TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1371 of 3000

CH–222GR-FE CHARGING – GENERATOR

CH

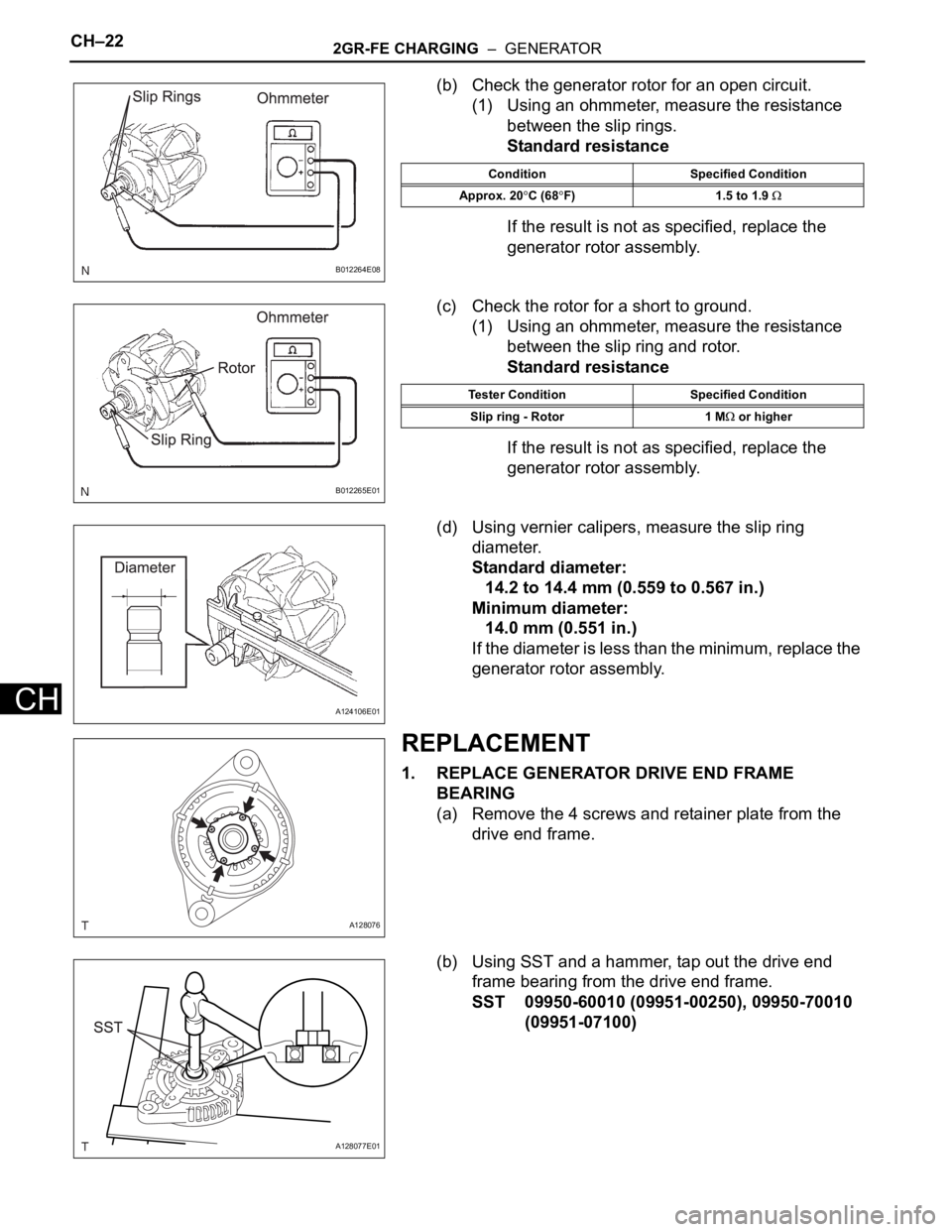

(b) Check the generator rotor for an open circuit.

(1) Using an ohmmeter, measure the resistance

between the slip rings.

Standard resistance

If the result is not as specified, replace the

generator rotor assembly.

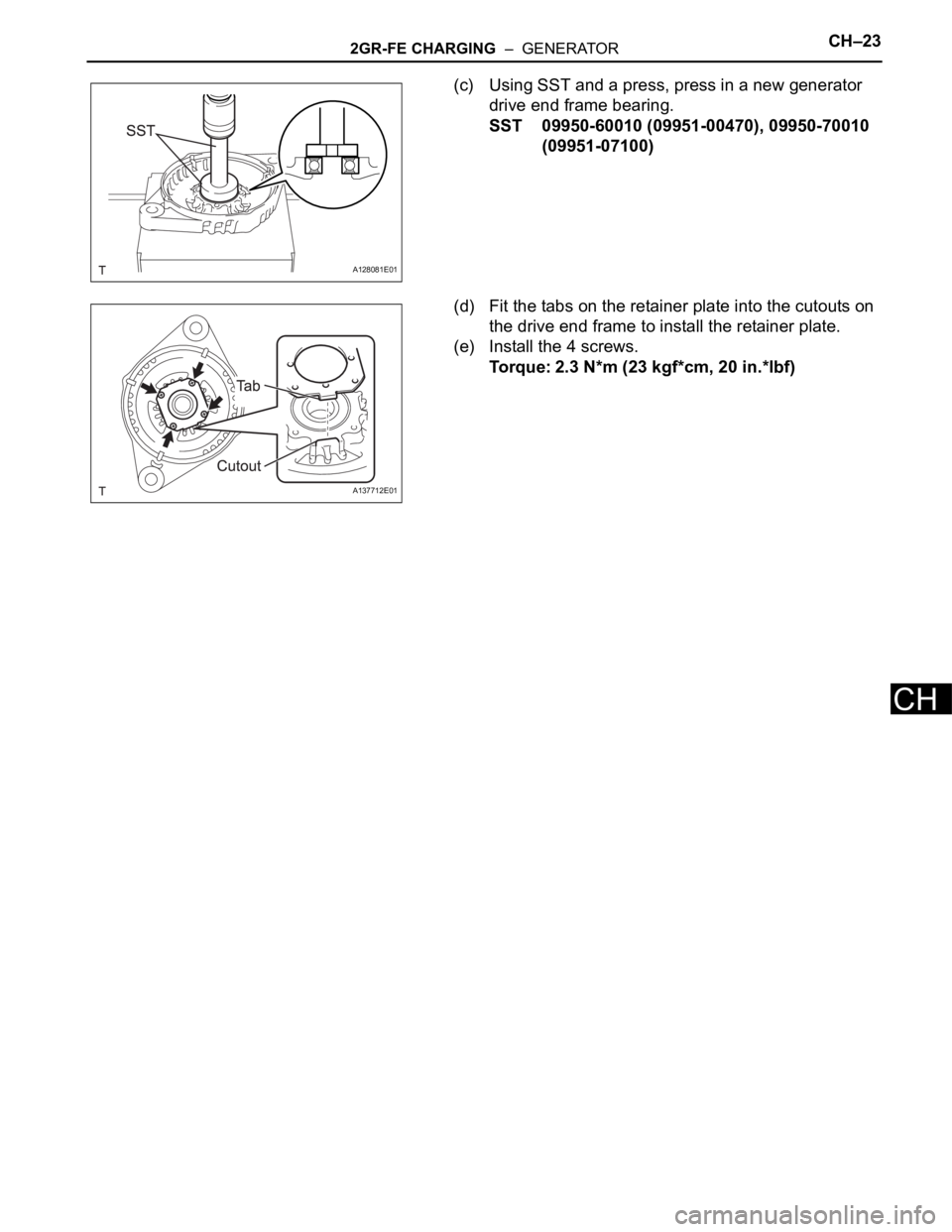

(c) Check the rotor for a short to ground.

(1) Using an ohmmeter, measure the resistance

between the slip ring and rotor.

Standard resistance

If the result is not as specified, replace the

generator rotor assembly.

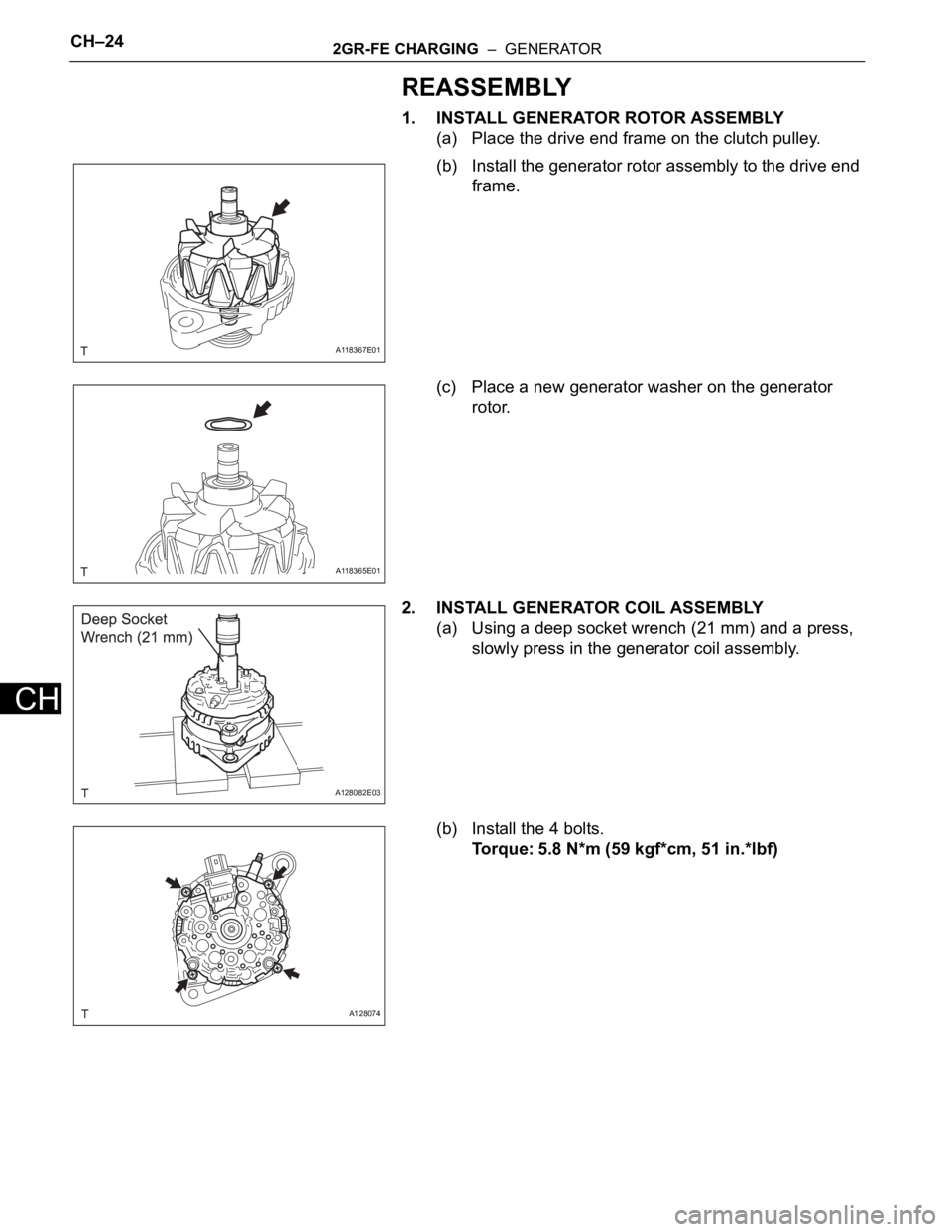

(d) Using vernier calipers, measure the slip ring

diameter.

Standard diameter:

14.2 to 14.4 mm (0.559 to 0.567 in.)

Minimum diameter:

14.0 mm (0.551 in.)

If the diameter is less than the minimum, replace the

generator rotor assembly.

REPLACEMENT

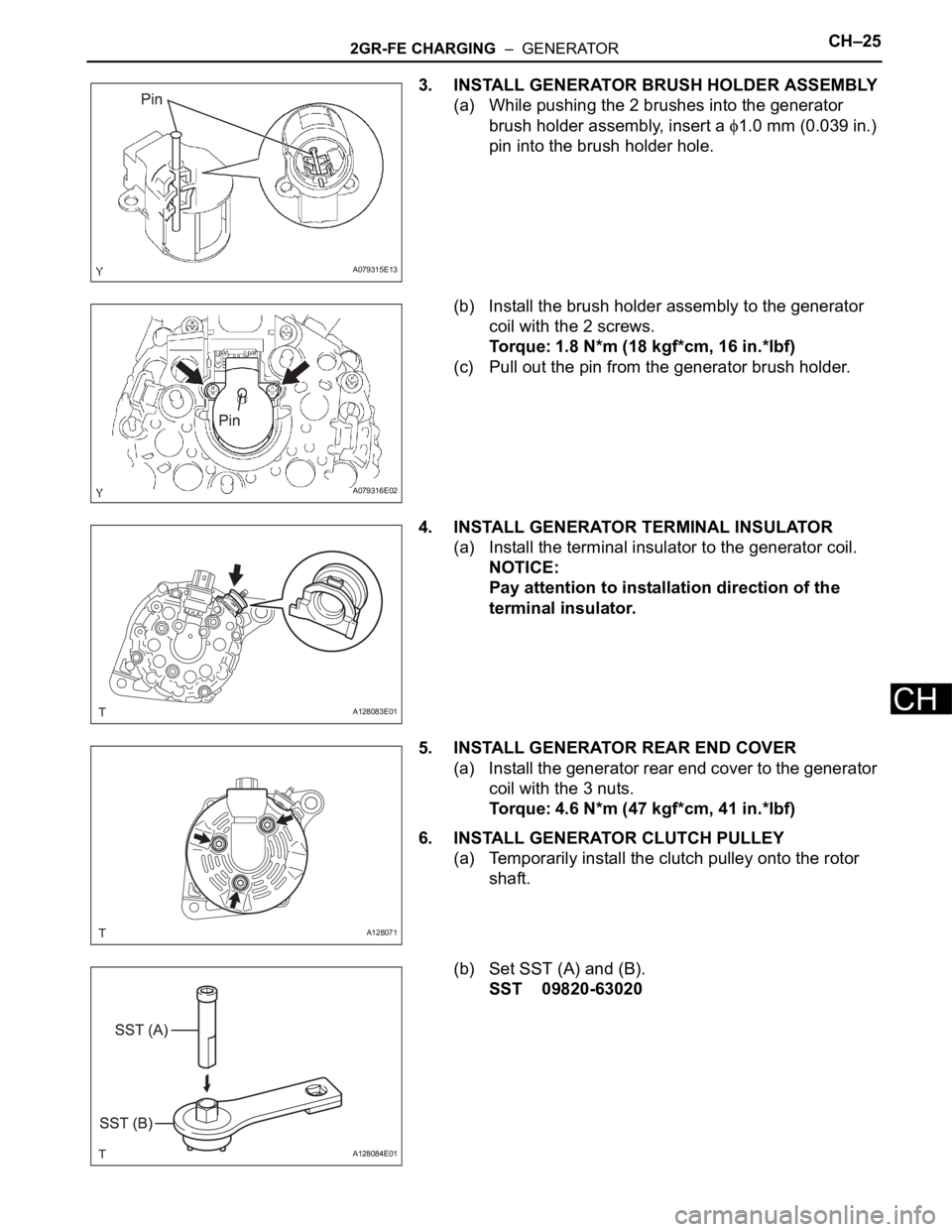

1. REPLACE GENERATOR DRIVE END FRAME

BEARING

(a) Remove the 4 screws and retainer plate from the

drive end frame.

(b) Using SST and a hammer, tap out the drive end

frame bearing from the drive end frame.

SST 09950-60010 (09951-00250), 09950-70010

(09951-07100)

B012264E08

Condition Specified Condition

Approx. 20

C (68F) 1.5 to 1.9

B012265E01

Tester Condition Specified Condition

Slip ring - Rotor 1 M

or higher

A124106E01

A128076

A128077E01

Page 1372 of 3000

2GR-FE CHARGING – GENERATORCH–23

CH

(c) Using SST and a press, press in a new generator

drive end frame bearing.

SST 09950-60010 (09951-00470), 09950-70010

(09951-07100)

(d) Fit the tabs on the retainer plate into the cutouts on

the drive end frame to install the retainer plate.

(e) Install the 4 screws.

Torque: 2.3 N*m (23 kgf*cm, 20 in.*lbf)

A128081E01

A137712E01

Page 1373 of 3000

CH–242GR-FE CHARGING – GENERATOR

CH

REASSEMBLY

1. INSTALL GENERATOR ROTOR ASSEMBLY

(a) Place the drive end frame on the clutch pulley.

(b) Install the generator rotor assembly to the drive end

frame.

(c) Place a new generator washer on the generator

rotor.

2. INSTALL GENERATOR COIL ASSEMBLY

(a) Using a deep socket wrench (21 mm) and a press,

slowly press in the generator coil assembly.

(b) Install the 4 bolts.

Torque: 5.8 N*m (59 kgf*cm, 51 in.*lbf)

A118367E01

A118365E01

A128082E03

A128074

Page 1374 of 3000

2GR-FE CHARGING – GENERATORCH–25

CH

3. INSTALL GENERATOR BRUSH HOLDER ASSEMBLY

(a) While pushing the 2 brushes into the generator

brush holder assembly, insert a

1.0 mm (0.039 in.)

pin into the brush holder hole.

(b) Install the brush holder assembly to the generator

coil with the 2 screws.

Torque: 1.8 N*m (18 kgf*cm, 16 in.*lbf)

(c) Pull out the pin from the generator brush holder.

4. INSTALL GENERATOR TERMINAL INSULATOR

(a) Install the terminal insulator to the generator coil.

NOTICE:

Pay attention to installation direction of the

terminal insulator.

5. INSTALL GENERATOR REAR END COVER

(a) Install the generator rear end cover to the generator

coil with the 3 nuts.

Torque: 4.6 N*m (47 kgf*cm, 41 in.*lbf)

6. INSTALL GENERATOR CLUTCH PULLEY

(a) Temporarily install the clutch pulley onto the rotor

shaft.

(b) Set SST (A) and (B).

SST 09820-63020

A079315E13

A079316E02

A128083E01

A128071

A128084E01

Page 1375 of 3000

CH–262GR-FE CHARGING – GENERATOR

CH

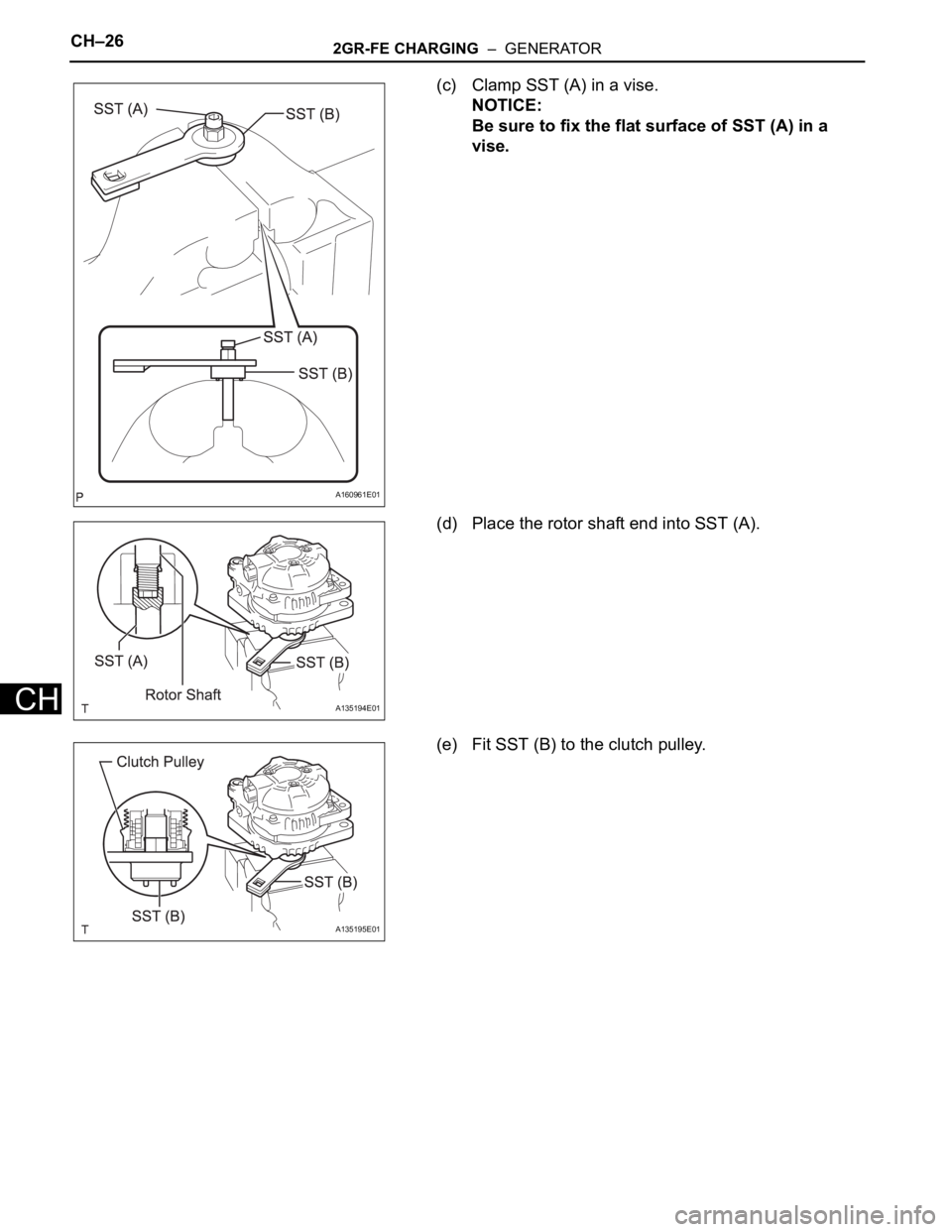

(c) Clamp SST (A) in a vise.

NOTICE:

Be sure to fix the flat surface of SST (A) in a

vise.

(d) Place the rotor shaft end into SST (A).

(e) Fit SST (B) to the clutch pulley.

A160961E01

A135194E01

A135195E01

Page 1376 of 3000

2GR-FE CHARGING – GENERATORCH–27

CH

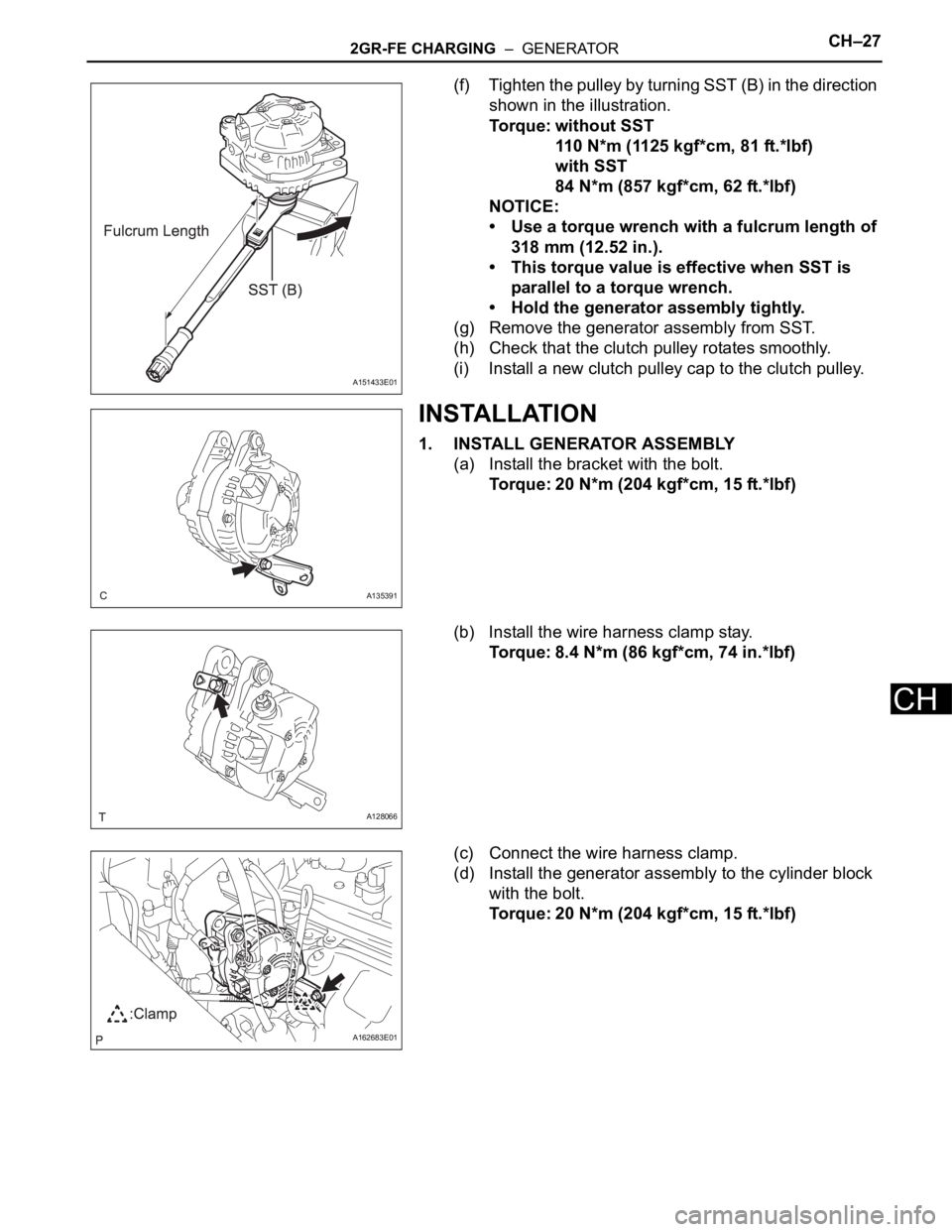

(f) Tighten the pulley by turning SST (B) in the direction

shown in the illustration.

Torque: without SST

110 N*m (1125 kgf*cm, 81 ft.*lbf)

with SST

84 N*m (857 kgf*cm, 62 ft.*lbf)

NOTICE:

• Use a torque wrench with a fulcrum length of

318 mm (12.52 in.).

• This torque value is effective when SST is

parallel to a torque wrench.

• Hold the generator assembly tightly.

(g) Remove the generator assembly from SST.

(h) Check that the clutch pulley rotates smoothly.

(i) Install a new clutch pulley cap to the clutch pulley.

INSTALLATION

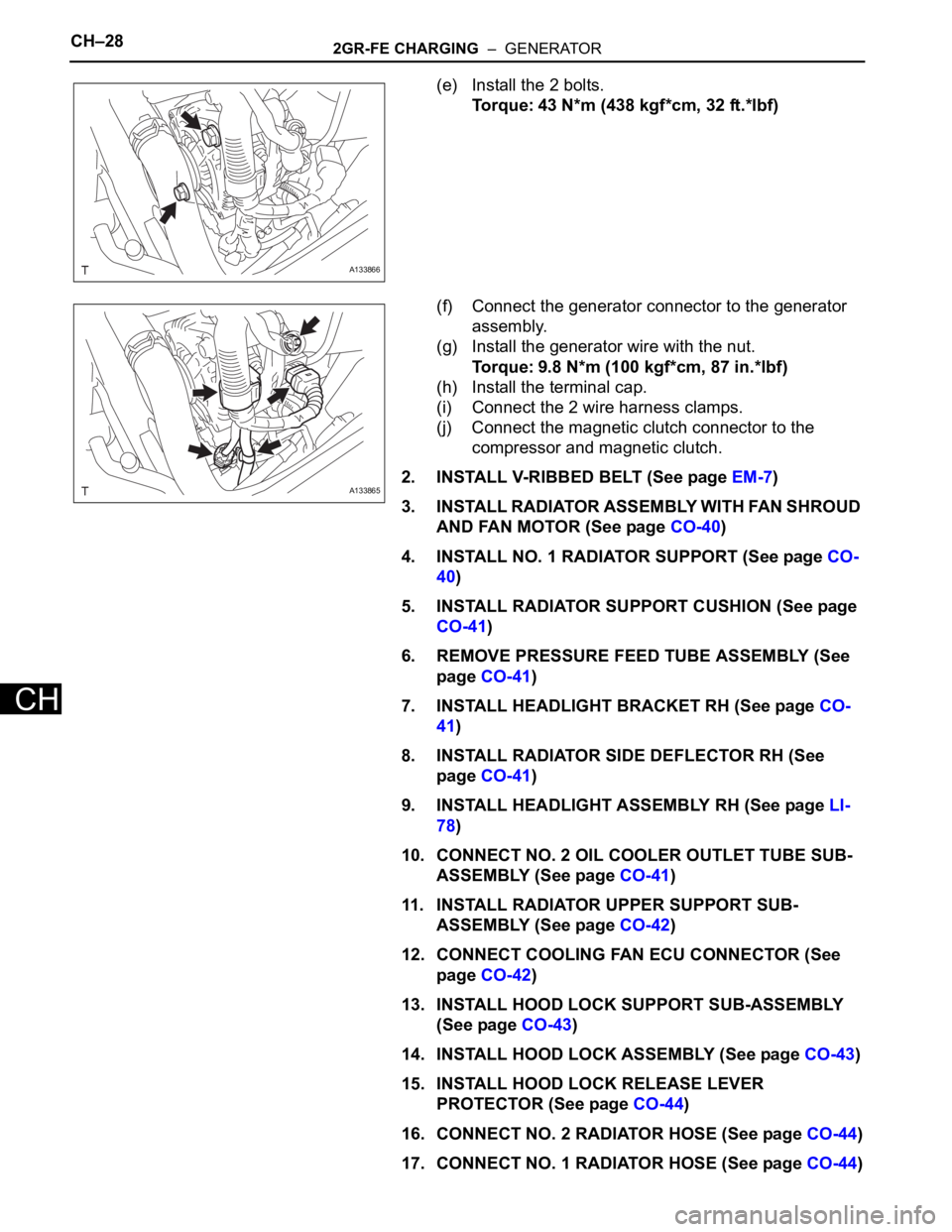

1. INSTALL GENERATOR ASSEMBLY

(a) Install the bracket with the bolt.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf)

(b) Install the wire harness clamp stay.

Torque: 8.4 N*m (86 kgf*cm, 74 in.*lbf)

(c) Connect the wire harness clamp.

(d) Install the generator assembly to the cylinder block

with the bolt.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf)

A151433E01

A135391

A128066

A162683E01

Page 1377 of 3000

CH–282GR-FE CHARGING – GENERATOR

CH

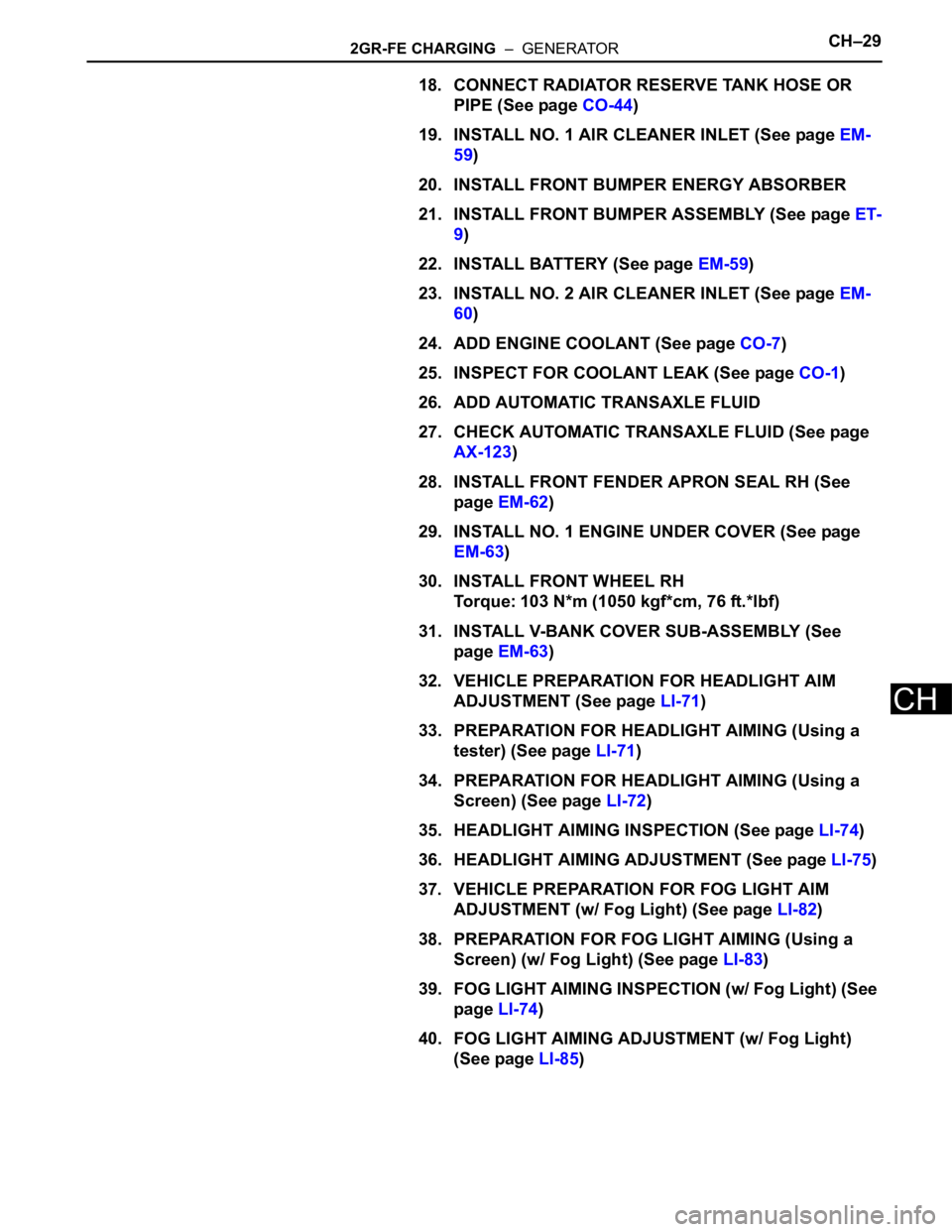

(e) Install the 2 bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

(f) Connect the generator connector to the generator

assembly.

(g) Install the generator wire with the nut.

Torque: 9.8 N*m (100 kgf*cm, 87 in.*lbf)

(h) Install the terminal cap.

(i) Connect the 2 wire harness clamps.

(j) Connect the magnetic clutch connector to the

compressor and magnetic clutch.

2. INSTALL V-RIBBED BELT (See page EM-7)

3. INSTALL RADIATOR ASSEMBLY WITH FAN SHROUD

AND FAN MOTOR (See page CO-40)

4. INSTALL NO. 1 RADIATOR SUPPORT (See page CO-

40)

5. INSTALL RADIATOR SUPPORT CUSHION (See page

CO-41)

6. REMOVE PRESSURE FEED TUBE ASSEMBLY (See

page CO-41)

7. INSTALL HEADLIGHT BRACKET RH (See page CO-

41)

8. INSTALL RADIATOR SIDE DEFLECTOR RH (See

page CO-41)

9. INSTALL HEADLIGHT ASSEMBLY RH (See page LI-

78)

10. CONNECT NO. 2 OIL COOLER OUTLET TUBE SUB-

ASSEMBLY (See page CO-41)

11. INSTALL RADIATOR UPPER SUPPORT SUB-

ASSEMBLY (See page CO-42)

12. CONNECT COOLING FAN ECU CONNECTOR (See

page CO-42)

13. INSTALL HOOD LOCK SUPPORT SUB-ASSEMBLY

(See page CO-43)

14. INSTALL HOOD LOCK ASSEMBLY (See page CO-43)

15. INSTALL HOOD LOCK RELEASE LEVER

PROTECTOR (See page CO-44)

16. CONNECT NO. 2 RADIATOR HOSE (See page CO-44)

17. CONNECT NO. 1 RADIATOR HOSE (See page CO-44)

A133866

A133865

Page 1378 of 3000

2GR-FE CHARGING – GENERATORCH–29

CH

18. CONNECT RADIATOR RESERVE TANK HOSE OR

PIPE (See page CO-44)

19. INSTALL NO. 1 AIR CLEANER INLET (See page EM-

59)

20. INSTALL FRONT BUMPER ENERGY ABSORBER

21. INSTALL FRONT BUMPER ASSEMBLY (See page ET-

9)

22. INSTALL BATTERY (See page EM-59)

23. INSTALL NO. 2 AIR CLEANER INLET (See page EM-

60)

24. ADD ENGINE COOLANT (See page CO-7)

25. INSPECT FOR COOLANT LEAK (See page CO-1)

26. ADD AUTOMATIC TRANSAXLE FLUID

27. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

28. INSTALL FRONT FENDER APRON SEAL RH (See

page EM-62)

29. INSTALL NO. 1 ENGINE UNDER COVER (See page

EM-63)

30. INSTALL FRONT WHEEL RH

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

31. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

32. VEHICLE PREPARATION FOR HEADLIGHT AIM

ADJUSTMENT (See page LI-71)

33. PREPARATION FOR HEADLIGHT AIMING (Using a

tester) (See page LI-71)

34. PREPARATION FOR HEADLIGHT AIMING (Using a

Screen) (See page LI-72)

35. HEADLIGHT AIMING INSPECTION (See page LI-74)

36. HEADLIGHT AIMING ADJUSTMENT (See page LI-75)

37. VEHICLE PREPARATION FOR FOG LIGHT AIM

ADJUSTMENT (w/ Fog Light) (See page LI-82)

38. PREPARATION FOR FOG LIGHT AIMING (Using a

Screen) (w/ Fog Light) (See page LI-83)

39. FOG LIGHT AIMING INSPECTION (w/ Fog Light) (See

page LI-74)

40. FOG LIGHT AIMING ADJUSTMENT (w/ Fog Light)

(See page LI-85)

Page 1379 of 3000

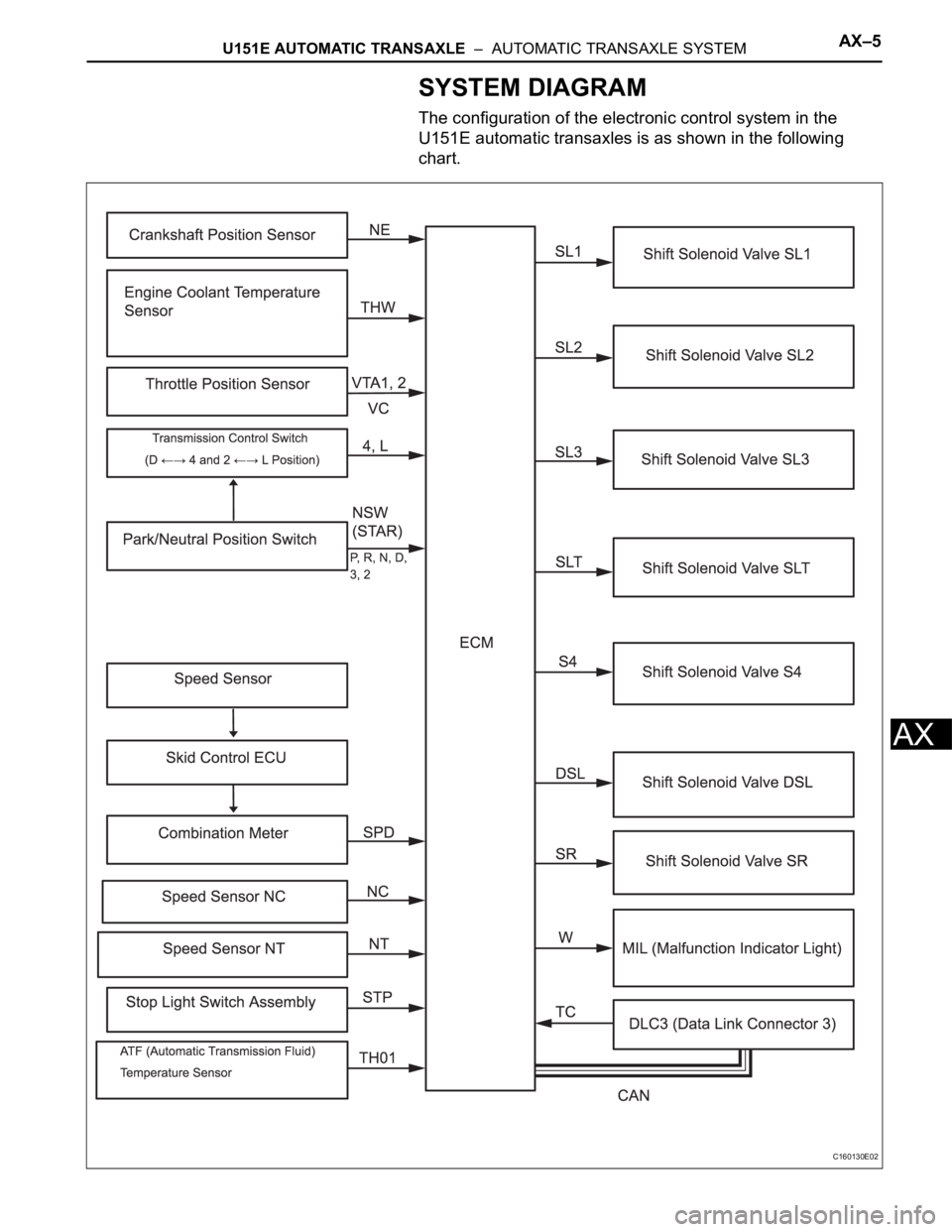

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–5

AX

SYSTEM DIAGRAM

The configuration of the electronic control system in the

U151E automatic transaxles is as shown in the following

chart.

C160130E02

Page 1380 of 3000

AX–6U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

SYSTEM DESCRIPTION

1. SYSTEM DESCRIPTION

(a) The ECT (Electronic controlled automatic

transmission/transaxle) is an automatic

transmission/transaxle that electronically controls

shift timing using the ECM. The ECM detects

electrical signals that indicate engine and driving

conditions, and controls the shift point, based on

driver habits and road conditions. As a result, fuel

efficiency and power transmission performance are

improved.

Shift shock has been reduced by controlling the

engine and transmission simultaneously.

In addition, the ECT has features such as follows:

• Diagnostic function.

• Fail-safe function when a malfunction occurs.