position sensor TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1 of 2000

ENGINE - 2AZ-FE ENGINE EG-4

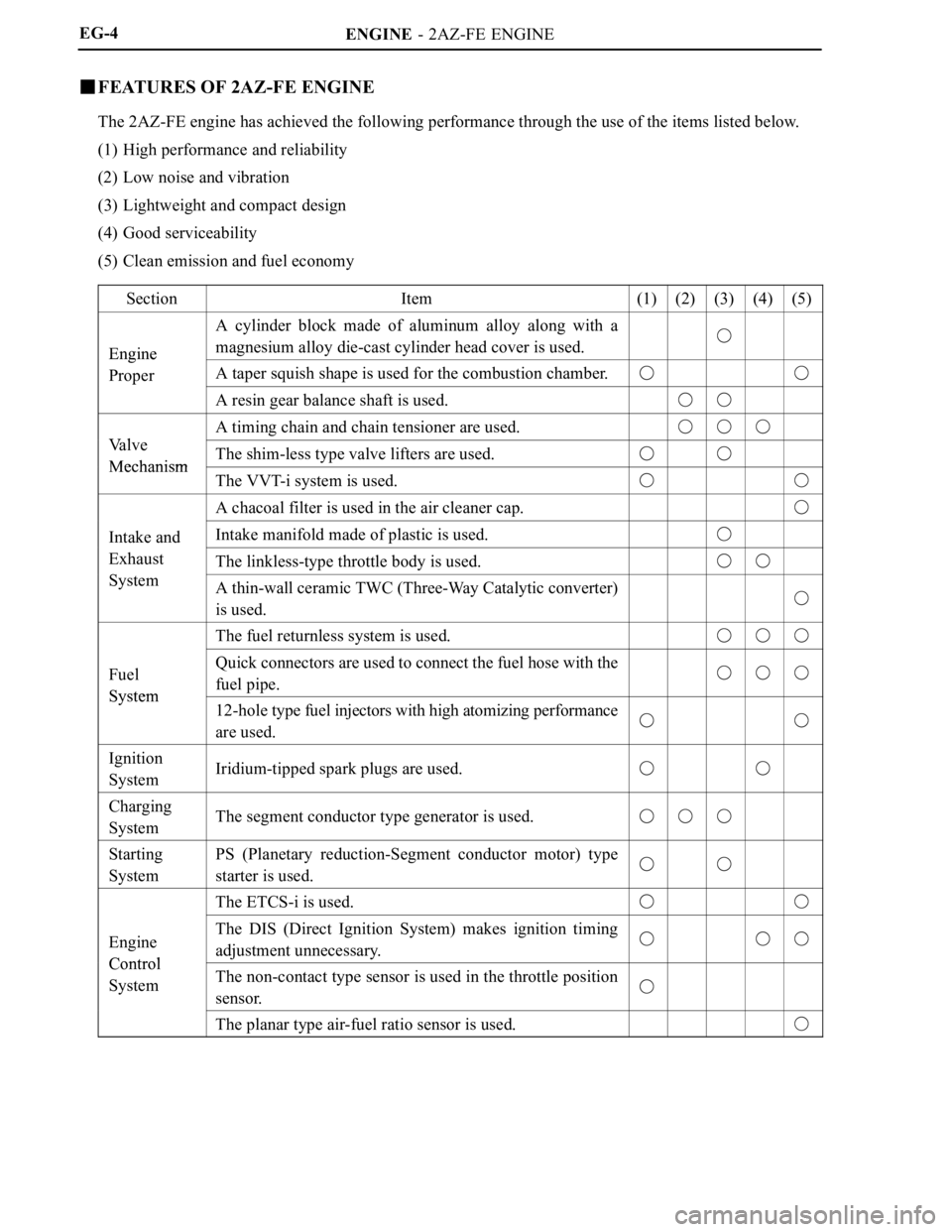

FEATURES OF 2AZ-FE ENGINE

The 2AZ-FE engine has achieved the following performance through the use of the items listed below.

(1) High performance and reliability

(2) Low noise and vibration

(3) Lightweight and compact design

(4) Good serviceability

(5) Clean emission and fuel economy

Section

Item(1)(2)(3)(4)(5)

Engine

A cylinder block made of aluminum alloy along with a

magnesium alloy die-cast cylinder head cover is used.

Engine

ProperA taper squish shape is used for the combustion chamber.p

A resin gear balance shaft is used.

Vl

A timing chain and chain tensioner are used.

Va l v e

MechanismThe shim-less type valve lifters are used.MechanismThe VVT-i system is used.

A chacoal filter is used in the air cleaner cap.

Intake andIntake manifold made of plastic is used.Intake and

ExhaustThe linkless-type throttle body is used.

SystemA thin-wall ceramic TWC (Three-Way Catalytic converter)

is used.

The fuel returnless system is used.

Fuel

System

Quick connectors are used to connect the fuel hose with the

fuel pipe.

System12-hole type fuel injectors with high atomizing performance

are used.

Ignition

SystemIridium-tipped spark plugs are used.

Charging

SystemThe segment conductor type generator is used.

Starting

SystemPS (Planetary reduction-Segment conductor motor) type

starter is used.

The ETCS-i is used.

Engine

Control

The DIS (Direct Ignition System) makes ignition timing

adjustment unnecessary.

Control

SystemThe non-contact type sensor is used in the throttle position

sensor.

The planar type air-fuel ratio sensor is used.

Page 10 of 2000

ENGINE - 2AZ-FE ENGINE

181EG11

VVT-i ControllerIntake CamshaftTiming Rotor

Exhaust Camshaft

Timing Sprocket

185EG25 181EG14

Cam Spring

Cam

Plunger

SpringChain

Te n s i o n e r

Chain Damper

Oil Jet

Chain TensionerChain SlipperEG-13

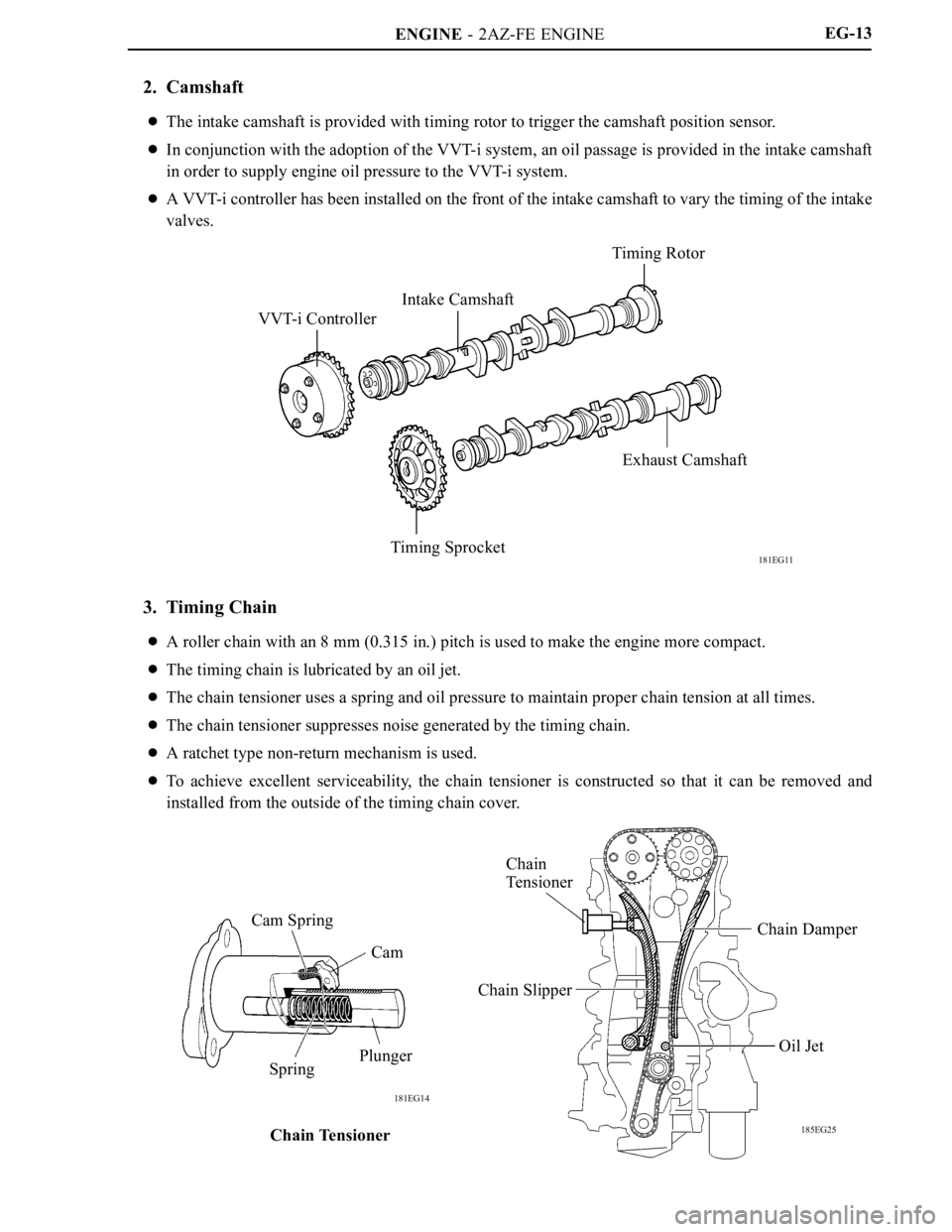

2. Camshaft

The intake camshaft is provided with timing rotor to trigger the camshaft position sensor.

In conjunction with the adoption of the VVT-i system, an oil passage is provided in the intake camshaft

in order to supply engine oil pressure to the VVT-i system.

A VVT-i controller has been installed on the front of the intake camshaft to vary the timing of the intake

valves.

3. Timing Chain

A roller chain with an 8 mm (0.315 in.) pitch is used to make the engine more compact.

The timing chain is lubricated by an oil jet.

The chain tensioner uses a spring and oil pressure to maintain proper chain tension at all times.

The chain tensioner suppresses noise generated by the timing chain.

A ratchet type non-return mechanism is used.

To achieve excellent serviceability, the chain tensioner is constructed so that it can be removed and

installed from the outside of the timing chain cover.

Page 16 of 2000

ENGINE - 2AZ-FE ENGINE

01MEG10Y

Charcoal FilterAir Cleaner Cap

Air Cleaner Element

(Nonwoven Fabric)

Service Tip

The charcoal filter, which is maintenance-free, cannot be removed from the air cleaner cap.

01NEG42Y

Throttle Position

Sensor

Throttle Control MotorEG-19

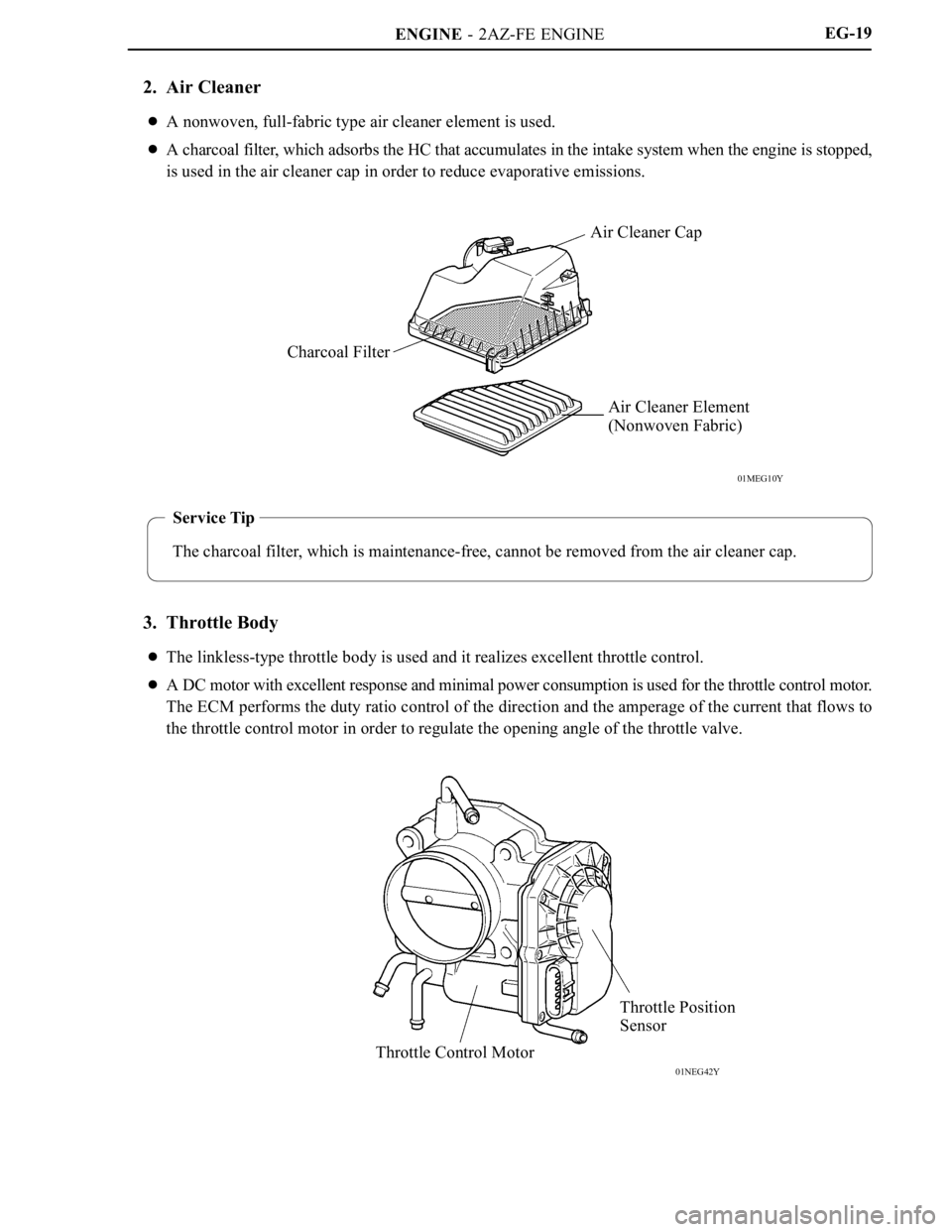

2. Air Cleaner

A nonwoven, full-fabric type air cleaner element is used.

A charcoal filter, which adsorbs the HC that accumulates in the intake system when the engine is stopped,

is used in the air cleaner cap in order to reduce evaporative emissions.

3. Throttle Body

The linkless-type throttle body is used and it realizes excellent throttle control.

A DC motor with excellent response and minimal power consumption is used for the throttle control motor.

The ECM performs the duty ratio control of the direction and the amperage of the current that flows to

the throttle control motor in order to regulate the opening angle of the throttle valve.

Page 21 of 2000

ENGINE - 2AZ-FE ENGINE

165EG25

Camshaft

Position

Sensor

Crankshaft

Position

Sensor

Va r i o u s

SensorG2

NE

ECMIGT1

IGT2

IGT3

IGT4

IGF+BIgnition Coil

(with Igniter)

No.1 Cylinder

No.2 Cylinder

No.3 Cylinder

No.4 Cylinder

185EG38

0.7 mm

(0.028 in.)

Iridium Tip EG-24

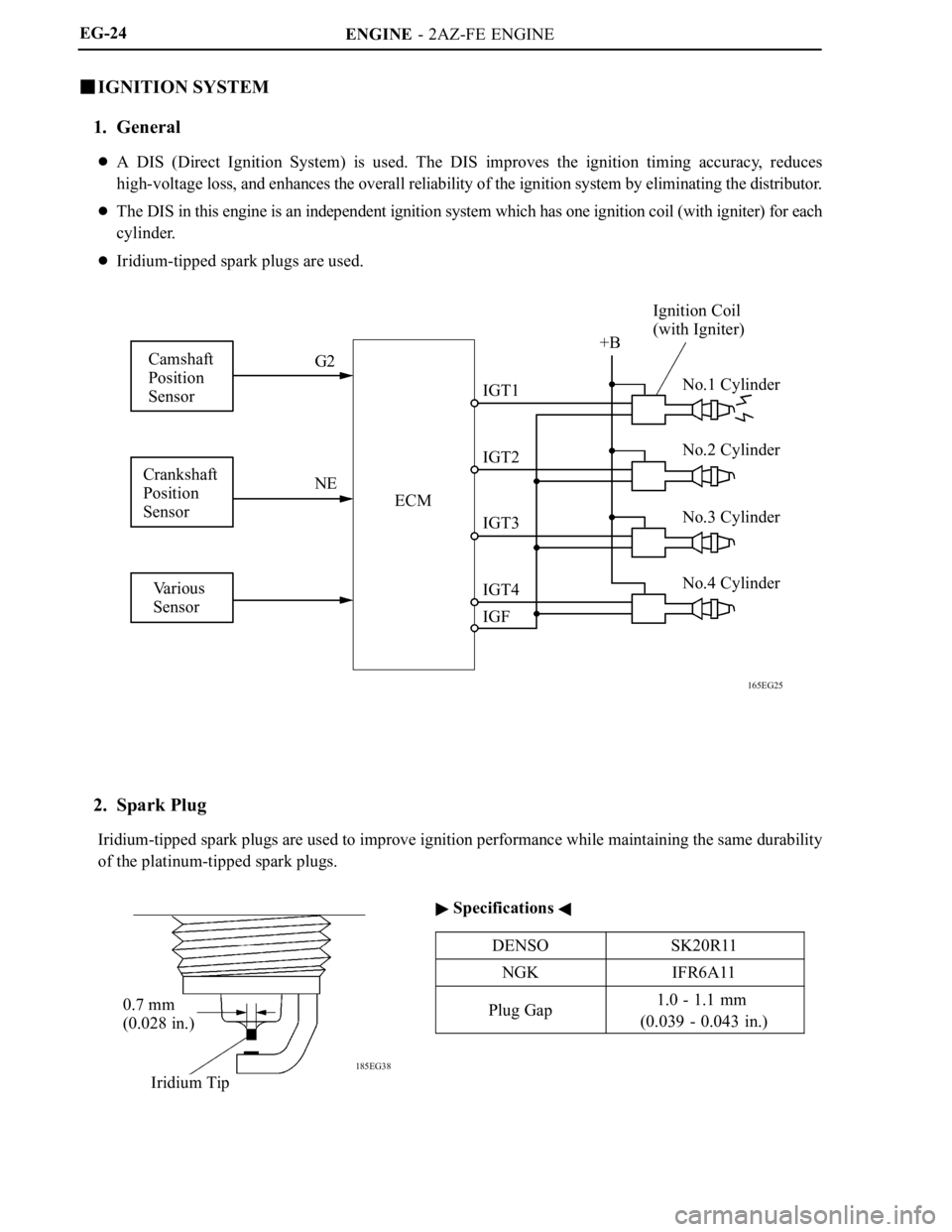

IGNITION SYSTEM

1. General

A DIS (Direct Ignition System) is used. The DIS improves the ignition timing accuracy, reduces

high-voltage loss, and enhances the overall reliability of the ignition system by eliminating the distributor.

The DIS in this engine is an independent ignition system which has one ignition coil (with igniter) for each

cylinder.

Iridium-tipped spark plugs are used.

2. Spark Plug

Iridium-tipped spark plugs are used to improve ignition performance while maintaining the same durability

of the platinum-tipped spark plugs.

Specifications

DENSOSK20R11

NGKIFR6A11

Plug Gap1.0 - 1.1 mm

(0.039 - 0.043 in.)

Page 27 of 2000

ENGINE - 2AZ-FE ENGINE EG-30

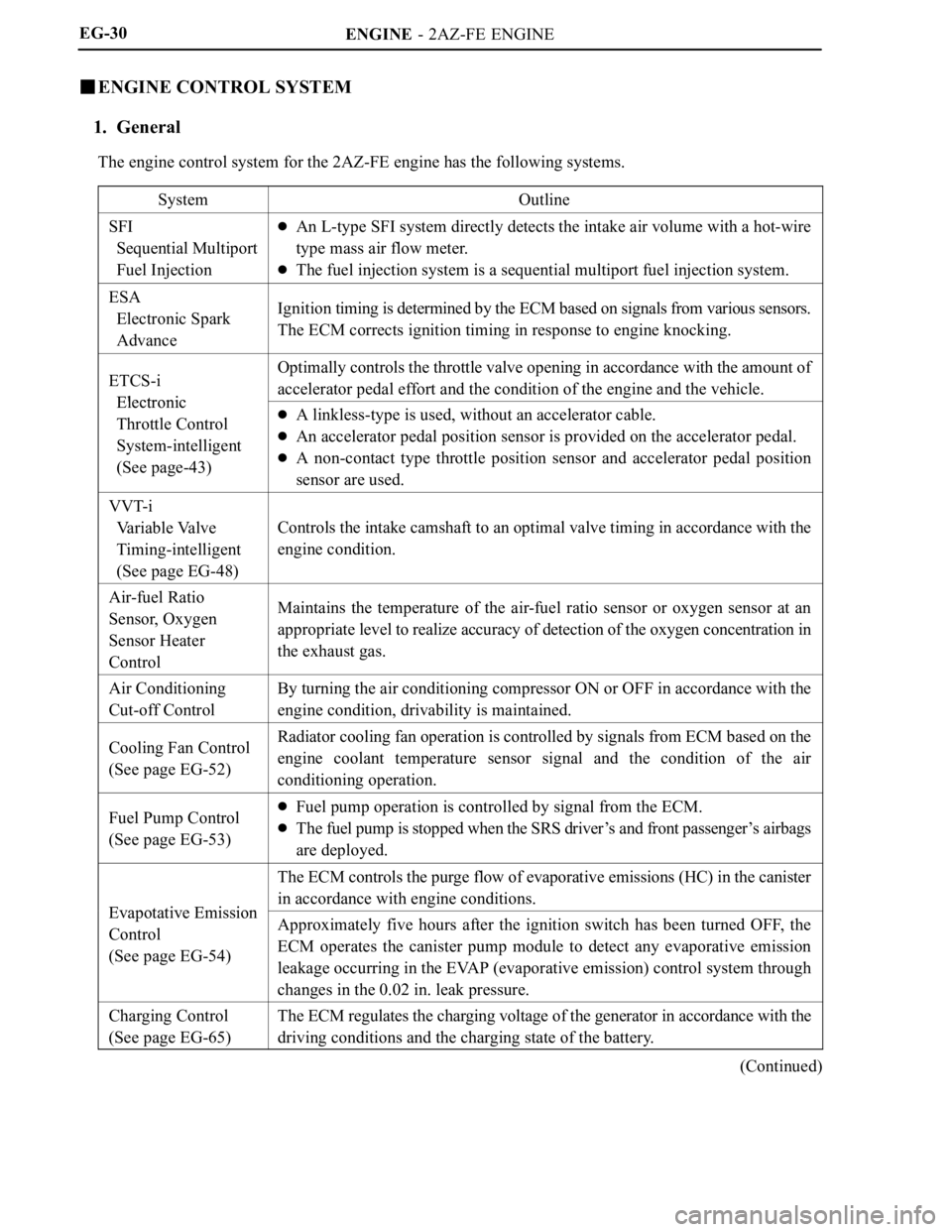

ENGINE CONTROL SYSTEM

1. General

The engine control system for the 2AZ-FE engine has the following systems.

System

Outline

SFI

Sequential Multiport

Fuel InjectionAn L-type SFI system directly detects the intake air volume with a hot-wire

type mass air flow meter.

The fuel injection system is a sequential multiport fuel injection system.

ESA

Electronic Spark

AdvanceIgnition timing is determined by the ECM based on signals from various sensors.

The ECM corrects ignition timing in response to engine knocking.

ETCS-i

Electronic

Optimally controls the throttle valve opening in accordance with the amount of

accelerator pedal effort and the condition of the engine and the vehicle.

Electronic

Throttle Control

System-intelligent

(See page-43)A linkless-type is used, without an accelerator cable.

An accelerator pedal position sensor is provided on the accelerator pedal.

A non-contact type throttle position sensor and accelerator pedal position

sensor are used.

VVT-i

Va r i a b l e Va l v e

Timing-intelligent

(See page EG-48)

Controls the intake camshaft to an optimal valve timing in accordance with the

engine condition.

Air-fuel Ratio

Sensor, Oxygen

Sensor Heater

ControlMaintains the temperature of the air-fuel ratio sensor or oxygen sensor at an

appropriate level to realize accuracy of detection of the oxygen concentration in

the exhaust gas.

Air Conditioning

Cut-off ControlBy turning the air conditioning compressor ON or OFF in accordance with the

engine condition, drivability is maintained.

Cooling Fan Control

(See page EG-52)Radiator cooling fan operation is controlled by signals from ECM based on the

engine coolant temperature sensor signal and the condition of the air

conditioning operation.

Fuel Pump Control

(See page EG-53)Fuel pump operation is controlled by signal from the ECM.

The fuel pump is stopped when the SRS driver’s and front passenger’s airbags

are deployed.

Evapotative Emission

The ECM controls the purge flow of evaporative emissions (HC) in the canister

in accordance with engine conditions.

Evapotative Emission

Control

(See page EG-54)Approximately five hours after the ignition switch has been turned OFF, the

ECM operates the canister pump module to detect any evaporative emission

leakage occurring in the EVAP (evaporative emission) control system through

changes in the 0.02 in. leak pressure.

Charging Control

(See page EG-65)The ECM regulates the charging voltage of the generator in accordance with the

driving conditions and the charging state of the battery.

(Continued)

Page 29 of 2000

ENGINE - 2AZ-FE ENGINE

01MEG04Y

SENSORSACTUATORS

MASS AIR FLOW METER

INTAKE AIR TEMPERATURE

SENSOR

ENGIEN COOLANT

TEMPERATURE SENSOR

THROTTLE POSITION

SENSOR

CRANKSHAFT POSITION

SENSOR

CAMSHAFT POSITION

SENSOR

ACCELERATOR PEDAL

POSITION SENSOR

AIR-FUEL RATIO SENSOR

(Bank 1, Sensor 1)

HEATED OXYGEN SENSOR

(Bank 1, Sensor 2)

KNOCK SENSOR

COMBINATION METER

Vehicle Speed Signal

IGNITION SWITCH

Ignition Signal

Starter Signal

PA R K / N E U T R A L P O S I T I O N

SWITCH

TRANSMISSION CONTROL

SWITCH

CRUISE CONTROL SWITCHVG

THA

THW

VTA1

VTA2

NE

G2

VPA

VPA2

A1A

OX1B

KNK1

SPD

IGSW

STA

D, 2, L

R, P, N

3

CCSECM#10

#20

#30

#40

IGT1 IGT4

IGF1

M

OC1

FC

HA1A

HT1BSFI

No.1 INJECTOR

No.2 INJECTOR

No.3 INJECTOR

No.4 INJECTOR

ESA

IGNITION COIL

with IGNITER

SPARK PLUGS

ETCS-i

THROTTLE CONTROL

MOTOR

VVT-i

CAMSHAFT TIMING OIL

CONTROL VALVE

FUEL PUMP CONTROL

CIRCUIT OPENING

RELAY

AIR-FUEL RATIO AND

HEATED OXYGEN SENSOR

HEATER CONTROL

AIR-FUEL RATIO SENSOR

HEATER (Bank1, Sensor1)

HEATED OXYGEN SENSOR

HEATER (Bank1, Sensor2)

EG-32

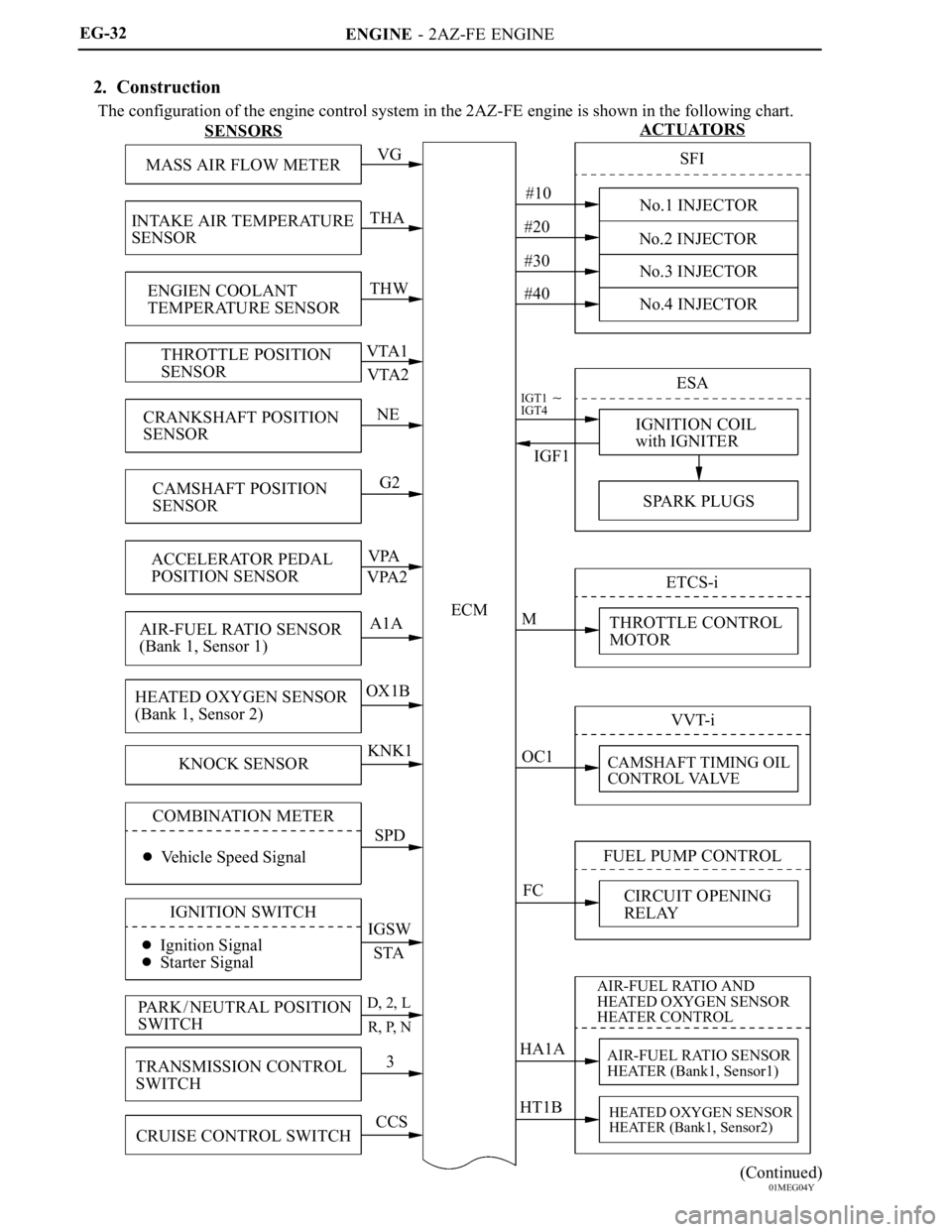

2. Construction

The configuration of the engine control system in the 2AZ-FE engine is shown in the following chart.

(Continued)

Page 31 of 2000

ENGINE - 2AZ-FE ENGINE

01MEG09Y

Accelerator Pedal

Position Sensor

Generator

MIL

DLC3Park / Neutral

Position Switch

Ignition

Switch

Circuit Opening RelayECM

Battery

Throttle

Position

Sensor

Throttle

Control

Motor

Purge VSVMass Air Flow Meter

Intake Air Temperature

Sensor

Camshaft Position

Sensor

Camshaft

Timing

Oil Control

Va l v e

Ignition Coil

with Igniter

Injector

Knock Sensor

Engine

Coolant

Temperature

Sensor

Crankshaft Position

Sensor

Canister

Filter

Fuel Pump

Canister Pump Module

Ve n t Va l v e

Leak Detection Pump

Canister Pressure SensorTWCs

Heated Oxygen Sensor

(Bank 1, Sensor 2)

Air-fuel Ratio Sensor

(Bank 1, Sensor 1) EG-34

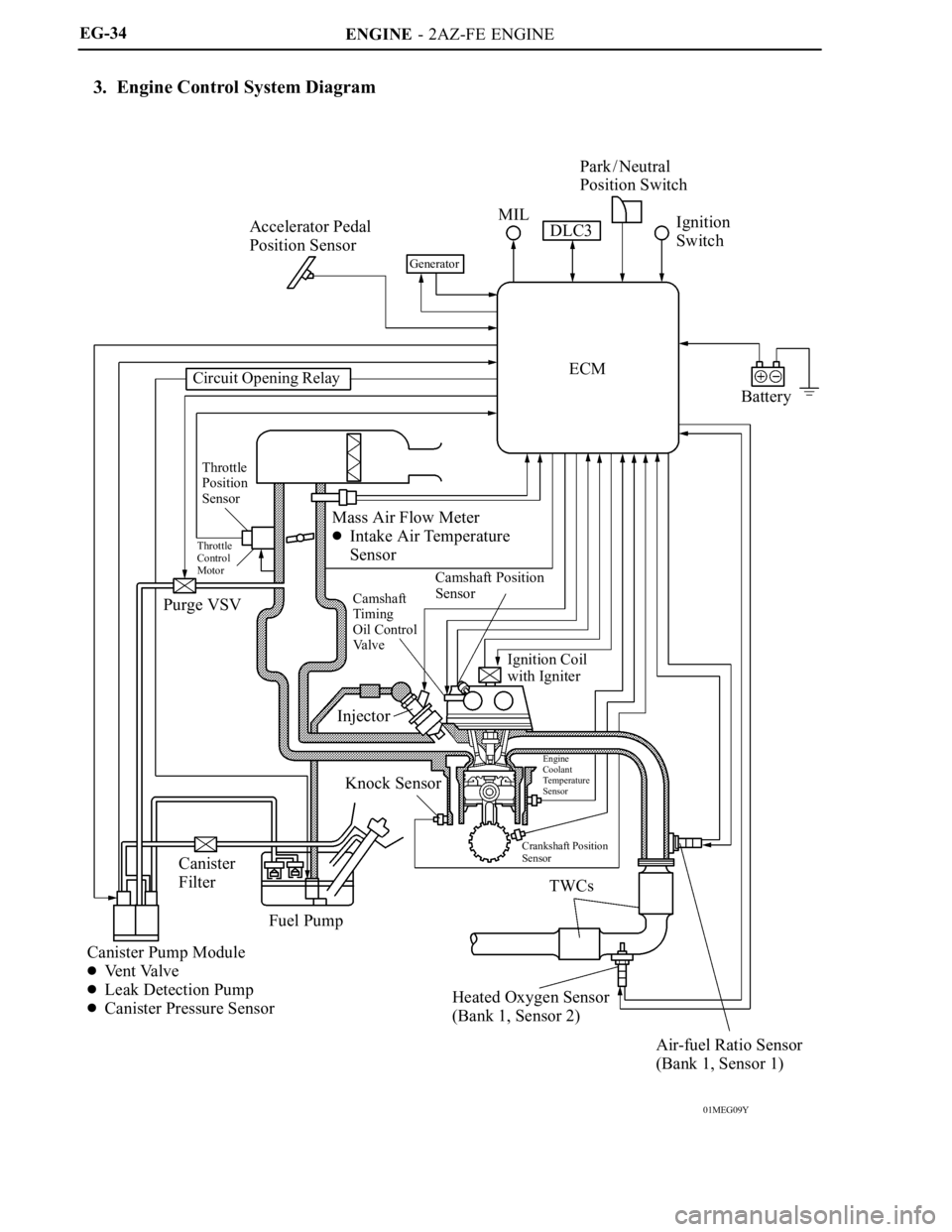

3. Engine Control System Diagram

Page 32 of 2000

ENGINE - 2AZ-FE ENGINE

01MEG31Y

DLC3

Accelerator Pedal

Position Sensor

Mass Air Flow Meter

(Built-in Intake Air

Temperature Sensor)

VSV (for EVAP)

Battery Current

Sensor

Fuel Pump

Canister Pump Module

Ve n t Va l v e

Leak Detection Pump

Canister Pressure Sensor

ECM

Heated Oxygen Sensor

(Bank 1, Sensor 2) Air Fuel Ratio Sensor

(Bank 1, Sensor 1)

Camshaft Timing

Oil Control ValveInjectorKnock Sensor

Ignition Coil with Igniter

Throttle Position

Sensor

Camshaft Position

Sensor

Water Temperature

Sensor

Crakshaft Position

SensorEG-35

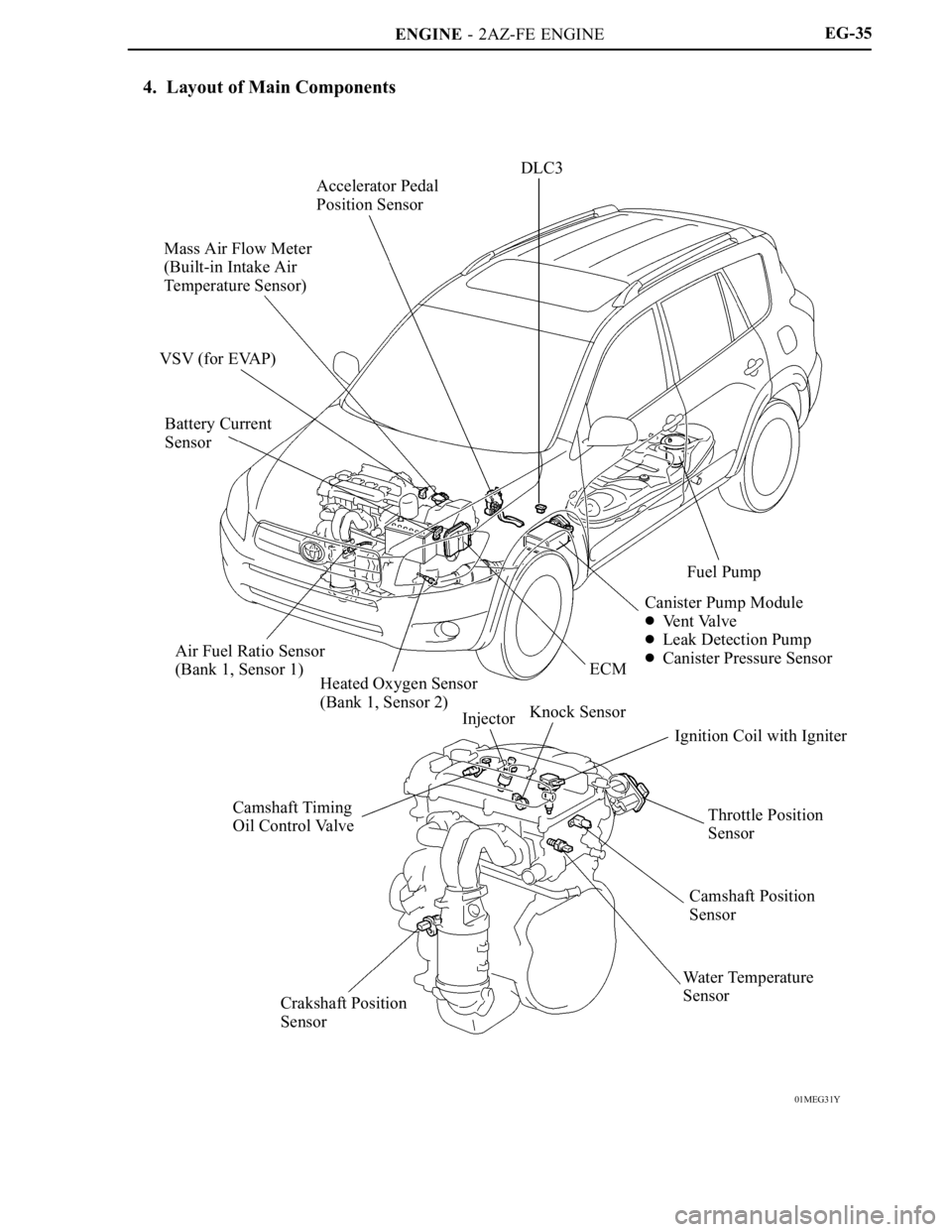

4. Layout of Main Components

Page 33 of 2000

ENGINE - 2AZ-FE ENGINE EG-36

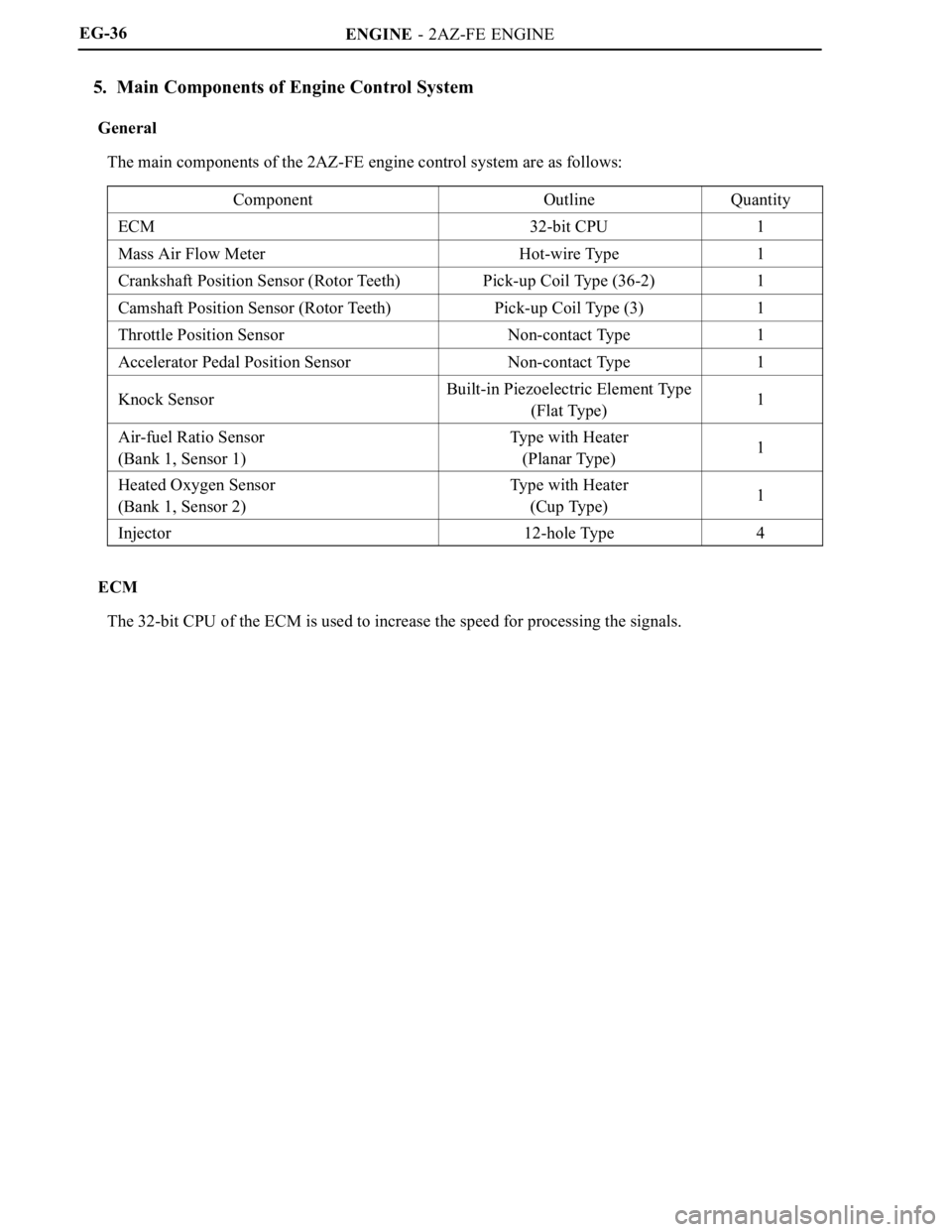

5. Main Components of Engine Control System

General

The main components of the 2AZ-FE engine control system are as follows:

Component

OutlineQuantity

ECM32-bit CPU1

Mass Air Flow MeterHot-wire Type1

Crankshaft Position Sensor (Rotor Teeth)Pick-up Coil Type (36-2)1

Camshaft Position Sensor (Rotor Teeth)Pick-up Coil Type (3)1

Throttle Position SensorNon-contact Type1

Accelerator Pedal Position SensorNon-contact Type1

Knock SensorBuilt-in Piezoelectric Element Type

(Flat Type)1

Air-fuel Ratio Sensor

(Bank 1, Sensor 1)Type with Heater

(Planar Type)1

Heated Oxygen Sensor

(Bank 1, Sensor 2)Type with Heater

(Cup Type)1

Injector12-hole Type4

ECM

The 32-bit CPU of the ECM is used to increase the speed for processing the signals.

Page 37 of 2000

ENGINE - 2AZ-FE ENGINE

214CE08

Steel Weight

Inertia

Piezoelectric

Element

214CE06

Knock Sensor

200 k

Piezoelectric

ElementOpen / Short Circuit

Detection ResistorKNK1

EKNKECM

5 V

200 k

IC

Service Tip

In accordance with the adoption of an open / short circuit detection resistor, the inspection

method for the sensor has been changed. For details, refer to the 2006 RAV4 Repair Manual

(Pub. No. RM01M1U).

To prevent the water accumulation in the connecter, make sure to install the flat type knock

sensor in the position as shown in the following illustration.

251EG12

10

10

Knock Sensor EG-40

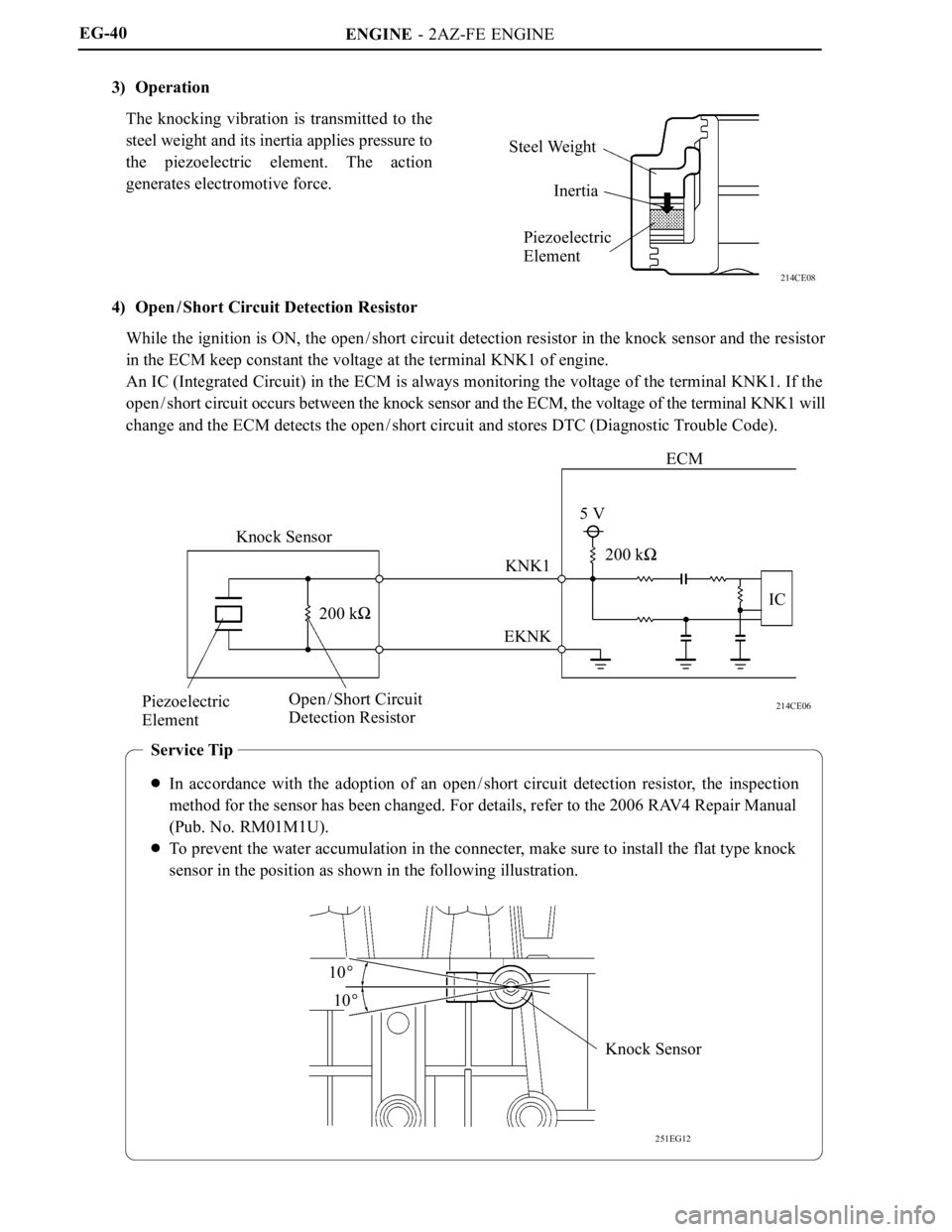

3) Operation

The knocking vibration is transmitted to the

steel weight and its inertia applies pressure to

the piezoelectric element. The action

generates electromotive force.

4) Open / Short Circuit Detection Resistor

While the ignition is ON, the open / short circuit detection resistor in the knock sensor and the resistor

in the ECM keep constant the voltage at the terminal KNK1 of engine.

An IC (Integrated Circuit) in the ECM is always monitoring the voltage of the terminal KNK1. If the

open / short circuit occurs between the knock sensor and the ECM, the voltage of the terminal KNK1 will

change and the ECM detects the open / short circuit and stores DTC (Diagnostic Trouble Code).