key battery TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 30 of 2000

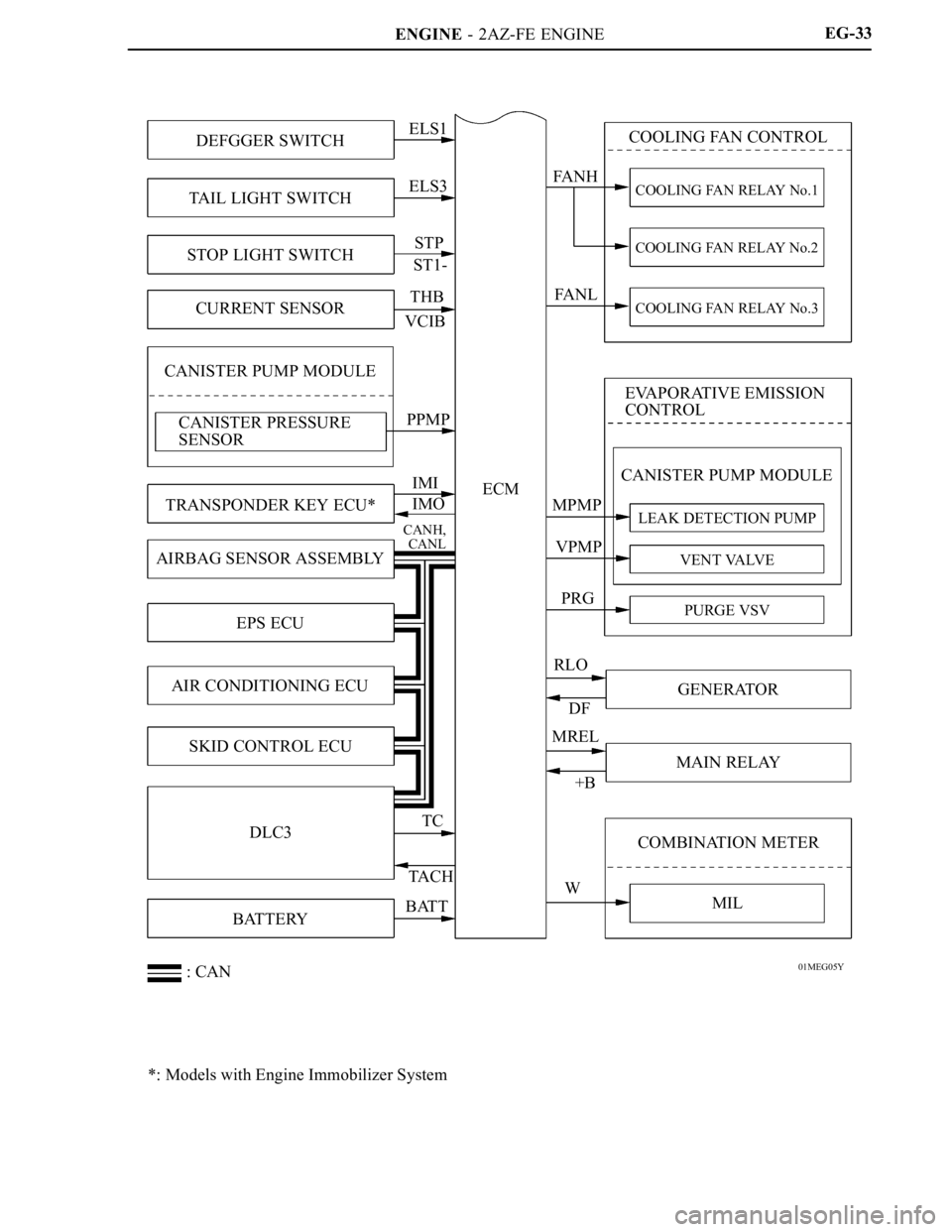

ENGINE - 2AZ-FE ENGINE

01MEG05Y

DEFGGER SWITCH

TA I L L I G H T S W I T C H

STOP LIGHT SWITCH

CURRENT SENSOR

CANISTER PUMP MODULE

CANISTER PRESSURE

SENSOR

TRANSPONDER KEY ECU*

AIRBAG SENSOR ASSEMBLY

EPS ECU

AIR CONDITIONING ECU

SKID CONTROL ECU

DLC3

BATTERYELS1

ELS3

STP

ST1-

THB

VCIB

PPMP

IMI

IMO

CANH,

CANL

TC

TA C H

BATTECMFA N H

FA N L

MPMP

VPMP

PRG

RLO

DF

MREL

+B

WCOOLING FAN CONTROL

COOLING FAN RELAY No.1

COOLING FAN RELAY No.2

COOLING FAN RELAY No.3

EVAPORATIVE EMISSION

CONTROL

CANISTER PUMP MODULE

LEAK DETECTION PUMP

VENT VALVE

GENERATOR

MAIN RELAY

COMBINATION METER

MIL

PURGE VSV

: CANEG-33

*: Models with Engine Immobilizer System

Page 100 of 2000

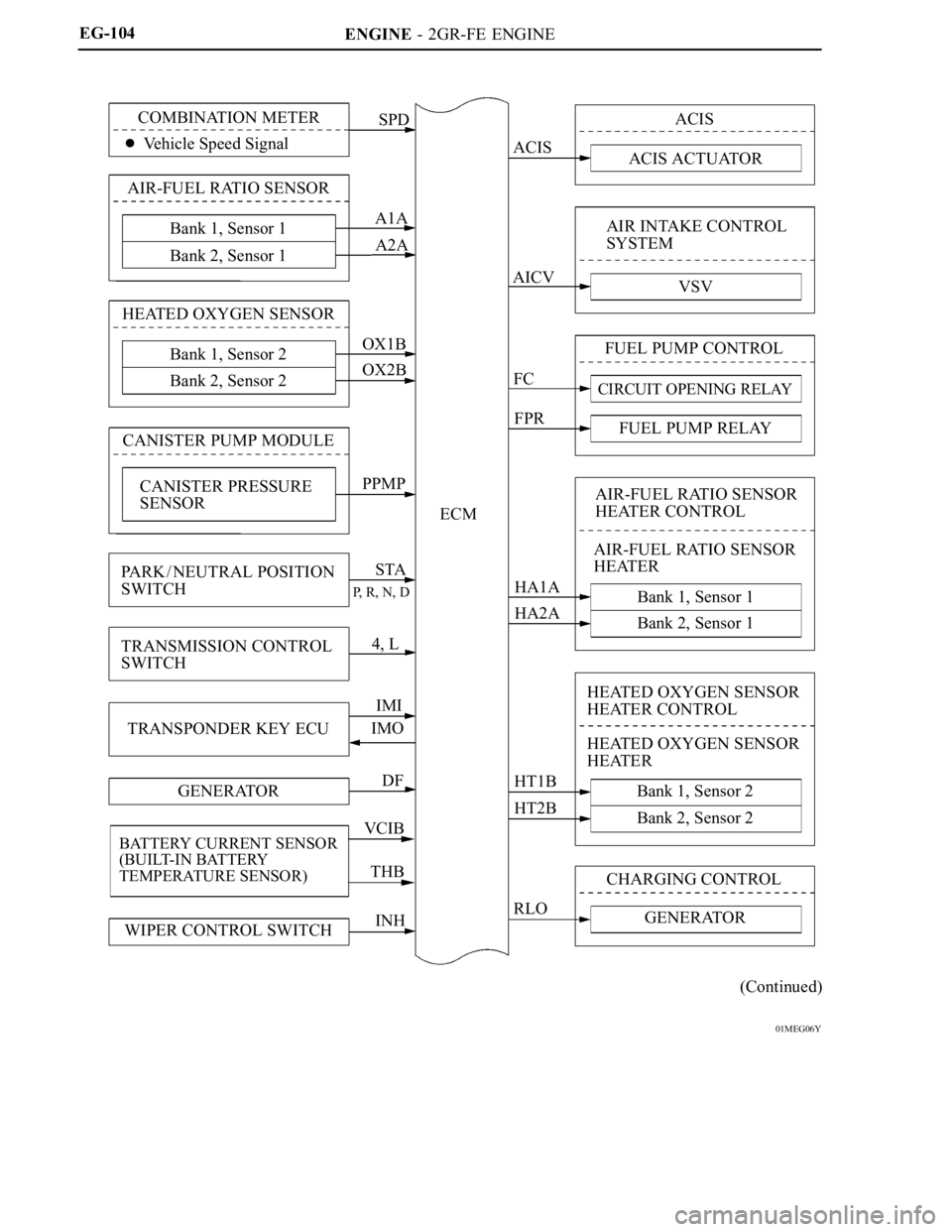

ENGINE - 2GR-FE ENGINE

01MEG06Y

COMBINATION METER

Vehicle Speed Signal

AIR-FUEL RATIO SENSOR

Bank 1, Sensor 1

Bank 2, Sensor 1

HEATED OXYGEN SENSOR

Bank 1, Sensor 2

Bank 2, Sensor 2

CANISTER PUMP MODULE

CANISTER PRESSURE

SENSOR

PARK / NEUTRAL POSITION

SWITCH

TRANSMISSION CONTROL

SWITCH

TRANSPONDER KEY ECU

GENERATOR

BATTERY CURRENT SENSOR

(BUILT-IN BATTERY

TEMPERATURE SENSOR)

WIPER CONTROL SWITCHSPD

A1A

A2A

OX1B

OX2B

PPMP

STA

P, R, N, D

4, L

IMI

IMO

DF

THB VCIB

INHECMACIS

AICV

FC

FPR

HA1A

HA2A

HT1B

HT2B

RLOACIS

ACIS ACTUATOR

AIR INTAKE CONTROL

SYSTEM

VSV

FUEL PUMP CONTROL

CIRCUIT OPENING RELAY

FUEL PUMP RELAY

AIR-FUEL RATIO SENSOR

HEATER CONTROL

AIR-FUEL RATIO SENSOR

HEATER

Bank 1, Sensor 1

Bank 2, Sensor 1

HEATED OXYGEN SENSOR

HEATER CONTROL

HEATED OXYGEN SENSOR

HEATER

Bank 1, Sensor 2

Bank 2, Sensor 2

CHARGING CONTROL

GENERATOR EG-104

(Continued)

Page 453 of 2000

LI–126LIGHTING – IGNITION KEY CYLINDER LIGHT

LI

INSTALLATION

1. INSTALL TRANSPONDER KEY AMPLIFIER (See page

SR-18)

2. INSTALL STEERING COLUMN COVER (See page SR-

20)

3. INSTALL STEERING WHEEL ASSEMBLY (See page

SR-21)

4. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

5. INSPECT STEERING WHEEL CENTER POINT

6. INSTALL STEERING PAD ASSEMBLY (See page RS-

336)

7. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

8. INSPECT STEERING PAD ASSEMBLY (See page RS-

337)

9. CHECK SRS WARNING LIGHT

(a) Check the SRS warning light (see page RS-337).

Page 908 of 2000

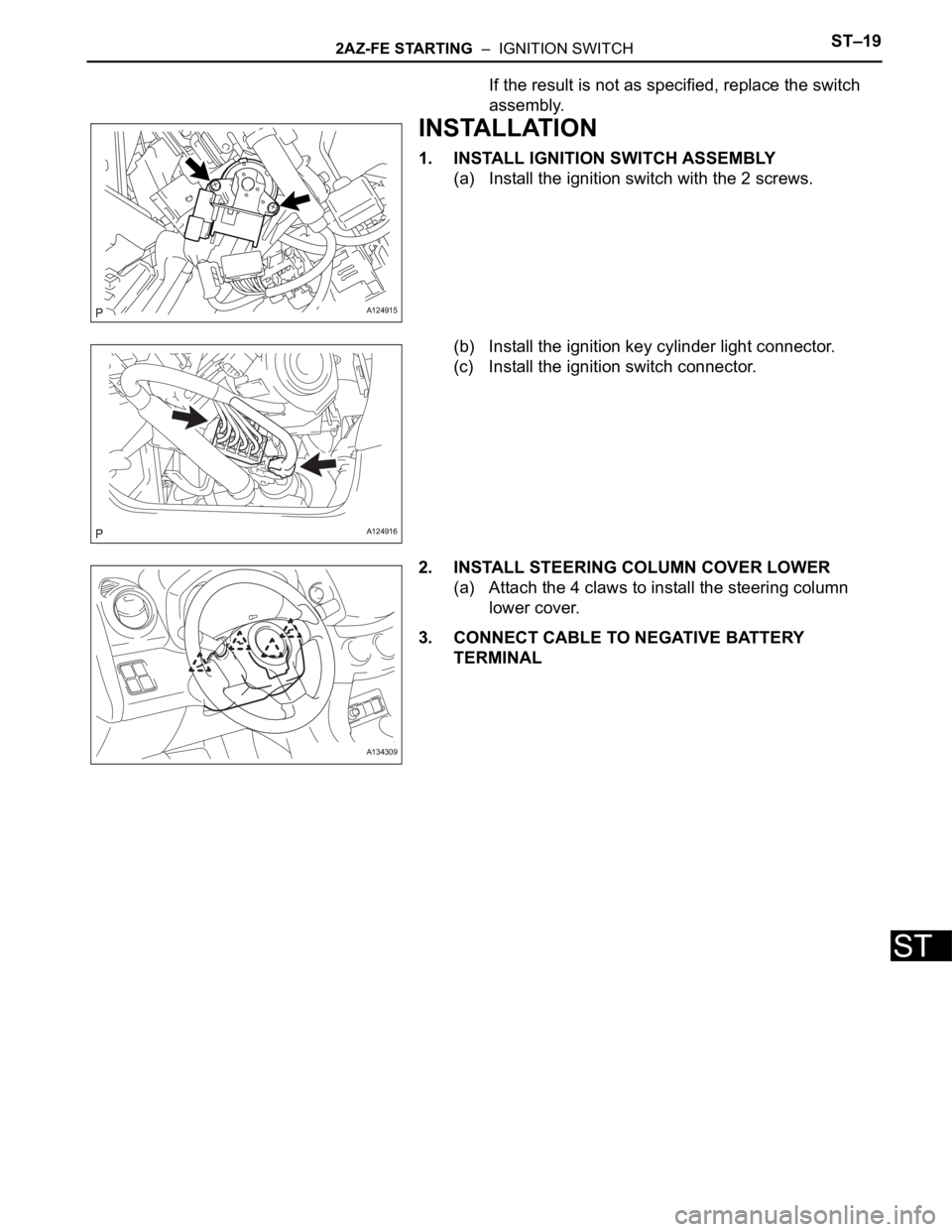

2AZ-FE STARTING – IGNITION SWITCHST–19

ST

If the result is not as specified, replace the switch

assembly.

INSTALLATION

1. INSTALL IGNITION SWITCH ASSEMBLY

(a) Install the ignition switch with the 2 screws.

(b) Install the ignition key cylinder light connector.

(c) Install the ignition switch connector.

2. INSTALL STEERING COLUMN COVER LOWER

(a) Attach the 4 claws to install the steering column

lower cover.

3. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

A124915

A124916

A134309

Page 919 of 2000

2GR-FE STARTING – IGNITION SWITCHST–19

ST

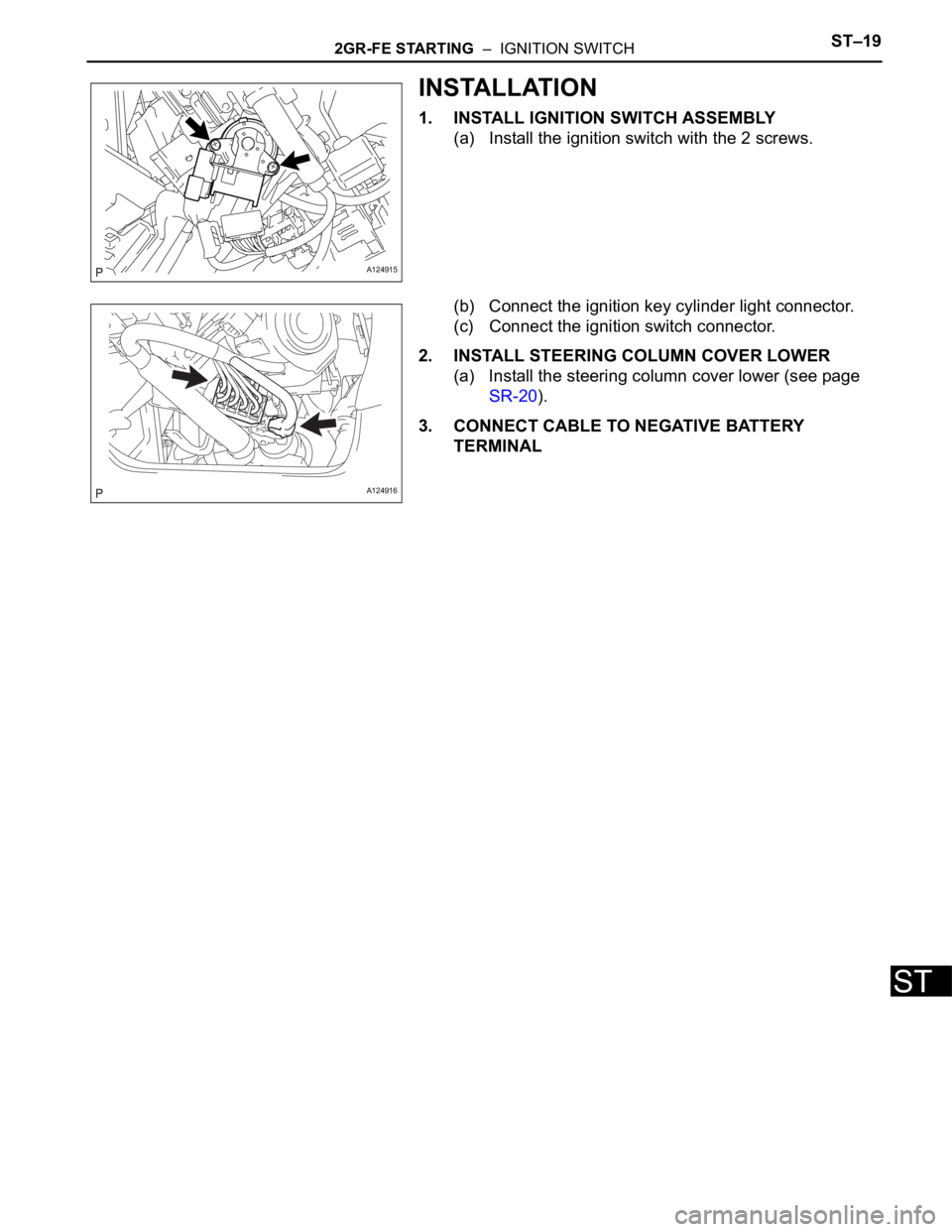

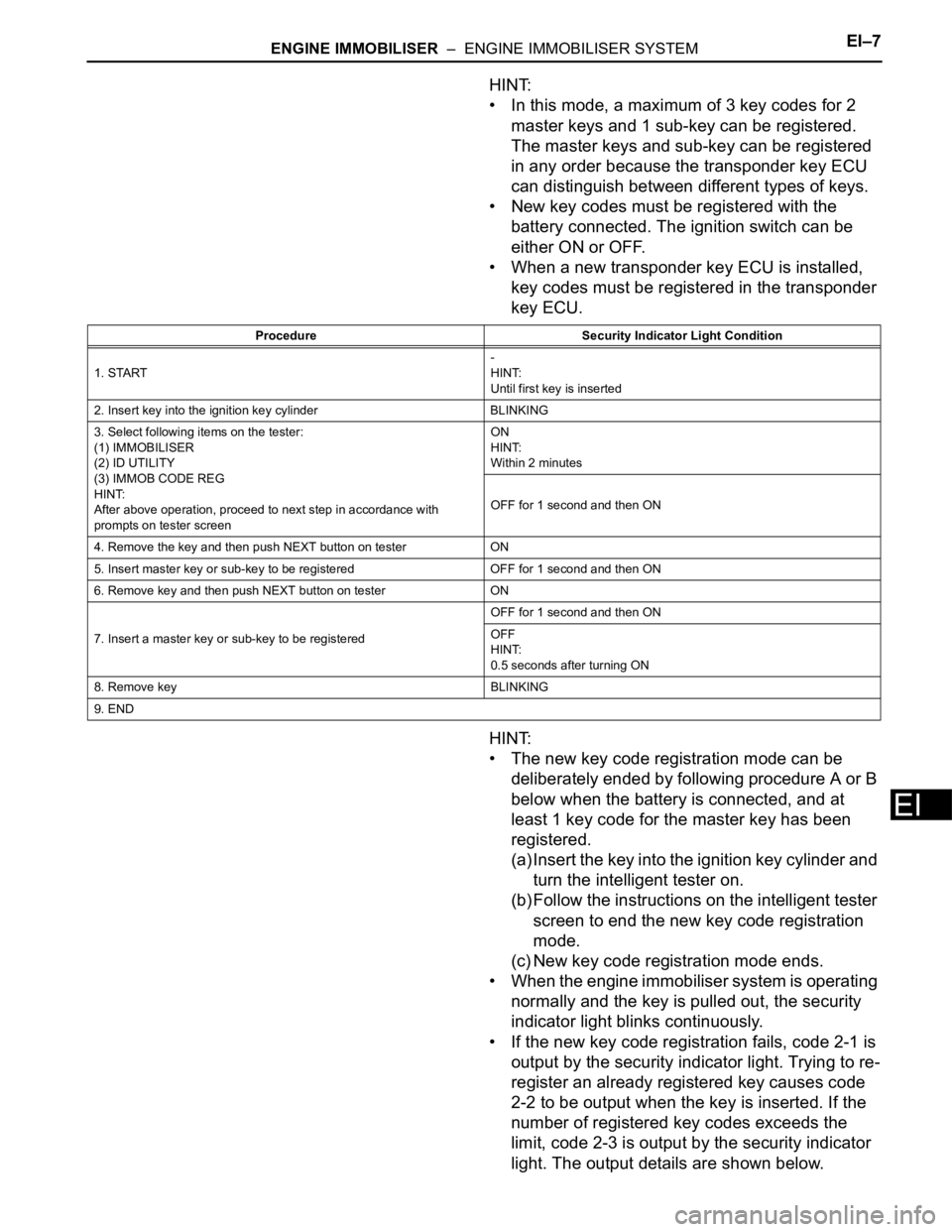

INSTALLATION

1. INSTALL IGNITION SWITCH ASSEMBLY

(a) Install the ignition switch with the 2 screws.

(b) Connect the ignition key cylinder light connector.

(c) Connect the ignition switch connector.

2. INSTALL STEERING COLUMN COVER LOWER

(a) Install the steering column cover lower (see page

SR-20).

3. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

A124915

A124916

Page 1778 of 2000

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEMEI–7

EI

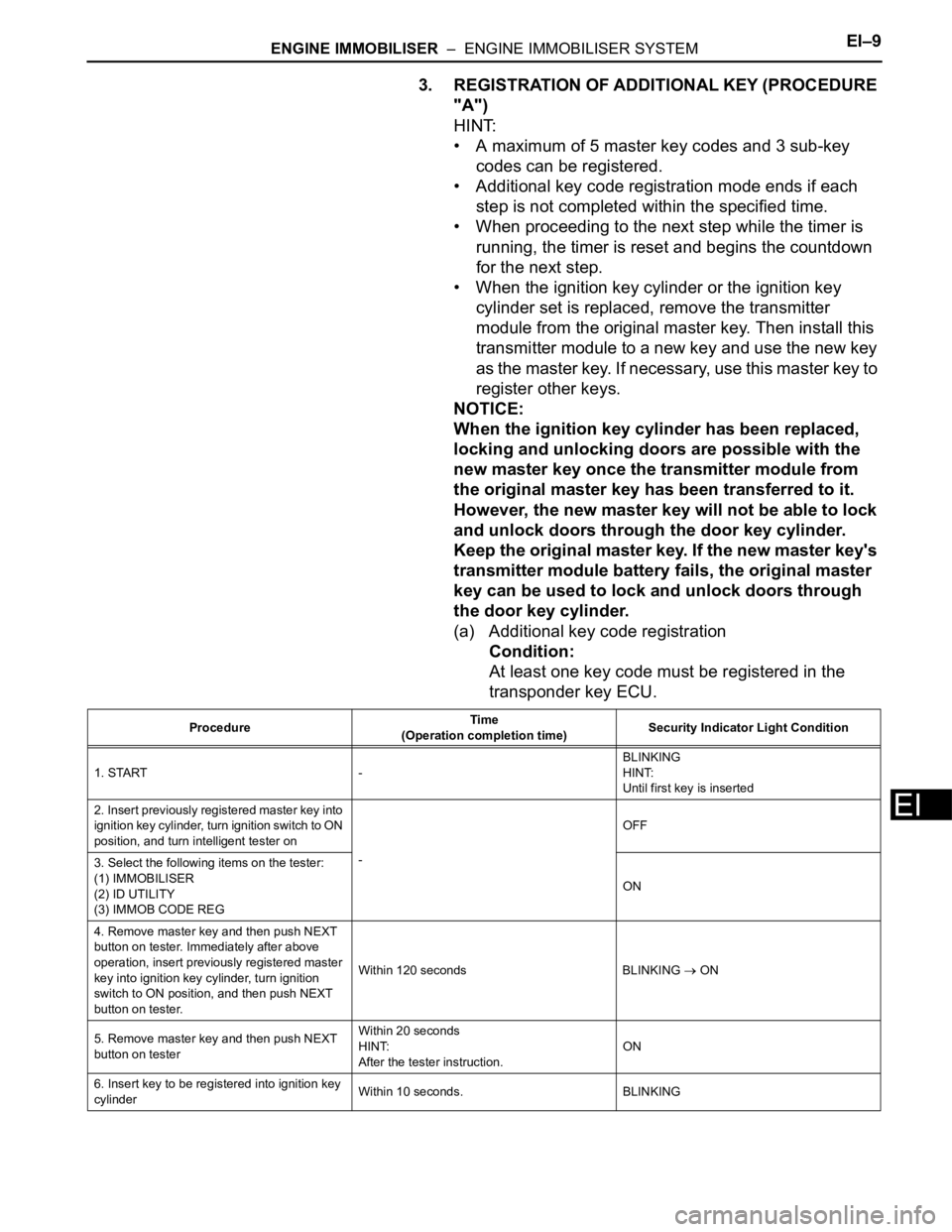

HINT:

• In this mode, a maximum of 3 key codes for 2

master keys and 1 sub-key can be registered.

The master keys and sub-key can be registered

in any order because the transponder key ECU

can distinguish between different types of keys.

• New key codes must be registered with the

battery connected. The ignition switch can be

either ON or OFF.

• When a new transponder key ECU is installed,

key codes must be registered in the transponder

key ECU.

HINT:

• The new key code registration mode can be

deliberately ended by following procedure A or B

below when the battery is connected, and at

least 1 key code for the master key has been

registered.

(a) Insert the key into the ignition key cylinder and

turn the intelligent tester on.

(b) Follow the instructions on the intelligent tester

screen to end the new key code registration

mode.

(c) New key code registration mode ends.

• When the engine immobiliser system is operating

normally and the key is pulled out, the security

indicator light blinks continuously.

• If the new key code registration fails, code 2-1 is

output by the security indicator light. Trying to re-

register an already registered key causes code

2-2 to be output when the key is inserted. If the

number of registered key codes exceeds the

limit, code 2-3 is output by the security indicator

light. The output details are shown below.

Procedure Security Indicator Light Condition

1. START-

HINT:

Until first key is inserted

2. Insert key into the ignition key cylinder BLINKING

3. Select following items on the tester:

(1) IMMOBILISER

(2) ID UTILITY

(3) IMMOB CODE REG

HINT:

After above operation, proceed to next step in accordance with

prompts on tester screenON

HINT:

Within 2 minutes

OFF for 1 second and then ON

4. Remove the key and then push NEXT button on tester ON

5. Insert master key or sub-key to be registered OFF for 1 second and then ON

6. Remove key and then push NEXT button on tester ON

7. Insert a master key or sub-key to be registeredOFF for 1 second and then ON

OFF

HINT:

0.5 seconds after turning ON

8. Remove key BLINKING

9. END

Page 1780 of 2000

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEMEI–9

EI

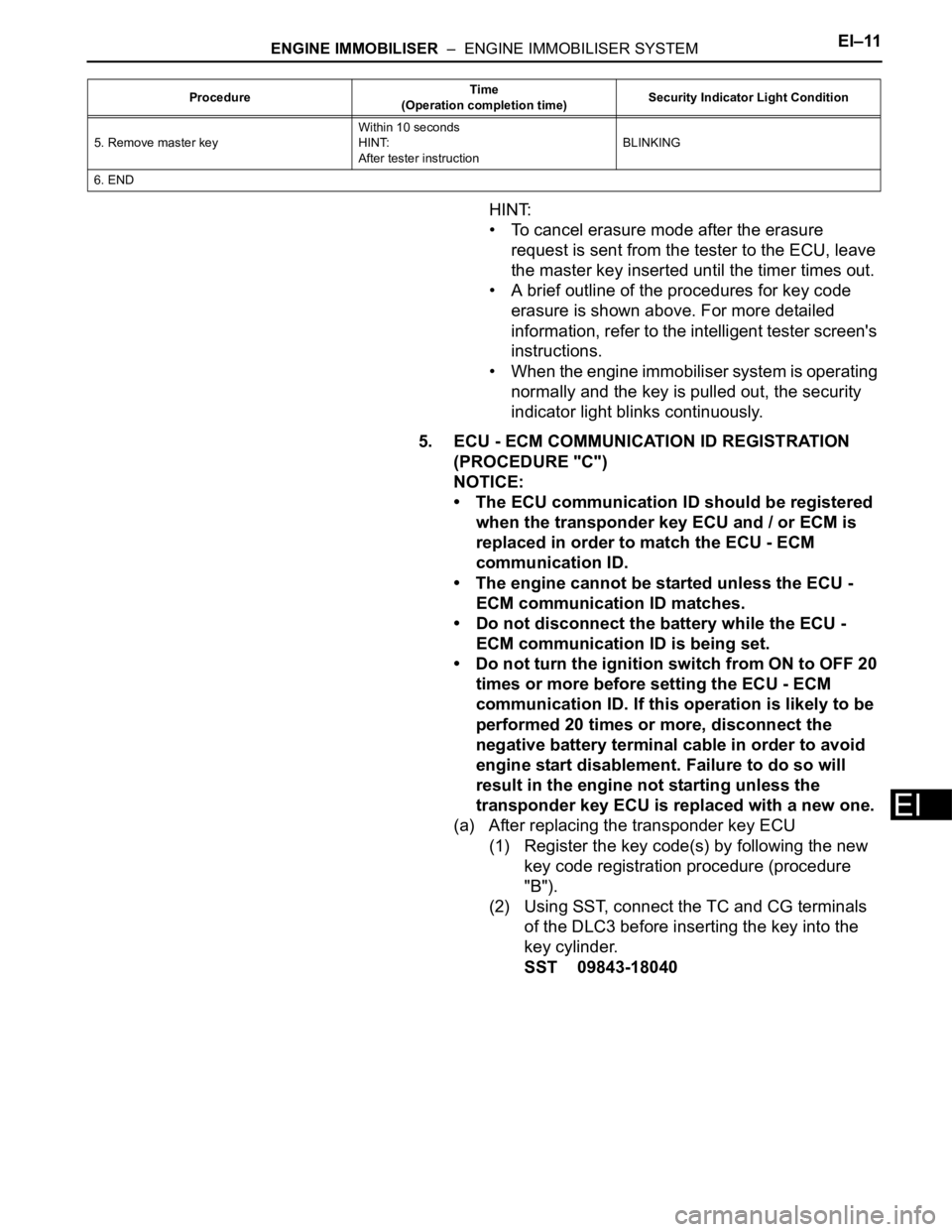

3. REGISTRATION OF ADDITIONAL KEY (PROCEDURE

"A")

HINT:

• A maximum of 5 master key codes and 3 sub-key

codes can be registered.

• Additional key code registration mode ends if each

step is not completed within the specified time.

• When proceeding to the next step while the timer is

running, the timer is reset and begins the countdown

for the next step.

• When the ignition key cylinder or the ignition key

cylinder set is replaced, remove the transmitter

module from the original master key. Then install this

transmitter module to a new key and use the new key

as the master key. If necessary, use this master key to

register other keys.

NOTICE:

When the ignition key cylinder has been replaced,

locking and unlocking doors are possible with the

new master key once the transmitter module from

the original master key has been transferred to it.

However, the new master key will not be able to lock

and unlock doors through the door key cylinder.

Keep the original master key. If the new master key's

transmitter module battery fails, the original master

key can be used to lock and unlock doors through

the door key cylinder.

(a) Additional key code registration

Condition:

At least one key code must be registered in the

transponder key ECU.

ProcedureTime

(Operation completion time)Security Indicator Light Condition

1. START -BLINKING

HINT:

Until first key is inserted

2. Insert previously registered master key into

ignition key cylinder, turn ignition switch to ON

position, and turn intelligent tester on

-OFF

3. Select the following items on the tester:

(1) IMMOBILISER

(2) ID UTILITY

(3) IMMOB CODE REGON

4. Remove master key and then push NEXT

button on tester. Immediately after above

operation, insert previously registered master

key into ignition key cylinder, turn ignition

switch to ON position, and then push NEXT

button on tester.Within 120 seconds BLINKING

ON

5. Remove master key and then push NEXT

button on testerWithin 20 seconds

HINT:

After the tester instruction.ON

6. Insert key to be registered into ignition key

cylinderWithin 10 seconds. BLINKING

Page 1782 of 2000

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEMEI–11

EI

HINT:

• To cancel erasure mode after the erasure

request is sent from the tester to the ECU, leave

the master key inserted until the timer times out.

• A brief outline of the procedures for key code

erasure is shown above. For more detailed

information, refer to the intelligent tester screen's

instructions.

• When the engine immobiliser system is operating

normally and the key is pulled out, the security

indicator light blinks continuously.

5. ECU - ECM COMMUNICATION ID REGISTRATION

(PROCEDURE "C")

NOTICE:

• The ECU communication ID should be registered

when the transponder key ECU and / or ECM is

replaced in order to match the ECU - ECM

communication ID.

• The engine cannot be started unless the ECU -

ECM communication ID matches.

• Do not disconnect the battery while the ECU -

ECM communication ID is being set.

• Do not turn the ignition switch from ON to OFF 20

times or more before setting the ECU - ECM

communication ID. If this operation is likely to be

performed 20 times or more, disconnect the

negative battery terminal cable in order to avoid

engine start disablement. Failure to do so will

result in the engine not starting unless the

transponder key ECU is replaced with a new one.

(a) After replacing the transponder key ECU

(1) Register the key code(s) by following the new

key code registration procedure (procedure

"B").

(2) Using SST, connect the TC and CG terminals

of the DLC3 before inserting the key into the

key cylinder.

SST 09843-18040

5. Remove master keyWithin 10 seconds

HINT:

After tester instructionBLINKING

6. ENDProcedureTime

(Operation completion time)Security Indicator Light Condition

Page 1786 of 2000

ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEMEI–15

EI

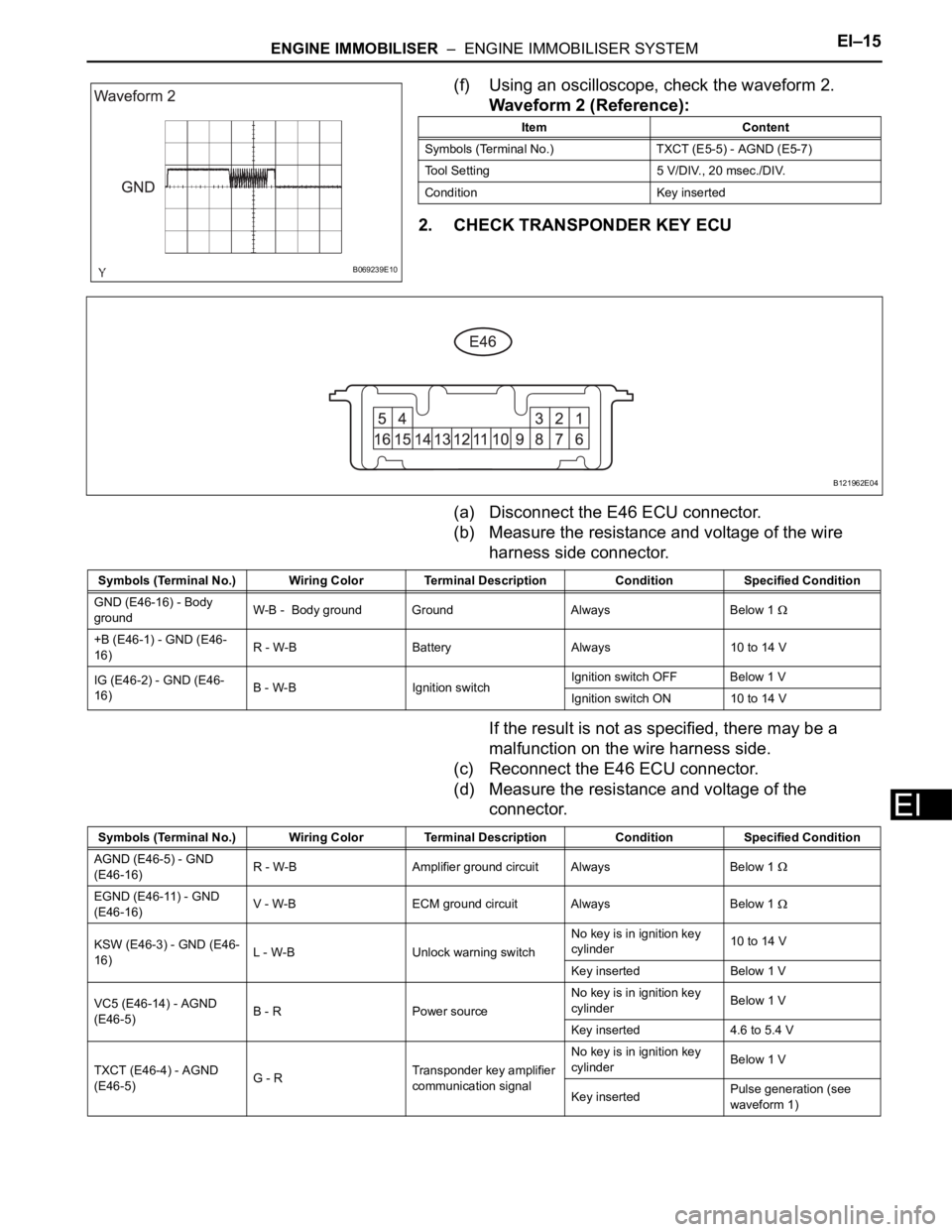

(f) Using an oscilloscope, check the waveform 2.

Waveform 2 (Reference):

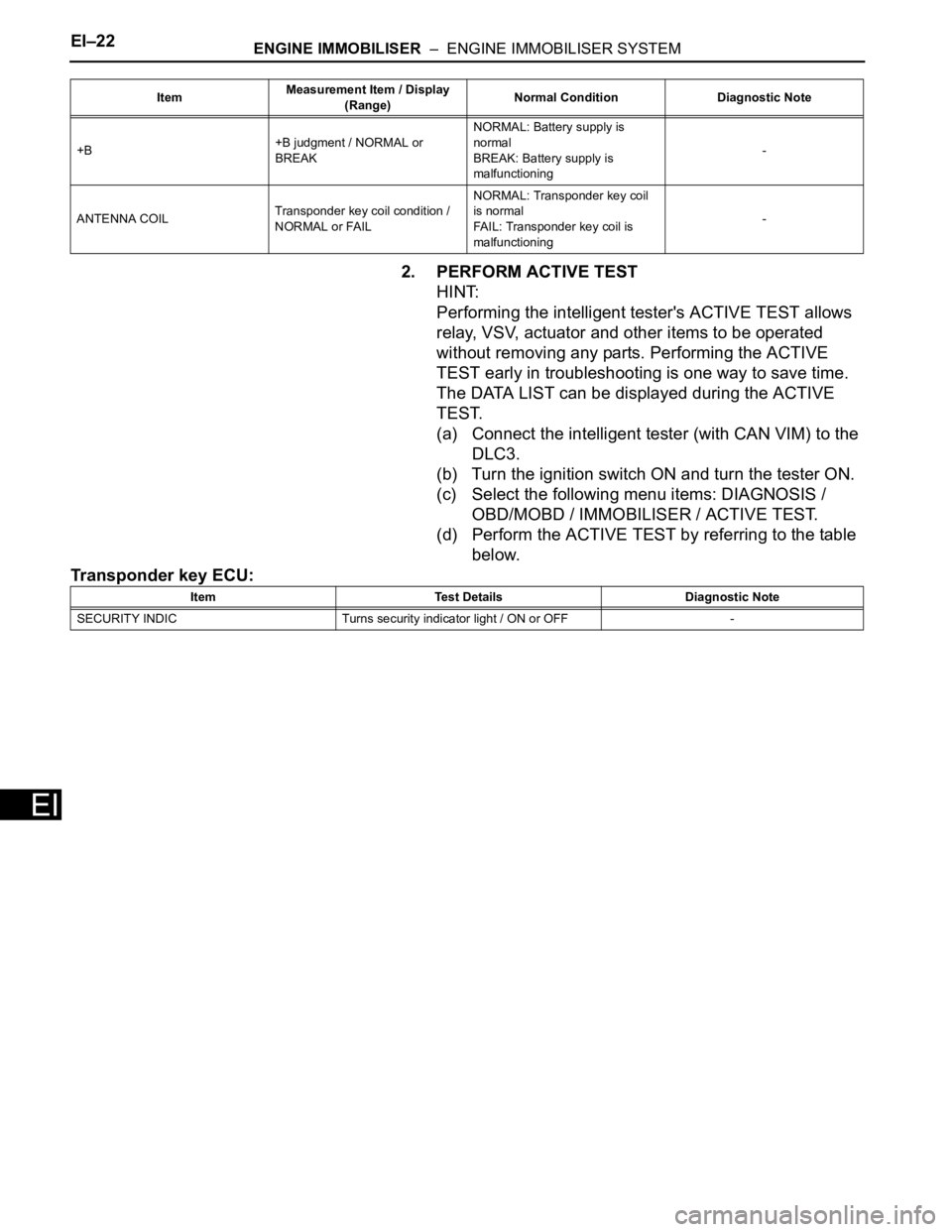

2. CHECK TRANSPONDER KEY ECU

(a) Disconnect the E46 ECU connector.

(b) Measure the resistance and voltage of the wire

harness side connector.

If the result is not as specified, there may be a

malfunction on the wire harness side.

(c) Reconnect the E46 ECU connector.

(d) Measure the resistance and voltage of the

connector.

B069239E10

Item Content

Symbols (Terminal No.) TXCT (E5-5) - AGND (E5-7)

Tool Setting 5 V/DIV., 20 msec./DIV.

Condition Key inserted

B121962E04

Symbols (Terminal No.) Wiring Color Terminal Description ConditionSpecified Condition

GND (E46-16) - Body

groundW-B - Body ground Ground Always Below 1

+B (E46-1) - GND (E46-

16)R - W-B Battery Always 10 to 14 V

IG (E46-2) - GND (E46-

16)B - W-B Ignition switchIgnition switch OFF Below 1 V

Ignition switch ON 10 to 14 V

Symbols (Terminal No.) Wiring Color Terminal Description ConditionSpecified Condition

AGND (E46-5) - GND

(E46-16)R - W-B Amplifier ground circuit Always Below 1

EGND (E46-11) - GND

(E46-16)V - W-B ECM ground circuit Always Below 1

KSW (E46-3) - GND (E46-

16)L - W-B Unlock warning switchNo key is in ignition key

cylinder10 to 14 V

Key inserted Below 1 V

VC5 (E46-14) - AGND

(E46-5)B - R Power sourceNo key is in ignition key

cylinderBelow 1 V

Key inserted 4.6 to 5.4 V

TXCT (E46-4) - AGND

(E46-5)G - RTransponder key amplifier

communication signalNo key is in ignition key

cylinderBelow 1 V

Key insertedPulse generation (see

waveform 1)

Page 1793 of 2000

EI–22ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM

EI

2. PERFORM ACTIVE TEST

HINT:

Performing the intelligent tester's ACTIVE TEST allows

relay, VSV, actuator and other items to be operated

without removing any parts. Performing the ACTIVE

TEST early in troubleshooting is one way to save time.

The DATA LIST can be displayed during the ACTIVE

TEST.

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

(b) Turn the ignition switch ON and turn the tester ON.

(c) Select the following menu items: DIAGNOSIS /

OBD/MOBD / IMMOBILISER / ACTIVE TEST.

(d) Perform the ACTIVE TEST by referring to the table

below.

Transponder key ECU:

+B+B judgment / NORMAL or

BREAKNORMAL: Battery supply is

normal

BREAK: Battery supply is

malfunctioning-

ANTENNA COILTransponder key coil condition /

NORMAL or FAILNORMAL: Transponder key coil

is normal

FAIL: Transponder key coil is

malfunctioning- ItemMeasurement Item / Display

(Range)Normal Condition Diagnostic Note

Item Test Details Diagnostic Note

SECURITY INDIC Turns security indicator light / ON or OFF -