light TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1 of 2000

ENGINE - 2AZ-FE ENGINE EG-4

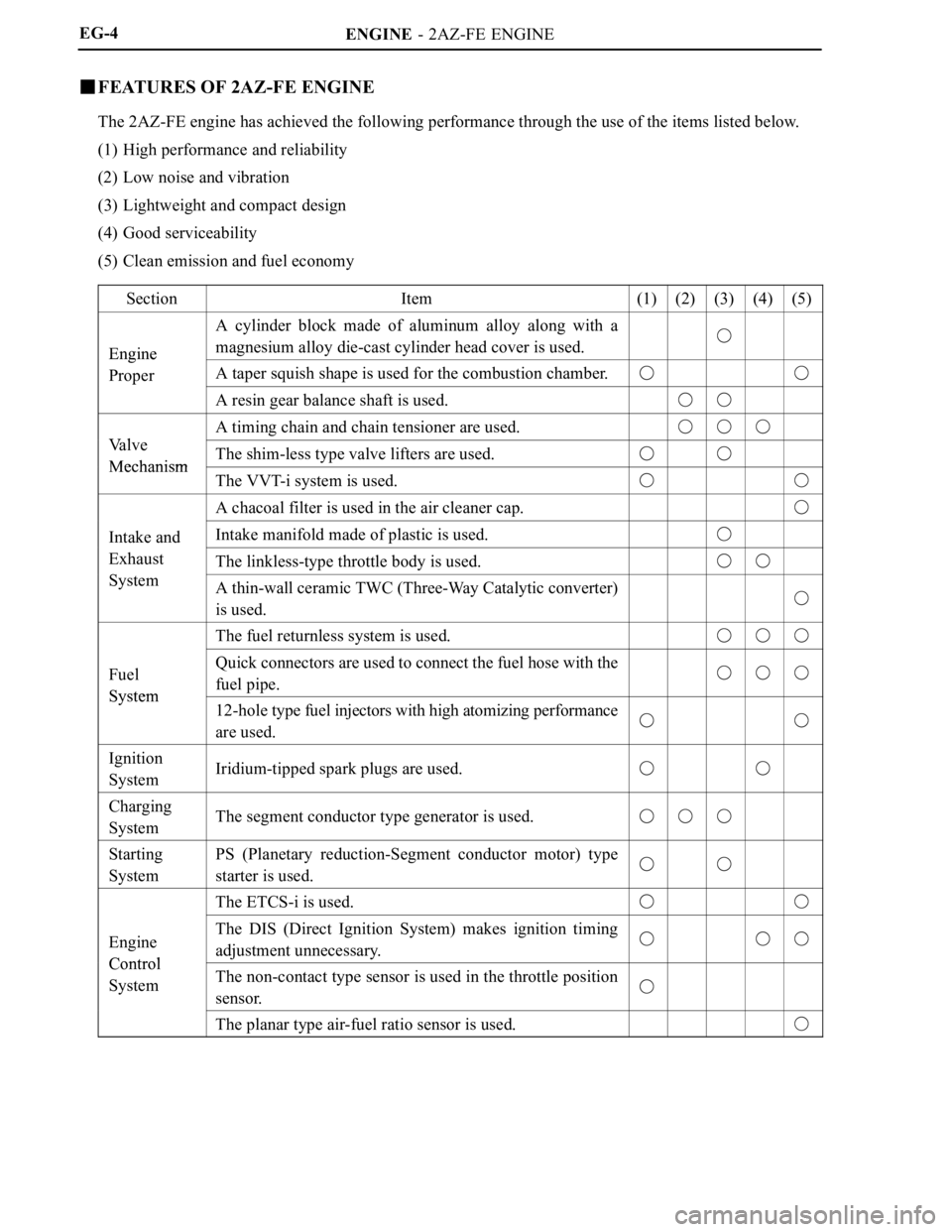

FEATURES OF 2AZ-FE ENGINE

The 2AZ-FE engine has achieved the following performance through the use of the items listed below.

(1) High performance and reliability

(2) Low noise and vibration

(3) Lightweight and compact design

(4) Good serviceability

(5) Clean emission and fuel economy

Section

Item(1)(2)(3)(4)(5)

Engine

A cylinder block made of aluminum alloy along with a

magnesium alloy die-cast cylinder head cover is used.

Engine

ProperA taper squish shape is used for the combustion chamber.p

A resin gear balance shaft is used.

Vl

A timing chain and chain tensioner are used.

Va l v e

MechanismThe shim-less type valve lifters are used.MechanismThe VVT-i system is used.

A chacoal filter is used in the air cleaner cap.

Intake andIntake manifold made of plastic is used.Intake and

ExhaustThe linkless-type throttle body is used.

SystemA thin-wall ceramic TWC (Three-Way Catalytic converter)

is used.

The fuel returnless system is used.

Fuel

System

Quick connectors are used to connect the fuel hose with the

fuel pipe.

System12-hole type fuel injectors with high atomizing performance

are used.

Ignition

SystemIridium-tipped spark plugs are used.

Charging

SystemThe segment conductor type generator is used.

Starting

SystemPS (Planetary reduction-Segment conductor motor) type

starter is used.

The ETCS-i is used.

Engine

Control

The DIS (Direct Ignition System) makes ignition timing

adjustment unnecessary.

Control

SystemThe non-contact type sensor is used in the throttle position

sensor.

The planar type air-fuel ratio sensor is used.

Page 2 of 2000

ENGINE - 2AZ-FE ENGINE

DR011EG20

Cylinder Head Cover

Cylinder Head Cover Gasket

02AEG02Y 02AEG01Y

Cylinder

Bore Side

FrontOuter

Side

Shim A

A

A - A Cross SectionEG-5

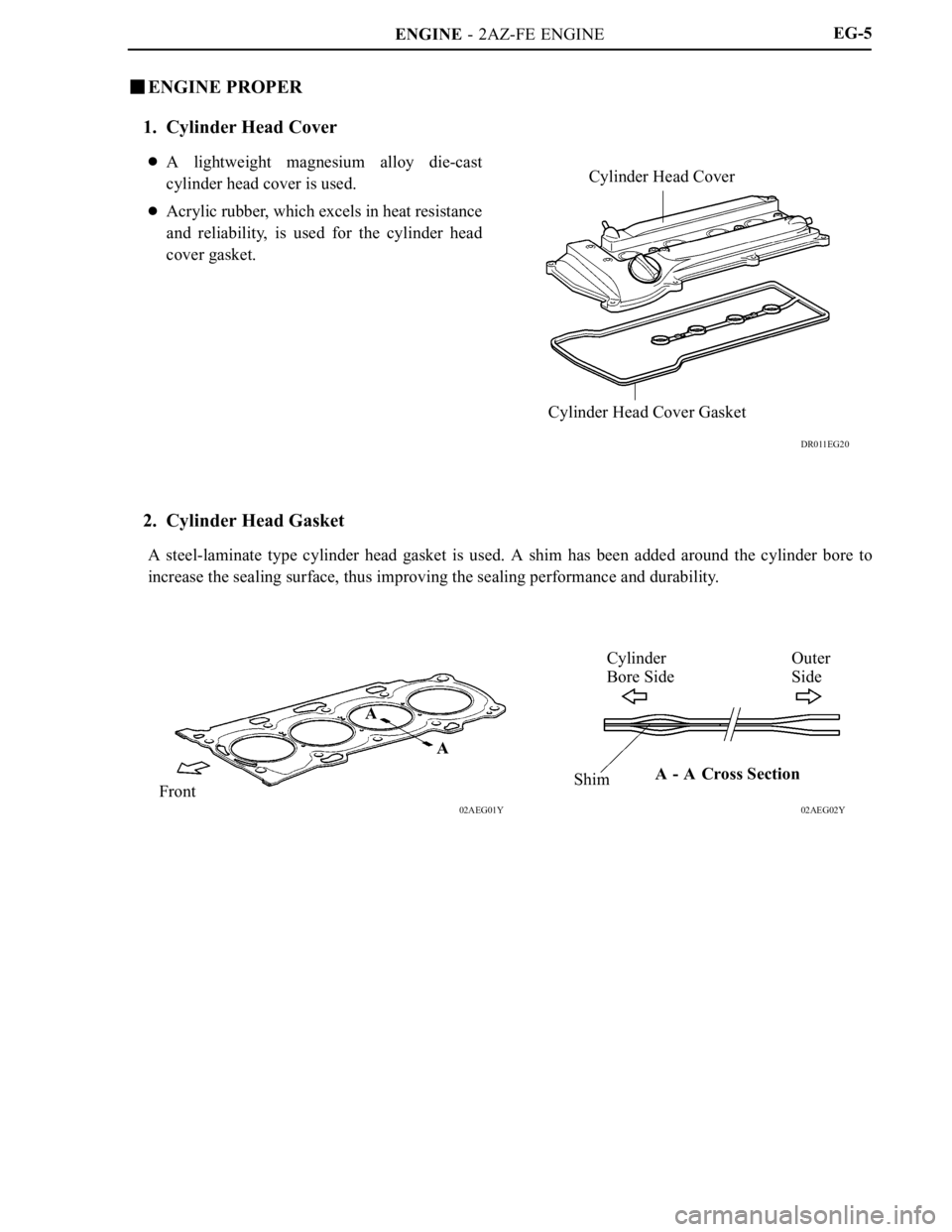

ENGINE PROPER

1. Cylinder Head Cover

A lightweight magnesium alloy die-cast

cylinder head cover is used.

Acrylic rubber, which excels in heat resistance

and reliability, is used for the cylinder head

cover gasket.

2. Cylinder Head Gasket

A steel-laminate type cylinder head gasket is used. A shim has been added around the cylinder bore to

increase the sealing surface, thus improving the sealing performance and durability.

Page 4 of 2000

ENGINE - 2AZ-FE ENGINE

DR011EG22 01NEG26Y

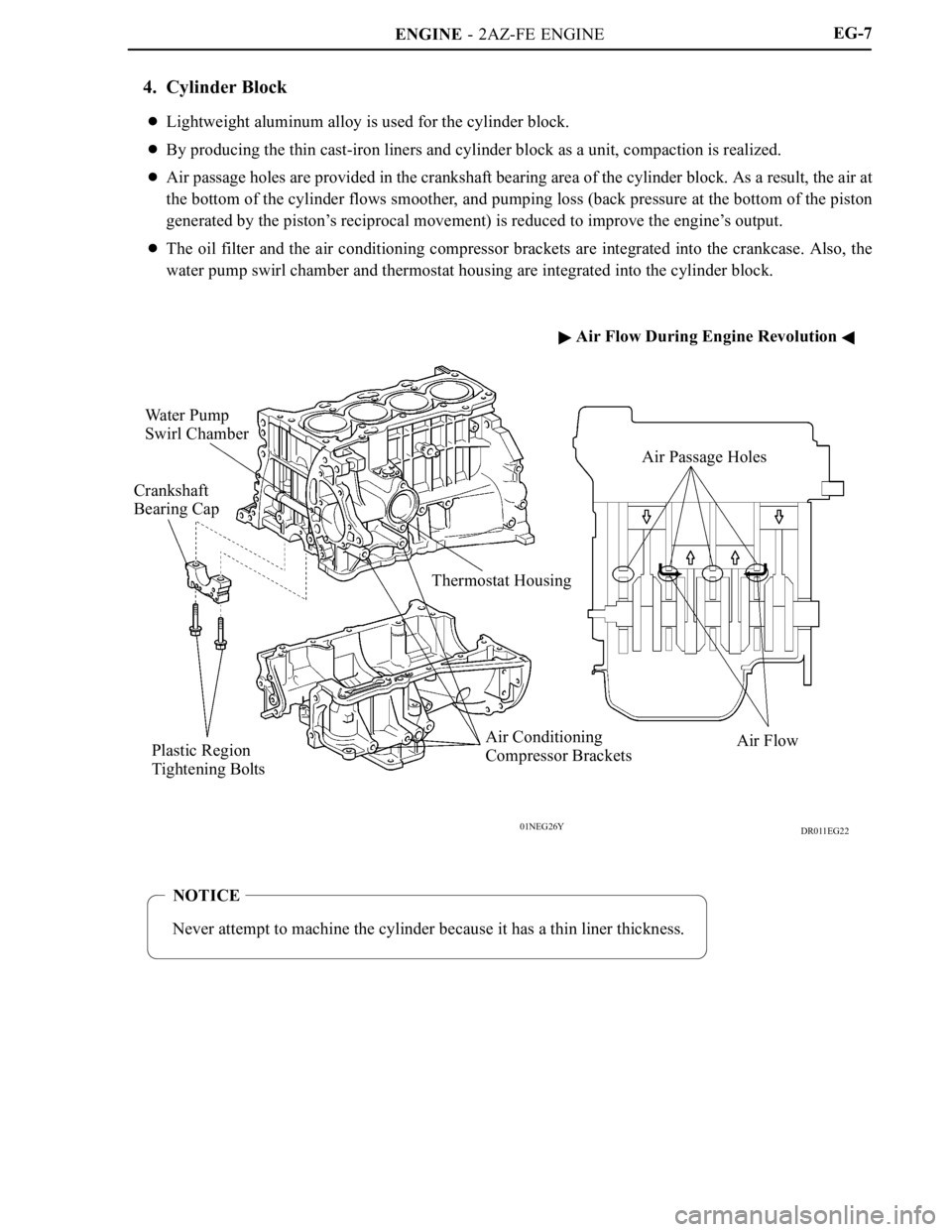

Air Flow During Engine Revolution

Wa t e r P u m p

Swirl Chamber

Crankshaft

Bearing Cap

Plastic Region

Tightening BoltsThermostat Housing

Air Conditioning

Compressor BracketsAir Passage Holes

Air Flow

NOTICE

Never attempt to machine the cylinder because it has a thin liner thickness.

EG-7

4. Cylinder Block

Lightweight aluminum alloy is used for the cylinder block.

By producing the thin cast-iron liners and cylinder block as a unit, compaction is realized.

Air passage holes are provided in the crankshaft bearing area of the cylinder block. As a result, the air at

the bottom of the cylinder flows smoother, and pumping loss (back pressure at the bottom of the piston

generated by the piston’s reciprocal movement) is reduced to improve the engine’s output.

The oil filter and the air conditioning compressor brackets are integrated into the crankcase. Also, the

water pump swirl chamber and thermostat housing are integrated into the cylinder block.

Page 6 of 2000

ENGINE - 2AZ-FE ENGINE

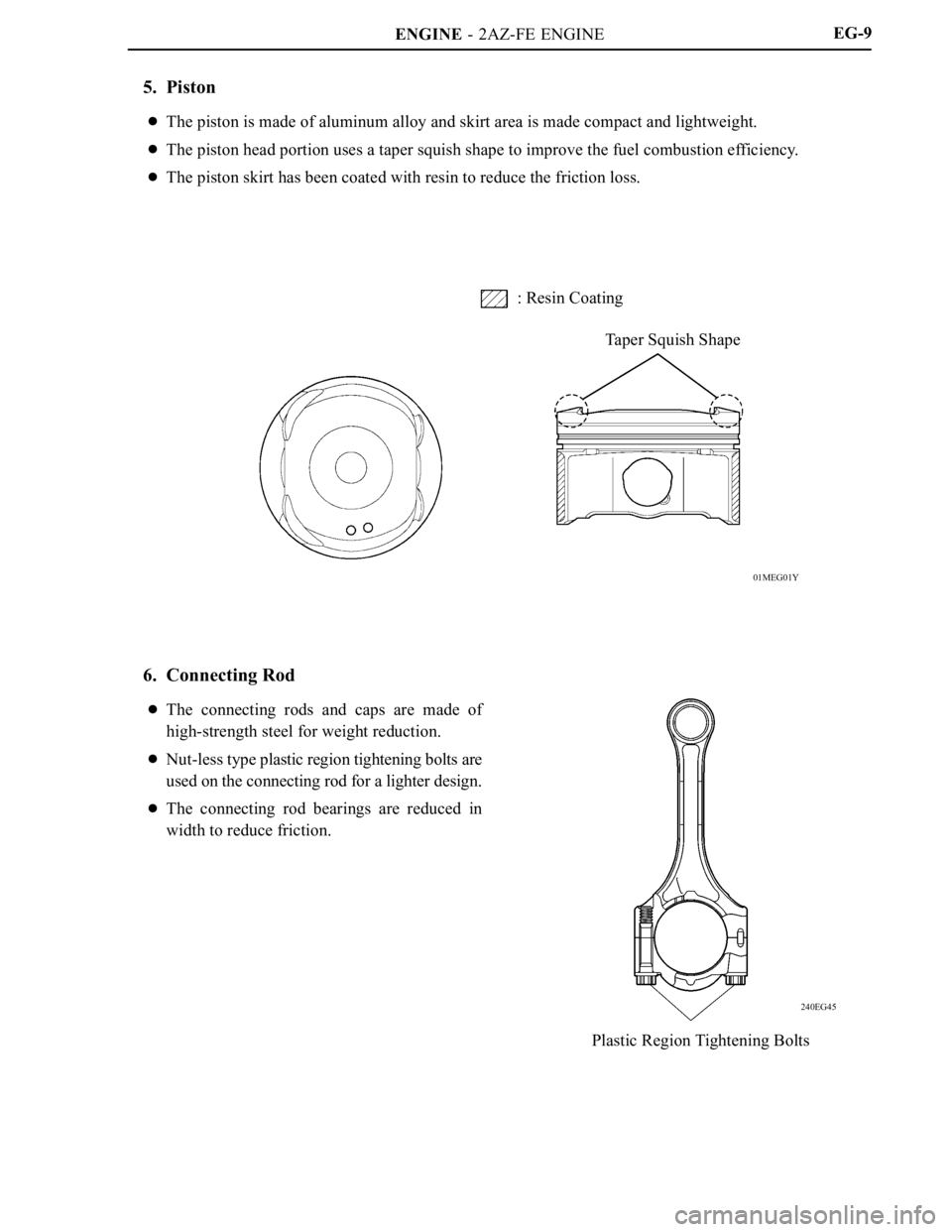

01MEG01Y

Taper Squish Shape : Resin Coating

240EG45

Plastic Region Tightening BoltsEG-9

5. Piston

The piston is made of aluminum alloy and skirt area is made compact and lightweight.

The piston head portion uses a taper squish shape to improve the fuel combustion efficiency.

The piston skirt has been coated with resin to reduce the friction loss.

6. Connecting Rod

The connecting rods and caps are made of

high-strength steel for weight reduction.

Nut-less type plastic region tightening bolts are

used on the connecting rod for a lighter design.

The connecting rod bearings are reduced in

width to reduce friction.

Page 7 of 2000

ENGINE - 2AZ-FE ENGINE

01NEG31Y

No.1 JournalBalance Shaft Drive Gear

Oil Hole

Crank Pin

Balance Weight

01NEG32Y

: Resin Gear

Balance Shaft

HousingBalance Shaft No.1 Balance Shaft No.2Crankshaft

Balance Shaft Drive Gear EG-10

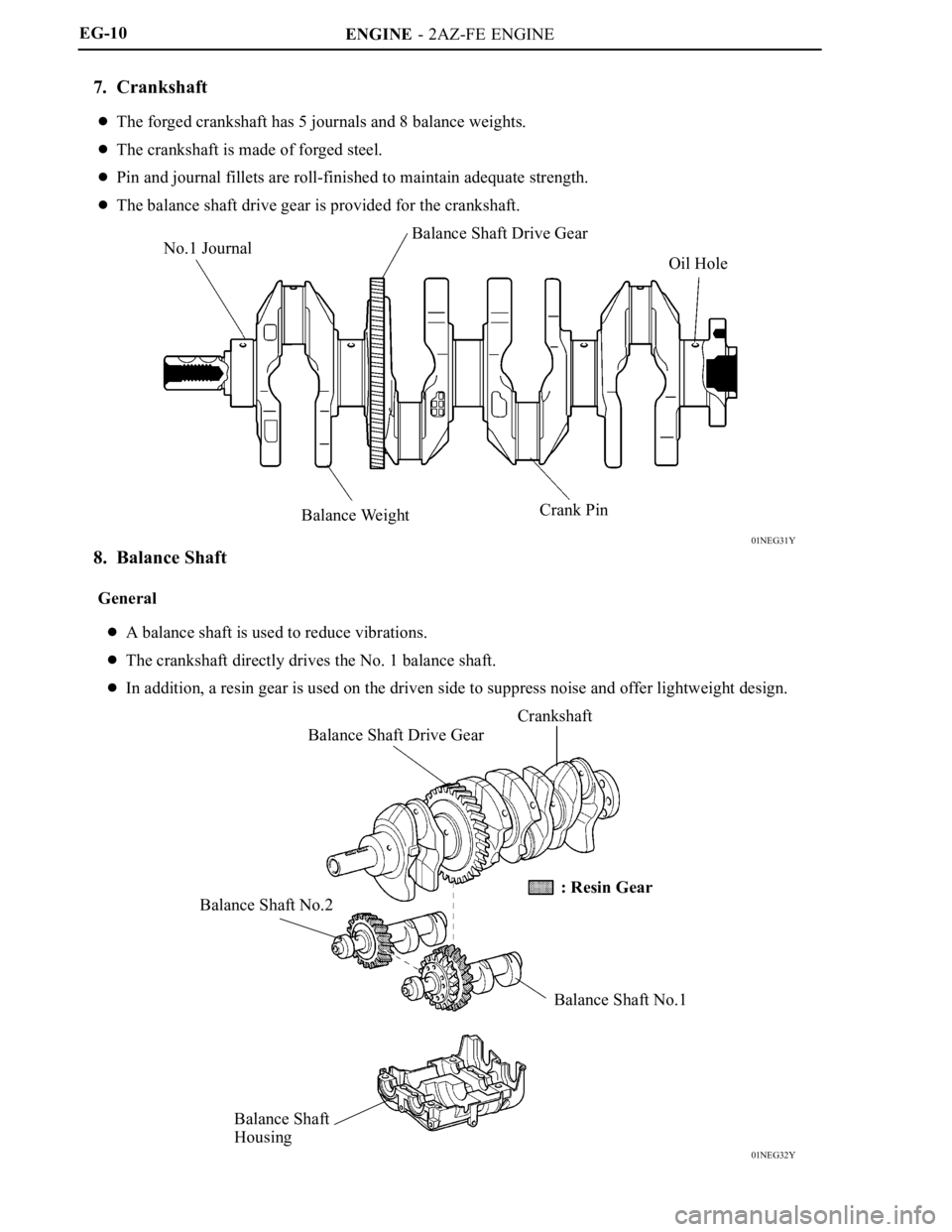

7. Crankshaft

The forged crankshaft has 5 journals and 8 balance weights.

The crankshaft is made of forged steel.

Pin and journal fillets are roll-finished to maintain adequate strength.

The balance shaft drive gear is provided for the crankshaft.

8. Balance Shaft

General

A balance shaft is used to reduce vibrations.

The crankshaft directly drives the No. 1 balance shaft.

In addition, a resin gear is used on the driven side to suppress noise and offer lightweight design.

Page 20 of 2000

ENGINE - 2AZ-FE ENGINE

185EG16

Pulsation

Dumper

Pressure Regulator

Fuel Pump

AssemblyFuel Tank

Fuel Filter

Fuel Pump

DR011EG18

EG-23

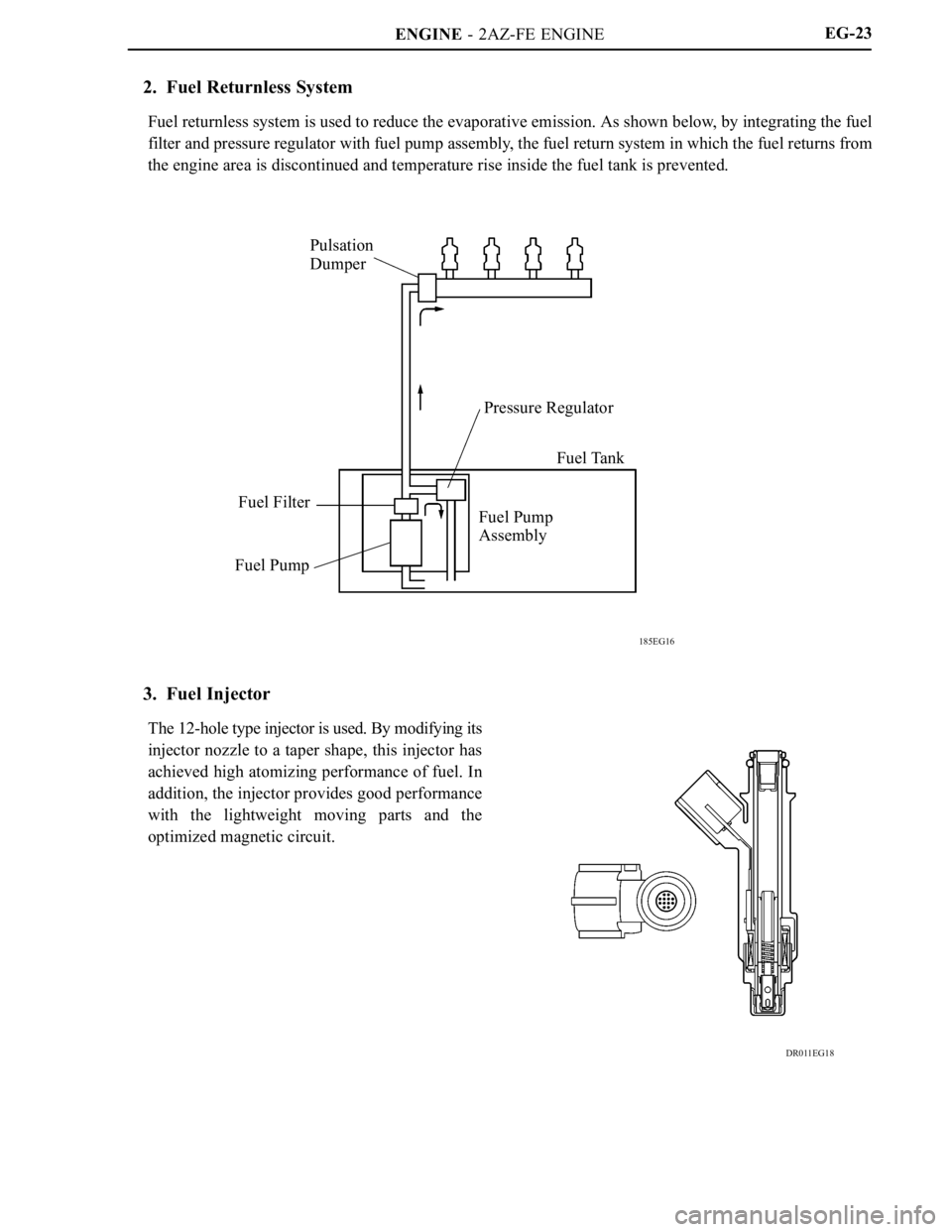

2. Fuel Returnless System

Fuel returnless system is used to reduce the evaporative emission. As shown below, by integrating the fuel

filter and pressure regulator with fuel pump assembly, the fuel return system in which the fuel returns from

the engine area is discontinued and temperature rise inside the fuel tank is prevented.

3. Fuel Injector

The 12-hole type injector is used. By modifying its

injector nozzle to a taper shape, this injector has

achieved high atomizing performance of fuel. In

addition, the injector provides good performance

with the lightweight moving parts and the

optimized magnetic circuit.

Page 22 of 2000

ENGINE - 2AZ-FE ENGINE

206EG40206EG41

206EG42

Stator Segment

ConductorStator

Joined

Joined Segment

Conductor SystemSegment

ConductorStator

StatorConductor

Wire

Conductor Wire

A

AA - A Cross

Section

Segment Conductor Type GeneratorB

BB - B Cross

Section

Conventional Type GeneratorWinding System

Stator

Segment

Conductor

Cross Section

Stator of Segment Conductor Type GeneratorEG-25

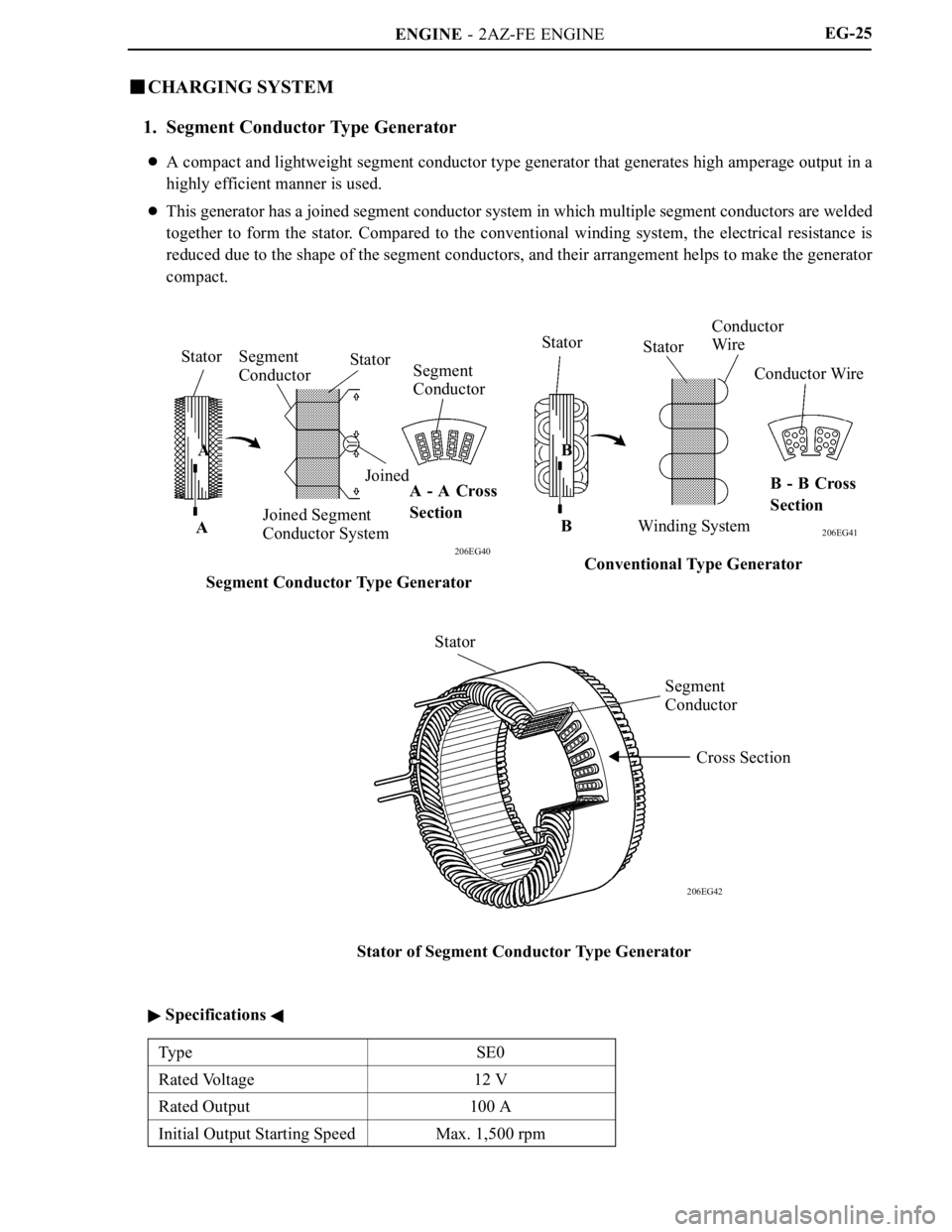

CHARGING SYSTEM

1. Segment Conductor Type Generator

A compact and lightweight segment conductor type generator that generates high amperage output in a

highly efficient manner is used.

This generator has a joined segment conductor system in which multiple segment conductors are welded

together to form the stator. Compared to the conventional winding system, the electrical resistance is

reduced due to the shape of the segment conductors, and their arrangement helps to make the generator

compact.

Specifications

Ty p eSE0

Rated Voltage12 V

Rated Output100 A

Initial Output Starting SpeedMax. 1,500 rpm

Page 24 of 2000

ENGINE - 2AZ-FE ENGINE

01NEG46Y

ArmatureSurface Commutator

Permanent Magnet

Brush

LengthEG-27

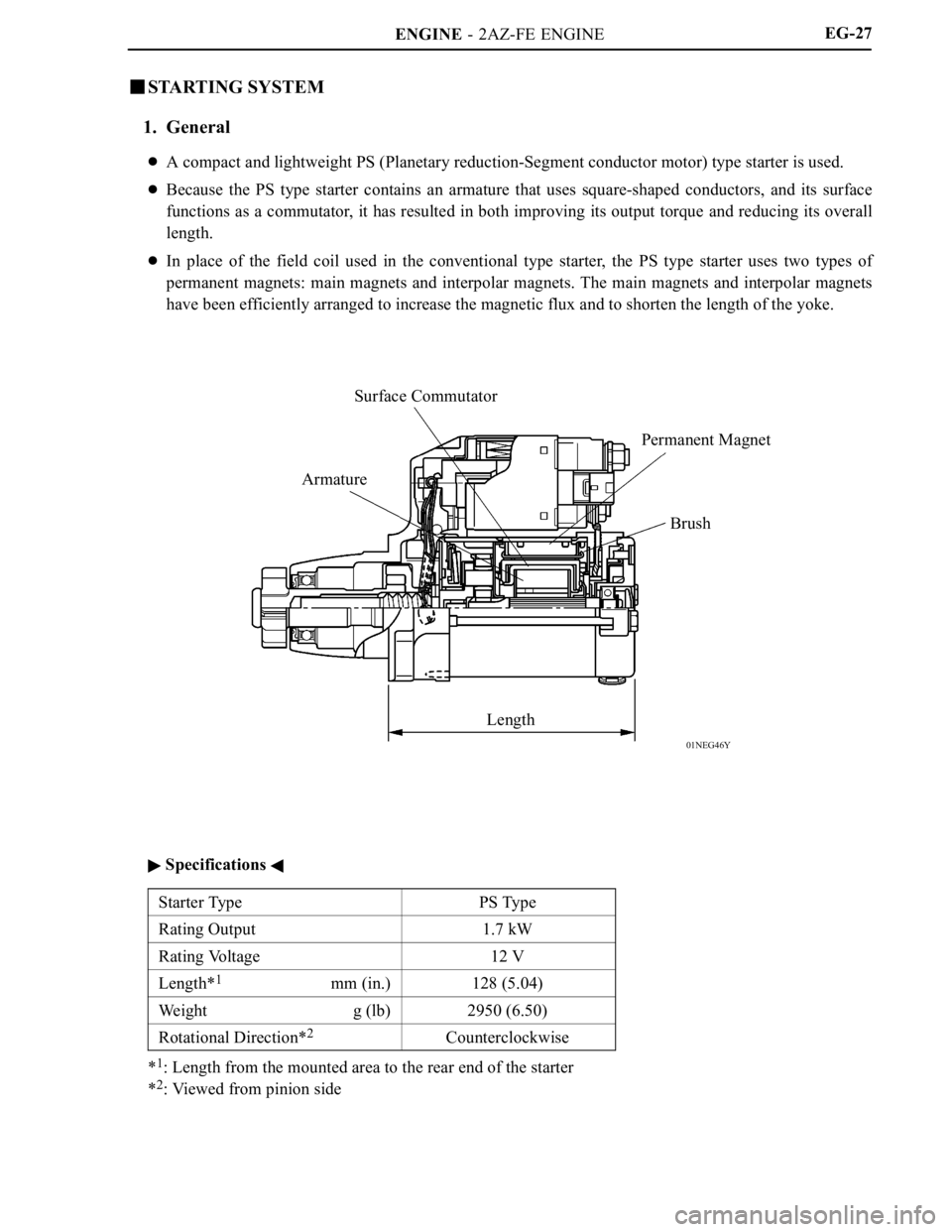

STARTING SYSTEM

1. General

A compact and lightweight PS (Planetary reduction-Segment conductor motor) type starter is used.

Because the PS type starter contains an armature that uses square-shaped conductors, and its surface

functions as a commutator, it has resulted in both improving its output torque and reducing its overall

length.

In place of the field coil used in the conventional type starter, the PS type starter uses two types of

permanent magnets: main magnets and interpolar magnets. The main magnets and interpolar magnets

have been efficiently arranged to increase the magnetic flux and to shorten the length of the yoke.

Specifications

Starter TypePS Type

Rating Output1.7 kW

Rating Voltage12 V

Length*1mm (in.)128 (5.04)

Weight g (lb)2950 (6.50)

Rotational Direction*2Counterclockwise

*1: Length from the mounted area to the rear end of the starter

*

2: Viewed from pinion side

Page 30 of 2000

ENGINE - 2AZ-FE ENGINE

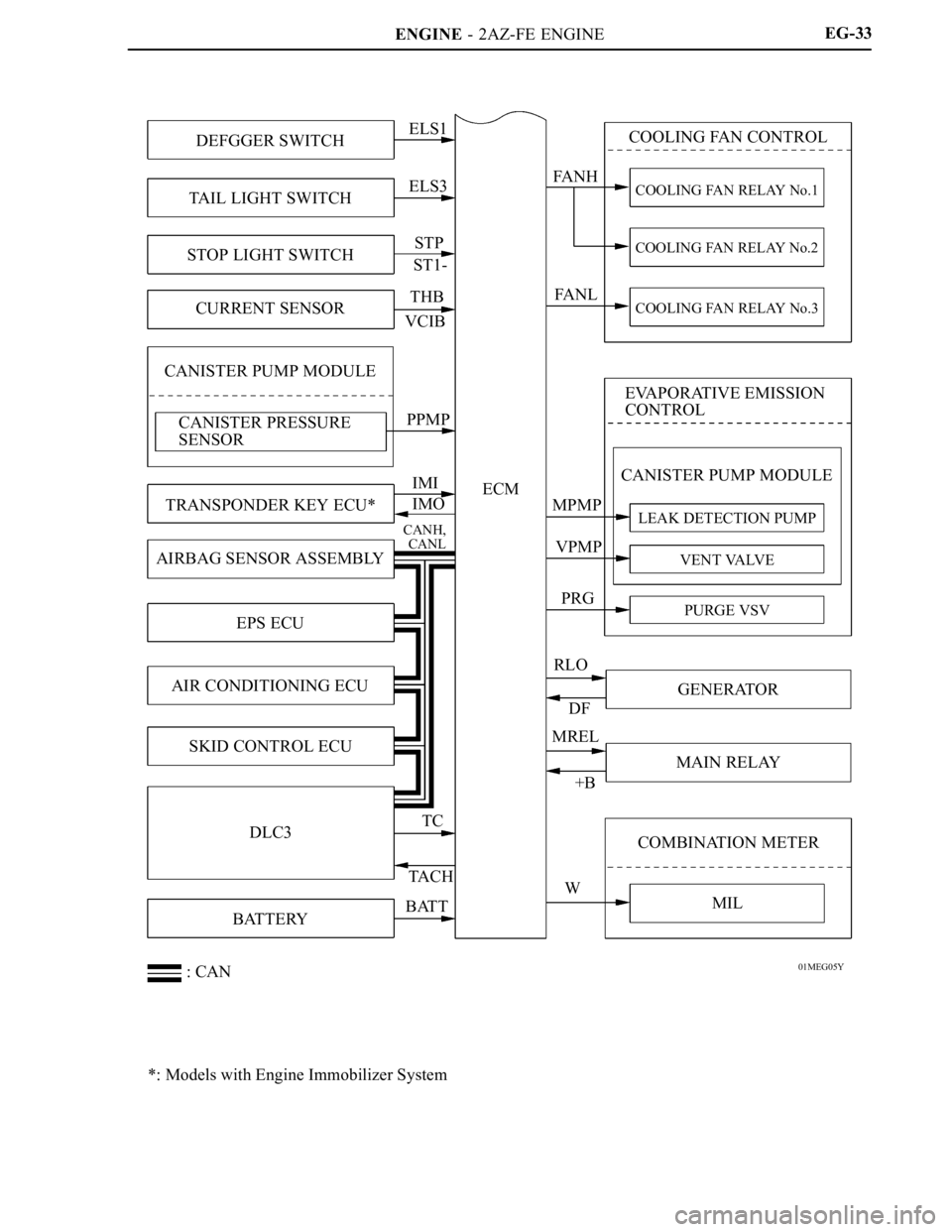

01MEG05Y

DEFGGER SWITCH

TA I L L I G H T S W I T C H

STOP LIGHT SWITCH

CURRENT SENSOR

CANISTER PUMP MODULE

CANISTER PRESSURE

SENSOR

TRANSPONDER KEY ECU*

AIRBAG SENSOR ASSEMBLY

EPS ECU

AIR CONDITIONING ECU

SKID CONTROL ECU

DLC3

BATTERYELS1

ELS3

STP

ST1-

THB

VCIB

PPMP

IMI

IMO

CANH,

CANL

TC

TA C H

BATTECMFA N H

FA N L

MPMP

VPMP

PRG

RLO

DF

MREL

+B

WCOOLING FAN CONTROL

COOLING FAN RELAY No.1

COOLING FAN RELAY No.2

COOLING FAN RELAY No.3

EVAPORATIVE EMISSION

CONTROL

CANISTER PUMP MODULE

LEAK DETECTION PUMP

VENT VALVE

GENERATOR

MAIN RELAY

COMBINATION METER

MIL

PURGE VSV

: CANEG-33

*: Models with Engine Immobilizer System

Page 35 of 2000

ENGINE - 2AZ-FE ENGINE

271EG45

Alumina

Dilation Layer

Alumina

Platinum

Electrode

Sensor Element (Zirconia)Heater AtmospherePlatinum

ElectrodeHeater

Atmosphere

Sensor Element

(Zirconia)

Planar Type Air-fuel Ratio Sensor Cup Type Heated Oxygen Sensor

204EG54

Temperature Sensing

Element

Platinum Hot-wire

ElementAir FlowIntake Air

Temperature

Sensor EG-38

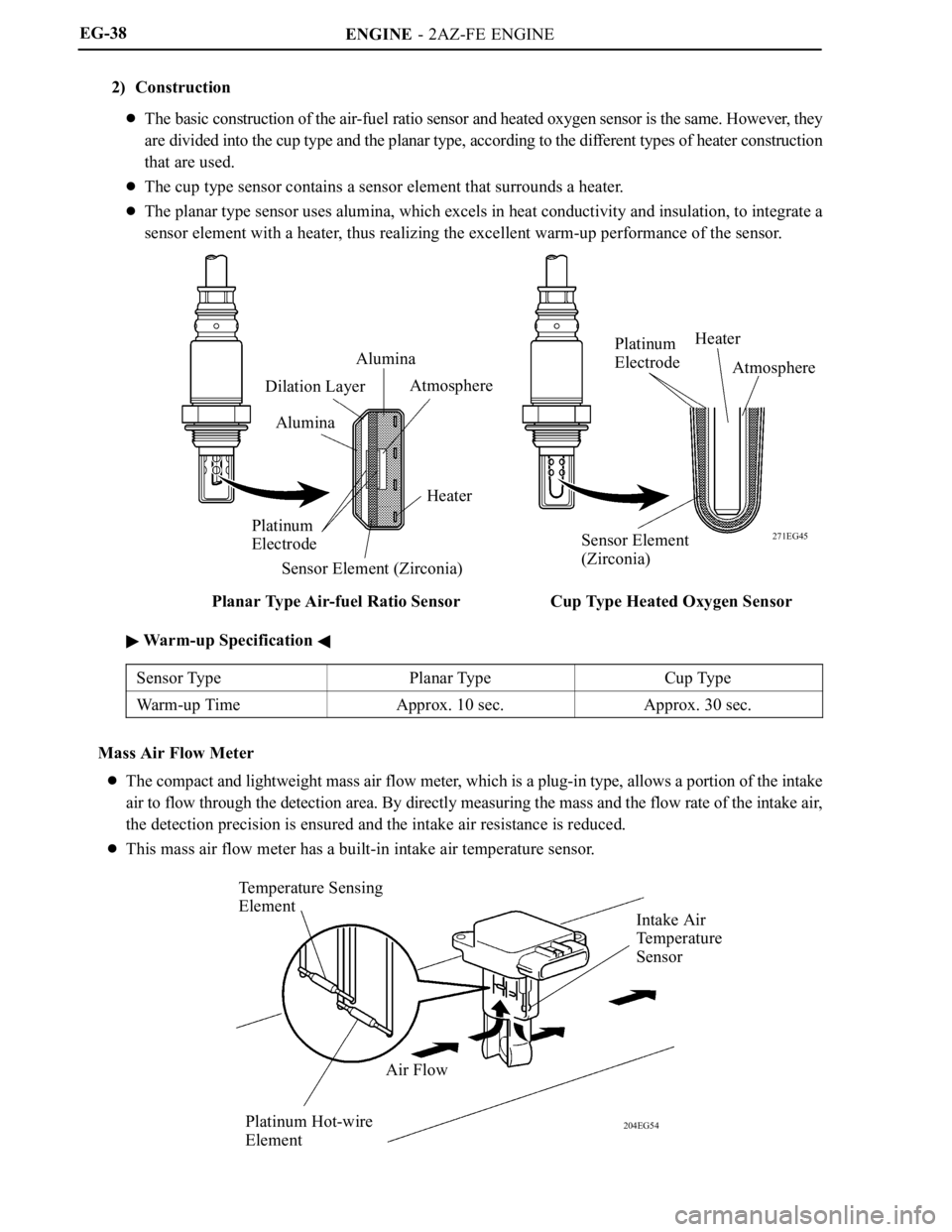

2) Construction

The basic construction of the air-fuel ratio sensor and heated oxygen sensor is the same. However, they

are divided into the cup type and the planar type, according to the different types of heater construction

that are used.

The cup type sensor contains a sensor element that surrounds a heater.

The planar type sensor uses alumina, which excels in heat conductivity and insulation, to integrate a

sensor element with a heater, thus realizing the excellent warm-up performance of the sensor.

Warm-up Specification

Sensor TypePlanar TypeCup Type

Warm-up TimeApprox. 10 sec.Approx. 30 sec.

Mass Air Flow Meter

The compact and lightweight mass air flow meter, which is a plug-in type, allows a portion of the intake

air to flow through the detection area. By directly measuring the mass and the flow rate of the intake air,

the detection precision is ensured and the intake air resistance is reduced.

This mass air flow meter has a built-in intake air temperature sensor.