coolant TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1774 of 3000

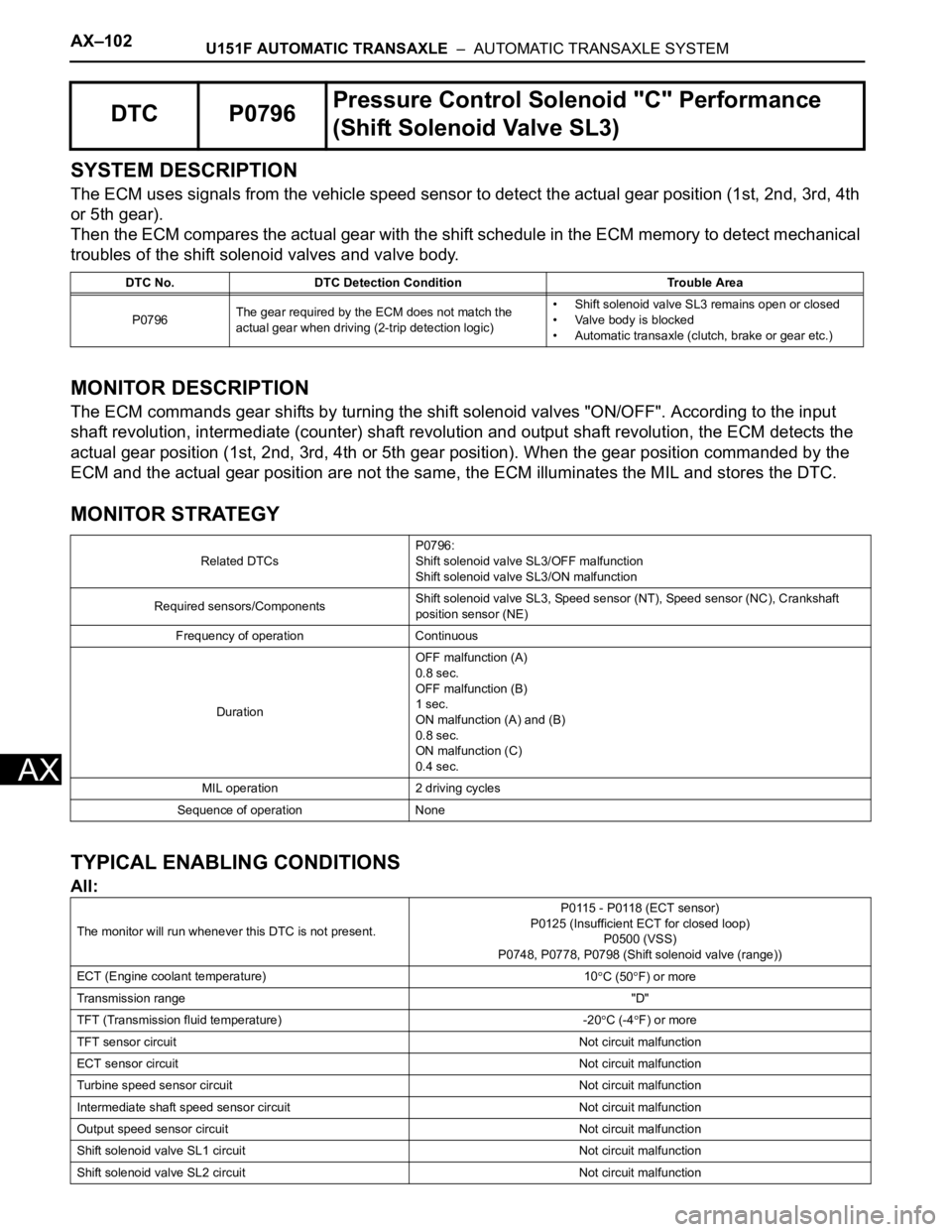

AX–102U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shift schedule in the ECM memory to detect mechanical

troubles of the shift solenoid valves and valve body.

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". According to the input

shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ECM detects the

actual gear position (1st, 2nd, 3rd, 4th or 5th gear position). When the gear position commanded by the

ECM and the actual gear position are not the same, the ECM illuminates the MIL and stores the DTC.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

All:

DTC P0796Pressure Control Solenoid "C" Performance

(Shift Solenoid Valve SL3)

DTC No. DTC Detection Condition Trouble Area

P0796The gear required by the ECM does not match the

actual gear when driving (2-trip detection logic)• Shift solenoid valve SL3 remains open or closed

• Valve body is blocked

• Automatic transaxle (clutch, brake or gear etc.)

Related DTCsP0796:

Shift solenoid valve SL3/OFF malfunction

Shift solenoid valve SL3/ON malfunction

Required sensors/ComponentsShift solenoid valve SL3, Speed sensor (NT), Speed sensor (NC), Crankshaft

position sensor (NE)

Frequency of operation Continuous

DurationOFF malfunction (A)

0.8 sec.

OFF malfunction (B)

1 sec.

ON malfunction (A) and (B)

0.8 sec.

ON malfunction (C)

0.4 sec.

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present.P0115 - P0118 (ECT sensor)

P0125 (Insufficient ECT for closed loop)

P0500 (VSS)

P0748, P0778, P0798 (Shift solenoid valve (range))

ECT (Engine coolant temperature) 10

C (50F) or more

Transmission range"D"

TFT (Transmission fluid temperature) -20

C (-4F) or more

TFT sensor circuitNot circuit malfunction

ECT sensor circuitNot circuit malfunction

Turbine speed sensor circuit Not circuit malfunction

Intermediate shaft speed sensor circuit Not circuit malfunction

Output speed sensor circuit Not circuit malfunction

Shift solenoid valve SL1 circuit Not circuit malfunction

Shift solenoid valve SL2 circuit Not circuit malfunction

Page 1802 of 3000

AX–10U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

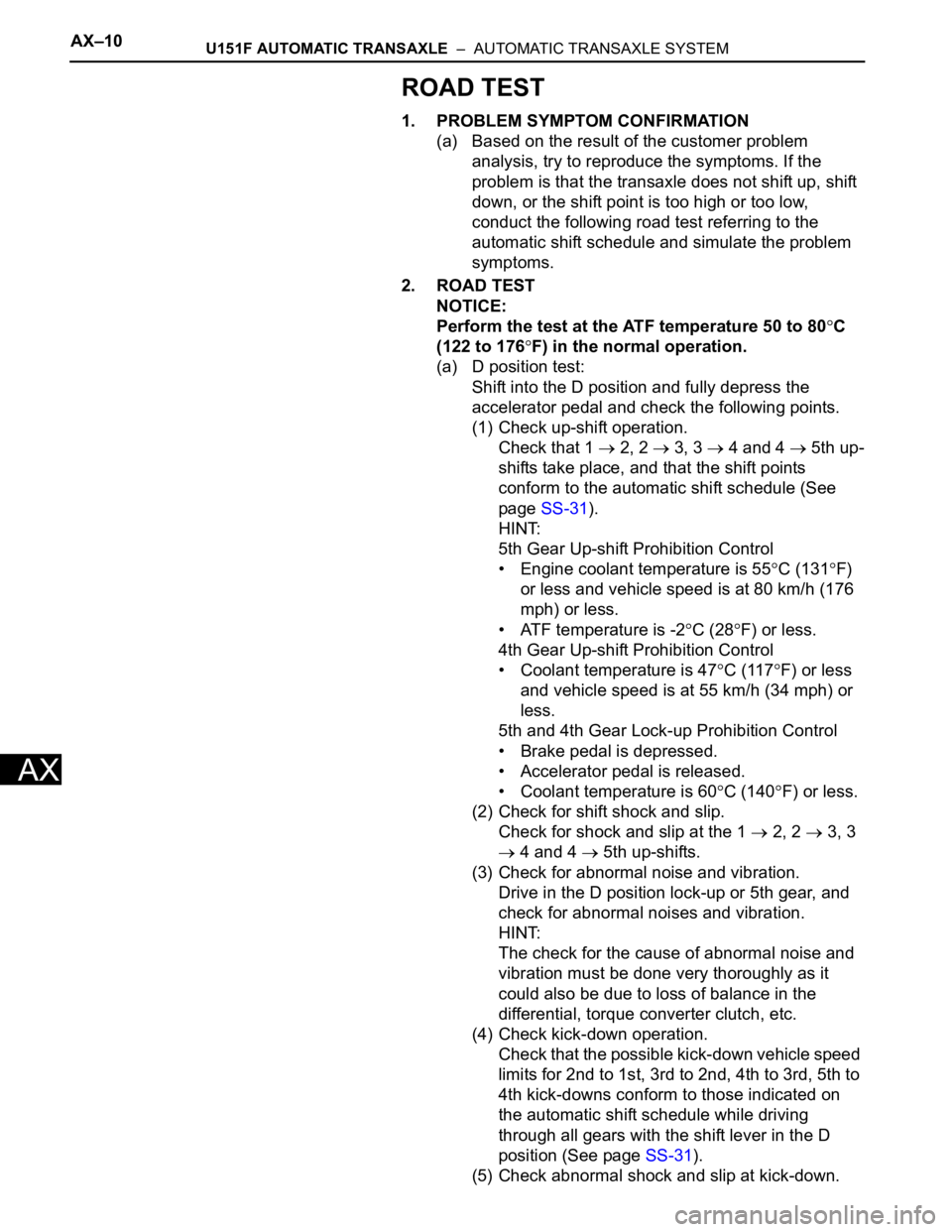

ROAD TEST

1. PROBLEM SYMPTOM CONFIRMATION

(a) Based on the result of the customer problem

analysis, try to reproduce the symptoms. If the

problem is that the transaxle does not shift up, shift

down, or the shift point is too high or too low,

conduct the following road test referring to the

automatic shift schedule and simulate the problem

symptoms.

2. ROAD TEST

NOTICE:

Perform the test at the ATF temperature 50 to 80

C

(122 to 176

F) in the normal operation.

(a) D position test:

Shift into the D position and fully depress the

accelerator pedal and check the following points.

(1) Check up-shift operation.

Check that 1

2, 2 3, 3 4 and 4 5th up-

shifts take place, and that the shift points

conform to the automatic shift schedule (See

page SS-31).

HINT:

5th Gear Up-shift Prohibition Control

• Engine coolant temperature is 55

C (131F)

or less and vehicle speed is at 80 km/h (176

mph) or less.

• ATF temperature is -2

C (28F) or less.

4th Gear Up-shift Prohibition Control

• Coolant temperature is 47

C (117F) or less

and vehicle speed is at 55 km/h (34 mph) or

less.

5th and 4th Gear Lock-up Prohibition Control

• Brake pedal is depressed.

• Accelerator pedal is released.

• Coolant temperature is 60

C (140F) or less.

(2) Check for shift shock and slip.

Check for shock and slip at the 1

2, 2 3, 3

4 and 4 5th up-shifts.

(3) Check for abnormal noise and vibration.

Drive in the D position lock-up or 5th gear, and

check for abnormal noises and vibration.

HINT:

The check for the cause of abnormal noise and

vibration must be done very thoroughly as it

could also be due to loss of balance in the

differential, torque converter clutch, etc.

(4) Check kick-down operation.

Check that the possible kick-down vehicle speed

limits for 2nd to 1st, 3rd to 2nd, 4th to 3rd, 5th to

4th kick-downs conform to those indicated on

the automatic shift schedule while driving

through all gears with the shift lever in the D

position (See page SS-31).

(5) Check abnormal shock and slip at kick-down.

Page 1820 of 3000

AX–20U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

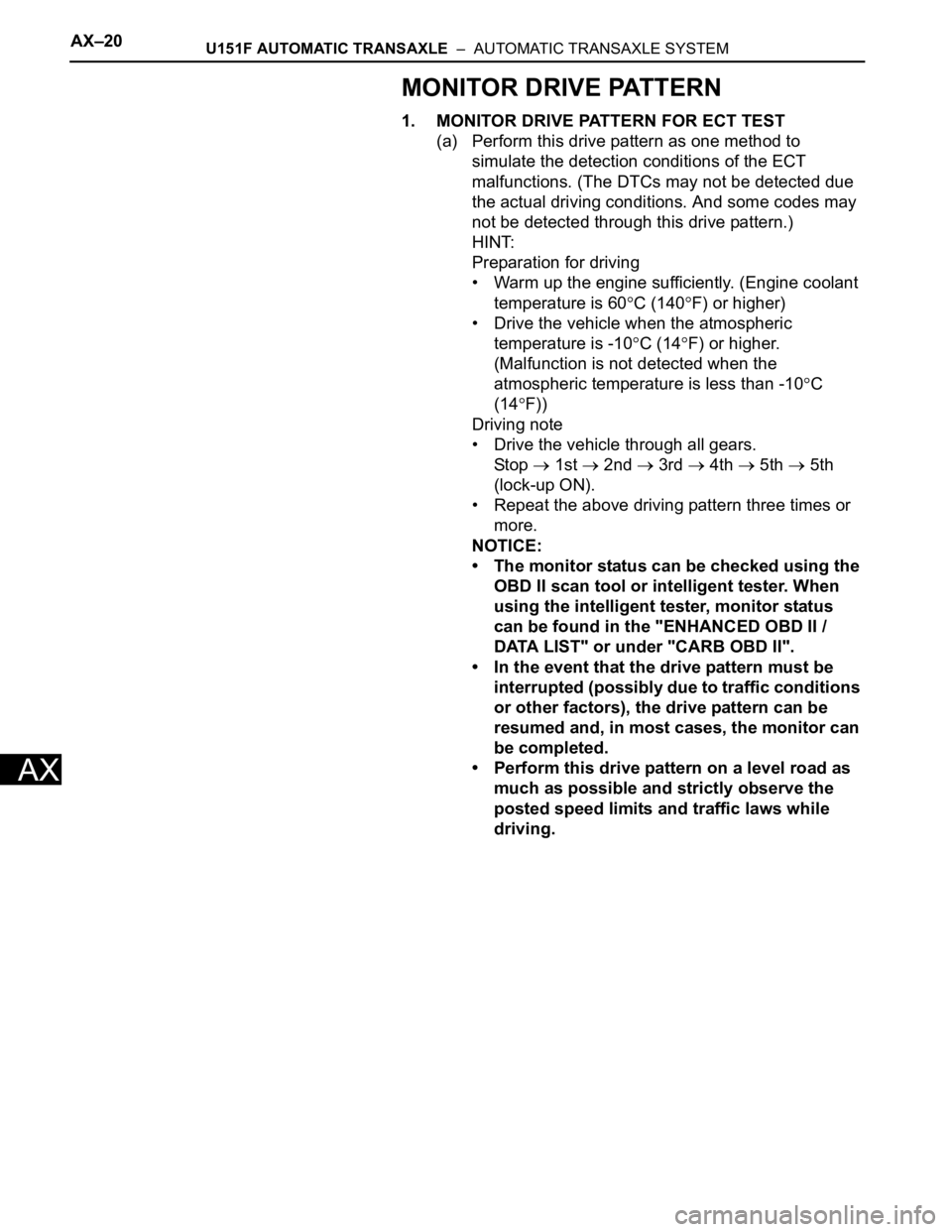

MONITOR DRIVE PATTERN

1. MONITOR DRIVE PATTERN FOR ECT TEST

(a) Perform this drive pattern as one method to

simulate the detection conditions of the ECT

malfunctions. (The DTCs may not be detected due

the actual driving conditions. And some codes may

not be detected through this drive pattern.)

HINT:

Preparation for driving

• Warm up the engine sufficiently. (Engine coolant

temperature is 60

C (140F) or higher)

• Drive the vehicle when the atmospheric

temperature is -10

C (14F) or higher.

(Malfunction is not detected when the

atmospheric temperature is less than -10

C

(14

F))

Driving note

• Drive the vehicle through all gears.

Stop

1st 2nd 3rd 4th 5th 5th

(lock-up ON).

• Repeat the above driving pattern three times or

more.

NOTICE:

• The monitor status can be checked using the

OBD II scan tool or intelligent tester. When

using the intelligent tester, monitor status

can be found in the "ENHANCED OBD II /

DATA LIST" or under "CARB OBD II".

• In the event that the drive pattern must be

interrupted (possibly due to traffic conditions

or other factors), the drive pattern can be

resumed and, in most cases, the monitor can

be completed.

• Perform this drive pattern on a level road as

much as possible and strictly observe the

posted speed limits and traffic laws while

driving.

Page 1828 of 3000

AX–22U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

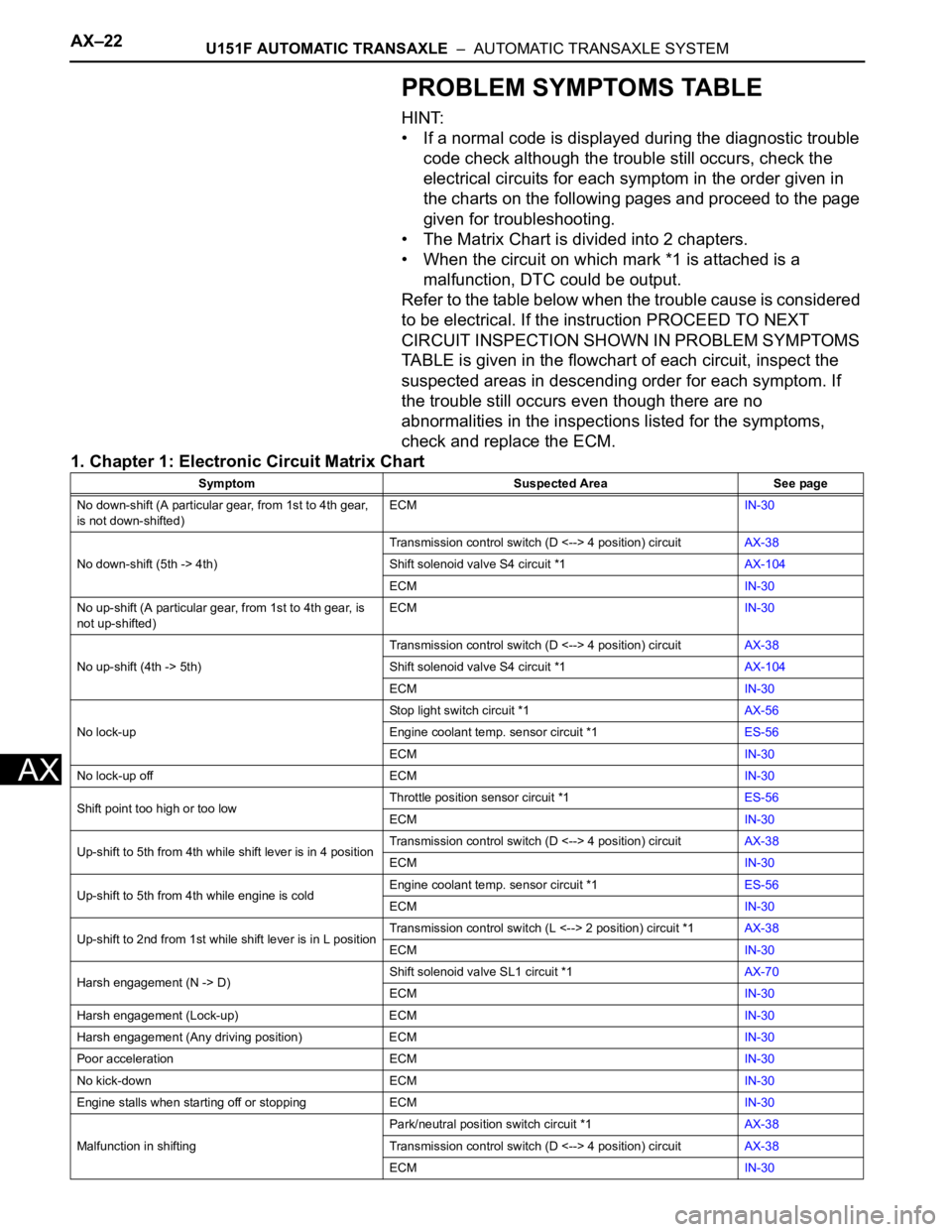

PROBLEM SYMPTOMS TABLE

HINT:

• If a normal code is displayed during the diagnostic trouble

code check although the trouble still occurs, check the

electrical circuits for each symptom in the order given in

the charts on the following pages and proceed to the page

given for troubleshooting.

• The Matrix Chart is divided into 2 chapters.

• When the circuit on which mark *1 is attached is a

malfunction, DTC could be output.

Refer to the table below when the trouble cause is considered

to be electrical. If the instruction PROCEED TO NEXT

CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS

TABLE is given in the flowchart of each circuit, inspect the

suspected areas in descending order for each symptom. If

the trouble still occurs even though there are no

abnormalities in the inspections listed for the symptoms,

check and replace the ECM.

1. Chapter 1: Electronic Circuit Matrix Chart

Symptom Suspected Area See page

No down-shift (A particular gear, from 1st to 4th gear,

is not down-shifted)ECMIN-30

No down-shift (5th -> 4th)Transmission control switch (D <--> 4 position) circuitAX-38

Shift solenoid valve S4 circuit *1AX-104

ECMIN-30

No up-shift (A particular gear, from 1st to 4th gear, is

not up-shifted)ECMIN-30

No up-shift (4th -> 5th)Transmission control switch (D <--> 4 position) circuitAX-38

Shift solenoid valve S4 circuit *1AX-104

ECMIN-30

No lock-upStop light switch circuit *1AX-56

Engine coolant temp. sensor circuit *1ES-56

ECMIN-30

No lock-up off ECMIN-30

Shift point too high or too lowThrottle position sensor circuit *1ES-56

ECMIN-30

Up-shift to 5th from 4th while shift lever is in 4 positionTransmission control switch (D <--> 4 position) circuitAX-38

ECMIN-30

Up-shift to 5th from 4th while engine is coldEngine coolant temp. sensor circuit *1ES-56

ECMIN-30

Up-shift to 2nd from 1st while shift lever is in L positionTransmission control switch (L <--> 2 position) circuit *1AX-38

ECMIN-30

Harsh engagement (N -> D)Shift solenoid valve SL1 circuit *1AX-70

ECMIN-30

Harsh engagement (Lock-up) ECMIN-30

Harsh engagement (Any driving position) ECMIN-30

Poor acceleration ECMIN-30

No kick-down ECMIN-30

Engine stalls when starting off or stopping ECMIN-30

Malfunction in shiftingPark/neutral position switch circuit *1AX-38

Transmission control switch (D <--> 4 position) circuitAX-38

ECMIN-30

Page 1846 of 3000

AX–30U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

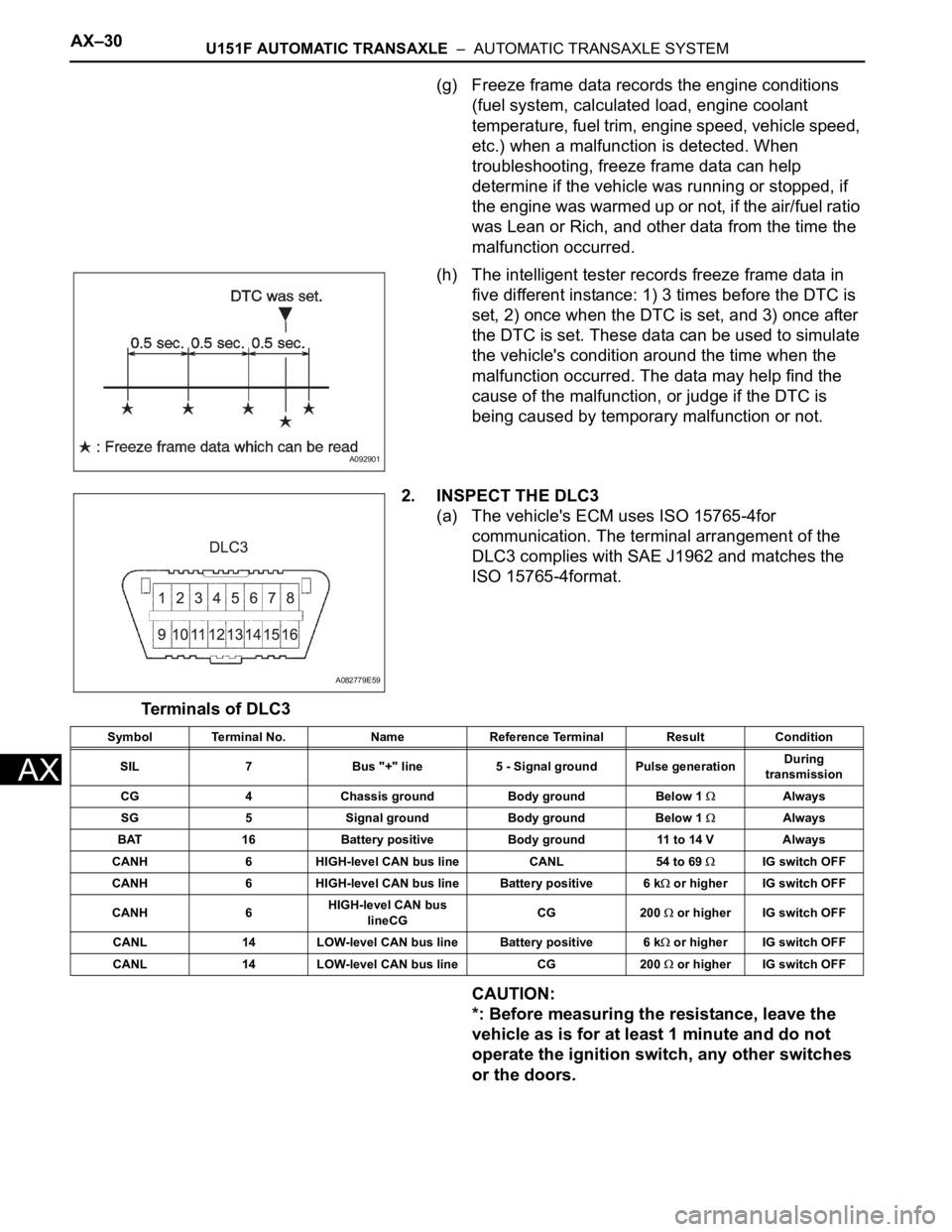

(g) Freeze frame data records the engine conditions

(fuel system, calculated load, engine coolant

temperature, fuel trim, engine speed, vehicle speed,

etc.) when a malfunction is detected. When

troubleshooting, freeze frame data can help

determine if the vehicle was running or stopped, if

the engine was warmed up or not, if the air/fuel ratio

was Lean or Rich, and other data from the time the

malfunction occurred.

(h) The intelligent tester records freeze frame data in

five different instance: 1) 3 times before the DTC is

set, 2) once when the DTC is set, and 3) once after

the DTC is set. These data can be used to simulate

the vehicle's condition around the time when the

malfunction occurred. The data may help find the

cause of the malfunction, or judge if the DTC is

being caused by temporary malfunction or not.

2. INSPECT THE DLC3

(a) The vehicle's ECM uses ISO 15765-4for

communication. The terminal arrangement of the

DLC3 complies with SAE J1962 and matches the

ISO 15765-4format.

Terminals of DLC3

CAUTION:

*: Before measuring the resistance, leave the

vehicle as is for at least 1 minute and do not

operate the ignition switch, any other switches

or the doors.

A092901

A082779E59

Symbol Terminal No. Name Reference Terminal Result Condition

SIL 7 Bus "+" line 5 - Signal ground Pulse generationDuring

transmission

CG 4 Chassis ground Body ground Below 1

Always

SG 5 Signal ground Body ground Below 1

Always

BAT 16 Battery positive Body ground 11 to 14 V Always

CANH 6 HIGH-level CAN bus line CANL 54 to 69

IG switch OFF

CANH 6 HIGH-level CAN bus line Battery positive 6 k

or higher IG switch OFF

CANH 6HIGH-level CAN bus

lineCGCG 200

or higher IG switch OFF

CANL 14 LOW-level CAN bus line Battery positive 6 k

or higher IG switch OFF

CANL 14 LOW-level CAN bus line CG 200

or higher IG switch OFF

Page 2918 of 3000

AC–18AIR CONDITIONING – AIR CONDITIONING SYSTEM (for Automatic Air Conditioning Sys-

tem)

AC

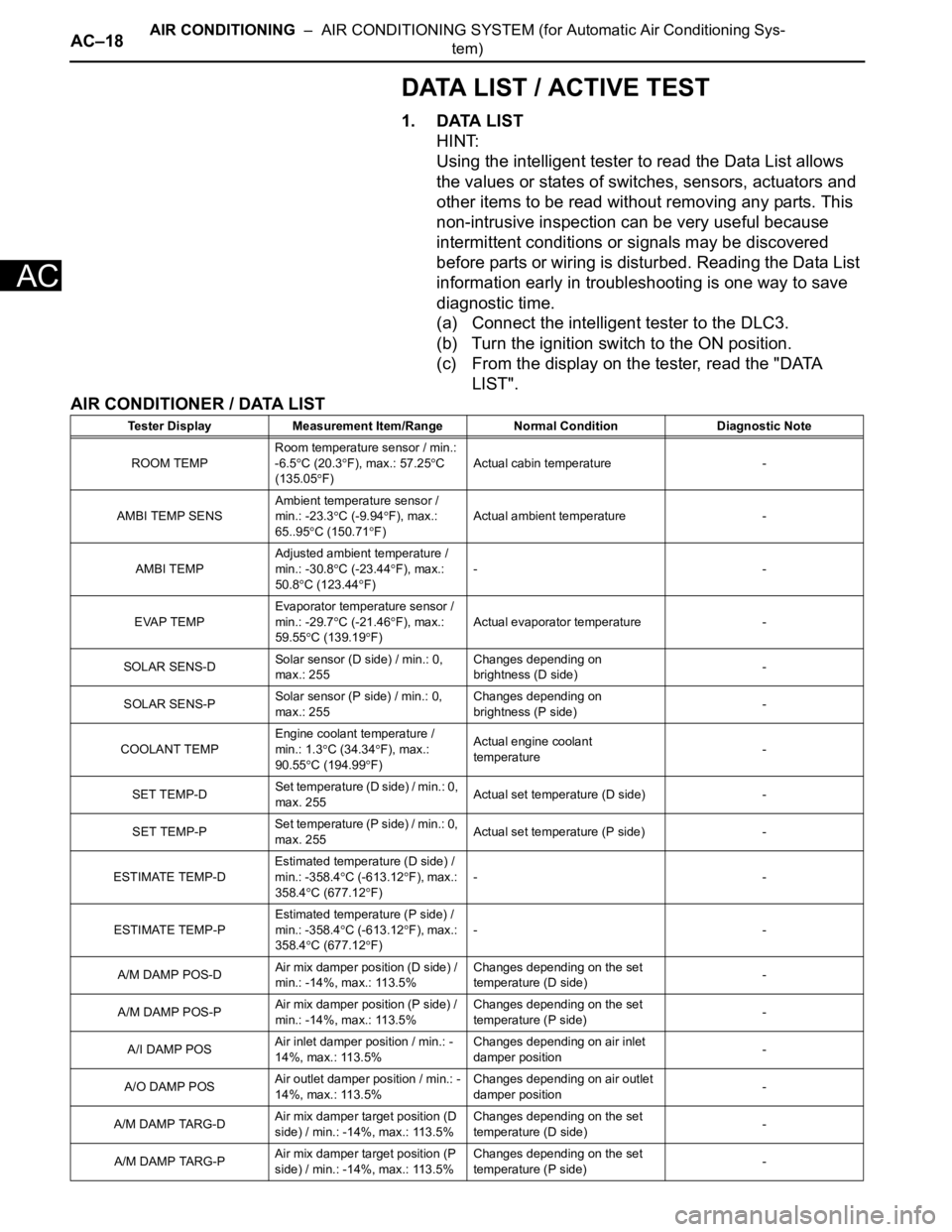

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the intelligent tester to read the Data List allows

the values or states of switches, sensors, actuators and

other items to be read without removing any parts. This

non-intrusive inspection can be very useful because

intermittent conditions or signals may be discovered

before parts or wiring is disturbed. Reading the Data List

information early in troubleshooting is one way to save

diagnostic time.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) From the display on the tester, read the "DATA

LIST".

AIR CONDITIONER / DATA LIST

Tester Display Measurement Item/Range Normal Condition Diagnostic Note

ROOM TEMPRoom temperature sensor / min.:

-6.5

C (20.3F), max.: 57.25C

(135.05

F)Actual cabin temperature -

AMBI TEMP SENSAmbient temperature sensor /

min.: -23.3

C (-9.94F), max.:

65..95C (150.71F)Actual ambient temperature -

AMBI TEMPAdjusted ambient temperature /

min.: -30.8

C (-23.44F), max.:

50.8

C (123.44F)--

EVAP TEMPEvaporator temperature sensor /

min.: -29.7

C (-21.46F), max.:

59.55

C (139.19F)Actual evaporator temperature -

SOLAR SENS-DSolar sensor (D side) / min.: 0,

max.: 255Changes depending on

brightness (D side)-

SOLAR SENS-PSolar sensor (P side) / min.: 0,

max.: 255Changes depending on

brightness (P side)-

COOLANT TEMPEngine coolant temperature /

min.: 1.3

C (34.34F), max.:

90.55C (194.99F)Actual engine coolant

temperature-

SET TEMP-DSet temperature (D side) / min.: 0,

max. 255Actual set temperature (D side) -

SET TEMP-PSet temperature (P side) / min.: 0,

max. 255Actual set temperature (P side) -

ESTIMATE TEMP-DEstimated temperature (D side) /

min.: -358.4

C (-613.12F), max.:

358.4

C (677.12F)--

ESTIMATE TEMP-PEstimated temperature (P side) /

min.: -358.4

C (-613.12F), max.:

358.4

C (677.12F)--

A/M DAMP POS-DAir mix damper position (D side) /

min.: -14%, max.: 113.5%Changes depending on the set

temperature (D side)-

A/M DAMP POS-PAir mix damper position (P side) /

min.: -14%, max.: 113.5%Changes depending on the set

temperature (P side)-

A/I DAMP POSAir inlet damper position / min.: -

14%, max.: 113.5%Changes depending on air inlet

damper position-

A/O DAMP POSAir outlet damper position / min.: -

14%, max.: 113.5%Changes depending on air outlet

damper position-

A/M DAMP TARG-DAir mix damper target position (D

side) / min.: -14%, max.: 113.5%Changes depending on the set

temperature (D side)-

A/M DAMP TARG-PAir mix damper target position (P

side) / min.: -14%, max.: 113.5%Changes depending on the set

temperature (P side)-