TOYOTA RAV4 2006 Service Workshop Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 51 of 2000

ENGINE - 2AZ-FE ENGINE

Service Tip

The canister pump module performs the EVAP leak check. This check is done approximately five

hours after the engine is turned off. So you may hear sound coming from underneath the luggage

compartment for several minutes. It does not indicate a malfunction.

The pinpoint pressure test procedure is carried out by pressurizing the fresh air line that runs from

the pump module to the air filler neck. For details, refer to the 2006 RAV4 Repair Manual (Pub.

No. RM01M1U).

EG-54

10. EVAP (evaporative Emission) Control System

General

The EVAP (evaporative emission) control system prevents the vapor gas that is created in the fuel tank from

being released directly into the atmosphere.

The canister stores the vapor gas that has been created in the fuel tank.

The ECM controls the purge VSV in accordance with the driving conditions in order to direct the vapor

gas into the engine, where it is burned.

In this system, the ECM checks the evaporative emission leak and outputs DTC (Diagnostic Trouble

Code) in the event of a malfunction. An EVAP (evaporative emission) leak check consists of an

application of a vacuum pressure to the system and monitoring the changes in the system pressure in order

to detect a leakage.

This system consists of the purge VSV, canister, refueling valve, canister pump module, and ECM.

The ORVR (Onboard Refueling Vapor Recovery) function is provided in the refueling valve.

The canister pressure sensor has been included to the canister pump module.

The canister filter has been provided on the fresh air line. This canister filter is maintenance-free.

The followings are the typical conditions for enabling an EVAP leak check:

Typical Enabling

Condition

Five hours have elapsed after the engine has been turned OFF*.

Altitude: Below 2400 m (8000 feet)

Battery voltage: 10.5 V or more

Ignition switch: OFF

Engine coolant temperature: 4.4 to 35C (40 to 95F)

Intake air temperature: 4.4 to 35C (40 to 95F)

*: If engine coolant temperature does not drop below 35C (95F), this time should be extended to 7hours.

Even after that, if the temperature is not less than 35

C (95F), the time should be extended to 9.5 hours.

Page 52 of 2000

ENGINE - 2AZ-FE ENGINE

00REG22Y

To Intake Manifold

Purge VSV

Purge Air

Line

ECMFuel Tank

Canister Filter

Fresh Air LineRefueling Valve

Canister Pump Module

Ve n t

Va l v e

Leak Detection Pump

& Pump Motor

Canister

Pressure SensorCanisterP M

EG-55

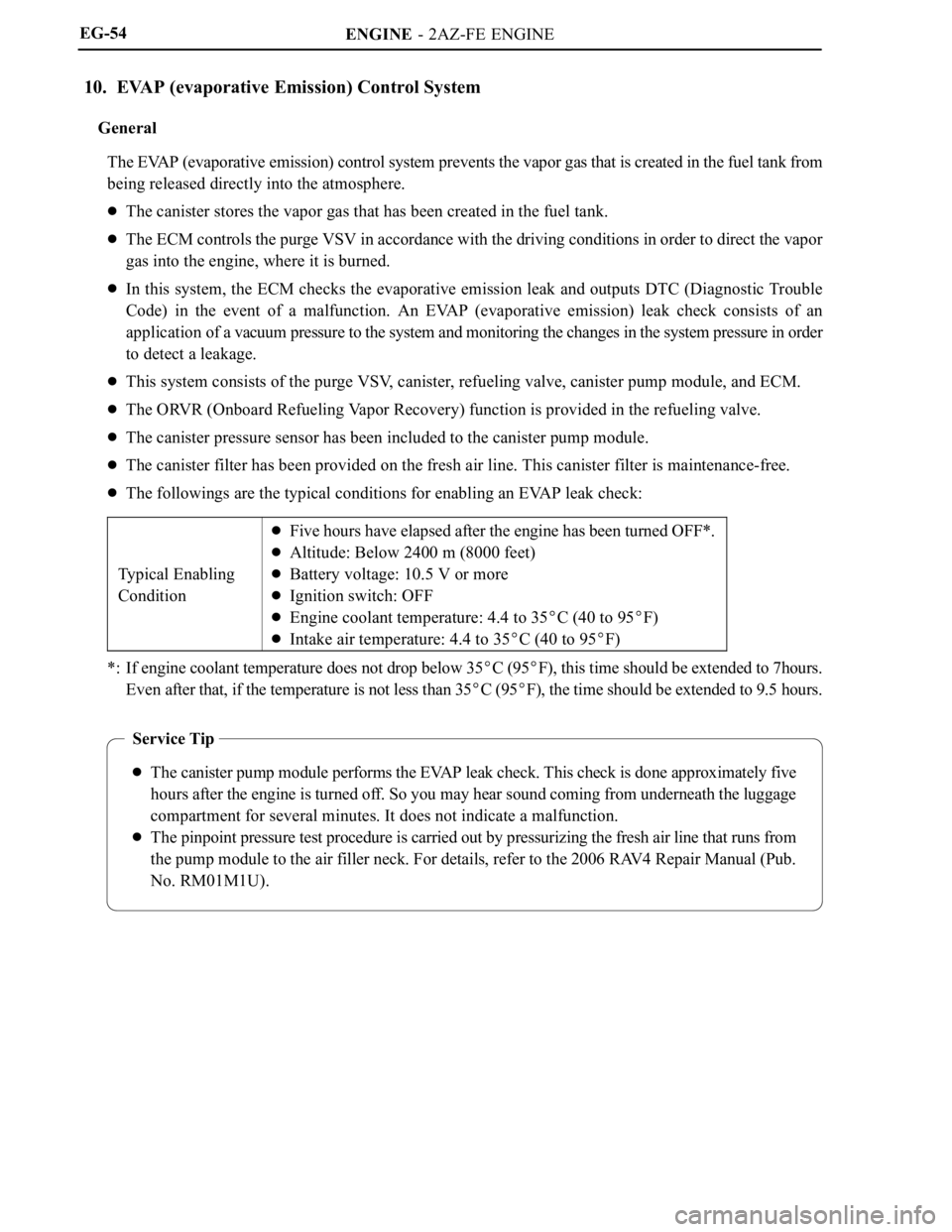

System Diagram

Function of Main Components

ComponentFunction

CanisterContains activated charcoal to absorb the vapor gas that is created in the

fuel tank.

Refueling

Controls the flow rate of the vapor gas from the fuel tank to the canister

when the system is purging or during refueling.

Refueling

Va l v eRestrictor PassagePrevents a large amount of vacuum during purge operation or system

monitoring operation from affecting the pressure in the fuel tank.

Fresh Air LineFresh air goes into the canister and the cleaned drain air goes out into

the atmosphere.

Vent ValveOpens and closes the fresh air line in accordance with the signals from

the ECM.

Canister

Pump ModuleLeak Detection

PumpApplies vacuum pressure to the EVAP control system in accordance

with the signals from the ECM.

p

Canister

Pressure SensorDetects the pressure in the EVAP control system and sends the signals

to the ECM.

Purge VSV

Opens in accordance with the signals from the ECM when the system

is purging, in order to send the vapor gas that was absorbed by the

canister into the intake manifold. In system monitoring mode, this valve

controls the introduction of the vacuum into the fuel tank.

Canister FilterPrevents dust and debris in the fresh air from entering the system.

ECM

Controls the canister pump module and purge VSV in accordance with

the signals from various sensors, in order to achieve a purge volume that

suits the driving conditions. In addition, the ECM monitors the system

for any leakage and outputs a DTC if a malfunction is found.

Page 53 of 2000

ENGINE - 2AZ-FE ENGINE

D13N07 285EG76

Chamber A

Fresh Air Line

Refueling

Valve (Open)

Chamber B

From Fuel

Ta n k

Internal PressureCanister

To F u e l

Ta n k

Positive Pressure

(Fuel Tank Pressure)

Restrictor PassageNegative Pressure

(Intake Manifold Pressure)

During Refueling During Purge Operation or

System Monitoring Operation

228TU119

Fuel Tank Cap

Fresh Air

Fuel Inlet PipeTo Canister

Cleaned Drain Air EG-56

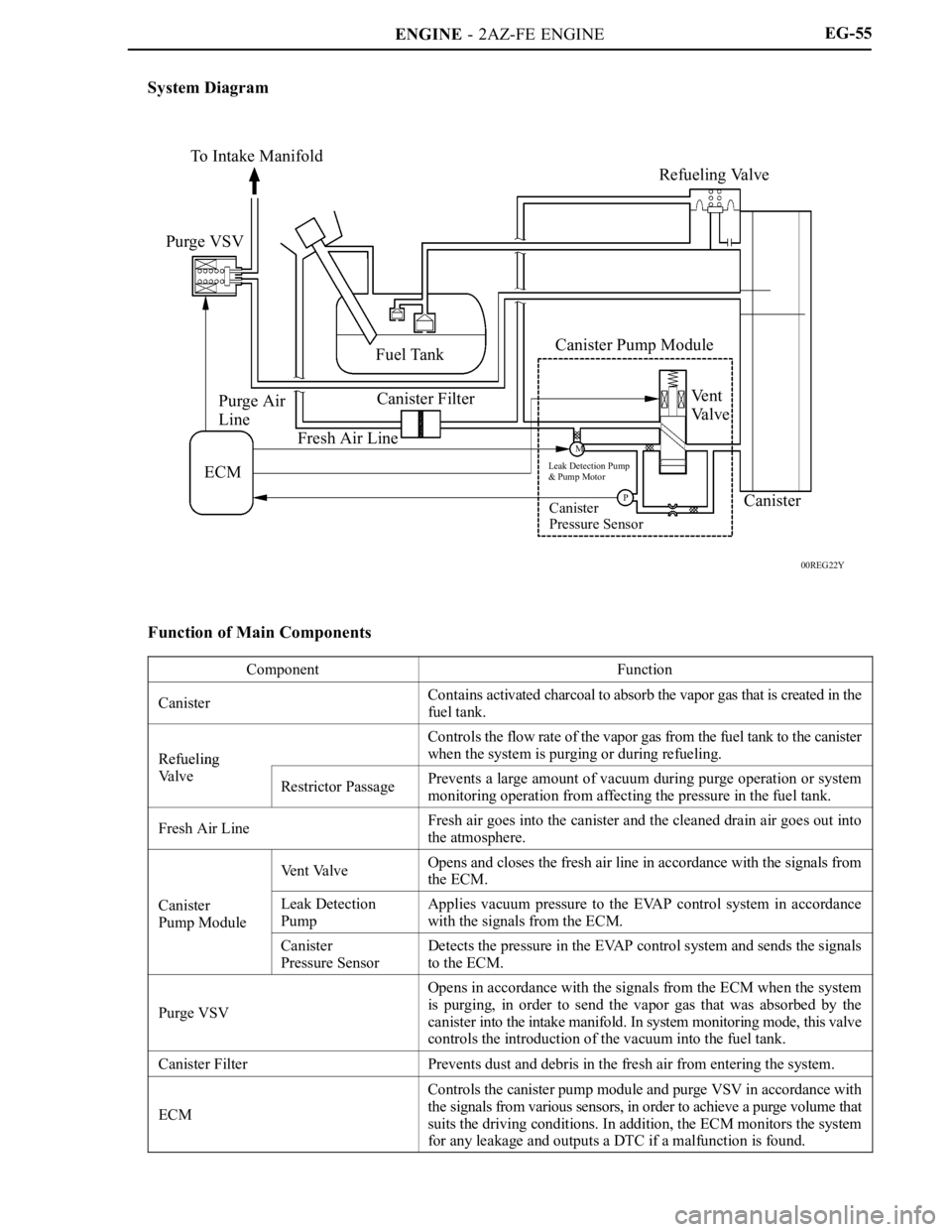

Construction and Operation

1) Refueling Valve

The refueling valve consists of the chamber A, chamber B, and restrictor passage. A constant

atmospheric pressure is applied to the chamber A.

During refueling, the internal pressure of the fuel tank increases. This pressure causes the refueling

valve to lift up, allowing the vapor gas to enter the canister.

The restrictor passage prevents the large amount of vacuum that is created during purge operation or

system monitoring operation from entering the fuel tank, and limits the flow of the vapor gas from the

fuel tank to the canister. If a large volume of vapor gas recirculates into the intake manifold, it will

affect the air-fuel ratio control of the engine. Therefore, the role of the restrictor passage is to help

prevent this from occurring.

2) Fuel Inlet (Fresh Air Line)

In accordance with the change of structure of the EVAP control system, the location of a fresh air line

inlet has been changed from the air cleaner section to the near fuel inlet. The flesh air from the atmosphere

and drain air cleaned by the canister will go in and out of the system through the passage shown below.

Page 54 of 2000

ENGINE - 2AZ-FE ENGINE

279EG26

D13N17 279EG25

Fresh Air

Canister

Pressure SensorLeak Detection Pump

Pump Motor

Vane PumpCanister

Pressure SensorVe n t Va l v e

Fresh Air

Canister

Canister Pump Module

Fresh AirVent Valve

Filter Filter

M

Leak Detection Pump

& Pump Motor

Canister

Pressure SensorP

Reference Orifice

[0.5 mm (0.02 in.) Diameter]Filter

To Canister

EG-57

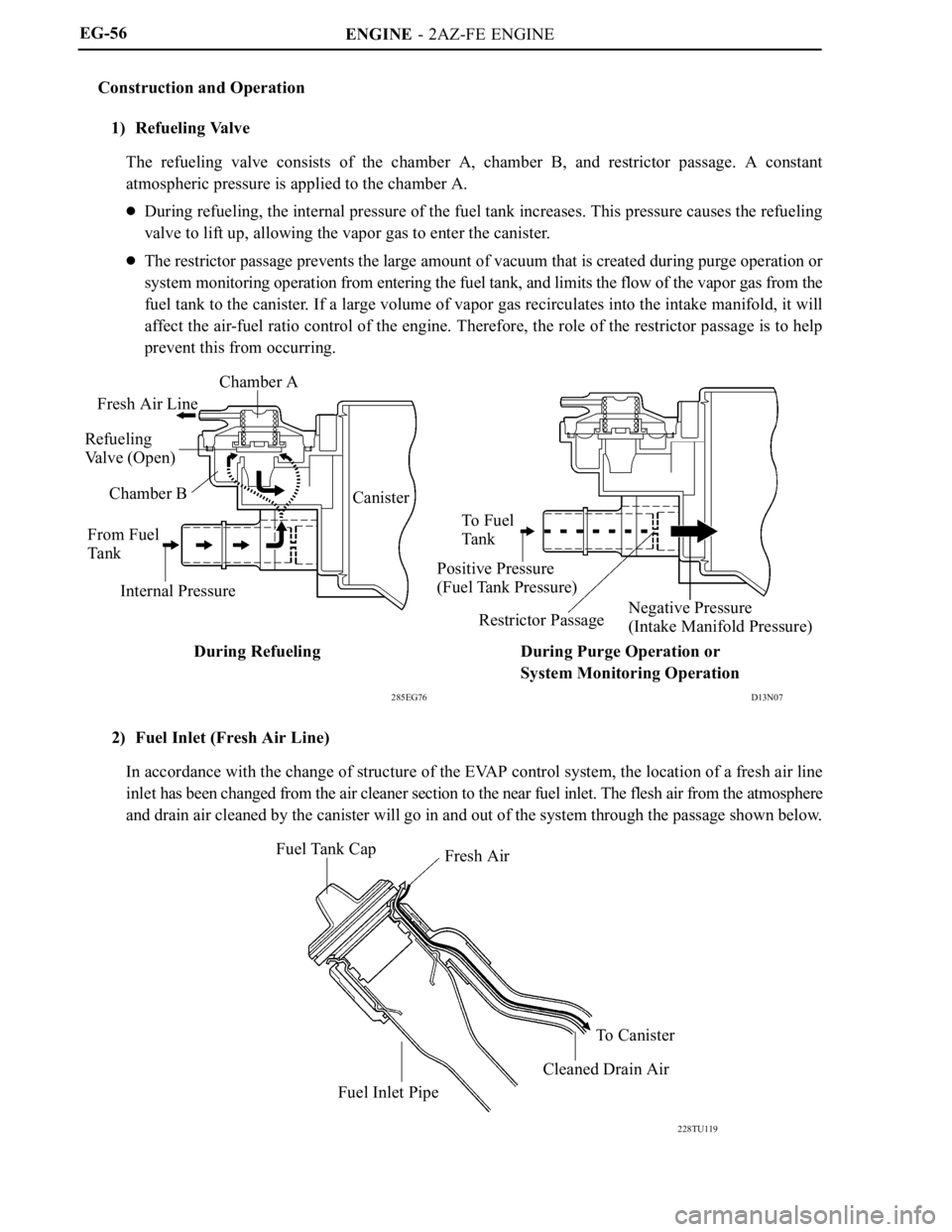

3) Canister Pump Module

Canister pump module consists of the vent valve, leak detection pump, and canister pressure sensor.

The vent valve switches the passages in accordance with the signals received from the ECM.

A DC type brushless motor is used for the pump motor.

A vane type vacuum pump is used.

Simple Diagram

Page 55 of 2000

ENGINE - 2AZ-FE ENGINE

00REG23Y

To Intake Manifold

Atmosphere

Purge VSV

(Open)

ECM

00REG24Y

CloseOpen EG-58

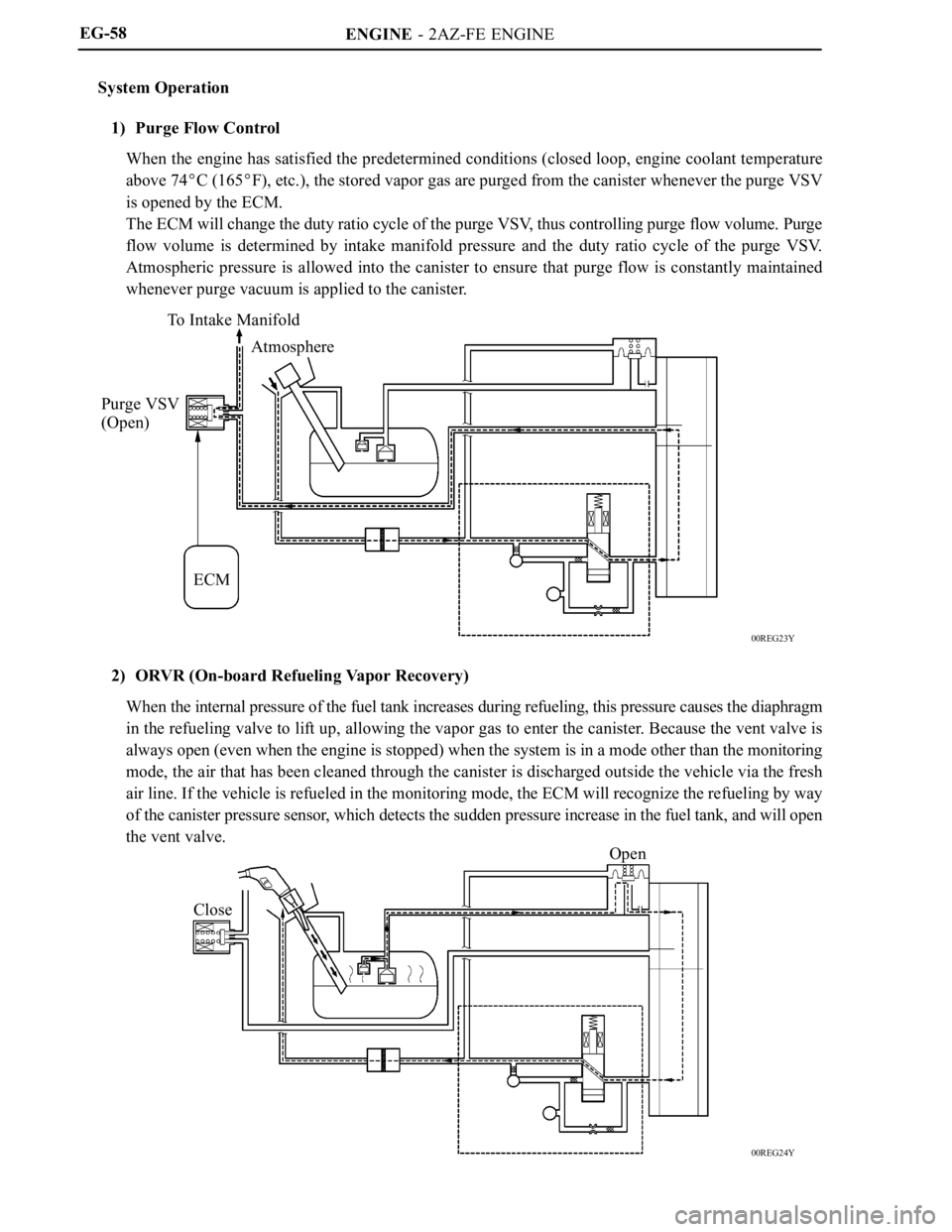

System Operation

1) Purge Flow Control

When the engine has satisfied the predetermined conditions (closed loop, engine coolant temperature

above 74

C (165F), etc.), the stored vapor gas are purged from the canister whenever the purge VSV

is opened by the ECM.

The ECM will change the duty ratio cycle of the purge VSV, thus controlling purge flow volume. Purge

flow volume is determined by intake manifold pressure and the duty ratio cycle of the purge VSV.

Atmospheric pressure is allowed into the canister to ensure that purge flow is constantly maintained

whenever purge vacuum is applied to the canister.

2) ORVR (On-board Refueling Vapor Recovery)

When the internal pressure of the fuel tank increases during refueling, this pressure causes the diaphragm

in the refueling valve to lift up, allowing the vapor gas to enter the canister. Because the vent valve is

always open (even when the engine is stopped) when the system is in a mode other than the monitoring

mode, the air that has been cleaned through the canister is discharged outside the vehicle via the fresh

air line. If the vehicle is refueled in the monitoring mode, the ECM will recognize the refueling by way

of the canister pressure sensor, which detects the sudden pressure increase in the fuel tank, and will open

the vent valve.

Page 56 of 2000

ENGINE - 2AZ-FE ENGINE

275TU47

Purge

VSV

Ve n t

Va l v e

Pump Motor

System

PressureON (Open)

OFF (Close)

ON

OFF (Vent)

ON

OFF

Atmospheric Pressure

0.02 in. Leak Pressure

1) 2) 3) 4) 5) 6)EG-59

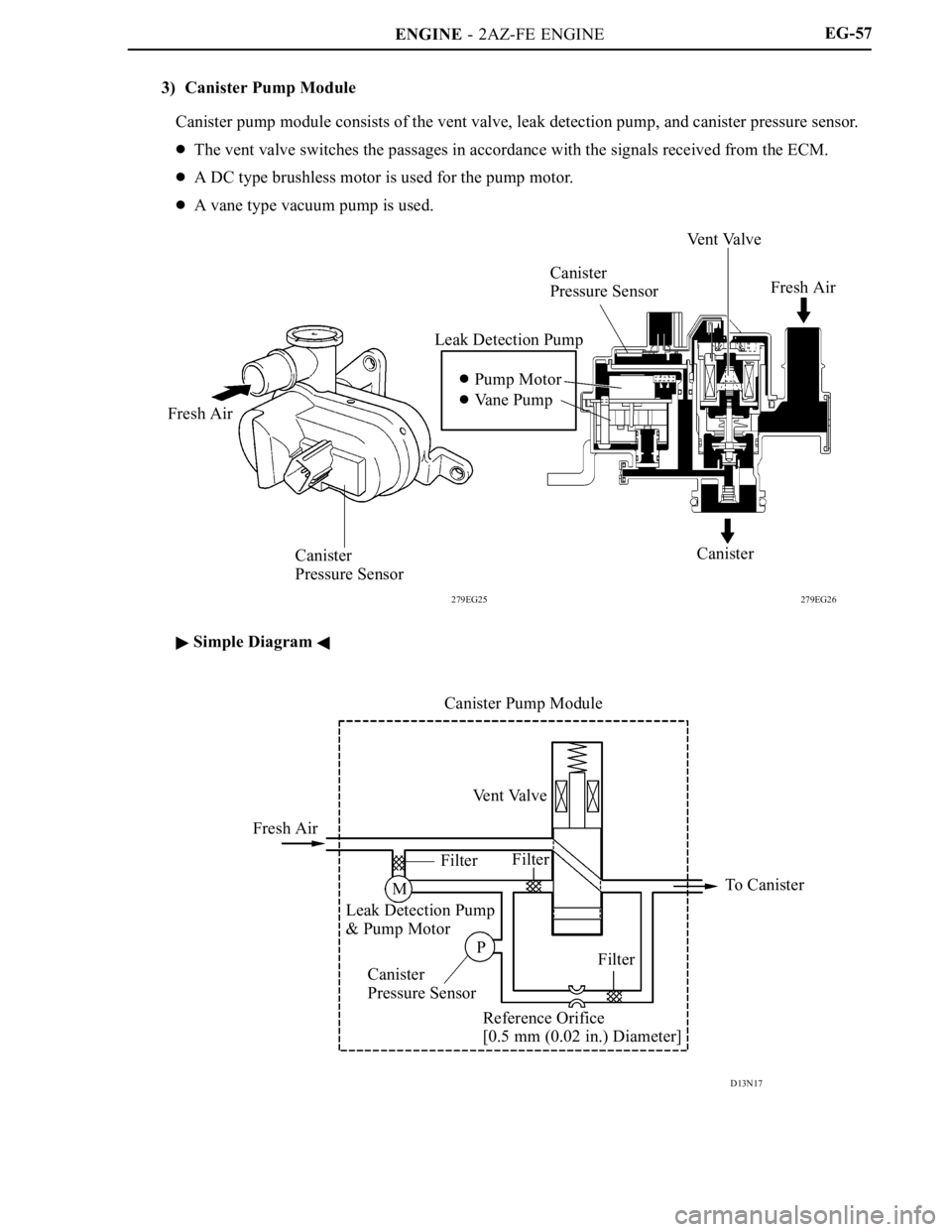

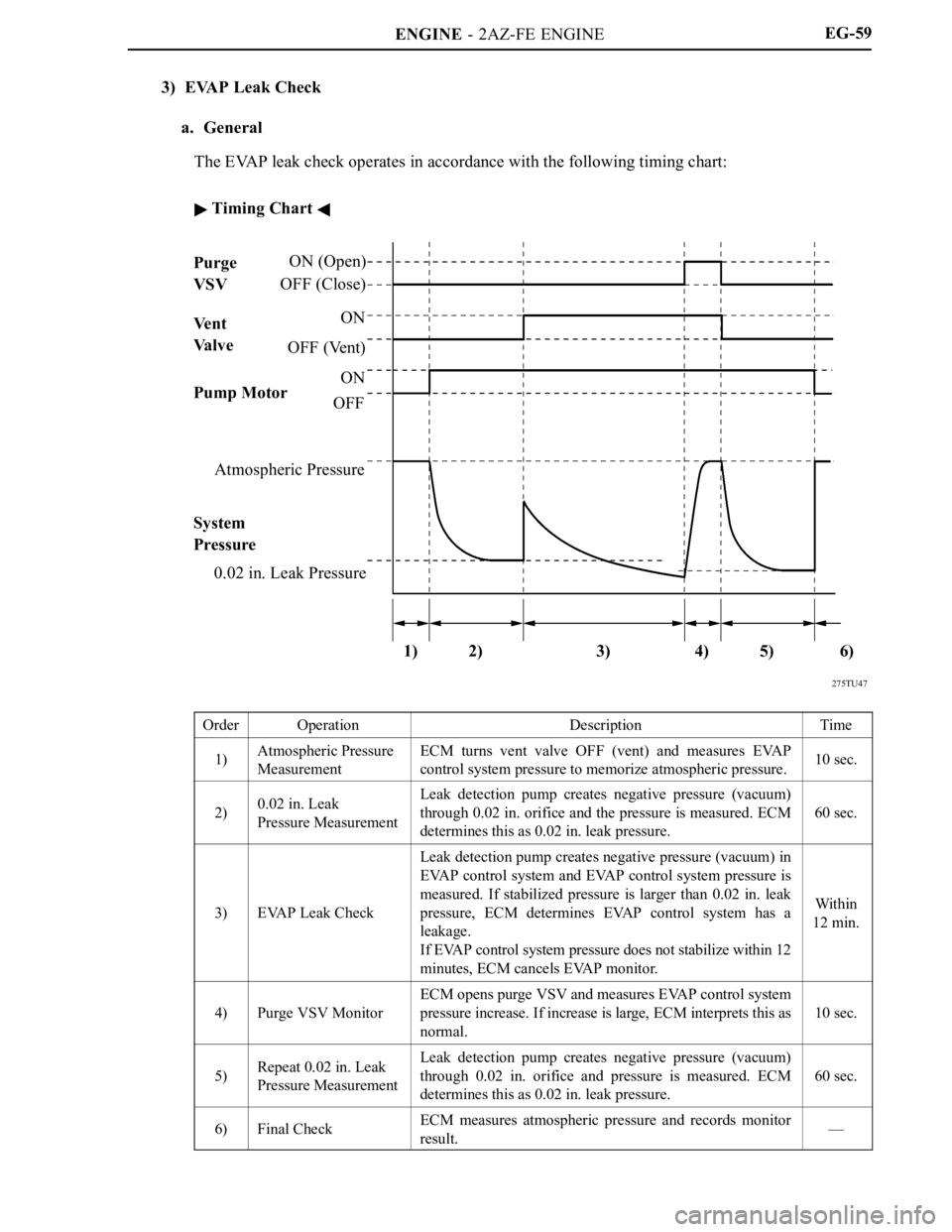

3) EVAP Leak Check

a. General

The EVAP leak check operates in accordance with the following timing chart:

Timing Chart

OrderOperationDescriptionTime

1)Atmospheric Pressure

MeasurementECM turns vent valve OFF (vent) and measures EVAP

control system pressure to memorize atmospheric pressure.10 sec.

2)0.02 in. Leak

Pressure MeasurementLeak detection pump creates negative pressure (vacuum)

through 0.02 in. orifice and the pressure is measured. ECM

determines this as 0.02 in. leak pressure.

60 sec.

3)EVAP Leak Check

Leak detection pump creates negative pressure (vacuum) in

EVAP control system and EVAP control system pressure is

measured. If stabilized pressure is larger than 0.02 in. leak

pressure, ECM determines EVAP control system has a

leakage.

If EVAP control system pressure does not stabilize within 12

minutes, ECM cancels EVAP monitor.

Within

12 min.

4)Purge VSV Monitor

ECM opens purge VSV and measures EVAP control system

pressure increase. If increase is large, ECM interprets this as

normal.

10 sec.

5)Repeat 0.02 in. Leak

Pressure MeasurementLeak detection pump creates negative pressure (vacuum)

through 0.02 in. orifice and pressure is measured. ECM

determines this as 0.02 in. leak pressure.

60 sec.

6)Final CheckECM measures atmospheric pressure and records monitor

result.—

Page 57 of 2000

ENGINE - 2AZ-FE ENGINE

00REG25Y

D13N22

Atmosphere

Purge VSV

(OFF)

ECMCanister Pump Module

Ve n t Va l v e

(OFF)

Leak Detection Pump

& Pump Motor

Canister

Pressure Sensor

Purge VSV

Vent Valve

Pump Motor

System PressureON (Open)

OFF (Close)

ON

OFF (Vent)

ON

OFF

Atmospheric Pressure

0.02 in. Leak Pressure

Atmospheric Pressure Measurement

P

M

EG-60

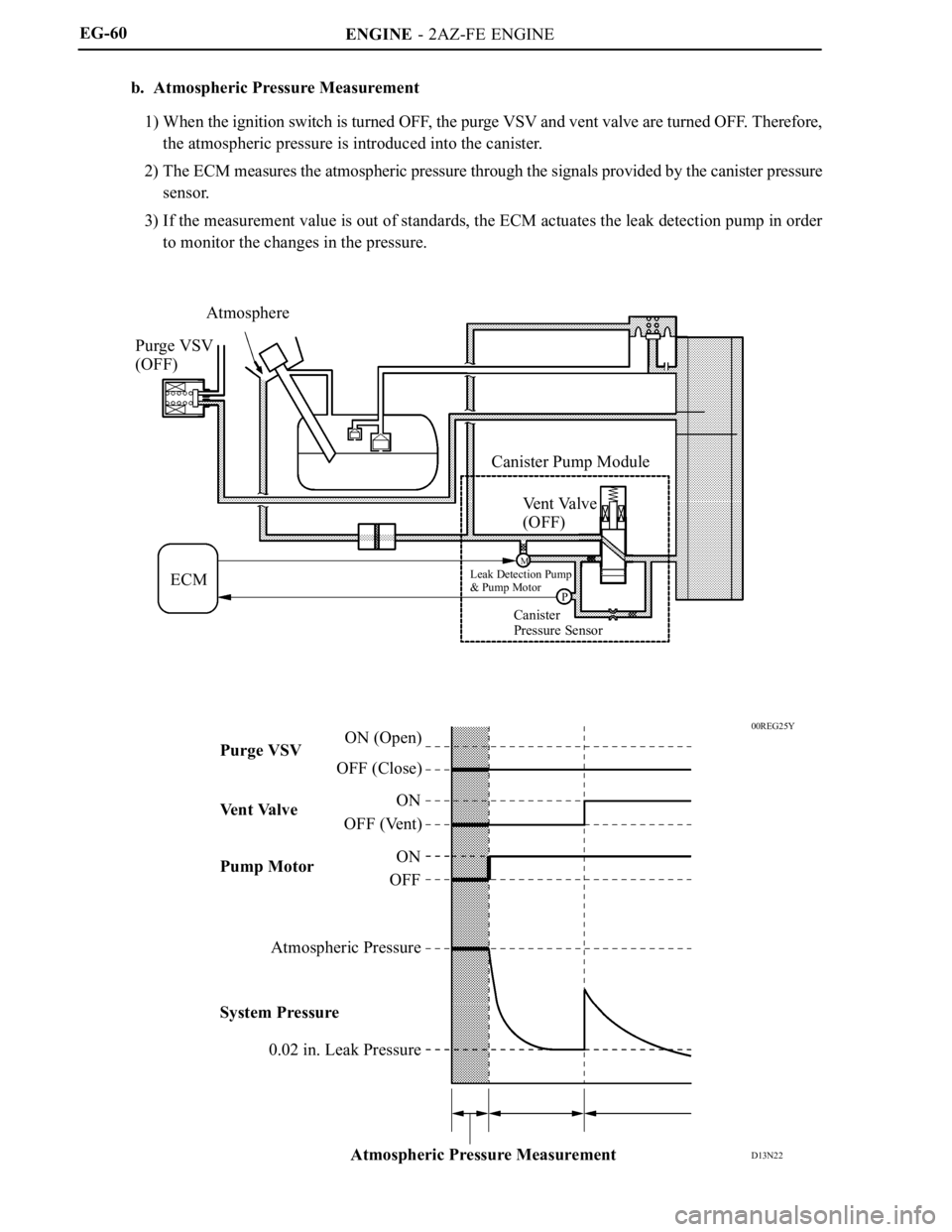

b. Atmospheric Pressure Measurement

1) When the ignition switch is turned OFF, the purge VSV and vent valve are turned OFF. Therefore,

the atmospheric pressure is introduced into the canister.

2) The ECM measures the atmospheric pressure through the signals provided by the canister pressure

sensor.

3) If the measurement value is out of standards, the ECM actuates the leak detection pump in order

to monitor the changes in the pressure.

Page 58 of 2000

ENGINE - 2AZ-FE ENGINE

00REG26Y

275TU48

Atmosphere

Purge VSV

(OFF)

ECMCanister Pump Module

Ve n t Va l v e

(OFF)

Leak Detection Pump

& Pump Motor

Canister Pressure

Sensor

Reference Orifice

Purge VSV

Vent Valve

Pump Motor

System PressureON (Open)

OFF (Close)

ON

OFF (Vent)

ON

OFF

Atmospheric Pressure

0.02 in. Leak Pressure

0.02 in. Leak Pressure Measurement

M

P

EG-61

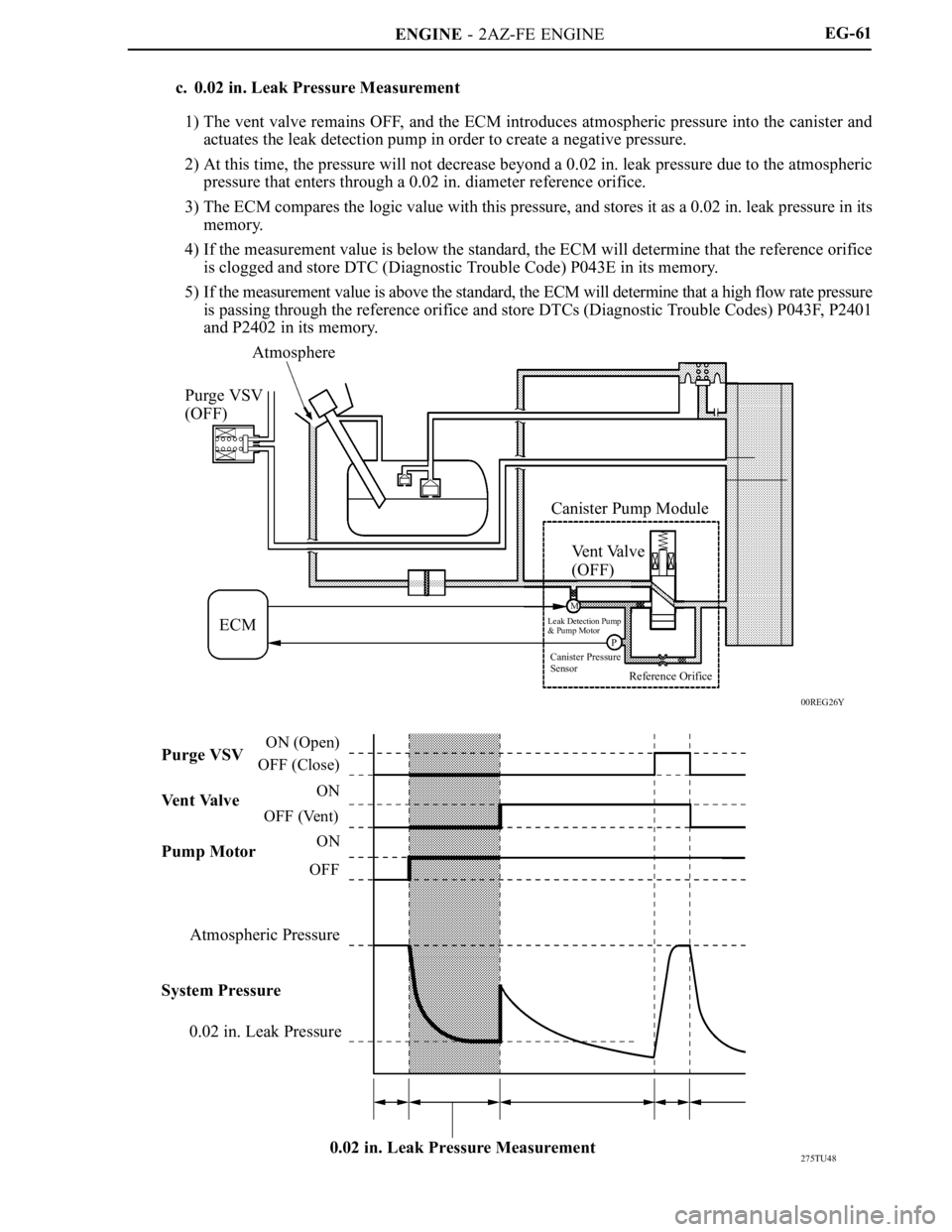

c. 0.02 in. Leak Pressure Measurement

1) The vent valve remains OFF, and the ECM introduces atmospheric pressure into the canister and

actuates the leak detection pump in order to create a negative pressure.

2) At this time, the pressure will not decrease beyond a 0.02 in. leak pressure due to the atmospheric

pressure that enters through a 0.02 in. diameter reference orifice.

3) The ECM compares the logic value with this pressure, and stores it as a 0.02 in. leak pressure in its

memory.

4) If the measurement value is below the standard, the ECM will determine that the reference orifice

is clogged and store DTC (Diagnostic Trouble Code) P043E in its memory.

5) If the measurement value is above the standard, the ECM will determine that a high flow rate pressure

is passing through the reference orifice and store DTCs (Diagnostic Trouble Codes) P043F, P2401

and P2402 in its memory.

Page 59 of 2000

ENGINE - 2AZ-FE ENGINE

00REG27Y

275TU49

Purge VSV

(OFF)Atmosphere

ECMCanister Pump Module

Vent Valve

(ON)

Leak Detection Pump

& Pump Motor

Canister

Pressure Sensor

M

P

Reference Orifice

Va c u u m

Purge VSV

Ve n t Va l v e

Pump Motor

System PressureOFF (Close)

ON (Open)

ON

OFF (Vent)

ON

OFF

Atmospheric Pressure

0.02 in. Leak Pressure

EVAP Leak CheckP0455

P0456

Normal EG-62

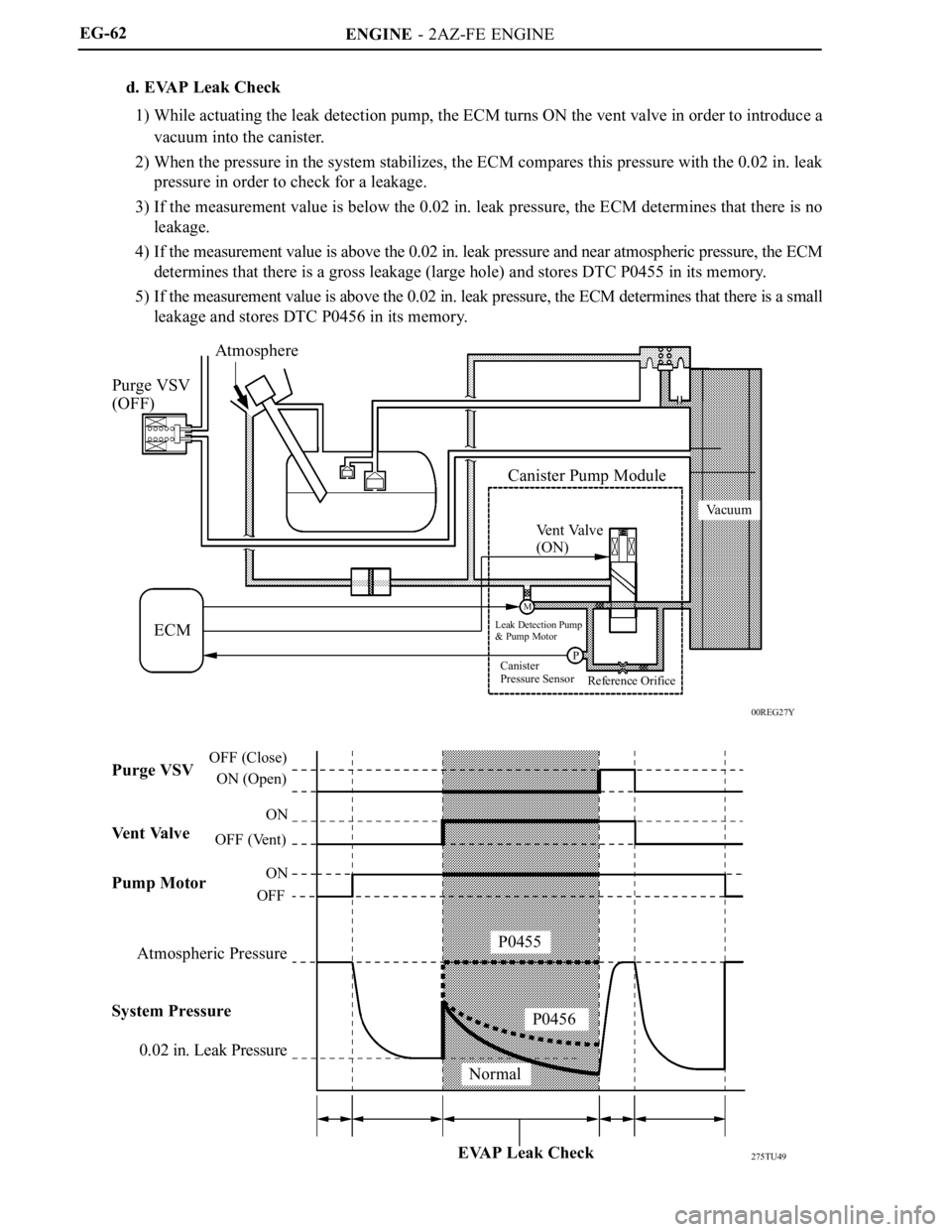

d. EVAP Leak Check

1) While actuating the leak detection pump, the ECM turns ON the vent valve in order to introduce a

vacuum into the canister.

2) When the pressure in the system stabilizes, the ECM compares this pressure with the 0.02 in. leak

pressure in order to check for a leakage.

3) If the measurement value is below the 0.02 in. leak pressure, the ECM determines that there is no

leakage.

4) If the measurement value is above the 0.02 in. leak pressure and near atmospheric pressure, the ECM

determines that there is a gross leakage (large hole) and stores DTC P0455 in its memory.

5) If the measurement value is above the 0.02 in. leak pressure, the ECM determines that there is a small

leakage and stores DTC P0456 in its memory.

Page 60 of 2000

ENGINE - 2AZ-FE ENGINE

00REG28Y

275TU50 M

P

Atmosphere

Atmosphere

Purge VSV

(ON)

ECMCanister Pump Module

Vent Valve

(ON)

Leak Detection Pump

& Pump Motor

Canister

Pressure Sensor

Purge VSV Monitor

P0441

Normal

Purge VSV

Vent Valve

Pump Motor

System PressureON (Open)

OFF (Close)

ON

OFF (Vent)

ON

OFF

Atmospheric Pressure

0.02 in. Leak PressureEG-63

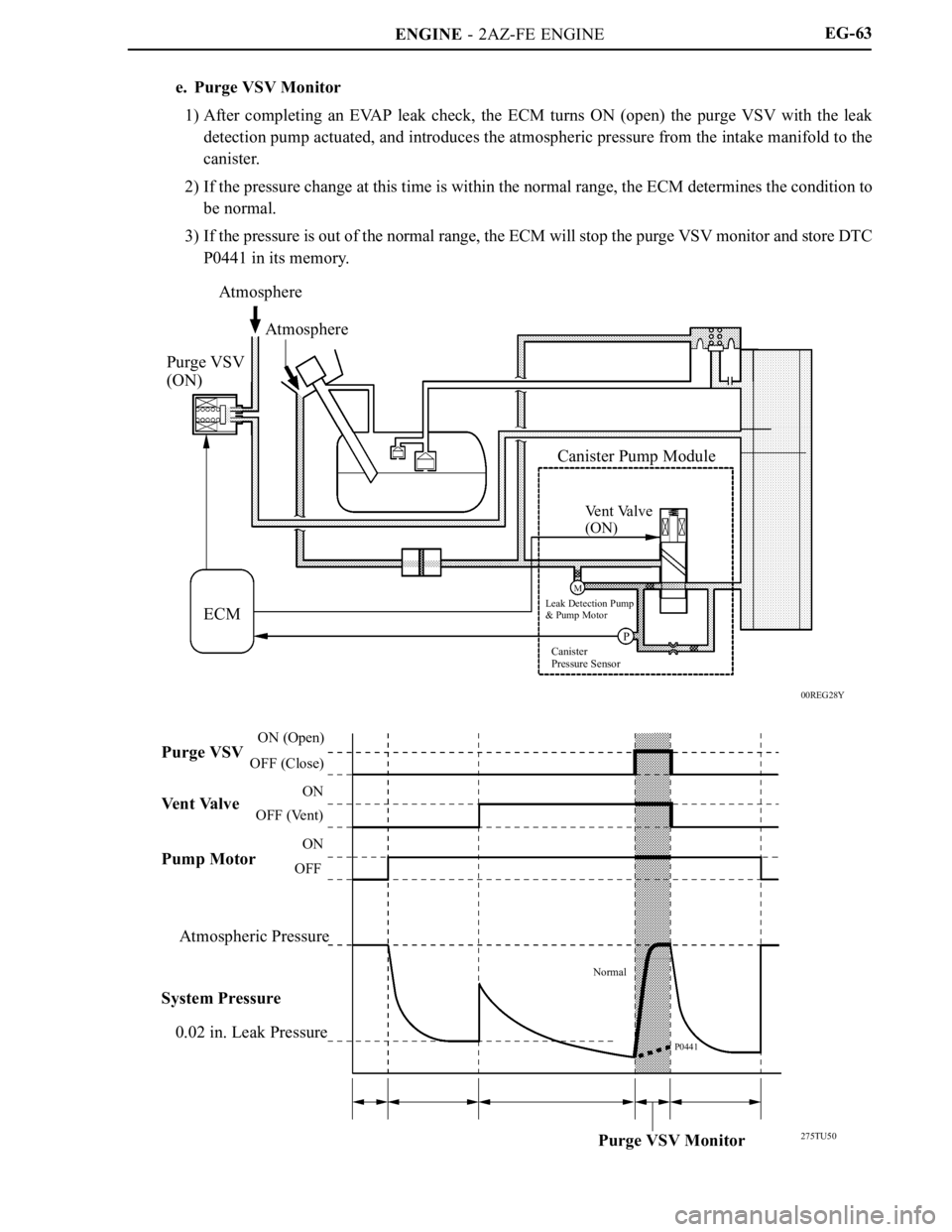

e. Purge VSV Monitor

1) After completing an EVAP leak check, the ECM turns ON (open) the purge VSV with the leak

detection pump actuated, and introduces the atmospheric pressure from the intake manifold to the

canister.

2) If the pressure change at this time is within the normal range, the ECM determines the condition to

be normal.

3) If the pressure is out of the normal range, the ECM will stop the purge VSV monitor and store DTC

P0441 in its memory.