TOYOTA RAV4 2006 Service Manual Online

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 81 of 2000

ENGINE - 2GR-FE ENGINE

285EG77

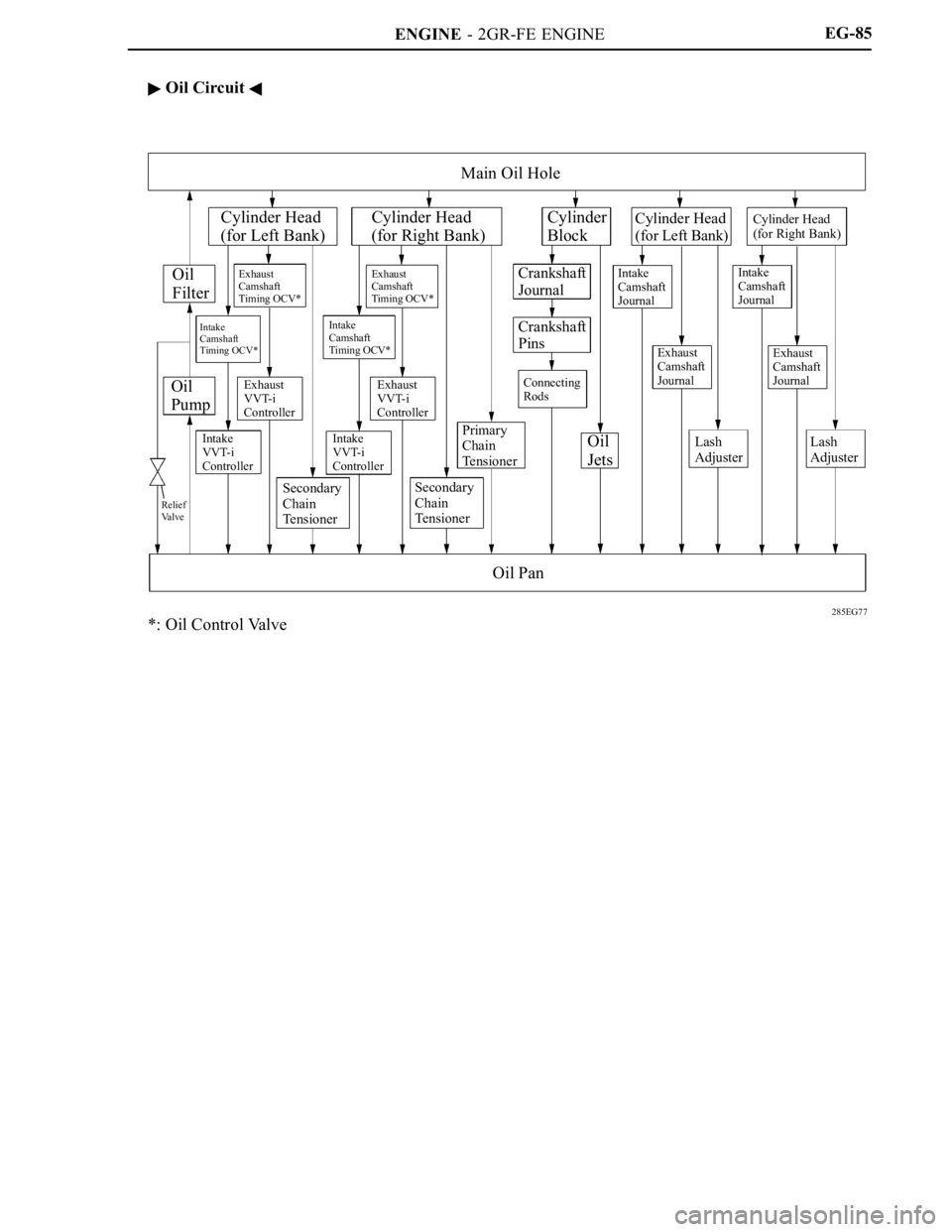

Main Oil Hole

Cylinder Head

(for Left Bank)

Oil

Filter

Exhaust

Camshaft

Timing OCV*

Intake

Camshaft

Timing OCV*

Oil

PumpExhaust

VVT-i

Controller

Intake

VVT-i

Controller

Relief

Va l v e

Cylinder Head

(for Right Bank)

Exhaust

Camshaft

Timing OCV*

Intake

Camshaft

Timing OCV*

Exhaust

VVT-i

Controller

Intake

VVT-i

Controller

Secondary

Chain

TensionerPrimary

Chain

Tensioner

Secondary

Chain

Tensioner

Cylinder

Block

Crankshaft

Journal

Crankshaft

Pins

Connecting

Rods

Cylinder Head

(for Left Bank)

Oil

Jets

Intake

Camshaft

Journal

Exhaust

Camshaft

Journal

Lash

Adjuster

Cylinder Head

(for Right Bank)

Intake

Camshaft

Journal

Exhaust

Camshaft

Journal

Lash

Adjuster

Oil PanEG-85

Oil Circuit

*: Oil Control Valve

Page 82 of 2000

ENGINE - 2GR-FE ENGINE

285EG24

Timing Chain Cover

Oil Pump

Housing

Oil Pump Rotors

(Cycloid Rotor)Crankshaft

To Cylinder

Block

From Oil

Filter

To

Oil FilterFrom

Oil Strainer

Oil passage in the oil pump

285EG25

Oil Jet Cross Section

Oil JetsCheck

Va l v eEngine Oil EG-86

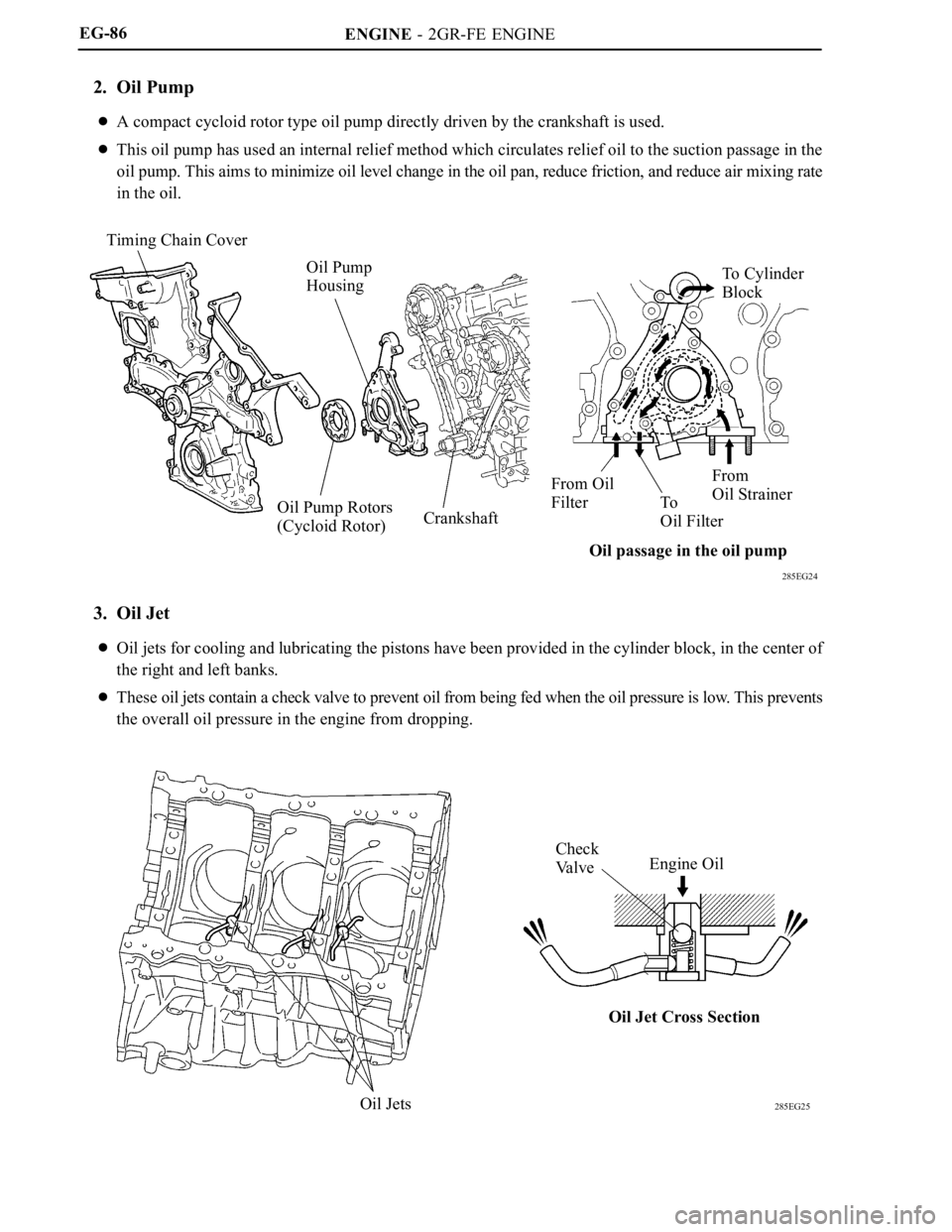

2. Oil Pump

A compact cycloid rotor type oil pump directly driven by the crankshaft is used.

This oil pump has used an internal relief method which circulates relief oil to the suction passage in the

oil pump. This aims to minimize oil level change in the oil pan, reduce friction, and reduce air mixing rate

in the oil.

3. Oil Jet

Oil jets for cooling and lubricating the pistons have been provided in the cylinder block, in the center of

the right and left banks.

These oil jets contain a check valve to prevent oil from being fed when the oil pressure is low. This prevents

the overall oil pressure in the engine from dropping.

Page 83 of 2000

ENGINE - 2GR-FE ENGINE

01MEG12Y

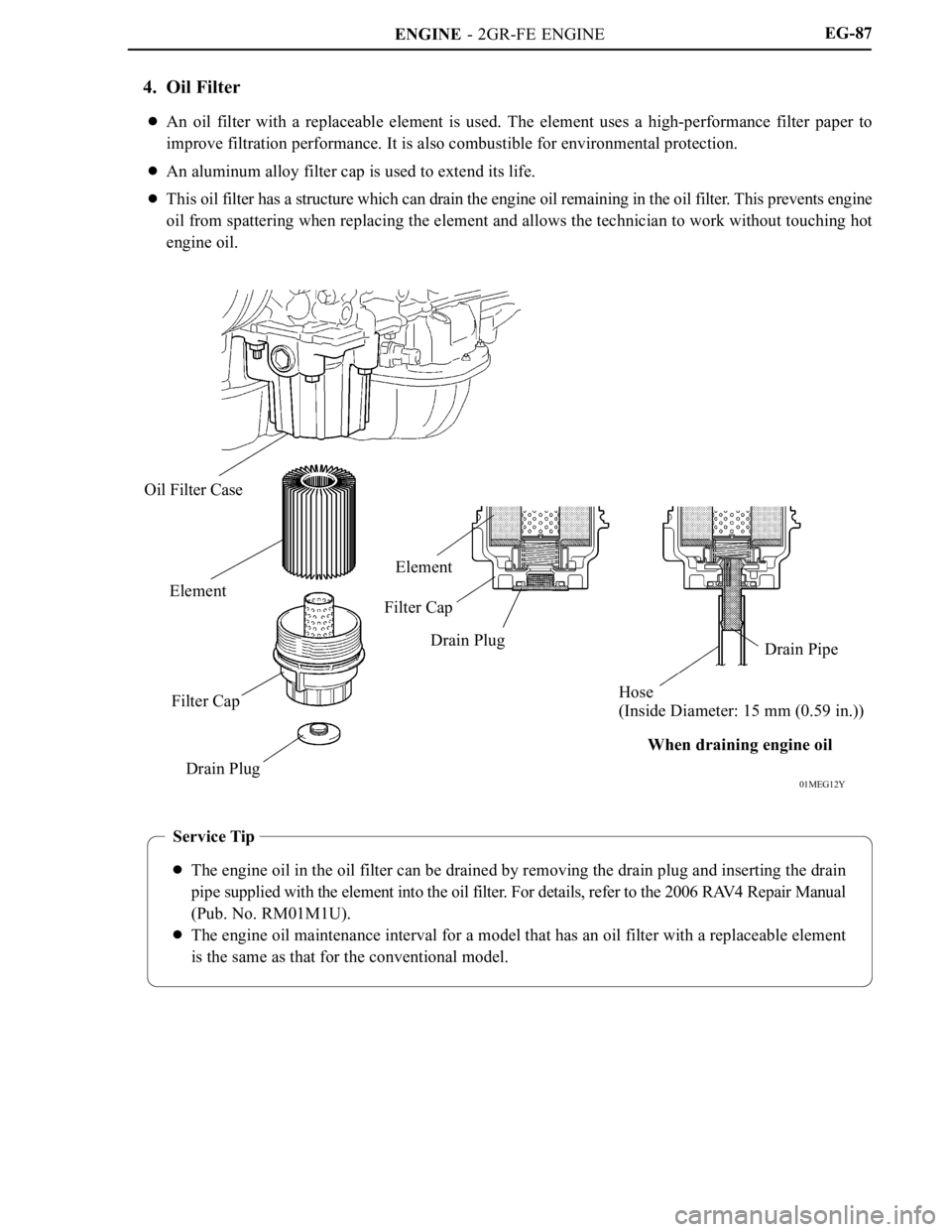

Oil Filter Case

Element

Filter Cap

Drain PlugElement

Filter Cap

Drain Plug

Drain Pipe

Hose

(Inside Diameter: 15 mm (0.59 in.))

When draining engine oil

Service Tip

The engine oil in the oil filter can be drained by removing the drain plug and inserting the drain

pipe supplied with the element into the oil filter. For details, refer to the 2006 RAV4 Repair Manual

(Pub. No. RM01M1U).

The engine oil maintenance interval for a model that has an oil filter with a replaceable element

is the same as that for the conventional model.

EG-87

4. Oil Filter

An oil filter with a replaceable element is used. The element uses a high-performance filter paper to

improve filtration performance. It is also combustible for environmental protection.

An aluminum alloy filter cap is used to extend its life.

This oil filter has a structure which can drain the engine oil remaining in the oil filter. This prevents engine

oil from spattering when replacing the element and allows the technician to work without touching hot

engine oil.

Page 84 of 2000

ENGINE - 2GR-FE ENGINE

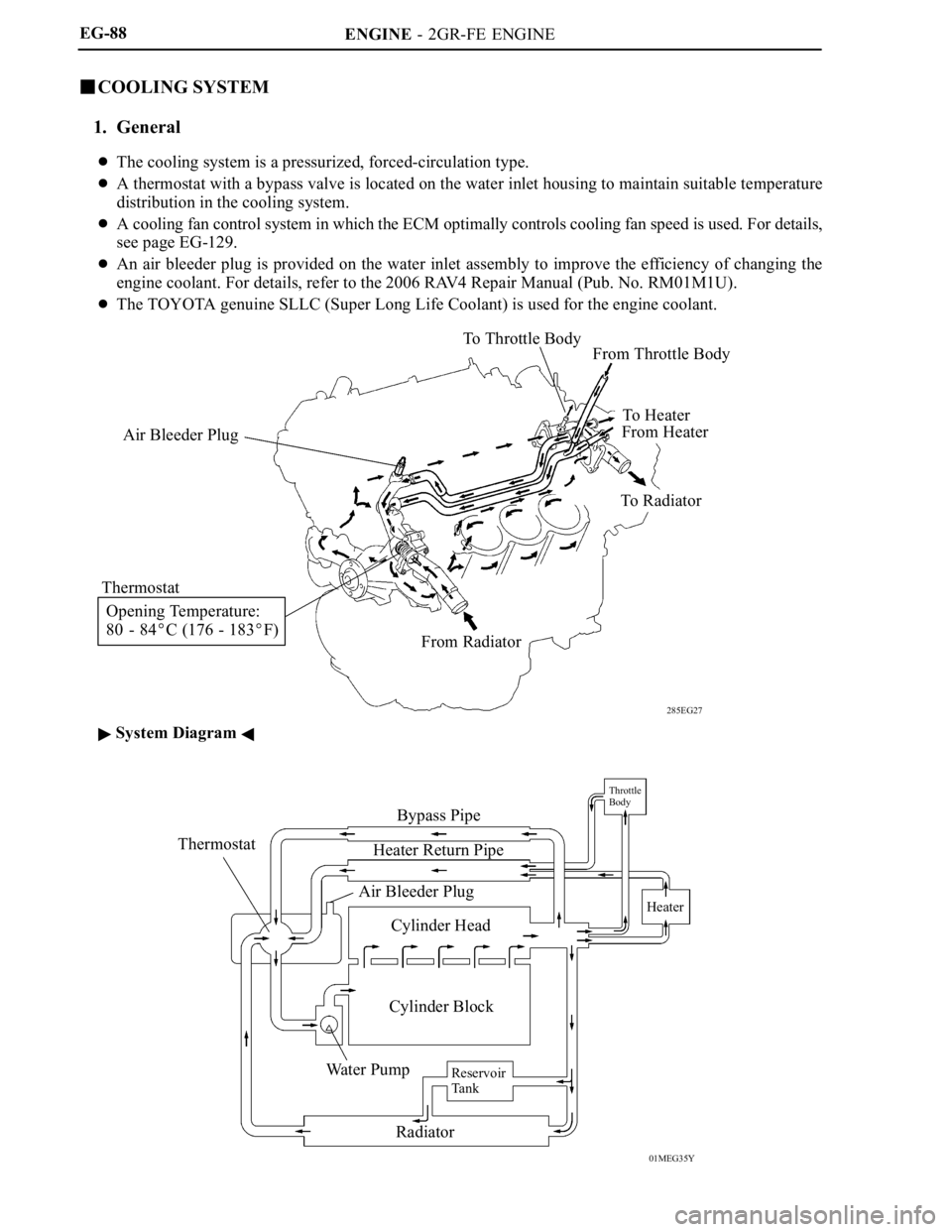

285EG27

Air Bleeder PlugTo Throttle Body

From Throttle Body

To H e a t e r

From Heater

To Radiator

From Radiator Thermostat

Opening Temperature:

80 - 84

C (176 - 183F)

01MEG35Y

ThermostatBypass Pipe

Heater Return Pipe

Air Bleeder Plug

Cylinder Head

Cylinder Block

Wa t e r P u m p

Radiator

Throttle

Body

Heater

Reservoir

Ta n k

EG-88

COOLING SYSTEM

1. General

The cooling system is a pressurized, forced-circulation type.

A thermostat with a bypass valve is located on the water inlet housing to maintain suitable temperature

distribution in the cooling system.

A cooling fan control system in which the ECM optimally controls cooling fan speed is used. For details,

see page EG-129.

An air bleeder plug is provided on the water inlet assembly to improve the efficiency of changing the

engine coolant. For details, refer to the 2006 RAV4 Repair Manual (Pub. No. RM01M1U).

The TOYOTA genuine SLLC (Super Long Life Coolant) is used for the engine coolant.

System Diagram

Page 85 of 2000

ENGINE - 2GR-FE ENGINE

285EG29

Timing Chain Cover

Wa t e r P u m p G a s k e t

Wa t e r P u m pVolute ChambersFrom Water Inlet Housing

Rotor

View from Back Side

Cross SectionEG-89

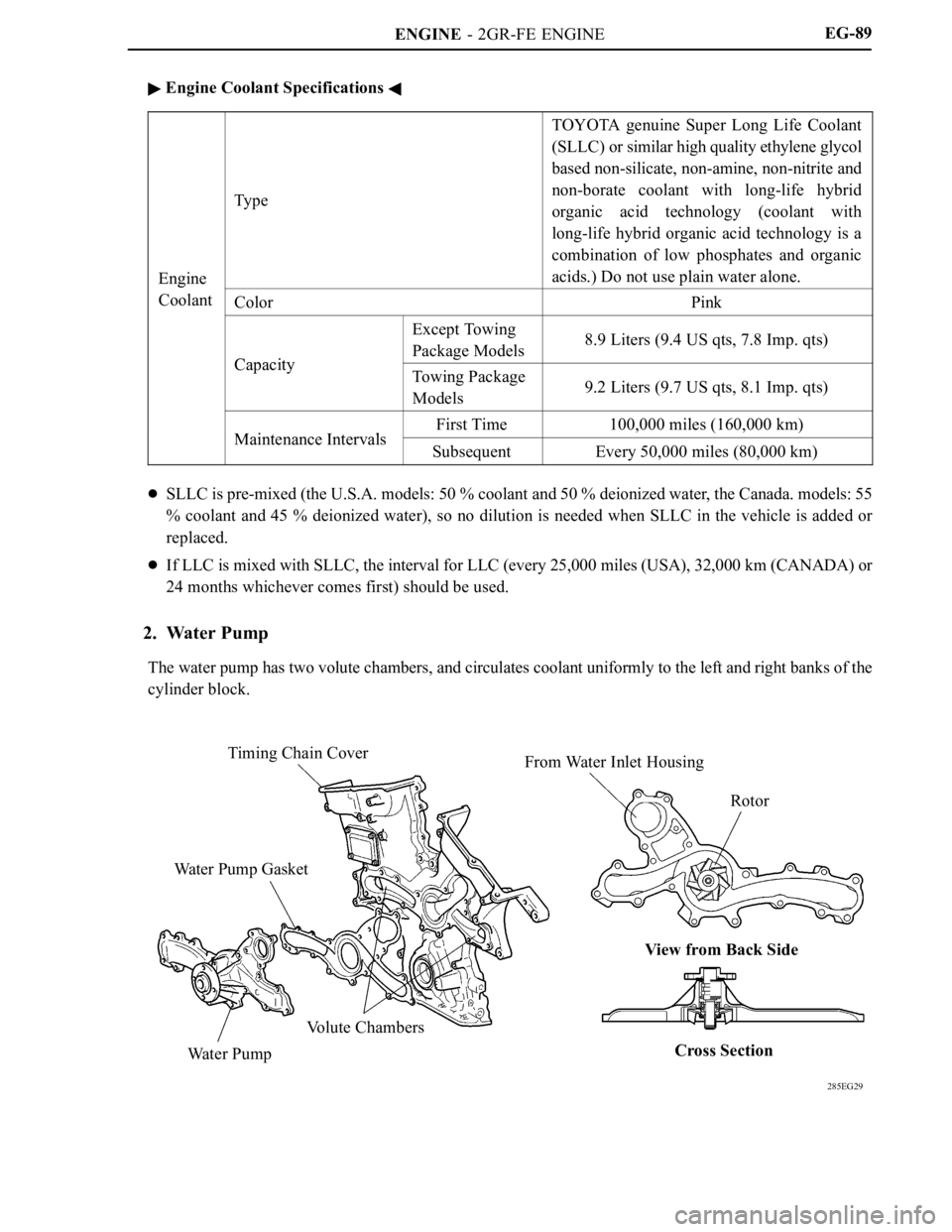

Engine Coolant Specifications

Engine

Ty p e

TOYOTA genuine Super Long Life Coolant

(SLLC) or similar high quality ethylene glycol

based non-silicate, non-amine, non-nitrite and

non-borate coolant with long-life hybrid

organic acid technology (coolant with

long-life hybrid organic acid technology is a

combination of low phosphates and organic

acids.) Do not use plain water alone.

Engine

CoolantColorPink

Capacity

Except Towing

Package Models8.9 Liters (9.4 US qts, 7.8 Imp. qts)

CapacityTowing Package

Models9.2 Liters (9.7 US qts, 8.1 Imp. qts)

Maintenance IntervalsFirst Time100,000 miles (160,000 km)Maintenance IntervalsSubsequentEvery 50,000 miles (80,000 km)

SLLC is pre-mixed (the U.S.A. models: 50 % coolant and 50 % deionized water, the Canada. models: 55

% coolant and 45 % deionized water), so no dilution is needed when SLLC in the vehicle is added or

replaced.

If LLC is mixed with SLLC, the interval for LLC (every 25,000 miles (USA), 32,000 km (CANADA) or

24 months whichever comes first) should be used.

2. Water Pump

The water pump has two volute chambers, and circulates coolant uniformly to the left and right banks of the

cylinder block.

Page 86 of 2000

ENGINE - 2GR-FE ENGINE

01MEG15Y

Throttle Body

Intake Air

Chamber

ACIS Actuator

Intake Manifold

Left Bank Exhaust

ManifoldRight Bank

Exhaust ManifoldAir CleanerExhaust Pipe EG-90

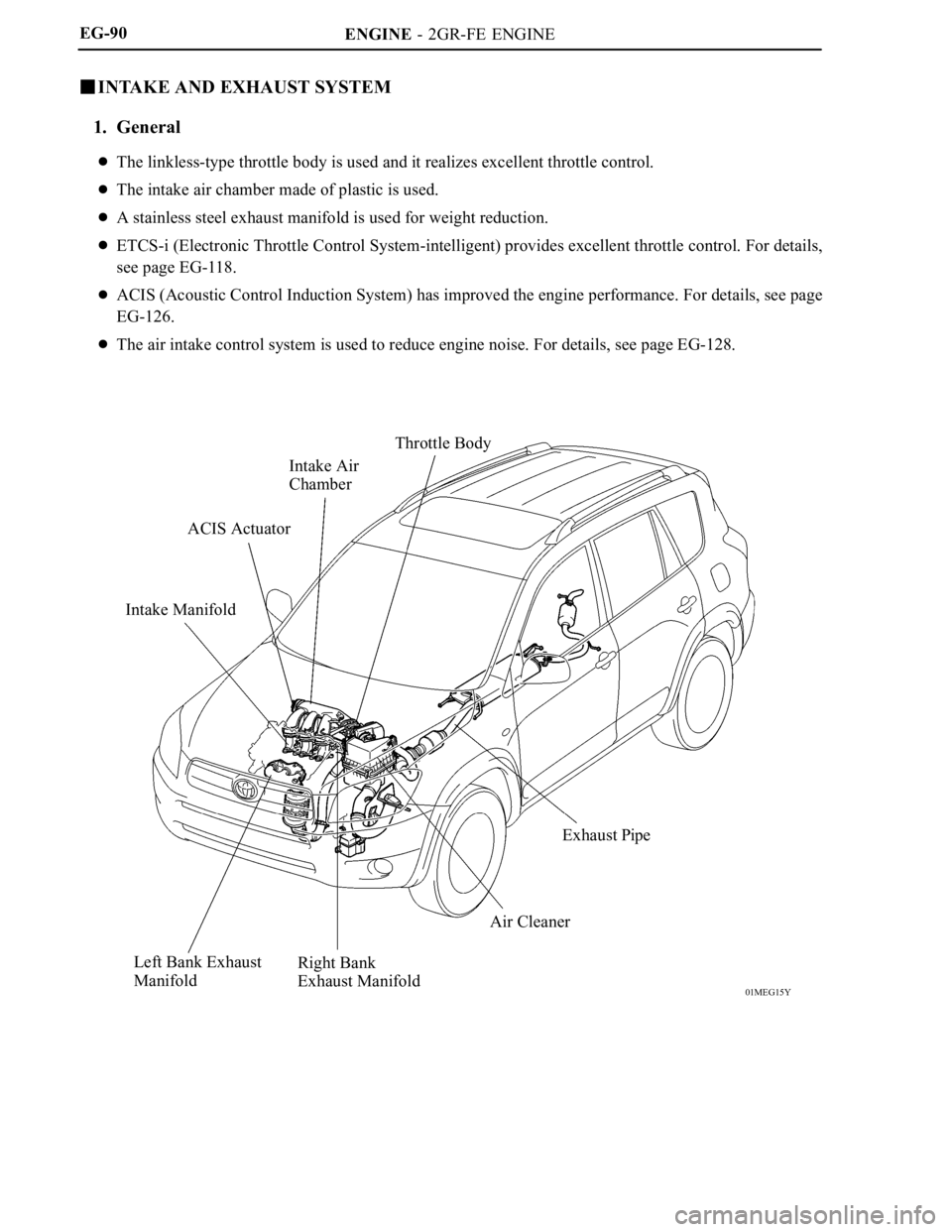

INTAKE AND EXHAUST SYSTEM

1. General

The linkless-type throttle body is used and it realizes excellent throttle control.

The intake air chamber made of plastic is used.

A stainless steel exhaust manifold is used for weight reduction.

ETCS-i (Electronic Throttle Control System-intelligent) provides excellent throttle control. For details,

see page EG-118.

ACIS (Acoustic Control Induction System) has improved the engine performance. For details, see page

EG-126.

The air intake control system is used to reduce engine noise. For details, see page EG-128.

Page 87 of 2000

ENGINE - 2GR-FE ENGINE

01MEG13Y

Air Cleaner Hose with

Resonator

Air Cleaner Cap

Charcoal Filter

Air Cleaner Element

(Nonwoven Fabric)

Air Cleaner Case

Actuator

(For Air Intake Control)

Air Cleaner Inlet

Resonator

285EG32

Throttle Position Sensor

Throttle Control MotorEG-91

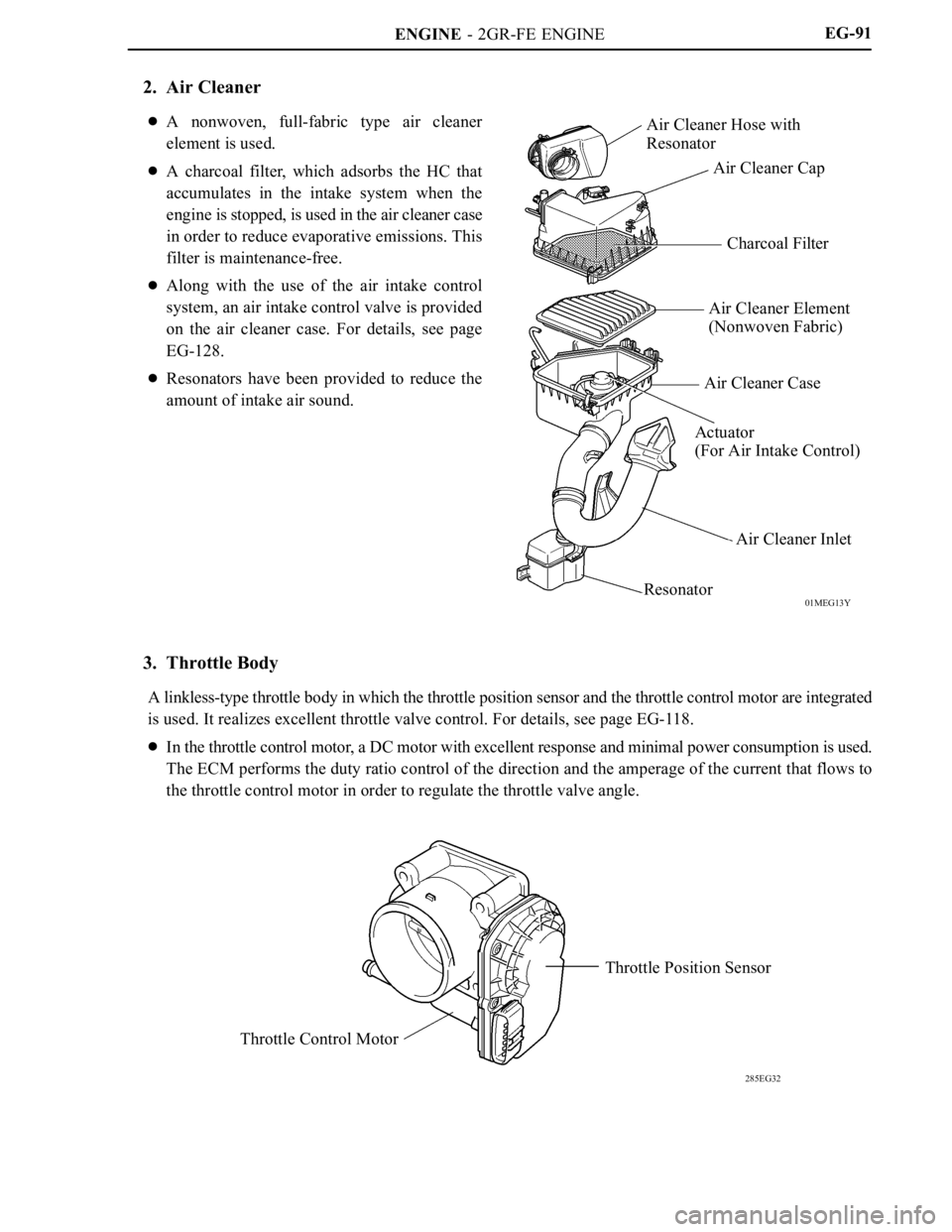

2. Air Cleaner

A nonwoven, full-fabric type air cleaner

element is used.

A charcoal filter, which adsorbs the HC that

accumulates in the intake system when the

engine is stopped, is used in the air cleaner case

in order to reduce evaporative emissions. This

filter is maintenance-free.

Along with the use of the air intake control

system, an air intake control valve is provided

on the air cleaner case. For details, see page

EG-128.

Resonators have been provided to reduce the

amount of intake air sound.

3. Throttle Body

A linkless-type throttle body in which the throttle position sensor and the throttle control motor are integrated

is used. It realizes excellent throttle valve control. For details, see page EG-118.

In the throttle control motor, a DC motor with excellent response and minimal power consumption is used.

The ECM performs the duty ratio control of the direction and the amperage of the current that flows to

the throttle control motor in order to regulate the throttle valve angle.

Page 88 of 2000

ENGINE - 2GR-FE ENGINE

285EG33

Intake Air

Control Valve

ACIS ActuatorLaser-welding

285EG34GasketsRubber Coating

Outer SideIntake

Port Side

A

A

A - A Cross Section EG-92

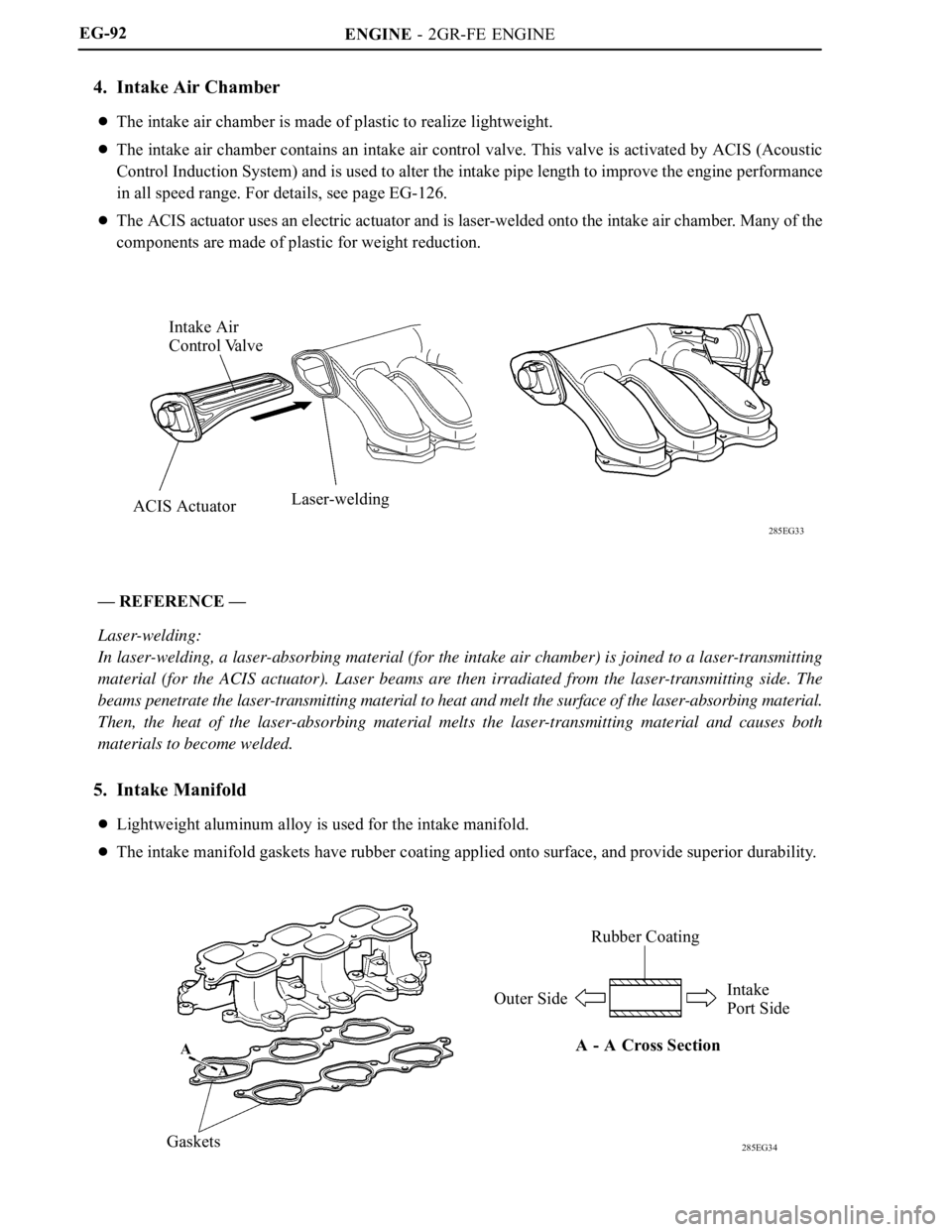

4. Intake Air Chamber

The intake air chamber is made of plastic to realize lightweight.

The intake air chamber contains an intake air control valve. This valve is activated by ACIS (Acoustic

Control Induction System) and is used to alter the intake pipe length to improve the engine performance

in all speed range. For details, see page EG-126.

The ACIS actuator uses an electric actuator and is laser-welded onto the intake air chamber. Many of the

components are made of plastic for weight reduction.

— REFERENCE —

Laser-welding:

In laser-welding, a laser-absorbing material (for the intake air chamber) is joined to a laser-transmitting

material (for the ACIS actuator). Laser beams are then irradiated from the laser-transmitting side. The

beams penetrate the laser-transmitting material to heat and melt the surface of the laser-absorbing material.

Then, the heat of the laser-absorbing material melts the laser-transmitting material and causes both

materials to become welded.

5. Intake Manifold

Lightweight aluminum alloy is used for the intake manifold.

The intake manifold gaskets have rubber coating applied onto surface, and provide superior durability.

Page 89 of 2000

ENGINE - 2GR-FE ENGINE

01MEG14Y

TWC

Right Bank Exhaust

ManifoldTWC

Left Bank Exhaust

ManifoldUltra

Thin-Wall

01MEG16Y

Exhaust Front PipeExhaust Center PipeTailpipe

Sub Muffler

Ball Joint

Main Muffler

TWC

Ball Joint

Spring

Bolt

Gasket Ball JointEG-93

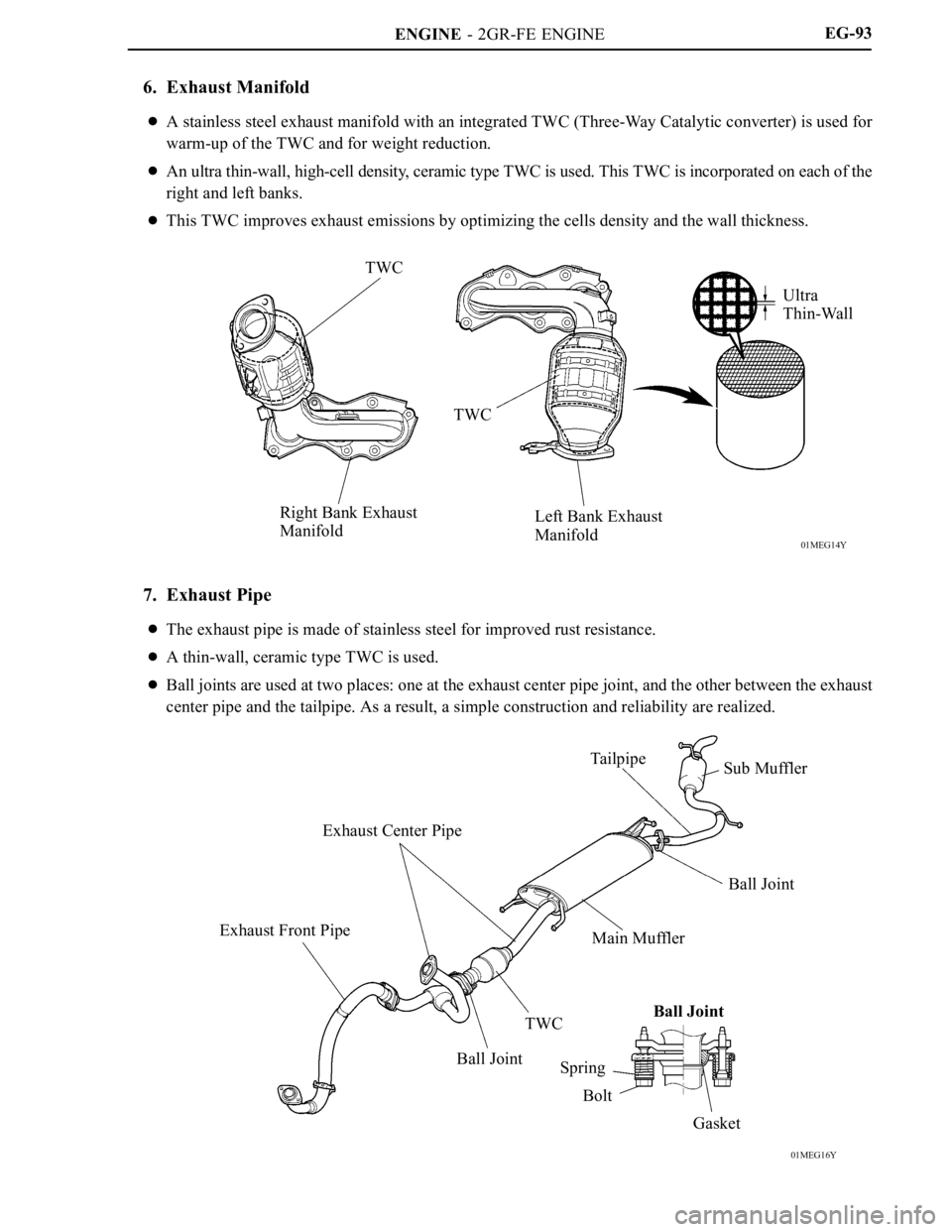

6. Exhaust Manifold

A stainless steel exhaust manifold with an integrated TWC (Three-Way Catalytic converter) is used for

warm-up of the TWC and for weight reduction.

An ultra thin-wall, high-cell density, ceramic type TWC is used. This TWC is incorporated on each of the

right and left banks.

This TWC improves exhaust emissions by optimizing the cells density and the wall thickness.

7. Exhaust Pipe

The exhaust pipe is made of stainless steel for improved rust resistance.

A thin-wall, ceramic type TWC is used.

Ball joints are used at two places: one at the exhaust center pipe joint, and the other between the exhaust

center pipe and the tailpipe. As a result, a simple construction and reliability are realized.

Page 90 of 2000

ENGINE - 2GR-FE ENGINE

01MEG17Y

Injector

Quick Connector

Pulsation Damper

Fuel Pump Assembly

Fuel Filter

Pressure Regulator

Fuel Tank

Canister

Injector Fuel Delivery Pipe EG-94

FUEL SYSTEM

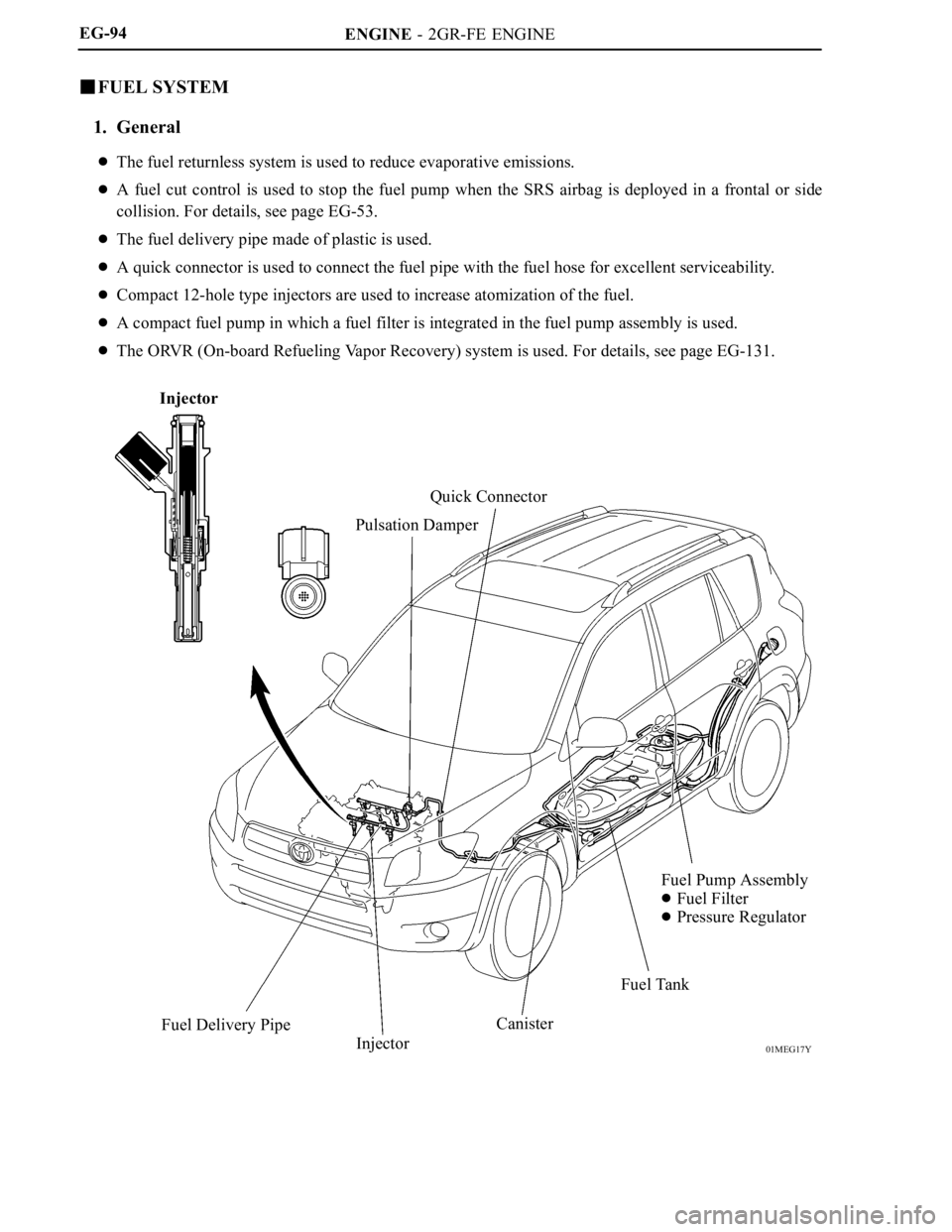

1. General

The fuel returnless system is used to reduce evaporative emissions.

A fuel cut control is used to stop the fuel pump when the SRS airbag is deployed in a frontal or side

collision. For details, see page EG-53.

The fuel delivery pipe made of plastic is used.

A quick connector is used to connect the fuel pipe with the fuel hose for excellent serviceability.

Compact 12-hole type injectors are used to increase atomization of the fuel.

A compact fuel pump in which a fuel filter is integrated in the fuel pump assembly is used.

The ORVR (On-board Refueling Vapor Recovery) system is used. For details, see page EG-131.