engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1527 of 3000

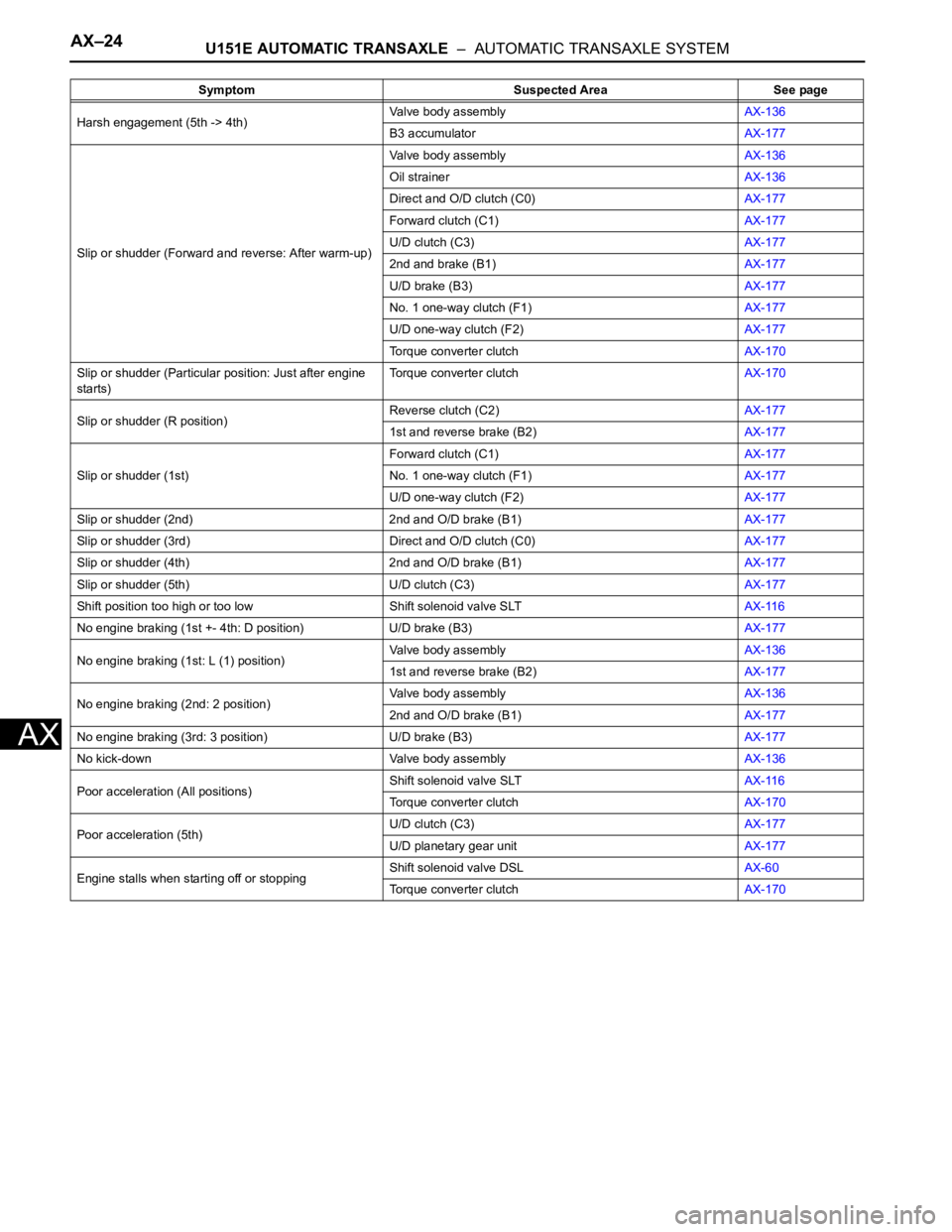

AX–24U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

Harsh engagement (5th -> 4th)Valve body assemblyAX-136

B3 accumulatorAX-177

Slip or shudder (Forward and reverse: After warm-up)Valve body assemblyAX-136

Oil strainerAX-136

Direct and O/D clutch (C0)AX-177

Forward clutch (C1)AX-177

U/D clutch (C3)AX-177

2nd and brake (B1)AX-177

U/D brake (B3)AX-177

No. 1 one-way clutch (F1)AX-177

U/D one-way clutch (F2)AX-177

Torque converter clutchAX-170

Slip or shudder (Particular position: Just after engine

starts)Torque converter clutchAX-170

Slip or shudder (R position)Reverse clutch (C2)AX-177

1st and reverse brake (B2)AX-177

Slip or shudder (1st)Forward clutch (C1)AX-177

No. 1 one-way clutch (F1)AX-177

U/D one-way clutch (F2)AX-177

Slip or shudder (2nd) 2nd and O/D brake (B1)AX-177

Slip or shudder (3rd) Direct and O/D clutch (C0)AX-177

Slip or shudder (4th) 2nd and O/D brake (B1)AX-177

Slip or shudder (5th) U/D clutch (C3)AX-177

Shift position too high or too low Shift solenoid valve SLTAX-116

No engine braking (1st +- 4th: D position) U/D brake (B3)AX-177

No engine braking (1st: L (1) position)Valve body assemblyAX-136

1st and reverse brake (B2)AX-177

No engine braking (2nd: 2 position)Valve body assemblyAX-136

2nd and O/D brake (B1)AX-177

No engine braking (3rd: 3 position) U/D brake (B3)AX-177

No kick-down Valve body assemblyAX-136

Poor acceleration (All positions)Shift solenoid valve SLTAX-116

Torque converter clutchAX-170

Poor acceleration (5th)U/D clutch (C3)AX-177

U/D planetary gear unitAX-177

Engine stalls when starting off or stoppingShift solenoid valve DSLAX-60

Torque converter clutchAX-170 Symptom Suspected Area See page

Page 1531 of 3000

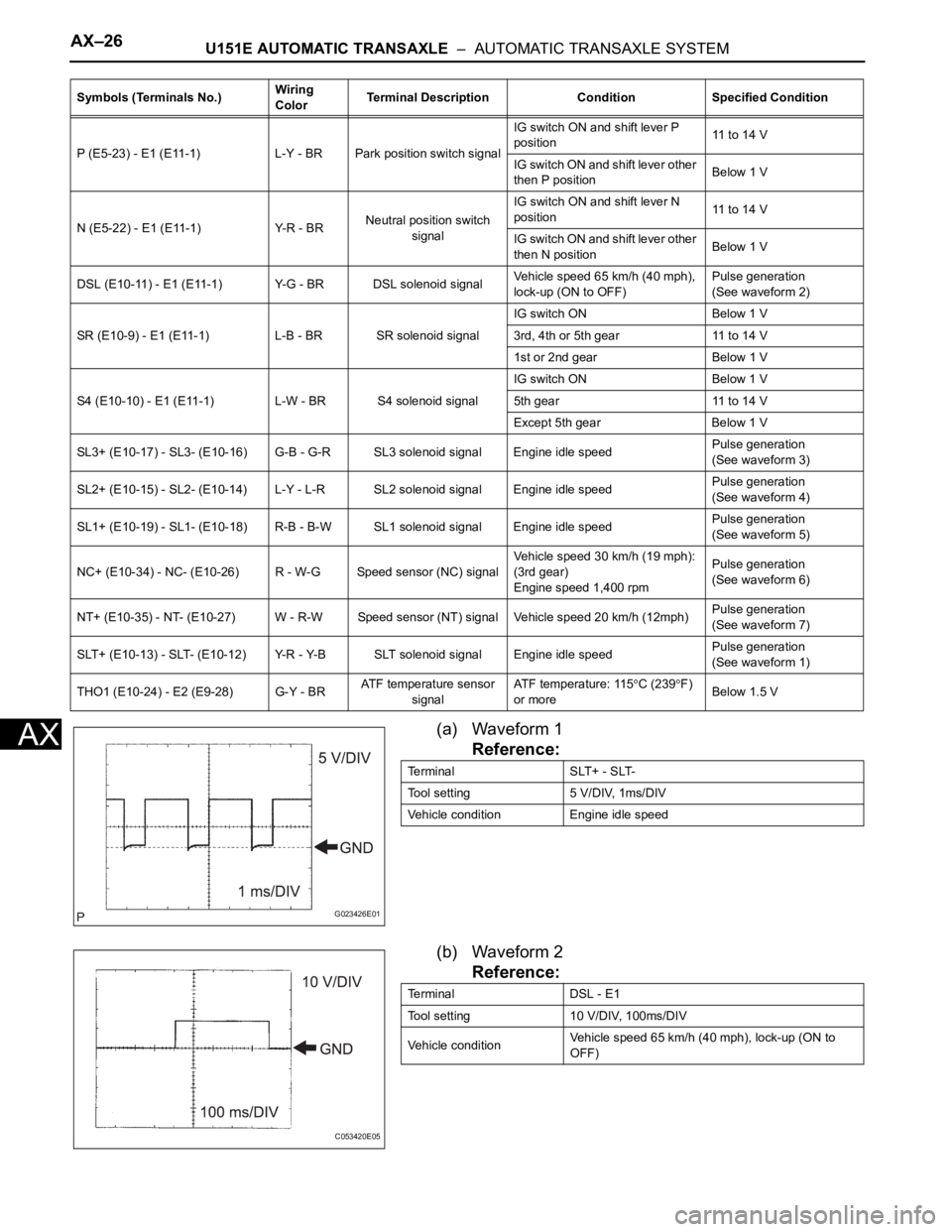

AX–26U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX(a) Waveform 1

Reference:

(b) Waveform 2

Reference:

P (E5-23) - E1 (E11-1) L-Y - BR Park position switch signalIG switch ON and shift lever P

position11 to 14 V

IG switch ON and shift lever other

then P positionBelow 1 V

N (E5-22) - E1 (E11-1) Y-R - BRNeutral position switch

signalIG switch ON and shift lever N

position11 to 14 V

IG switch ON and shift lever other

then N positionBelow 1 V

DSL (E10-11) - E1 (E11-1) Y-G - BR DSL solenoid signalVehicle speed 65 km/h (40 mph),

lock-up (ON to OFF)Pulse generation

(See waveform 2)

SR (E10-9) - E1 (E11-1) L-B - BR SR solenoid signalIG switch ON Below 1 V

3rd, 4th or 5th gear 11 to 14 V

1st or 2nd gear Below 1 V

S4 (E10-10) - E1 (E11-1) L-W - BR S4 solenoid signalIG switch ON Below 1 V

5th gear 11 to 14 V

Except 5th gear Below 1 V

SL3+ (E10-17) - SL3- (E10-16) G-B - G-R SL3 solenoid signal Engine idle speedPulse generation

(See waveform 3)

SL2+ (E10-15) - SL2- (E10-14) L-Y - L-R SL2 solenoid signal Engine idle speedPulse generation

(See waveform 4)

SL1+ (E10-19) - SL1- (E10-18) R-B - B-W SL1 solenoid signal Engine idle speedPulse generation

(See waveform 5)

NC+ (E10-34) - NC- (E10-26) R - W-G Speed sensor (NC) signalVehicle speed 30 km/h (19 mph):

(3rd gear)

Engine speed 1,400 rpmPulse generation

(See waveform 6)

NT+ (E10-35) - NT- (E10-27) W - R-W Speed sensor (NT) signal Vehicle speed 20 km/h (12mph)Pulse generation

(See waveform 7)

SLT+ (E10-13) - SLT- (E10-12) Y-R - Y-B SLT solenoid signal Engine idle speedPulse generation

(See waveform 1)

THO1 (E10-24) - E2 (E9-28) G-Y - BRATF temperature sensor

signalATF temperature: 115

C (239F)

or moreBelow 1.5 V Symbols (Terminals No.)Wiring

ColorTerminal Description Condition Specified Condition

G023426E01

Terminal SLT+ - SLT-

Tool setting 5 V/DIV, 1ms/DIV

Vehicle condition Engine idle speed

C053420E05

Terminal DSL - E1

Tool setting 10 V/DIV, 100ms/DIV

Vehicle conditionVehicle speed 65 km/h (40 mph), lock-up (ON to

OFF)

Page 1532 of 3000

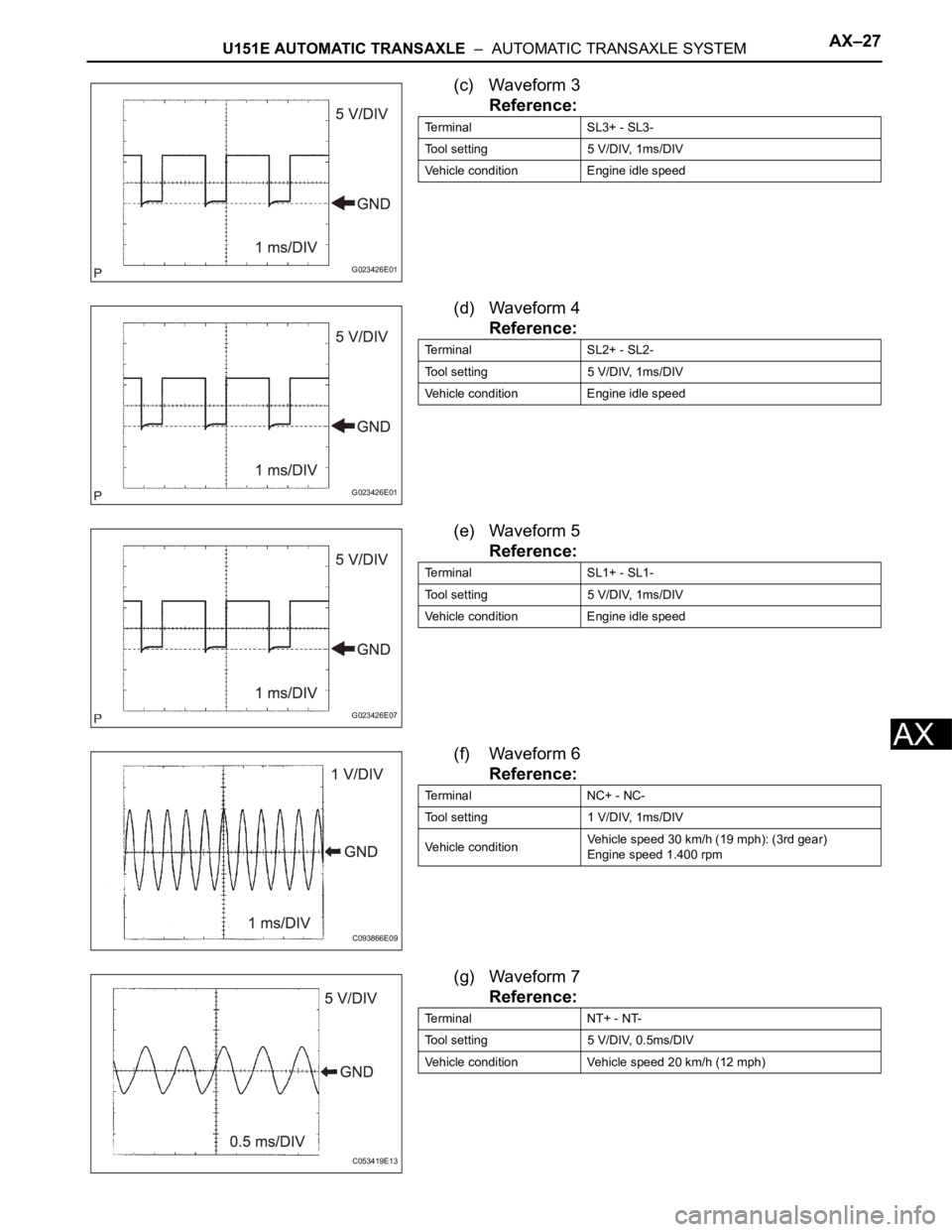

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–27

AX

(c) Waveform 3

Reference:

(d) Waveform 4

Reference:

(e) Waveform 5

Reference:

(f) Waveform 6

Reference:

(g) Waveform 7

Reference:

G023426E01

Terminal SL3+ - SL3-

Tool setting 5 V/DIV, 1ms/DIV

Vehicle condition Engine idle speed

G023426E01

Terminal SL2+ - SL2-

Tool setting 5 V/DIV, 1ms/DIV

Vehicle condition Engine idle speed

G023426E07

Terminal SL1+ - SL1-

Tool setting 5 V/DIV, 1ms/DIV

Vehicle condition Engine idle speed

C093866E09

Terminal NC+ - NC-

Tool setting 1 V/DIV, 1ms/DIV

Vehicle conditionVehicle speed 30 km/h (19 mph): (3rd gear)

Engine speed 1.400 rpm

C053419E13

Terminal NT+ - NT-

Tool setting 5 V/DIV, 0.5ms/DIV

Vehicle condition Vehicle speed 20 km/h (12 mph)

Page 1538 of 3000

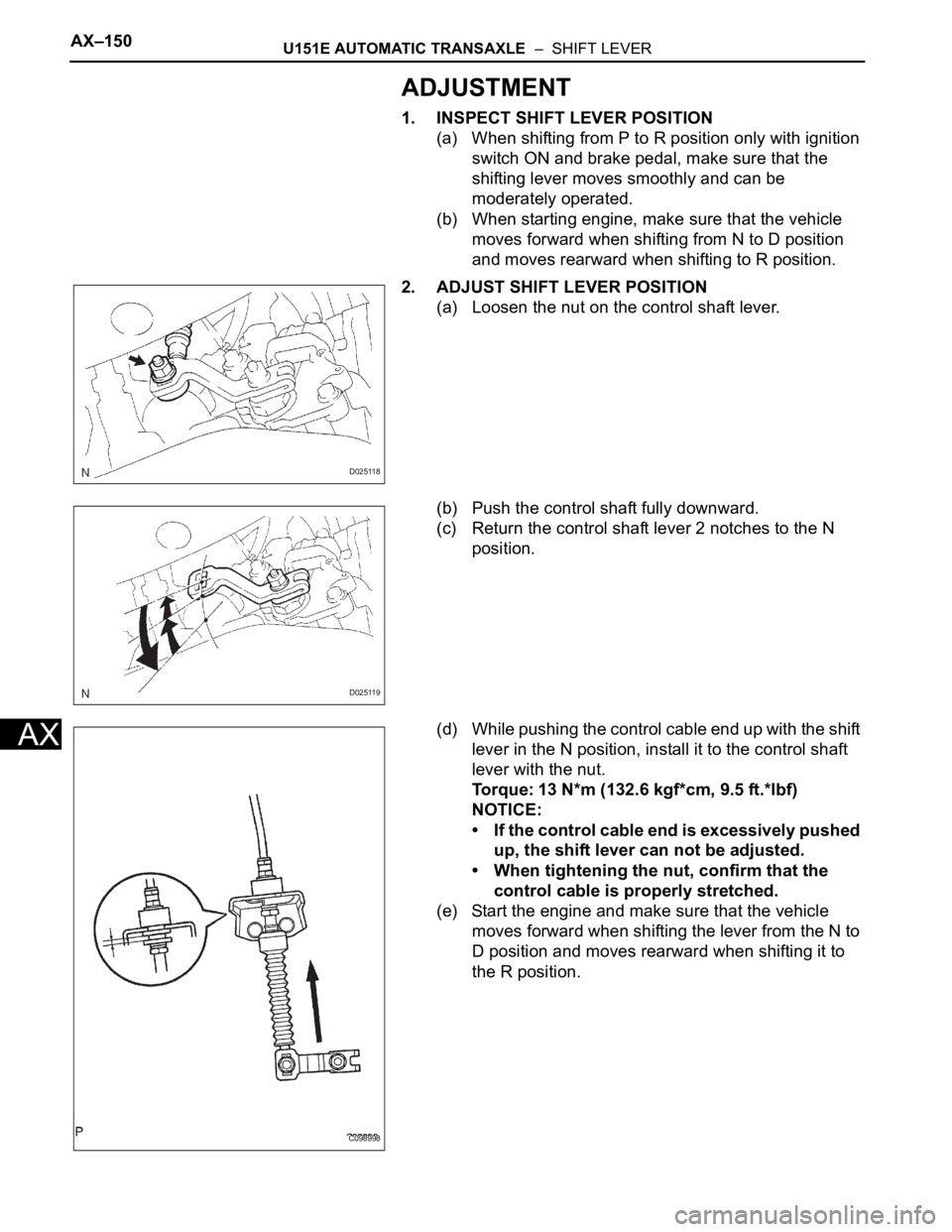

AX–150U151E AUTOMATIC TRANSAXLE – SHIFT LEVER

AX

ADJUSTMENT

1. INSPECT SHIFT LEVER POSITION

(a) When shifting from P to R position only with ignition

switch ON and brake pedal, make sure that the

shifting lever moves smoothly and can be

moderately operated.

(b) When starting engine, make sure that the vehicle

moves forward when shifting from N to D position

and moves rearward when shifting to R position.

2. ADJUST SHIFT LEVER POSITION

(a) Loosen the nut on the control shaft lever.

(b) Push the control shaft fully downward.

(c) Return the control shaft lever 2 notches to the N

position.

(d) While pushing the control cable end up with the shift

lever in the N position, install it to the control shaft

lever with the nut.

Torque: 13 N*m (132.6 kgf*cm, 9.5 ft.*lbf)

NOTICE:

• If the control cable end is excessively pushed

up, the shift lever can not be adjusted.

• When tightening the nut, confirm that the

control cable is properly stretched.

(e) Start the engine and make sure that the vehicle

moves forward when shifting the lever from the N to

D position and moves rearward when shifting it to

the R position.

D025118

D025119

C098998

Page 1542 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–29

AX

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) When troubleshooting OBD II vehicles, the only

difference from the usual troubleshooting procedure

is to connect an OBD II scan tool complying with

SAE J1987 or a intelligent tester to the vehicle, and

read off various data output from the vehicle's ECM.

(b) OBD II regulations require that the vehicle's on-

board computer illuminate the Malfunction Indicator

Lamp (MIL) on the instrument panel when the

computer detects a malfunction in the computer

itself or in the drive system components whic h affect

the vehicle emissions. In addition to illuminating the

MIL when a malfunction is detected, the applicable

DTCs prescribed by SAE J2012 are recorded in the

ECM memory (See page AX-35).

If the malfunction does not occur in 3 consecutive

trips, the MIL goes off but the DTCs remain in the

ECM memory.

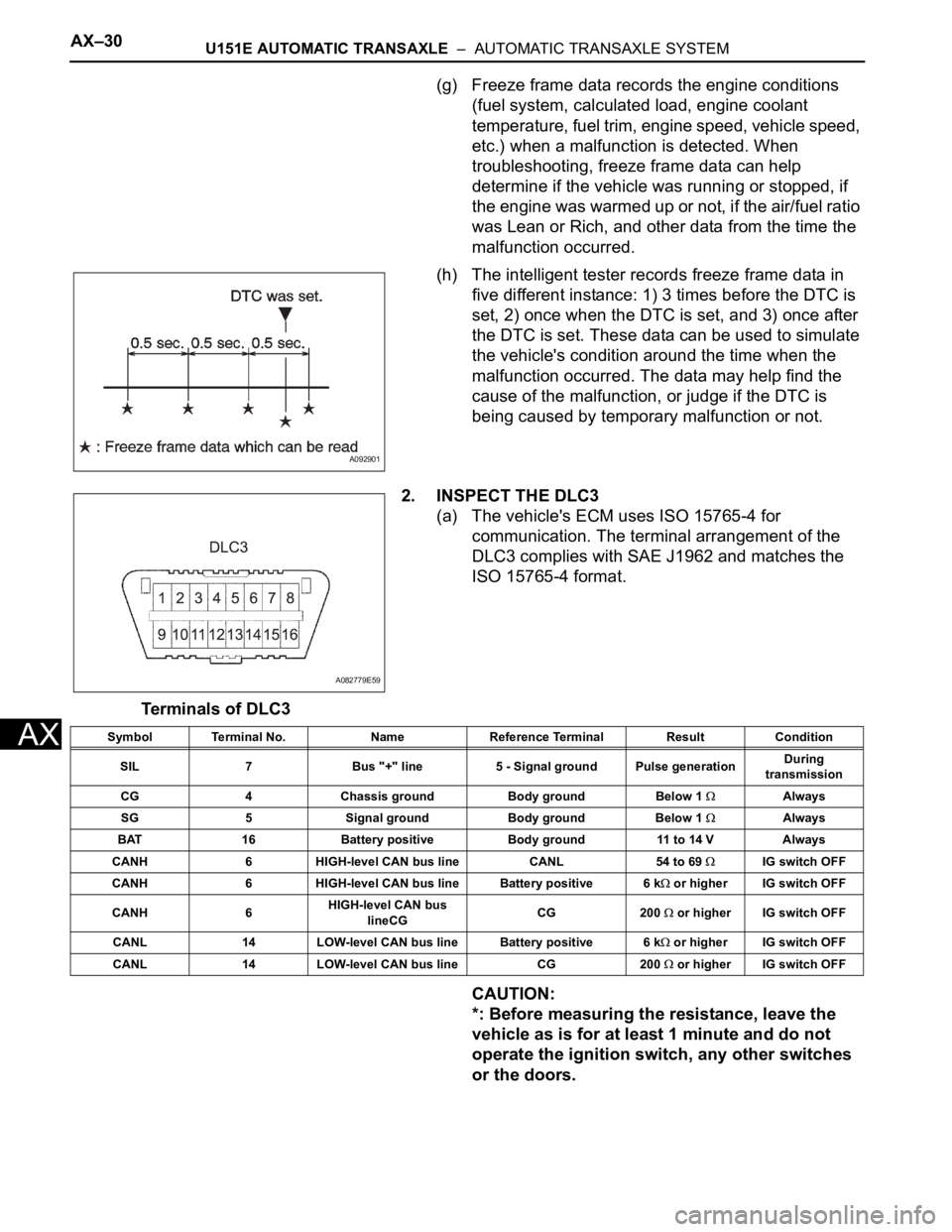

(c) To check the DTCs, connect the OBD II scan tool or

intelligent tester to the DLC3 of the vehicle. The

OBD II scan tool or intelligent tester also enables

you to erase the DTCs and check freeze frame data

and various forms of engine data (For operating

instructions, see the instruction book).

(d) The DTCs include SAE controlled codes and

Manufacturer controlled codes. SAE controlled

codes must be set as prescribed by the SAE, while

Manufacturer controlled codes can be set freely by

a manufacturer within the prescribed limits (See

page AX-35).

(e) The diagnosis system operates in "normal mode"

during the normal vehicle use. In normal mode, "2-

trip detection logic" is used to ensure accurate

detection of malfunction. "Check mode" is also

available to technicians as an option. In check

mode, "1-trip detection logic" is used for simulating

malfunction symptoms and increasing the system's

ability to detect malfunctions, including intermittent

malfunction.

(f) *2 trip detection logic: When a malfunction is first

detected, the malfunction is temporarily stored in

the ECM memory (1st trip). If the ignition switch is

turned off and then turned to the ON position again,

and same malfunction is detected again, the MIL will

illuminate.

FI00534

C159873E01

Page 1543 of 3000

AX–30U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

(g) Freeze frame data records the engine conditions

(fuel system, calculated load, engine coolant

temperature, fuel trim, engine speed, vehicle speed,

etc.) when a malfunction is detected. When

troubleshooting, freeze frame data can help

determine if the vehicle was running or stopped, if

the engine was warmed up or not, if the air/fuel ratio

was Lean or Rich, and other data from the time the

malfunction occurred.

(h) The intelligent tester records freeze frame data in

five different instance: 1) 3 times before the DTC is

set, 2) once when the DTC is set, and 3) once after

the DTC is set. These data can be used to simulate

the vehicle's condition around the time when the

malfunction occurred. The data may help find the

cause of the malfunction, or judge if the DTC is

being caused by temporary malfunction or not.

2. INSPECT THE DLC3

(a) The vehicle's ECM uses ISO 15765-4 for

communication. The terminal arrangement of the

DLC3 complies with SAE J1962 and matches the

ISO 15765-4 format.

Terminals of DLC3

CAUTION:

*: Before measuring the resistance, leave the

vehicle as is for at least 1 minute and do not

operate the ignition switch, any other switches

or the doors.

A092901

A082779E59

Symbol Terminal No. Name Reference Terminal Result Condition

SIL 7 Bus "+" line 5 - Signal ground Pulse generationDuring

transmission

CG 4 Chassis ground Body ground Below 1

Always

SG 5 Signal ground Body ground Below 1

Always

BAT 16 Battery positive Body ground 11 to 14 V Always

CANH 6 HIGH-level CAN bus line CANL 54 to 69

IG switch OFF

CANH 6 HIGH-level CAN bus line Battery positive 6 k

or higher IG switch OFF

CANH 6HIGH-level CAN bus

lineCGCG 200

or higher IG switch OFF

CANL 14 LOW-level CAN bus line Battery positive 6 k

or higher IG switch OFF

CANL 14 LOW-level CAN bus line CG 200

or higher IG switch OFF

Page 1544 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–31

AX

HINT:

If your display shows UNABLE TO CONNECT TO

VEHICLE when you have connected the cable of

the OBD II scan tool or intelligent tester to the

DLC3, turned the ignition switch to the ON position

and operated the scan tool, there is a problem on

the vehicle side or tool side.

• If the communication is normal when the tool is

connected to another vehicle, inspect the DLC3

on the original vehicle.

• If the communication is still impossible when the

tool is connected to another vehicle, the problem

is probably in the tool itself, so consult the

Service Department listed in the tool's instruction

manual.

3. CHECK BATTERY VOLTAGE

(a) Measure the battery voltage.

Battery voltage:

11 to 14 V

If voltage is below 11 V, replace the battery before

proceeding.

4. CHECK MIL

(a) The MIL comes on when the ignition switch is

turned to the ON position and the engine is not

running.

HINT:

If the MIL does not light up, troubleshoot the

combination meter.

(b) When the engine is started, the MIL should go off. If

the lamp remains on, it means that the diagnosis

system has detected a malfunction or abnormality in

the system.

Page 1548 of 3000

AX–156U151E AUTOMATIC TRANSAXLE – TRANSMISSION CONTROL CABLE ASSEMBLY

AX

ADJUSTMENT

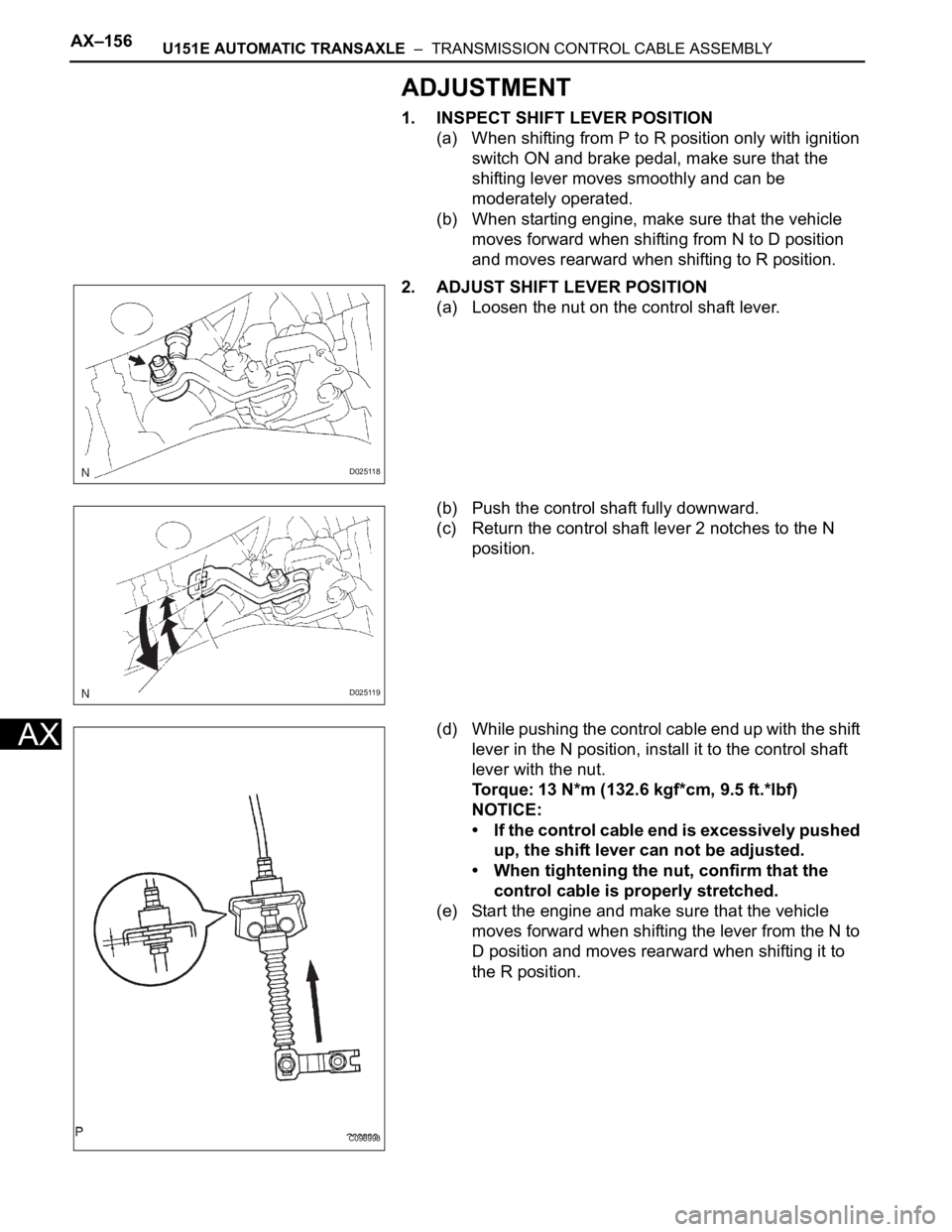

1. INSPECT SHIFT LEVER POSITION

(a) When shifting from P to R position only with ignition

switch ON and brake pedal, make sure that the

shifting lever moves smoothly and can be

moderately operated.

(b) When starting engine, make sure that the vehicle

moves forward when shifting from N to D position

and moves rearward when shifting to R position.

2. ADJUST SHIFT LEVER POSITION

(a) Loosen the nut on the control shaft lever.

(b) Push the control shaft fully downward.

(c) Return the control shaft lever 2 notches to the N

position.

(d) While pushing the control cable end up with the shift

lever in the N position, install it to the control shaft

lever with the nut.

Torque: 13 N*m (132.6 kgf*cm, 9.5 ft.*lbf)

NOTICE:

• If the control cable end is excessively pushed

up, the shift lever can not be adjusted.

• When tightening the nut, confirm that the

control cable is properly stretched.

(e) Start the engine and make sure that the vehicle

moves forward when shifting the lever from the N to

D position and moves rearward when shifting it to

the R position.

D025118

D025119

C098998

Page 1552 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–33

AX

(b) When not using the OBD II scan tool or intelligent

tester: Clearing the DTCs.

(1) Disconnect the battery terminal or remove the

EFI and ETCS fuses from the engine room J/B

for 60 seconds or more. However, if you

disconnect the battery terminal, perform do the

"INITIALIZE" procedure.

Page 1554 of 3000

U151E AUTOMATIC TRANSAXLE – DIFFERENTIAL OIL SEALAX–159

AX

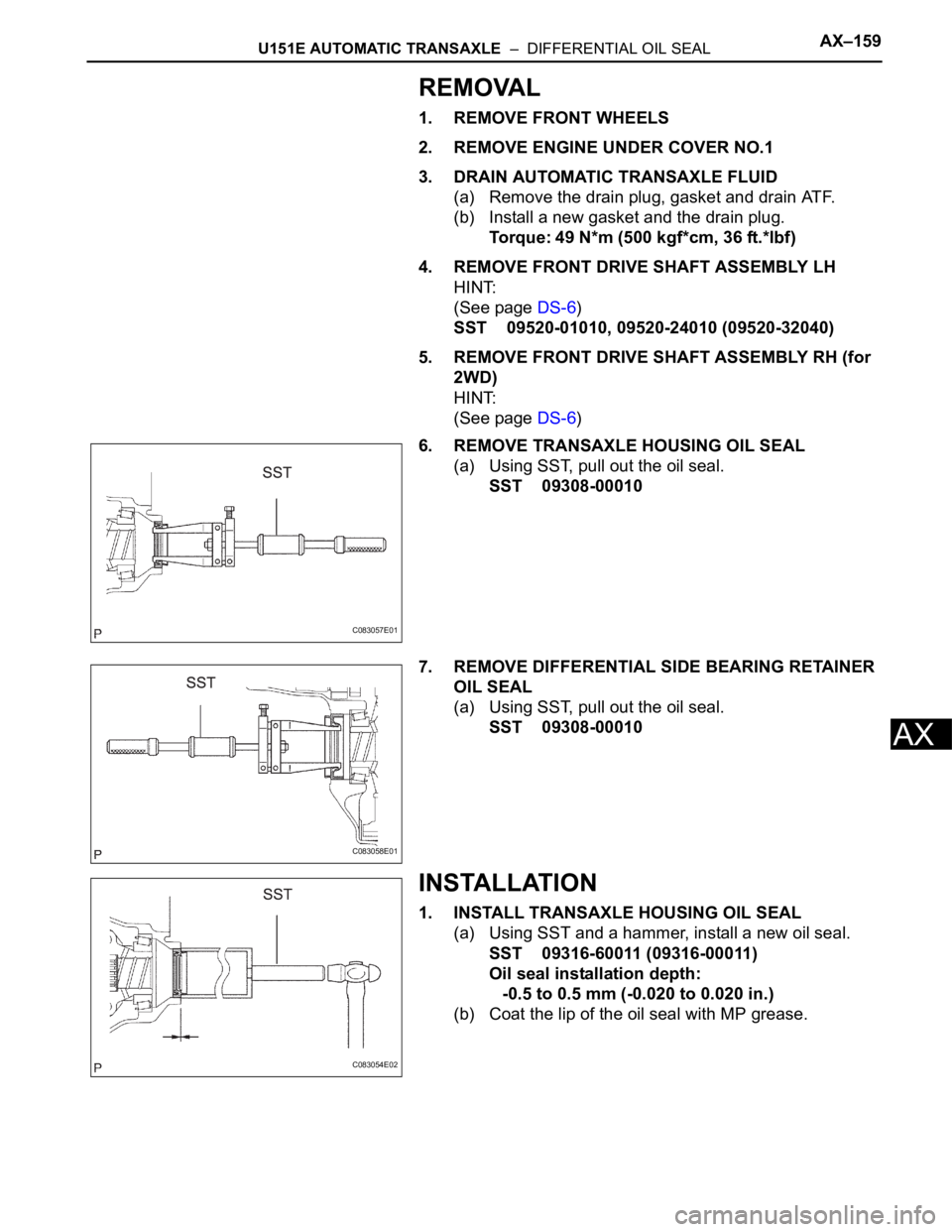

REMOVAL

1. REMOVE FRONT WHEELS

2. REMOVE ENGINE UNDER COVER NO.1

3. DRAIN AUTOMATIC TRANSAXLE FLUID

(a) Remove the drain plug, gasket and drain ATF.

(b) Install a new gasket and the drain plug.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

4. REMOVE FRONT DRIVE SHAFT ASSEMBLY LH

HINT:

(See page DS-6)

SST 09520-01010, 09520-24010 (09520-32040)

5. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH (for

2WD)

HINT:

(See page DS-6)

6. REMOVE TRANSAXLE HOUSING OIL SEAL

(a) Using SST, pull out the oil seal.

SST 09308-00010

7. REMOVE DIFFERENTIAL SIDE BEARING RETAINER

OIL SEAL

(a) Using SST, pull out the oil seal.

SST 09308-00010

INSTALLATION

1. INSTALL TRANSAXLE HOUSING OIL SEAL

(a) Using SST and a hammer, install a new oil seal.

SST 09316-60011 (09316-00011)

Oil seal installation depth:

-0.5 to 0.5 mm (-0.020 to 0.020 in.)

(b) Coat the lip of the oil seal with MP grease.

C083057E01

C083058E01

C083054E02