cooling TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 3 of 2000

ENGINE - 2AZ-FE ENGINE

208EG67 DR011EG21

Exhaust Side

Intake Side A A

A - A Cross Section Injector

IN

EX

Bypass

Passage

Ta p e r S q u i s h EG-6

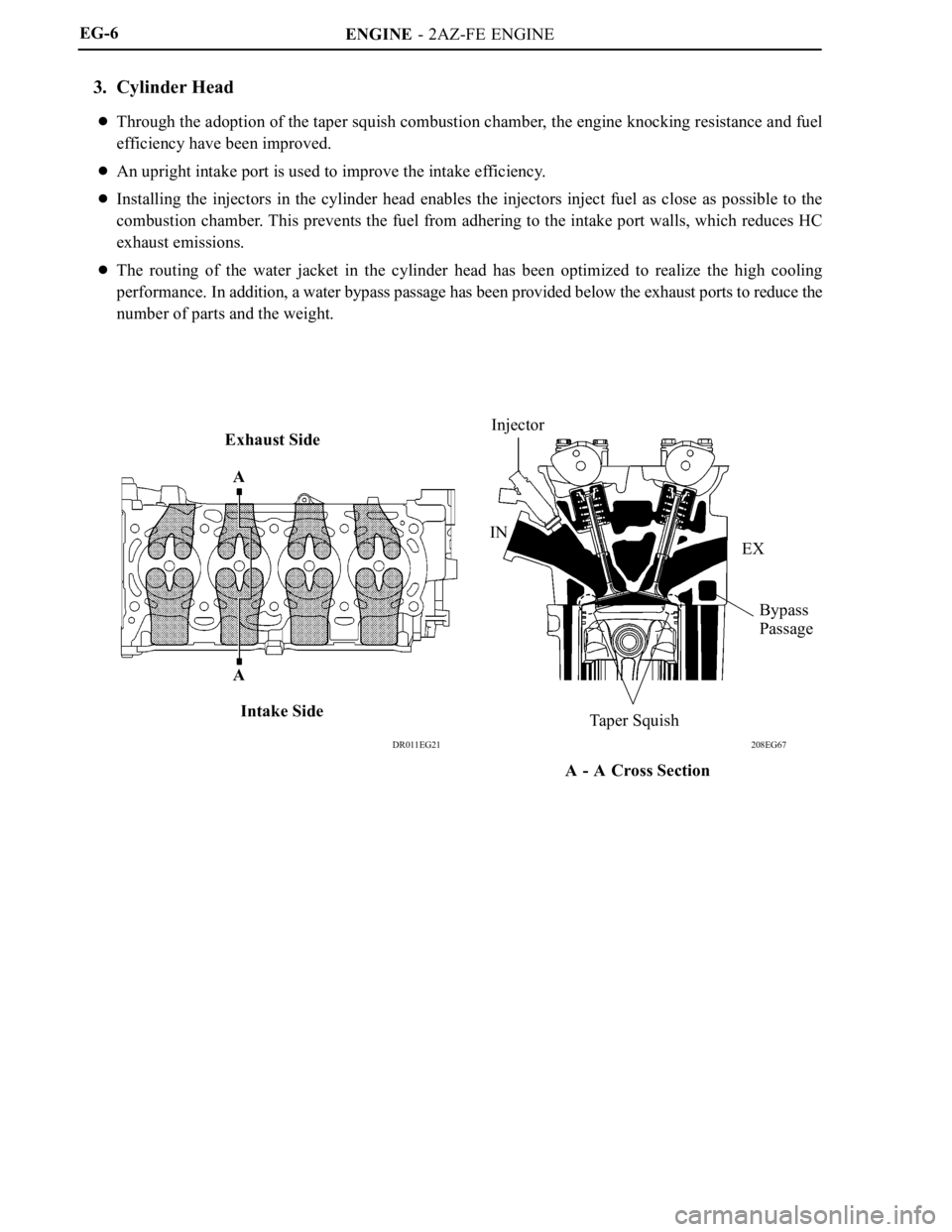

3. Cylinder Head

Through the adoption of the taper squish combustion chamber, the engine knocking resistance and fuel

efficiency have been improved.

An upright intake port is used to improve the intake efficiency.

Installing the injectors in the cylinder head enables the injectors inject fuel as close as possible to the

combustion chamber. This prevents the fuel from adhering to the intake port walls, which reduces HC

exhaust emissions.

The routing of the water jacket in the cylinder head has been optimized to realize the high cooling

performance. In addition, a water bypass passage has been provided below the exhaust ports to reduce the

number of parts and the weight.

Page 12 of 2000

ENGINE - 2AZ-FE ENGINE

01NEG34Y

Oil Jets

Check

Va l v e

Oil

Bottom Side View Oil Jet Cross SectionEG-15

Oil Capacity

Liters (US qts, Imp. qts)

Dry

5.0 (5.3, 4.4)

with Oil Filter4.3 (4.5, 3.8)

without Oil Filter4.1 (3.8, 3.1)

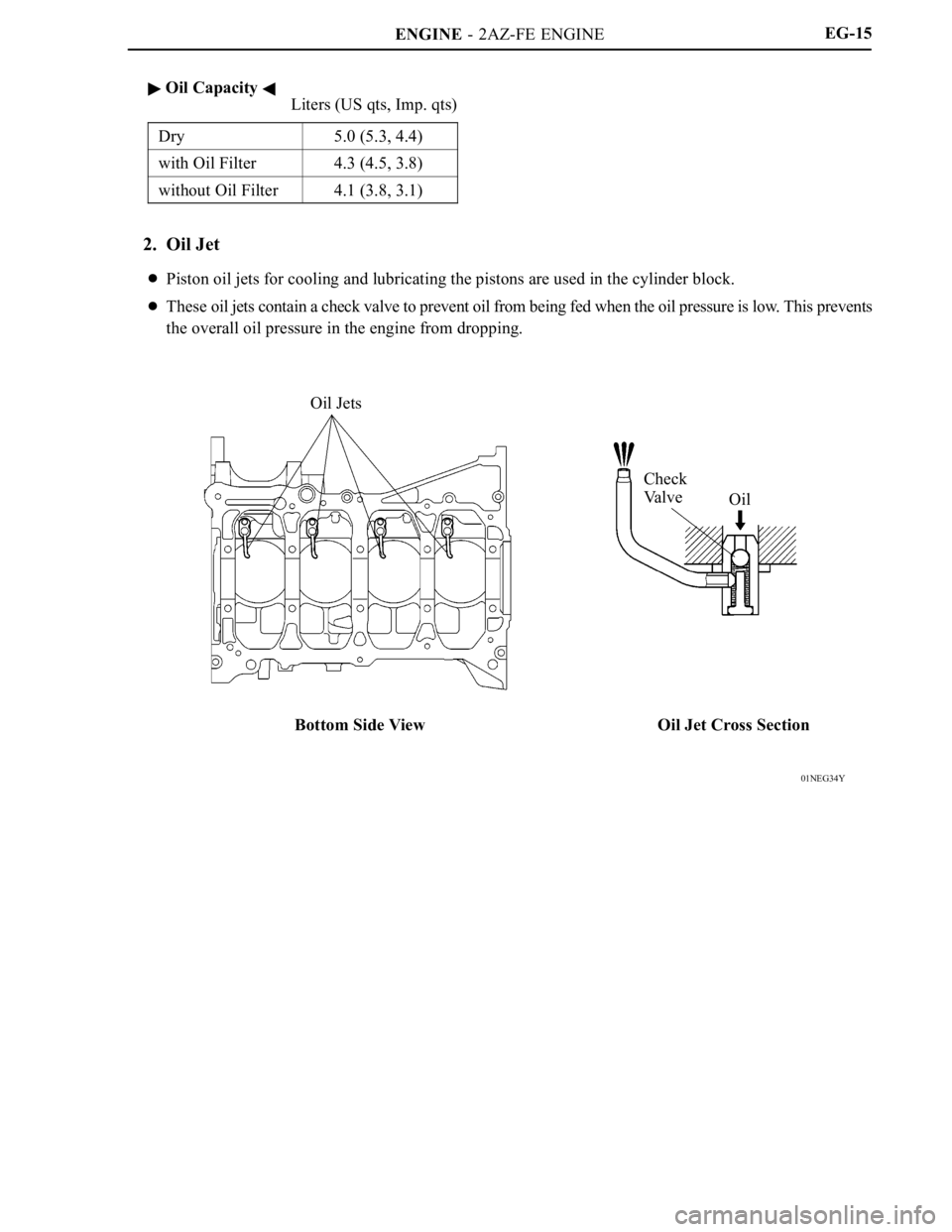

2. Oil Jet

Piston oil jets for cooling and lubricating the pistons are used in the cylinder block.

These oil jets contain a check valve to prevent oil from being fed when the oil pressure is low. This prevents

the overall oil pressure in the engine from dropping.

Page 13 of 2000

ENGINE - 2AZ-FE ENGINE

01NEG35Y

Throttle Body

To H e a t e r C o r e

To R a d i a t o r

Thermostat

From Radiator Wa t e r P u m pBypass Passage

01NEG59Y

Bypass PassageCylinder Head

Wa t e r P u m p

Cylinder Block

Thermostat

Reservoir

Ta n k

RadiatorThrottle

BodyHeater Core EG-16

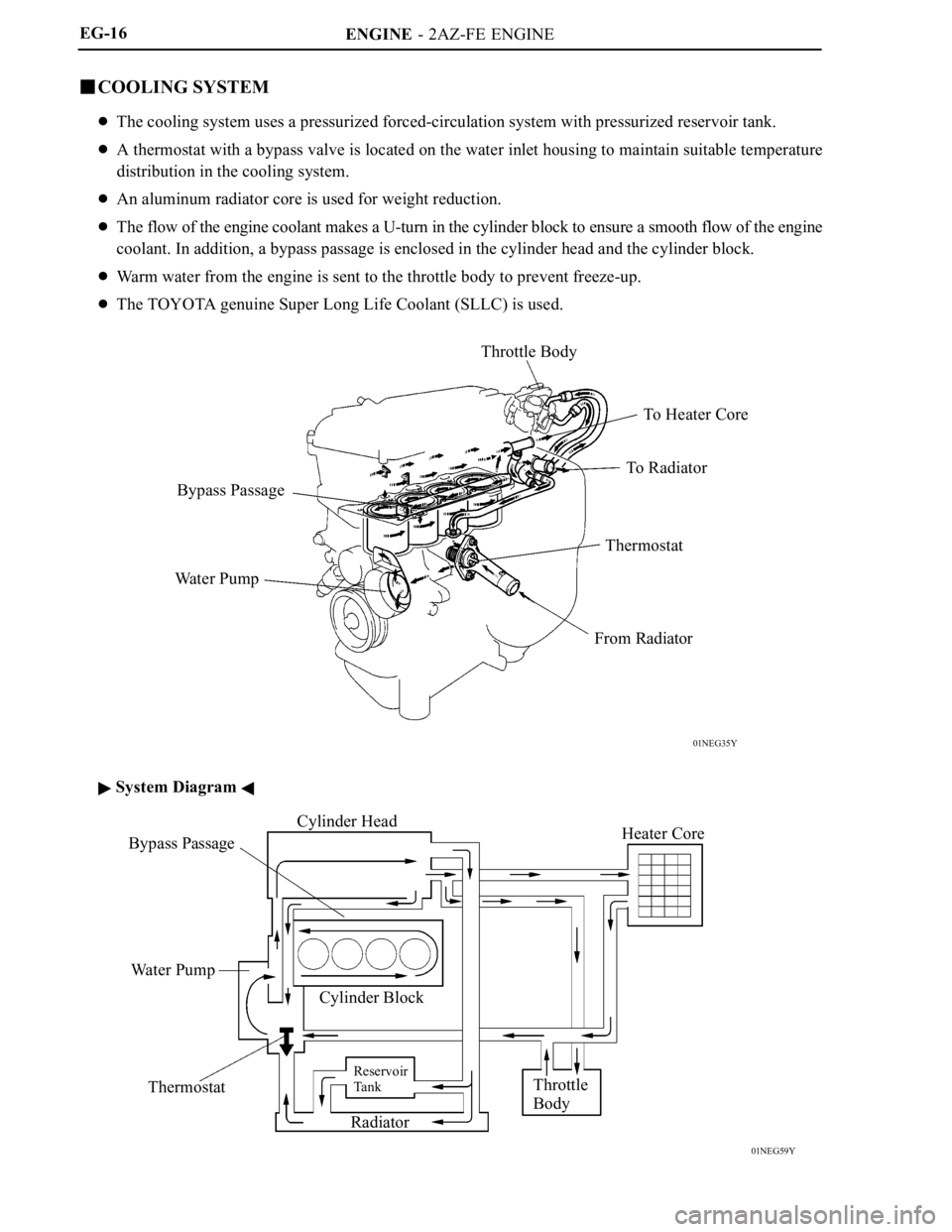

COOLING SYSTEM

The cooling system uses a pressurized forced-circulation system with pressurized reservoir tank.

A thermostat with a bypass valve is located on the water inlet housing to maintain suitable temperature

distribution in the cooling system.

An aluminum radiator core is used for weight reduction.

The flow of the engine coolant makes a U-turn in the cylinder block to ensure a smooth flow of the engine

coolant. In addition, a bypass passage is enclosed in the cylinder head and the cylinder block.

Warm water from the engine is sent to the throttle body to prevent freeze-up.

The TOYOTA genuine Super Long Life Coolant (SLLC) is used.

System Diagram

Page 27 of 2000

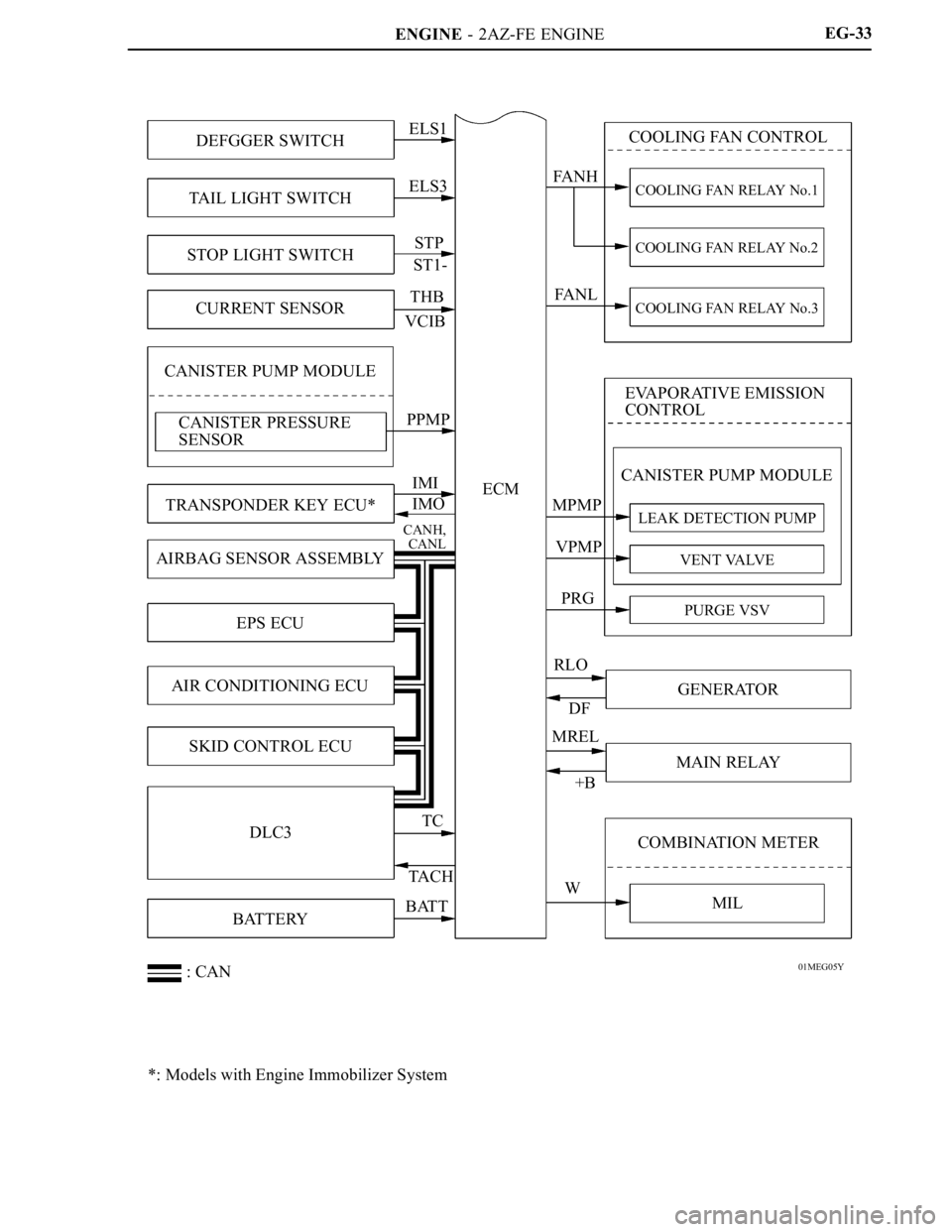

ENGINE - 2AZ-FE ENGINE EG-30

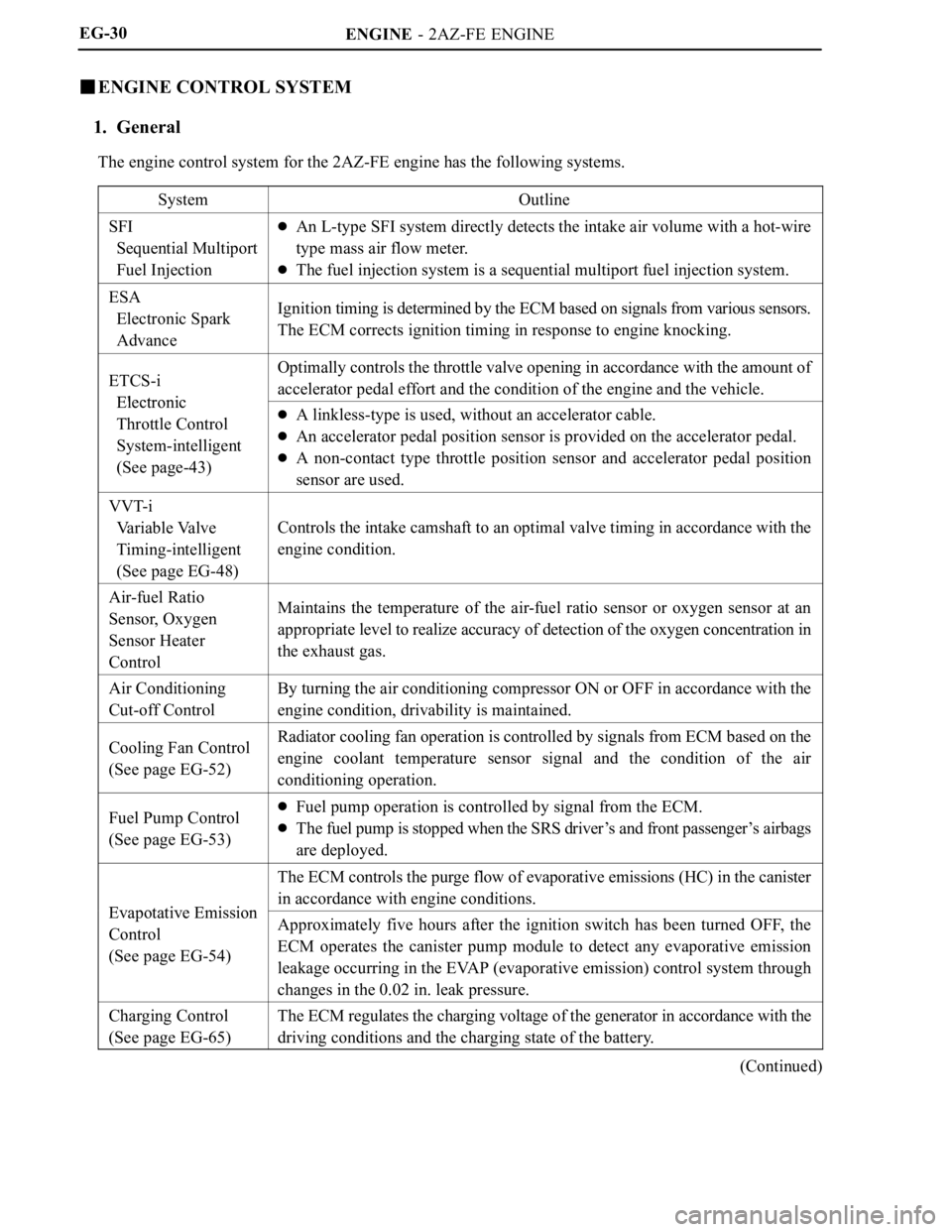

ENGINE CONTROL SYSTEM

1. General

The engine control system for the 2AZ-FE engine has the following systems.

System

Outline

SFI

Sequential Multiport

Fuel InjectionAn L-type SFI system directly detects the intake air volume with a hot-wire

type mass air flow meter.

The fuel injection system is a sequential multiport fuel injection system.

ESA

Electronic Spark

AdvanceIgnition timing is determined by the ECM based on signals from various sensors.

The ECM corrects ignition timing in response to engine knocking.

ETCS-i

Electronic

Optimally controls the throttle valve opening in accordance with the amount of

accelerator pedal effort and the condition of the engine and the vehicle.

Electronic

Throttle Control

System-intelligent

(See page-43)A linkless-type is used, without an accelerator cable.

An accelerator pedal position sensor is provided on the accelerator pedal.

A non-contact type throttle position sensor and accelerator pedal position

sensor are used.

VVT-i

Va r i a b l e Va l v e

Timing-intelligent

(See page EG-48)

Controls the intake camshaft to an optimal valve timing in accordance with the

engine condition.

Air-fuel Ratio

Sensor, Oxygen

Sensor Heater

ControlMaintains the temperature of the air-fuel ratio sensor or oxygen sensor at an

appropriate level to realize accuracy of detection of the oxygen concentration in

the exhaust gas.

Air Conditioning

Cut-off ControlBy turning the air conditioning compressor ON or OFF in accordance with the

engine condition, drivability is maintained.

Cooling Fan Control

(See page EG-52)Radiator cooling fan operation is controlled by signals from ECM based on the

engine coolant temperature sensor signal and the condition of the air

conditioning operation.

Fuel Pump Control

(See page EG-53)Fuel pump operation is controlled by signal from the ECM.

The fuel pump is stopped when the SRS driver’s and front passenger’s airbags

are deployed.

Evapotative Emission

The ECM controls the purge flow of evaporative emissions (HC) in the canister

in accordance with engine conditions.

Evapotative Emission

Control

(See page EG-54)Approximately five hours after the ignition switch has been turned OFF, the

ECM operates the canister pump module to detect any evaporative emission

leakage occurring in the EVAP (evaporative emission) control system through

changes in the 0.02 in. leak pressure.

Charging Control

(See page EG-65)The ECM regulates the charging voltage of the generator in accordance with the

driving conditions and the charging state of the battery.

(Continued)

Page 30 of 2000

ENGINE - 2AZ-FE ENGINE

01MEG05Y

DEFGGER SWITCH

TA I L L I G H T S W I T C H

STOP LIGHT SWITCH

CURRENT SENSOR

CANISTER PUMP MODULE

CANISTER PRESSURE

SENSOR

TRANSPONDER KEY ECU*

AIRBAG SENSOR ASSEMBLY

EPS ECU

AIR CONDITIONING ECU

SKID CONTROL ECU

DLC3

BATTERYELS1

ELS3

STP

ST1-

THB

VCIB

PPMP

IMI

IMO

CANH,

CANL

TC

TA C H

BATTECMFA N H

FA N L

MPMP

VPMP

PRG

RLO

DF

MREL

+B

WCOOLING FAN CONTROL

COOLING FAN RELAY No.1

COOLING FAN RELAY No.2

COOLING FAN RELAY No.3

EVAPORATIVE EMISSION

CONTROL

CANISTER PUMP MODULE

LEAK DETECTION PUMP

VENT VALVE

GENERATOR

MAIN RELAY

COMBINATION METER

MIL

PURGE VSV

: CANEG-33

*: Models with Engine Immobilizer System

Page 49 of 2000

ENGINE - 2AZ-FE ENGINE

01NEG09Y

01NEG10Y

Air

Conditioning

ECU

Engine Coolant

Temperature SensorFANL

ECM

FA N HCooling Fan

Relay No.3

Cooling Fan

Motor No.2

Cooling Fan

Relay No.1

Cooling Fan

Motor No.1

Low Speed (Series Connection)

High Speed (Parallel Connection) Air

Conditioning

ECU

Engine Coolant

Temperature SensorFA N L

ECM

FA N HCooling Fan

Relay No.3

Cooling Fan

Motor No.2

Cooling Fan

Relay No.1

Cooling Fan

Relay No.2

Cooling Fan

Motor No.1 : CAN

Cooling Fan

Relay No.2

EG-52

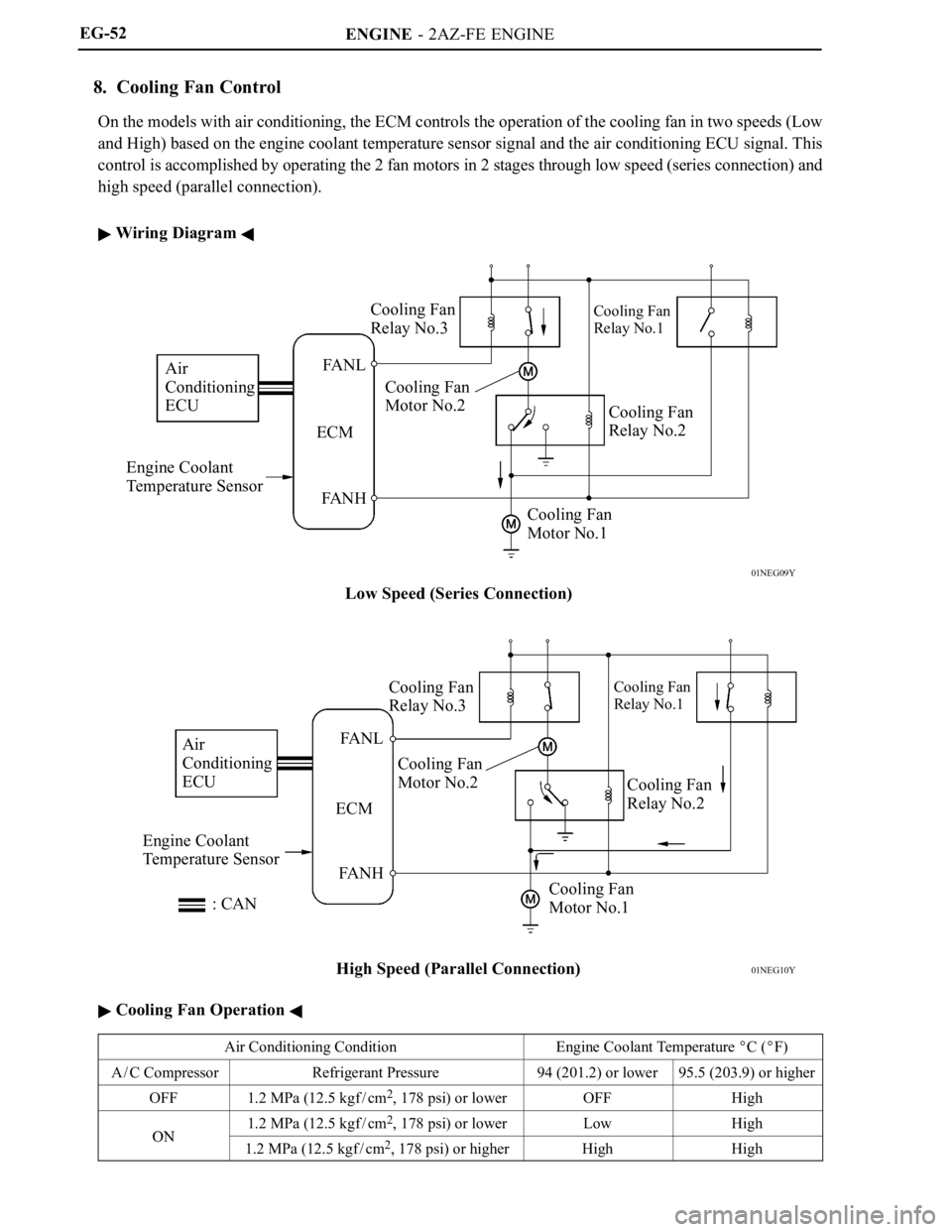

8. Cooling Fan Control

On the models with air conditioning, the ECM controls the operation of the cooling fan in two speeds (Low

and High) based on the engine coolant temperature sensor signal and the air conditioning ECU signal. This

control is accomplished by operating the 2 fan motors in 2 stages through low speed (series connection) and

high speed (parallel connection).

Wiring Diagram

Cooling Fan Operation

Air Conditioning ConditionEngine Coolant Temperature C (F)

A / C CompressorRefrigerant Pressure94 (201.2) or lower95.5 (203.9) or higher

OFF1.2 MPa (12.5 kgf / cm2, 178 psi) or lowerOFFHigh

ON1.2 MPa (12.5 kgf / cm2, 178 psi) or lowerLowHighON1.2 MPa (12.5 kgf / cm2, 178 psi) or higherHighHigh

Page 67 of 2000

ENGINE - 2GR-FE ENGINEEG-71

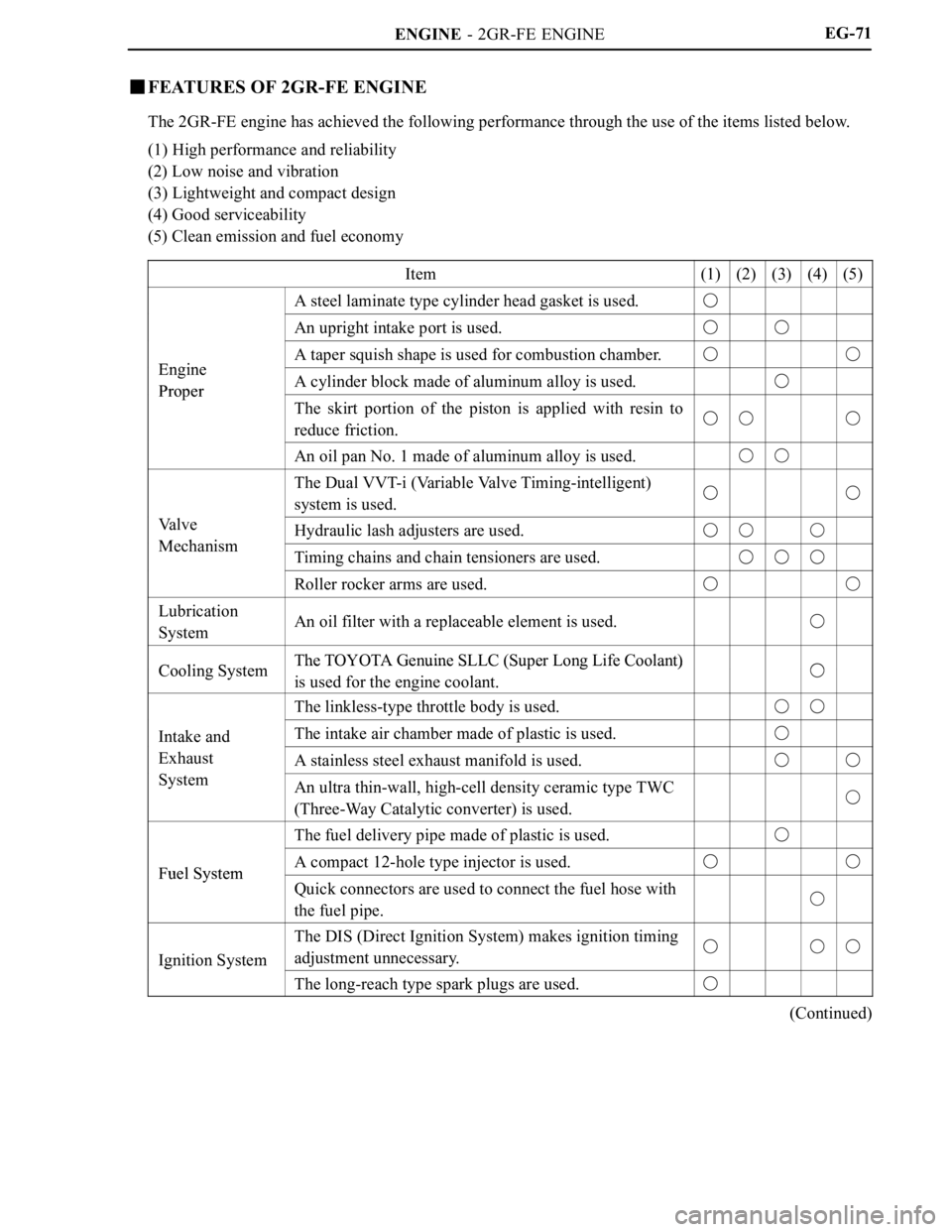

FEATURES OF 2GR-FE ENGINE

The 2GR-FE engine has achieved the following performance through the use of the items listed below.

(1) High performance and reliability

(2) Low noise and vibration

(3) Lightweight and compact design

(4) Good serviceability

(5) Clean emission and fuel economy

Item

(1)(2)(3)(4)(5)

A steel laminate type cylinder head gasket is used.

An upright intake port is used.

EngineA taper squish shape is used for combustion chamber.Engine

ProperA cylinder block made of aluminum alloy is used.Proper

The skirt portion of the piston is applied with resin to

reduce friction.

An oil pan No. 1 made of aluminum alloy is used.

The Dual VVT-i (Variable Valve Timing-intelligent)

system is used.

Va l v e

Mh i

Hydraulic lash adjusters are used.

MechanismTiming chains and chain tensioners are used.

Roller rocker arms are used.

Lubrication

SystemAn oil filter with a replaceable element is used.

Cooling SystemThe TOYOTA Genuine SLLC (Super Long Life Coolant)Cooling SystemThe TOYOTA Genuine SLLC (Super Long Life Coolant)

is used for the engine coolant.

The linkless-type throttle body is used.

Intake andThe intake air chamber made of plastic is used.Intake and

Exhaust

S

A stainless steel exhaust manifold is used.

SystemAn ultra thin-wall, high-cell density ceramic type TWC

(Three-Way Catalytic converter) is used.

The fuel delivery pipe made of plastic is used.

Fuel SystemA compact 12-hole type injector is used.Fuel SystemQuick connectors are used to connect the fuel hose with

the fuel pipe.

Ignition System

The DIS (Direct Ignition System) makes ignition timing

adjustment unnecessary.

Ignition System

The long-reach type spark plugs are used.

(Continued)

Page 79 of 2000

ENGINE - 2GR-FE ENGINE

285EG21

Timing Chain Cover

Wa t e r P u m p G a s k e t

Wa t e r P u m pWater Pump Swirl

Chamber

Oil Pump

Housing

Oil Pump RotorsTiming Chain

Cover

Oil Pump Chamber

View from Front Side View from Back Side

285EG22

Oil

Passage

Check Ball

Check Ball

Spring

Plunger SpringPlunger

Roller Rocker ArmCam

Oil

Passage

Hydraulic

Lash Adjuster

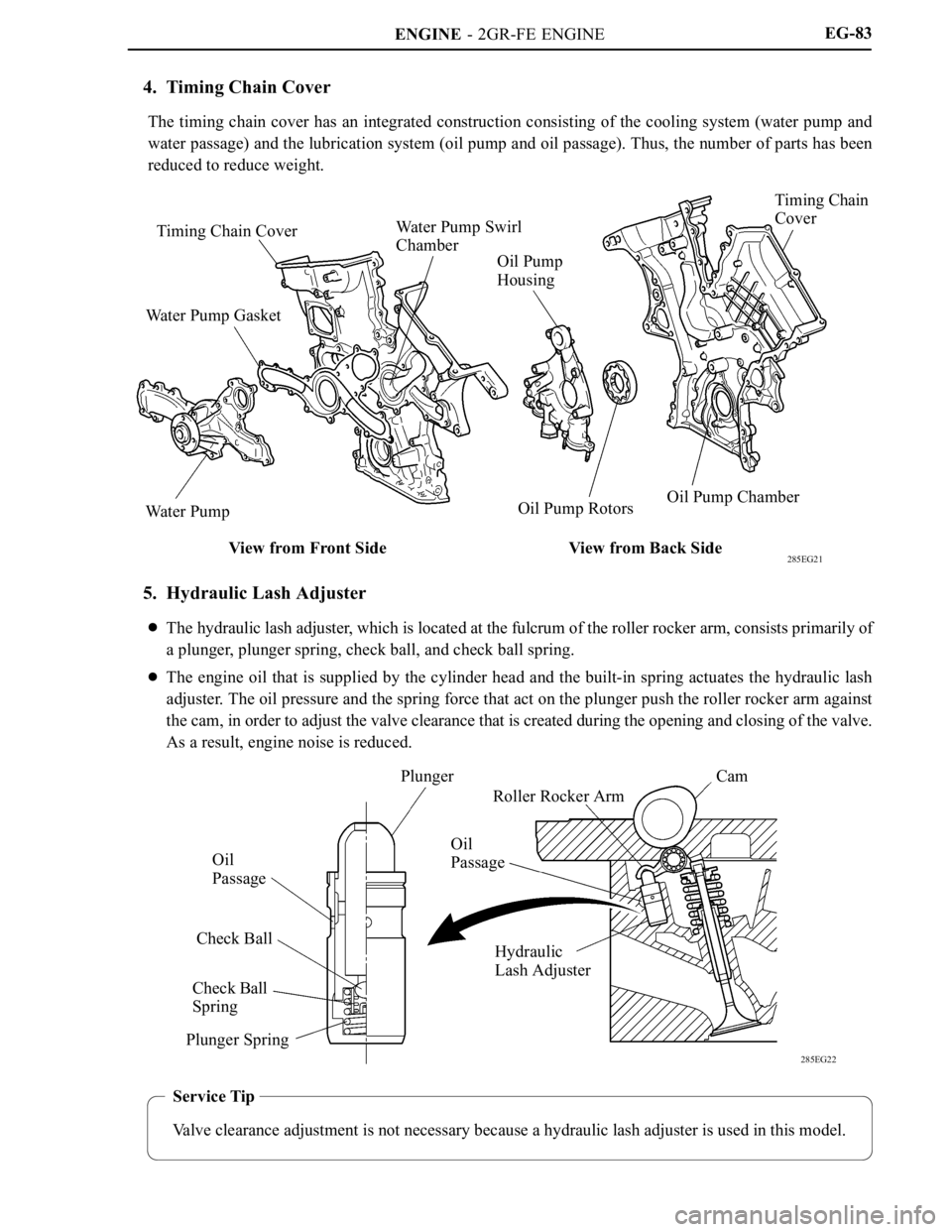

Service Tip

Valve clearance adjustment is not necessary because a hydraulic lash adjuster is used in this model.

EG-83

4. Timing Chain Cover

The timing chain cover has an integrated construction consisting of the cooling system (water pump and

water passage) and the lubrication system (oil pump and oil passage). Thus, the number of parts has been

reduced to reduce weight.

5. Hydraulic Lash Adjuster

The hydraulic lash adjuster, which is located at the fulcrum of the roller rocker arm, consists primarily of

a plunger, plunger spring, check ball, and check ball spring.

The engine oil that is supplied by the cylinder head and the built-in spring actuates the hydraulic lash

adjuster. The oil pressure and the spring force that act on the plunger push the roller rocker arm against

the cam, in order to adjust the valve clearance that is created during the opening and closing of the valve.

As a result, engine noise is reduced.

Page 82 of 2000

ENGINE - 2GR-FE ENGINE

285EG24

Timing Chain Cover

Oil Pump

Housing

Oil Pump Rotors

(Cycloid Rotor)Crankshaft

To Cylinder

Block

From Oil

Filter

To

Oil FilterFrom

Oil Strainer

Oil passage in the oil pump

285EG25

Oil Jet Cross Section

Oil JetsCheck

Va l v eEngine Oil EG-86

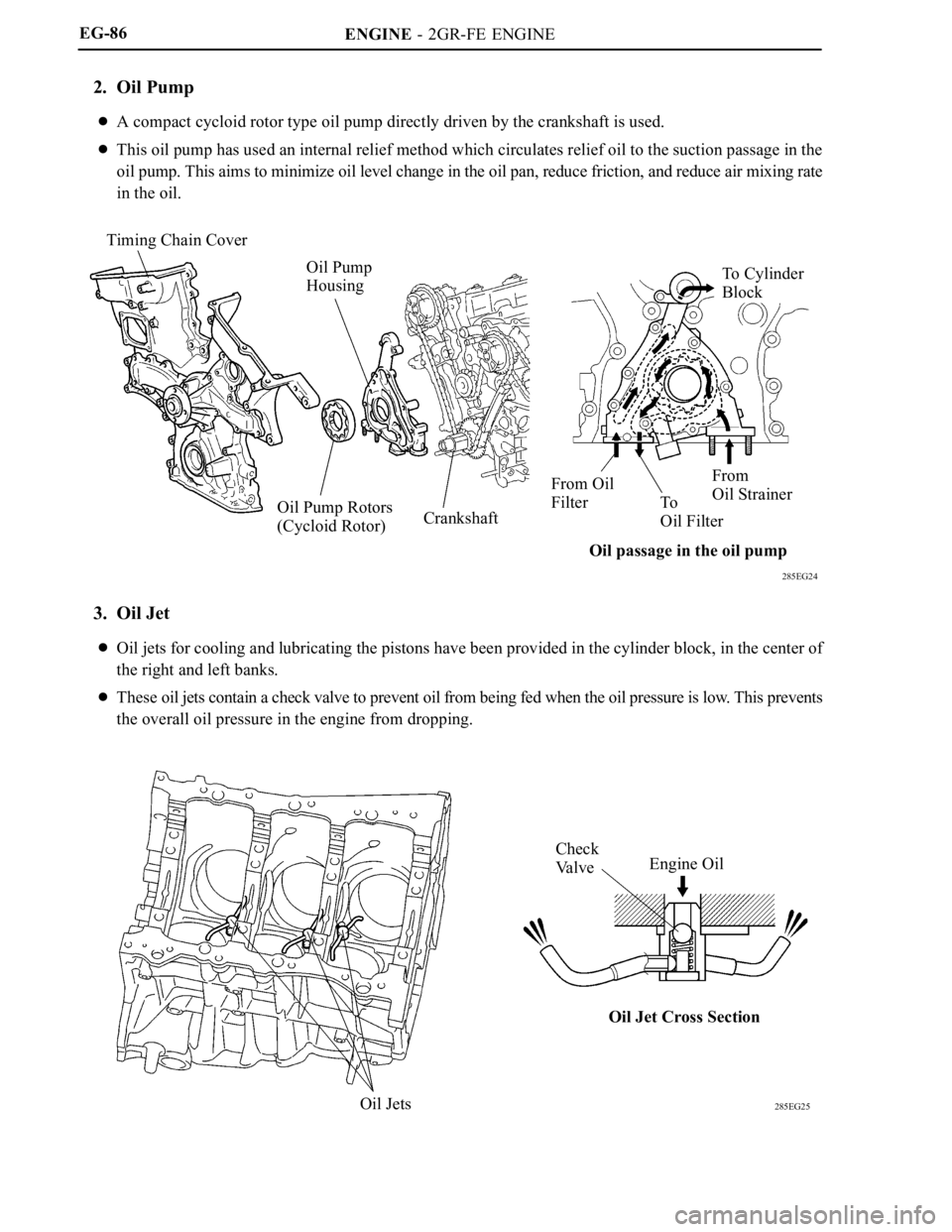

2. Oil Pump

A compact cycloid rotor type oil pump directly driven by the crankshaft is used.

This oil pump has used an internal relief method which circulates relief oil to the suction passage in the

oil pump. This aims to minimize oil level change in the oil pan, reduce friction, and reduce air mixing rate

in the oil.

3. Oil Jet

Oil jets for cooling and lubricating the pistons have been provided in the cylinder block, in the center of

the right and left banks.

These oil jets contain a check valve to prevent oil from being fed when the oil pressure is low. This prevents

the overall oil pressure in the engine from dropping.

Page 84 of 2000

ENGINE - 2GR-FE ENGINE

285EG27

Air Bleeder PlugTo Throttle Body

From Throttle Body

To H e a t e r

From Heater

To Radiator

From Radiator Thermostat

Opening Temperature:

80 - 84

C (176 - 183F)

01MEG35Y

ThermostatBypass Pipe

Heater Return Pipe

Air Bleeder Plug

Cylinder Head

Cylinder Block

Wa t e r P u m p

Radiator

Throttle

Body

Heater

Reservoir

Ta n k

EG-88

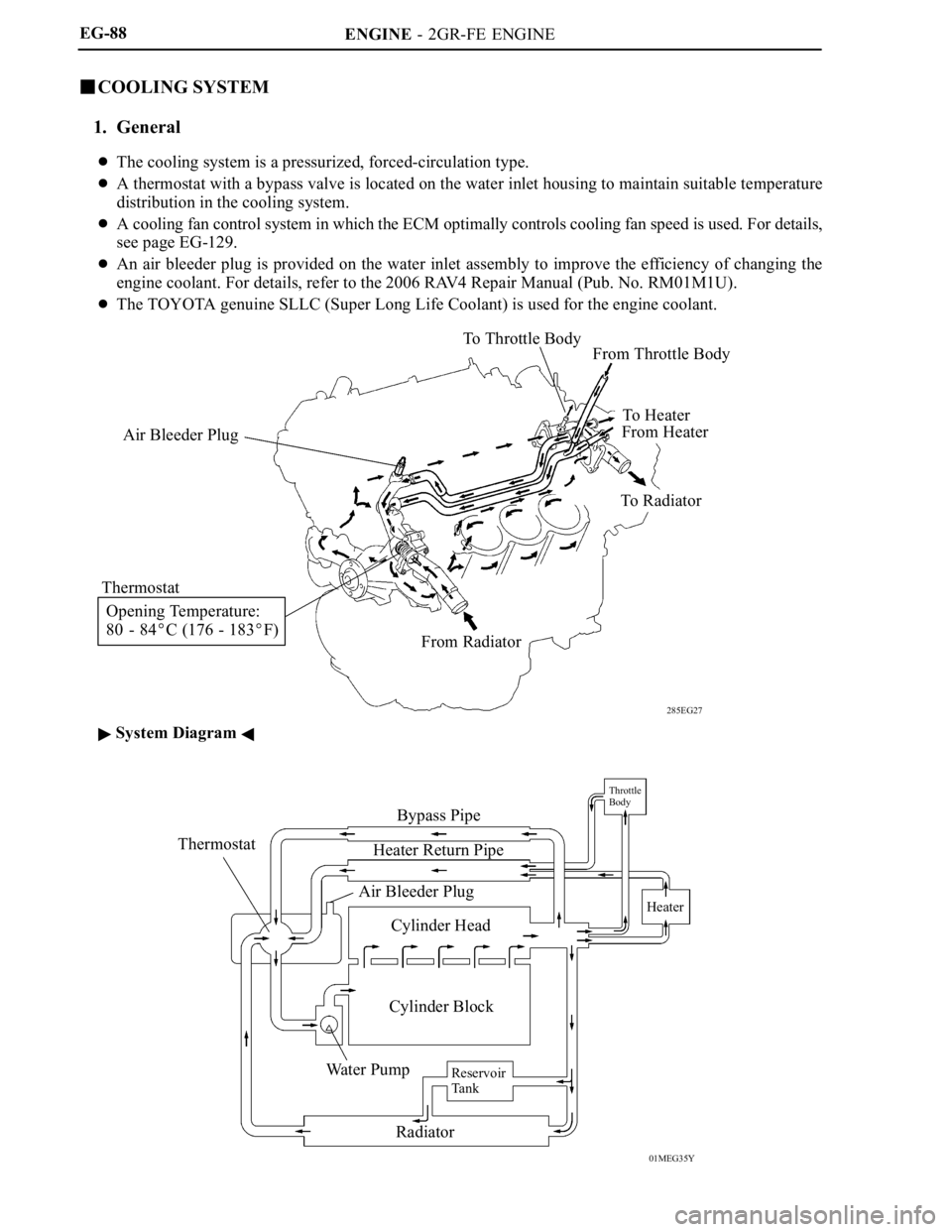

COOLING SYSTEM

1. General

The cooling system is a pressurized, forced-circulation type.

A thermostat with a bypass valve is located on the water inlet housing to maintain suitable temperature

distribution in the cooling system.

A cooling fan control system in which the ECM optimally controls cooling fan speed is used. For details,

see page EG-129.

An air bleeder plug is provided on the water inlet assembly to improve the efficiency of changing the

engine coolant. For details, refer to the 2006 RAV4 Repair Manual (Pub. No. RM01M1U).

The TOYOTA genuine SLLC (Super Long Life Coolant) is used for the engine coolant.

System Diagram