position sensor TOYOTA RAV4 2006 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 38 of 2000

ENGINE - 2AZ-FE ENGINE

01NEG43Y

238EG79

230LX12

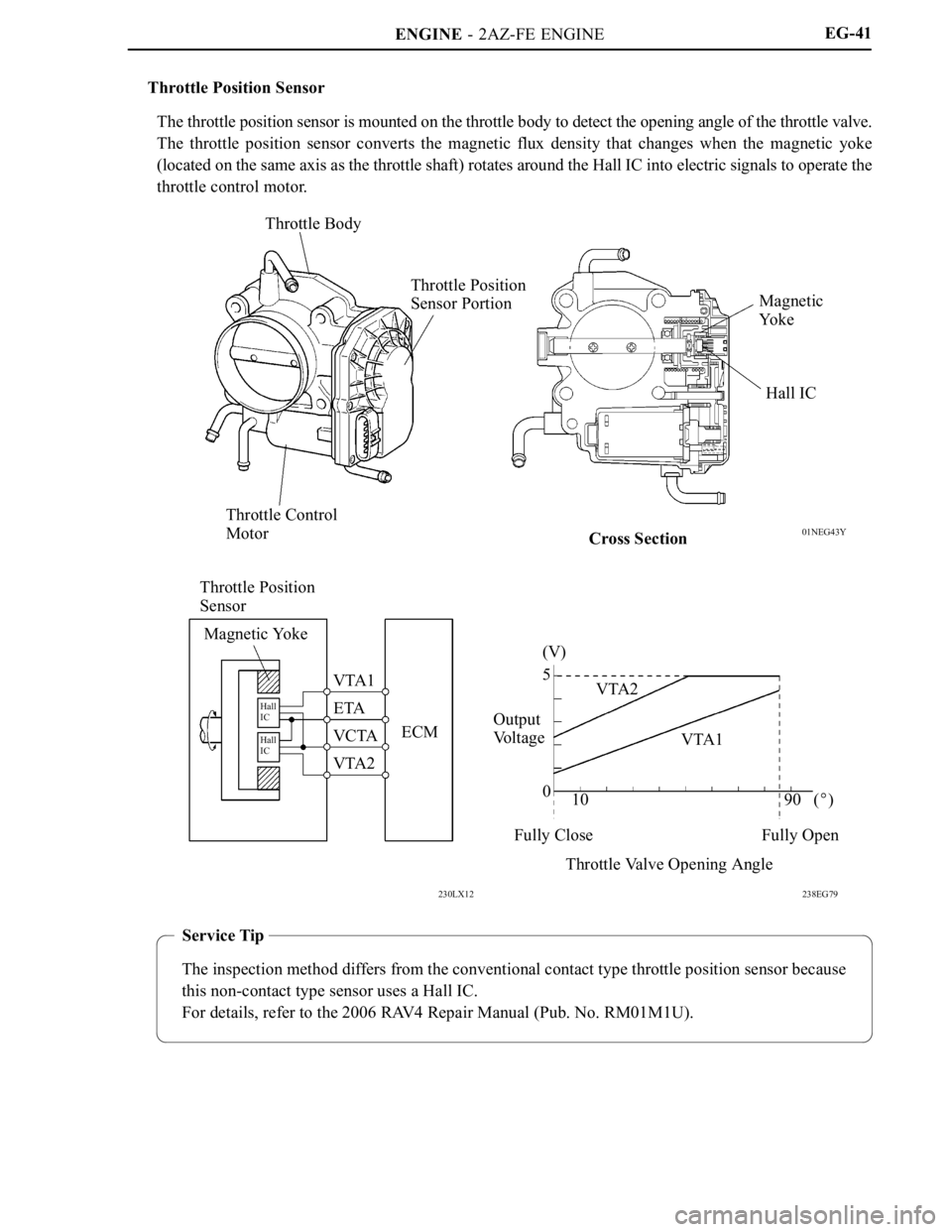

Throttle Body

Throttle Position

Sensor Portion

Throttle Control

MotorMagnetic

Yo k e

Hall IC

Cross Section

Throttle Position

Sensor

Magnetic Yoke

Hall

IC

Hall

IC

VTA1

ETA

VCTA

VTA2ECMOutput

Voltage(V)

5

0

Fully Close10 90 (

)

Fully Open VTA2

VTA1

Throttle Valve Opening Angle

Service Tip

The inspection method differs from the conventional contact type throttle position sensor because

this non-contact type sensor uses a Hall IC.

For details, refer to the 2006 RAV4 Repair Manual (Pub. No. RM01M1U).

EG-41

Throttle Position Sensor

The throttle position sensor is mounted on the throttle body to detect the opening angle of the throttle valve.

The throttle position sensor converts the magnetic flux density that changes when the magnetic yoke

(located on the same axis as the throttle shaft) rotates around the Hall IC into electric signals to operate the

throttle control motor.

Page 39 of 2000

ENGINE - 2AZ-FE ENGINE

00SEG39Y

228TU25 228TU24

A

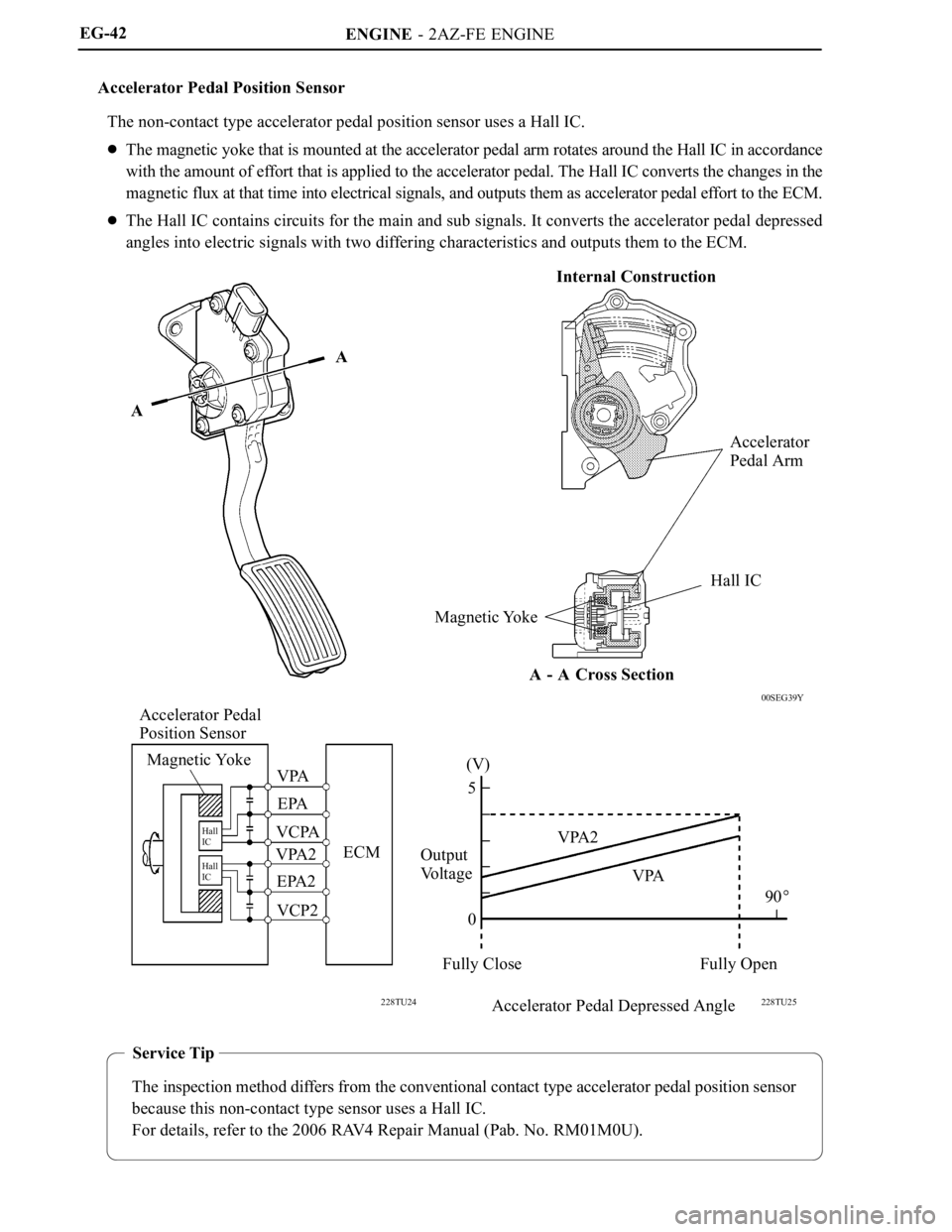

AInternal Construction

A - A Cross SectionAccelerator

Pedal Arm

Hall IC

Magnetic Yoke

Accelerator Pedal

Position Sensor

Magnetic Yoke

Hall

IC

Hall

IC

VPA

EPA

VCPA

VPA2

EPA2ECM

Output

Voltage(V)

5

0VPA2

VPA

Fully Close Fully Open90

Accelerator Pedal Depressed Angle VCP2

Service Tip

The inspection method differs from the conventional contact type accelerator pedal position sensor

because this non-contact type sensor uses a Hall IC.

For details, refer to the 2006 RAV4 Repair Manual (Pab. No. RM01M0U).

EG-42

Accelerator Pedal Position Sensor

The non-contact type accelerator pedal position sensor uses a Hall IC.

The magnetic yoke that is mounted at the accelerator pedal arm rotates around the Hall IC in accordance

with the amount of effort that is applied to the accelerator pedal. The Hall IC converts the changes in the

magnetic flux at that time into electrical signals, and outputs them as accelerator pedal effort to the ECM.

The Hall IC contains circuits for the main and sub signals. It converts the accelerator pedal depressed

angles into electric signals with two differing characteristics and outputs them to the ECM.

Page 40 of 2000

ENGINE - 2AZ-FE ENGINE

00REG17Y

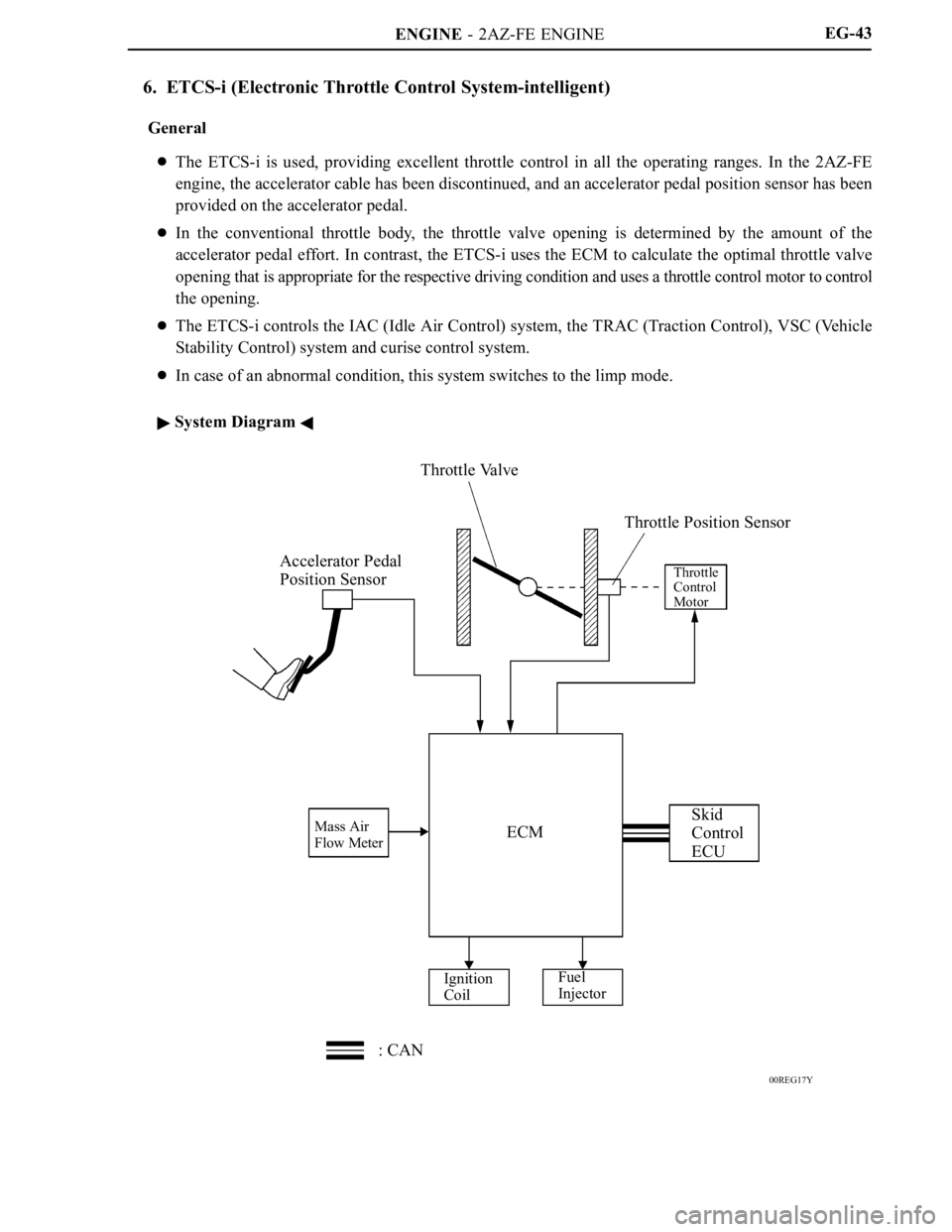

Accelerator Pedal

Position SensorThrottle Valve

Throttle Position SensorThrottle

Control

Motor

Mass Air

Flow MeterECMSkid

Control

ECU

Ignition

CoilFuel

Injector

: CANEG-43

6. ETCS-i (Electronic Throttle Control System-intelligent)

General

The ETCS-i is used, providing excellent throttle control in all the operating ranges. In the 2AZ-FE

engine, the accelerator cable has been discontinued, and an accelerator pedal position sensor has been

provided on the accelerator pedal.

In the conventional throttle body, the throttle valve opening is determined by the amount of the

accelerator pedal effort. In contrast, the ETCS-i uses the ECM to calculate the optimal throttle valve

opening that is appropriate for the respective driving condition and uses a throttle control motor to control

the opening.

The ETCS-i controls the IAC (Idle Air Control) system, the TRAC (Traction Control), VSC (Vehicle

Stability Control) system and curise control system.

In case of an abnormal condition, this system switches to the limp mode.

System Diagram

Page 41 of 2000

ENGINE - 2AZ-FE ENGINE

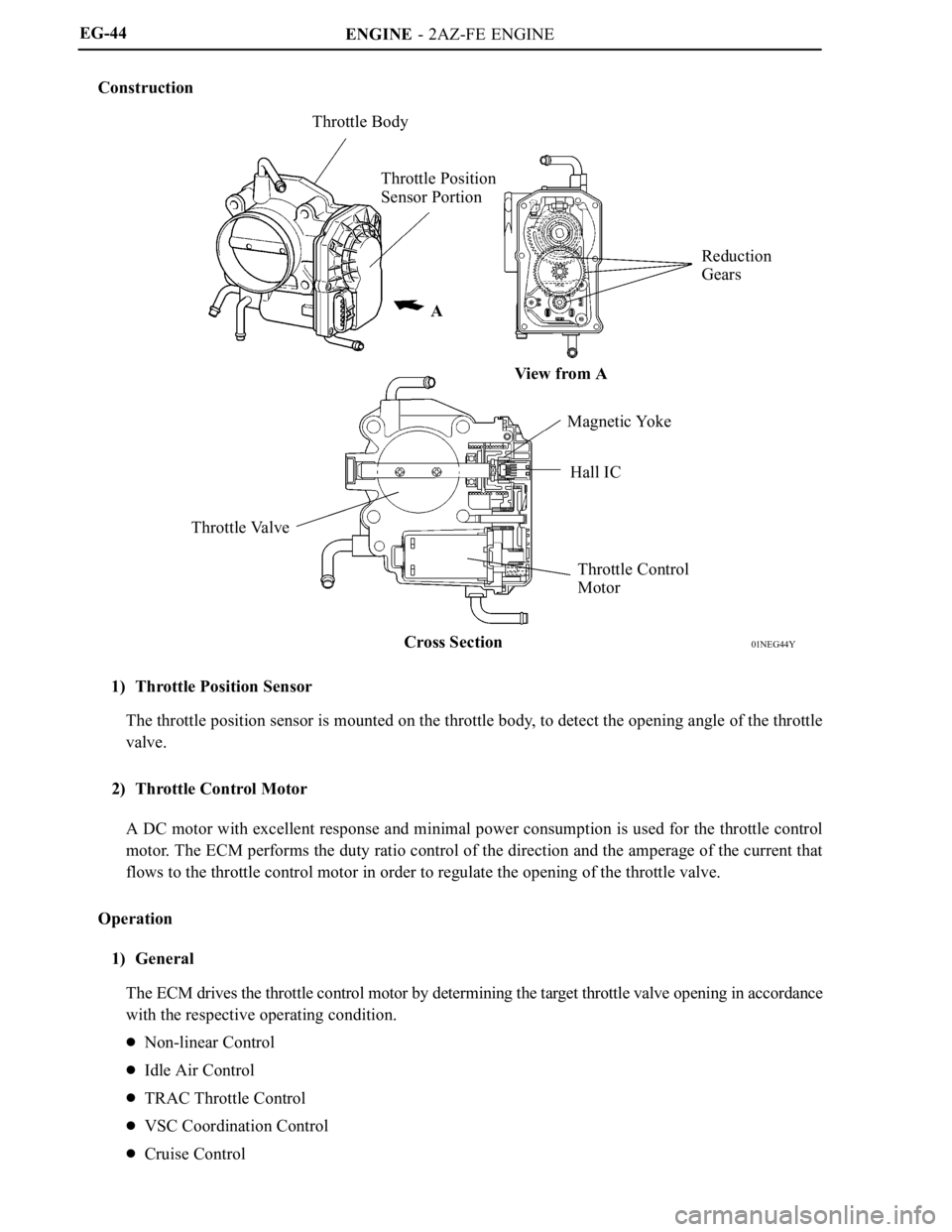

Throttle Body

Throttle Position

Sensor Portion

Reduction

Gears

Throttle ValveMagnetic Yoke

Hall IC

Throttle Control

Motor A

View from A

Cross Section

01NEG44Y

EG-44

Construction

1) Throttle Position Sensor

The throttle position sensor is mounted on the throttle body, to detect the opening angle of the throttle

valve.

2) Throttle Control Motor

A DC motor with excellent response and minimal power consumption is used for the throttle control

motor. The ECM performs the duty ratio control of the direction and the amperage of the current that

flows to the throttle control motor in order to regulate the opening of the throttle valve.

Operation

1) General

The ECM drives the throttle control motor by determining the target throttle valve opening in accordance

with the respective operating condition.

Non-linear Control

Idle Air Control

TRAC Throttle Control

VSC Coordination Control

Cruise Control

Page 43 of 2000

ENGINE - 2AZ-FE ENGINE

199EG45

ECM

Accelerator Pedal

Position Sensor

Main

Sub

Main

Sub

Throttle

Position

Sensor

Open

Throttle ValveReturn

SpringThrottle

Control

Motor

Accelerator Pedal Throttle Body

199EG46

Accelerator Pedal Throttle BodyECM

Accelerator Pedal

Position Sensor

Main

Sub

Close by

Return Spring

Main

Sub

Throttle

Position

SensorThrottle ValveReturn

SpringThrottle

Control

Motor EG-46

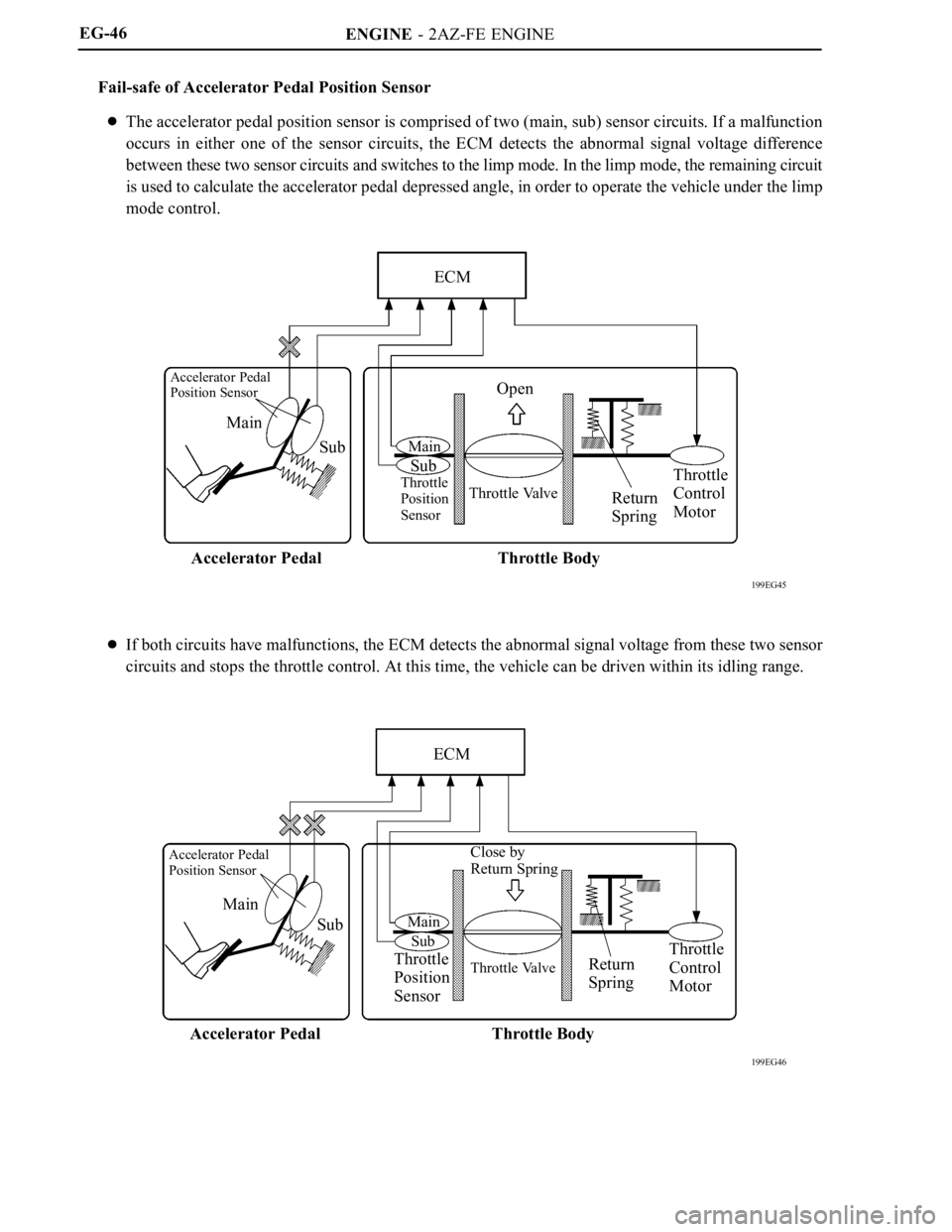

Fail-safe of Accelerator Pedal Position Sensor

The accelerator pedal position sensor is comprised of two (main, sub) sensor circuits. If a malfunction

occurs in either one of the sensor circuits, the ECM detects the abnormal signal voltage difference

between these two sensor circuits and switches to the limp mode. In the limp mode, the remaining circuit

is used to calculate the accelerator pedal depressed angle, in order to operate the vehicle under the limp

mode control.

If both circuits have malfunctions, the ECM detects the abnormal signal voltage from these two sensor

circuits and stops the throttle control. At this time, the vehicle can be driven within its idling range.

Page 44 of 2000

ENGINE - 2AZ-FE ENGINE

199EG47

Injectors

ECMIgnition Coils

Accelerator Pedal

Position Sensor

Main

Sub

Main

Sub

Return to

Prescribed Angle

Throttle ValveReturn

SpringThrottle

Control

Motor

Accelerator Pedal Throttle BodyEG-47

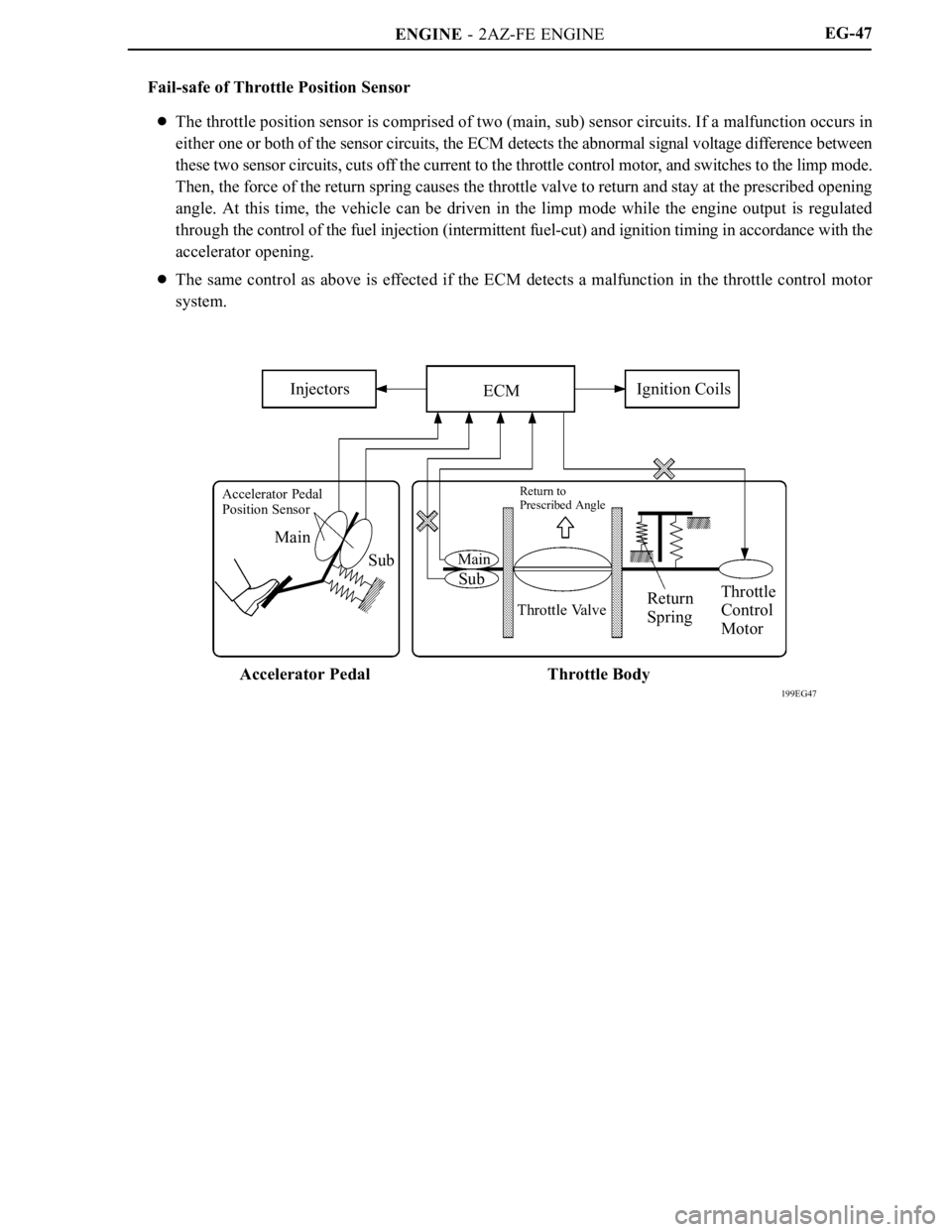

Fail-safe of Throttle Position Sensor

The throttle position sensor is comprised of two (main, sub) sensor circuits. If a malfunction occurs in

either one or both of the sensor circuits, the ECM detects the abnormal signal voltage difference between

these two sensor circuits, cuts off the current to the throttle control motor, and switches to the limp mode.

Then, the force of the return spring causes the throttle valve to return and stay at the prescribed opening

angle. At this time, the vehicle can be driven in the limp mode while the engine output is regulated

through the control of the fuel injection (intermittent fuel-cut) and ignition timing in accordance with the

accelerator opening.

The same control as above is effected if the ECM detects a malfunction in the throttle control motor

system.

Page 45 of 2000

ENGINE - 2AZ-FE ENGINE

DR011EG25

Camshaft Position Sensor

Engine Coolant

Temperature Sensor

Crankshaft

Position Sensor

Camshaft Timing

Oil Control Valve

Throttle Position

Sensor

ECM

Mass Air Flow Meter Vehicle Speed Signal

221EG16

Crankshaft Position Sensor

Mass Air Flow Meter

Throttle Position Sensor

Engine Coolant Temp. Sensor

Camshaft Position Sensor

Vehicle Speed SignalECM

Target Valve Timing

Feedback

Correction

Actual Valve Timing

Duty-cycle

Control

Camshaft Timing

Oil Control Valve

EG-48

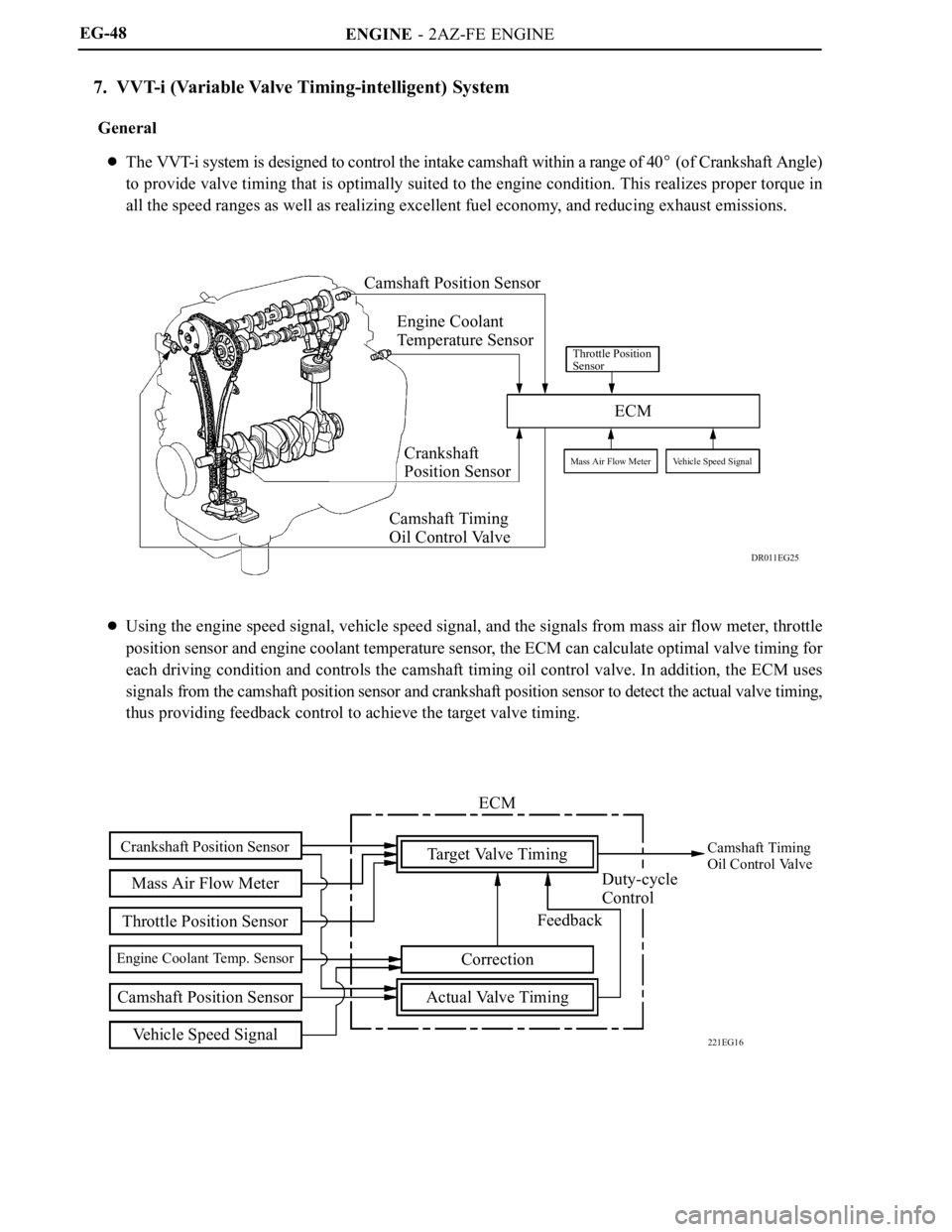

7. VVT-i (Variable Valve Timing-intelligent) System

General

The VVT-i system is designed to control the intake camshaft within a range of 40 (of Crankshaft Angle)

to provide valve timing that is optimally suited to the engine condition. This realizes proper torque in

all the speed ranges as well as realizing excellent fuel economy, and reducing exhaust emissions.

Using the engine speed signal, vehicle speed signal, and the signals from mass air flow meter, throttle

position sensor and engine coolant temperature sensor, the ECM can calculate optimal valve timing for

each driving condition and controls the camshaft timing oil control valve. In addition, the ECM uses

signals from the camshaft position sensor and crankshaft position sensor to detect the actual valve timing,

thus providing feedback control to achieve the target valve timing.

Page 62 of 2000

ENGINE - 2AZ-FE ENGINE

01NEG13Y

Generator

RegulatorB

DF

RLOECM

Various Electrical

Loads

Battery Current Sensor

Battery Temperature Sensor

Battery Voltage

Battery

Various Sensors and Switches

Throttle Position Sensor

Crankshaft Position Sensor

Accelerator Pedal Position

SensorEG-65

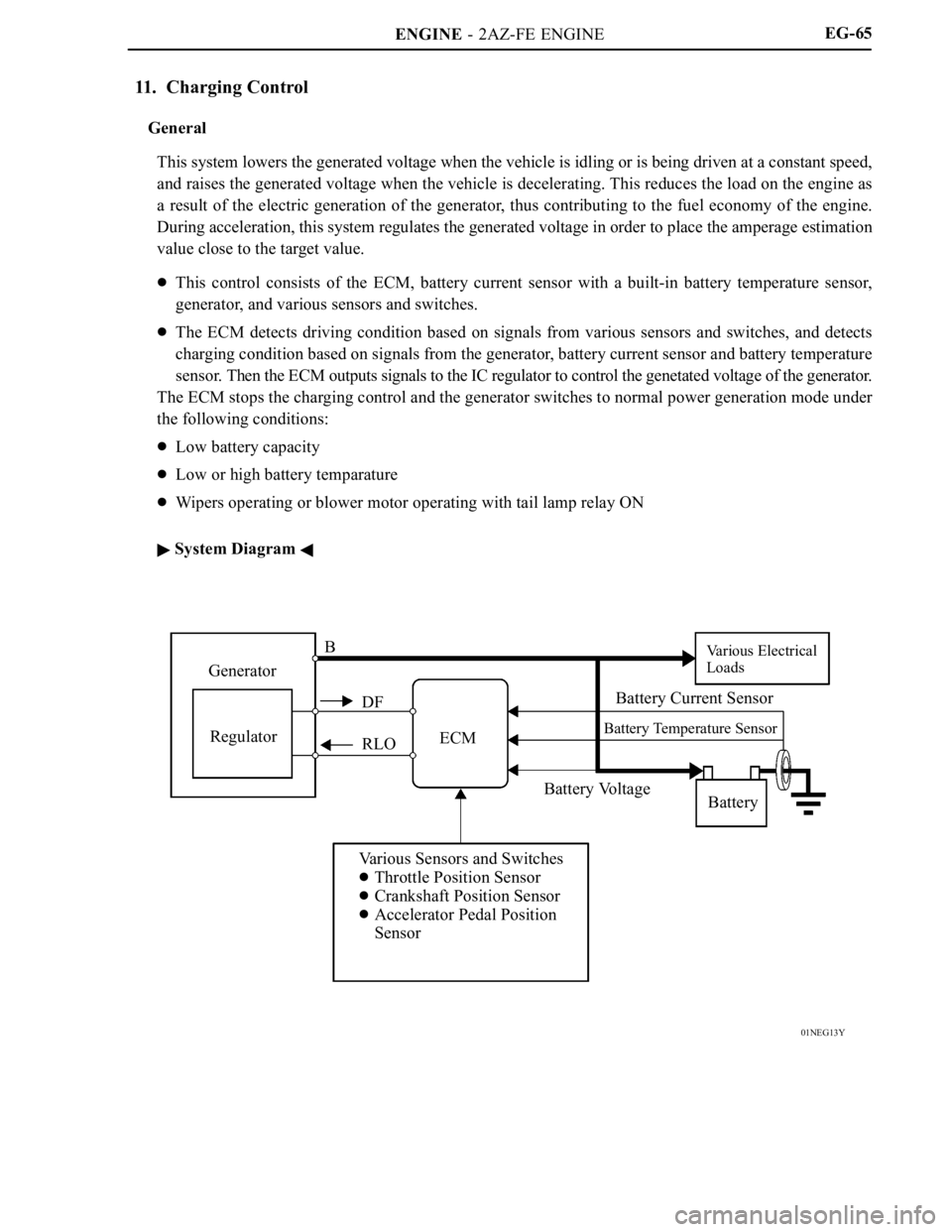

11. Charging Control

General

This system lowers the generated voltage when the vehicle is idling or is being driven at a constant speed,

and raises the generated voltage when the vehicle is decelerating. This reduces the load on the engine as

a result of the electric generation of the generator, thus contributing to the fuel economy of the engine.

During acceleration, this system regulates the generated voltage in order to place the amperage estimation

value close to the target value.

This control consists of the ECM, battery current sensor with a built-in battery temperature sensor,

generator, and various sensors and switches.

The ECM detects driving condition based on signals from various sensors and switches, and detects

charging condition based on signals from the generator, battery current sensor and battery temperature

sensor. Then the ECM outputs signals to the IC regulator to control the genetated voltage of the generator.

The ECM stops the charging control and the generator switches to normal power generation mode under

the following conditions:

Low battery capacity

Low or high battery temparature

Wipers operating or blower motor operating with tail lamp relay ON

System Diagram

Page 87 of 2000

ENGINE - 2GR-FE ENGINE

01MEG13Y

Air Cleaner Hose with

Resonator

Air Cleaner Cap

Charcoal Filter

Air Cleaner Element

(Nonwoven Fabric)

Air Cleaner Case

Actuator

(For Air Intake Control)

Air Cleaner Inlet

Resonator

285EG32

Throttle Position Sensor

Throttle Control MotorEG-91

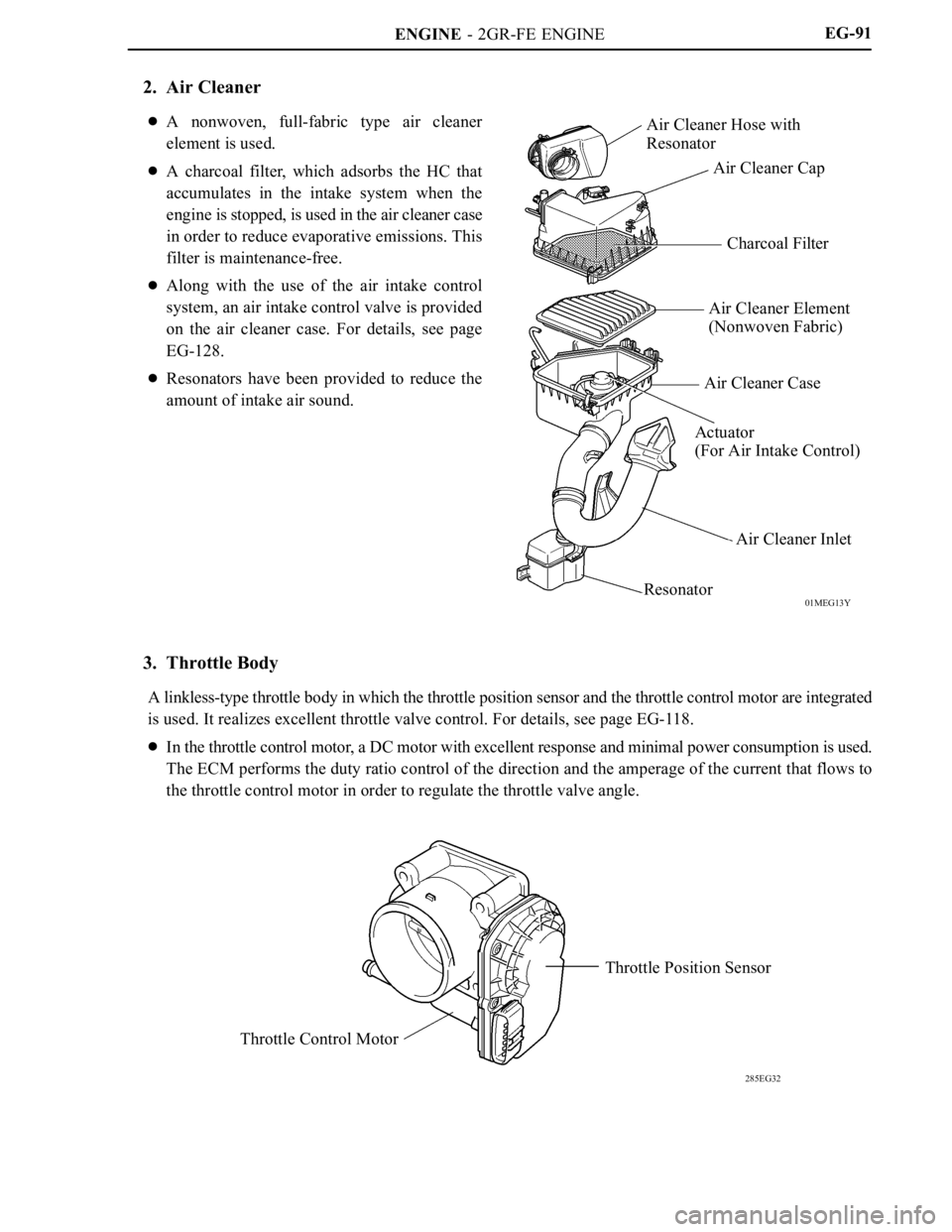

2. Air Cleaner

A nonwoven, full-fabric type air cleaner

element is used.

A charcoal filter, which adsorbs the HC that

accumulates in the intake system when the

engine is stopped, is used in the air cleaner case

in order to reduce evaporative emissions. This

filter is maintenance-free.

Along with the use of the air intake control

system, an air intake control valve is provided

on the air cleaner case. For details, see page

EG-128.

Resonators have been provided to reduce the

amount of intake air sound.

3. Throttle Body

A linkless-type throttle body in which the throttle position sensor and the throttle control motor are integrated

is used. It realizes excellent throttle valve control. For details, see page EG-118.

In the throttle control motor, a DC motor with excellent response and minimal power consumption is used.

The ECM performs the duty ratio control of the direction and the amperage of the current that flows to

the throttle control motor in order to regulate the throttle valve angle.

Page 92 of 2000

ENGINE - 2GR-FE ENGINE

238EG68

VVT Sensors

Crankshaft

Position

Sensor

Va r i o u s

SensorsVV1

VV2

NE

ECMIGT1

IGT2

IGT3

IGT4

IGT5

IGT6

IGF+B Ignition Coil (with Igniter)

No. 1 Cylinder

No. 2 Cylinder

No. 3 Cylinder

No. 4 Cylinder

No. 5 Cylinder

No. 6 Cylinder

285EG39

Igniter

Iron Core

Secondary

Coil

Primary Coil

Plug Cap EG-96

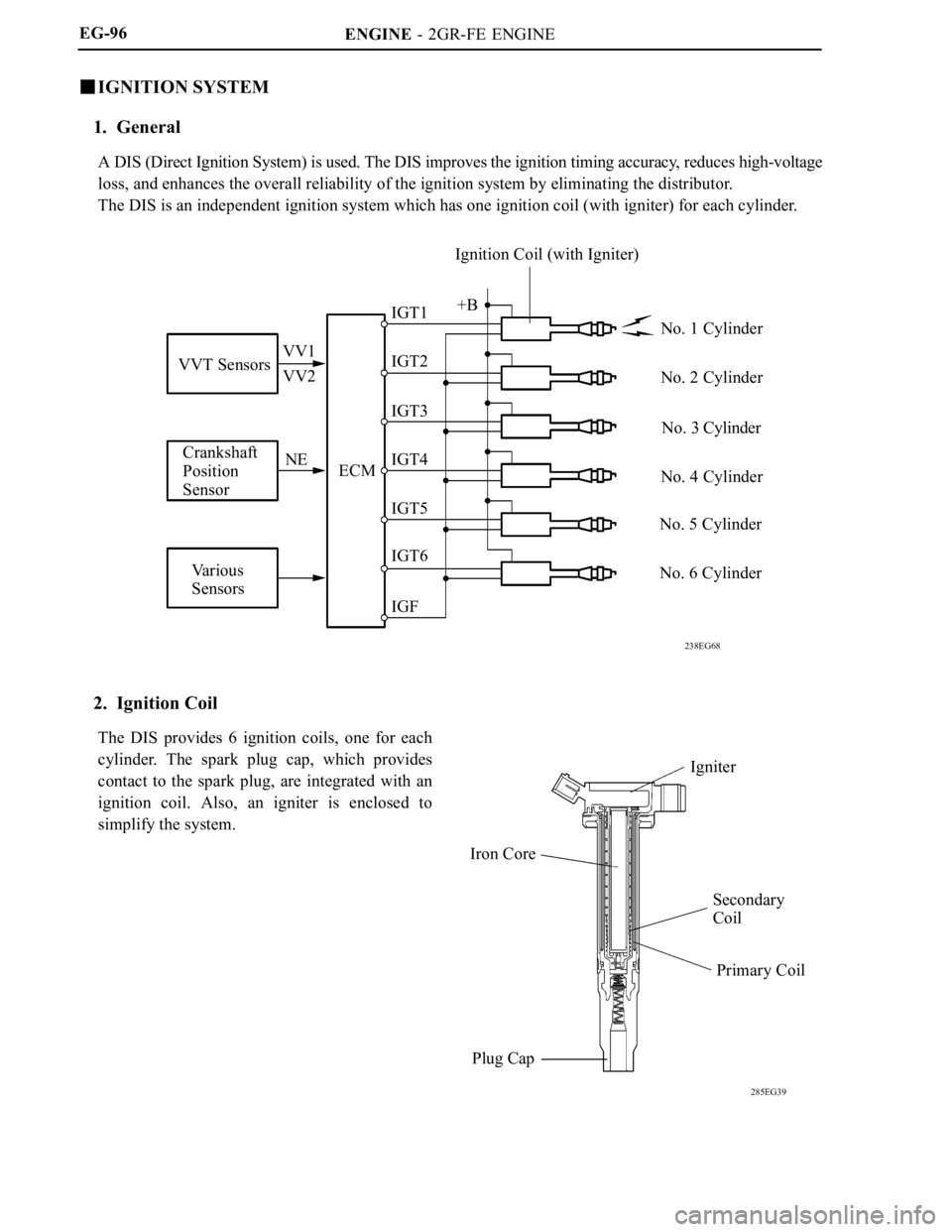

IGNITION SYSTEM

1. General

A DIS (Direct Ignition System) is used. The DIS improves the ignition timing accuracy, reduces high-voltage

loss, and enhances the overall reliability of the ignition system by eliminating the distributor.

The DIS is an independent ignition system which has one ignition coil (with igniter) for each cylinder.

2. Ignition Coil

The DIS provides 6 ignition coils, one for each

cylinder. The spark plug cap, which provides

contact to the spark plug, are integrated with an

ignition coil. Also, an igniter is enclosed to

simplify the system.