pan TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 11 of 2000

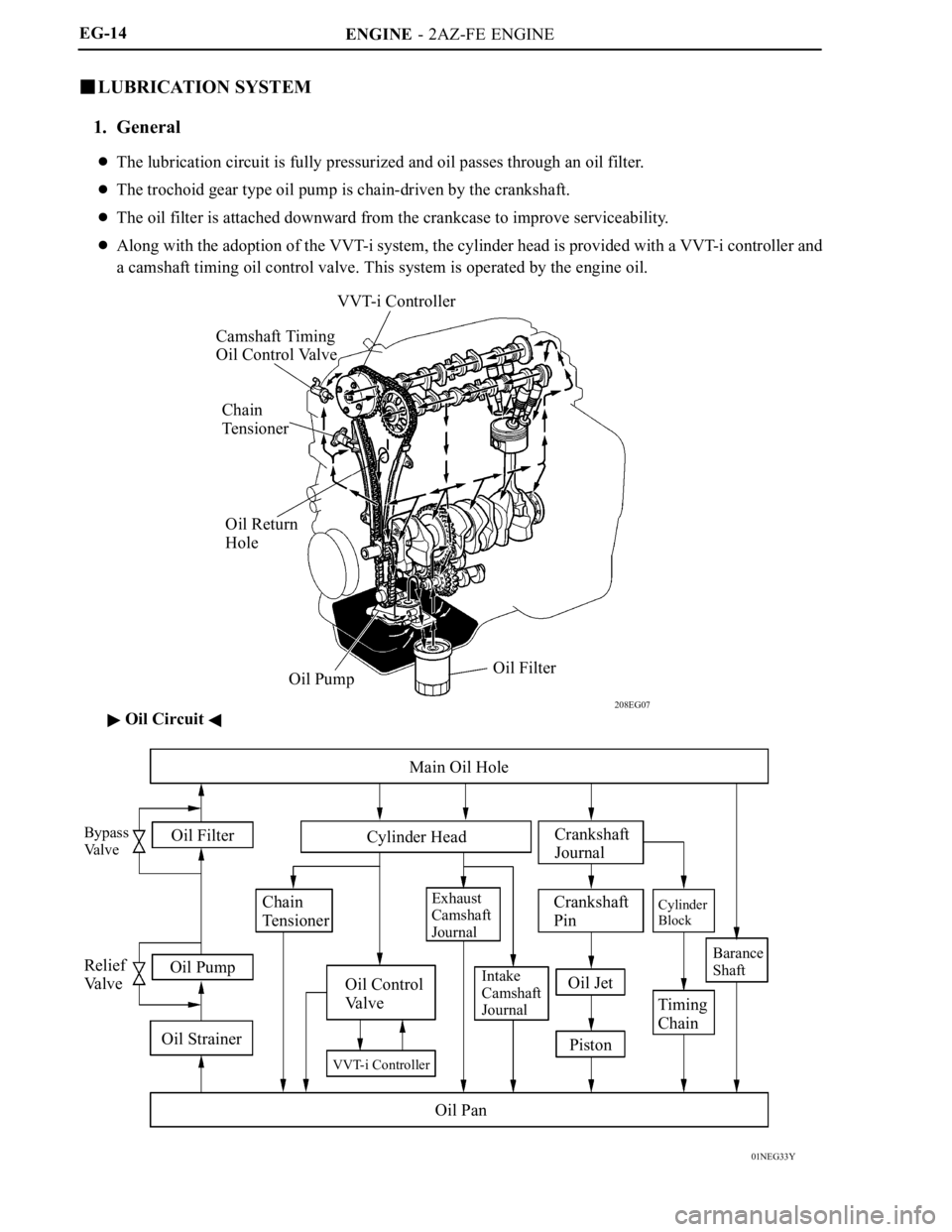

ENGINE - 2AZ-FE ENGINE

208EG07

VVT-i Controller

Camshaft Timing

Oil Control Valve

Oil Return

Hole

Oil PumpOil Filter Chain

Te n s i o n e r

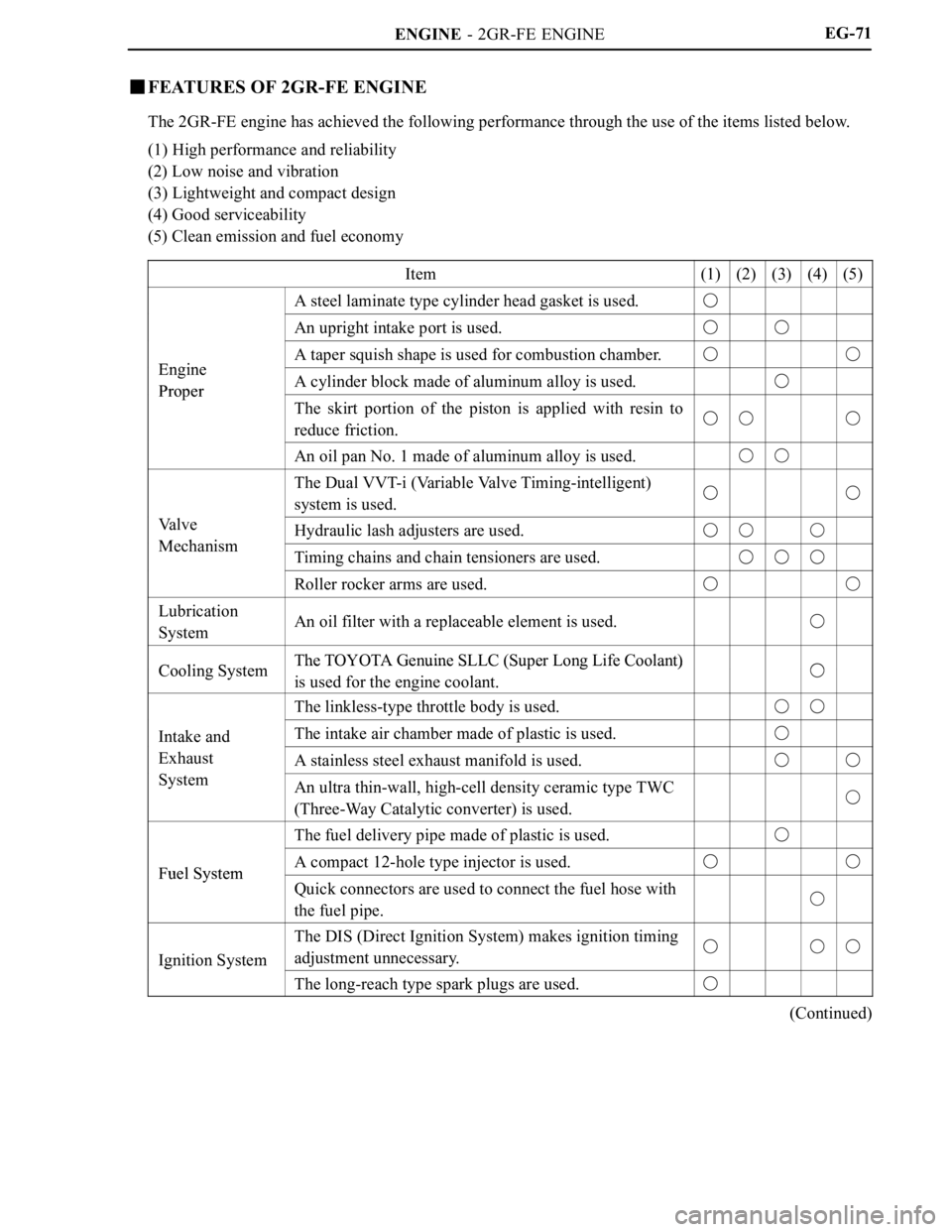

01NEG33Y

Bypass

Va l v e

Relief

Va l v eMain Oil Hole

Oil Filter

Oil Pump

Oil StrainerChain

Te n s i o n e rCylinder Head

Exhaust

Camshaft

Journal

Oil Control

Va l v e

VVT-i Controller

Oil Pan

Intake

Camshaft

Journal

Crankshaft

Journal

Crankshaft

Pin

Oil Jet

Piston

Cylinder

Block

Barance

Shaft

Timing

Chain EG-14

LUBRICATION SYSTEM

1. General

The lubrication circuit is fully pressurized and oil passes through an oil filter.

The trochoid gear type oil pump is chain-driven by the crankshaft.

The oil filter is attached downward from the crankcase to improve serviceability.

Along with the adoption of the VVT-i system, the cylinder head is provided with a VVT-i controller and

a camshaft timing oil control valve. This system is operated by the engine oil.

Oil Circuit

Page 67 of 2000

ENGINE - 2GR-FE ENGINEEG-71

FEATURES OF 2GR-FE ENGINE

The 2GR-FE engine has achieved the following performance through the use of the items listed below.

(1) High performance and reliability

(2) Low noise and vibration

(3) Lightweight and compact design

(4) Good serviceability

(5) Clean emission and fuel economy

Item

(1)(2)(3)(4)(5)

A steel laminate type cylinder head gasket is used.

An upright intake port is used.

EngineA taper squish shape is used for combustion chamber.Engine

ProperA cylinder block made of aluminum alloy is used.Proper

The skirt portion of the piston is applied with resin to

reduce friction.

An oil pan No. 1 made of aluminum alloy is used.

The Dual VVT-i (Variable Valve Timing-intelligent)

system is used.

Va l v e

Mh i

Hydraulic lash adjusters are used.

MechanismTiming chains and chain tensioners are used.

Roller rocker arms are used.

Lubrication

SystemAn oil filter with a replaceable element is used.

Cooling SystemThe TOYOTA Genuine SLLC (Super Long Life Coolant)Cooling SystemThe TOYOTA Genuine SLLC (Super Long Life Coolant)

is used for the engine coolant.

The linkless-type throttle body is used.

Intake andThe intake air chamber made of plastic is used.Intake and

Exhaust

S

A stainless steel exhaust manifold is used.

SystemAn ultra thin-wall, high-cell density ceramic type TWC

(Three-Way Catalytic converter) is used.

The fuel delivery pipe made of plastic is used.

Fuel SystemA compact 12-hole type injector is used.Fuel SystemQuick connectors are used to connect the fuel hose with

the fuel pipe.

Ignition System

The DIS (Direct Ignition System) makes ignition timing

adjustment unnecessary.

Ignition System

The long-reach type spark plugs are used.

(Continued)

Page 75 of 2000

ENGINE - 2GR-FE ENGINE

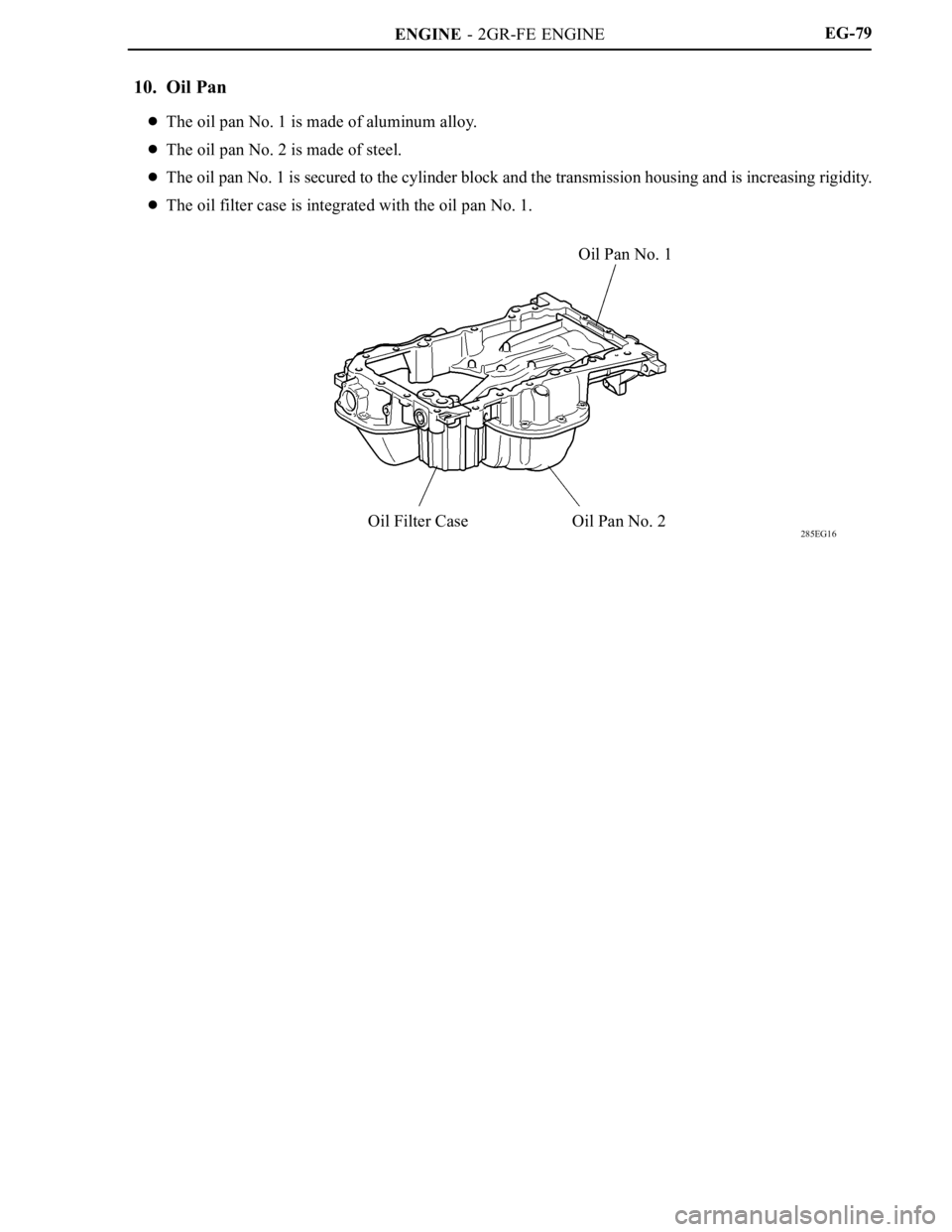

285EG16

Oil Pan No. 1

Oil Filter Case Oil Pan No. 2EG-79

10. Oil Pan

The oil pan No. 1 is made of aluminum alloy.

The oil pan No. 2 is made of steel.

The oil pan No. 1 is secured to the cylinder block and the transmission housing and is increasing rigidity.

The oil filter case is integrated with the oil pan No. 1.

Page 81 of 2000

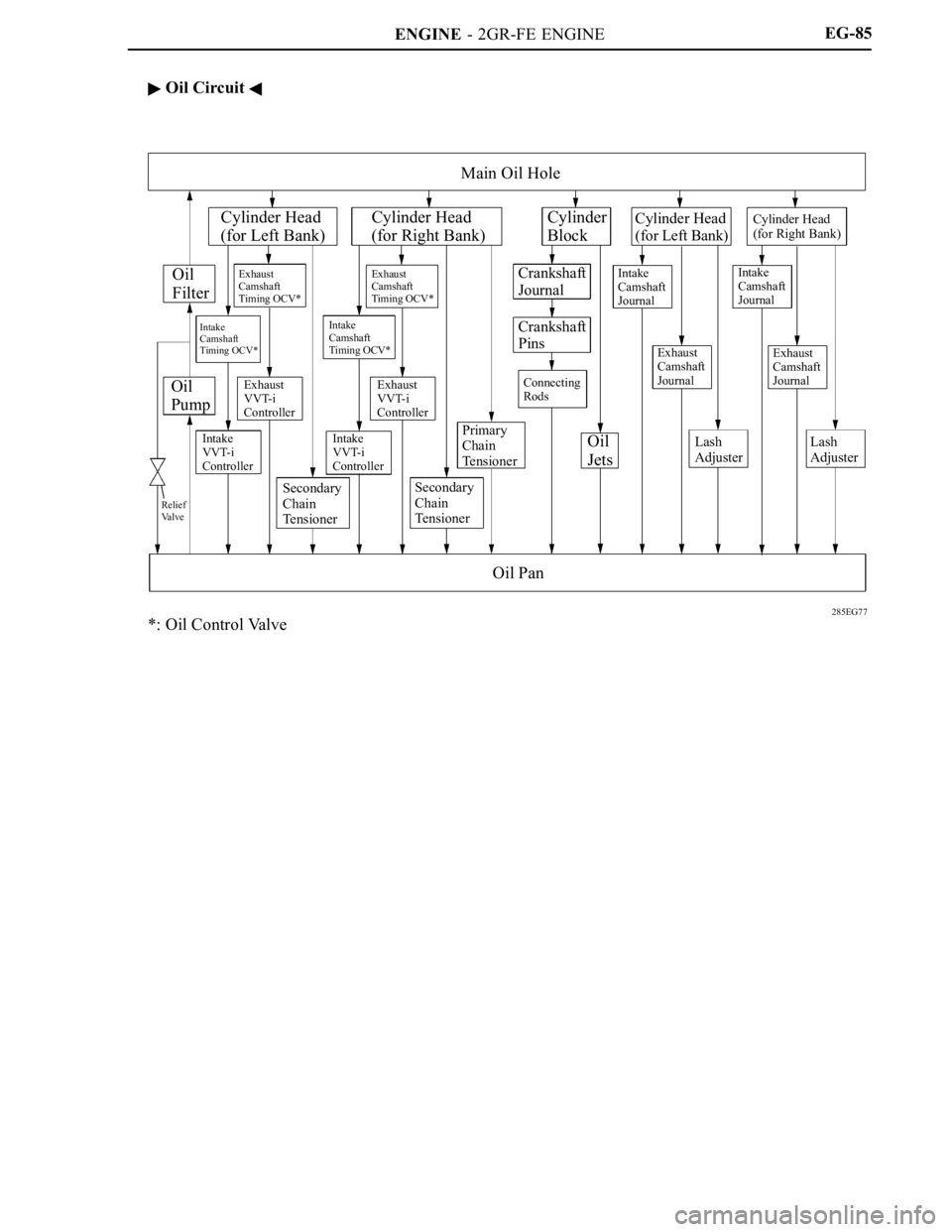

ENGINE - 2GR-FE ENGINE

285EG77

Main Oil Hole

Cylinder Head

(for Left Bank)

Oil

Filter

Exhaust

Camshaft

Timing OCV*

Intake

Camshaft

Timing OCV*

Oil

PumpExhaust

VVT-i

Controller

Intake

VVT-i

Controller

Relief

Va l v e

Cylinder Head

(for Right Bank)

Exhaust

Camshaft

Timing OCV*

Intake

Camshaft

Timing OCV*

Exhaust

VVT-i

Controller

Intake

VVT-i

Controller

Secondary

Chain

TensionerPrimary

Chain

Tensioner

Secondary

Chain

Tensioner

Cylinder

Block

Crankshaft

Journal

Crankshaft

Pins

Connecting

Rods

Cylinder Head

(for Left Bank)

Oil

Jets

Intake

Camshaft

Journal

Exhaust

Camshaft

Journal

Lash

Adjuster

Cylinder Head

(for Right Bank)

Intake

Camshaft

Journal

Exhaust

Camshaft

Journal

Lash

Adjuster

Oil PanEG-85

Oil Circuit

*: Oil Control Valve

Page 82 of 2000

ENGINE - 2GR-FE ENGINE

285EG24

Timing Chain Cover

Oil Pump

Housing

Oil Pump Rotors

(Cycloid Rotor)Crankshaft

To Cylinder

Block

From Oil

Filter

To

Oil FilterFrom

Oil Strainer

Oil passage in the oil pump

285EG25

Oil Jet Cross Section

Oil JetsCheck

Va l v eEngine Oil EG-86

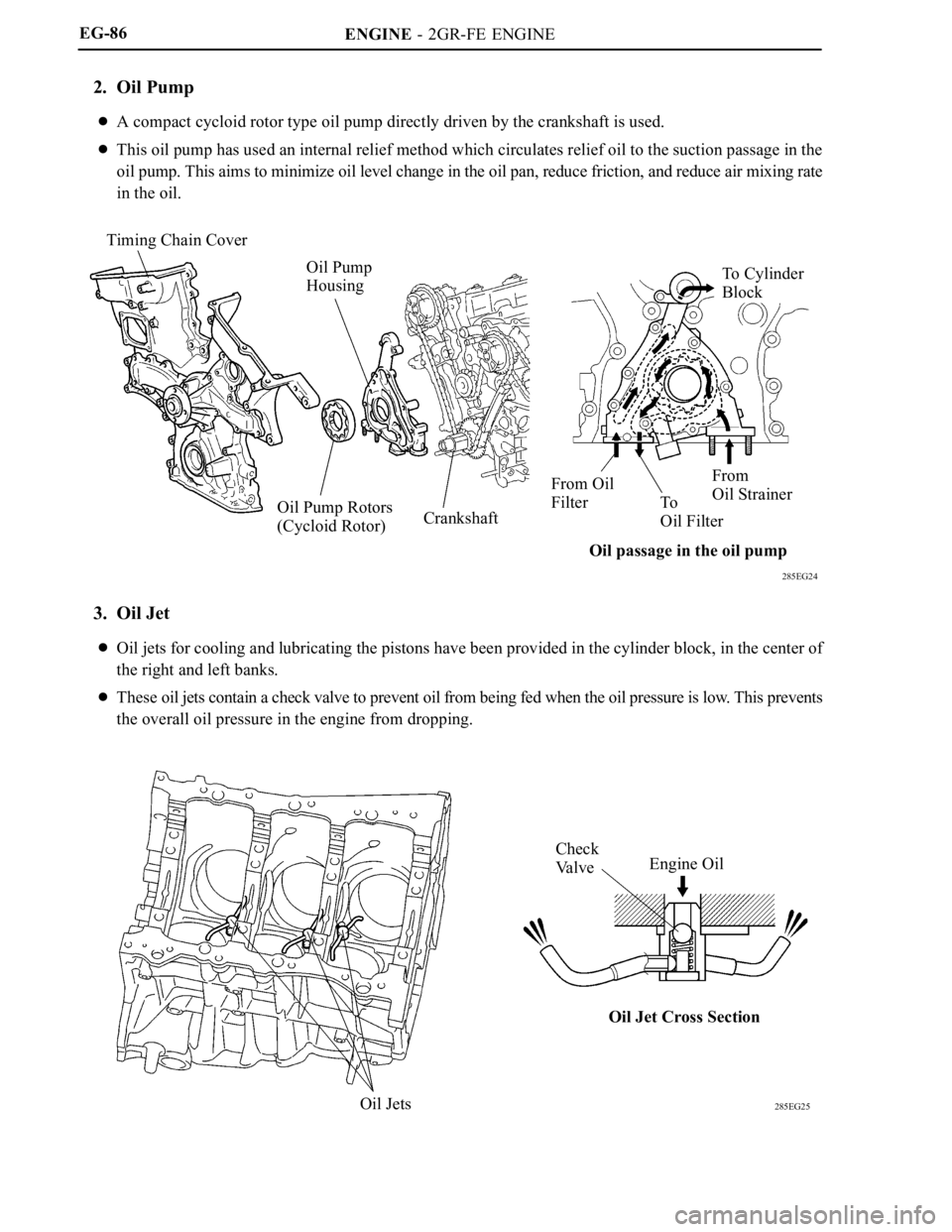

2. Oil Pump

A compact cycloid rotor type oil pump directly driven by the crankshaft is used.

This oil pump has used an internal relief method which circulates relief oil to the suction passage in the

oil pump. This aims to minimize oil level change in the oil pan, reduce friction, and reduce air mixing rate

in the oil.

3. Oil Jet

Oil jets for cooling and lubricating the pistons have been provided in the cylinder block, in the center of

the right and left banks.

These oil jets contain a check valve to prevent oil from being fed when the oil pressure is low. This prevents

the overall oil pressure in the engine from dropping.

Page 168 of 2000

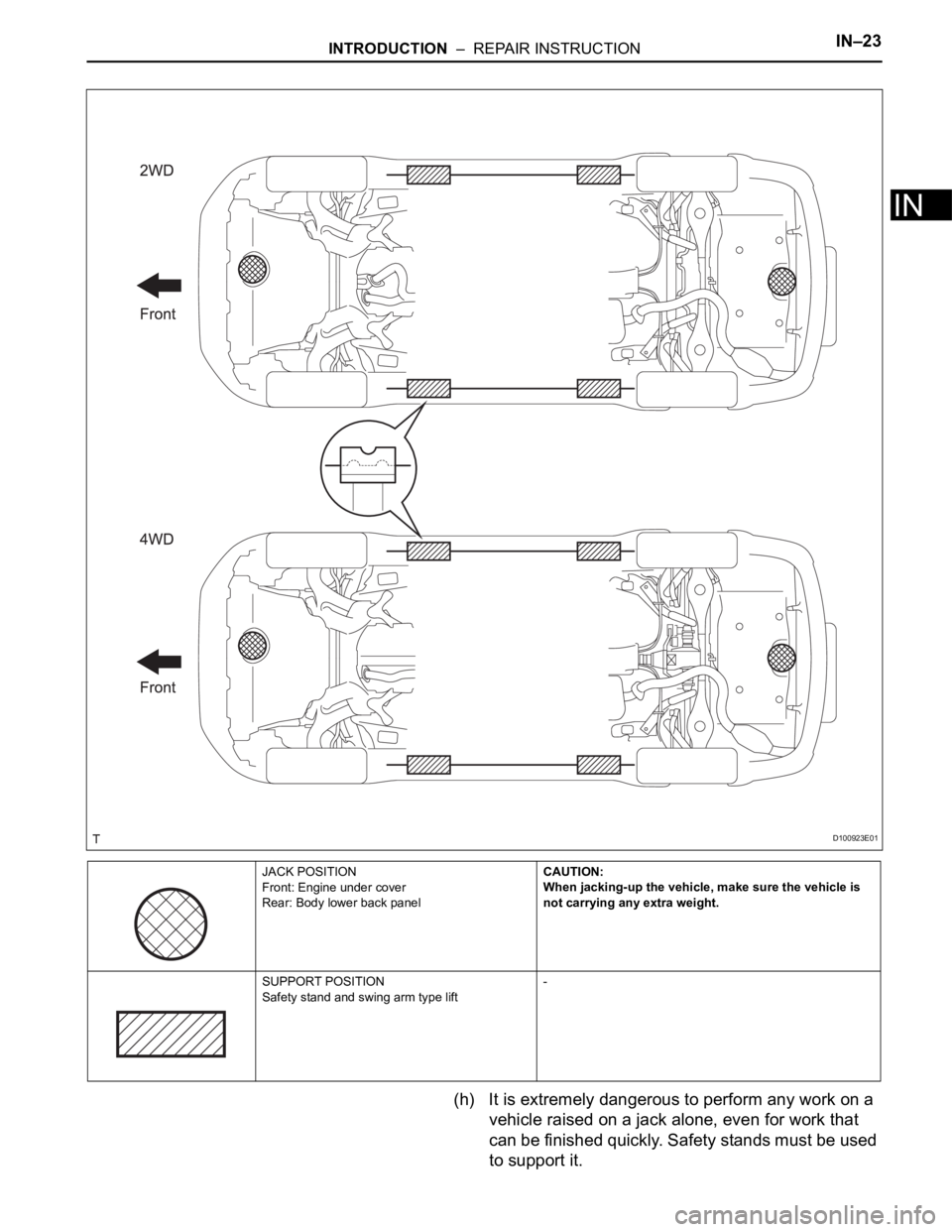

INTRODUCTION – REPAIR INSTRUCTIONIN–23

IN

(h) It is extremely dangerous to perform any work on a

vehicle raised on a jack alone, even for work that

can be finished quickly. Safety stands must be used

to support it.

JACK POSITION

Front: Engine under cover

Rear: Body lower back panelCAUTION:

When jacking-up the vehicle, make sure the vehicle is

not carrying any extra weight.

SUPPORT POSITION

Safety stand and swing arm type lift-

D100923E01

Page 179 of 2000

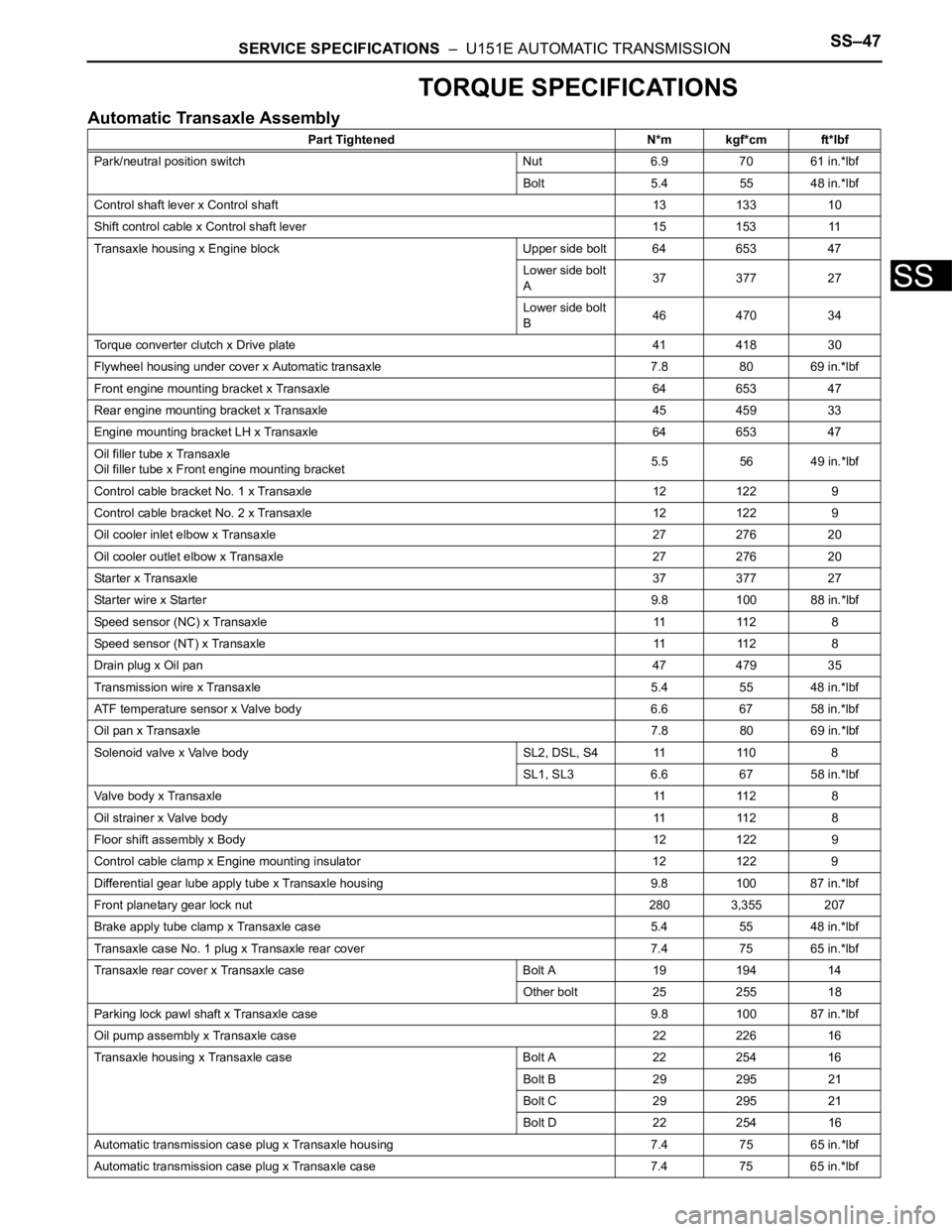

SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSMISSIONSS–47

SS

TORQUE SPECIFICATIONS

Automatic Transaxle Assembly

Part Tightened N*m kgf*cm ft*lbf

Park/neutral position switch Nut 6.9 70 61 in.*lbf

Bolt 5.4 55 48 in.*lbf

Control shaft lever x Control shaft 13 133 10

Shift control cable x Control shaft lever 15 153 11

Transaxle housing x Engine block Upper side bolt 64 653 47

Lower side bolt

A37 377 27

Lower side bolt

B46 470 34

Torque converter clutch x Drive plate 41 418 30

Flywheel housing under cover x Automatic transaxle 7.8 80 69 in.*lbf

Front engine mounting bracket x Transaxle 64 653 47

Rear engine mounting bracket x Transaxle 45 459 33

Engine mounting bracket LH x Transaxle 64 653 47

Oil filler tube x Transaxle

Oil filler tube x Front engine mounting bracket5.5 56 49 in.*lbf

Control cable bracket No. 1 x Transaxle 12 122 9

Control cable bracket No. 2 x Transaxle 12 122 9

Oil cooler inlet elbow x Transaxle 27 276 20

Oil cooler outlet elbow x Transaxle 27 276 20

Starter x Transaxle37 377 27

Starter wire x Starter9.8 100 88 in.*lbf

Speed sensor (NC) x Transaxle 11 112 8

Speed sensor (NT) x Transaxle 11 112 8

Drain plug x Oil pan47 479 35

Transmission wire x Transaxle 5.4 55 48 in.*lbf

ATF temperature sensor x Valve body 6.6 67 58 in.*lbf

Oil pan x Transaxle7.8 80 69 in.*lbf

Solenoid valve x Valve body SL2, DSL, S4 11 110 8

SL1, SL3 6.6 67 58 in.*lbf

Valve body x Transaxle11 11 2 8

Oil strainer x Valve body11 11 2 8

Floor shift assembly x Body12 122 9

Control cable clamp x Engine mounting insulator 12 122 9

Differential gear lube apply tube x Transaxle housing 9.8 100 87 in.*lbf

Front planetary gear lock nut 280 3,355 207

Brake apply tube clamp x Transaxle case 5.4 55 48 in.*lbf

Transaxle case No. 1 plug x Transaxle rear cover 7.4 75 65 in.*lbf

Transaxle rear cover x Transaxle case Bolt A 19 194 14

Other bolt 25 255 18

Parking lock pawl shaft x Transaxle case 9.8 100 87 in.*lbf

Oil pump assembly x Transaxle case 22 226 16

Transaxle housing x Transaxle case Bolt A 22 254 16

Bolt B 29 295 21

Bolt C 29 295 21

Bolt D 22 254 16

Automatic transmission case plug x Transaxle housing 7.4 75 65 in.*lbf

Automatic transmission case plug x Transaxle case 7.4 75 65 in.*lbf

Page 180 of 2000

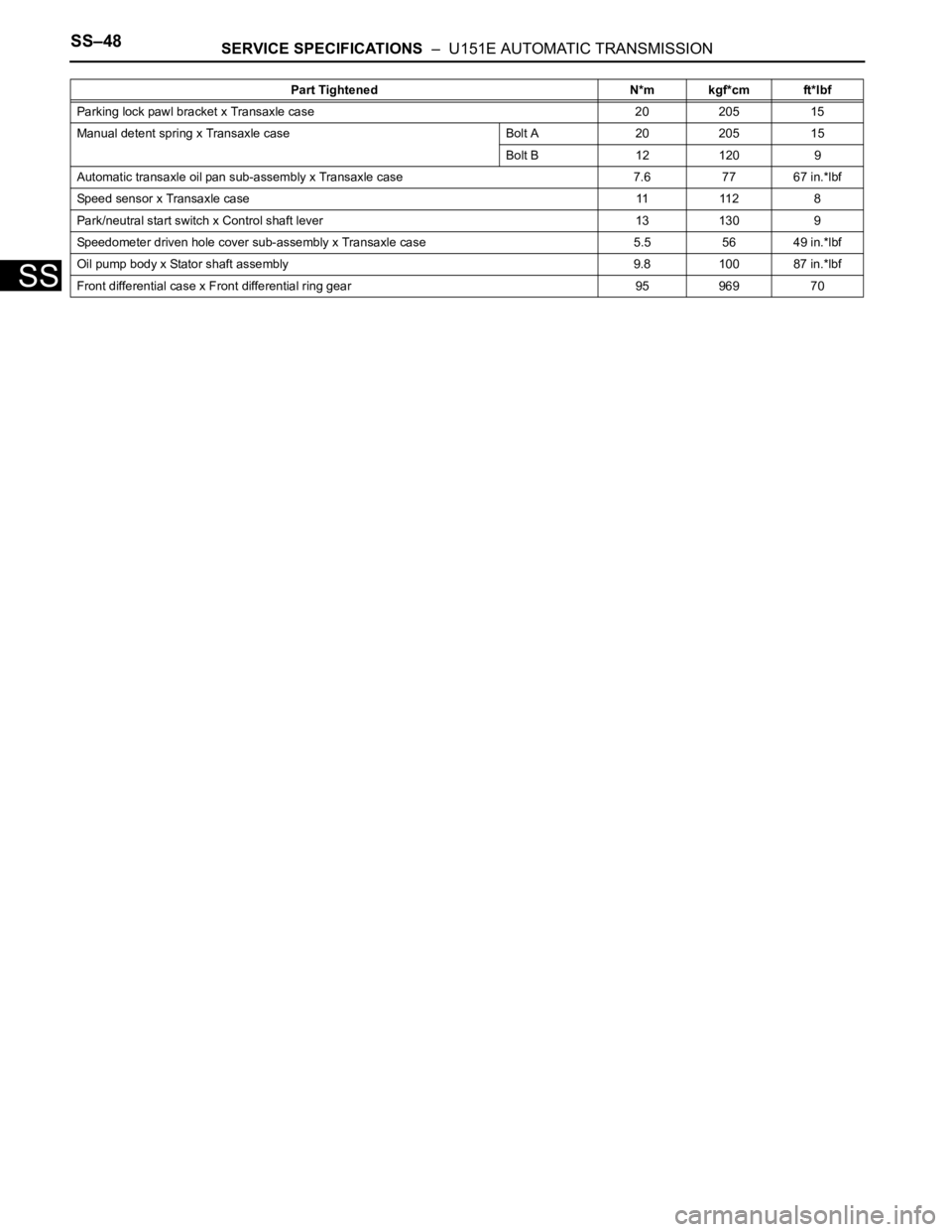

SS–48SERVICE SPECIFICATIONS – U151E AUTOMATIC TRANSMISSION

SS

Parking lock pawl bracket x Transaxle case 20 205 15

Manual detent spring x Transaxle case Bolt A 20 205 15

Bolt B 12 120 9

Automatic transaxle oil pan sub-assembly x Transaxle case 7.6 77 67 in.*lbf

Speed sensor x Transaxle case 11 112 8

Park/neutral start switch x Control shaft lever 13 130 9

Speedometer driven hole cover sub-assembly x Transaxle case 5.5 56 49 in.*lbf

Oil pump body x Stator shaft assembly 9.8 100 87 in.*lbf

Front differential case x Front differential ring gear 95 969 70Part Tightened N*m kgf*cm ft*lbf

Page 210 of 2000

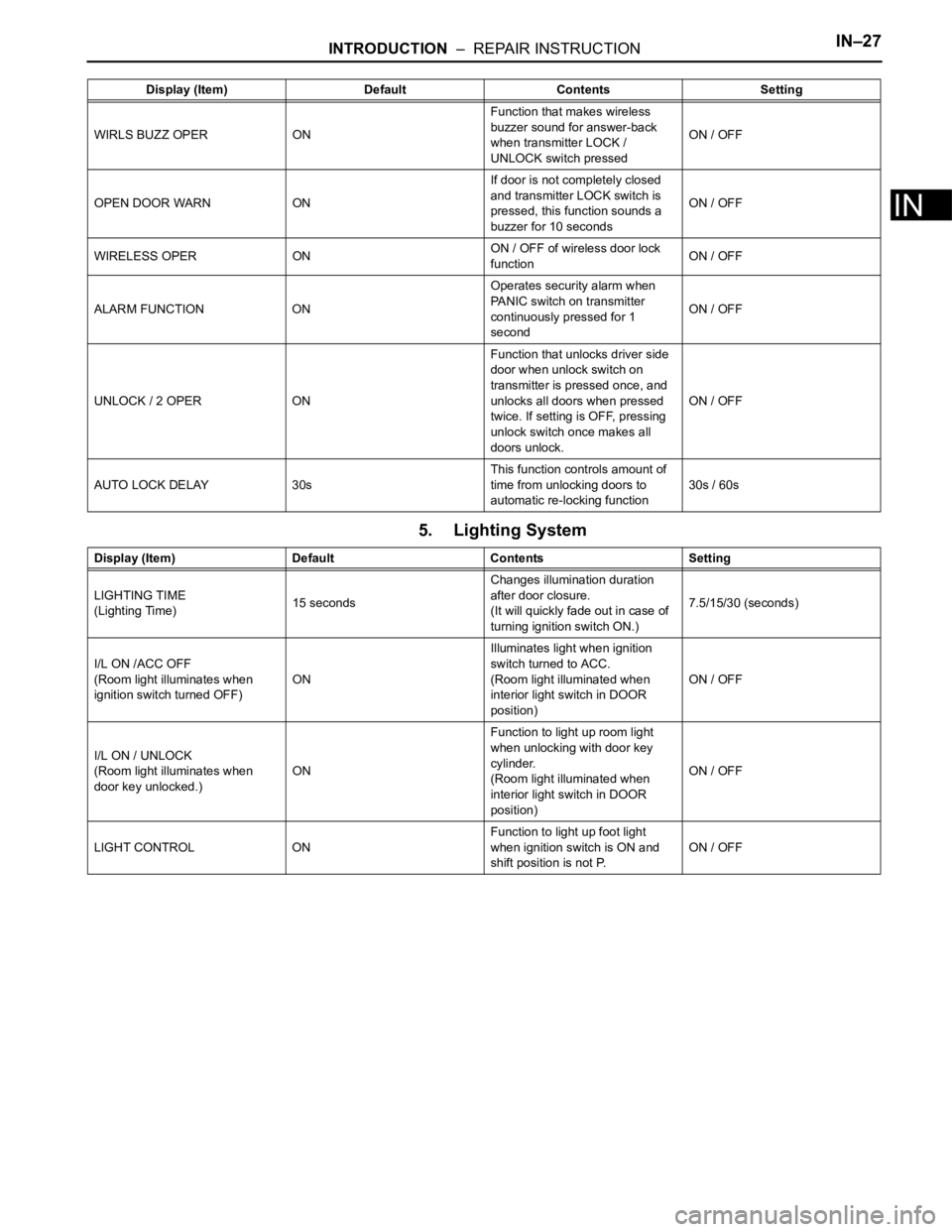

INTRODUCTION – REPAIR INSTRUCTIONIN–27

IN

5. Lighting System

WIRLS BUZZ OPER ONFunction that makes wireless

buzzer sound for answer-back

when transmitter LOCK /

UNLOCK switch pressedON / OFF

OPEN DOOR WARN ONIf door is not completely closed

and transmitter LOCK switch is

pressed, this function sounds a

buzzer for 10 secondsON / OFF

WIRELESS OPER ONON / OFF of wireless door lock

functionON / OFF

ALARM FUNCTION ONOperates security alarm when

PANIC switch on transmitter

continuously pressed for 1

secondON / OFF

UNLOCK / 2 OPER ONFunction that unlocks driver side

door when unlock switch on

transmitter is pressed once, and

unlocks all doors when pressed

twice. If setting is OFF, pressing

unlock switch once makes all

doors unlock.ON / OFF

AUTO LOCK DELAY 30sThis function controls amount of

time from unlocking doors to

automatic re-locking function30s / 60s Display (Item) Default Contents Setting

Display (Item) Default Contents Setting

LIGHTING TIME

(Lighting Time)15 secondsChanges illumination duration

after door closure.

(It will quickly fade out in case of

turning ignition switch ON.)7.5/15/30 (seconds)

I/L ON /ACC OFF

(Room light illuminates when

ignition switch turned OFF)ONIlluminates light when ignition

switch turned to ACC.

(Room light illuminated when

interior light switch in DOOR

position)ON / OFF

I/L ON / UNLOCK

(Room light illuminates when

door key unlocked.)ONFunction to light up room light

when unlocking with door key

cylinder.

(Room light illuminated when

interior light switch in DOOR

position)ON / OFF

LIGHT CONTROL ONFunction to light up foot light

when ignition switch is ON and

shift position is not P.ON / OFF

Page 216 of 2000

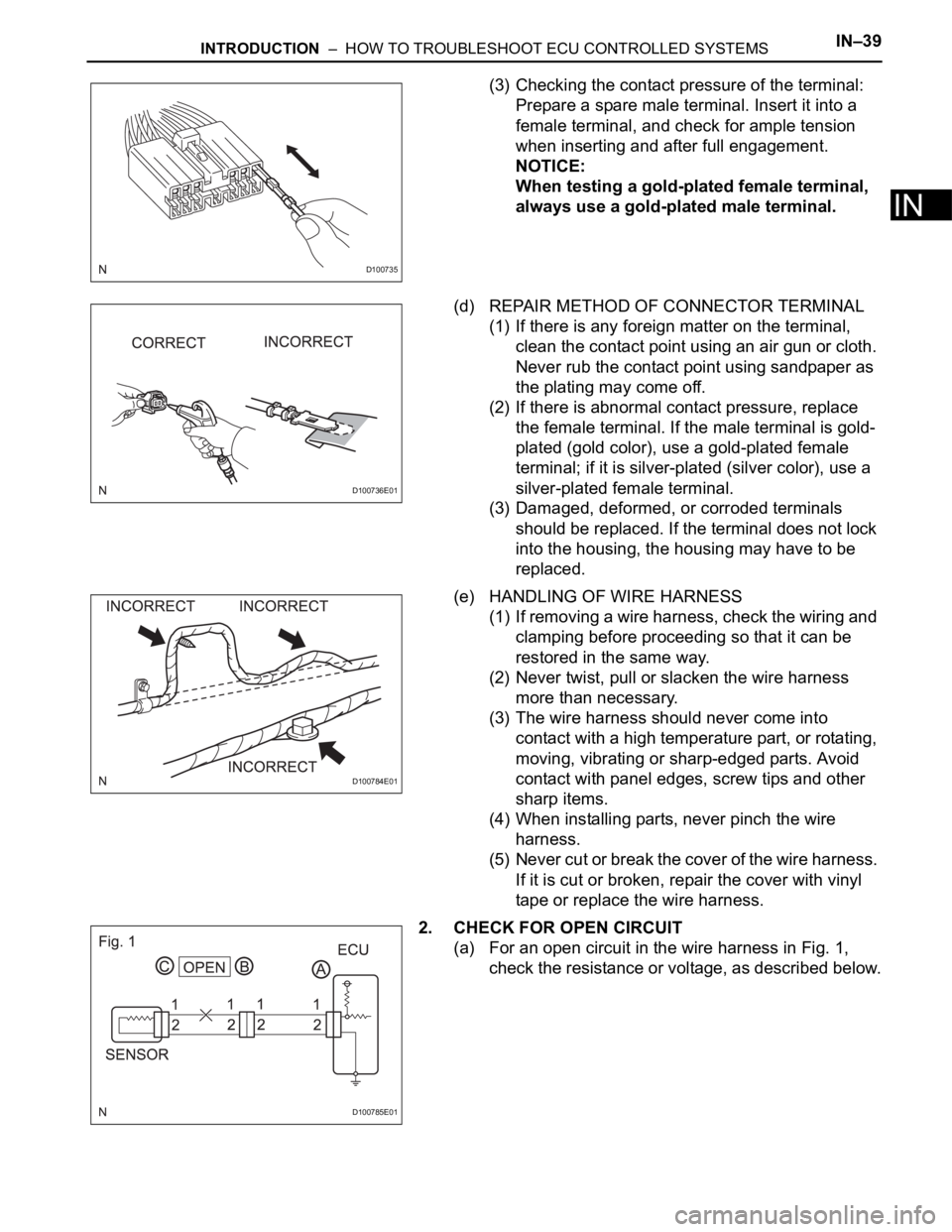

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMSIN–39

IN

(3) Checking the contact pressure of the terminal:

Prepare a spare male terminal. Insert it into a

female terminal, and check for ample tension

when inserting and after full engagement.

NOTICE:

When testing a gold-plated female terminal,

always use a gold-plated male terminal.

(d) REPAIR METHOD OF CONNECTOR TERMINAL

(1) If there is any foreign matter on the terminal,

clean the contact point using an air gun or cloth.

Never rub the contact point using sandpaper as

the plating may come off.

(2) If there is abnormal contact pressure, replace

the female terminal. If the male terminal is gold-

plated (gold color), use a gold-plated female

terminal; if it is silver-plated (silver color), use a

silver-plated female terminal.

(3) Damaged, deformed, or corroded terminals

should be replaced. If the terminal does not lock

into the housing, the housing may have to be

replaced.

(e) HANDLING OF WIRE HARNESS

(1) If removing a wire harness, check the wiring and

clamping before proceeding so that it can be

restored in the same way.

(2) Never twist, pull or slacken the wire harness

more than necessary.

(3) The wire harness should never come into

contact with a high temperature part, or rotating,

moving, vibrating or sharp-edged parts. Avoid

contact with panel edges, screw tips and other

sharp items.

(4) When installing parts, never pinch the wire

harness.

(5) Ne ver c ut or break th e c ov er of t he w ir e har ness .

If it is cut or broken, repair the cover with vinyl

tape or replace the wire harness.

2. CHECK FOR OPEN CIRCUIT

(a) For an open circuit in the wire harness in Fig. 1,

check the resistance or voltage, as described below.

D100735

D100736E01

D100784E01

D100785E01