engine TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1869 of 2000

LI–38LIGHTING – LIGHTING SYSTEM

LI

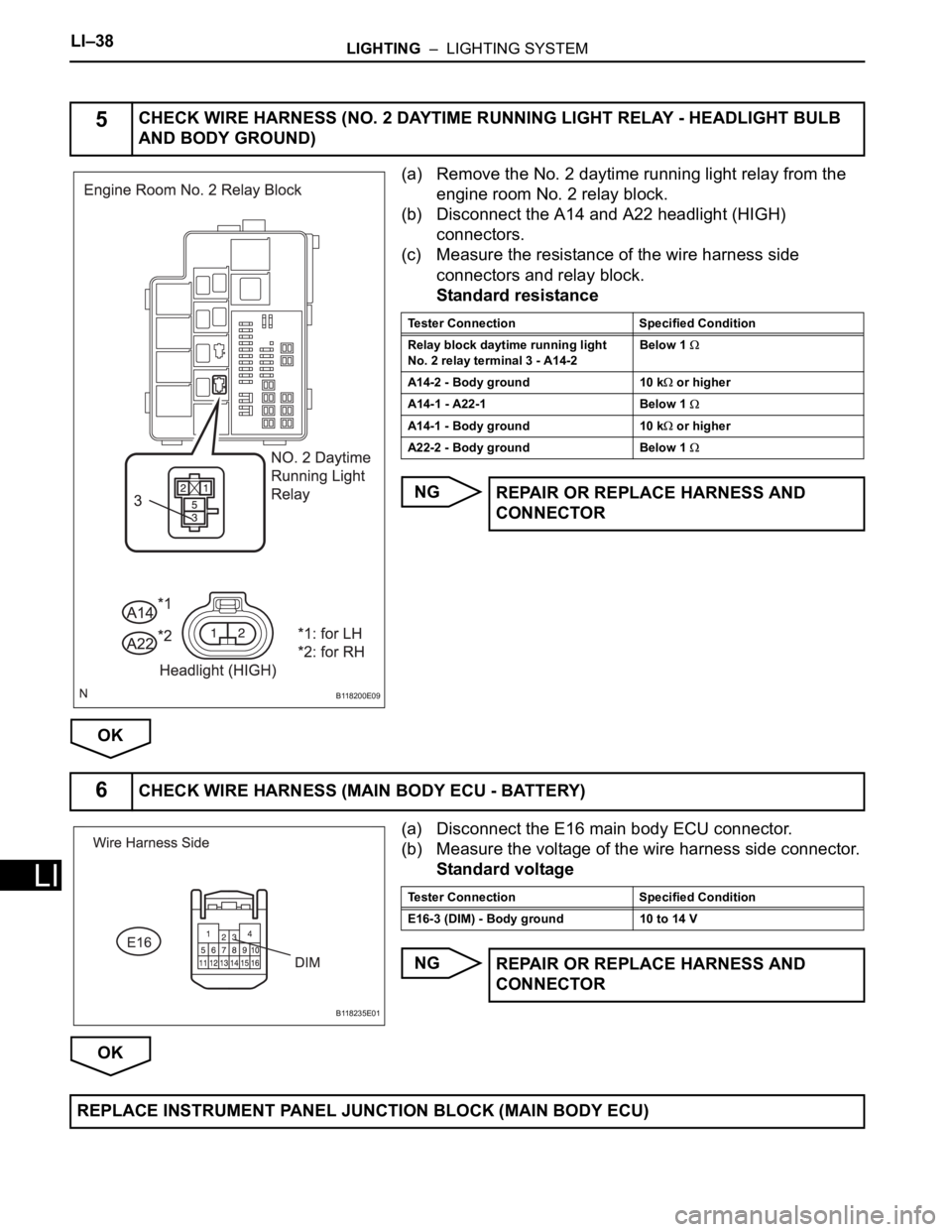

(a) Remove the No. 2 daytime running light relay from the

engine room No. 2 relay block.

(b) Disconnect the A14 and A22 headlight (HIGH)

connectors.

(c) Measure the resistance of the wire harness side

connectors and relay block.

Standard resistance

NG

OK

(a) Disconnect the E16 main body ECU connector.

(b) Measure the voltage of the wire harness side connector.

Standard voltage

NG

OK

5CHECK WIRE HARNESS (NO. 2 DAYTIME RUNNING LIGHT RELAY - HEADLIGHT BULB

AND BODY GROUND)

B118200E09

Tester Connection Specified Condition

Relay block daytime running light

No. 2 relay terminal 3 - A14-2Below 1

A14-2 - Body ground 10 k or higher

A14-1 - A22-1 Below 1

A14-1 - Body ground 10 k or higher

A22-2 - Body ground Below 1

REPAIR OR REPLACE HARNESS AND

CONNECTOR

6CHECK WIRE HARNESS (MAIN BODY ECU - BATTERY)

B118235E01

Tester Connection Specified Condition

E16-3 (DIM) - Body ground 10 to 14 V

REPAIR OR REPLACE HARNESS AND

CONNECTOR

REPLACE INSTRUMENT PANEL JUNCTION BLOCK (MAIN BODY ECU)

Page 1872 of 2000

LIGHTING – LIGHTING SYSTEMLI–41

LI

NG

(a) Check that the headlight (LOW) comes on when the light

control switch is on (HEAD).

OK:

Headlight (LOW) comes on.

NG

OK

(a) Remove the HEAD LH fuse and HEAD RH fuse from the

engine room No. 2 relay block.

(b) Measure the resistance of the fuses.

Standard resistance:

Below 1

NG

OK

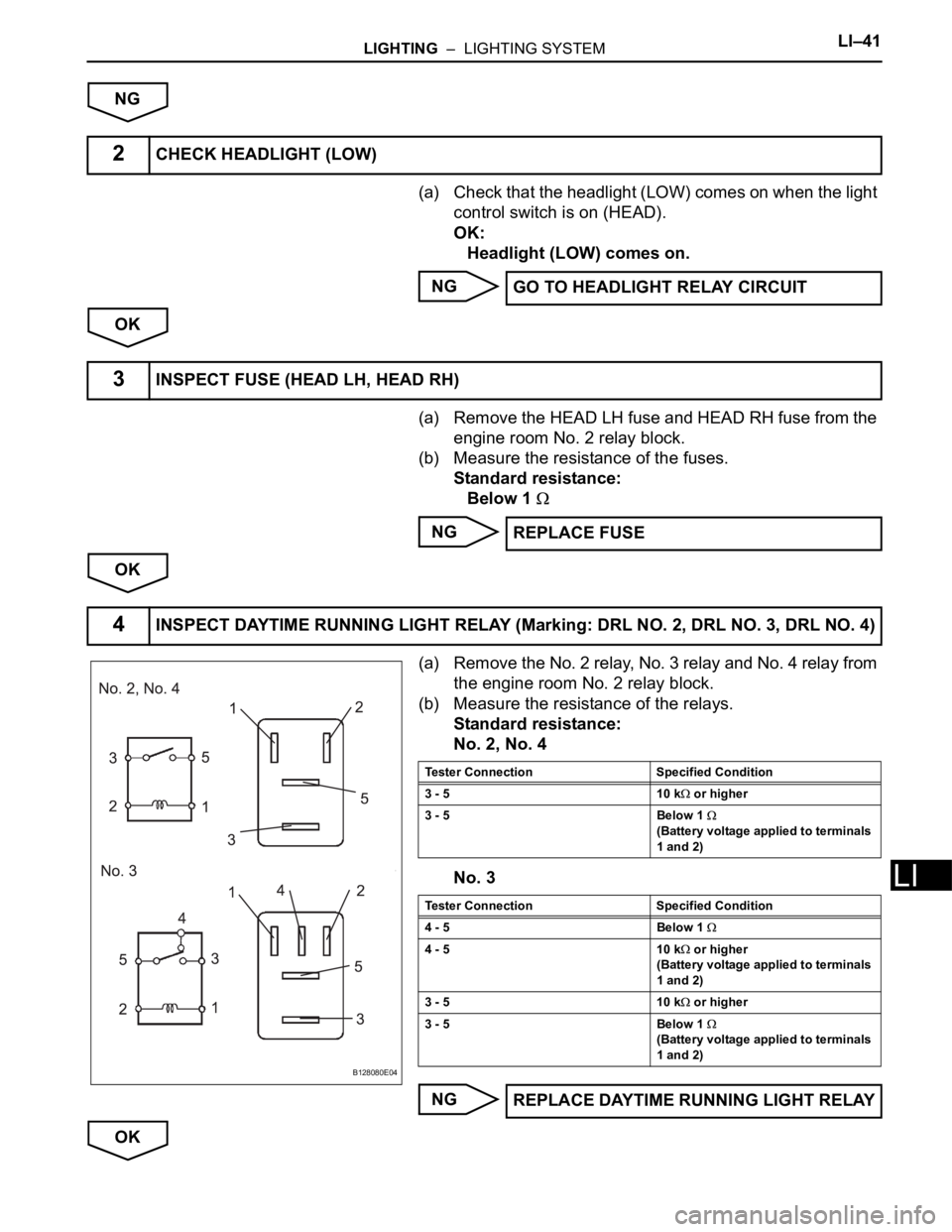

(a) Remove the No. 2 relay, No. 3 relay and No. 4 relay from

the engine room No. 2 relay block.

(b) Measure the resistance of the relays.

Standard resistance:

No. 2, No. 4

No. 3

NG

OK

2CHECK HEADLIGHT (LOW)

GO TO HEADLIGHT RELAY CIRCUIT

3INSPECT FUSE (HEAD LH, HEAD RH)

REPLACE FUSE

4INSPECT DAYTIME RUNNING LIGHT RELAY (Marking: DRL NO. 2, DRL NO. 3, DRL NO. 4)

B128080E04

Tester Connection Specified Condition

3 - 5 10 k

or higher

3 - 5 Below 1

(Battery voltage applied to terminals

1 and 2)

Tester Connection Specified Condition

4 - 5 Below 1

4 - 5 10 k or higher

(Battery voltage applied to terminals

1 and 2)

3 - 5 10 k

or higher

3 - 5 Below 1

(Battery voltage applied to terminals

1 and 2)

REPLACE DAYTIME RUNNING LIGHT RELAY

Page 1873 of 2000

LI–42LIGHTING – LIGHTING SYSTEM

LI

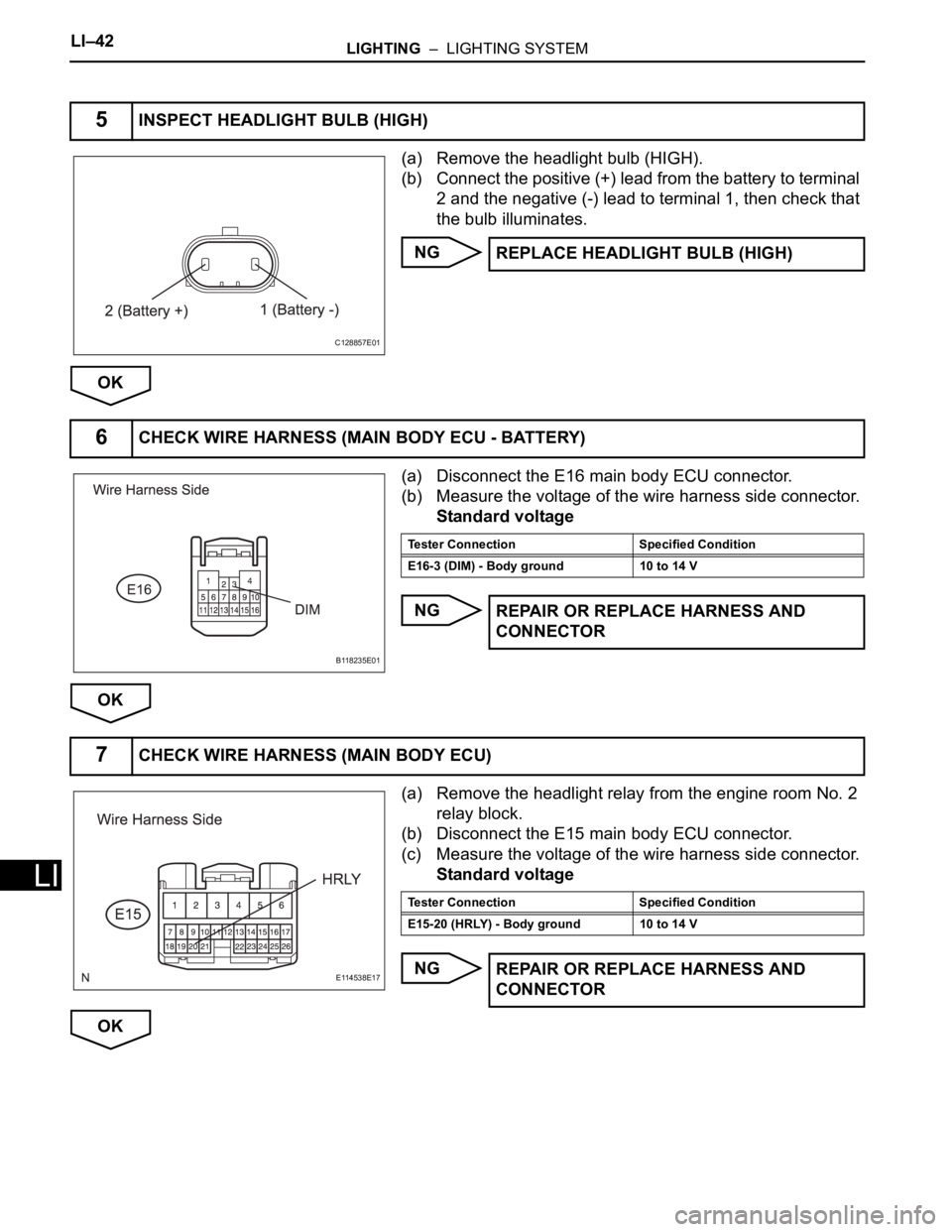

(a) Remove the headlight bulb (HIGH).

(b) Connect the positive (+) lead from the battery to terminal

2 and the negative (-) lead to terminal 1, then check that

the bulb illuminates.

NG

OK

(a) Disconnect the E16 main body ECU connector.

(b) Measure the voltage of the wire harness side connector.

Standard voltage

NG

OK

(a) Remove the headlight relay from the engine room No. 2

relay block.

(b) Disconnect the E15 main body ECU connector.

(c) Measure the voltage of the wire harness side connector.

Standard voltage

NG

OK

5INSPECT HEADLIGHT BULB (HIGH)

C128857E01

REPLACE HEADLIGHT BULB (HIGH)

6CHECK WIRE HARNESS (MAIN BODY ECU - BATTERY)

B118235E01

Tester Connection Specified Condition

E16-3 (DIM) - Body ground 10 to 14 V

REPAIR OR REPLACE HARNESS AND

CONNECTOR

7CHECK WIRE HARNESS (MAIN BODY ECU)

E114538E17

Tester Connection Specified Condition

E15-20 (HRLY) - Body ground 10 to 14 V

REPAIR OR REPLACE HARNESS AND

CONNECTOR

Page 1874 of 2000

LIGHTING – LIGHTING SYSTEMLI–43

LI

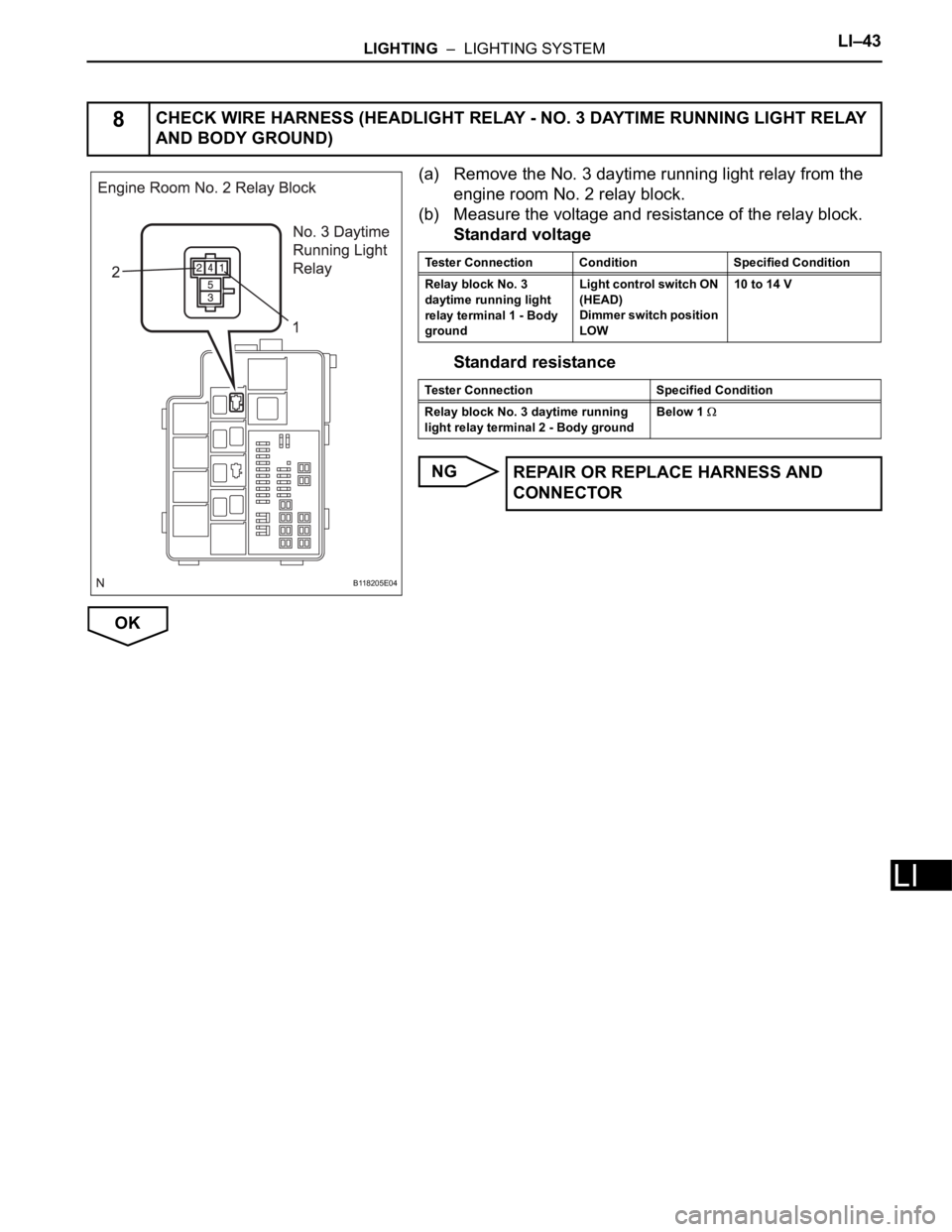

(a) Remove the No. 3 daytime running light relay from the

engine room No. 2 relay block.

(b) Measure the voltage and resistance of the relay block.

Standard voltage

Standard resistance

NG

OK

8CHECK WIRE HARNESS (HEADLIGHT RELAY - NO. 3 DAYTIME RUNNING LIGHT RELAY

AND BODY GROUND)

B118205E04

Tester Connection Condition Specified Condition

Relay block No. 3

daytime running light

relay terminal 1 - Body

groundLight control switch ON

(HEAD)

Dimmer switch position

LOW10 to 14 V

Tester Connection Specified Condition

Relay block No. 3 daytime running

light relay terminal 2 - Body groundBelow 1

REPAIR OR REPLACE HARNESS AND

CONNECTOR

Page 1875 of 2000

LI–44LIGHTING – LIGHTING SYSTEM

LI

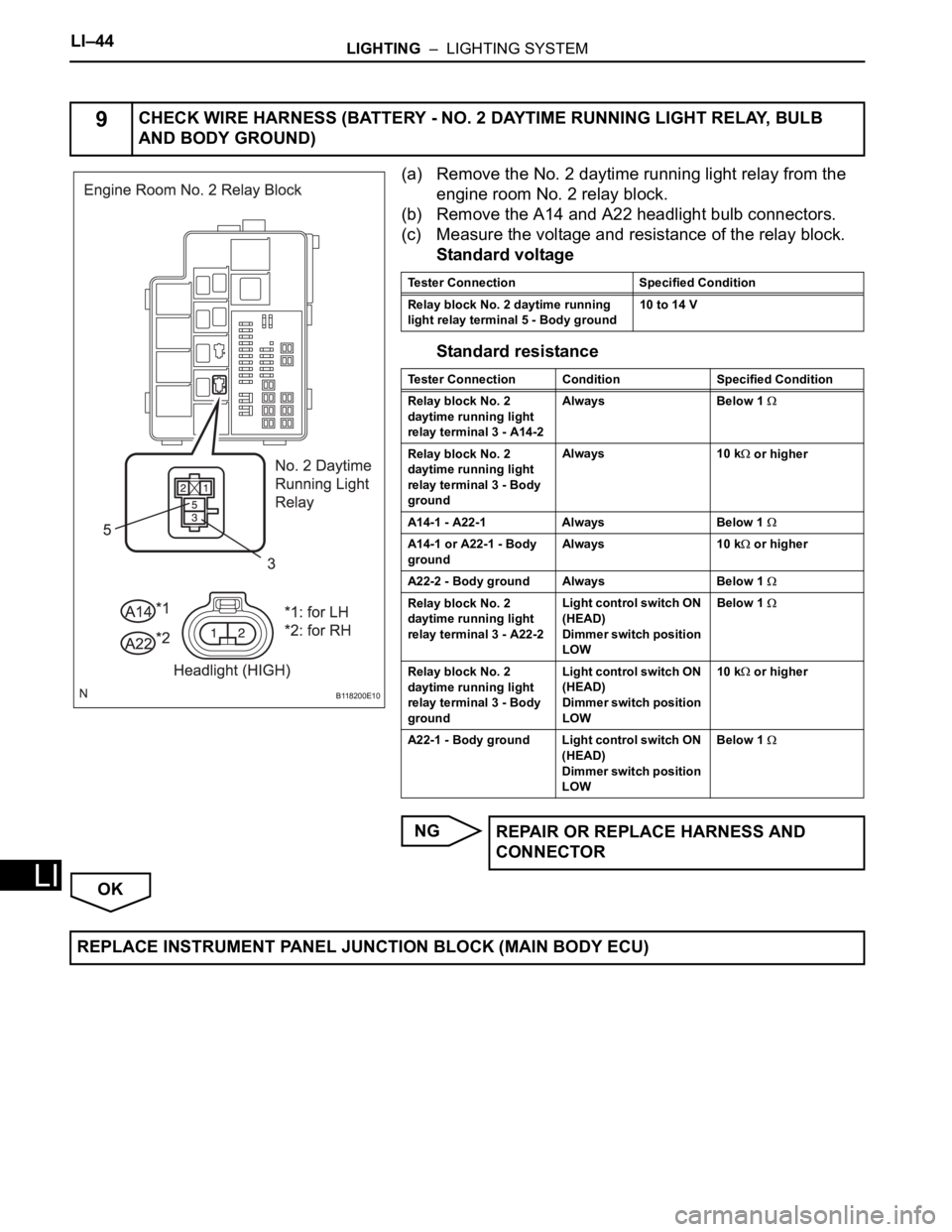

(a) Remove the No. 2 daytime running light relay from the

engine room No. 2 relay block.

(b) Remove the A14 and A22 headlight bulb connectors.

(c) Measure the voltage and resistance of the relay block.

Standard voltage

Standard resistance

NG

OK

9CHECK WIRE HARNESS (BATTERY - NO. 2 DAYTIME RUNNING LIGHT RELAY, BULB

AND BODY GROUND)

B118200E10

Tester Connection Specified Condition

Relay block No. 2 daytime running

light relay terminal 5 - Body ground10 to 14 V

Tester Connection Condition Specified Condition

Relay block No. 2

daytime running light

relay terminal 3 - A14-2Always Below 1

Relay block No. 2

daytime running light

relay terminal 3 - Body

groundAlways 10 k or higher

A14-1 - A22-1 Always Below 1

A14-1 or A22-1 - Body

groundAlways 10 k or higher

A22-2 - Body ground Always Below 1

Relay block No. 2

daytime running light

relay terminal 3 - A22-2Light control switch ON

(HEAD)

Dimmer switch position

LOWBelow 1

Relay block No. 2

daytime running light

relay terminal 3 - Body

groundLight control switch ON

(HEAD)

Dimmer switch position

LOW10 k or higher

A22-1 - Body ground Light control switch ON

(HEAD)

Dimmer switch position

LOWBelow 1

REPAIR OR REPLACE HARNESS AND

CONNECTOR

REPLACE INSTRUMENT PANEL JUNCTION BLOCK (MAIN BODY ECU)

Page 1914 of 2000

DL–18DOOR LOCK – POWER DOOR LOCK CONTROL SYSTEM

DL

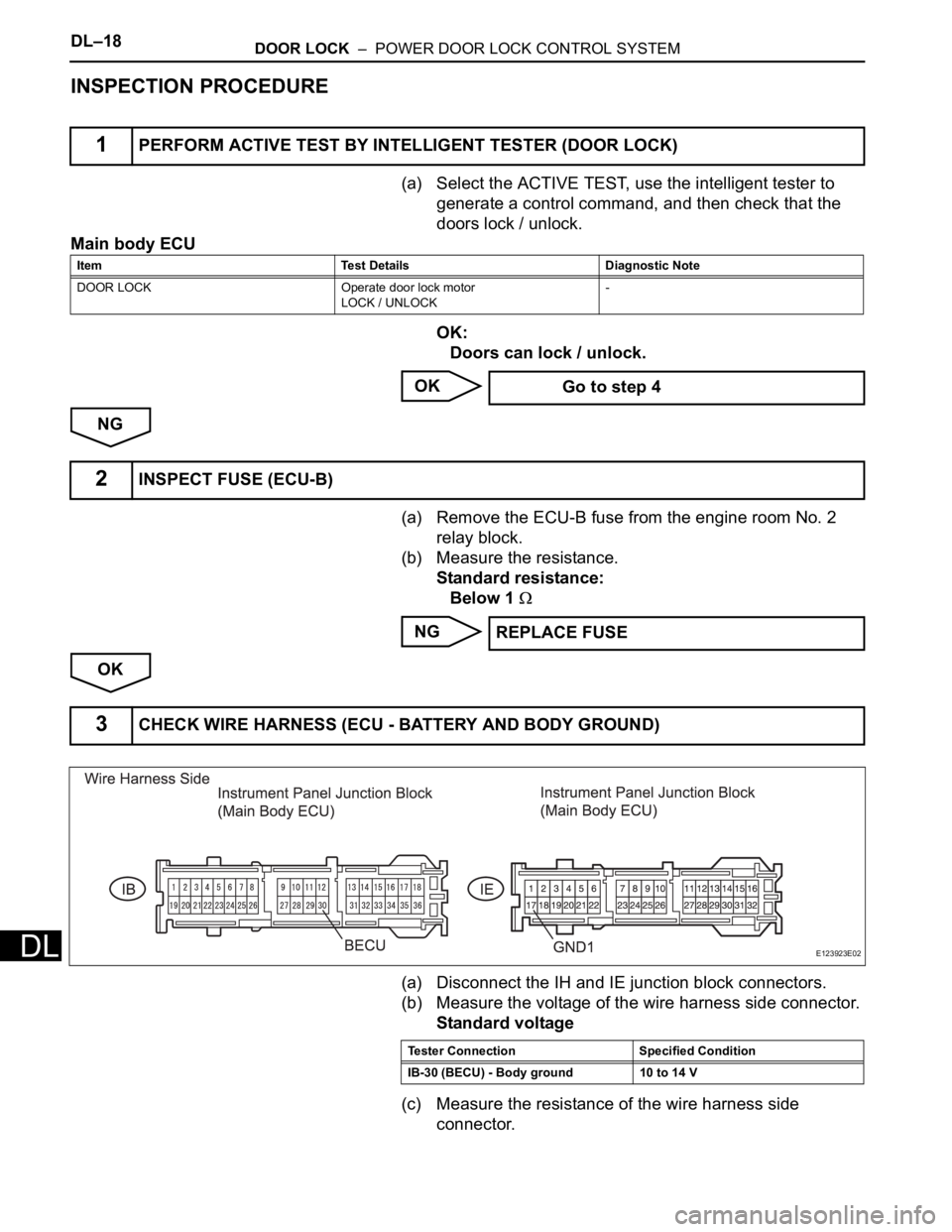

INSPECTION PROCEDURE

(a) Select the ACTIVE TEST, use the intelligent tester to

generate a control command, and then check that the

doors lock / unlock.

Main body ECU

OK:

Doors can lock / unlock.

OK

NG

(a) Remove the ECU-B fuse from the engine room No. 2

relay block.

(b) Measure the resistance.

Standard resistance:

Below 1

NG

OK

(a) Disconnect the IH and IE junction block connectors.

(b) Measure the voltage of the wire harness side connector.

Standard voltage

(c) Measure the resistance of the wire harness side

connector.

1PERFORM ACTIVE TEST BY INTELLIGENT TESTER (DOOR LOCK)

Item Test Details Diagnostic Note

DOOR LOCK Operate door lock motor

LOCK / UNLOCK-

Go to step 4

2INSPECT FUSE (ECU-B)

REPLACE FUSE

3CHECK WIRE HARNESS (ECU - BATTERY AND BODY GROUND)

E123923E02

Tester Connection Specified Condition

IB-30 (BECU) - Body ground 10 to 14 V

Page 1933 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–45

ES

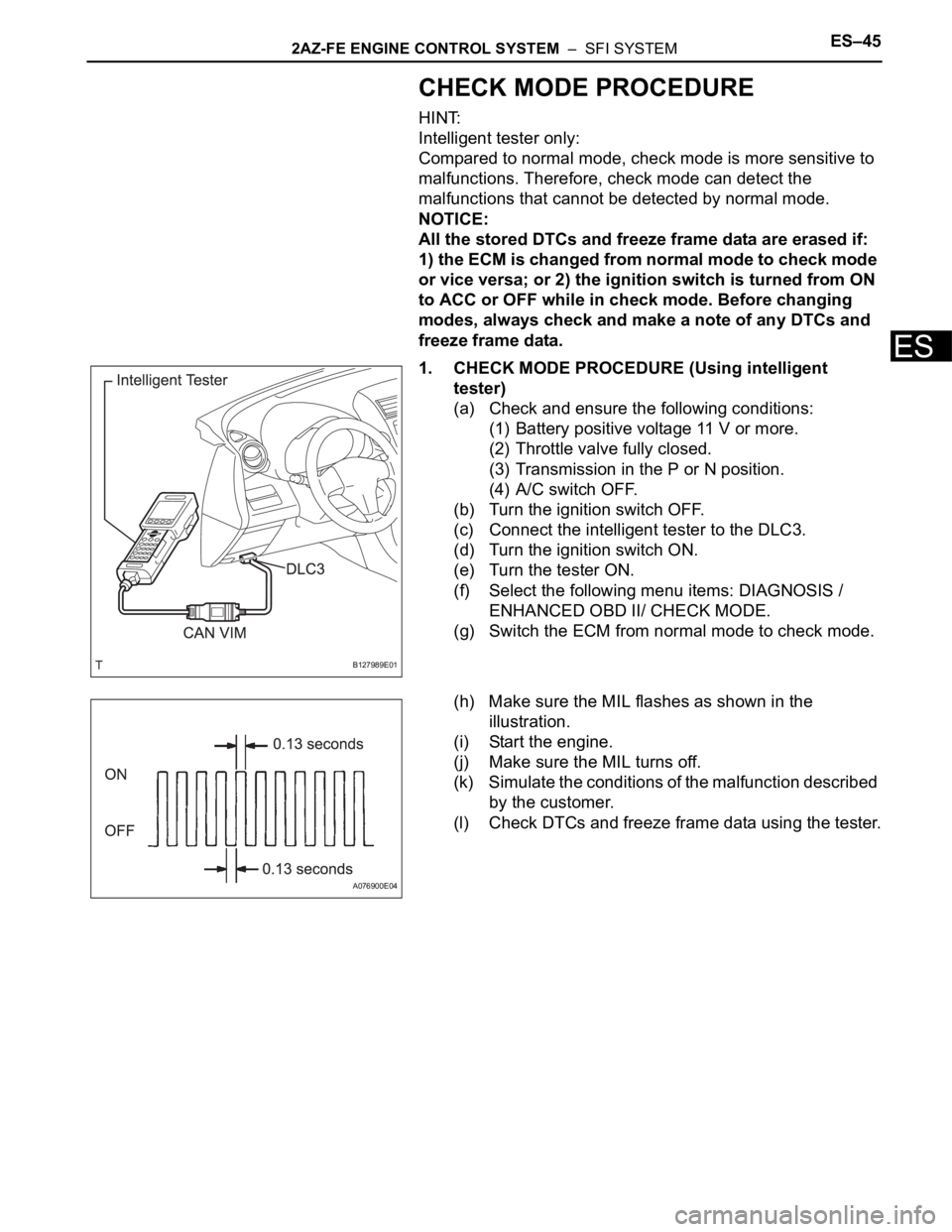

CHECK MODE PROCEDURE

HINT:

Intelligent tester only:

Compared to normal mode, check mode is more sensitive to

malfunctions. Therefore, check mode can detect the

malfunctions that cannot be detected by normal mode.

NOTICE:

All the stored DTCs and freeze frame data are erased if:

1) the ECM is changed from normal mode to check mode

or vice versa; or 2) the ignition switch is turned from ON

to ACC or OFF while in check mode. Before changing

modes, always check and make a note of any DTCs and

freeze frame data.

1. CHECK MODE PROCEDURE (Using intelligent

tester)

(a) Check and ensure the following conditions:

(1) Battery positive voltage 11 V or more.

(2) Throttle valve fully closed.

(3) Transmission in the P or N position.

(4) A/C switch OFF.

(b) Turn the ignition switch OFF.

(c) Connect the intelligent tester to the DLC3.

(d) Turn the ignition switch ON.

(e) Turn the tester ON.

(f) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II/ CHECK MODE.

(g) Switch the ECM from normal mode to check mode.

(h) Make sure the MIL flashes as shown in the

illustration.

(i) Start the engine.

(j) Make sure the MIL turns off.

(k) Simulate the conditions of the malfunction described

by the customer.

(l) Check DTCs and freeze frame data using the tester.

B127989E01

A076900E04

Page 1934 of 2000

ES–462AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

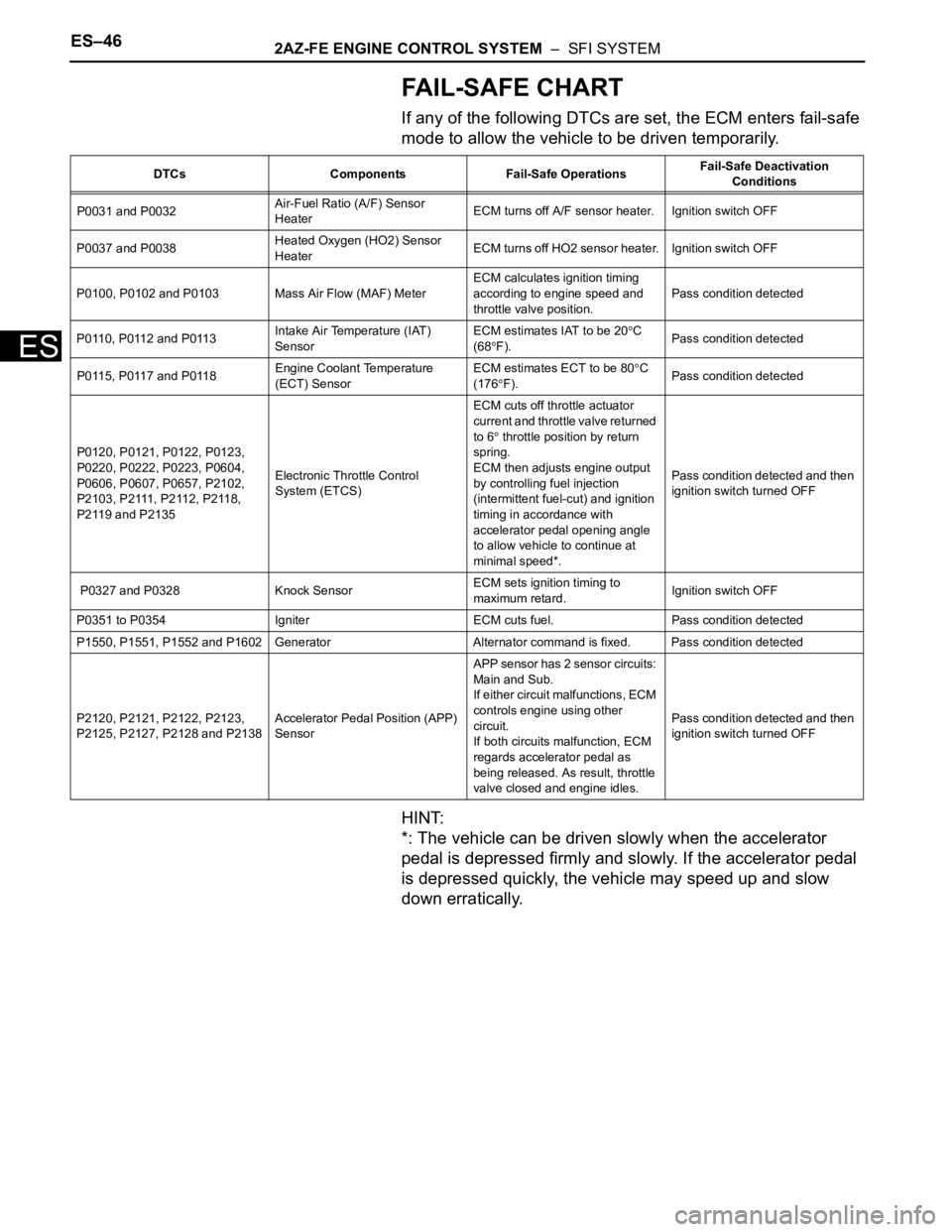

FAIL-SAFE CHART

If any of the following DTCs are set, the ECM enters fail-safe

mode to allow the vehicle to be driven temporarily.

HINT:

*: The vehicle can be driven slowly when the accelerator

pedal is depressed firmly and slowly. If the accelerator pedal

is depressed quickly, the vehicle may speed up and slow

down erratically.

DTCs Components Fail-Safe OperationsFail-Safe Deactivation

Conditions

P0031 and P0032Air-Fuel Ratio (A/F) Sensor

HeaterECM turns off A/F sensor heater. Ignition switch OFF

P0037 and P0038Heated Oxygen (HO2) Sensor

HeaterECM turns off HO2 sensor heater. Ignition switch OFF

P0100, P0102 and P0103 Mass Air Flow (MAF) MeterECM calculates ignition timing

according to engine speed and

throttle valve position.Pass condition detected

P0110, P0112 and P0113Intake Air Temperature (IAT)

SensorECM estimates IAT to be 20

C

(68

F).Pass condition detected

P0115, P0117 and P0118Engine Coolant Temperature

(ECT) SensorECM estimates ECT to be 80

C

(176

F).Pass condition detected

P0120, P0121, P0122, P0123,

P0220, P0222, P0223, P0604,

P0606, P0607, P0657, P2102,

P2103, P2111, P2112, P2118,

P2119 and P2135Electronic Throttle Control

System (ETCS)ECM cuts off throttle actuator

current and throttle valve returned

to 6

throttle position by return

spring.

ECM then adjusts engine output

by controlling fuel injection

(intermittent fuel-cut) and ignition

timing in accordance with

accelerator pedal opening angle

to allow vehicle to continue at

minimal speed*.Pass condition detected and then

ignition switch turned OFF

P0327 and P0328 Knock SensorECM sets ignition timing to

maximum retard.Ignition switch OFF

P0351 to P0354 Igniter ECM cuts fuel. Pass condition detected

P1550, P1551, P1552 and P1602 Generator Alternator command is fixed. Pass condition detected

P2120, P2121, P2122, P2123,

P2125, P2127, P2128 and P2138Accelerator Pedal Position (APP)

SensorAPP sensor has 2 sensor circuits:

Main and Sub.

If either circuit malfunctions, ECM

controls engine using other

circuit.

If both circuits malfunction, ECM

regards accelerator pedal as

being released. As result, throttle

valve closed and engine idles.Pass condition detected and then

ignition switch turned OFF

Page 1935 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–47

ES

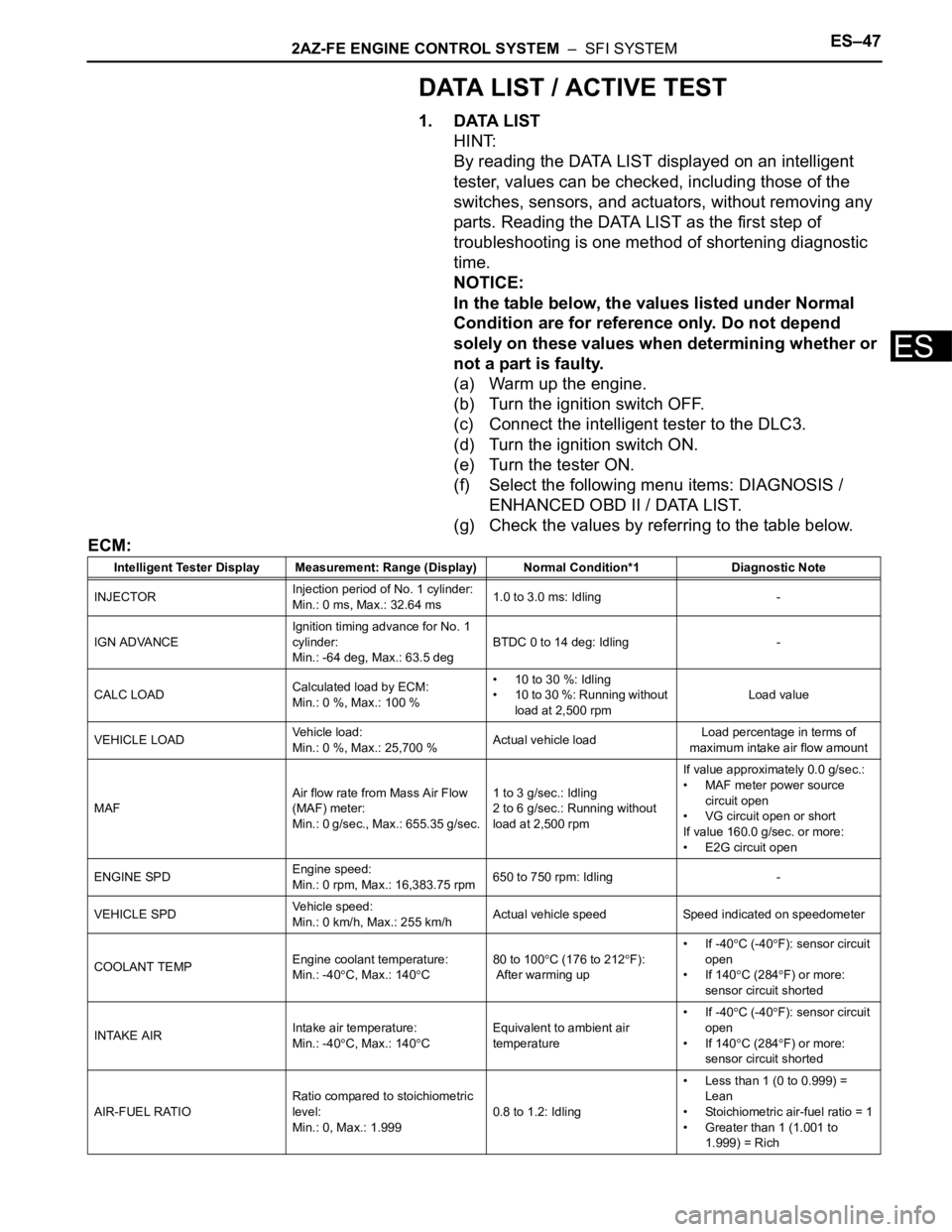

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

By reading the DATA LIST displayed on an intelligent

tester, values can be checked, including those of the

switches, sensors, and actuators, without removing any

parts. Reading the DATA LIST as the first step of

troubleshooting is one method of shortening diagnostic

time.

NOTICE:

In the table below, the values listed under Normal

Condition are for reference only. Do not depend

solely on these values when determining whether or

not a part is faulty.

(a) Warm up the engine.

(b) Turn the ignition switch OFF.

(c) Connect the intelligent tester to the DLC3.

(d) Turn the ignition switch ON.

(e) Turn the tester ON.

(f) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST.

(g) Check the values by referring to the table below.

ECM:

Intelligent Tester Display Measurement: Range (Display) Normal Condition*1 Diagnostic Note

INJECTORInjection period of No. 1 cylinder:

Min.: 0 ms, Max.: 32.64 ms1.0 to 3.0 ms: Idling -

IGN ADVANCE Ignition timing advance for No. 1

cylinder:

Min.: -64 deg, Max.: 63.5 degBTDC 0 to 14 deg: Idling -

CALC LOADCalculated load by ECM:

Min.: 0 %, Max.: 100 %• 10 to 30 %: Idling

• 10 to 30 %: Running without

load at 2,500 rpmLoad value

VEHICLE LOADVehicle load:

Min.: 0 %, Max.: 25,700 %Actual vehicle loadLoad percentage in terms of

maximum intake air flow amount

MAFAir flow rate from Mass Air Flow

(MAF) meter:

Min.: 0 g/sec., Max.: 655.35 g/sec.1 to 3 g/sec.: Idling

2 to 6 g/sec.: Running without

load at 2,500 rpmIf value approximately 0.0 g/sec.:

• MAF meter power source

circuit open

• VG circuit open or short

If value 160.0 g/sec. or more:

• E2G circuit open

ENGINE SPDEngine speed:

Min.: 0 rpm, Max.: 16,383.75 rpm650 to 750 rpm: Idling -

VEHICLE SPDVehicle speed:

Min.: 0 km/h, Max.: 255 km/hActual vehicle speed Speed indicated on speedometer

COOLANT TEMPEngine coolant temperature:

Min.: -40

C, Max.: 140C80 to 100C (176 to 212F):

After warming up• If -40

C (-40F): sensor circuit

open

• If 140

C (284F) or more:

sensor circuit shorted

INTAKE AIRIntake air temperature:

Min.: -40

C, Max.: 140CEquivalent to ambient air

temperature• If -40

C (-40F): sensor circuit

open

• If 140

C (284F) or more:

sensor circuit shorted

AIR-FUEL RATIORatio compared to stoichiometric

level:

Min.: 0, Max.: 1.9990.8 to 1.2: Idling• Less than 1 (0 to 0.999) =

Lean

• Stoichiometric air-fuel ratio = 1

• Greater than 1 (1.001 to

1.999) = Rich

Page 1936 of 2000

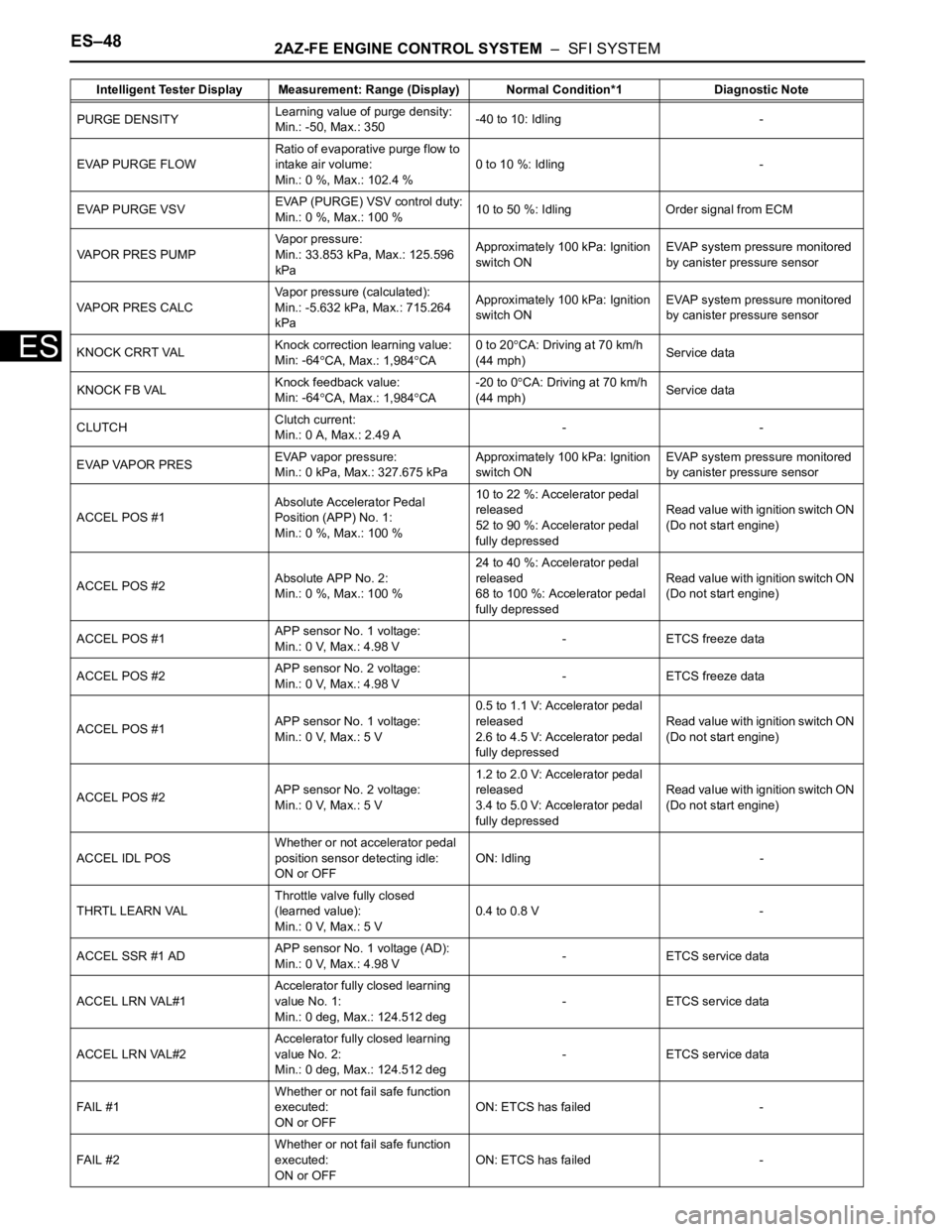

ES–482AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

PURGE DENSITY Learning value of purge density:

Min.: -50, Max.: 350-40 to 10: Idling -

EVAP PURGE FLOWRatio of evaporative purge flow to

intake air volume:

Min.: 0 %, Max.: 102.4 %0 to 10 %: Idling -

EVAP PURGE VSVEVAP (PURGE) VSV control duty:

Min.: 0 %, Max.: 100 %10 to 50 %: Idling Order signal from ECM

VAPOR PRES PUMPVapor pressure:

Min.: 33.853 kPa, Max.: 125.596

kPaApproximately 100 kPa: Ignition

switch ONEVAP system pressure monitored

by canister pressure sensor

VAPOR PRES CALCVapor pressure (calculated):

Min.: -5.632 kPa, Max.: 715.264

kPaApproximately 100 kPa: Ignition

switch ONEVAP system pressure monitored

by canister pressure sensor

KNOCK CRRT VALKnock correction learning value:

Min: -64

CA, Max.: 1,984CA0 to 20

CA: Driving at 70 km/h

(44 mph)Service data

KNOCK FB VALKnock feedback value:

Min: -64

CA, Max.: 1,984CA-20 to 0

CA: Driving at 70 km/h

(44 mph)Service data

CLUTCHClutch current:

Min.: 0 A, Max.: 2.49 A--

EVAP VAPOR PRESEVAP vapor pressure:

Min.: 0 kPa, Max.: 327.675 kPaApproximately 100 kPa: Ignition

switch ONEVAP system pressure monitored

by canister pressure sensor

ACCEL POS #1Absolute Accelerator Pedal

Position (APP) No. 1:

Min.: 0 %, Max.: 100 %10 to 22 %: Accelerator pedal

released

52 to 90 %: Accelerator pedal

fully depressedRead value with ignition switch ON

(Do not start engine)

ACCEL POS #2Absolute APP No. 2:

Min.: 0 %, Max.: 100 %24 to 40 %: Accelerator pedal

released

68 to 100 %: Accelerator pedal

fully depressedRead value with ignition switch ON

(Do not start engine)

ACCEL POS #1APP sensor No. 1 voltage:

Min.: 0 V, Max.: 4.98 V- ETCS freeze data

ACCEL POS #2APP sensor No. 2 voltage:

Min.: 0 V, Max.: 4.98 V- ETCS freeze data

ACCEL POS #1APP sensor No. 1 voltage:

Min.: 0 V, Max.: 5 V0.5 to 1.1 V: Accelerator pedal

released

2.6 to 4.5 V: Accelerator pedal

fully depressedRead value with ignition switch ON

(Do not start engine)

ACCEL POS #2APP sensor No. 2 voltage:

Min.: 0 V, Max.: 5 V1.2 to 2.0 V: Accelerator pedal

released

3.4 to 5.0 V: Accelerator pedal

fully depressedRead value with ignition switch ON

(Do not start engine)

ACCEL IDL POSWhether or not accelerator pedal

position sensor detecting idle:

ON or OFFON: Idling -

THRTL LEARN VALThrottle valve fully closed

(learned value):

Min.: 0 V, Max.: 5 V0.4 to 0.8 V -

ACCEL SSR #1 ADAPP sensor No. 1 voltage (AD):

Min.: 0 V, Max.: 4.98 V-ETCS service data

ACCEL LRN VAL#1 Accelerator fully closed learning

value No. 1:

Min.: 0 deg, Max.: 124.512 deg-ETCS service data

ACCEL LRN VAL#2Accelerator fully closed learning

value No. 2:

Min.: 0 deg, Max.: 124.512 deg-ETCS service data

FAIL #1 Whether or not fail safe function

executed:

ON or OFFON: ETCS has failed -

FAIL #2 Whether or not fail safe function

executed:

ON or OFFON: ETCS has failed - Intelligent Tester Display Measurement: Range (Display) Normal Condition*1 Diagnostic Note