sensor TOYOTA RAV4 2006 Service Manual PDF

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 203 of 2000

EM–282GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

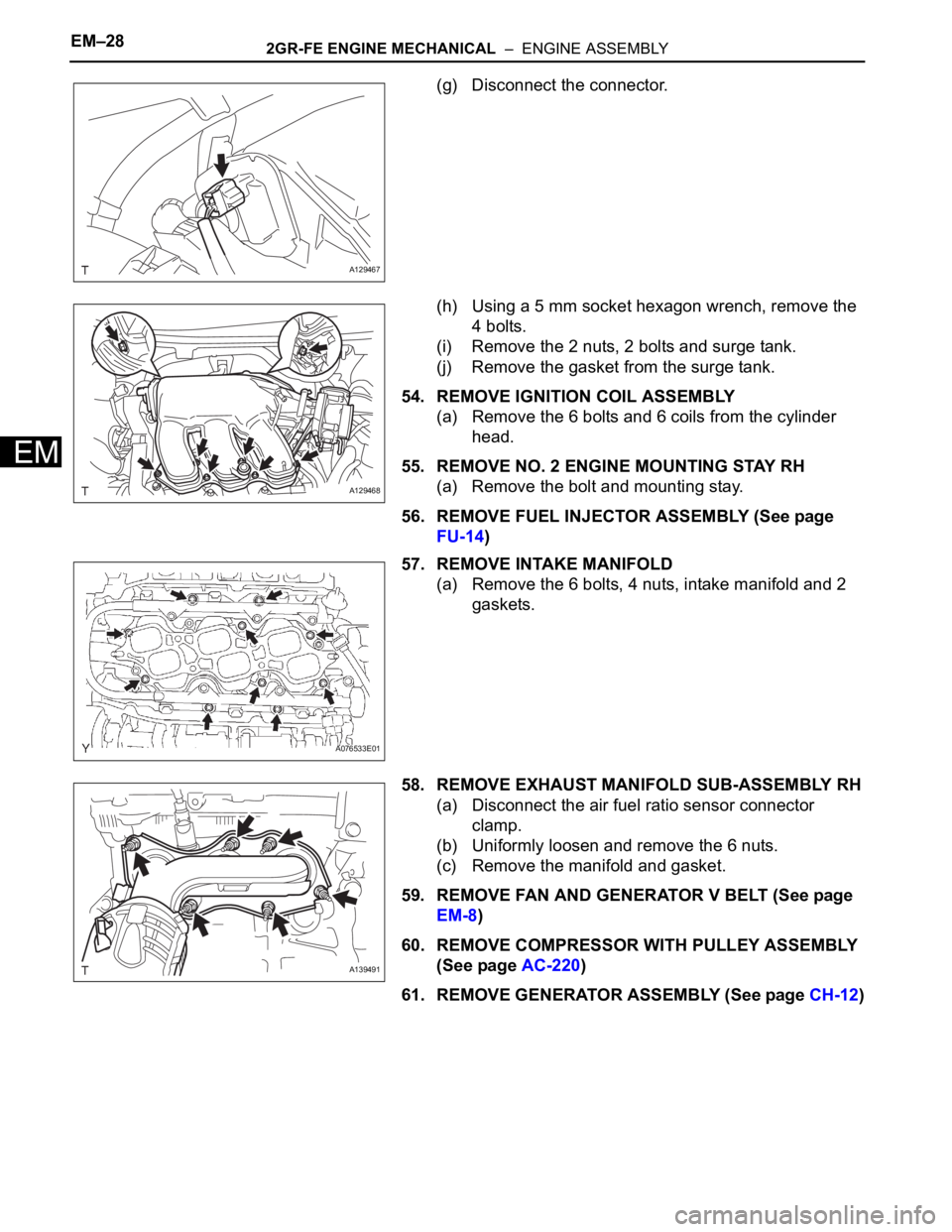

(g) Disconnect the connector.

(h) Using a 5 mm socket hexagon wrench, remove the

4 bolts.

(i) Remove the 2 nuts, 2 bolts and surge tank.

(j) Remove the gasket from the surge tank.

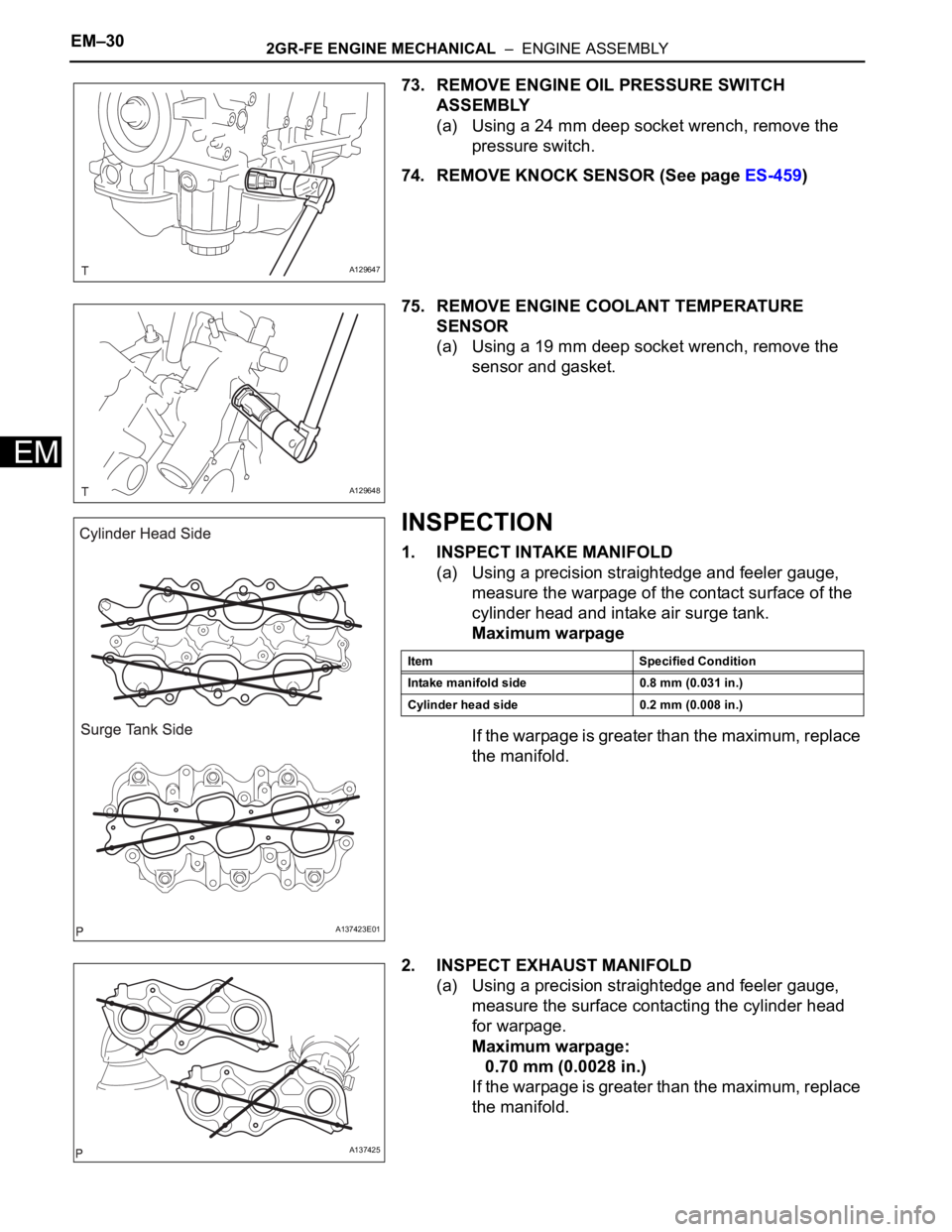

54. REMOVE IGNITION COIL ASSEMBLY

(a) Remove the 6 bolts and 6 coils from the cylinder

head.

55. REMOVE NO. 2 ENGINE MOUNTING STAY RH

(a) Remove the bolt and mounting stay.

56. REMOVE FUEL INJECTOR ASSEMBLY (See page

FU-14)

57. REMOVE INTAKE MANIFOLD

(a) Remove the 6 bolts, 4 nuts, intake manifold and 2

gaskets.

58. REMOVE EXHAUST MANIFOLD SUB-ASSEMBLY RH

(a) Disconnect the air fuel ratio sensor connector

clamp.

(b) Uniformly loosen and remove the 6 nuts.

(c) Remove the manifold and gasket.

59. REMOVE FAN AND GENERATOR V BELT (See page

EM-8)

60. REMOVE COMPRESSOR WITH PULLEY ASSEMBLY

(See page AC-220)

61. REMOVE GENERATOR ASSEMBLY (See page CH-12)

A129467

A129468

A076533E01

A139491

Page 205 of 2000

EM–302GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

73. REMOVE ENGINE OIL PRESSURE SWITCH

ASSEMBLY

(a) Using a 24 mm deep socket wrench, remove the

pressure switch.

74. REMOVE KNOCK SENSOR (See page ES-459)

75. REMOVE ENGINE COOLANT TEMPERATURE

SENSOR

(a) Using a 19 mm deep socket wrench, remove the

sensor and gasket.

INSPECTION

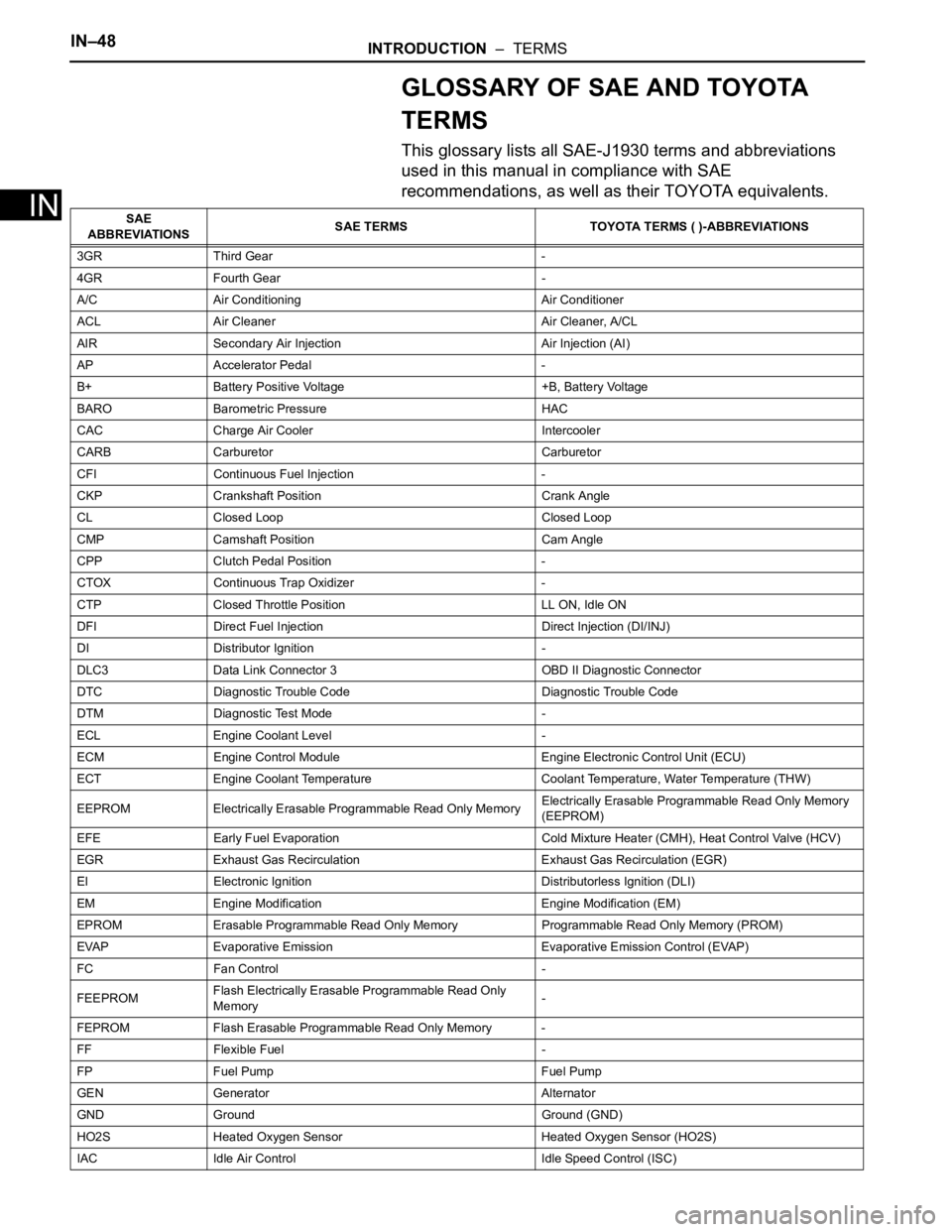

1. INSPECT INTAKE MANIFOLD

(a) Using a precision straightedge and feeler gauge,

measure the warpage of the contact surface of the

cylinder head and intake air surge tank.

Maximum warpage

If the warpage is greater than the maximum, replace

the manifold.

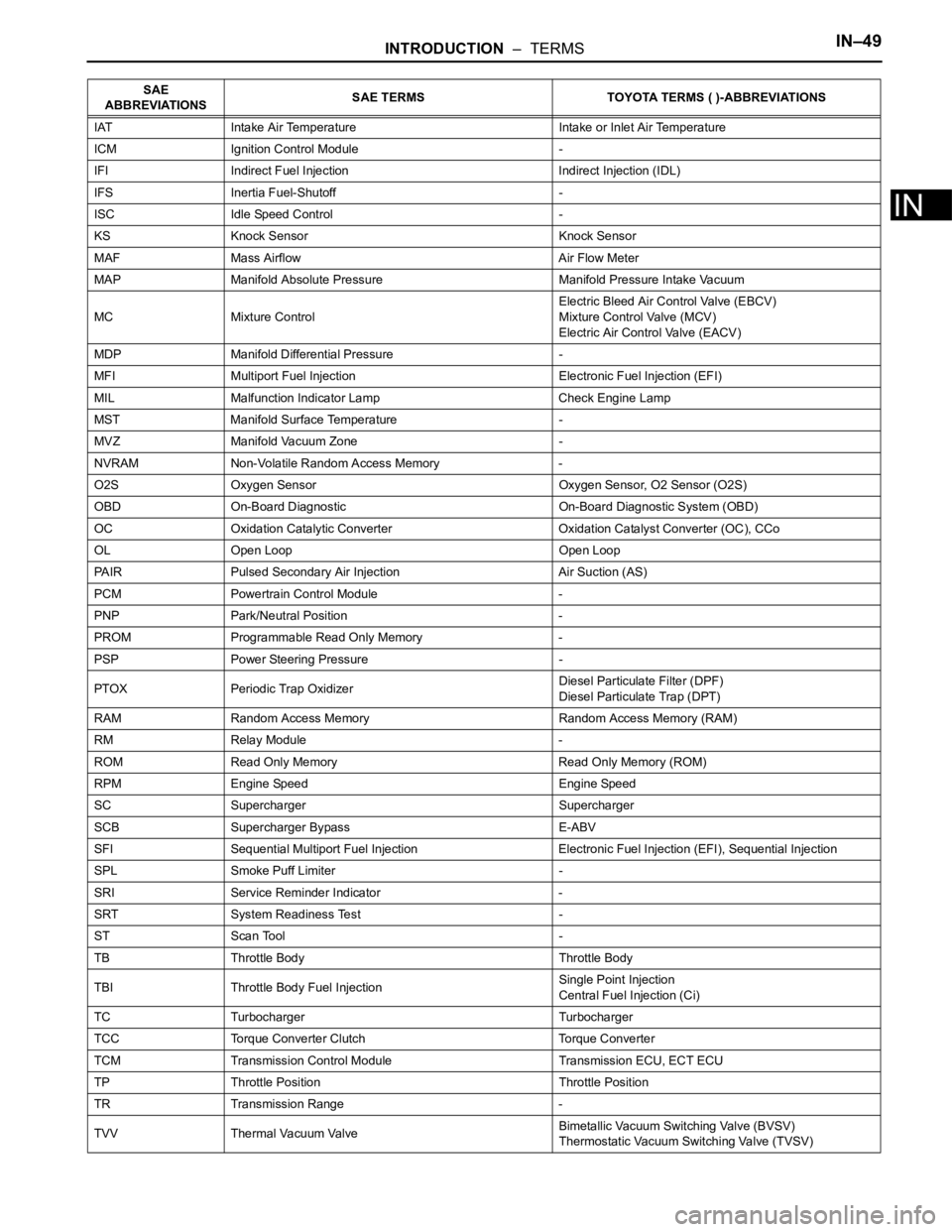

2. INSPECT EXHAUST MANIFOLD

(a) Using a precision straightedge and feeler gauge,

measure the surface contacting the cylinder head

for warpage.

Maximum warpage:

0.70 mm (0.0028 in.)

If the warpage is greater than the maximum, replace

the manifold.

A129647

A129648

A137423E01

Item Specified Condition

Intake manifold side 0.8 mm (0.031 in.)

Cylinder head side 0.2 mm (0.008 in.)

A137425

Page 220 of 2000

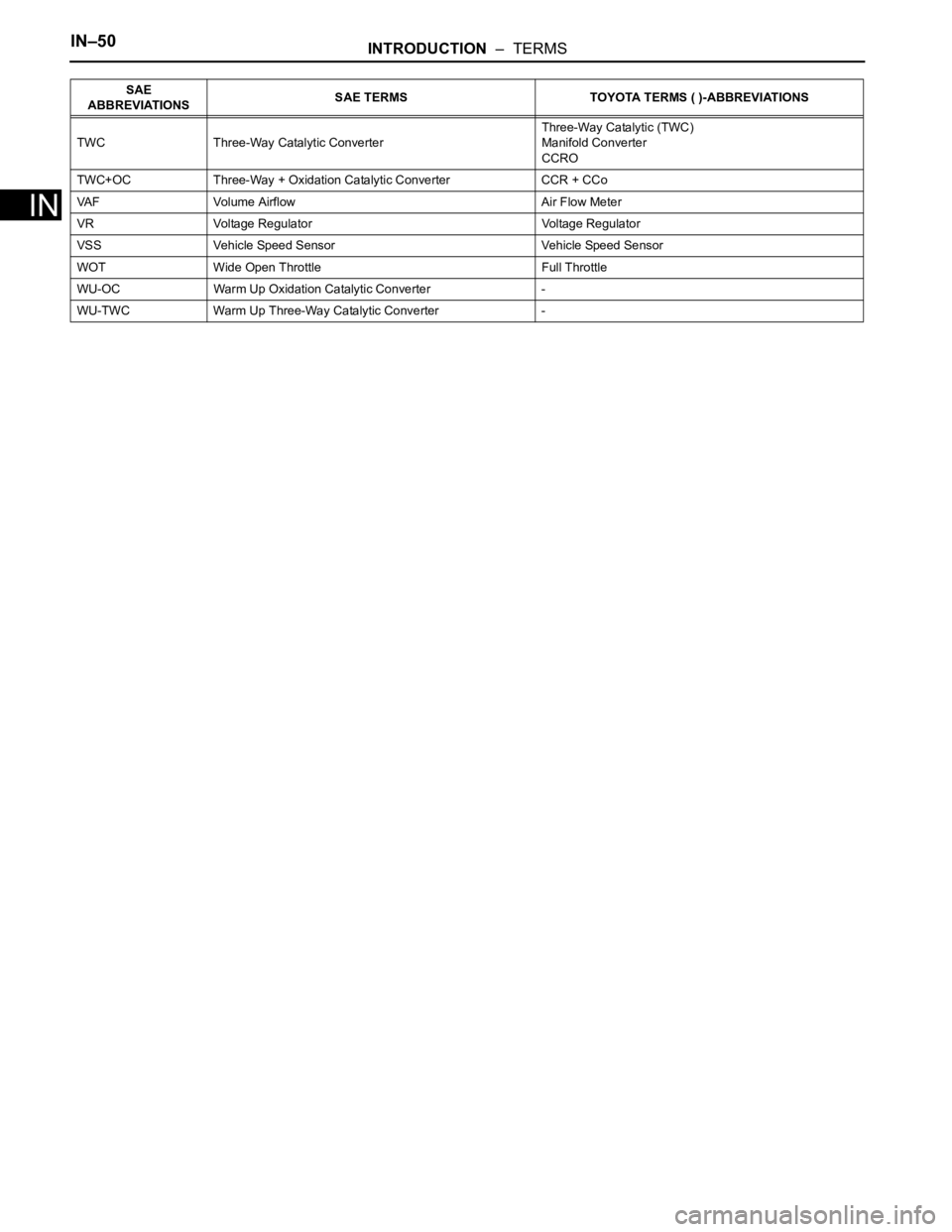

IN–48INTRODUCTION – TERMS

IN

GLOSSARY OF SAE AND TOYOTA

TERMS

This glossary lists all SAE-J1930 terms and abbreviations

used in this manual in compliance with SAE

recommendations, as well as their TOYOTA equivalents.

SAE

ABBREVIATIONSSAE TERMS TOYOTA TERMS ( )-ABBREVIATIONS

3GR Third Gear -

4GR Fourth Gear -

A/C Air Conditioning Air Conditioner

ACL Air Cleaner Air Cleaner, A/CL

AIR Secondary Air Injection Air Injection (AI)

AP Accelerator Pedal -

B+ Battery Positive Voltage +B, Battery Voltage

BARO Barometric Pressure HAC

CAC Charge Air Cooler Intercooler

CARB Carburetor Carburetor

CFI Continuous Fuel Injection -

CKP Crankshaft Position Crank Angle

CL Closed Loop Closed Loop

CMP Camshaft Position Cam Angle

CPP Clutch Pedal Position -

CTOX Continuous Trap Oxidizer -

CTP Closed Throttle Position LL ON, Idle ON

DFI Direct Fuel Injection Direct Injection (DI/INJ)

DI Distributor Ignition -

DLC3 Data Link Connector 3 OBD II Diagnostic Connector

DTC Diagnostic Trouble Code Diagnostic Trouble Code

DTM Diagnostic Test Mode -

ECL Engine Coolant Level -

ECM Engine Control Module Engine Electronic Control Unit (ECU)

ECT Engine Coolant Temperature Coolant Temperature, Water Temperature (THW)

EEPROM Electrically Erasable Programmable Read Only MemoryElectrically Erasable Programmable Read Only Memory

(EEPROM)

EFE Early Fuel Evaporation Cold Mixture Heater (CMH), Heat Control Valve (HCV)

EGR Exhaust Gas Recirculation Exhaust Gas Recirculation (EGR)

EI Electronic Ignition Distributorless Ignition (DLI)

EM Engine Modification Engine Modification (EM)

EPROM Erasable Programmable Read Only Memory Programmable Read Only Memory (PROM)

EVAP Evaporative Emission Evaporative Emission Control (EVAP)

FC Fan Control -

FEEPROMFlash Electrically Erasable Programmable Read Only

Memory-

FEPROM Flash Erasable Programmable Read Only Memory -

FF Flexible Fuel -

FP Fuel Pump Fuel Pump

GEN Generator Alternator

GND Ground Ground (GND)

HO2S Heated Oxygen Sensor Heated Oxygen Sensor (HO2S)

IAC Idle Air Control Idle Speed Control (ISC)

Page 221 of 2000

INTRODUCTION – TERMSIN–49

IN

IAT Intake Air Temperature Intake or Inlet Air Temperature

ICM Ignition Control Module -

IFI Indirect Fuel Injection Indirect Injection (IDL)

IFS Inertia Fuel-Shutoff -

ISC Idle Speed Control -

KS Knock Sensor Knock Sensor

MAF Mass Airflow Air Flow Meter

MAP Manifold Absolute Pressure Manifold Pressure Intake Vacuum

MC Mixture ControlElectric Bleed Air Control Valve (EBCV)

Mixture Control Valve (MCV)

Electric Air Control Valve (EACV)

MDP Manifold Differential Pressure -

MFI Multiport Fuel Injection Electronic Fuel Injection (EFI)

MIL Malfunction Indicator Lamp Check Engine Lamp

MST Manifold Surface Temperature -

MVZ Manifold Vacuum Zone -

NVRAM Non-Volatile Random Access Memory -

O2S Oxygen Sensor Oxygen Sensor, O2 Sensor (O2S)

OBD On-Board Diagnostic On-Board Diagnostic System (OBD)

OC Oxidation Catalytic Converter Oxidation Catalyst Converter (OC), CCo

OL Open Loop Open Loop

PAIR Pulsed Secondary Air Injection Air Suction (AS)

PCM Powertrain Control Module -

PNP Park/Neutral Position -

PROM Programmable Read Only Memory -

PSP Power Steering Pressure -

PTOX Periodic Trap OxidizerDiesel Particulate Filter (DPF)

Diesel Particulate Trap (DPT)

RAM Random Access Memory Random Access Memory (RAM)

RM Relay Module -

ROM Read Only Memory Read Only Memory (ROM)

RPM Engine Speed Engine Speed

SC Supercharger Supercharger

SCB Supercharger Bypass E-ABV

SFI Sequential Multiport Fuel Injection Electronic Fuel Injection (EFI), Sequential Injection

SPL Smoke Puff Limiter -

SRI Service Reminder Indicator -

SRT System Readiness Test -

ST Scan Tool -

TB Throttle Body Throttle Body

TBI Throttle Body Fuel InjectionSingle Point Injection

Central Fuel Injection (Ci)

TC Turbocharger Turbocharger

TCC Torque Converter Clutch Torque Converter

TCM Transmission Control Module Transmission ECU, ECT ECU

TP Throttle Position Throttle Position

TR Transmission Range -

TVV Thermal Vacuum ValveBimetallic Vacuum Switching Valve (BVSV)

Thermostatic Vacuum Switching Valve (TVSV) SAE

ABBREVIATIONSSAE TERMS TOYOTA TERMS ( )-ABBREVIATIONS

Page 222 of 2000

IN–50INTRODUCTION – TERMS

IN

TWC Three-Way Catalytic ConverterThree-Way Catalytic (TWC)

Manifold Converter

CCRO

TWC+OC Three-Way + Oxidation Catalytic Converter CCR + CCo

VAF Volume Airflow Air Flow Meter

VR Voltage Regulator Voltage Regulator

VSS Vehicle Speed Sensor Vehicle Speed Sensor

WOT Wide Open Throttle Full Throttle

WU-OC Warm Up Oxidation Catalytic Converter -

WU-TWC Warm Up Three-Way Catalytic Converter -SAE

ABBREVIATIONSSAE TERMS TOYOTA TERMS ( )-ABBREVIATIONS

Page 236 of 2000

EX–62AZ-FE EXHAUST – EXHAUST PIPE

EX

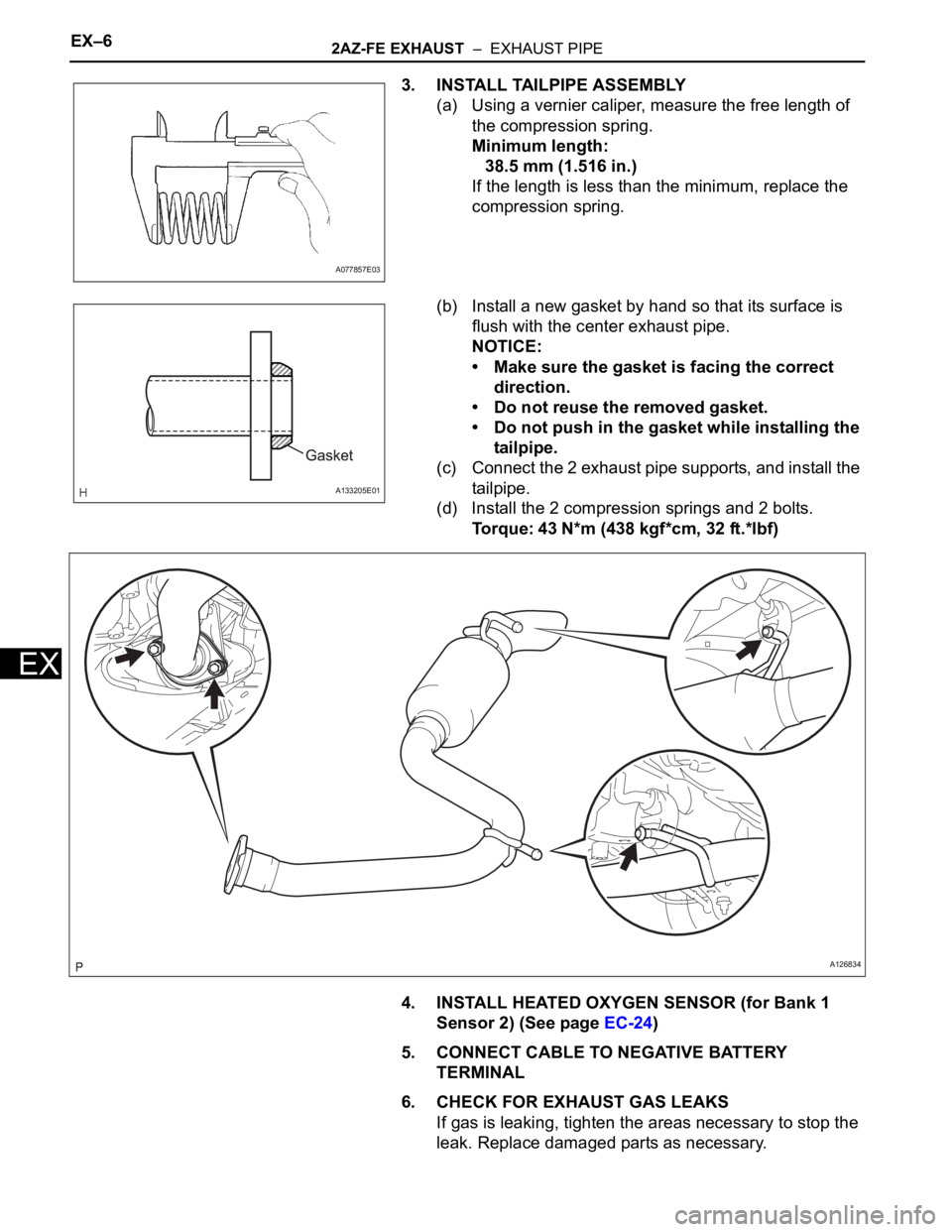

3. INSTALL TAILPIPE ASSEMBLY

(a) Using a vernier caliper, measure the free length of

the compression spring.

Minimum length:

38.5 mm (1.516 in.)

If the length is less than the minimum, replace the

compression spring.

(b) Install a new gasket by hand so that its surface is

flush with the center exhaust pipe.

NOTICE:

• Make sure the gasket is facing the correct

direction.

• Do not reuse the removed gasket.

• Do not push in the gasket while installing the

tailpipe.

(c) Connect the 2 exhaust pipe supports, and install the

tailpipe.

(d) Install the 2 compression springs and 2 bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

4. INSTALL HEATED OXYGEN SENSOR (for Bank 1

Sensor 2) (See page EC-24)

5. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

6. CHECK FOR EXHAUST GAS LEAKS

If gas is leaking, tighten the areas necessary to stop the

leak. Replace damaged parts as necessary.

A077857E03

A133205E01

A126834

Page 239 of 2000

EX–62GR-FE EXHAUST – EXHAUST PIPE

EX

5. INSTALL HEATED OXYGEN SENSOR (for Sensor 2)

(See page EC-27)

6. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

7. CHECK FOR EXHAUST GAS LEAKS

If gas is leaking, tighten the problem areas to stop the

leak. Replace damaged parts as necessary.

A132395

Page 240 of 2000

CO–42AZ-FE COOLING – COOLING FAN SYSTEM

CO

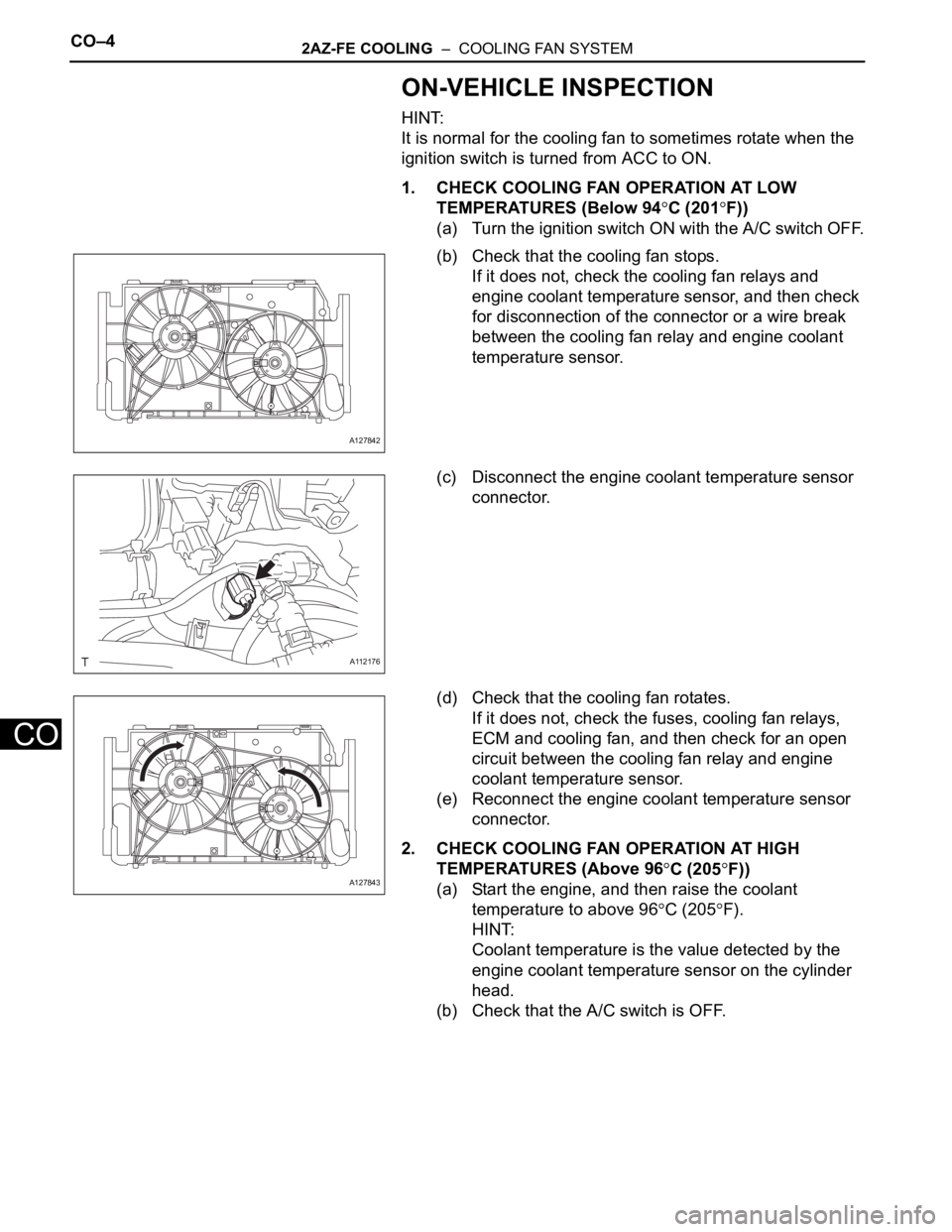

ON-VEHICLE INSPECTION

HINT:

It is normal for the cooling fan to sometimes rotate when the

ignition switch is turned from ACC to ON.

1. CHECK COOLING FAN OPERATION AT LOW

TEMPERATURES (Below 94

C (201F))

(a) Turn the ignition switch ON with the A/C switch OFF.

(b) Check that the cooling fan stops.

If it does not, check the cooling fan relays and

engine coolant temperature sensor, and then check

for disconnection of the connector or a wire break

between the cooling fan relay and engine coolant

temperature sensor.

(c) Disconnect the engine coolant temperature sensor

connector.

(d) Check that the cooling fan rotates.

If it does not, check the fuses, cooling fan relays,

ECM and cooling fan, and then check for an open

circuit between the cooling fan relay and engine

coolant temperature sensor.

(e) Reconnect the engine coolant temperature sensor

connector.

2. CHECK COOLING FAN OPERATION AT HIGH

TEMPERATURES (Above 96

C (205F))

(a) Start the engine, and then raise the coolant

temperature to above 96

C (205F).

HINT:

Coolant temperature is the value detected by the

engine coolant temperature sensor on the cylinder

head.

(b) Check that the A/C switch is OFF.

A127842

A112176

A127843

Page 241 of 2000

2AZ-FE COOLING – COOLING FAN SYSTEMCO–5

CO

(c) Check that the cooling fan rotates.

If it does not, check the engine coolant temperature

sensor, cooling fan, harness or connector.

A127843

Page 344 of 2000

U140F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–3

AX

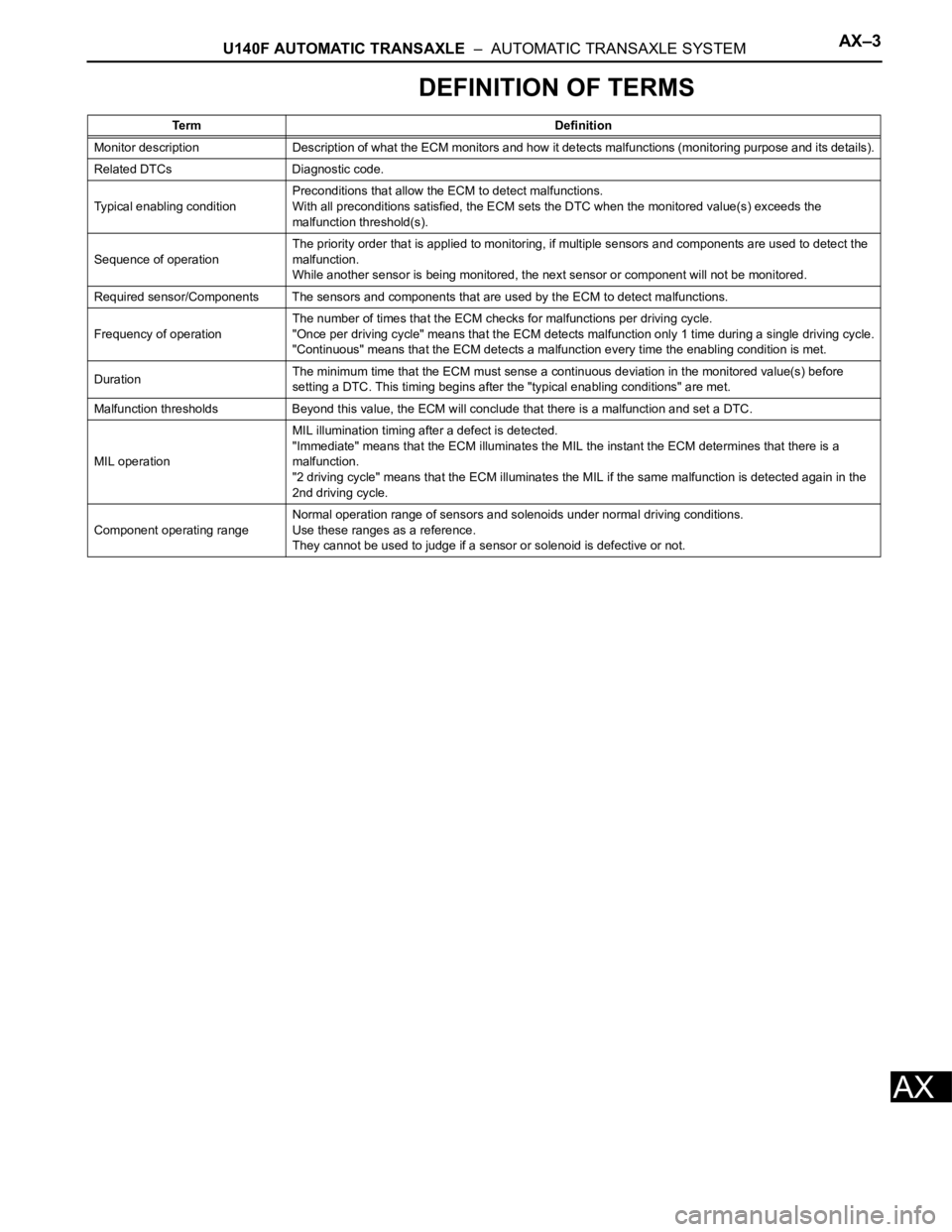

DEFINITION OF TERMS

Te r m D e f i n i t i o n

Monitor description Description of what the ECM monitors and how it detects malfunctions (monitoring purpose and its details).

Related DTCs Diagnostic code.

Typical enabling conditionPreconditions that allow the ECM to detect malfunctions.

With all preconditions satisfied, the ECM sets the DTC when the monitored value(s) exceeds the

malfunction threshold(s).

Sequence of operationThe priority order that is applied to monitoring, if multiple sensors and components are used to detect the

malfunction.

While another sensor is being monitored, the next sensor or component will not be monitored.

Required sensor/Components The sensors and components that are used by the ECM to detect malfunctions.

Frequency of operationThe number of times that the ECM checks for malfunctions per driving cycle.

"Once per driving cycle" means that the ECM detects malfunction only 1 time during a single driving cycle.

"Continuous" means that the ECM detects a malfunction every time the enabling condition is met.

DurationThe minimum time that the ECM must sense a continuous deviation in the monitored value(s) before

setting a DTC. This timing begins after the "typical enabling conditions" are met.

Malfunction thresholds Beyond this value, the ECM will conclude that there is a malfunction and set a DTC.

MIL operationMIL illumination timing after a defect is detected.

"Immediate" means that the ECM illuminates the MIL the instant the ECM determines that there is a

malfunction.

"2 driving cycle" means that the ECM illuminates the MIL if the same malfunction is detected again in the

2nd driving cycle.

Component operating rangeNormal operation range of sensors and solenoids under normal driving conditions.

Use these ranges as a reference.

They cannot be used to judge if a sensor or solenoid is defective or not.