engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1736 of 3000

AX–64U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

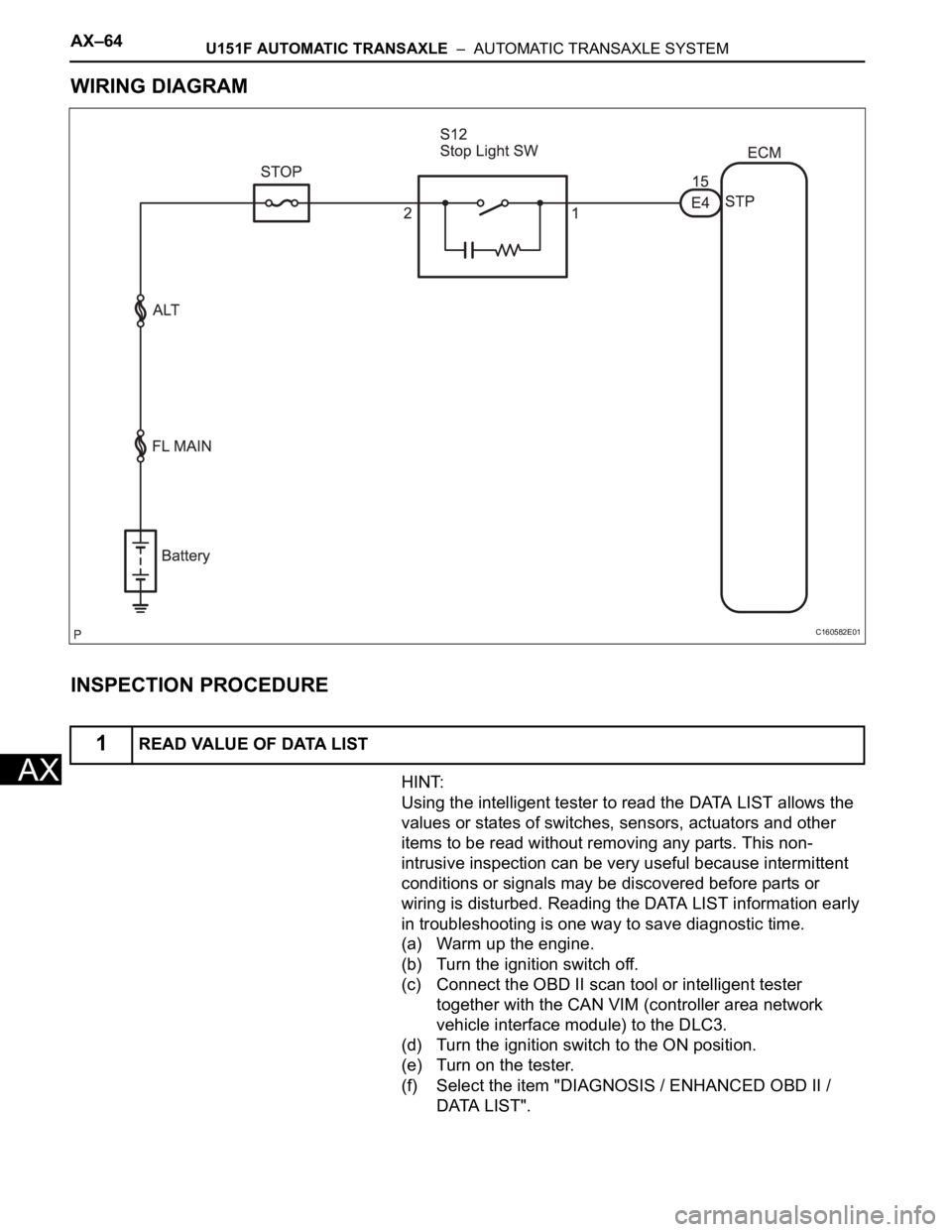

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

Using the intelligent tester to read the DATA LIST allows the

values or states of switches, sensors, actuators and other

items to be read without removing any parts. This non-

intrusive inspection can be very useful because intermittent

conditions or signals may be discovered before parts or

wiring is disturbed. Reading the DATA LIST information early

in troubleshooting is one way to save diagnostic time.

(a) Warm up the engine.

(b) Turn the ignition switch off.

(c) Connect the OBD II scan tool or intelligent tester

together with the CAN VIM (controller area network

vehicle interface module) to the DLC3.

(d) Turn the ignition switch to the ON position.

(e) Turn on the tester.

(f) Select the item "DIAGNOSIS / ENHANCED OBD II /

DATA LIST".

1READ VALUE OF DATA LIST

C160582E01

Page 1739 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–67

AX

SYSTEM DESCRIPTION

The ECM uses the signals from the throttle position sensor, air-flow meter, turbine (input) speed sensor,

intermediate (counter) shaft speed sensor and crankshaft position sensor to monitor the engagement

condition of the lock-up clutch.

Then the ECM compares the engagement condition of the lock-up clutch with the lock-up schedule in the

ECM memory to detect a mechanical problems of the shift solenoid valve DSL, valve body and torque

converter clutch.

MONITOR DESCRIPTION

Torque converter lock-up is controlled by the ECM based on the speed sensor (NT), speed sensor (NC),

engine rpm, engine load, engine temperature, vehicle speed, transmission temperature, and gear

selection. The ECM determines the lock-up status of the torque converter by comparing the engine rpm

(NE) to the input turbine rpm (NT). The ECM calculates the actual transmission gear by comparing input

turbine rpm (NT) to counter gear rpm (NC). When conditions are appropriate, the ECM requests "lock-up"

by applying control voltage to the shift solenoid DSL. When the DSL is turned on, it applies pressure to the

lock-up relay valve and locks the torque converter clutch.

If the ECM detects no lock-up after lock-up has been requested or if it detects lock-up when it is not

requested, the ECM interprets this as a fault in the shift solenoid valve DSL or lock-up system

performance. The ECM will turn on the MIL and store the DTC.

HINT:

Example:

When any of the following is met, the system judges it as a malfunction.

• There is a difference in rotation between the input side (engine speed) and output side (input turbine

speed) of the torque converter when the ECM commands lock-up.

(Engine speed is at least 100 rpm greater than input turbine speed.)

• There is no difference in rotation between the input side (engine speed) and output side (input turbine

speed) of the torque converter when the ECM commands lock-up off.

(The difference between engine speed and input turbine speed is less than 35 rpm.)

MONITOR STRATEGY

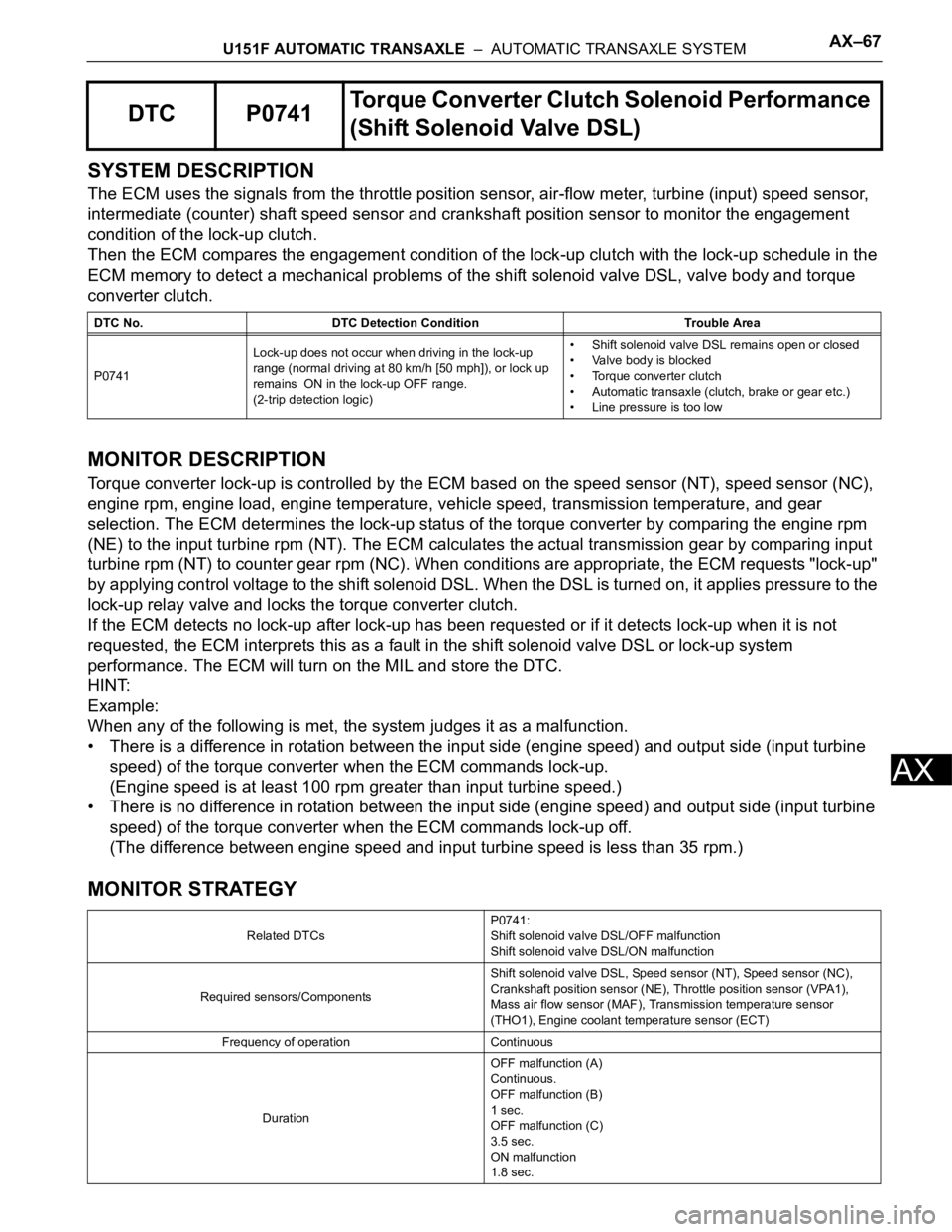

DTC P0741Torque Converter Clutch Solenoid Performance

(Shift Solenoid Valve DSL)

DTC No. DTC Detection Condition Trouble Area

P0741Lock-up does not occur when driving in the lock-up

range (normal driving at 80 km/h [50 mph]), or lock up

remains ON in the lock-up OFF range.

(2-trip detection logic)• Shift solenoid valve DSL remains open or closed

• Valve body is blocked

• Torque converter clutch

• Automatic transaxle (clutch, brake or gear etc.)

• Line pressure is too low

Related DTCsP0741:

Shift solenoid valve DSL/OFF malfunction

Shift solenoid valve DSL/ON malfunction

Required sensors/ComponentsShift solenoid valve DSL, Speed sensor (NT), Speed sensor (NC),

Crankshaft position sensor (NE), Throttle position sensor (VPA1),

Mass air flow sensor (MAF), Transmission temperature sensor

(THO1), Engine coolant temperature sensor (ECT)

Frequency of operation Continuous

DurationOFF malfunction (A)

Continuous.

OFF malfunction (B)

1 sec.

OFF malfunction (C)

3.5 sec.

ON malfunction

1.8 sec.

Page 1740 of 3000

AX–68U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

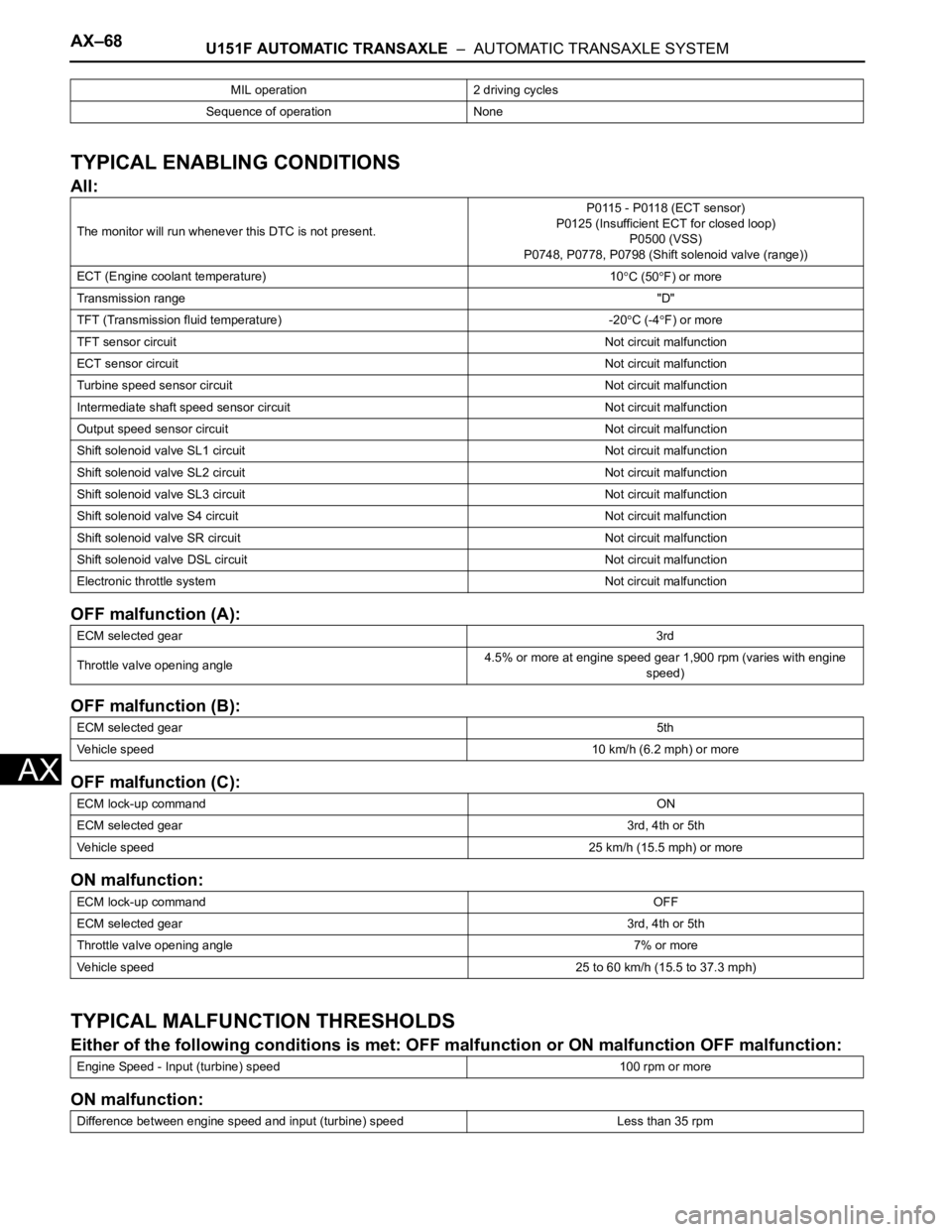

TYPICAL ENABLING CONDITIONS

All:

OFF malfunction (A):

OFF malfunction (B):

OFF malfunction (C):

ON malfunction:

TYPICAL MALFUNCTION THRESHOLDS

Either of the following conditions is met: OFF malfunction or ON malfunction OFF malfunction:

ON malfunction:

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present.P0115 - P0118 (ECT sensor)

P0125 (Insufficient ECT for closed loop)

P0500 (VSS)

P0748, P0778, P0798 (Shift solenoid valve (range))

ECT (Engine coolant temperature) 10

C (50F) or more

Transmission range"D"

TFT (Transmission fluid temperature) -20

C (-4F) or more

TFT sensor circuitNot circuit malfunction

ECT sensor circuitNot circuit malfunction

Turbine speed sensor circuit Not circuit malfunction

Intermediate shaft speed sensor circuit Not circuit malfunction

Output speed sensor circuit Not circuit malfunction

Shift solenoid valve SL1 circuit Not circuit malfunction

Shift solenoid valve SL2 circuit Not circuit malfunction

Shift solenoid valve SL3 circuit Not circuit malfunction

Shift solenoid valve S4 circuit Not circuit malfunction

Shift solenoid valve SR circuit Not circuit malfunction

Shift solenoid valve DSL circuit Not circuit malfunction

Electronic throttle systemNot circuit malfunction

ECM selected gear3rd

Throttle valve opening angle4.5% or more at engine speed gear 1,900 rpm (varies with engine

speed)

ECM selected gear5th

Vehicle speed10 km/h (6.2 mph) or more

ECM lock-up commandON

ECM selected gear3rd, 4th or 5th

Vehicle speed25 km/h (15.5 mph) or more

ECM lock-up commandOFF

ECM selected gear3rd, 4th or 5th

Throttle valve opening angle7% or more

Vehicle speed25 to 60 km/h (15.5 to 37.3 mph)

Engine Speed - Input (turbine) speed 100 rpm or more

Difference between engine speed and input (turbine) speed Less than 35 rpm

Page 1741 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–69

AX

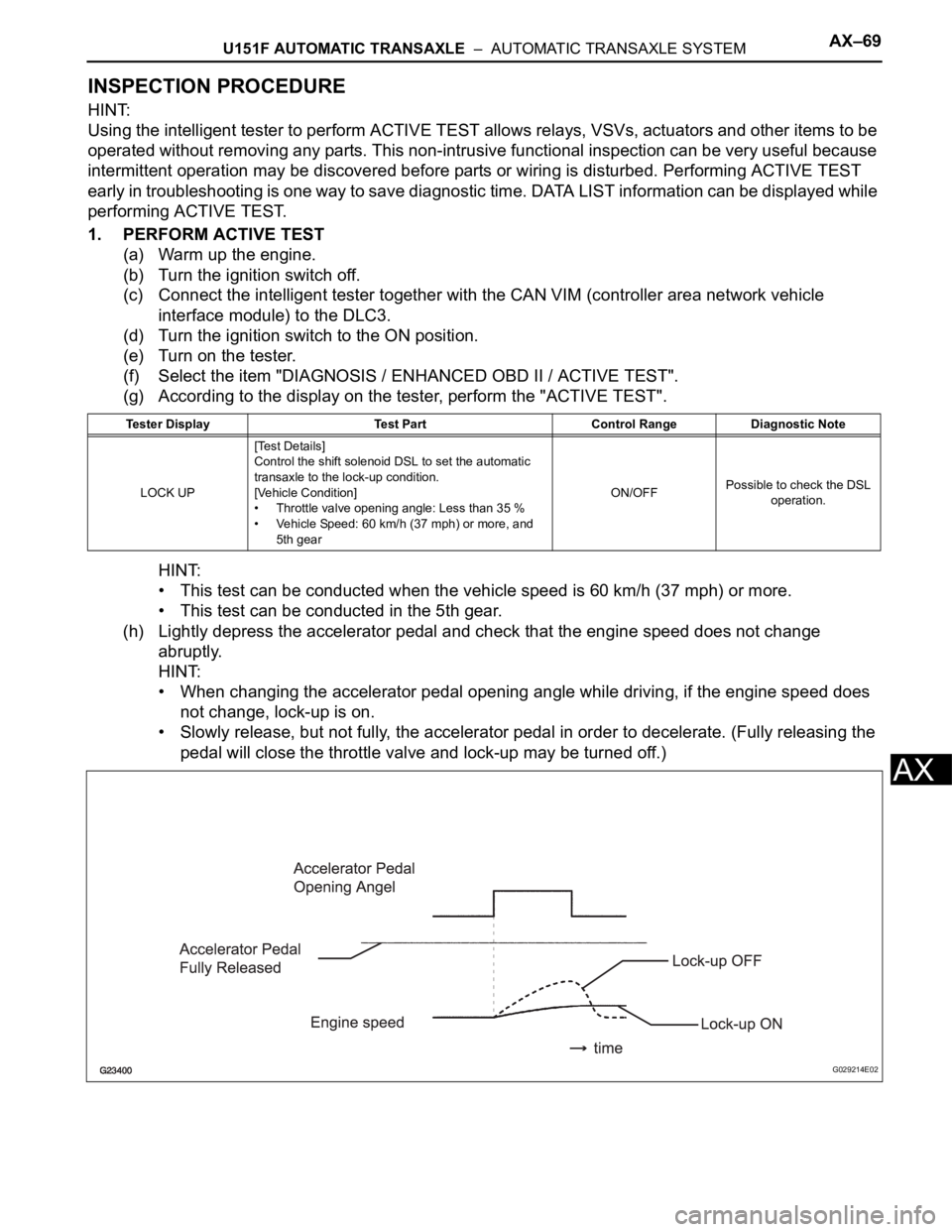

INSPECTION PROCEDURE

HINT:

Using the intelligent tester to perform ACTIVE TEST allows relays, VSVs, actuators and other items to be

operated without removing any parts. This non-intrusive functional inspection can be very useful because

intermittent operation may be discovered before parts or wiring is disturbed. Performing ACTIVE TEST

early in troubleshooting is one way to save diagnostic time. DATA LIST information can be displayed while

performing ACTIVE TEST.

1. PERFORM ACTIVE TEST

(a) Warm up the engine.

(b) Turn the ignition switch off.

(c) Connect the intelligent tester together with the CAN VIM (controller area network vehicle

interface module) to the DLC3.

(d) Turn the ignition switch to the ON position.

(e) Turn on the tester.

(f) Select the item "DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST".

(g) According to the display on the tester, perform the "ACTIVE TEST".

HINT:

• This test can be conducted when the vehicle speed is 60 km/h (37 mph) or more.

• This test can be conducted in the 5th gear.

(h) Lightly depress the accelerator pedal and check that the engine speed does not change

abruptly.

HINT:

• When changing the accelerator pedal opening angle while driving, if the engine speed does

not change, lock-up is on.

• Slowly release, but not fully, the accelerator pedal in order to decelerate. (Fully releasing the

pedal will close the throttle valve and lock-up may be turned off.)

Tester Display Test Part Control Range Diagnostic Note

LOCK UP[Test Details]

Control the shift solenoid DSL to set the automatic

transaxle to the lock-up condition.

[Vehicle Condition]

• Throttle valve opening angle: Less than 35 %

• Vehicle Speed: 60 km/h (37 mph) or more, and

5th gearON/OFFPossible to check the DSL

operation.

G029214E02

Page 1745 of 3000

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–73

AX

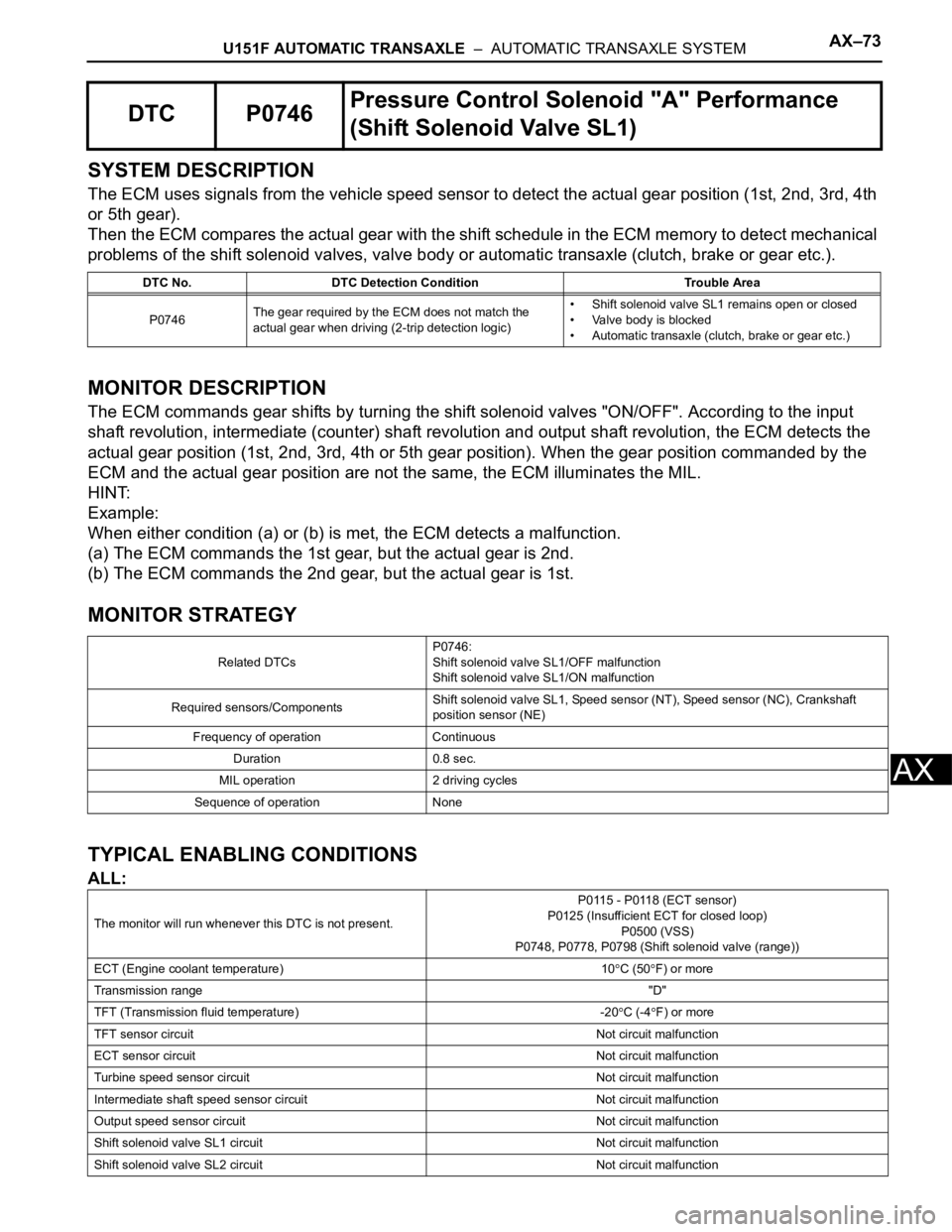

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shift schedule in the ECM memory to detect mechanical

problems of the shift solenoid valves, valve body or automatic transaxle (clutch, brake or gear etc.).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". According to the input

shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ECM detects the

actual gear position (1st, 2nd, 3rd, 4th or 5th gear position). When the gear position commanded by the

ECM and the actual gear position are not the same, the ECM illuminates the MIL.

HINT:

Example:

When either condition (a) or (b) is met, the ECM detects a malfunction.

(a) The ECM commands the 1st gear, but the actual gear is 2nd.

(b) The ECM commands the 2nd gear, but the actual gear is 1st.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

ALL:

DTC P0746Pressure Control Solenoid "A" Performance

(Shift Solenoid Valve SL1)

DTC No. DTC Detection Condition Trouble Area

P0746The gear required by the ECM does not match the

actual gear when driving (2-trip detection logic)• Shift solenoid valve SL1 remains open or closed

• Valve body is blocked

• Automatic transaxle (clutch, brake or gear etc.)

Related DTCsP0746:

Shift solenoid valve SL1/OFF malfunction

Shift solenoid valve SL1/ON malfunction

Required sensors/ComponentsShift solenoid valve SL1, Speed sensor (NT), Speed sensor (NC), Crankshaft

position sensor (NE)

Frequency of operation Continuous

Duration 0.8 sec.

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present.P0115 - P0118 (ECT sensor)

P0125 (Insufficient ECT for closed loop)

P0500 (VSS)

P0748, P0778, P0798 (Shift solenoid valve (range))

ECT (Engine coolant temperature) 10

C (50F) or more

Transmission range"D"

TFT (Transmission fluid temperature) -20

C (-4F) or more

TFT sensor circuitNot circuit malfunction

ECT sensor circuitNot circuit malfunction

Turbine speed sensor circuit Not circuit malfunction

Intermediate shaft speed sensor circuit Not circuit malfunction

Output speed sensor circuit Not circuit malfunction

Shift solenoid valve SL1 circuit Not circuit malfunction

Shift solenoid valve SL2 circuit Not circuit malfunction

Page 1746 of 3000

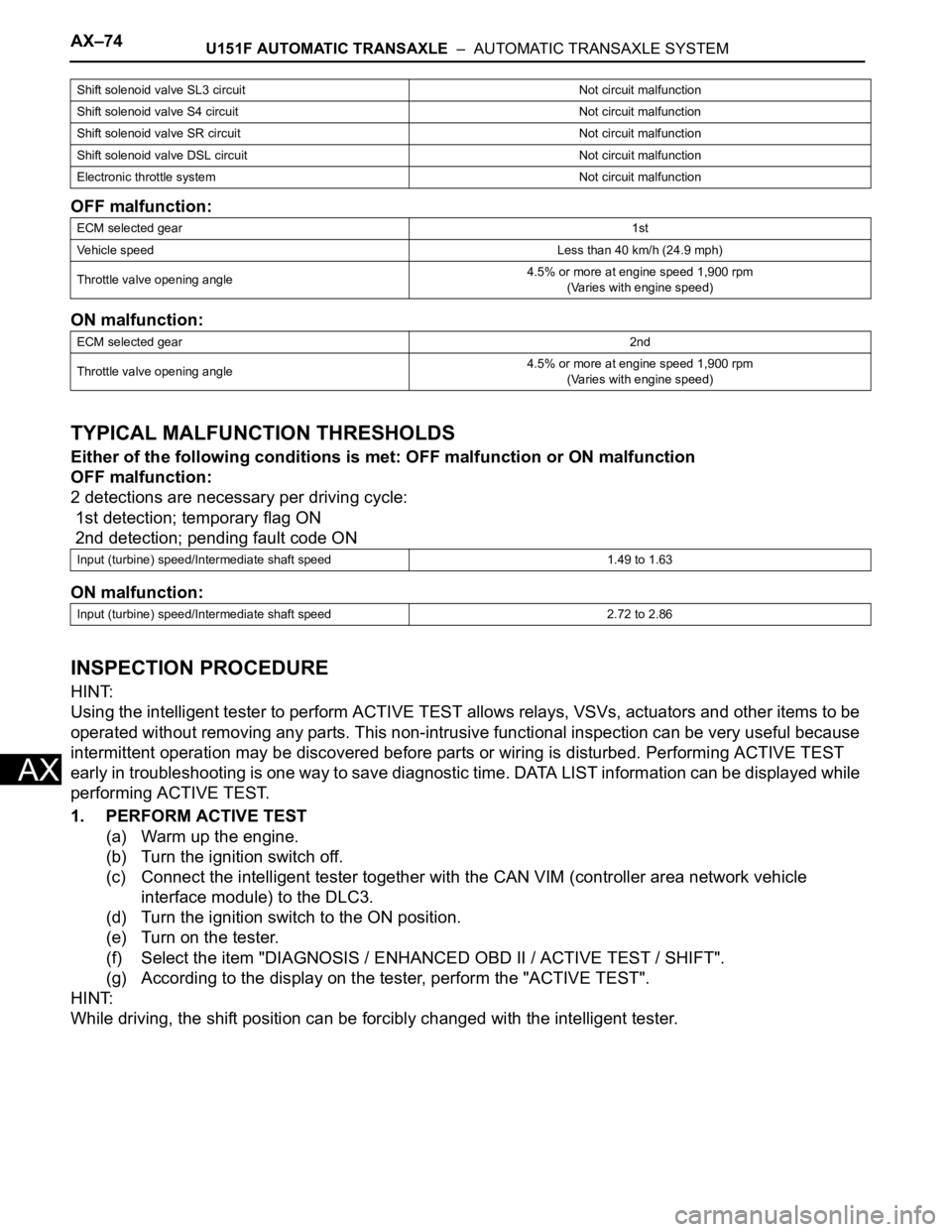

AX–74U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

OFF malfunction:

ON malfunction:

TYPICAL MALFUNCTION THRESHOLDS

Either of the following conditions is met: OFF malfunction or ON malfunction

OFF malfunction:

2 detections are necessary per driving cycle:

1st detection; temporary flag ON

2nd detection; pending fault code ON

ON malfunction:

INSPECTION PROCEDURE

HINT:

Using the intelligent tester to perform ACTIVE TEST allows relays, VSVs, actuators and other items to be

operated without removing any parts. This non-intrusive functional inspection can be very useful because

intermittent operation may be discovered before parts or wiring is disturbed. Performing ACTIVE TEST

early in troubleshooting is one way to save diagnostic time. DATA LIST information can be displayed while

performing ACTIVE TEST.

1. PERFORM ACTIVE TEST

(a) Warm up the engine.

(b) Turn the ignition switch off.

(c) Connect the intelligent tester together with the CAN VIM (controller area network vehicle

interface module) to the DLC3.

(d) Turn the ignition switch to the ON position.

(e) Turn on the tester.

(f) Select the item "DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / SHIFT".

(g) According to the display on the tester, perform the "ACTIVE TEST".

HINT:

While driving, the shift position can be forcibly changed with the intelligent tester.

Shift solenoid valve SL3 circuit Not circuit malfunction

Shift solenoid valve S4 circuit Not circuit malfunction

Shift solenoid valve SR circuit Not circuit malfunction

Shift solenoid valve DSL circuit Not circuit malfunction

Electronic throttle systemNot circuit malfunction

ECM selected gear1st

Vehicle speedLess than 40 km/h (24.9 mph)

Throttle valve opening angle4.5% or more at engine speed 1,900 rpm

(Varies with engine speed)

ECM selected gear2nd

Throttle valve opening angle4.5% or more at engine speed 1,900 rpm

(Varies with engine speed)

Input (turbine) speed/Intermediate shaft speed 1.49 to 1.63

Input (turbine) speed/Intermediate shaft speed 2.72 to 2.86

Page 1753 of 3000

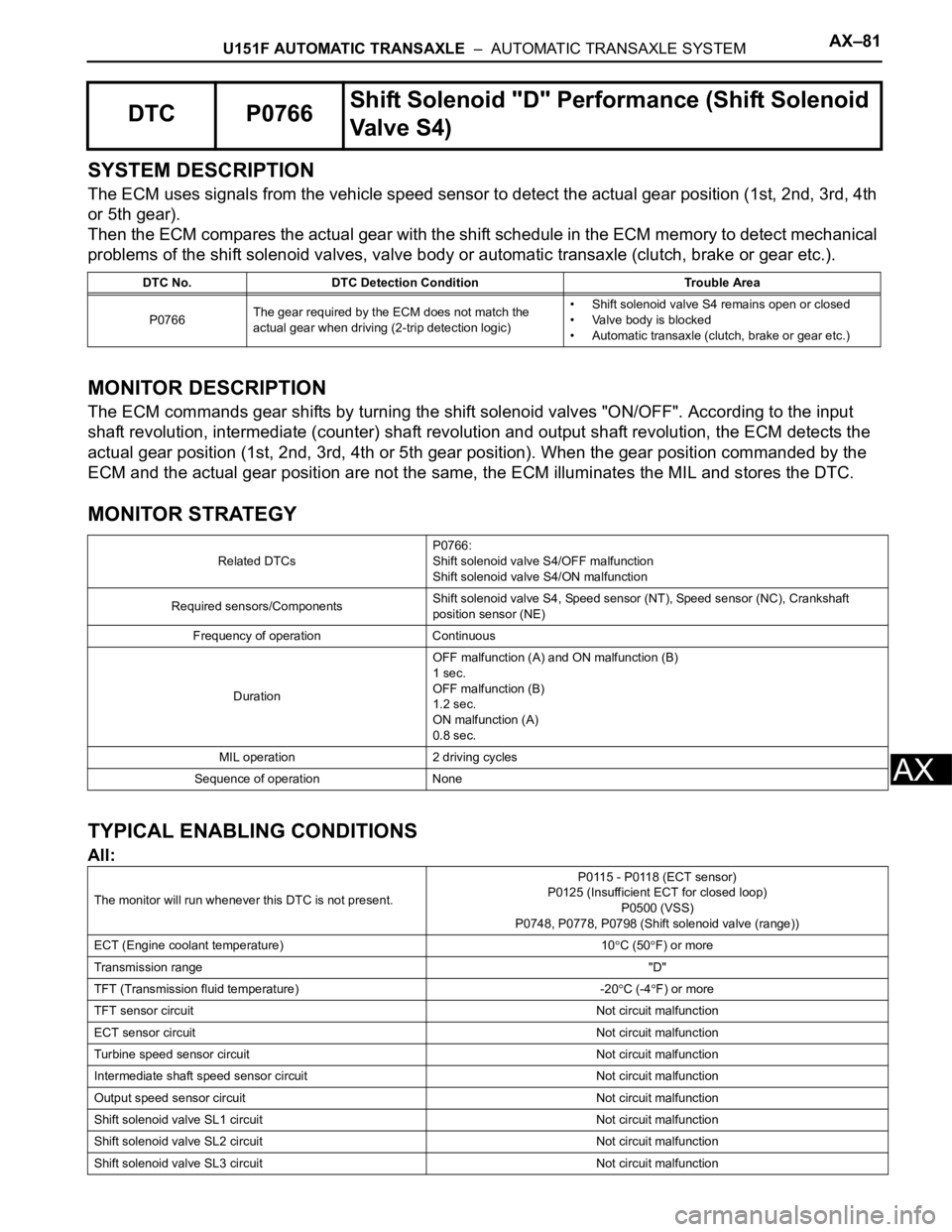

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–81

AX

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shift schedule in the ECM memory to detect mechanical

problems of the shift solenoid valves, valve body or automatic transaxle (clutch, brake or gear etc.).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". According to the input

shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ECM detects the

actual gear position (1st, 2nd, 3rd, 4th or 5th gear position). When the gear position commanded by the

ECM and the actual gear position are not the same, the ECM illuminates the MIL and stores the DTC.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

All:

DTC P0766Shift Solenoid "D" Performance (Shift Solenoid

Valve S4)

DTC No. DTC Detection Condition Trouble Area

P0766The gear required by the ECM does not match the

actual gear when driving (2-trip detection logic)• Shift solenoid valve S4 remains open or closed

• Valve body is blocked

• Automatic transaxle (clutch, brake or gear etc.)

Related DTCsP0766:

Shift solenoid valve S4/OFF malfunction

Shift solenoid valve S4/ON malfunction

Required sensors/ComponentsShift solenoid valve S4, Speed sensor (NT), Speed sensor (NC), Crankshaft

position sensor (NE)

Frequency of operation Continuous

DurationOFF malfunction (A) and ON malfunction (B)

1 sec.

OFF malfunction (B)

1.2 sec.

ON malfunction (A)

0.8 sec.

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present.P0115 - P0118 (ECT sensor)

P0125 (Insufficient ECT for closed loop)

P0500 (VSS)

P0748, P0778, P0798 (Shift solenoid valve (range))

ECT (Engine coolant temperature) 10

C (50F) or more

Transmission range"D"

TFT (Transmission fluid temperature) -20

C (-4F) or more

TFT sensor circuitNot circuit malfunction

ECT sensor circuitNot circuit malfunction

Turbine speed sensor circuit Not circuit malfunction

Intermediate shaft speed sensor circuit Not circuit malfunction

Output speed sensor circuit Not circuit malfunction

Shift solenoid valve SL1 circuit Not circuit malfunction

Shift solenoid valve SL2 circuit Not circuit malfunction

Shift solenoid valve SL3 circuit Not circuit malfunction

Page 1754 of 3000

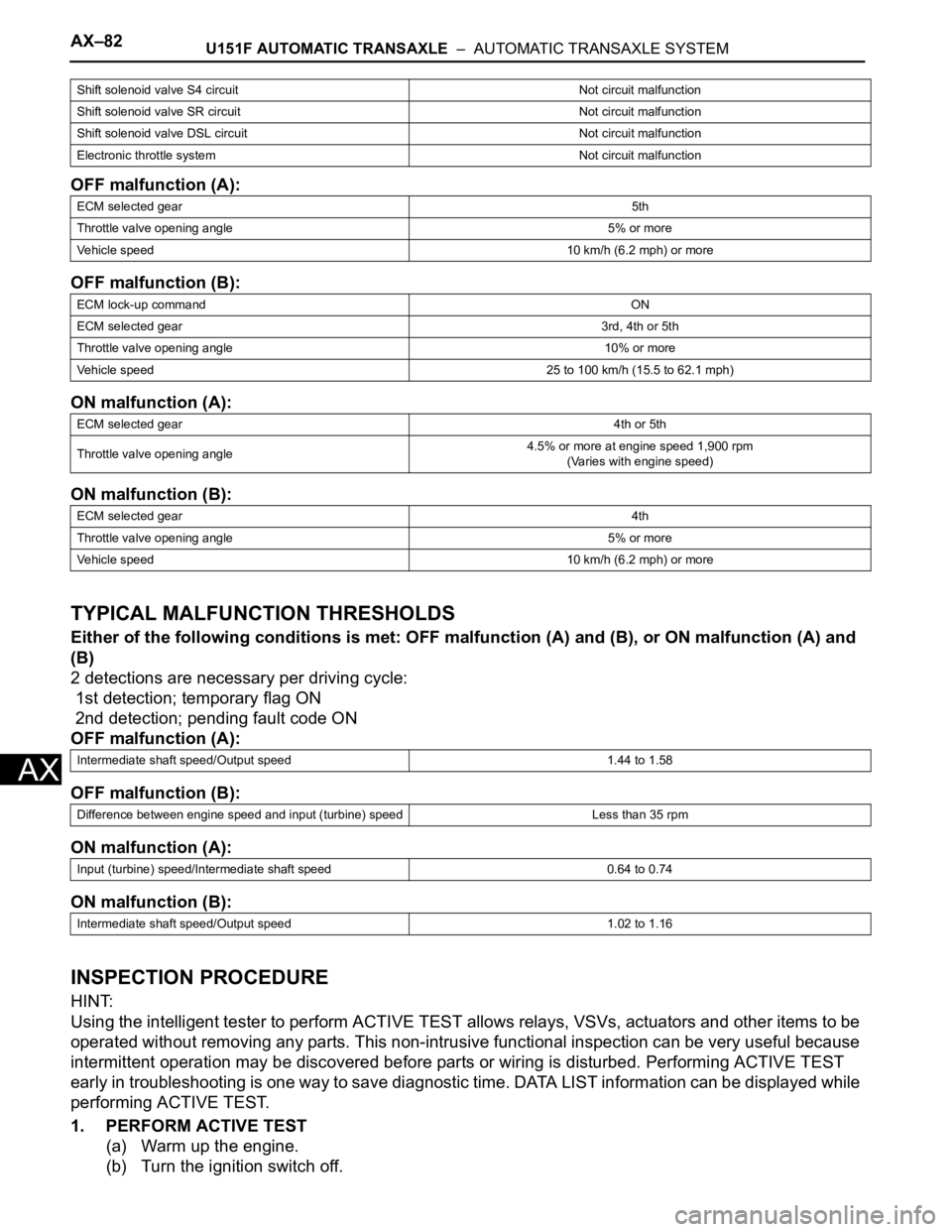

AX–82U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

OFF malfunction (A):

OFF malfunction (B):

ON malfunction (A):

ON malfunction (B):

TYPICAL MALFUNCTION THRESHOLDS

Either of the following conditions is met: OFF malfunction (A) and (B), or ON malfunction (A) and

(B)

2 detections are necessary per driving cycle:

1st detection; temporary flag ON

2nd detection; pending fault code ON

OFF malfunction (A):

OFF malfunction (B):

ON malfunction (A):

ON malfunction (B):

INSPECTION PROCEDURE

HINT:

Using the intelligent tester to perform ACTIVE TEST allows relays, VSVs, actuators and other items to be

operated without removing any parts. This non-intrusive functional inspection can be very useful because

intermittent operation may be discovered before parts or wiring is disturbed. Performing ACTIVE TEST

early in troubleshooting is one way to save diagnostic time. DATA LIST information can be displayed while

performing ACTIVE TEST.

1. PERFORM ACTIVE TEST

(a) Warm up the engine.

(b) Turn the ignition switch off.

Shift solenoid valve S4 circuit Not circuit malfunction

Shift solenoid valve SR circuit Not circuit malfunction

Shift solenoid valve DSL circuit Not circuit malfunction

Electronic throttle systemNot circuit malfunction

ECM selected gear5th

Throttle valve opening angle 5% or more

Vehicle speed10 km/h (6.2 mph) or more

ECM lock-up commandON

ECM selected gear3rd, 4th or 5th

Throttle valve opening angle 10% or more

Vehicle speed 25 to 100 km/h (15.5 to 62.1 mph)

ECM selected gear4th or 5th

Throttle valve opening angle4.5% or more at engine speed 1,900 rpm

(Varies with engine speed)

ECM selected gear4th

Throttle valve opening angle 5% or more

Vehicle speed10 km/h (6.2 mph) or more

Intermediate shaft speed/Output speed 1.44 to 1.58

Difference between engine speed and input (turbine) speed Less than 35 rpm

Input (turbine) speed/Intermediate shaft speed 0.64 to 0.74

Intermediate shaft speed/Output speed 1.02 to 1.16

Page 1757 of 3000

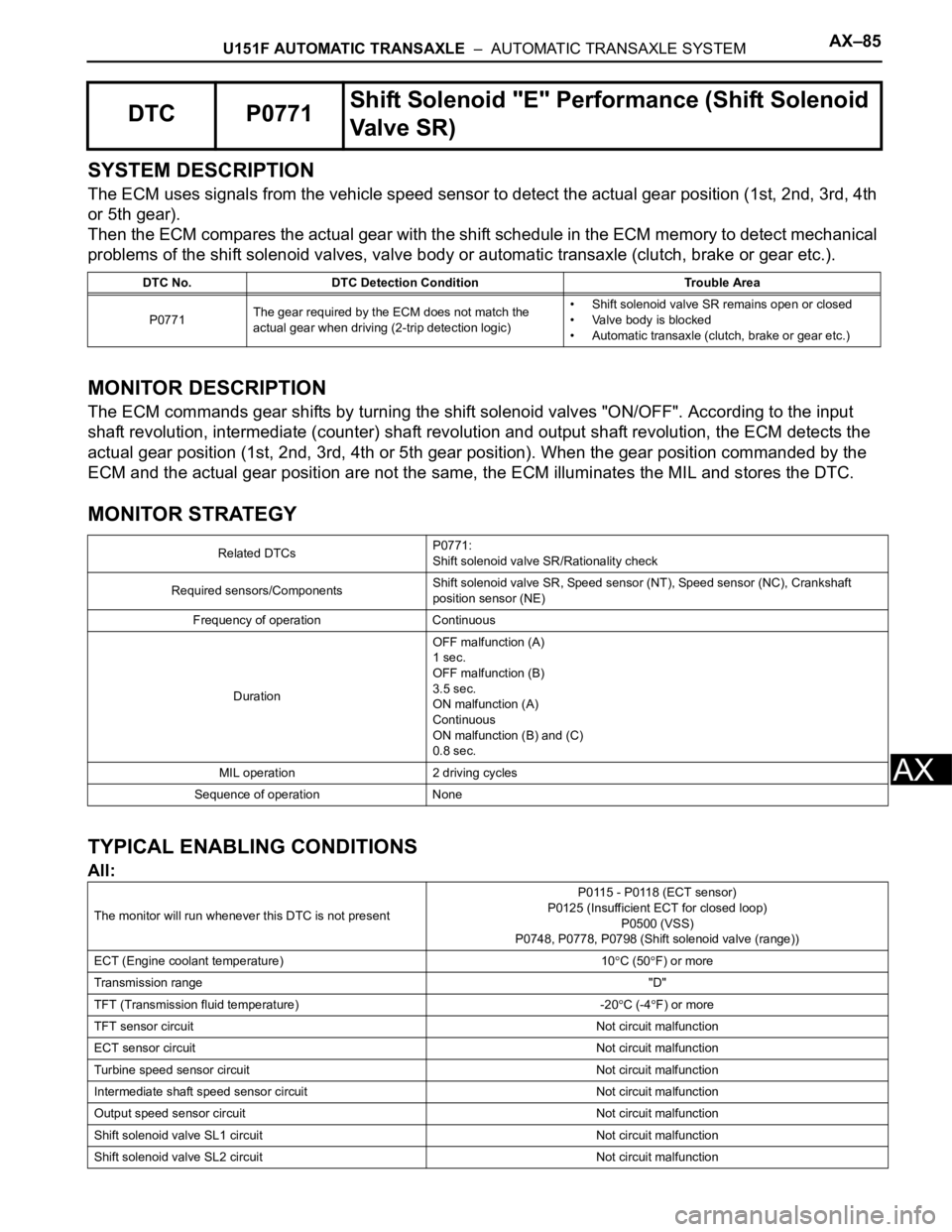

U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–85

AX

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shift schedule in the ECM memory to detect mechanical

problems of the shift solenoid valves, valve body or automatic transaxle (clutch, brake or gear etc.).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". According to the input

shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ECM detects the

actual gear position (1st, 2nd, 3rd, 4th or 5th gear position). When the gear position commanded by the

ECM and the actual gear position are not the same, the ECM illuminates the MIL and stores the DTC.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

All:

DTC P0771Shift Solenoid "E" Performance (Shift Solenoid

Va l v e S R )

DTC No. DTC Detection Condition Trouble Area

P0771The gear required by the ECM does not match the

actual gear when driving (2-trip detection logic)• Shift solenoid valve SR remains open or closed

• Valve body is blocked

• Automatic transaxle (clutch, brake or gear etc.)

Related DTCsP0771:

Shift solenoid valve SR/Rationality check

Required sensors/ComponentsShift solenoid valve SR, Speed sensor (NT), Speed sensor (NC), Crankshaft

position sensor (NE)

Frequency of operation Continuous

DurationOFF malfunction (A)

1 sec.

OFF malfunction (B)

3.5 sec.

ON malfunction (A)

Continuous

ON malfunction (B) and (C)

0.8 sec.

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not presentP0115 - P0118 (ECT sensor)

P0125 (Insufficient ECT for closed loop)

P0500 (VSS)

P0748, P0778, P0798 (Shift solenoid valve (range))

ECT (Engine coolant temperature) 10

C (50F) or more

Transmission range"D"

TFT (Transmission fluid temperature) -20

C (-4F) or more

TFT sensor circuitNot circuit malfunction

ECT sensor circuitNot circuit malfunction

Turbine speed sensor circuit Not circuit malfunction

Intermediate shaft speed sensor circuit Not circuit malfunction

Output speed sensor circuit Not circuit malfunction

Shift solenoid valve SL1 circuit Not circuit malfunction

Shift solenoid valve SL2 circuit Not circuit malfunction

Page 1758 of 3000

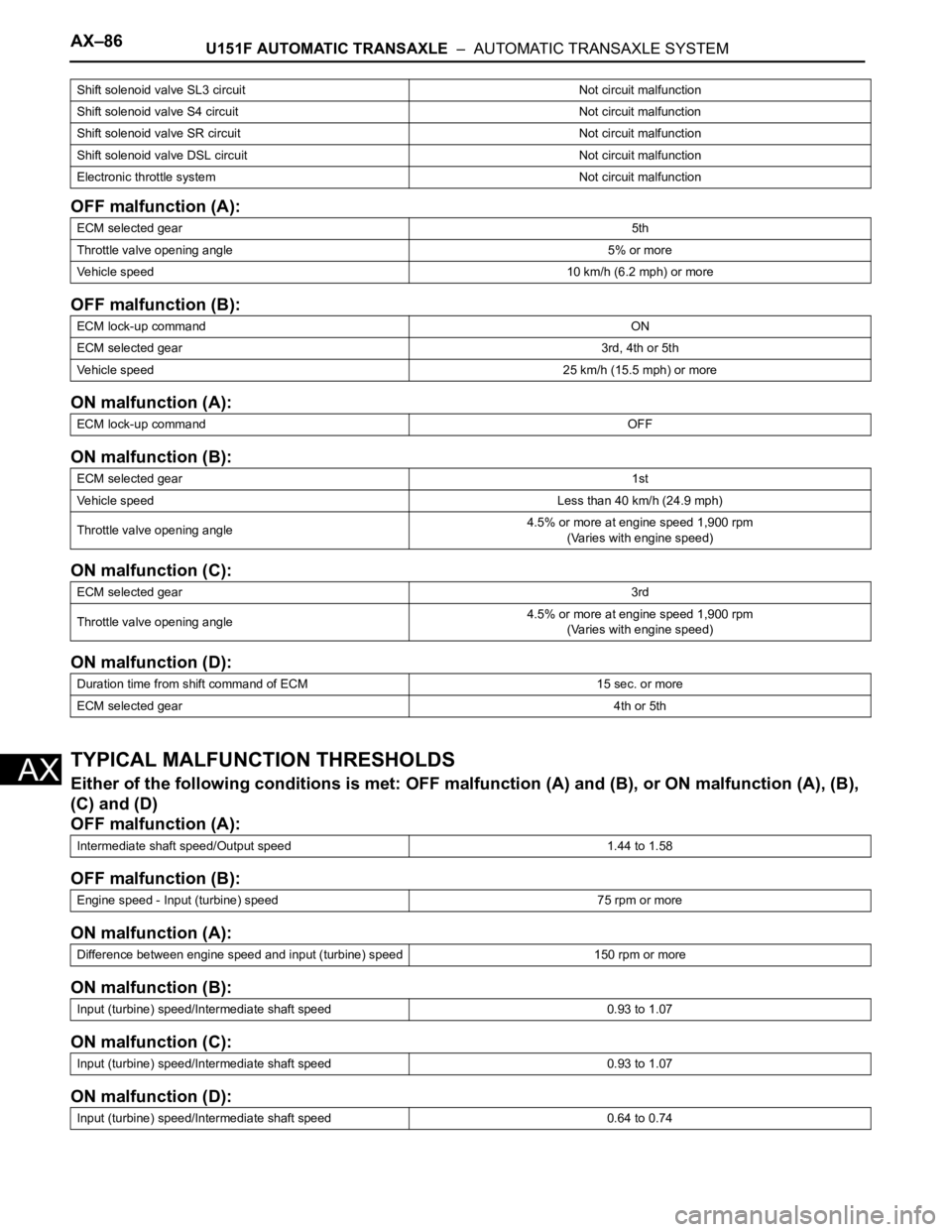

AX–86U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

OFF malfunction (A):

OFF malfunction (B):

ON malfunction (A):

ON malfunction (B):

ON malfunction (C):

ON malfunction (D):

TYPICAL MALFUNCTION THRESHOLDS

Either of the following conditions is met: OFF malfunction (A) and (B), or ON malfunction (A), (B),

(C) and (D)

OFF malfunction (A):

OFF malfunction (B):

ON malfunction (A):

ON malfunction (B):

ON malfunction (C):

ON malfunction (D):

Shift solenoid valve SL3 circuit Not circuit malfunction

Shift solenoid valve S4 circuit Not circuit malfunction

Shift solenoid valve SR circuit Not circuit malfunction

Shift solenoid valve DSL circuit Not circuit malfunction

Electronic throttle systemNot circuit malfunction

ECM selected gear5th

Throttle valve opening angle 5% or more

Vehicle speed10 km/h (6.2 mph) or more

ECM lock-up commandON

ECM selected gear3rd, 4th or 5th

Vehicle speed25 km/h (15.5 mph) or more

ECM lock-up commandOFF

ECM selected gear1st

Vehicle speedLess than 40 km/h (24.9 mph)

Throttle valve opening angle4.5% or more at engine speed 1,900 rpm

(Varies with engine speed)

ECM selected gear3rd

Throttle valve opening angle4.5% or more at engine speed 1,900 rpm

(Varies with engine speed)

Duration time from shift command of ECM 15 sec. or more

ECM selected gear4th or 5th

Intermediate shaft speed/Output speed 1.44 to 1.58

Engine speed - Input (turbine) speed 75 rpm or more

Difference between engine speed and input (turbine) speed 150 rpm or more

Input (turbine) speed/Intermediate shaft speed 0.93 to 1.07

Input (turbine) speed/Intermediate shaft speed 0.93 to 1.07

Input (turbine) speed/Intermediate shaft speed 0.64 to 0.74