Pull out the master cylinder from the brake booster.

NOTICE:

• The master cylinder and piston are designed

so that the piston can easily fall out. Prevent

this by making sure that the tip of the master

cylinder points downward when handling the

master cylinder.

C127053E01

C127054

Page 1577 of 2000

BR–24BRAKE – BRAKE MASTER CYLINDER

BR

REMOVAL

(2006/01- )

NOTICE:

• The master cylinder and piston are designed so that

the piston can easily fall out. Prevent this by making

sure that the tip of the master cylinder points

downward when handling the master cylinder.

• Make sure foreign matter does not attach to the

master cylinder's piston. If foreign matter attaches,

clean it off with a cloth. Then apply lithium soap base

glycol grease to the entire outer circumference

contact surface area of the piston.

1. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (for

2AZ-FE)

(a) Remove the air cleaner case (see page EM-98).

HINT:

Refer to the procedures from the removal of the

purge VSV up until the removal of the air cleaner

case.

2. REMOVE AIR CLEANER CASE (for 2GR-FE)

(a) Remove the air cleaner case (see page EM-21).

HINT:

Refer to the procedures from the removal of the air

cleaner cap sub-assembly up until the removal of

the air cleaner case.

3. DRAIN BRAKE FLUID

NOTICE:

Wash off brake fluid immediately if it comes in

contact with any painted surface.

4. REMOVE BRAKE MASTER CYLINDER SUB-

ASSEMBLY

(a) Release the vacuum pressure in the brake booster

as follows.

(1) Stop the engine.

(2) Depress the brake pedal several times.

(b) Disconnect the brake fluid level warning switch

connector labeled A.

(c) Using SST, disconnect the 2 brake lines labeled B

from the master cylinder.

SST 09023-00101

C127053E01

Page 1614 of 2000

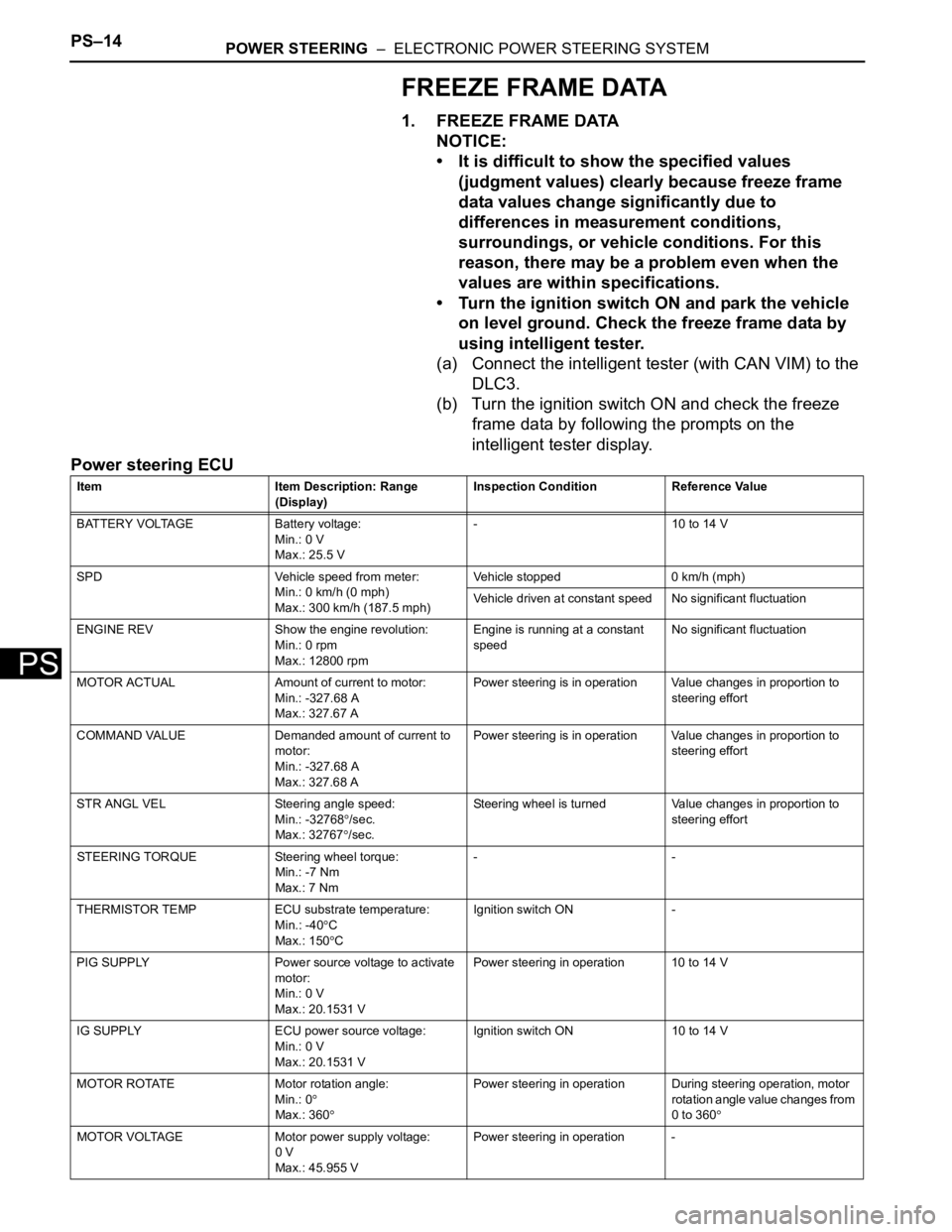

PS–14POWER STEERING – ELECTRONIC POWER STEERING SYSTEM

PS

FREEZE FRAME DATA

1. FREEZE FRAME DATA

NOTICE:

• It is difficult to show the specified values

(judgment values) clearly because freeze frame

data values change significantly due to

differences in measurement conditions,

surroundings, or vehicle conditions. For this

reason, there may be a problem even when the

values are within specifications.

• Turn the ignition switch ON and park the vehicle

on level ground. Check the freeze frame data by

using intelligent tester.

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

(b) Turn the ignition switch ON and check the freeze

frame data by following the prompts on the

intelligent tester display.

Power steering ECU

Item Item Description: Range

(Display)Inspection Condition Reference Value

BATTERY VOLTAGE Battery voltage:

Min.: 0 V

Max.: 25.5 V- 10 to 14 V

SPD Vehicle speed from meter:

Min.: 0 km/h (0 mph)

Max.: 300 km/h (187.5 mph)Vehicle stopped 0 km/h (mph)

Vehicle driven at constant speedNo significant fluctuation

ENGINE REV Show the engine revolution:

Min.: 0 rpm

Max.: 12800 rpmEngine is running at a constant

speedNo significant fluctuation

MOTOR ACTUAL Amount of current to motor:

Min.: -327.68 A

Max.: 327.67 APower steering is in operationValue changes in proportion to

steering effort

COMMAND VALUE Demanded amount of current to

motor:

Min.: -327.68 A

Max.: 327.68 APower steering is in operationValue changes in proportion to

steering effort

STR ANGL VEL Steering angle speed:

Min.: -32768

/sec.

Max.: 32767/sec.Steering wheel is turned Value changes in proportion to

steering effort

STEERING TORQUE Steering wheel torque:

Min.: -7 Nm

Max.: 7 Nm--

THERMISTOR TEMP ECU substrate temperature:

Min.: -40

C

Max.: 150

CIgnition switch ON -

PIG SUPPLY Power source voltage to activate

motor:

Min.: 0 V

Max.: 20.1531 VPower steering in operation 10 to 14 V

IG SUPPLY ECU power source voltage:

Min.: 0 V

Max.: 20.1531 VIgnition switch ON 10 to 14 V

MOTOR ROTATE Motor rotation angle:

Min.: 0

Max.: 360

Power steering in operation During steering operation, motor

rotation angle value changes from

0 to 360

MOTOR VOLTAGE Motor power supply voltage:

0 V

Max.: 45.955 VPower steering in operation -

Page 1616 of 2000

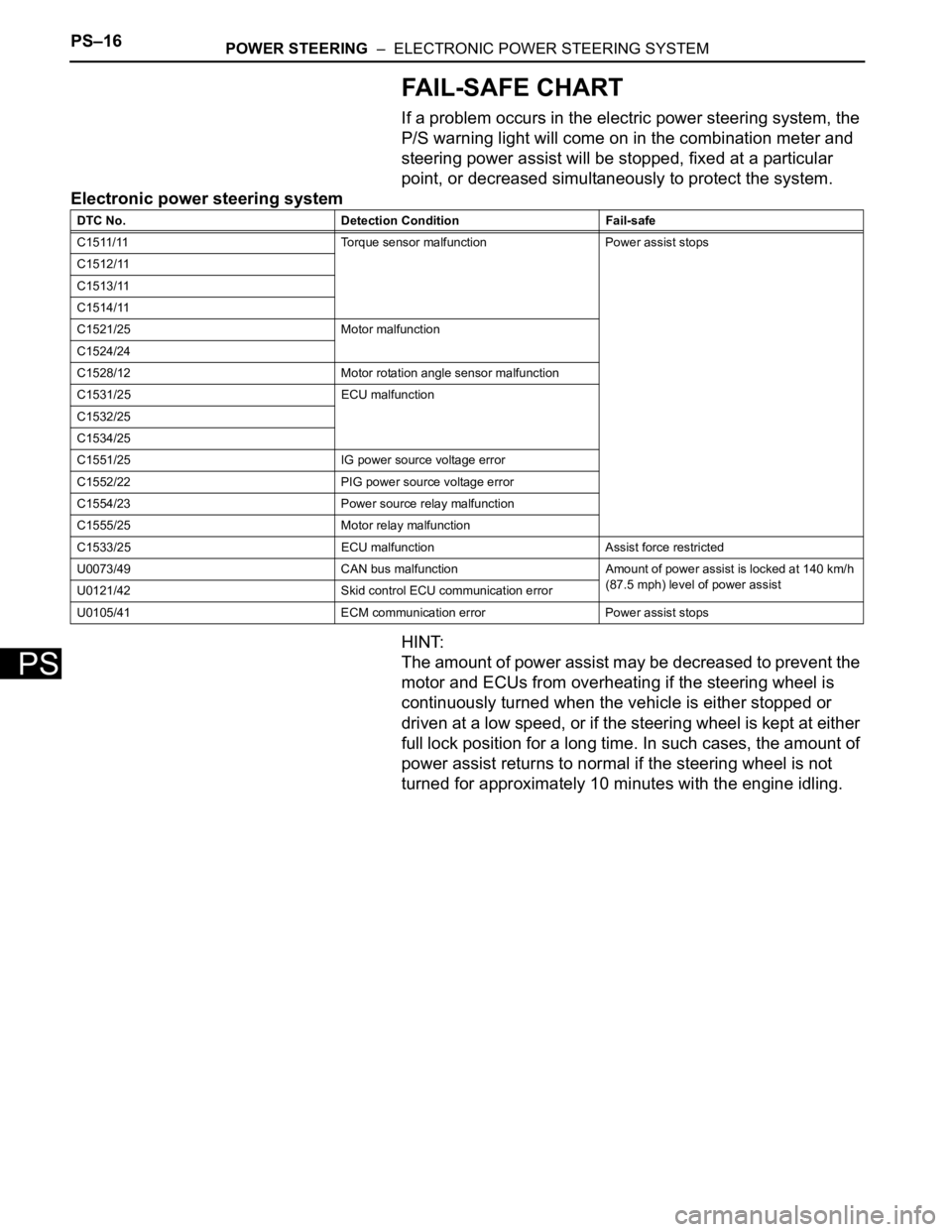

PS–16POWER STEERING – ELECTRONIC POWER STEERING SYSTEM

PS

FAIL-SAFE CHART

If a problem occurs in the electric power steering system, the

P/S warning light will come on in the combination meter and

steering power assist will be stopped, fixed at a particular

point, or decreased simultaneously to protect the system.

Electronic power steering system

HINT:

The amount of power assist may be decreased to prevent the

motor and ECUs from overheating if the steering wheel is

continuously turned when the vehicle is either stopped or

driven at a low speed, or if the steering wheel is kept at either

full lock position for a long time. In such cases, the amount of

power assist returns to normal if the steering wheel is not

turned for approximately 10 minutes with the engine idling.

DTC No. Detection Condition Fail-safe

C1511/11 Torque sensor malfunction Power assist stops

C1512/11

C1513/11

C1514/11

C1521/25 Motor malfunction

C1524/24

C1528/12 Motor rotation angle sensor malfunction

C1531/25 ECU malfunction

C1532/25

C1534/25

C1551/25 IG power source voltage error

C1552/22 PIG power source voltage error

C1554/23 Power source relay malfunction

C1555/25 Motor relay malfunction

C1533/25 ECU malfunction Assist force restricted

U0073/49 CAN bus malfunction Amount of power assist is locked at 140 km/h

(87.5 mph) level of power assist

U0121/42 Skid control ECU communication error

U0105/41 ECM communication error Power assist stops

Page 1617 of 2000

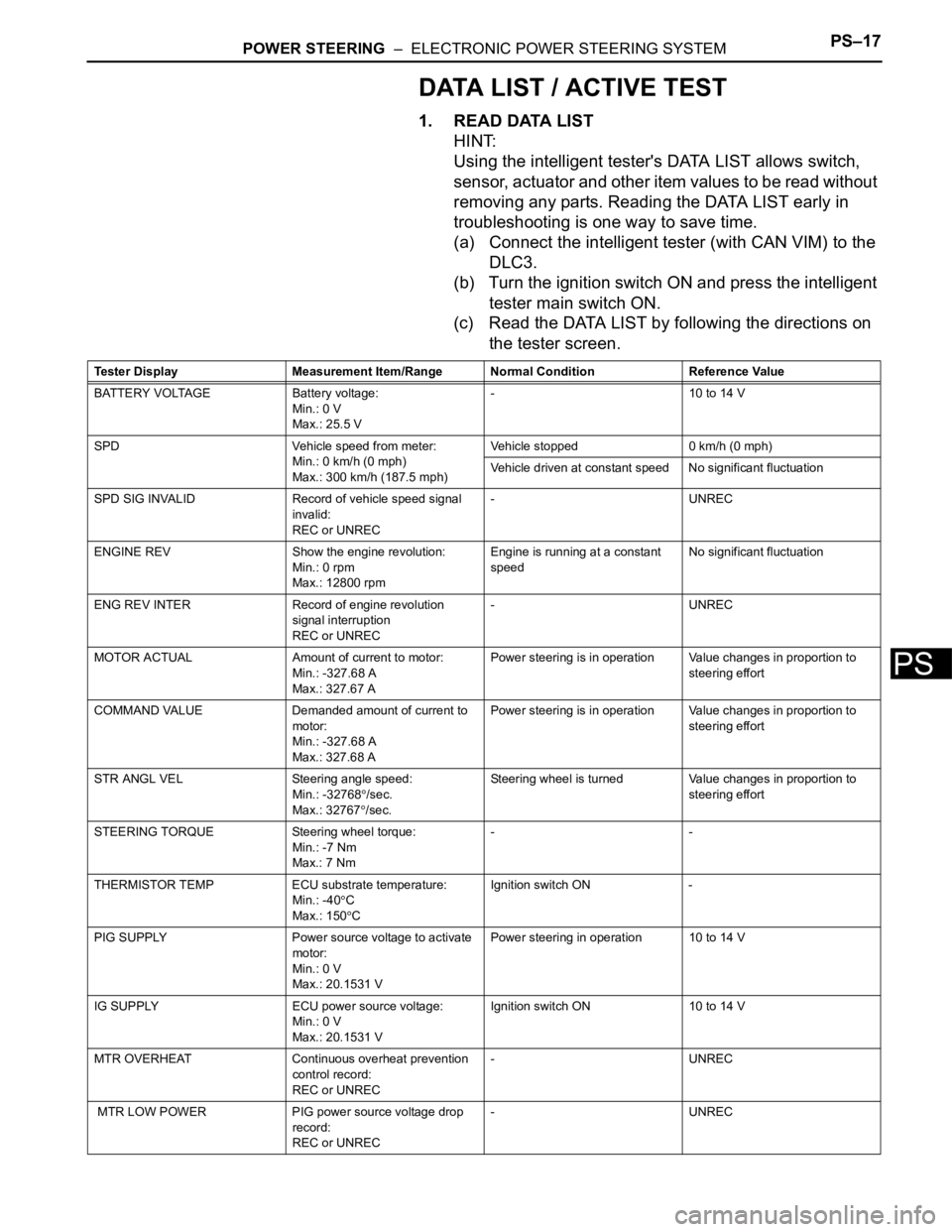

POWER STEERING – ELECTRONIC POWER STEERING SYSTEMPS–17

PS

DATA LIST / ACTIVE TEST

1. READ DATA LIST

HINT:

Using the intelligent tester's DATA LIST allows switch,

sensor, actuator and other item values to be read without

removing any parts. Reading the DATA LIST early in

troubleshooting is one way to save time.

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

(b) Turn the ignition switch ON and press the intelligent

tester main switch ON.

(c) Read the DATA LIST by following the directions on

the tester screen.

Tester Display Measurement Item/Range Normal Condition Reference Value

BATTERY VOLTAGE Battery voltage:

Min.: 0 V

Max.: 25.5 V- 10 to 14 V

SPD Vehicle speed from meter:

Min.: 0 km/h (0 mph)

Max.: 300 km/h (187.5 mph)Vehicle stopped 0 km/h (0 mph)

Vehicle driven at constant speed No significant fluctuation

SPD SIG INVALID Record of vehicle speed signal

invalid:

REC or UNREC- UNREC

ENGINE REV Show the engine revolution:

Min.: 0 rpm

Max.: 12800 rpmEngine is running at a constant

speedNo significant fluctuation

ENG REV INTER Record of engine revolution

signal interruption

REC or UNREC- UNREC

MOTOR ACTUAL Amount of current to motor:

Min.: -327.68 A

Max.: 327.67 APower steering is in operation Value changes in proportion to

steering effort

COMMAND VALUE Demanded amount of current to

motor:

Min.: -327.68 A

Max.: 327.68 APower steering is in operation Value changes in proportion to

steering effort

STR ANGL VEL Steering angle speed:

Min.: -32768

/sec.

Max.: 32767

/sec.Steering wheel is turned Value changes in proportion to

steering effort

STEERING TORQUE Steering wheel torque:

Min.: -7 Nm

Max.: 7 Nm--

THERMISTOR TEMP ECU substrate temperature:

Min.: -40

C

Max.: 150

CIgnition switch ON -

PIG SUPPLY Power source voltage to activate

motor:

Min.: 0 V

Max.: 20.1531 VPower steering in operation 10 to 14 V

IG SUPPLY ECU power source voltage:

Min.: 0 V

Max.: 20.1531 VIgnition switch ON 10 to 14 V

MTR OVERHEAT Continuous overheat prevention

control record:

REC or UNREC- UNREC

MTR LOW POWER PIG power source voltage drop

record:

REC or UNREC- UNREC

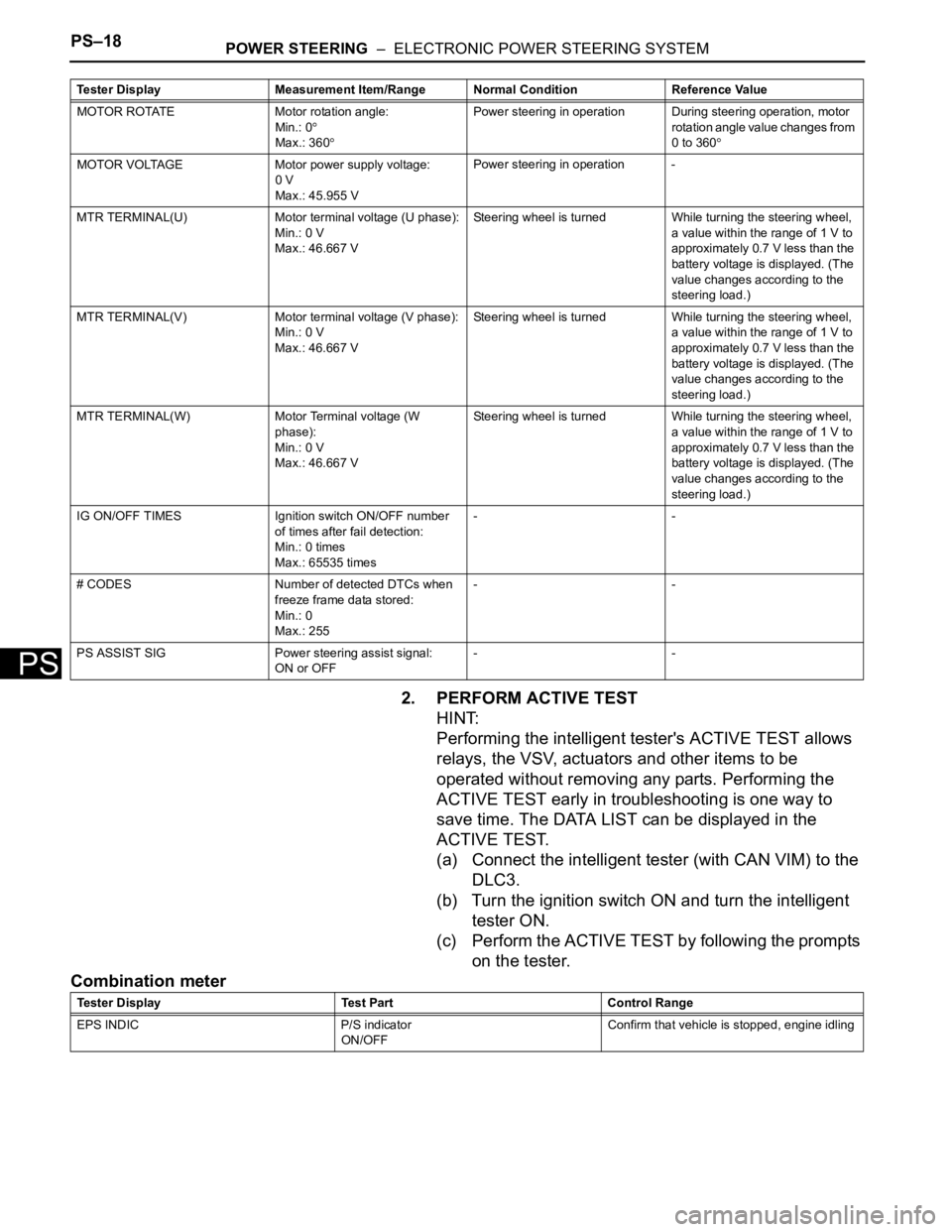

Page 1618 of 2000

PS–18POWER STEERING – ELECTRONIC POWER STEERING SYSTEM

PS

2. PERFORM ACTIVE TEST

HINT:

Performing the intelligent tester's ACTIVE TEST allows

relays, the VSV, actuators and other items to be

operated without removing any parts. Performing the

ACTIVE TEST early in troubleshooting is one way to

save time. The DATA LIST can be displayed in the

ACTIVE TEST.

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

(b) Turn the ignition switch ON and turn the intelligent

tester ON.

(c) Perform the ACTIVE TEST by following the prompts

on the tester.

Combination meter

MOTOR ROTATE Motor rotation angle:

Min.: 0

Max.: 360

Power steering in operation During steering operation, motor

rotation angle value changes from

0 to 360

MOTOR VOLTAGE Motor power supply voltage:

0 V

Max.: 45.955 VPower steering in operation -

MTR TERMINAL(U) Motor terminal voltage (U phase):

Min.: 0 V

Max.: 46.667 VSteering wheel is turned While turning the steering wheel,

a value within the range of 1 V to

approximately 0.7 V less than the

battery voltage is displayed. (The

value changes according to the

steering load.)

MTR TERMINAL(V) Motor terminal voltage (V phase):

Min.: 0 V

Max.: 46.667 VSteering wheel is turned While turning the steering wheel,

a value within the range of 1 V to

approximately 0.7 V less than the

battery voltage is displayed. (The

value changes according to the

steering load.)

MTR TERMINAL(W) Motor Terminal voltage (W

phase):

Min.: 0 V

Max.: 46.667 VSteering wheel is turned While turning the steering wheel,

a value within the range of 1 V to

approximately 0.7 V less than the

battery voltage is displayed. (The

value changes according to the

steering load.)

IG ON/OFF TIMES Ignition switch ON/OFF number

of times after fail detection:

Min.: 0 times

Max.: 65535 times--

# CODES Number of detected DTCs when

freeze frame data stored:

Min.: 0

Max.: 255 --

PS ASSIST SIG Power steering assist signal:

ON or OFF-- Tester Display Measurement Item/Range Normal Condition Reference Value

Tester Display Test Part Control Range

EPS INDIC P/S indicator

ON/OFFConfirm that vehicle is stopped, engine idling

Page 1638 of 2000

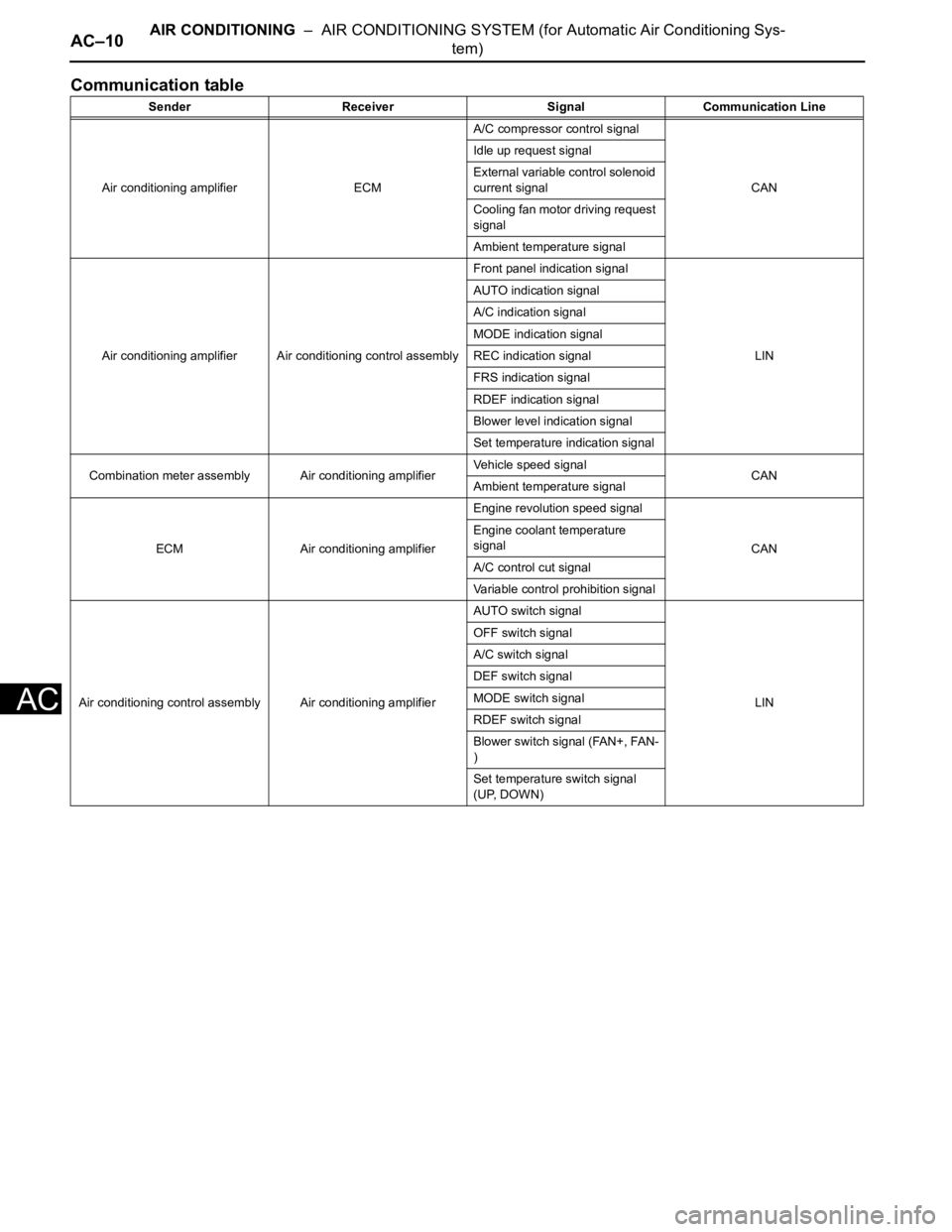

AC–10AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

Communication table

Sender Receiver Signal Communication Line

Air conditioning amplifier ECMA/C compressor control signal

CAN Idle up request signal

External variable control solenoid

current signal

Cooling fan motor driving request

signal

Ambient temperature signal

Air conditioning amplifier Air conditioning control assemblyFront panel indication signal

LIN AUTO indication signal

A/C indication signal

MODE indication signal

REC indication signal

FRS indication signal

RDEF indication signal

Blower level indication signal

Set temperature indication signal

Combination meter assembly Air conditioning amplifierVehicle speed signal

CAN

Ambient temperature signal

ECM Air conditioning amplifierEngine revolution speed signal

CAN Engine coolant temperature

signal

A/C control cut signal

Variable control prohibition signal

Air conditioning control assembly Air conditioning amplifierAUTO switch signal

LIN OFF switch signal

A/C switch signal

DEF switch signal

MODE switch signal

RDEF switch signal

Blower switch signal (FAN+, FAN-

)

Set temperature switch signal

(UP, DOWN)

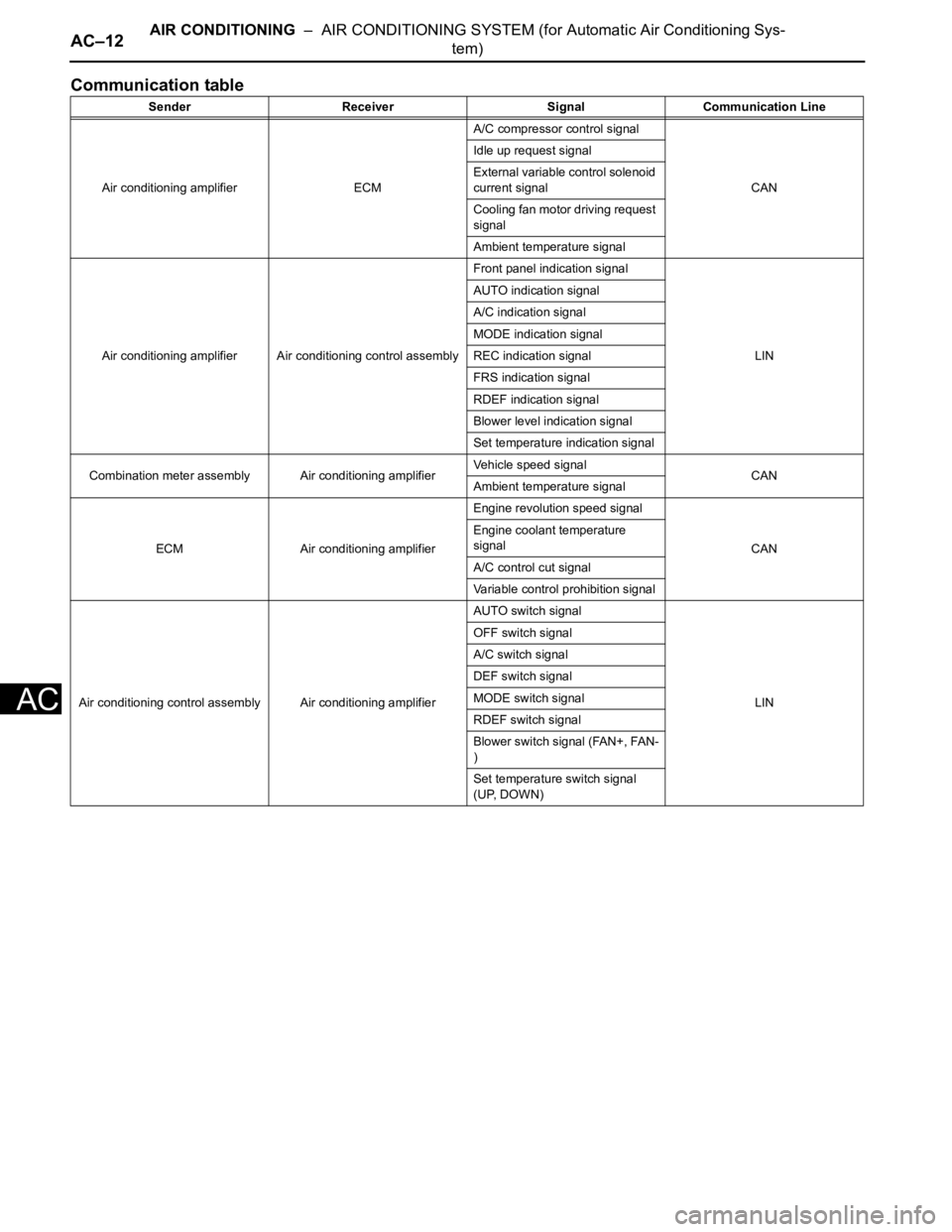

Page 1640 of 2000

AC–12AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

Communication table

Sender Receiver Signal Communication Line

Air conditioning amplifier ECMA/C compressor control signal

CAN Idle up request signal

External variable control solenoid

current signal

Cooling fan motor driving request

signal

Ambient temperature signal

Air conditioning amplifier Air conditioning control assemblyFront panel indication signal

LIN AUTO indication signal

A/C indication signal

MODE indication signal

REC indication signal

FRS indication signal

RDEF indication signal

Blower level indication signal

Set temperature indication signal

Combination meter assembly Air conditioning amplifierVehicle speed signal

CAN

Ambient temperature signal

ECM Air conditioning amplifierEngine revolution speed signal

CAN Engine coolant temperature

signal

A/C control cut signal

Variable control prohibition signal

Air conditioning control assembly Air conditioning amplifierAUTO switch signal

LIN OFF switch signal

A/C switch signal

DEF switch signal

MODE switch signal

RDEF switch signal

Blower switch signal (FAN+, FAN-

)

Set temperature switch signal

(UP, DOWN)