sensor TOYOTA RAV4 2006 Service Manual Online

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 352 of 2000

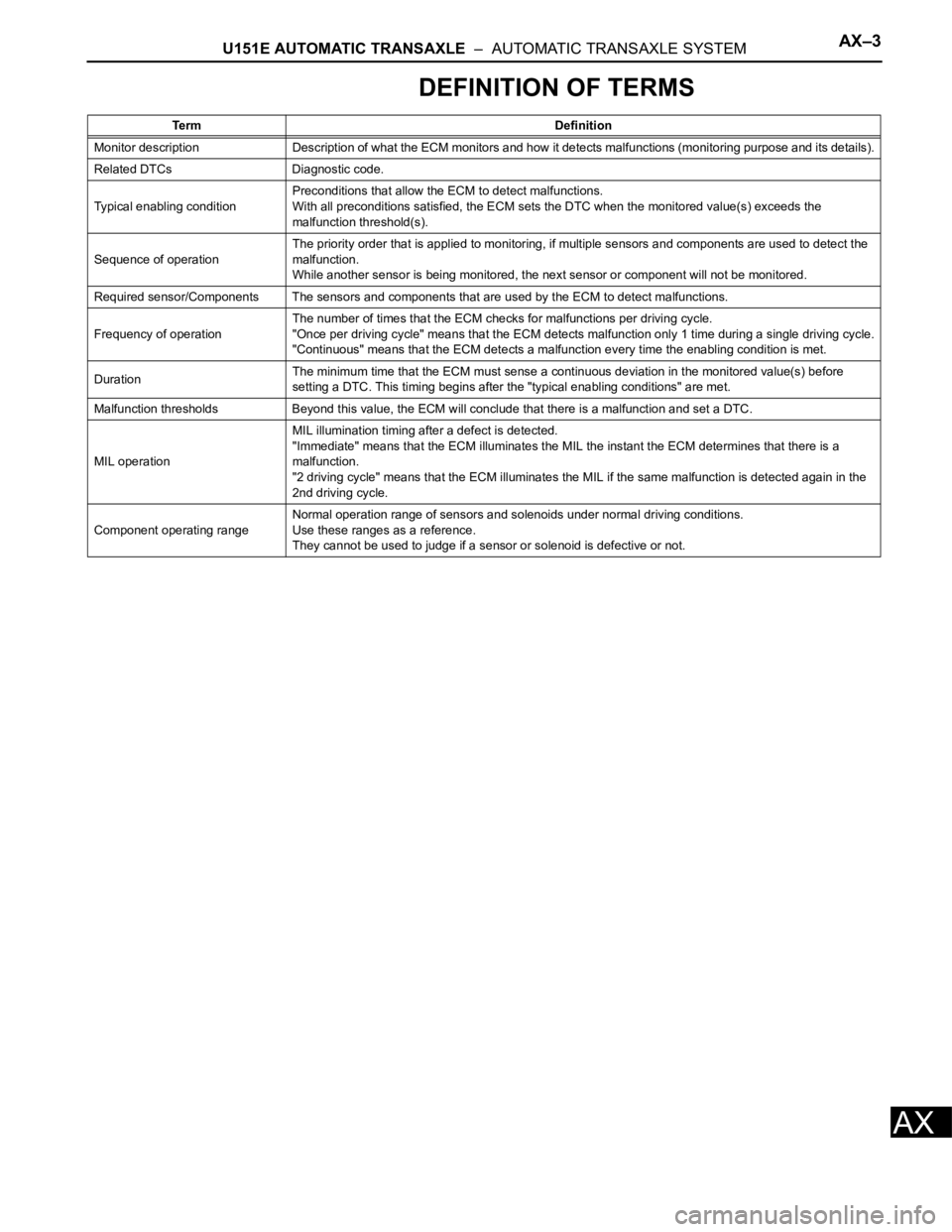

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–3

AX

DEFINITION OF TERMS

Te r m D e f i n i t i o n

Monitor description Description of what the ECM monitors and how it detects malfunctions (monitoring purpose and its details).

Related DTCs Diagnostic code.

Typical enabling conditionPreconditions that allow the ECM to detect malfunctions.

With all preconditions satisfied, the ECM sets the DTC when the monitored value(s) exceeds the

malfunction threshold(s).

Sequence of operationThe priority order that is applied to monitoring, if multiple sensors and components are used to detect the

malfunction.

While another sensor is being monitored, the next sensor or component will not be monitored.

Required sensor/Components The sensors and components that are used by the ECM to detect malfunctions.

Frequency of operationThe number of times that the ECM checks for malfunctions per driving cycle.

"Once per driving cycle" means that the ECM detects malfunction only 1 time during a single driving cycle.

"Continuous" means that the ECM detects a malfunction every time the enabling condition is met.

DurationThe minimum time that the ECM must sense a continuous deviation in the monitored value(s) before

setting a DTC. This timing begins after the "typical enabling conditions" are met.

Malfunction thresholds Beyond this value, the ECM will conclude that there is a malfunction and set a DTC.

MIL operationMIL illumination timing after a defect is detected.

"Immediate" means that the ECM illuminates the MIL the instant the ECM determines that there is a

malfunction.

"2 driving cycle" means that the ECM illuminates the MIL if the same malfunction is detected again in the

2nd driving cycle.

Component operating rangeNormal operation range of sensors and solenoids under normal driving conditions.

Use these ranges as a reference.

They cannot be used to judge if a sensor or solenoid is defective or not.

Page 358 of 2000

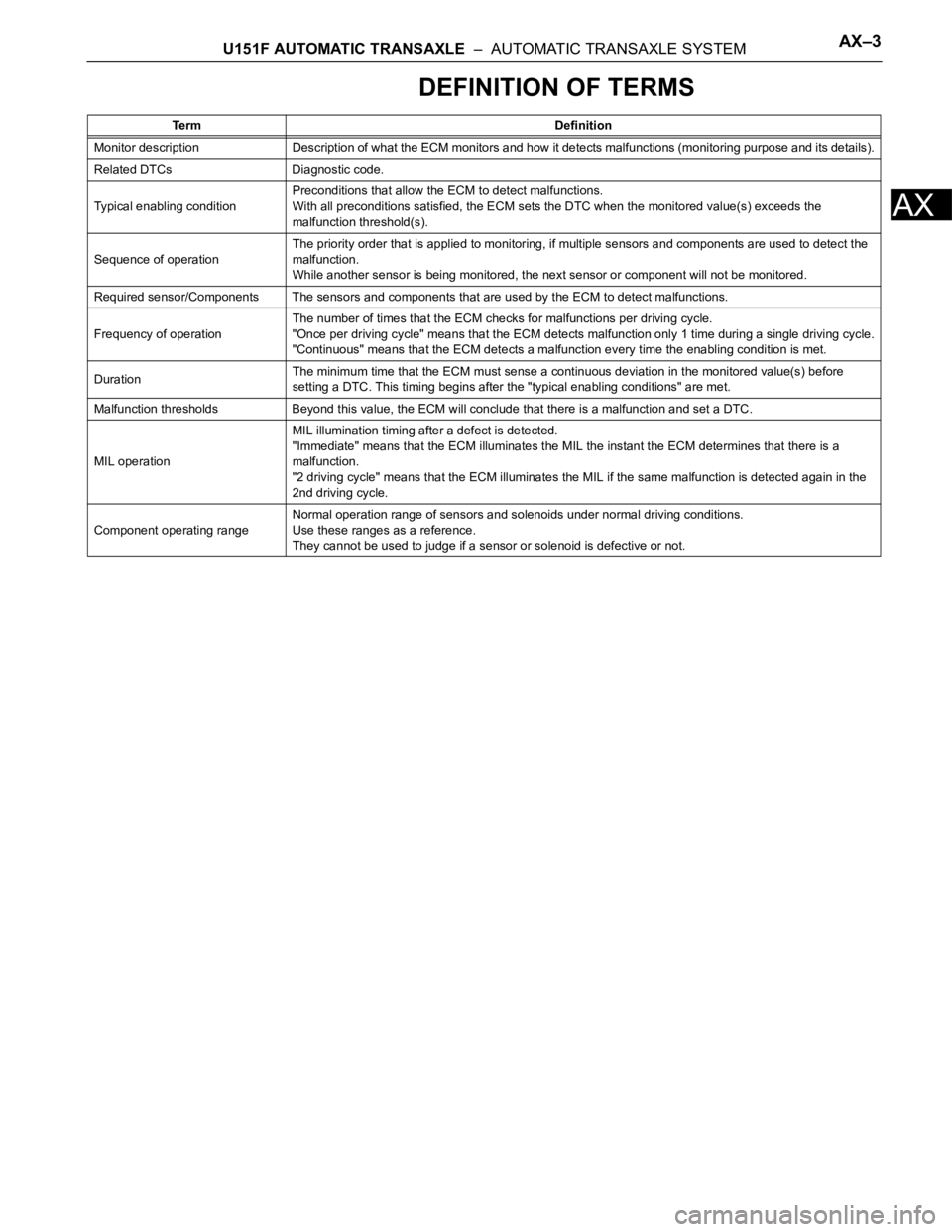

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–3

AX

DEFINITION OF TERMS

Te r m D e f i n i t i o n

Monitor description Description of what the ECM monitors and how it detects malfunctions (monitoring purpose and its details).

Related DTCs Diagnostic code.

Typical enabling conditionPreconditions that allow the ECM to detect malfunctions.

With all preconditions satisfied, the ECM sets the DTC when the monitored value(s) exceeds the

malfunction threshold(s).

Sequence of operationThe priority order that is applied to monitoring, if multiple sensors and components are used to detect the

malfunction.

While another sensor is being monitored, the next sensor or component will not be monitored.

Required sensor/Components The sensors and components that are used by the ECM to detect malfunctions.

Frequency of operationThe number of times that the ECM checks for malfunctions per driving cycle.

"Once per driving cycle" means that the ECM detects malfunction only 1 time during a single driving cycle.

"Continuous" means that the ECM detects a malfunction every time the enabling condition is met.

DurationThe minimum time that the ECM must sense a continuous deviation in the monitored value(s) before

setting a DTC. This timing begins after the "typical enabling conditions" are met.

Malfunction thresholds Beyond this value, the ECM will conclude that there is a malfunction and set a DTC.

MIL operationMIL illumination timing after a defect is detected.

"Immediate" means that the ECM illuminates the MIL the instant the ECM determines that there is a

malfunction.

"2 driving cycle" means that the ECM illuminates the MIL if the same malfunction is detected again in the

2nd driving cycle.

Component operating rangeNormal operation range of sensors and solenoids under normal driving conditions.

Use these ranges as a reference.

They cannot be used to judge if a sensor or solenoid is defective or not.

Page 370 of 2000

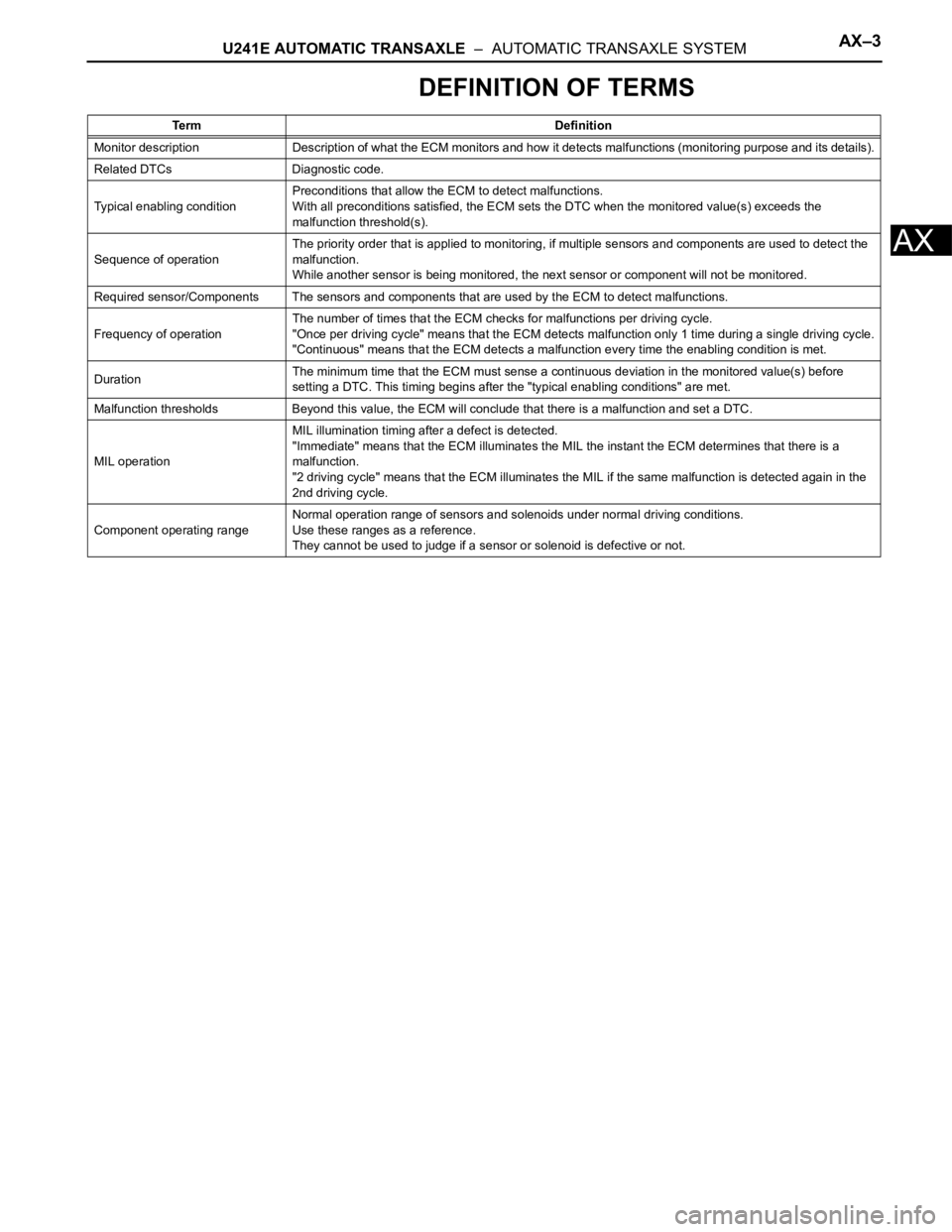

U241E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–3

AX

DEFINITION OF TERMS

Te r m D e f i n i t i o n

Monitor description Description of what the ECM monitors and how it detects malfunctions (monitoring purpose and its details).

Related DTCs Diagnostic code.

Typical enabling conditionPreconditions that allow the ECM to detect malfunctions.

With all preconditions satisfied, the ECM sets the DTC when the monitored value(s) exceeds the

malfunction threshold(s).

Sequence of operationThe priority order that is applied to monitoring, if multiple sensors and components are used to detect the

malfunction.

While another sensor is being monitored, the next sensor or component will not be monitored.

Required sensor/Components The sensors and components that are used by the ECM to detect malfunctions.

Frequency of operationThe number of times that the ECM checks for malfunctions per driving cycle.

"Once per driving cycle" means that the ECM detects malfunction only 1 time during a single driving cycle.

"Continuous" means that the ECM detects a malfunction every time the enabling condition is met.

DurationThe minimum time that the ECM must sense a continuous deviation in the monitored value(s) before

setting a DTC. This timing begins after the "typical enabling conditions" are met.

Malfunction thresholds Beyond this value, the ECM will conclude that there is a malfunction and set a DTC.

MIL operationMIL illumination timing after a defect is detected.

"Immediate" means that the ECM illuminates the MIL the instant the ECM determines that there is a

malfunction.

"2 driving cycle" means that the ECM illuminates the MIL if the same malfunction is detected again in the

2nd driving cycle.

Component operating rangeNormal operation range of sensors and solenoids under normal driving conditions.

Use these ranges as a reference.

They cannot be used to judge if a sensor or solenoid is defective or not.

Page 380 of 2000

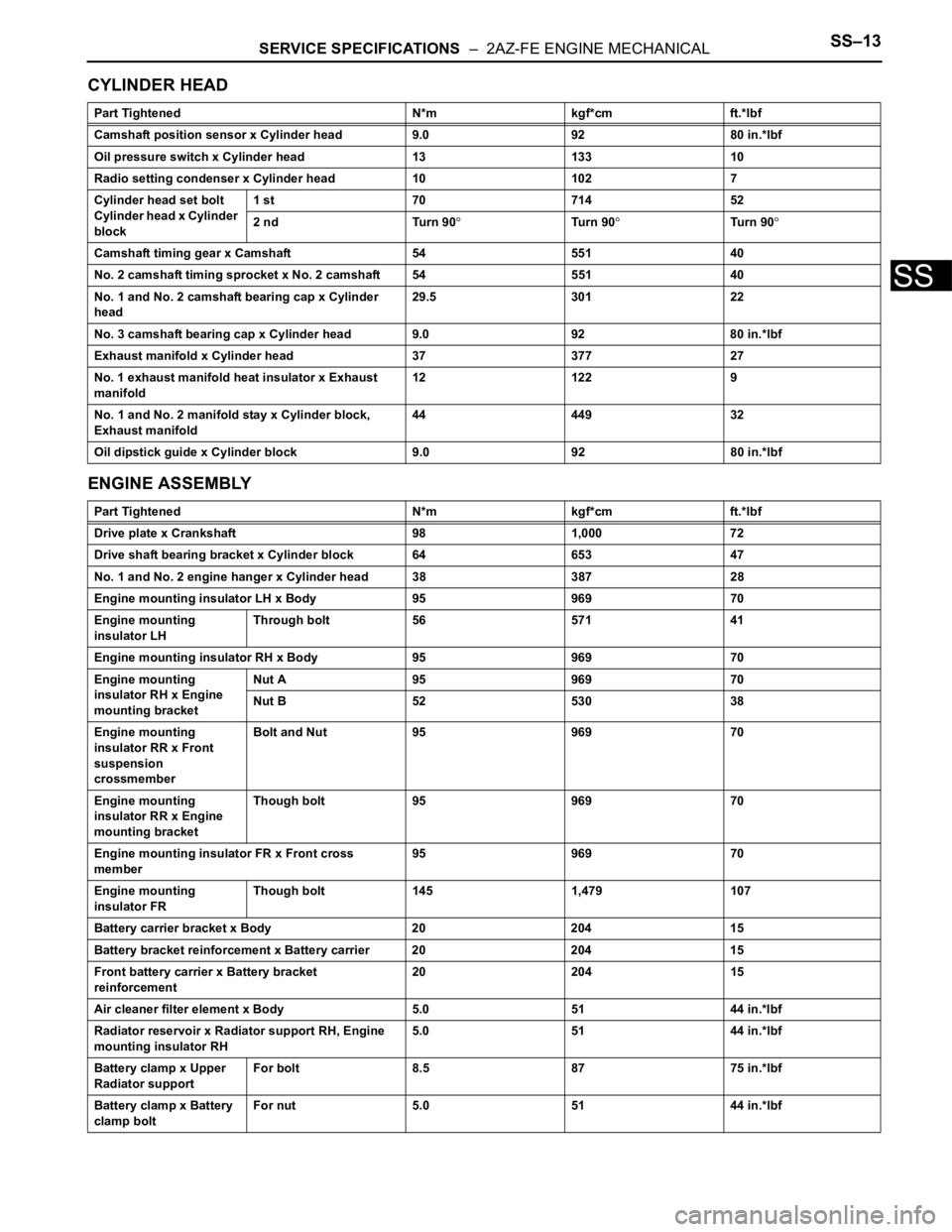

SERVICE SPECIFICATIONS – 2AZ-FE ENGINE MECHANICALSS–13

SS

CYLINDER HEAD

ENGINE ASSEMBLY

Part Tightened N*m kgf*cm ft.*lbf

Camshaft position sensor x Cylinder head 9.0 92 80 in.*lbf

Oil pressure switch x Cylinder head 13 133 10

Radio setting condenser x Cylinder head 10 102 7

Cylinder head set bolt

Cylinder head x Cylinder

block1 st 70 714 52

2 nd Turn 90

Tu r n 9 0Tu r n 9 0

Camshaft timing gear x Camshaft 54 551 40

No. 2 camshaft timing sprocket x No. 2 camshaft 54 551 40

No. 1 and No. 2 camshaft bearing cap x Cylinder

head29.5 301 22

No. 3 camshaft bearing cap x Cylinder head 9.0 92 80 in.*lbf

Exhaust manifold x Cylinder head 37 377 27

No. 1 exhaust manifold heat insulator x Exhaust

manifold12 122 9

No. 1 and No. 2 manifold stay x Cylinder block,

Exhaust manifold44 449 32

Oil dipstick guide x Cylinder block 9.0 92 80 in.*lbf

Part Tightened N*m kgf*cm ft.*lbf

Drive plate x Crankshaft 98 1,000 72

Drive shaft bearing bracket x Cylinder block 64 653 47

No. 1 and No. 2 engine hanger x Cylinder head 38 387 28

Engine mounting insulator LH x Body 95 969 70

Engine mounting

insulator LHThrough bolt 56 571 41

Engine mounting insulator RH x Body 95 969 70

Engine mounting

insulator RH x Engine

mounting bracketNut A 95 969 70

Nut B 52 530 38

Engine mounting

insulator RR x Front

suspension

crossmemberBolt and Nut 95 969 70

Engine mounting

insulator RR x Engine

mounting bracketThough bolt 95 969 70

Engine mounting insulator FR x Front cross

member95 969 70

Engine mounting

insulator FRThough bolt 145 1,479 107

Battery carrier bracket x Body 20 204 15

Battery bracket reinforcement x Battery carrier 20 204 15

Front battery carrier x Battery bracket

reinforcement20 204 15

Air cleaner filter element x Body 5.0 51 44 in.*lbf

Radiator reservoir x Radiator support RH, Engine

mounting insulator RH5.0 51 44 in.*lbf

Battery clamp x Upper

Radiator supportFor bolt 8.5 87 75 in.*lbf

Battery clamp x Battery

clamp boltFor nut 5.0 51 44 in.*lbf

Page 383 of 2000

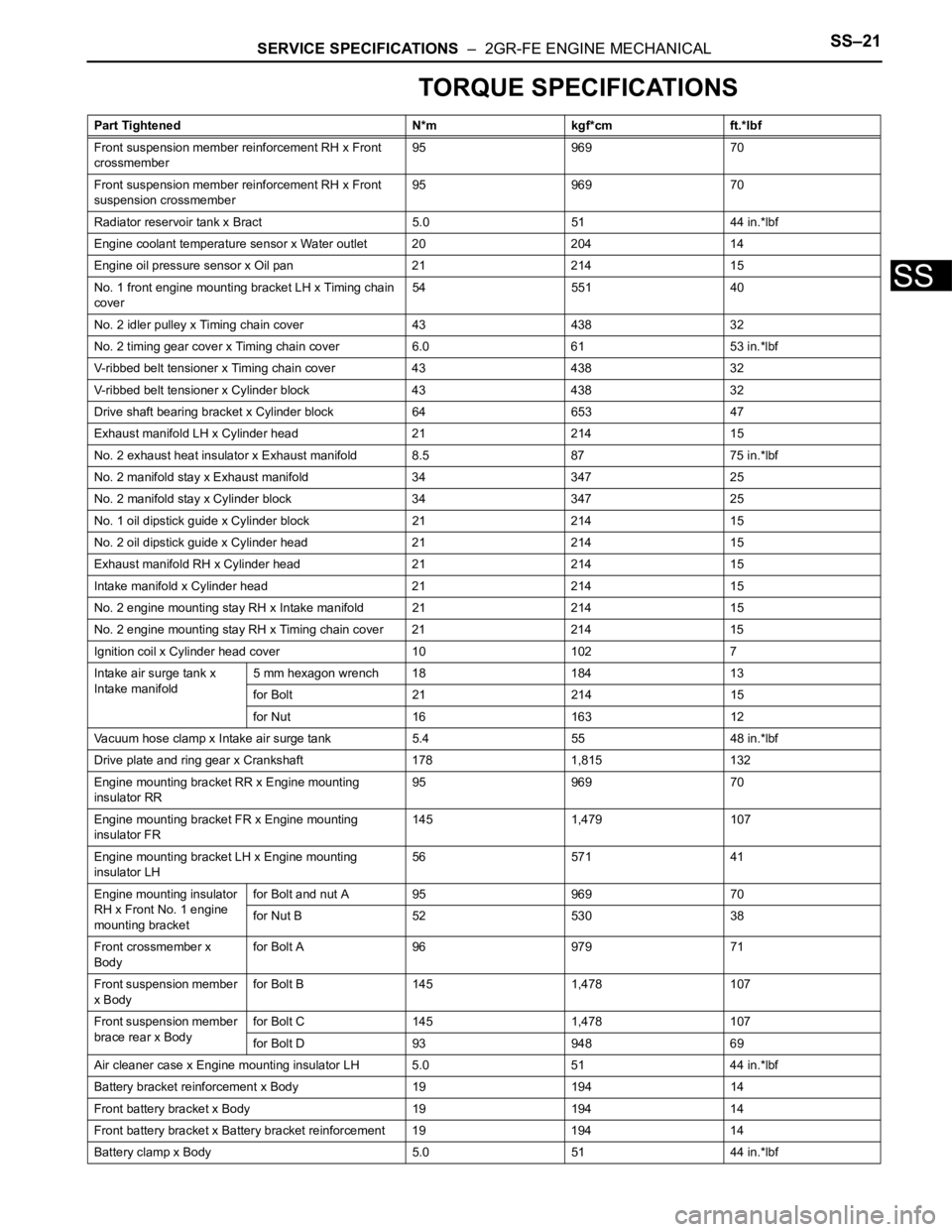

SERVICE SPECIFICATIONS – 2GR-FE ENGINE MECHANICALSS–21

SS

TORQUE SPECIFICATIONS

Part Tightened N*m kgf*cm ft.*lbf

Front suspension member reinforcement RH x Front

crossmember95 969 70

Front suspension member reinforcement RH x Front

suspension crossmember95 969 70

Radiator reservoir tank x Bract 5.0 51 44 in.*lbf

Engine coolant temperature sensor x Water outlet 20 204 14

Engine oil pressure sensor x Oil pan 21 214 15

No. 1 front engine mounting bracket LH x Timing chain

cover54 551 40

No. 2 idler pulley x Timing chain cover 43 438 32

No. 2 timing gear cover x Timing chain cover 6.0 61 53 in.*lbf

V-ribbed belt tensioner x Timing chain cover 43 438 32

V-ribbed belt tensioner x Cylinder block 43 438 32

Drive shaft bearing bracket x Cylinder block 64 653 47

Exhaust manifold LH x Cylinder head 21 214 15

No. 2 exhaust heat insulator x Exhaust manifold 8.5 87 75 in.*lbf

No. 2 manifold stay x Exhaust manifold 34 347 25

No. 2 manifold stay x Cylinder block 34 347 25

No. 1 oil dipstick guide x Cylinder block 21 214 15

No. 2 oil dipstick guide x Cylinder head 21 214 15

Exhaust manifold RH x Cylinder head 21 214 15

Intake manifold x Cylinder head 21 214 15

No. 2 engine mounting stay RH x Intake manifold 21 214 15

No. 2 engine mounting stay RH x Timing chain cover 21 214 15

Ignition coil x Cylinder head cover 10 102 7

Intake air surge tank x

Intake manifold5 mm hexagon wrench 18 184 13

for Bolt 21 214 15

for Nut 16 163 12

Vacuum hose clamp x Intake air surge tank 5.4 55 48 in.*lbf

Drive plate and ring gear x Crankshaft 178 1,815 132

Engine mounting bracket RR x Engine mounting

insulator RR95 969 70

Engine mounting bracket FR x Engine mounting

insulator FR145 1,479 107

Engine mounting bracket LH x Engine mounting

insulator LH56 571 41

Engine mounting insulator

RH x Front No. 1 engine

mounting bracketfor Bolt and nut A 95 969 70

for Nut B 52 530 38

Front crossmember x

Bodyfor Bolt A 96 979 71

Front suspension member

x Bodyfor Bolt B 145 1,478 107

Front suspension member

brace rear x Bodyfor Bolt C 145 1,478 107

for Bolt D 93 948 69

Air cleaner case x Engine mounting insulator LH 5.0 51 44 in.*lbf

Battery bracket reinforcement x Body 19 194 14

Front battery bracket x Body 19 194 14

Front battery bracket x Battery bracket reinforcement 19 194 14

Battery clamp x Body 5.0 51 44 in.*lbf

Page 384 of 2000

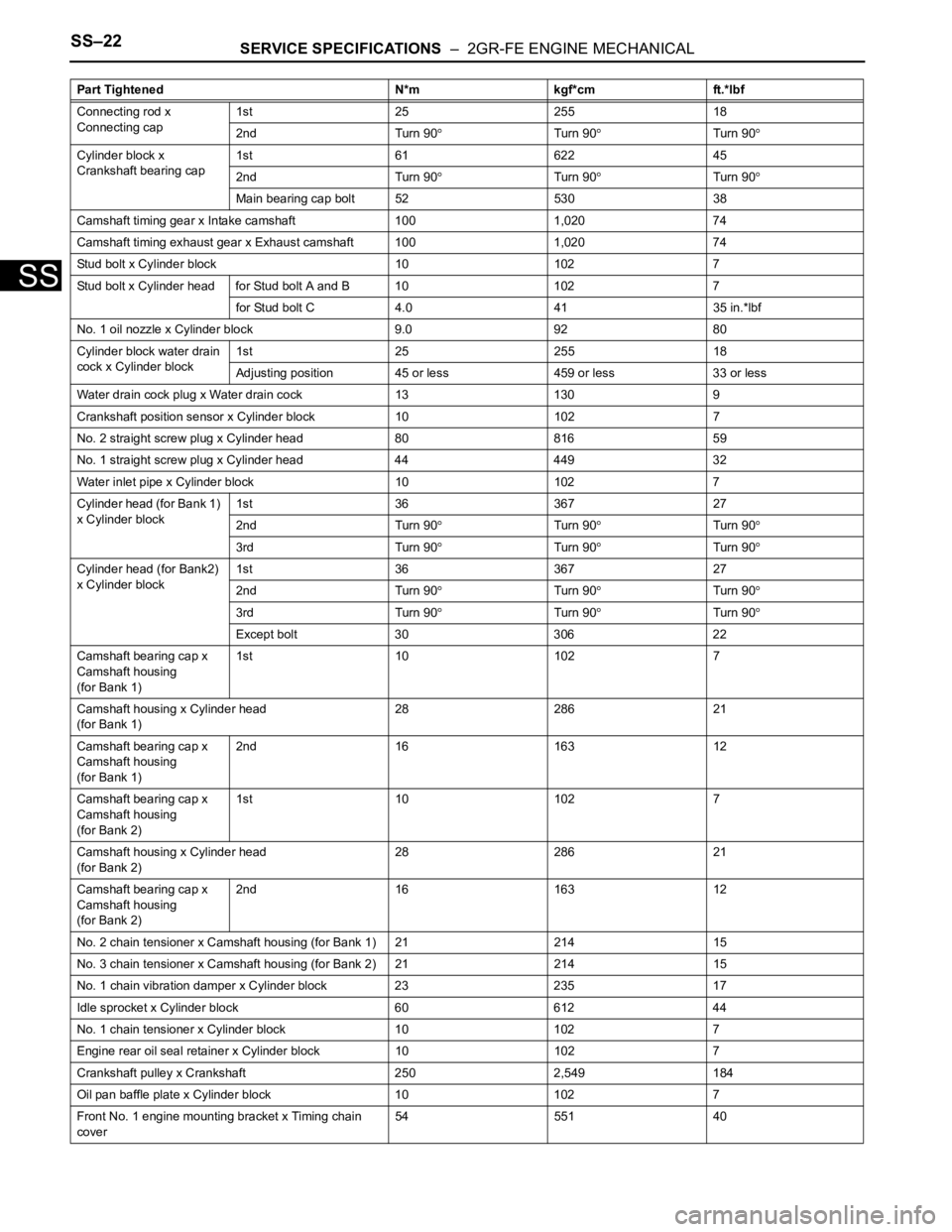

SS–22SERVICE SPECIFICATIONS – 2GR-FE ENGINE MECHANICAL

SS

Connecting rod x

Connecting cap1st 25 255 18

2nd Turn 90

Turn 90Turn 90

Cylinder block x

Crankshaft bearing cap1st 61 622 45

2nd Turn 90

Turn 90Turn 90

Main bearing cap bolt 52 530 38

Camshaft timing gear x Intake camshaft 100 1,020 74

Camshaft timing exhaust gear x Exhaust camshaft 100 1,020 74

Stud bolt x Cylinder block 10 102 7

Stud bolt x Cylinder head for Stud bolt A and B 10 102 7

for Stud bolt C 4.0 41 35 in.*lbf

No. 1 oil nozzle x Cylinder block 9.0 92 80

Cylinder block water drain

cock x Cylinder block1st 25 255 18

Adjusting position 45 or less 459 or less 33 or less

Water drain cock plug x Water drain cock 13 130 9

Crankshaft position sensor x Cylinder block 10 102 7

No. 2 straight screw plug x Cylinder head 80 816 59

No. 1 straight screw plug x Cylinder head 44 449 32

Water inlet pipe x Cylinder block 10 102 7

Cylinder head (for Bank 1)

x Cylinder block1st 36 367 27

2nd Turn 90

Turn 90Turn 90

3rd Turn 90Turn 90Turn 90

Cylinder head (for Bank2)

x Cylinder block1st 36 367 27

2nd Turn 90

Turn 90Turn 90

3rd Turn 90Turn 90Turn 90

Except bolt 30 306 22

Camshaft bearing cap x

Camshaft housing

(for Bank 1)1st 10 102 7

Camshaft housing x Cylinder head

(for Bank 1)28 286 21

Camshaft bearing cap x

Camshaft housing

(for Bank 1)2nd 16 163 12

Camshaft bearing cap x

Camshaft housing

(for Bank 2)1st 10 102 7

Camshaft housing x Cylinder head

(for Bank 2)28 286 21

Camshaft bearing cap x

Camshaft housing

(for Bank 2)2nd 16 163 12

No. 2 chain tensioner x Camshaft housing (for Bank 1) 21 214 15

No. 3 chain tensioner x Camshaft housing (for Bank 2) 21 214 15

No. 1 chain vibration damper x Cylinder block 23 235 17

Idle sprocket x Cylinder block 60 612 44

No. 1 chain tensioner x Cylinder block 10 102 7

Engine rear oil seal retainer x Cylinder block 10 102 7

Crankshaft pulley x Crankshaft 250 2,549 184

Oil pan baffle plate x Cylinder block 10 102 7

Front No. 1 engine mounting bracket x Timing chain

cover54 551 40 Part Tightened N*m kgf*cm ft.*lbf

Page 385 of 2000

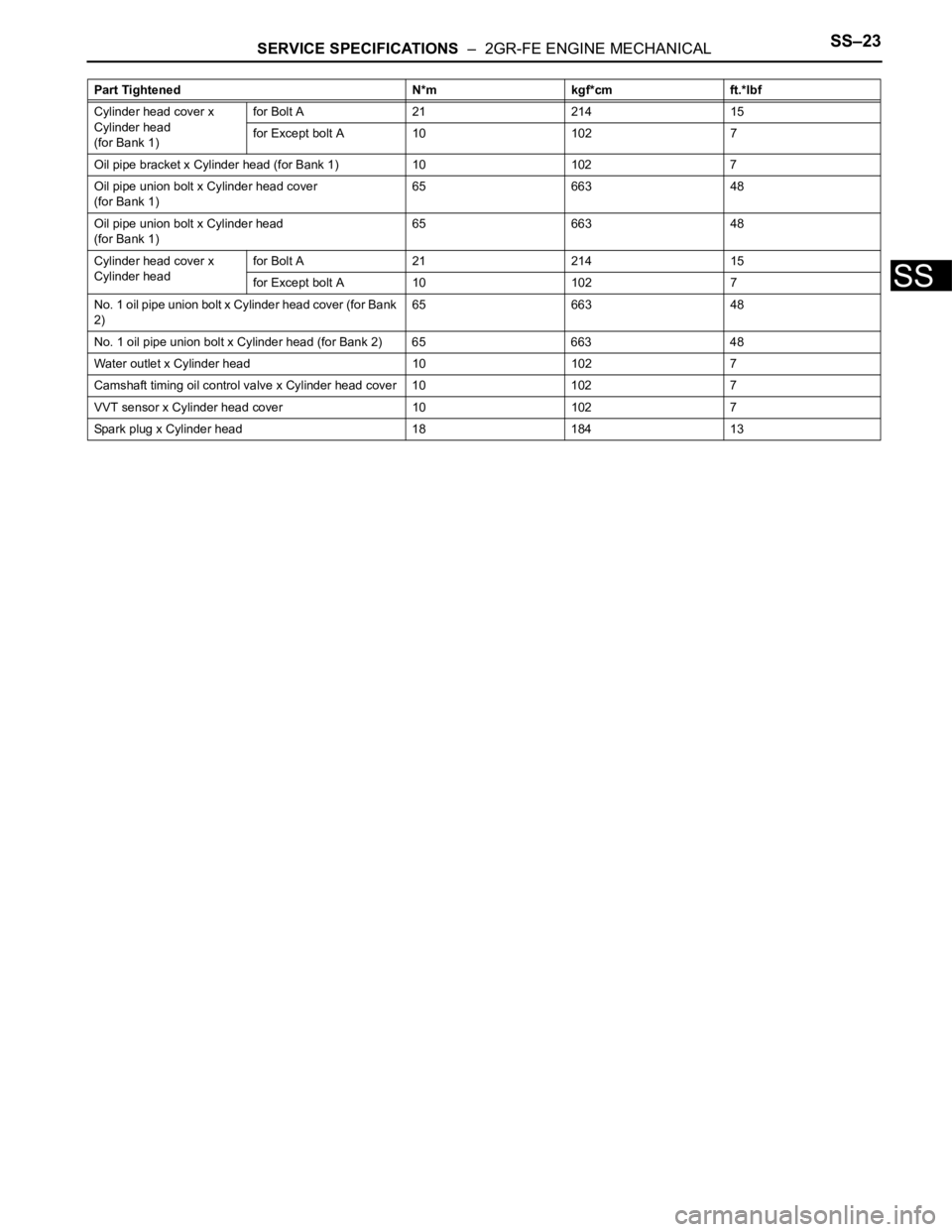

SERVICE SPECIFICATIONS – 2GR-FE ENGINE MECHANICALSS–23

SS

Cylinder head cover x

Cylinder head

(for Bank 1)for Bolt A 21 214 15

for Except bolt A 10 102 7

Oil pipe bracket x Cylinder head (for Bank 1) 10 102 7

Oil pipe union bolt x Cylinder head cover

(for Bank 1)65 663 48

Oil pipe union bolt x Cylinder head

(for Bank 1)65 663 48

Cylinder head cover x

Cylinder headfor Bolt A 21 214 15

for Except bolt A 10 102 7

No. 1 oil pipe union bolt x Cylinder head cover (for Bank

2)65 663 48

No. 1 oil pipe union bolt x Cylinder head (for Bank 2) 65 663 48

Water outlet x Cylinder head 10 102 7

Camshaft timing oil control valve x Cylinder head cover 10 102 7

VVT sensor x Cylinder head cover 10 102 7

Spark plug x Cylinder head 18 184 13 Part Tightened N*m kgf*cm ft.*lbf

Page 386 of 2000

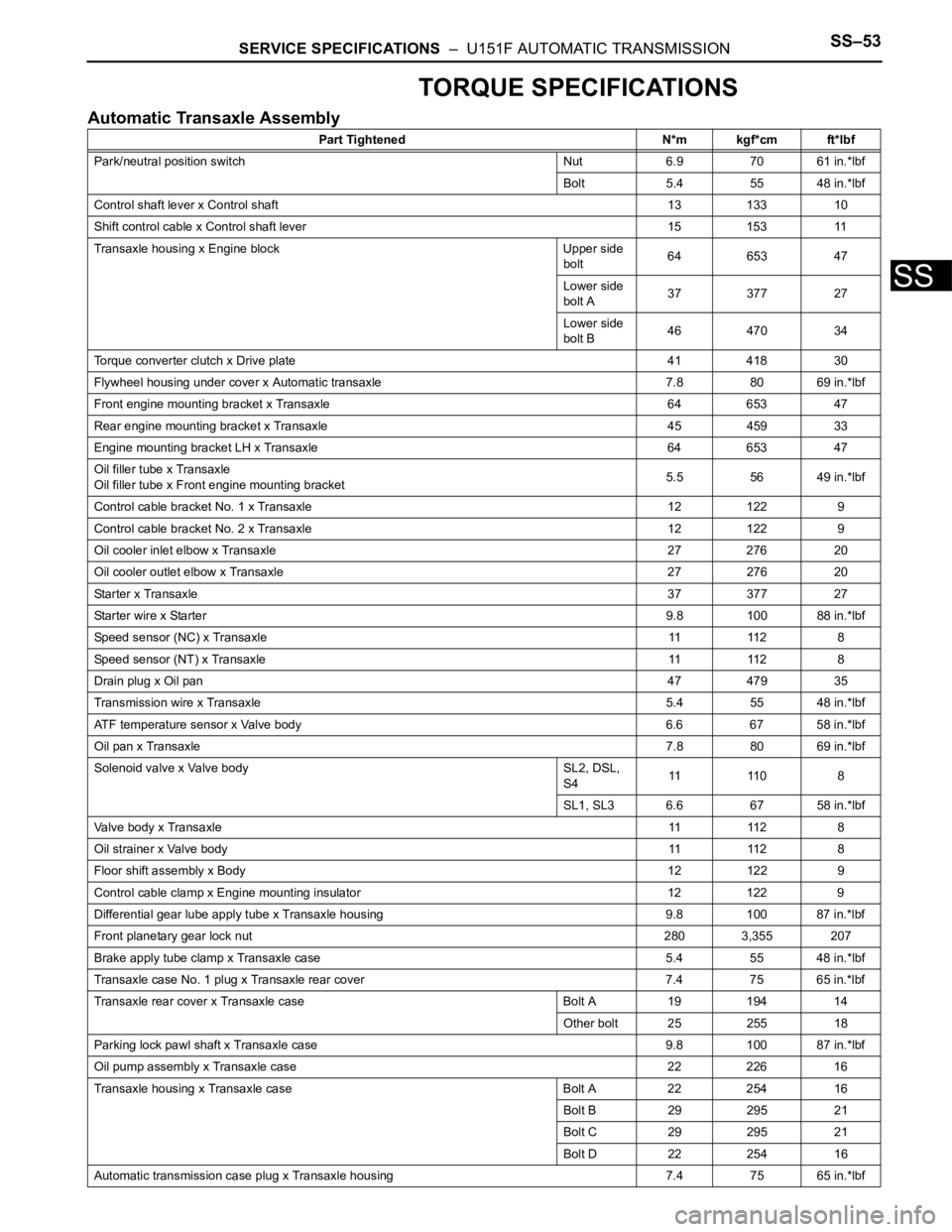

SERVICE SPECIFICATIONS – U151F AUTOMATIC TRANSMISSIONSS–53

SS

TORQUE SPECIFICATIONS

Automatic Transaxle Assembly

Part Tightened N*m kgf*cm ft*lbf

Park/neutral position switch Nut 6.9 70 61 in.*lbf

Bolt 5.4 55 48 in.*lbf

Control shaft lever x Control shaft 13 133 10

Shift control cable x Control shaft lever 15 153 11

Transaxle housing x Engine block Upper side

bolt64 653 47

Lower side

bolt A37 377 27

Lower side

bolt B46 470 34

Torque converter clutch x Drive plate 41 418 30

Flywheel housing under cover x Automatic transaxle 7.8 80 69 in.*lbf

Front engine mounting bracket x Transaxle 64 653 47

Rear engine mounting bracket x Transaxle 45 459 33

Engine mounting bracket LH x Transaxle 64 653 47

Oil filler tube x Transaxle

Oil filler tube x Front engine mounting bracket5.5 56 49 in.*lbf

Control cable bracket No. 1 x Transaxle 12 122 9

Control cable bracket No. 2 x Transaxle 12 122 9

Oil cooler inlet elbow x Transaxle 27 276 20

Oil cooler outlet elbow x Transaxle 27 276 20

Starter x Transaxle37 377 27

Starter wire x Starter9.8 100 88 in.*lbf

Speed sensor (NC) x Transaxle11 11 2 8

Speed sensor (NT) x Transaxle11 11 2 8

Drain plug x Oil pan47 479 35

Transmission wire x Transaxle5.4 55 48 in.*lbf

ATF temperature sensor x Valve body 6.6 67 58 in.*lbf

Oil pan x Transaxle7.8 80 69 in.*lbf

Solenoid valve x Valve body SL2, DSL,

S411 11 0 8

SL1, SL3 6.6 67 58 in.*lbf

Valve body x Transaxle11 11 2 8

Oil strainer x Valve body11 11 2 8

Floor shift assembly x Body12 122 9

Control cable clamp x Engine mounting insulator 12 122 9

Differential gear lube apply tube x Transaxle housing 9.8 100 87 in.*lbf

Front planetary gear lock nut280 3,355 207

Brake apply tube clamp x Transaxle case 5.4 55 48 in.*lbf

Transaxle case No. 1 plug x Transaxle rear cover 7.4 75 65 in.*lbf

Transaxle rear cover x Transaxle case Bolt A 19 194 14

Other bolt 25 255 18

Parking lock pawl shaft x Transaxle case 9.8 100 87 in.*lbf

Oil pump assembly x Transaxle case 22 226 16

Transaxle housing x Transaxle case Bolt A 22 254 16

Bolt B 29 295 21

Bolt C 29 295 21

Bolt D 22 254 16

Automatic transmission case plug x Transaxle housing 7.4 75 65 in.*lbf

Page 387 of 2000

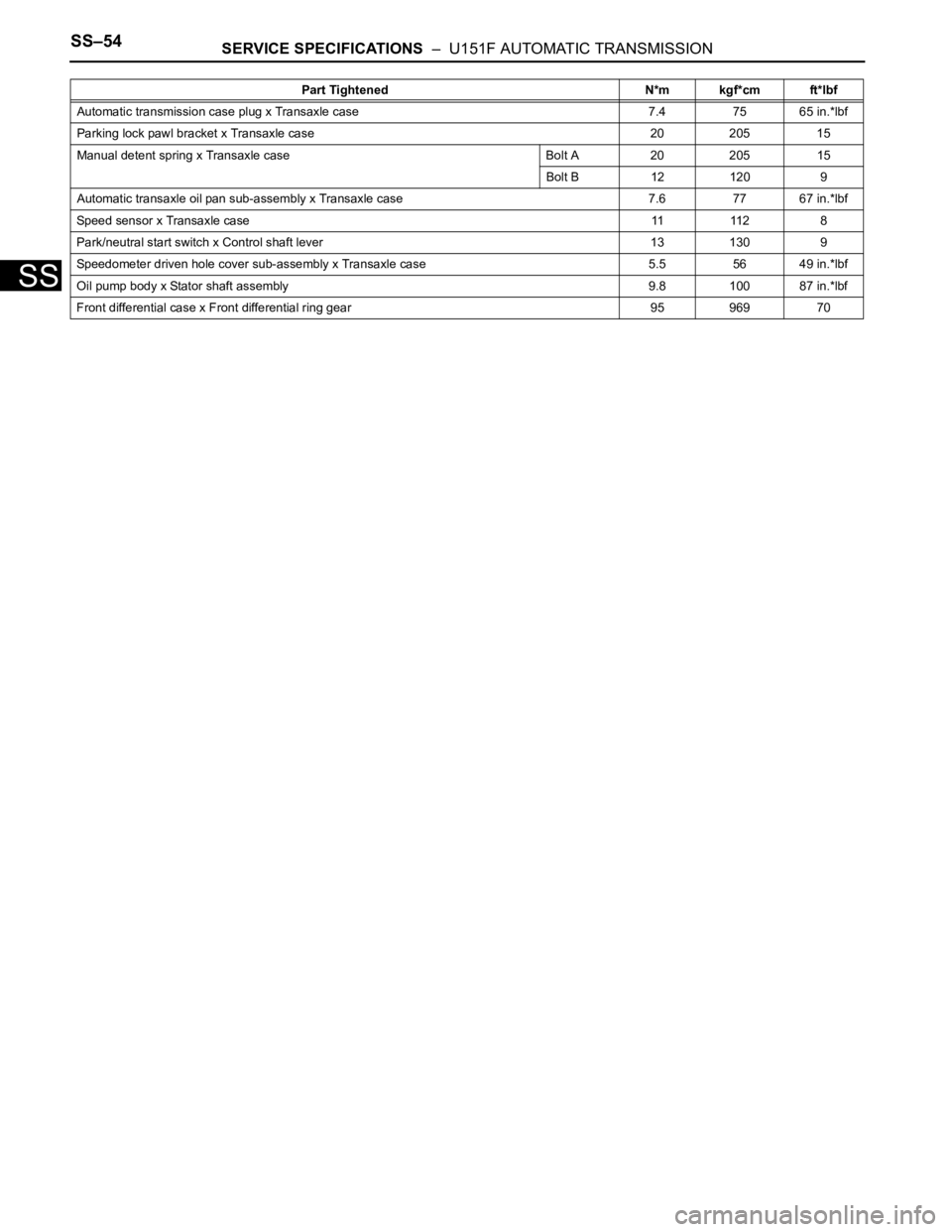

SS–54SERVICE SPECIFICATIONS – U151F AUTOMATIC TRANSMISSION

SS

Automatic transmission case plug x Transaxle case 7.4 75 65 in.*lbf

Parking lock pawl bracket x Transaxle case 20 205 15

Manual detent spring x Transaxle case Bolt A 20 205 15

Bolt B 12 120 9

Automatic transaxle oil pan sub-assembly x Transaxle case 7.6 77 67 in.*lbf

Speed sensor x Transaxle case11 11 2 8

Park/neutral start switch x Control shaft lever 13 130 9

Speedometer driven hole cover sub-assembly x Transaxle case 5.5 56 49 in.*lbf

Oil pump body x Stator shaft assembly 9.8 100 87 in.*lbf

Front differential case x Front differential ring gear 95 969 70Part Tightened N*m kgf*cm ft*lbf

Page 388 of 2000

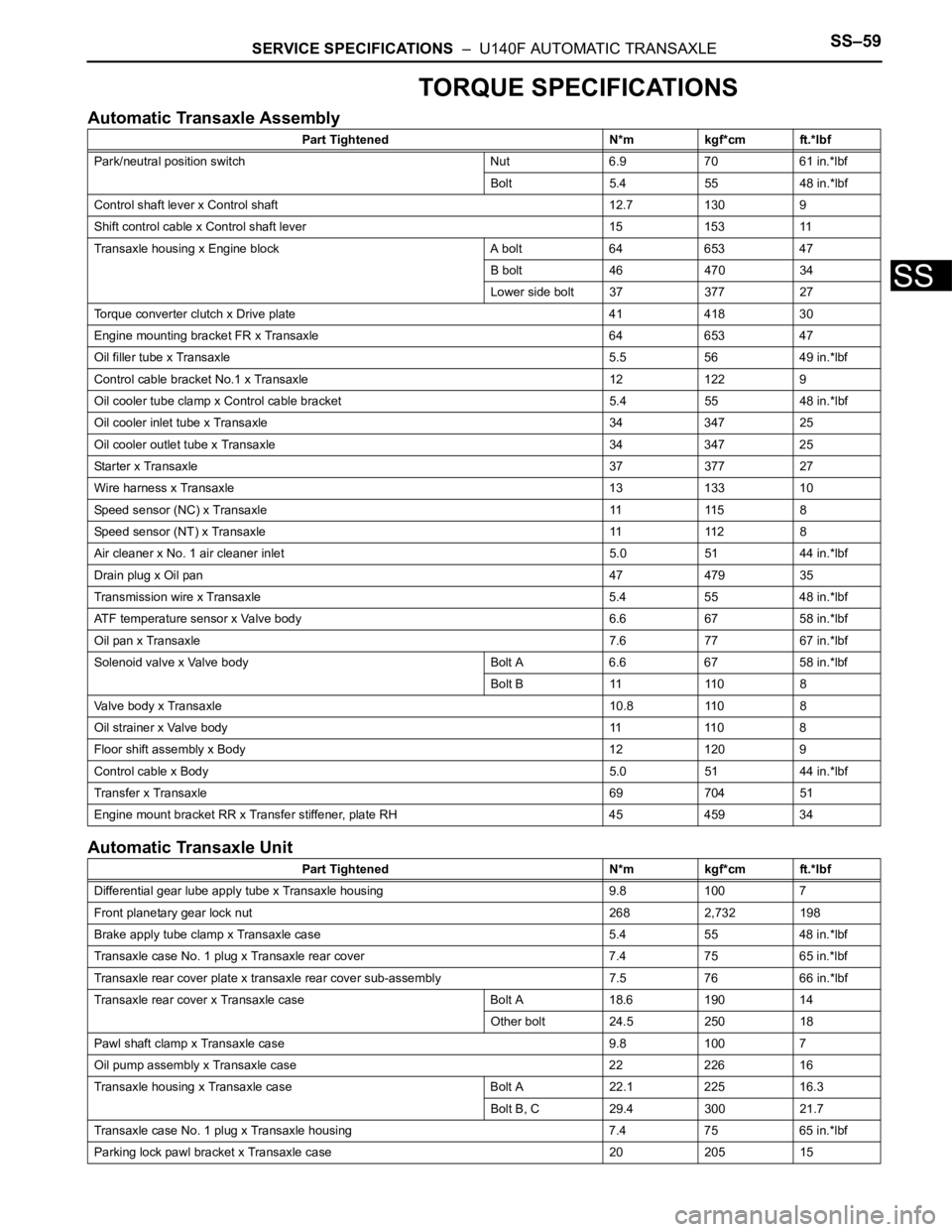

SERVICE SPECIFICATIONS – U140F AUTOMATIC TRANSAXLESS–59

SS

TORQUE SPECIFICATIONS

Automatic Transaxle Assembly

Automatic Transaxle Unit

Part Tightened N*m kgf*cm ft.*lbf

Park/neutral position switch Nut 6.9 70 61 in.*lbf

Bolt 5.4 55 48 in.*lbf

Control shaft lever x Control shaft 12.7 130 9

Shift control cable x Control shaft lever 15 153 11

Transaxle housing x Engine block A bolt 64 653 47

B bolt 46 470 34

Lower side bolt 37 377 27

Torque converter clutch x Drive plate 41 418 30

Engine mounting bracket FR x Transaxle 64 653 47

Oil filler tube x Transaxle 5.5 56 49 in.*lbf

Control cable bracket No.1 x Transaxle 12 122 9

Oil cooler tube clamp x Control cable bracket 5.4 55 48 in.*lbf

Oil cooler inlet tube x Transaxle 34 347 25

Oil cooler outlet tube x Transaxle 34 347 25

Starter x Transaxle37 377 27

Wire harness x Transaxle 13 133 10

Speed sensor (NC) x Transaxle 11 115 8

Speed sensor (NT) x Transaxle 11 112 8

Air cleaner x No. 1 air cleaner inlet 5.0 51 44 in.*lbf

Drain plug x Oil pan47 479 35

Transmission wire x Transaxle 5.4 55 48 in.*lbf

ATF temperature sensor x Valve body 6.6 67 58 in.*lbf

Oil pan x Transaxle7.6 77 67 in.*lbf

Solenoid valve x Valve body Bolt A 6.6 67 58 in.*lbf

Bolt B 11 110 8

Valve body x Transaxle 10.8 110 8

Oil strainer x Valve body 11 110 8

Floor shift assembly x Body 12 120 9

Control cable x Body5.0 51 44 in.*lbf

Transfer x Transaxle69 704 51

Engine mount bracket RR x Transfer stiffener, plate RH 45 459 34

Part Tightened N*m kgf*cm ft.*lbf

Differential gear lube apply tube x Transaxle housing 9.8 100 7

Front planetary gear lock nut 268 2,732 198

Brake apply tube clamp x Transaxle case 5.4 55 48 in.*lbf

Transaxle case No. 1 plug x Transaxle rear cover 7.4 75 65 in.*lbf

Transaxle rear cover plate x transaxle rear cover sub-assembly 7.5 76 66 in.*lbf

Transaxle rear cover x Transaxle case Bolt A 18.6 190 14

Other bolt 24.5 250 18

Pawl shaft clamp x Transaxle case 9.8 100 7

Oil pump assembly x Transaxle case 22 226 16

Transaxle housing x Transaxle case Bolt A 22.1 225 16.3

Bolt B, C 29.4 300 21.7

Transaxle case No. 1 plug x Transaxle housing 7.4 75 65 in.*lbf

Parking lock pawl bracket x Transaxle case 20 205 15