TOYOTA SIENNA 2007 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1421 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–55

AX

DESCRIPTION

The ATF (Automatic Transmission Fluid) temperature sensor converts the fluid temperature into a

resistance value which is input into the ECM.

MONITOR DESCRIPTION

The ATF temperature sensor converts the ATF temperature to an electrical resistance value. Based on

the resistance, the ECM determines the ATF temperature and detects an open or short in the ATF

temperature circuit or a fault in the ATF temperature sensor.

After running the vehicle for a certain period, the ATF temperature should increase. If the ATF

temperature is below 20

C (68F) after running the vehicle for a certain period, the ECM interprets this as

a fault, and turns on the MIL.

When the ATF temperature is 110

C (230F) or more after 17 minutes of engine cold start, the ECM also

determines this as a fault, turns on the MIL, and stores the DTC.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

All:

Condition (A):

Condition (B):

DTC P0711Transmission Fluid Temperature Sensor "A"

Performance

DTC No. DTC Detection Condition Trouble Area

P0711(A) Both (a) and (b) are detected: (2-trip detection logic)

(a) Intake air and engine coolant temperatures are

more than -10

C (14F) at engine start

(b) After normal driving for over 19 min. and 9 km (6

mile) or more, ATF temp. is less than 20

C (68F)

(B) When engine coolant temp. is less than 35

C (95F)

at engine start, the ATF temp. is 110C (230F) or more

after 17 min. of engine start (2-trip detection logic).Transmission wire (ATF temperature sensor)

Related DTCs P0711: ATF temperature sensor/Rationality check

Required sensors/Components ATF temperature sensor (TFT sensor)

Frequency of operation Continuous

Duration3 sec.: Condition (A), (B), (C)

Continuous.: Condition (D)

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present. None

TFT sensor circuitNot circuit malfunction

ECT sensor circuitNot circuit malfunction

IAT sensor circuitNot circuit malfunction

ETCSNot circuit malfunction

Time after engine start 18 min. and 20 sec.

Driving distance after engine start 9 km (5.6 mile) or more

IAT (Intake air temperature) (12 sec. after starting engine) -10

C (14F) or more

ECT (12 sec. after starting engine) -10

C (14F) or more

Time after engine start 30 min.

Driving distance after engine start 15 km (9.3 mile) or more

Page 1422 of 3000

AX–56U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

Condition (C):

Condition (D):

TYPICAL MALFUNCTION THRESHOLDS

Condition (A), (B), (C):

Condition (D):

COMPONENT OPERATING RANGE

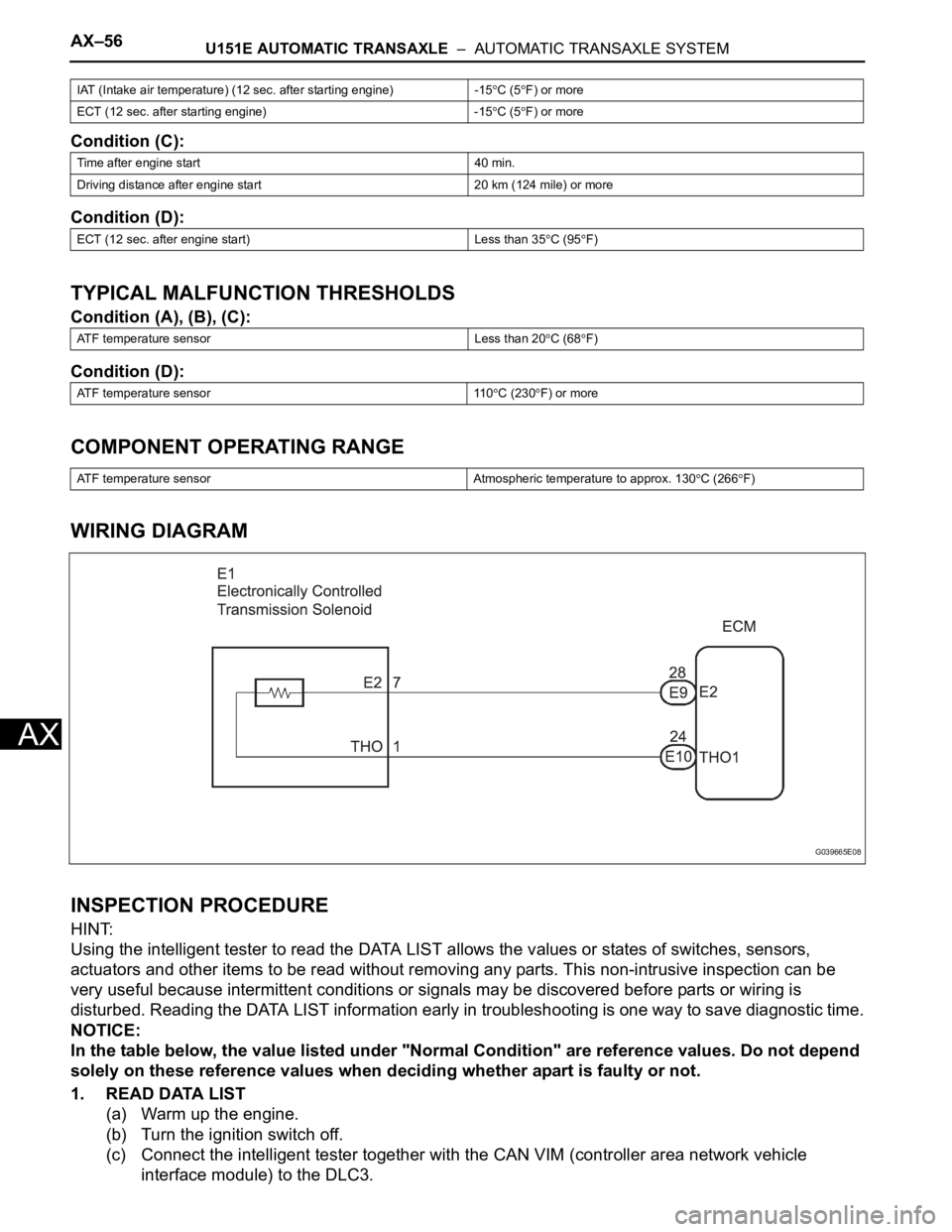

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

Using the intelligent tester to read the DATA LIST allows the values or states of switches, sensors,

actuators and other items to be read without removing any parts. This non-intrusive inspection can be

very useful because intermittent conditions or signals may be discovered before parts or wiring is

disturbed. Reading the DATA LIST information early in troubleshooting is one way to save diagnostic time.

NOTICE:

In the table below, the value listed under "Normal Condition" are reference values. Do not depend

solely on these reference values when deciding whether apart is faulty or not.

1. READ DATA LIST

(a) Warm up the engine.

(b) Turn the ignition switch off.

(c) Connect the intelligent tester together with the CAN VIM (controller area network vehicle

interface module) to the DLC3.

IAT (Intake air temperature) (12 sec. after starting engine) -15C (5F) or more

ECT (12 sec. after starting engine) -15

C (5F) or more

Time after engine start 40 min.

Driving distance after engine start 20 km (124 mile) or more

ECT (12 sec. after engine start) Less than 35

C (95F)

ATF temperature sensor Less than 20

C (68F)

ATF temperature sensor 110

C (230F) or more

ATF temperature sensor Atmospheric temperature to approx. 130

C (266F)

G039665E08

Page 1423 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–57

AX

(d) Turn the ignition switch to the ON position.

(e) Turn on the tester.

(f) Select the item "DIAGNOSIS / ENHANCED OBD II / DATA LIST".

(g) According to the display on the tester, read the "DATA LIST".

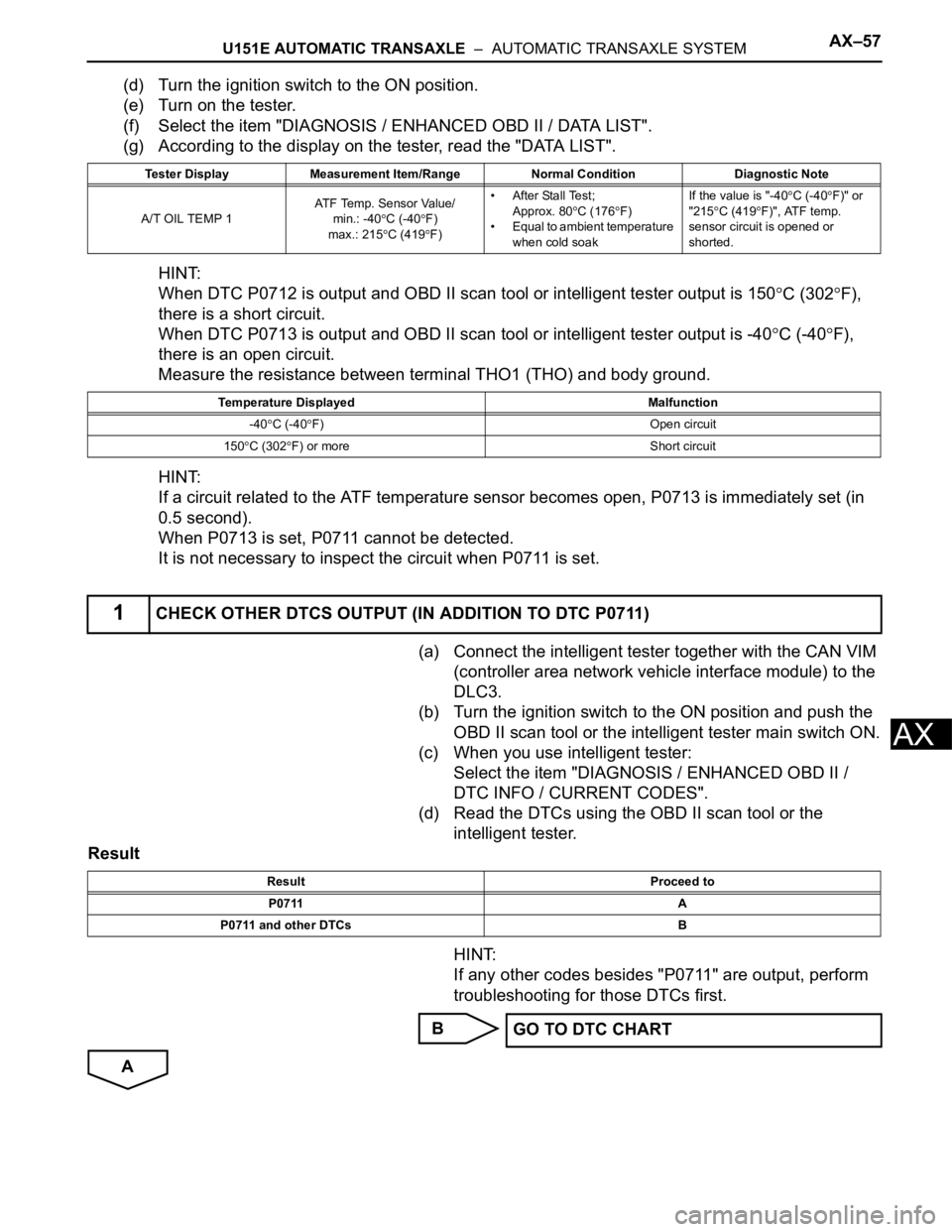

HINT:

When DTC P0712 is output and OBD II scan tool or intelligent tester output is 150

C (302F),

there is a short circuit.

When DTC P0713 is output and OBD II scan tool or intelligent tester output is -40

C (-40F),

there is an open circuit.

Measure the resistance between terminal THO1 (THO) and body ground.

HINT:

If a circuit related to the ATF temperature sensor becomes open, P0713 is immediately set (in

0.5 second).

When P0713 is set, P0711 cannot be detected.

It is not necessary to inspect the circuit when P0711 is set.

(a) Connect the intelligent tester together with the CAN VIM

(controller area network vehicle interface module) to the

DLC3.

(b) Turn the ignition switch to the ON position and push the

OBD II scan tool or the intelligent tester main switch ON.

(c) When you use intelligent tester:

Select the item "DIAGNOSIS / ENHANCED OBD II /

DTC INFO / CURRENT CODES".

(d) Read the DTCs using the OBD II scan tool or the

intelligent tester.

Result

HINT:

If any other codes besides "P0711" are output, perform

troubleshooting for those DTCs first.

B

A

Tester Display Measurement Item/Range Normal Condition Diagnostic Note

A/T OIL TEMP 1ATF Temp. Sensor Value/

min.: -40

C (-40F)

max.: 215

C (419F)• After Stall Test;

Approx. 80

C (176F)

• Equal to ambient temperature

when cold soakIf the value is "-40

C (-40F)" or

"215

C (419F)", ATF temp.

sensor circuit is opened or

shorted.

Temperature Displayed Malfunction

-40

C (-40F) Open circuit

150

C (302F) or more Short circuit

1CHECK OTHER DTCS OUTPUT (IN ADDITION TO DTC P0711)

Result Proceed to

P0711 A

P0711 and other DTCs B

GO TO DTC CHART

Page 1424 of 3000

AX–58U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

OK:

Automatic transmission fluid level is correct.

NG

OK

2CHECK TRANSMISSION FLUID LEVEL

ADD FLUID

REPLACE TRANSMISSION WIRE (ATF TEMPERATURE SENSOR)

Page 1425 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–59

AX

DESCRIPTION

This sensor detects the rotation speed of the input turbine. By comparing the input turbine speed signal

(NT) with the counter gear speed sensor signal (NC), the ECM detects the shift timing of the gears and

appropriately controls the engine torque and hydraulic pressure according to various conditions. Thus,

providing smooth gear shift.

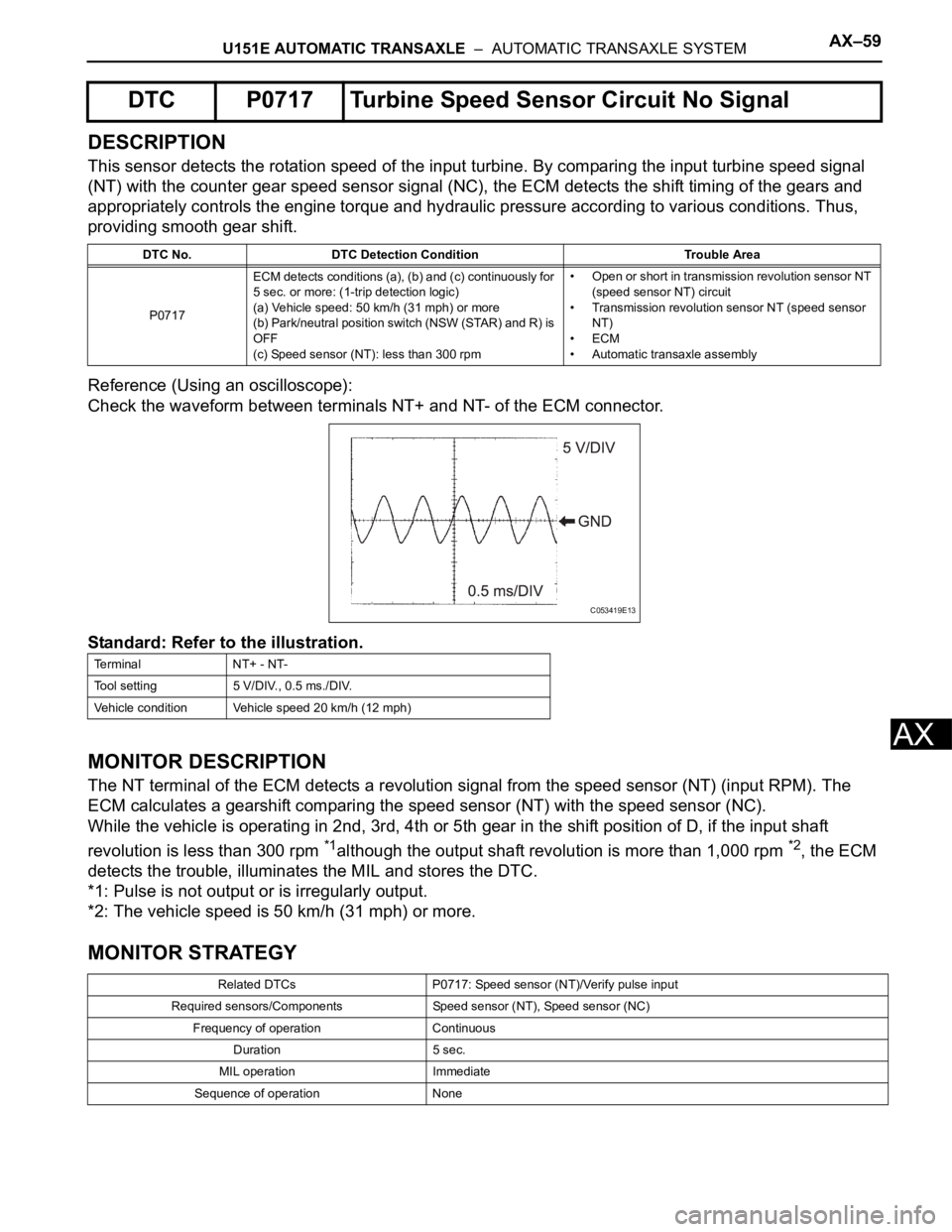

Reference (Using an oscilloscope):

Check the waveform between terminals NT+ and NT- of the ECM connector.

Standard: Refer to the illustration.

MONITOR DESCRIPTION

The NT terminal of the ECM detects a revolution signal from the speed sensor (NT) (input RPM). The

ECM calculates a gearshift comparing the speed sensor (NT) with the speed sensor (NC).

While the vehicle is operating in 2nd, 3rd, 4th or 5th gear in the shift position of D, if the input shaft

revolution is less than 300 rpm

*1although the output shaft revolution is more than 1,000 rpm *2, the ECM

detects the trouble, illuminates the MIL and stores the DTC.

*1: Pulse is not output or is irregularly output.

*2: The vehicle speed is 50 km/h (31 mph) or more.

MONITOR STRATEGY

DTC P0717 Turbine Speed Sensor Circuit No Signal

DTC No. DTC Detection Condition Trouble Area

P0717ECM detects conditions (a), (b) and (c) continuously for

5 sec. or more: (1-trip detection logic)

(a) Vehicle speed: 50 km/h (31 mph) or more

(b) Park/neutral position switch (NSW (STAR) and R) is

OFF

(c) Speed sensor (NT): less than 300 rpm• Open or short in transmission revolution sensor NT

(speed sensor NT) circuit

• Transmission revolution sensor NT (speed sensor

NT)

•ECM

• Automatic transaxle assembly

Te r m i n a l N T + - N T -

Tool setting 5 V/DIV., 0.5 ms./DIV.

Vehicle condition Vehicle speed 20 km/h (12 mph)

Related DTCs P0717: Speed sensor (NT)/Verify pulse input

Required sensors/Components Speed sensor (NT), Speed sensor (NC)

Frequency of operation Continuous

Duration 5 sec.

MIL operation Immediate

Sequence of operation None

C053419E13

Page 1426 of 3000

AX–60U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

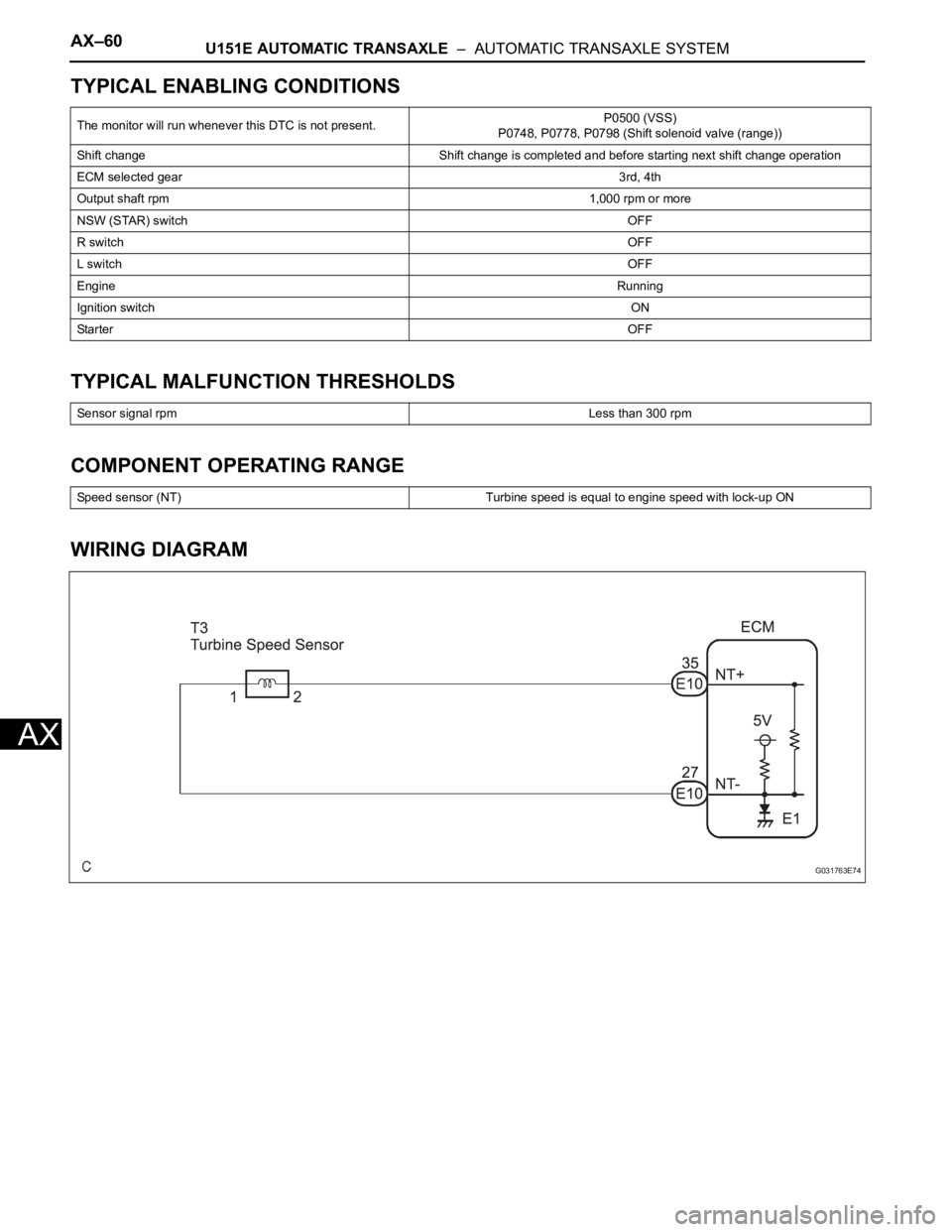

WIRING DIAGRAM

The monitor will run whenever this DTC is not present.P0500 (VSS)

P0748, P0778, P0798 (Shift solenoid valve (range))

Shift change Shift change is completed and before starting next shift change operation

ECM selected gear3rd, 4th

Output shaft rpm1,000 rpm or more

NSW (STAR) switchOFF

R switchOFF

L switchOFF

EngineRunning

Ignition switchON

StarterOFF

Sensor signal rpmLess than 300 rpm

Speed sensor (NT) Turbine speed is equal to engine speed with lock-up ON

G031763E74

Page 1427 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–61

AX

INSPECTION PROCEDURE

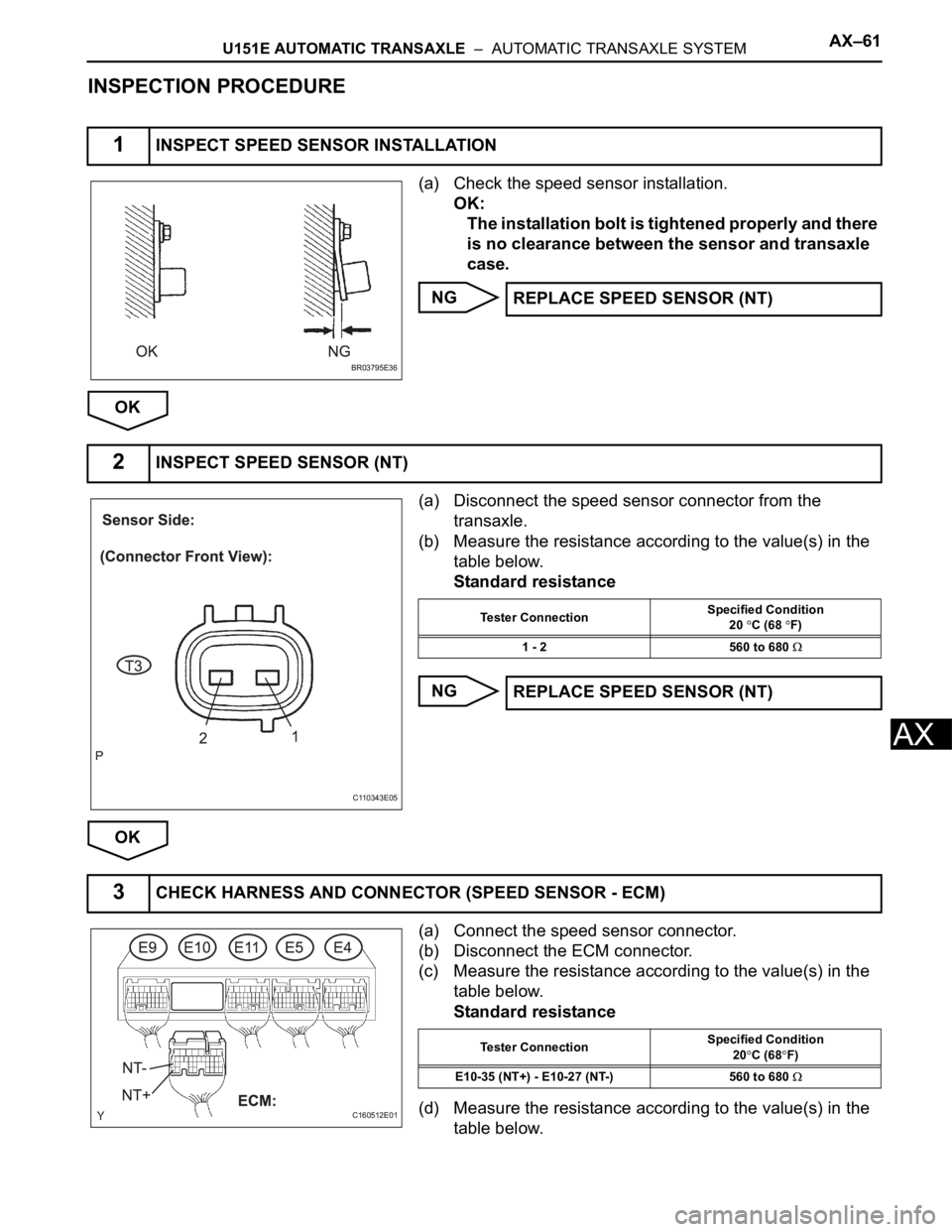

(a) Check the speed sensor installation.

OK:

The installation bolt is tightened properly and there

is no clearance between the sensor and transaxle

case.

NG

OK

(a) Disconnect the speed sensor connector from the

transaxle.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

NG

OK

(a) Connect the speed sensor connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(d) Measure the resistance according to the value(s) in the

table below.

1INSPECT SPEED SENSOR INSTALLATION

BR03795E36

REPLACE SPEED SENSOR (NT)

2INSPECT SPEED SENSOR (NT)

C110343E05

Tester ConnectionSpecified Condition

20 C (68 F)

1 - 2 560 to 680

REPLACE SPEED SENSOR (NT)

3CHECK HARNESS AND CONNECTOR (SPEED SENSOR - ECM)

C160512E01

Tester ConnectionSpecified Condition

20C (68F)

E10-35 (NT+) - E10-27 (NT-) 560 to 680

Page 1428 of 3000

AX–62U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

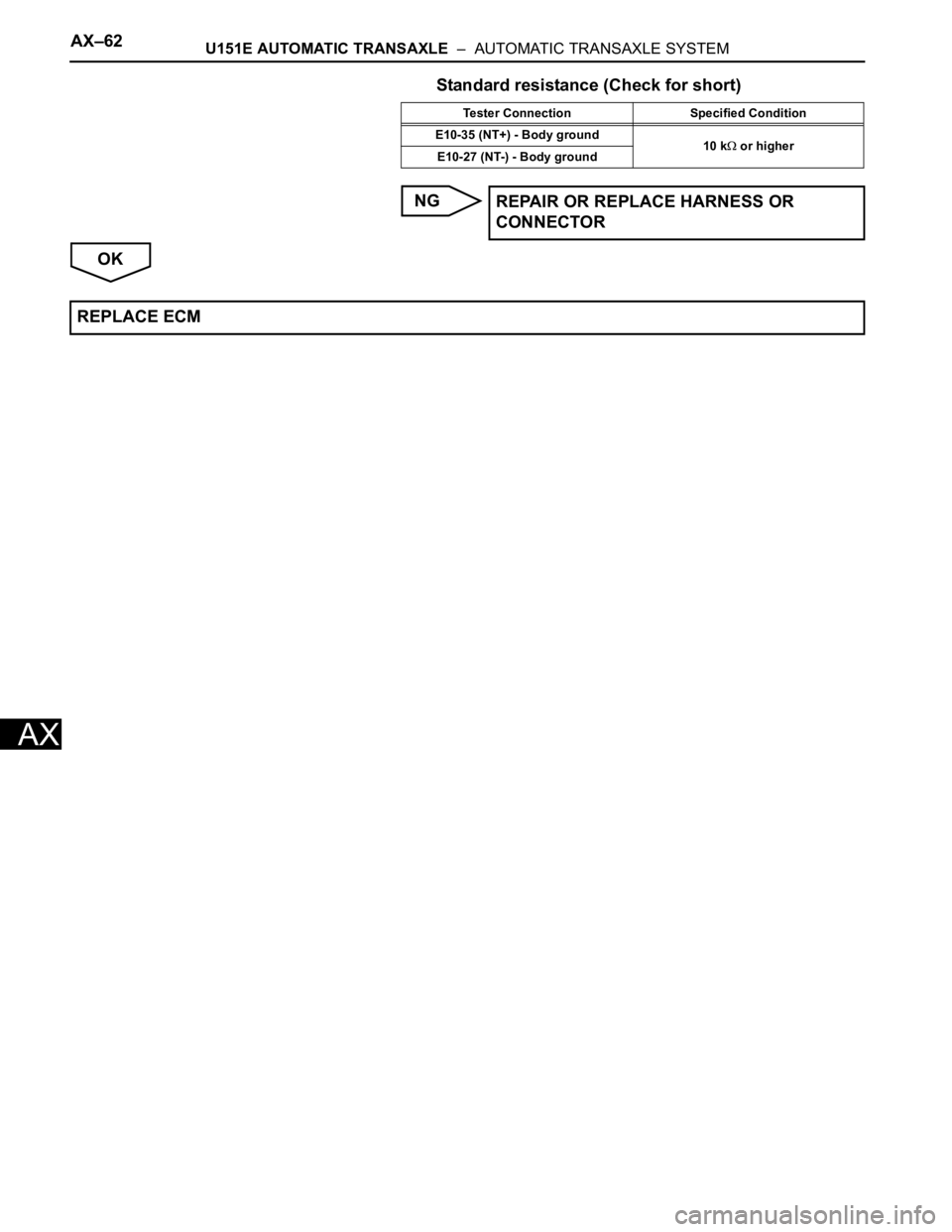

Standard resistance (Check for short)

NG

OK

Tester Connection Specified Condition

E10-35 (NT+) - Body ground

10 k

or higher

E10-27 (NT-) - Body ground

REPAIR OR REPLACE HARNESS OR

CONNECTOR

REPLACE ECM

Page 1429 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–63

AX

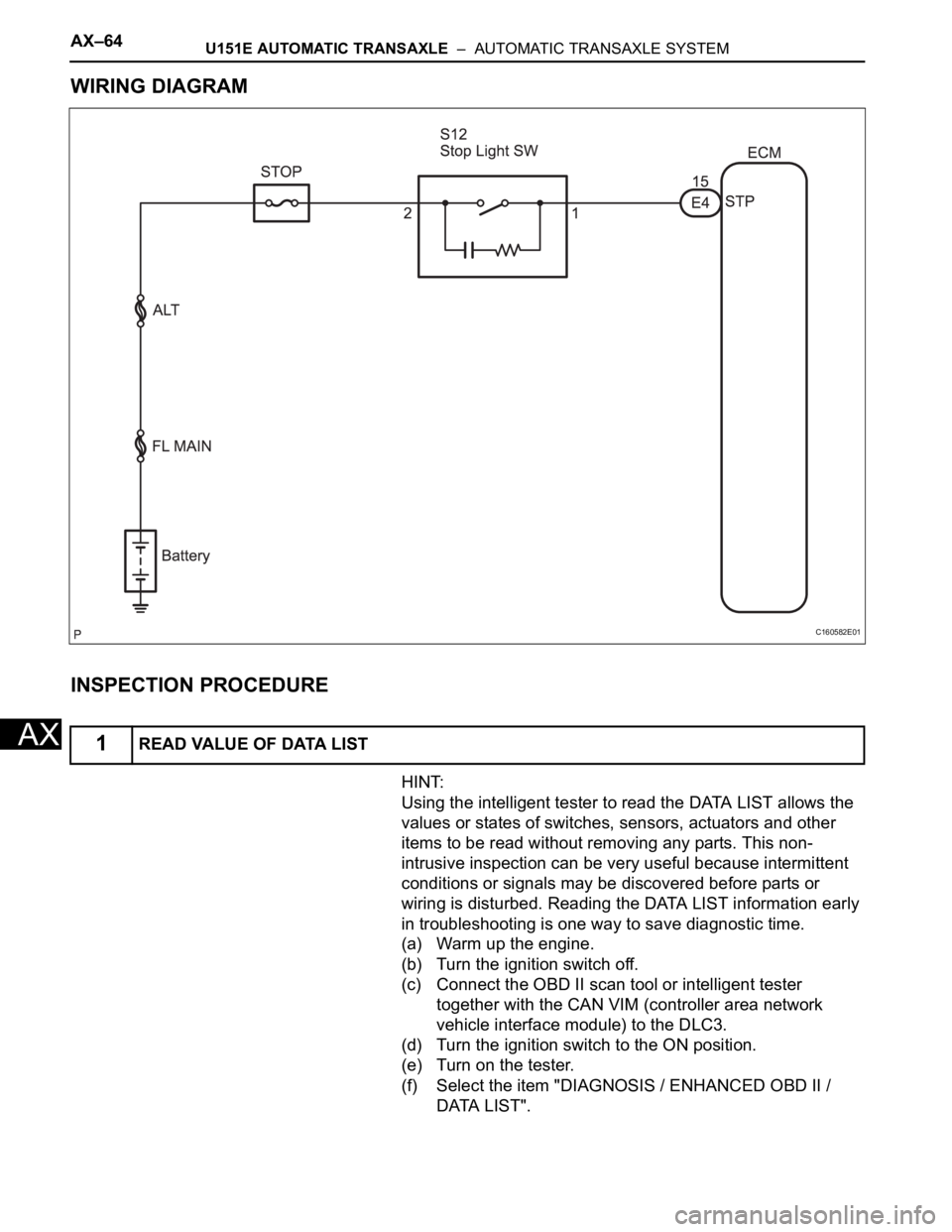

DESCRIPTION

The purpose of this circuit is to prevent the engine from stalling while driving in lock-up condition when

brakes are suddenly applied.

When the brake pedal is depressed, this switch sends a signals to the ECM. Then the ECM cancels the

operation of the lock-up clutch while braking is in progress.

MONITOR DESCRIPTION

This DTC indicates that the stop light switch remains on. When the stop light switch remains ON during

"stop and go" driving, the ECM interprets this as a fault in the stop light switch and the MIL comes on and

the ECM stores the DTC. The vehicle must stop (less than 3 km/h (2 mph)) and go (30 km/h (19 mph) or

more) 5 times for two driving cycles in order to detect a malfunction.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

DTC P0724 Brake Switch "B" Circuit High

DTC No. DTC Detection Condition Trouble Area

P0724The stop light switch remains ON even when the

vehicle is driven in a STOP (less than 3 km/h (2 mph)

and GO (30 km/h (19 mph) or more) fashion 5 times. (2-

trip detection logic).• Short in stop light switch circuit

• Stop light switch

•ECM

Related DTCs P0724: Stop light switch/Rationality

Required sensors/Components Stop light switch, Vehicle speed sensor

Frequency of operation Continuous

Duration GO and STOP 5 times

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present. None

Ignition switchON

Sta r t e rOFF

Battery voltage8 V or more

GO (Vehicle speed is 30 km/h (18.63 mph) or more) Once

STOP (Vehicle speed is less than 3 km/h (1.86 mph)) Once

Brake switch Remain ON during GO and STOP 5 times

Page 1430 of 3000

AX–64U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

Using the intelligent tester to read the DATA LIST allows the

values or states of switches, sensors, actuators and other

items to be read without removing any parts. This non-

intrusive inspection can be very useful because intermittent

conditions or signals may be discovered before parts or

wiring is disturbed. Reading the DATA LIST information early

in troubleshooting is one way to save diagnostic time.

(a) Warm up the engine.

(b) Turn the ignition switch off.

(c) Connect the OBD II scan tool or intelligent tester

together with the CAN VIM (controller area network

vehicle interface module) to the DLC3.

(d) Turn the ignition switch to the ON position.

(e) Turn on the tester.

(f) Select the item "DIAGNOSIS / ENHANCED OBD II /

DATA LIST".

1READ VALUE OF DATA LIST

C160582E01