check oil TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 12 of 2000

ENGINE - 2AZ-FE ENGINE

01NEG34Y

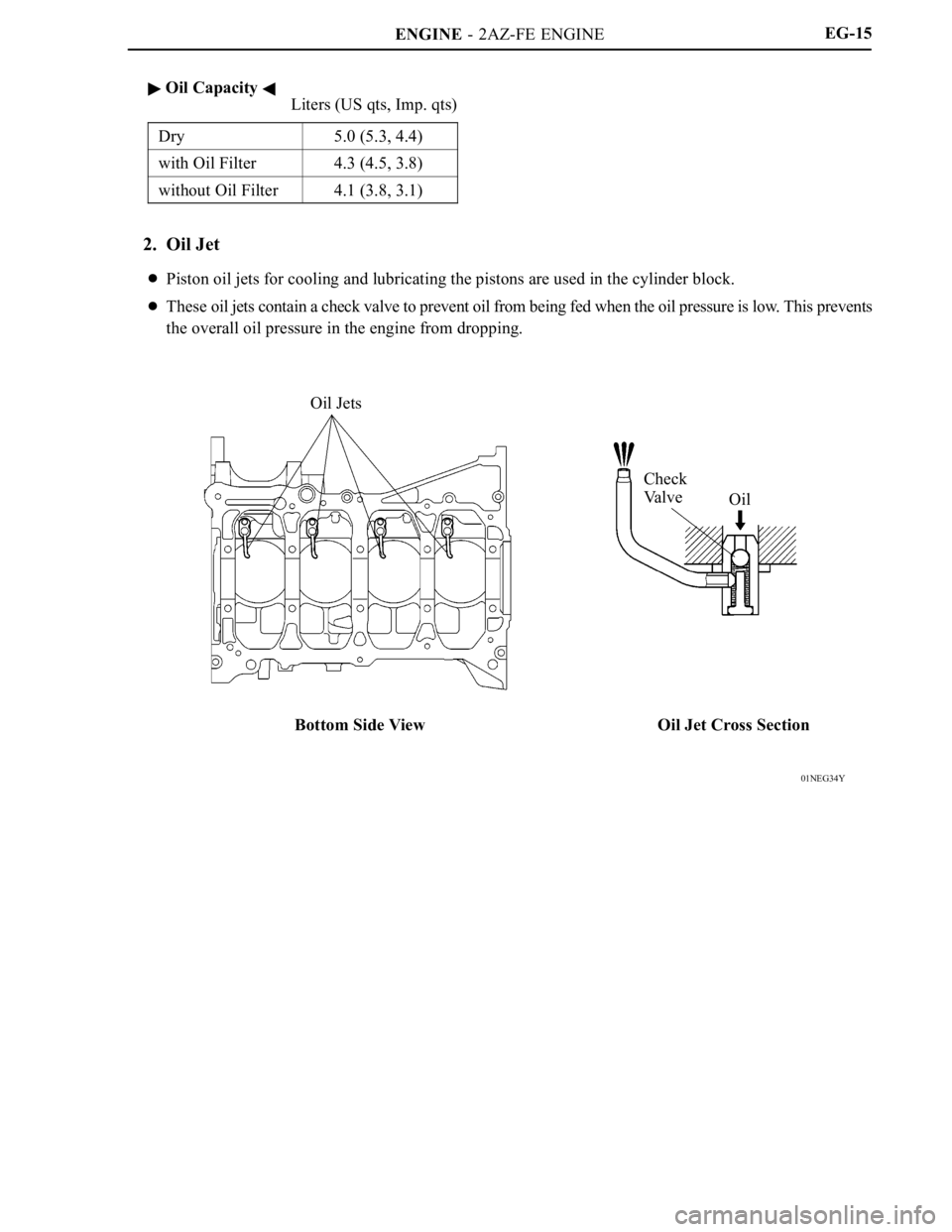

Oil Jets

Check

Va l v e

Oil

Bottom Side View Oil Jet Cross SectionEG-15

Oil Capacity

Liters (US qts, Imp. qts)

Dry

5.0 (5.3, 4.4)

with Oil Filter4.3 (4.5, 3.8)

without Oil Filter4.1 (3.8, 3.1)

2. Oil Jet

Piston oil jets for cooling and lubricating the pistons are used in the cylinder block.

These oil jets contain a check valve to prevent oil from being fed when the oil pressure is low. This prevents

the overall oil pressure in the engine from dropping.

Page 79 of 2000

ENGINE - 2GR-FE ENGINE

285EG21

Timing Chain Cover

Wa t e r P u m p G a s k e t

Wa t e r P u m pWater Pump Swirl

Chamber

Oil Pump

Housing

Oil Pump RotorsTiming Chain

Cover

Oil Pump Chamber

View from Front Side View from Back Side

285EG22

Oil

Passage

Check Ball

Check Ball

Spring

Plunger SpringPlunger

Roller Rocker ArmCam

Oil

Passage

Hydraulic

Lash Adjuster

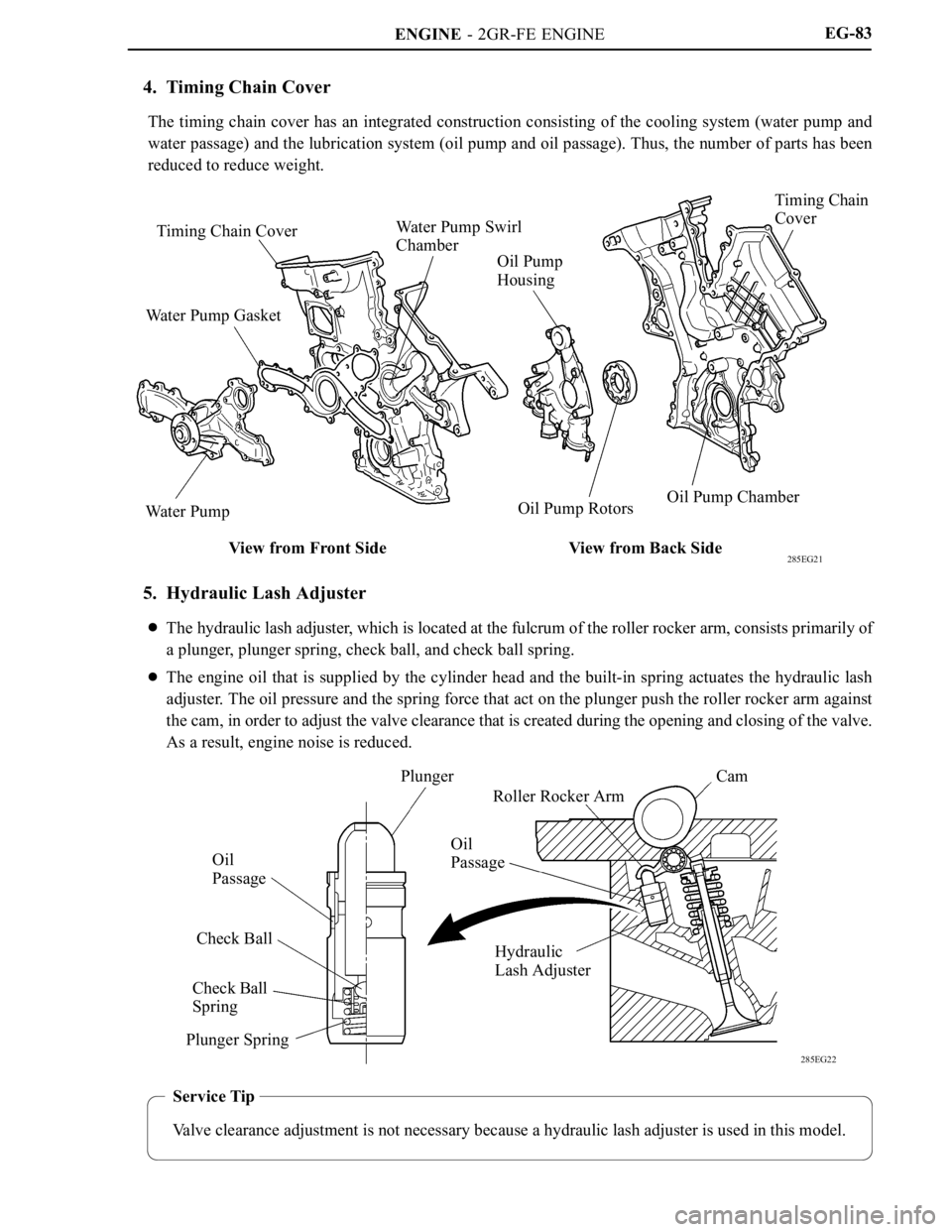

Service Tip

Valve clearance adjustment is not necessary because a hydraulic lash adjuster is used in this model.

EG-83

4. Timing Chain Cover

The timing chain cover has an integrated construction consisting of the cooling system (water pump and

water passage) and the lubrication system (oil pump and oil passage). Thus, the number of parts has been

reduced to reduce weight.

5. Hydraulic Lash Adjuster

The hydraulic lash adjuster, which is located at the fulcrum of the roller rocker arm, consists primarily of

a plunger, plunger spring, check ball, and check ball spring.

The engine oil that is supplied by the cylinder head and the built-in spring actuates the hydraulic lash

adjuster. The oil pressure and the spring force that act on the plunger push the roller rocker arm against

the cam, in order to adjust the valve clearance that is created during the opening and closing of the valve.

As a result, engine noise is reduced.

Page 82 of 2000

ENGINE - 2GR-FE ENGINE

285EG24

Timing Chain Cover

Oil Pump

Housing

Oil Pump Rotors

(Cycloid Rotor)Crankshaft

To Cylinder

Block

From Oil

Filter

To

Oil FilterFrom

Oil Strainer

Oil passage in the oil pump

285EG25

Oil Jet Cross Section

Oil JetsCheck

Va l v eEngine Oil EG-86

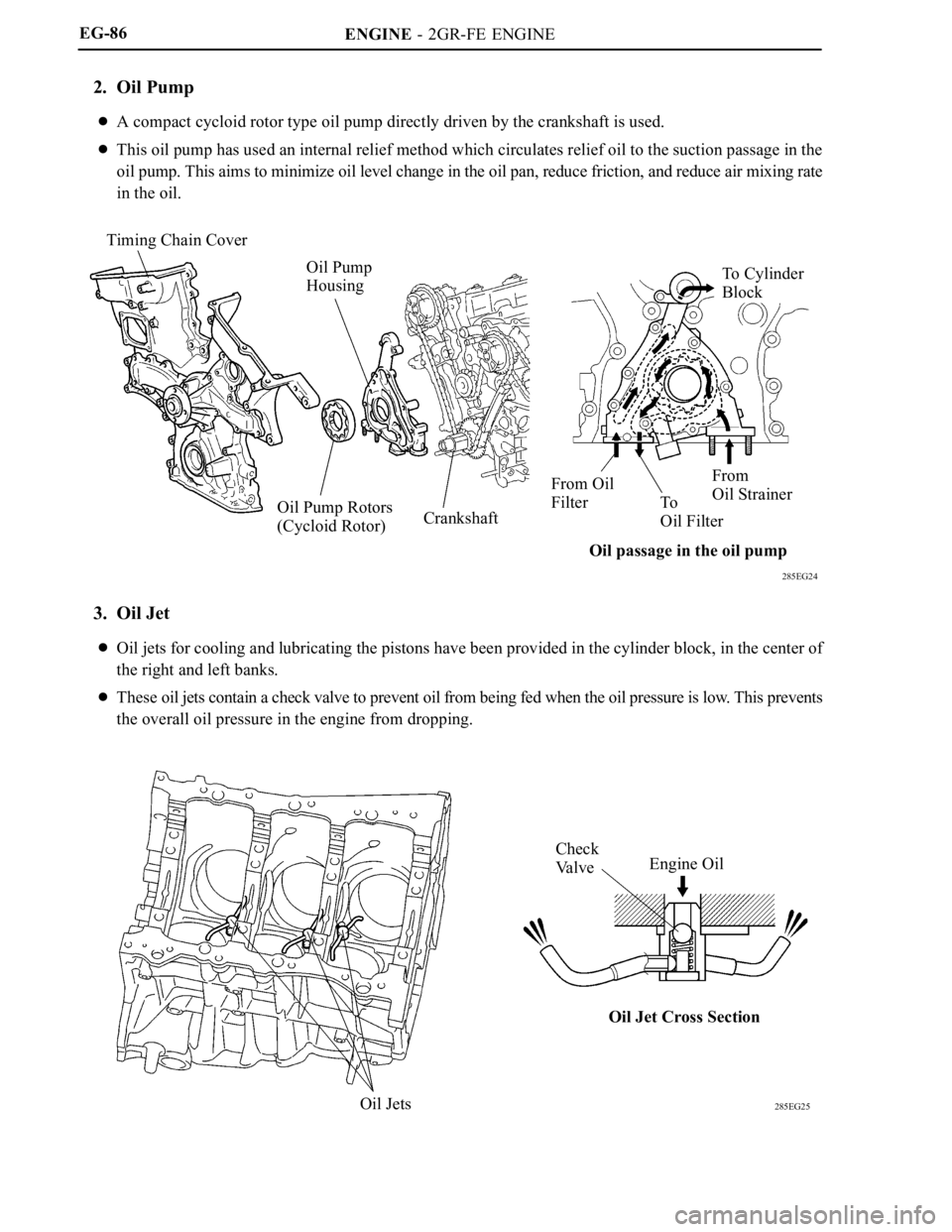

2. Oil Pump

A compact cycloid rotor type oil pump directly driven by the crankshaft is used.

This oil pump has used an internal relief method which circulates relief oil to the suction passage in the

oil pump. This aims to minimize oil level change in the oil pan, reduce friction, and reduce air mixing rate

in the oil.

3. Oil Jet

Oil jets for cooling and lubricating the pistons have been provided in the cylinder block, in the center of

the right and left banks.

These oil jets contain a check valve to prevent oil from being fed when the oil pressure is low. This prevents

the overall oil pressure in the engine from dropping.

Page 182 of 2000

MAINTENANCE – UNDER HOODMA–7

MA

GENERAL MAINTENANCE

(2006/01- )

1. GENERAL NOTES

• Maintenance requirements vary depending on the

country.

• Check the maintenance schedule in the owner's

manual supplement.

• Following the maintenance schedule is mandatory.

• Determine the appropriate time to service the vehicle

using either miles driven or time elapsed, whichever

reaches the specification first.

• Maintain similar intervals between periodic

maintenance, unless otherwise noted.

• Failing to check each vehicle part could lead to poor

engine performance and increase exhaust emissions.

2. WINDSHIELD WASHER FLUID

(a) Check that there is sufficient fluid in the tank.

3. ENGINE COOLANT LEVEL

(a) Check that the coolant level is between the "FULL"

and "LOW" lines on the see-through reservoir.

4. RADIATOR AND HOSES

(a) Check that the front of the radiator is clean and not

blocked by leaves, dirt or bugs.

(b) Check the hoses for cracks, kinks, rot or loose

connections.

5. BATTERY ELECTROLYTE LEVEL

(a) Check that the electrolyte level of all the battery

cells is between the upper and lower level lines on

the case.

HINT:

If the electrolyte level is difficult to see, lightly shake

the vehicle.

6. BRAKE FLUID LEVEL

(a) Check that the brake fluid levels are near the upper

level lines on the see-through reservoirs.

7. ENGINE DRIVE BELT

(a) Check the drive belt for fraying, cracks, wear or

oiliness.

8. ENGINE OIL LEVEL

(a) Check the level on the dipstick with the engine

stopped.

9. AUTOMATIC TRANSAXLE FLUID LEVEL

10. EXHAUST SYSTEM

(a) Check for unusual exhaust sounds or abnormal

exhaust fumes. Inspect the cause and repair it.

Type See procedures

U151E See page AX-126

U151F See page AX-126

Page 227 of 2000

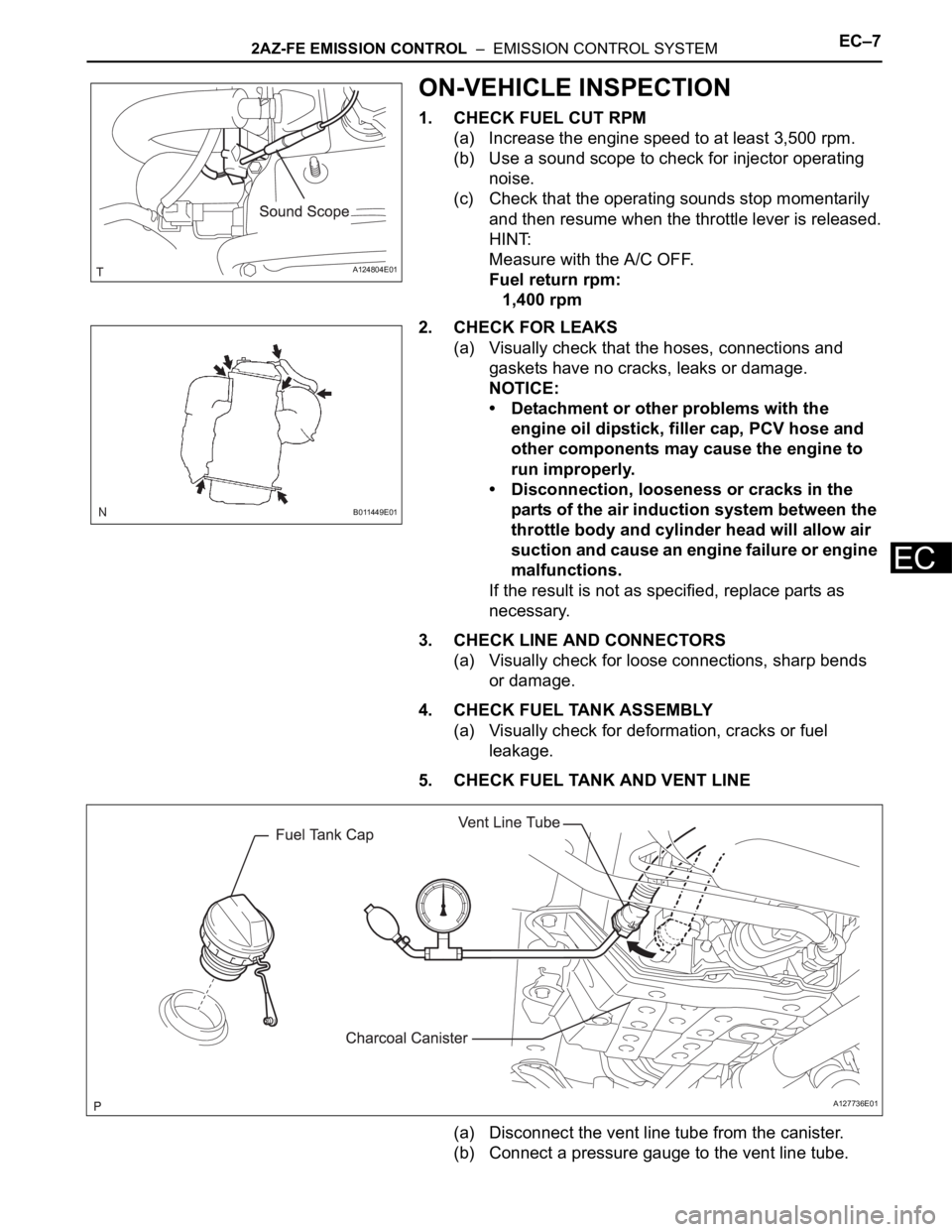

2AZ-FE EMISSION CONTROL – EMISSION CONTROL SYSTEMEC–7

EC

ON-VEHICLE INSPECTION

1. CHECK FUEL CUT RPM

(a) Increase the engine speed to at least 3,500 rpm.

(b) Use a sound scope to check for injector operating

noise.

(c) Check that the operating sounds stop momentarily

and then resume when the throttle lever is released.

HINT:

Measure with the A/C OFF.

Fuel return rpm:

1,400 rpm

2. CHECK FOR LEAKS

(a) Visually check that the hoses, connections and

gaskets have no cracks, leaks or damage.

NOTICE:

• Detachment or other problems with the

engine oil dipstick, filler cap, PCV hose and

other components may cause the engine to

run improperly.

• Disconnection, looseness or cracks in the

parts of the air induction system between the

throttle body and cylinder head will allow air

suction and cause an engine failure or engine

malfunctions.

If the result is not as specified, replace parts as

necessary.

3. CHECK LINE AND CONNECTORS

(a) Visually check for loose connections, sharp bends

or damage.

4. CHECK FUEL TANK ASSEMBLY

(a) Visually check for deformation, cracks or fuel

leakage.

5. CHECK FUEL TANK AND VENT LINE

(a) Disconnect the vent line tube from the canister.

(b) Connect a pressure gauge to the vent line tube.

A124804E01

B011449E01

A127736E01

Page 245 of 2000

2AZ-FE LUBRICATION – OIL PUMPLU–13

LU

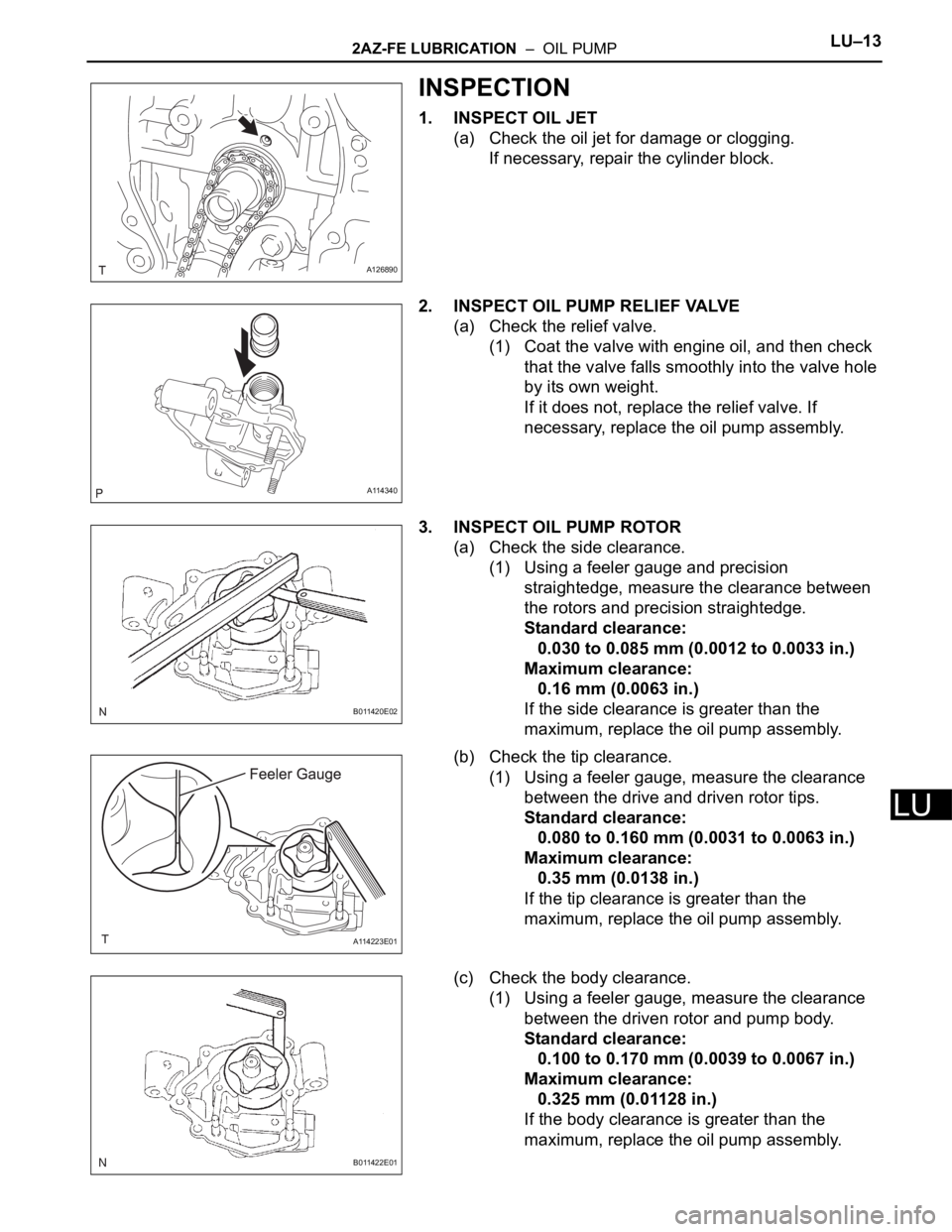

INSPECTION

1. INSPECT OIL JET

(a) Check the oil jet for damage or clogging.

If necessary, repair the cylinder block.

2. INSPECT OIL PUMP RELIEF VALVE

(a) Check the relief valve.

(1) Coat the valve with engine oil, and then check

that the valve falls smoothly into the valve hole

by its own weight.

If it does not, replace the relief valve. If

necessary, replace the oil pump assembly.

3. INSPECT OIL PUMP ROTOR

(a) Check the side clearance.

(1) Using a feeler gauge and precision

straightedge, measure the clearance between

the rotors and precision straightedge.

Standard clearance:

0.030 to 0.085 mm (0.0012 to 0.0033 in.)

Maximum clearance:

0.16 mm (0.0063 in.)

If the side clearance is greater than the

maximum, replace the oil pump assembly.

(b) Check the tip clearance.

(1) Using a feeler gauge, measure the clearance

between the drive and driven rotor tips.

Standard clearance:

0.080 to 0.160 mm (0.0031 to 0.0063 in.)

Maximum clearance:

0.35 mm (0.0138 in.)

If the tip clearance is greater than the

maximum, replace the oil pump assembly.

(c) Check the body clearance.

(1) Using a feeler gauge, measure the clearance

between the driven rotor and pump body.

Standard clearance:

0.100 to 0.170 mm (0.0039 to 0.0067 in.)

Maximum clearance:

0.325 mm (0.01128 in.)

If the body clearance is greater than the

maximum, replace the oil pump assembly.

A126890

A114340

B011420E02

A114223E01

B011422E01

Page 248 of 2000

2GR-FE LUBRICATION – OIL PUMPLU–13

LU

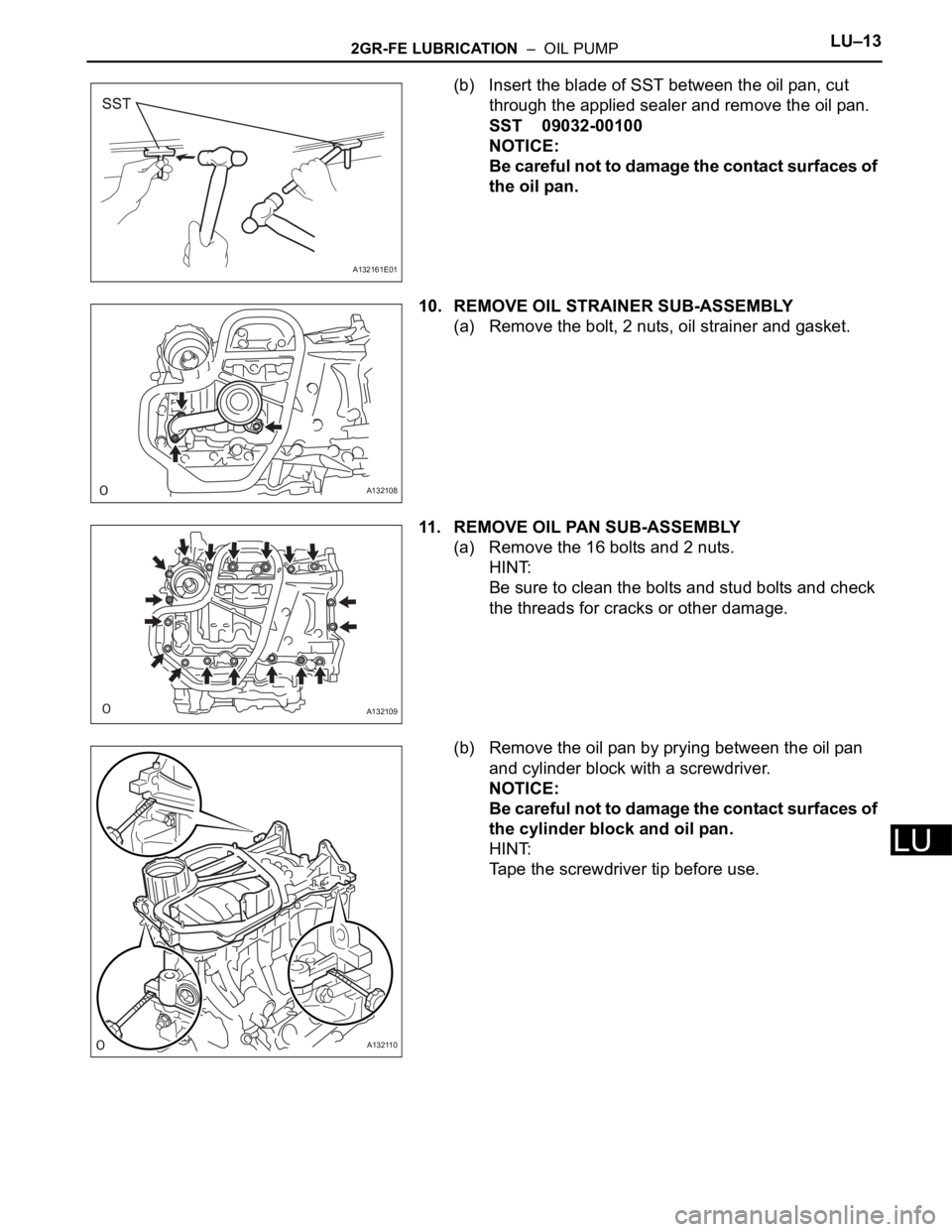

(b) Insert the blade of SST between the oil pan, cut

through the applied sealer and remove the oil pan.

SST 09032-00100

NOTICE:

Be careful not to damage the contact surfaces of

the oil pan.

10. REMOVE OIL STRAINER SUB-ASSEMBLY

(a) Remove the bolt, 2 nuts, oil strainer and gasket.

11. REMOVE OIL PAN SUB-ASSEMBLY

(a) Remove the 16 bolts and 2 nuts.

HINT:

Be sure to clean the bolts and stud bolts and check

the threads for cracks or other damage.

(b) Remove the oil pan by prying between the oil pan

and cylinder block with a screwdriver.

NOTICE:

Be careful not to damage the contact surfaces of

the cylinder block and oil pan.

HINT:

Tape the screwdriver tip before use.

A132161E01

A132108

A132109

A132110

Page 376 of 2000

AX–248U241E AUTOMATIC TRANSAXLE – UNDERDRIVE CLUTCH

AX

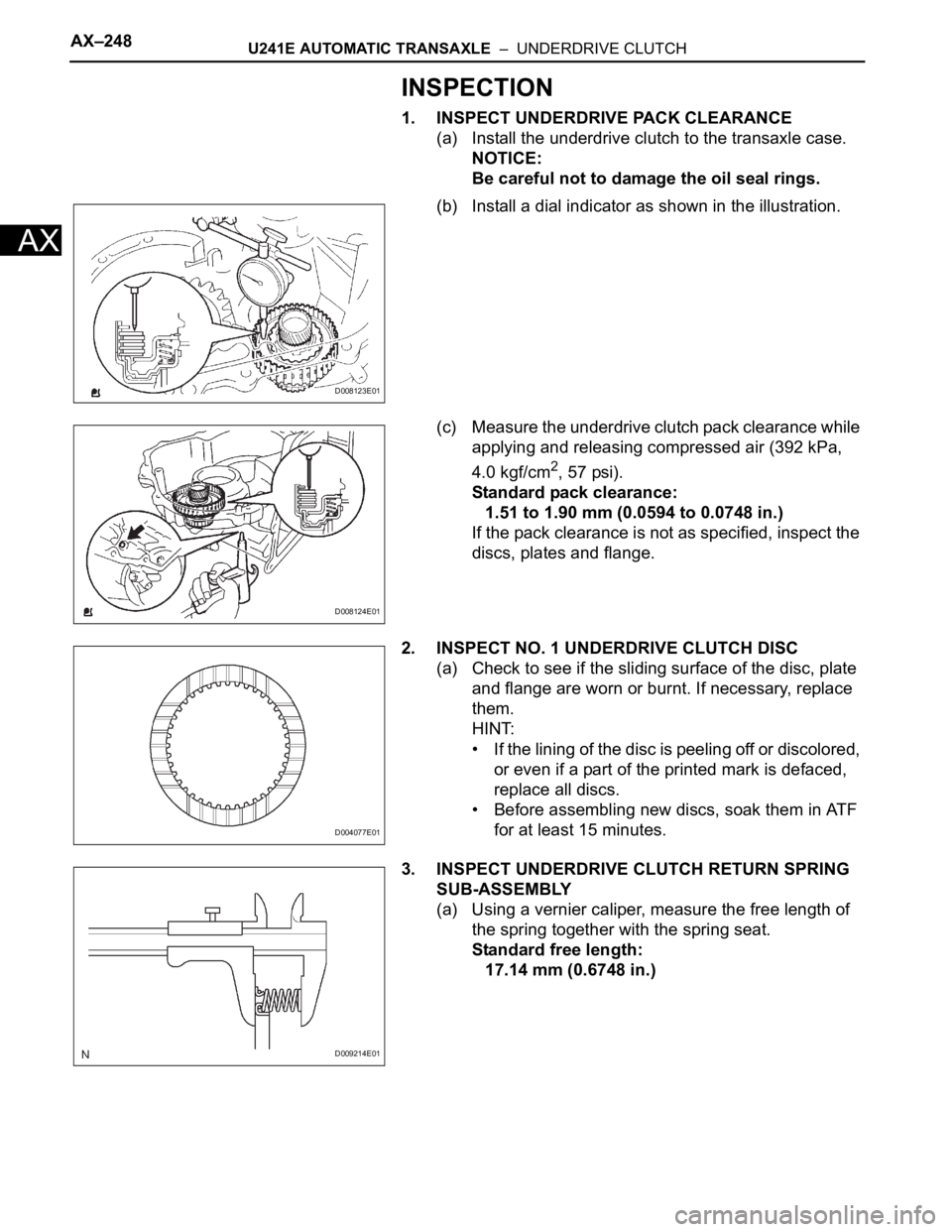

INSPECTION

1. INSPECT UNDERDRIVE PACK CLEARANCE

(a) Install the underdrive clutch to the transaxle case.

NOTICE:

Be careful not to damage the oil seal rings.

(b) Install a dial indicator as shown in the illustration.

(c) Measure the underdrive clutch pack clearance while

applying and releasing compressed air (392 kPa,

4.0 kgf/cm

2, 57 psi).

Standard pack clearance:

1.51 to 1.90 mm (0.0594 to 0.0748 in.)

If the pack clearance is not as specified, inspect the

discs, plates and flange.

2. INSPECT NO. 1 UNDERDRIVE CLUTCH DISC

(a) Check to see if the sliding surface of the disc, plate

and flange are worn or burnt. If necessary, replace

them.

HINT:

• If the lining of the disc is peeling off or discolored,

or even if a part of the printed mark is defaced,

replace all discs.

• Before assembling new discs, soak them in ATF

for at least 15 minutes.

3. INSPECT UNDERDRIVE CLUTCH RETURN SPRING

SUB-ASSEMBLY

(a) Using a vernier caliper, measure the free length of

the spring together with the spring seat.

Standard free length:

17.14 mm (0.6748 in.)

D008123E01

D008124E01

D004077E01

D009214E01

Page 378 of 2000

AX–250U241E AUTOMATIC TRANSAXLE – UNDERDRIVE CLUTCH

AX

• This prevents the spring sheet from being

deformed.

• Do not expand the snap ring excessively.

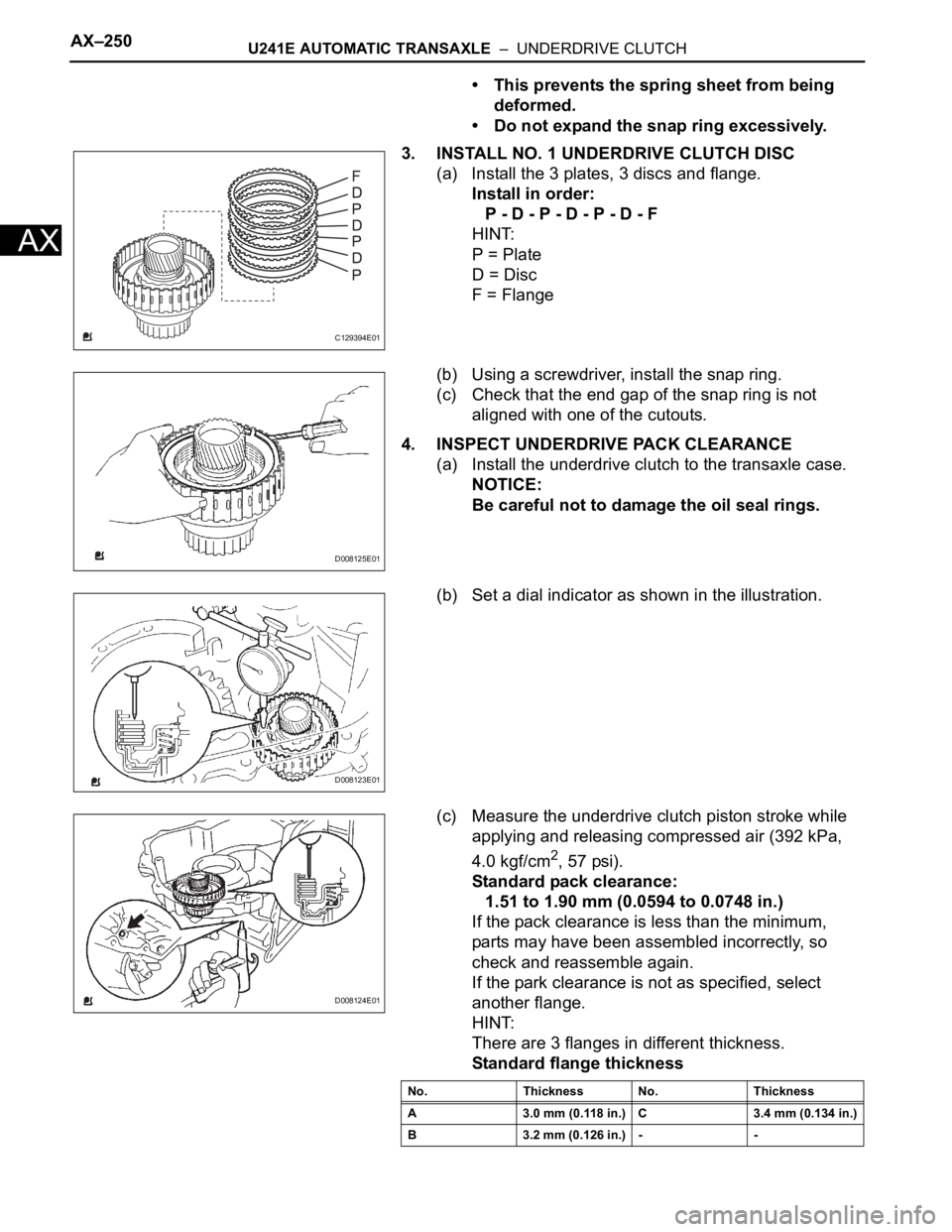

3. INSTALL NO. 1 UNDERDRIVE CLUTCH DISC

(a) Install the 3 plates, 3 discs and flange.

Install in order:

P - D - P - D - P - D - F

HINT:

P = Plate

D = Disc

F = Flange

(b) Using a screwdriver, install the snap ring.

(c) Check that the end gap of the snap ring is not

aligned with one of the cutouts.

4. INSPECT UNDERDRIVE PACK CLEARANCE

(a) Install the underdrive clutch to the transaxle case.

NOTICE:

Be careful not to damage the oil seal rings.

(b) Set a dial indicator as shown in the illustration.

(c) Measure the underdrive clutch piston stroke while

applying and releasing compressed air (392 kPa,

4.0 kgf/cm

2, 57 psi).

Standard pack clearance:

1.51 to 1.90 mm (0.0594 to 0.0748 in.)

If the pack clearance is less than the minimum,

parts may have been assembled incorrectly, so

check and reassemble again.

If the park clearance is not as specified, select

another flange.

HINT:

There are 3 flanges in different thickness.

Standard flange thickness

C129394E01

D008125E01

D008123E01

D008124E01

No. Thickness No. Thickness

A 3.0 mm (0.118 in.) C 3.4 mm (0.134 in.)

B 3.2 mm (0.126 in.) - -

Page 382 of 2000

GF1A TRANSFER – TRANSFER SYSTEMTF–3

TF

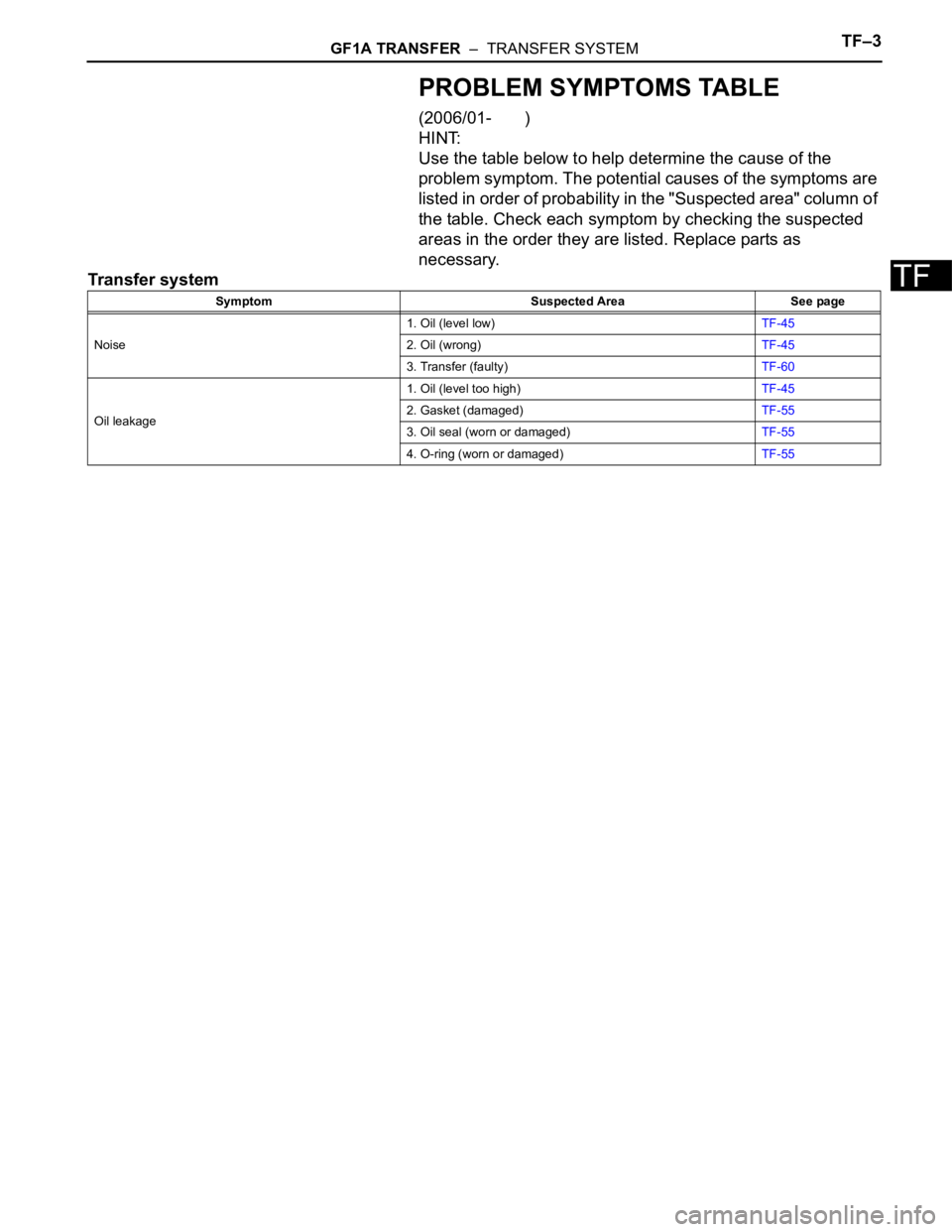

PROBLEM SYMPTOMS TABLE

(2006/01- )

HINT:

Use the table below to help determine the cause of the

problem symptom. The potential causes of the symptoms are

listed in order of probability in the "Suspected area" column of

the table. Check each symptom by checking the suspected

areas in the order they are listed. Replace parts as

necessary.

Transfer system

Symptom Suspected Area See page

Noise1. Oil (level low)TF-45

2. Oil (wrong)TF-45

3. Transfer (faulty)TF-60

Oil leakage1. Oil (level too high)TF-45

2. Gasket (damaged)TF-55

3. Oil seal (worn or damaged)TF-55

4. O-ring (worn or damaged)TF-55