fuel cap TOYOTA SIENNA 2007 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 574 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–281

ES

INSPECTION PROCEDURE

NOTICE:

• When a vehicle is brought into the workshop, leave it as it is. Do not change the vehicle

condition. For example, do not tighten the fuel cap.

• Do not disassemble the canister pump module.

• The intelligent tester is required to conduct the following diagnostic troubleshooting

procedure.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position (do not start

the engine).

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(e) Read DTCs.

(f) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / EVAP / EVAP VAPOR

PRESS.

(g) Read the EVAP (Evaporative Emission) pressure

displayed on the tester.

Result

B

C

A

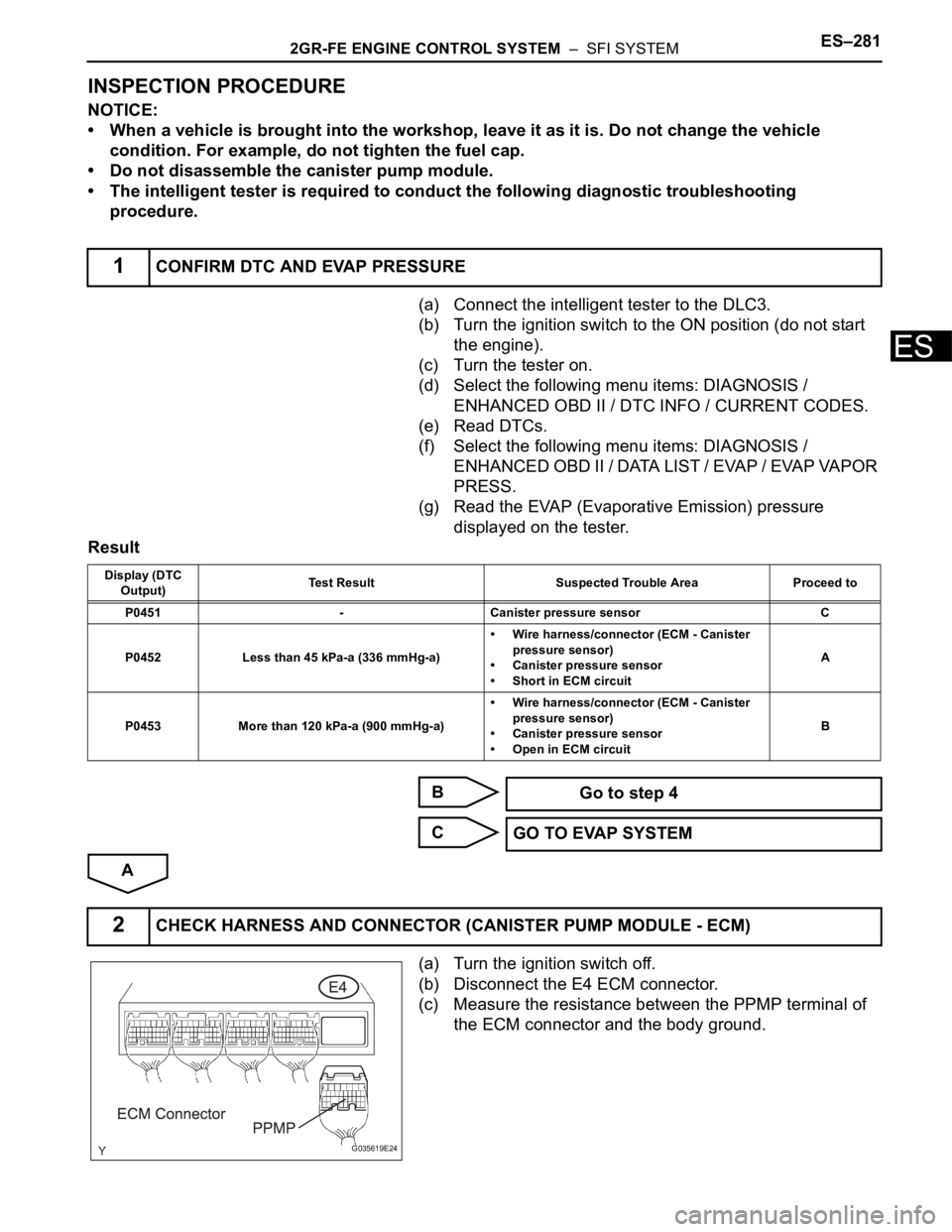

(a) Turn the ignition switch off.

(b) Disconnect the E4 ECM connector.

(c) Measure the resistance between the PPMP terminal of

the ECM connector and the body ground.

1CONFIRM DTC AND EVAP PRESSURE

Display (DTC

Output)Test Result Suspected Trouble Area Proceed to

P0451 - Canister pressure sensor C

P0452 Less than 45 kPa-a (336 mmHg-a)• Wire harness/connector (ECM - Canister

pressure sensor)

• Canister pressure sensor

• Short in ECM circuitA

P0453 More than 120 kPa-a (900 mmHg-a)• Wire harness/connector (ECM - Canister

pressure sensor)

• Canister pressure sensor

• Open in ECM circuitB

Go to step 4

GO TO EVAP SYSTEM

2CHECK HARNESS AND CONNECTOR (CANISTER PUMP MODULE - ECM)

G035619E24

Page 579 of 3000

ES–2862GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

DTC SUMMARY

DESCRIPTION

The circuit description can be found in the EVAP (Evaporative Emission) System (See page ES-409).

INSPECTION PROCEDURE

Refer to the EVAP System (See page ES-412).

MONITOR DESCRIPTION

5 hours*1 after the ignition switch is turned off, the electric vacuum pump creates negative pressure

(vacuum) in the EVAP (Evaporative Emission) system. The ECM monitors for leaks and actuator

malfunctions based on the EVAP pressure.

HINT:

*1: If the engine coolant temperature is not below 35

C (95F) 5 hours after the ignition switch is turned

off, the monitor check starts 2 hours later. If it is still not below 35

C (95F) 7 hours after the ignition switch

is turned off, the monitor check starts 2.5 hours later.

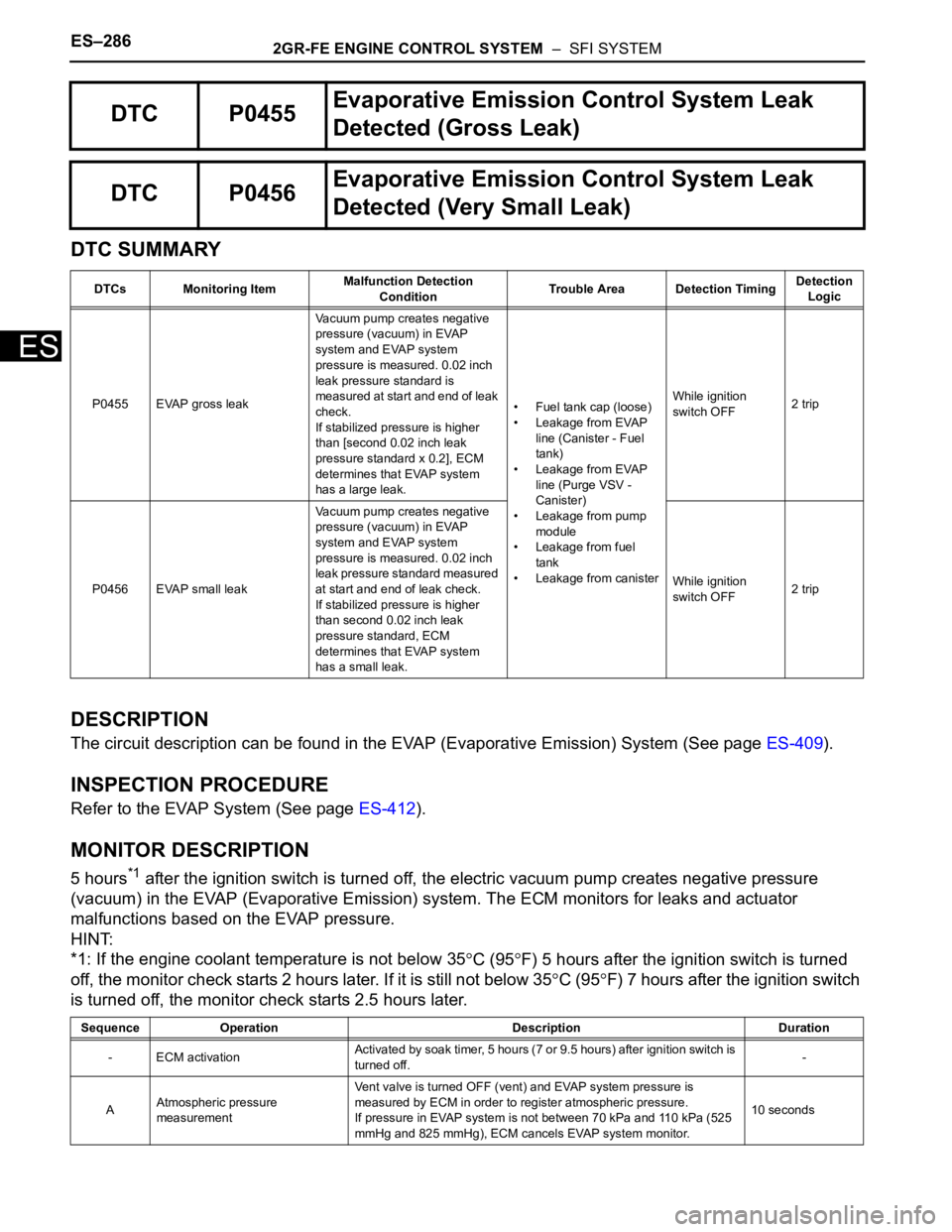

DTC P0455Evaporative Emission Control System Leak

Detected (Gross Leak)

DTC P0456Evaporative Emission Control System Leak

Detected (Very Small Leak)

DTCs Monitoring ItemMalfunction Detection

ConditionTrouble Area Detection TimingDetection

Logic

P0455 EVAP gross leakVacuum pump creates negative

pressure (vacuum) in EVAP

system and EVAP system

pressure is measured. 0.02 inch

leak pressure standard is

measured at start and end of leak

check.

If stabilized pressure is higher

than [second 0.02 inch leak

pressure standard x 0.2], ECM

determines that EVAP system

has a large leak.• Fuel tank cap (loose)

• Leakage from EVAP

line (Canister - Fuel

tank)

• Leakage from EVAP

line (Purge VSV -

Canister)

• Leakage from pump

module

• Leakage from fuel

tank

• Leakage from canisterWhile ignition

switch OFF2 trip

P0456 EVAP small leakVacuum pump creates negative

pressure (vacuum) in EVAP

system and EVAP system

pressure is measured. 0.02 inch

leak pressure standard measured

at start and end of leak check.

If stabilized pressure is higher

than second 0.02 inch leak

pressure standard, ECM

determines that EVAP system

has a small leak.While ignition

switch OFF2 trip

Sequence Operation Description Duration

- ECM activationActivated by soak timer, 5 hours (7 or 9.5 hours) after ignition switch is

turned off.-

AAtmospheric pressure

measurementVent valve is turned OFF (vent) and EVAP system pressure is

measured by ECM in order to register atmospheric pressure.

If pressure in EVAP system is not between 70 kPa and 110 kPa (525

mmHg and 825 mmHg), ECM cancels EVAP system monitor.10 seconds

Page 700 of 3000

ES–4142GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

(2) Turn the ignition switch off and wait for 6 hours (8 or 10.5 hours).

HINT:

Do not start the engine until checking MONITOR STATUS. If the engine is started, the steps

described above must be repeated.

(c) Monitor Status

(1) Connect the intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position and turn the tester on.

(3) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / MONITOR STATUS.

(4) Check the "Monitor Status" displayed on the tester.

HINT:

If INCMP is displayed, the monitor is not completed. Make sure that the preconditions have

been met, and perform "Monitor Conditions" again.

2. PURGE FLOW MONITOR CONFIRMATION (P0441)

HINT:

Perform this monitor confirmation after the Key-Off Monitor Confirmation shows COMPL (complete).

(a) Preconditions

The monitor will not run unless:

• The vehicle has been driven for 10 minutes or more (in a city area or on a freeway)

• The ECT is between 4.4

C and 35C (40F and 95F)

• The IAT is between 4.4

C and 35C (40F and 95F)

(b) Monitor Conditions

(1) Release the pressure from the fuel tank by removing and reinstalling the fuel tank cap.

(2) Warm the engine up until the ECT reaches more than 75

C (167F).

(3) Increase the engine speed to 3000 rpm once.

(4) Allow the engine to idle and turn the A/C ON for 1 minute.

(c) Monitor Status

(1) Turn the ignition switch off.

(2) Connect the intelligent tester to the DLC3.

(3) Turn the ignition switch to the ON position and turn the tester on.

(4) Select the following menu items: DIAGNOSIS / ENHANCED OBD II / MONITOR STATUS.

(5) Check the "Monitor Status" displayed on the tester.

HINT:

If INCMP is displayed, the monitor is not completed. Make sure that the preconditions have

been met, and perform "Monitor Conditions" again.

MONITOR RESULT

Refer to Checking Monitor Status for detailed information (See page ES-19).

The test value and test limit information are described as shown in the following table. This information is

included in MONITOR RESULT of the emissions-related DTC sections:

– MID (Monitor Identification Data) is assigned to each emissions-related component.

– TID (Test Identification Data) is assigned to each test value.

– Scaling is used to calculate the test value indicated on generic OBD II scan tools.

Thermostat

MID TID Scaling Description of Test Value Minimum Test Limit Maximum Test Limit

$3D $C9 Multiply by 0.01 [kPa]Test value for small leak (P0456)

Refer to pressure D*Minimum test limit for

small leakMaximum test limit for

small leak

$3D $CA Multiply by 0.01 [kPa]Test value for gross leak (P0455)

Refer to pressure E*Minimum test limit for

gross leakMaximum test limit for

gross leak

$3D $CB Multiply by 0.01 [kPa]Test value for vacuum pump stuck OFF

(P2401)

Refer to pressure A*Minimum test limit for

vacuum pump stuck

OFFMaximum test limit for

vacuum pump stuck

OFF

$3D $CD Multiply by 0.01 [kPa]Test value for vacuum pump stuck ON

(P2402)

Refer to pressure A*Minimum test limit for

vacuum pump stuck

ONMaximum test limit for

vacuum pump stuck

ON

Page 718 of 3000

ES–4322GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

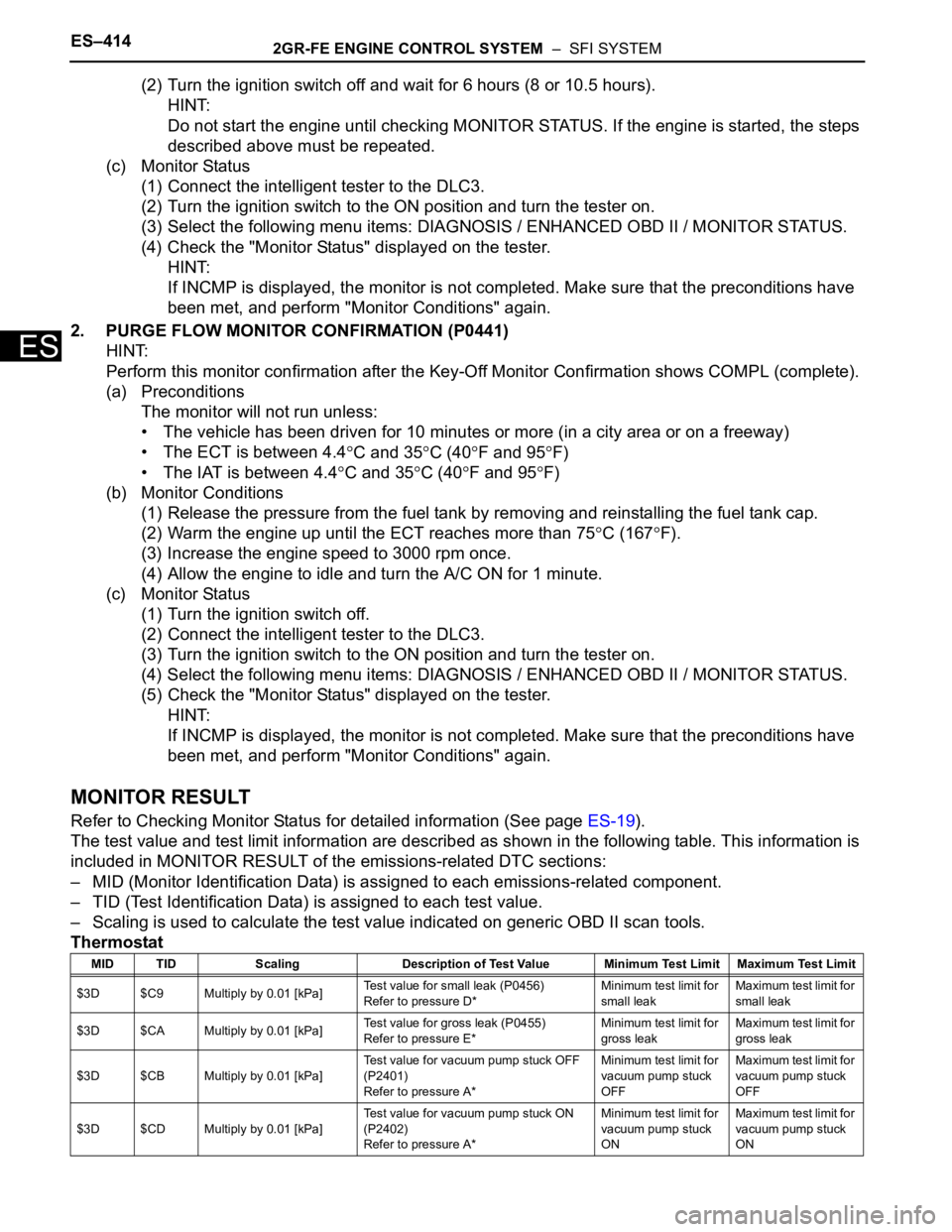

(a) Select the following menu items on the tester:

DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST /

EVAP VSV (ALONE).

(b) Disconnect the hose (connected to the canister) from the

purge VSV.

(c) Start the engine.

(d) Using the tester, turn off the purge VSV (EVAP VSV:

OFF).

(e) Confirm that the purge VSV has no suction with your

fingers.

(f) Using the tester, turn on the purge VSV (EVAP VSV:

ON).

(g) Confirm that the purge VSV has suction with your

fingers.

Result

(h) Reconnect the hose.

B

C

A

(a) Check that the fuel tank cap is correctly installed and

confirm the fuel tank cap meets OEM specification.

HINT:

If an EVAP tester is available, check the fuel tank cap

using the tester.

(1) Tighten the fuel tank cap

(2) Remove the fuel tank cap and install it onto the fuel

tank cap adaptor.

(3) Connect the EVAP tester pump hose to the adaptor,

and pressurize the cap to 3.2 to 3.7 kPa (24 to 28

mmHg) using an EVAP tester pump.

(4) Seal the adaptor and wait for 2 minutes.

(5) Check the pressure. If the pressure is 2 kPa (15

mmHg) or more, the fuel tank cap is normal.

12PERFORM ACTIVE TEST BY INTELLIGENT TESTER (PURGE VSV)

A136286E01

Test Result Suspected Trouble Area Proceed to

No suction when purge VSV

turned OFF, and suction

applied when turned ON-A

Suction applied when purge

VSV turned OFFPurge VSV stuck open B

No suction when purge VSV

turned ON• Purge VSV stuck closed

• Problems with EVAP

hose between purge VSV

and throttle bodyC

Go to step 14

Go to step 15

13CHECK FUEL TANK CAP ASSEMBLY

Page 719 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–433

ES

Result

A

B

C

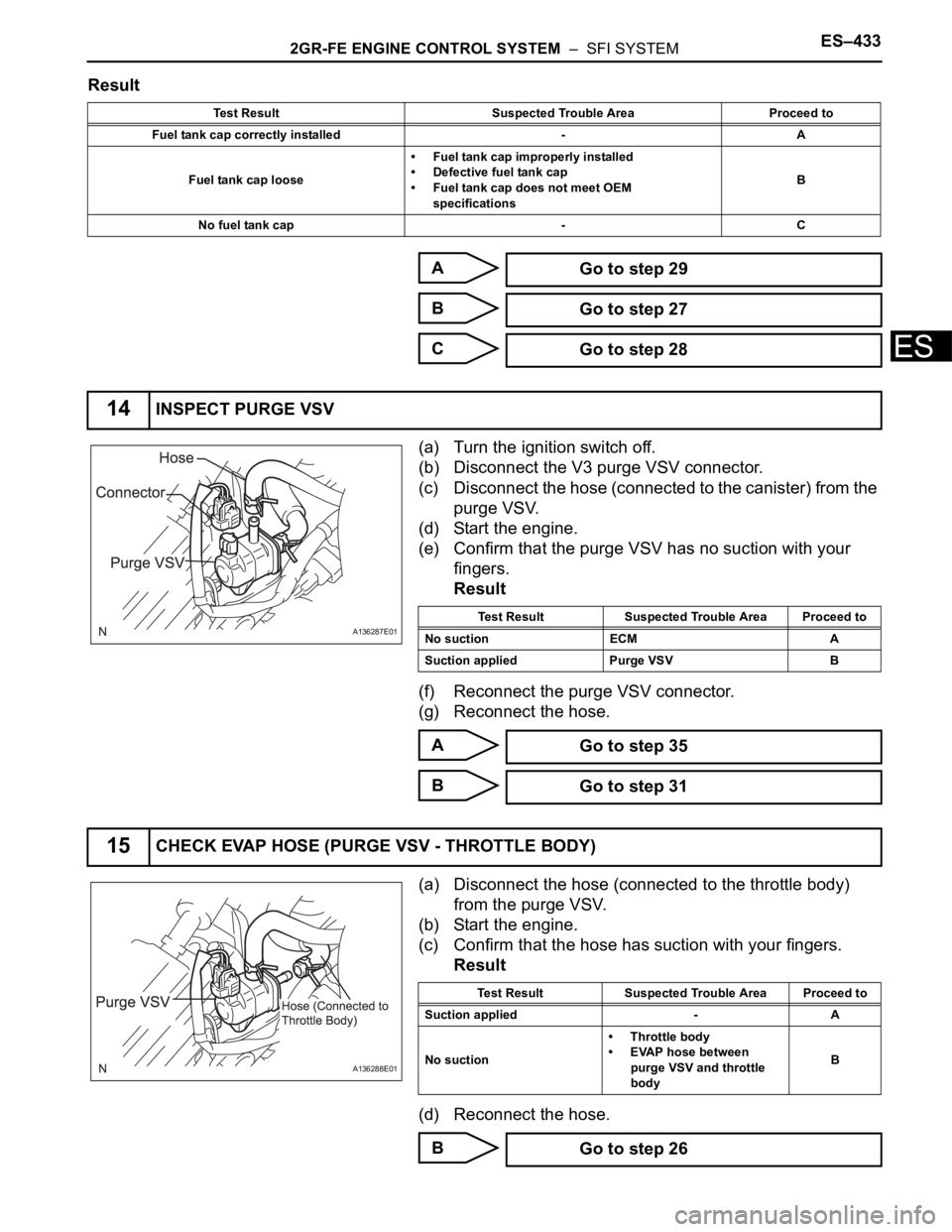

(a) Turn the ignition switch off.

(b) Disconnect the V3 purge VSV connector.

(c) Disconnect the hose (connected to the canister) from the

purge VSV.

(d) Start the engine.

(e) Confirm that the purge VSV has no suction with your

fingers.

Result

(f) Reconnect the purge VSV connector.

(g) Reconnect the hose.

A

B

(a) Disconnect the hose (connected to the throttle body)

from the purge VSV.

(b) Start the engine.

(c) Confirm that the hose has suction with your fingers.

Result

(d) Reconnect the hose.

B

Test Result Suspected Trouble Area Proceed to

Fuel tank cap correctly installed - A

Fuel tank cap loose• Fuel tank cap improperly installed

• Defective fuel tank cap

• Fuel tank cap does not meet OEM

specificationsB

No fuel tank cap - C

Go to step 29

Go to step 27

Go to step 28

14INSPECT PURGE VSV

A136287E01Test Result Suspected Trouble Area Proceed to

No suction ECM A

Suction applied Purge VSV B

Go to step 35

Go to step 31

15CHECK EVAP HOSE (PURGE VSV - THROTTLE BODY)

A136288E01

Test Result Suspected Trouble Area Proceed to

Suction applied - A

No suction• Throttle body

• EVAP hose between

purge VSV and throttle

bodyB

Go to step 26

Page 725 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–439

ES

A

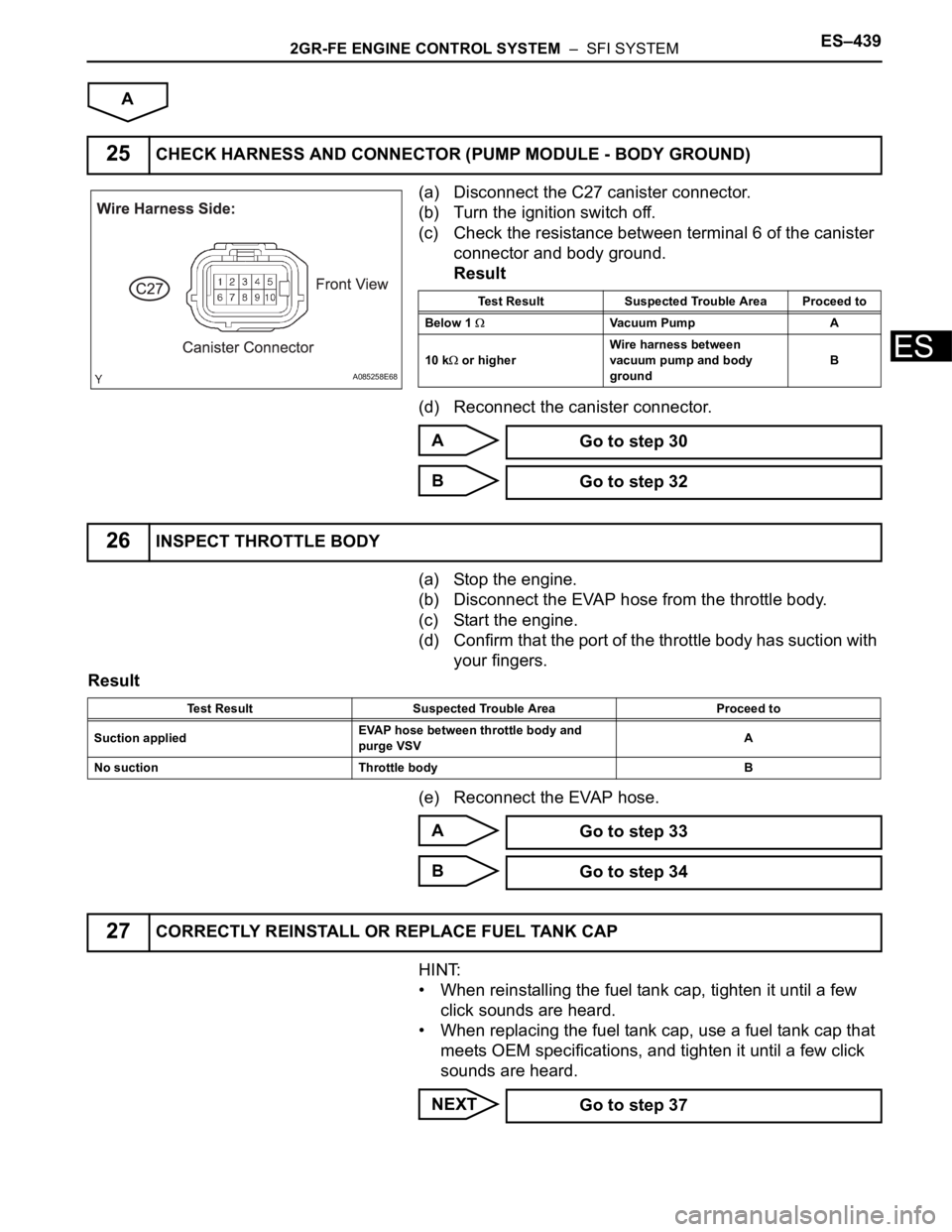

(a) Disconnect the C27 canister connector.

(b) Turn the ignition switch off.

(c) Check the resistance between terminal 6 of the canister

connector and body ground.

Result

(d) Reconnect the canister connector.

A

B

(a) Stop the engine.

(b) Disconnect the EVAP hose from the throttle body.

(c) Start the engine.

(d) Confirm that the port of the throttle body has suction with

your fingers.

Result

(e) Reconnect the EVAP hose.

A

B

HINT:

• When reinstalling the fuel tank cap, tighten it until a few

click sounds are heard.

• When replacing the fuel tank cap, use a fuel tank cap that

meets OEM specifications, and tighten it until a few click

sounds are heard.

NEXT

25CHECK HARNESS AND CONNECTOR (PUMP MODULE - BODY GROUND)

A085258E68

Test Result Suspected Trouble Area Proceed to

Below 1

Vacuum Pump A

10 k

or higherWire harness between

vacuum pump and body

groundB

Go to step 30

Go to step 32

26INSPECT THROTTLE BODY

Test Result Suspected Trouble Area Proceed to

Suction appliedEVAP hose between throttle body and

purge VSVA

No suction Throttle body B

Go to step 33

Go to step 34

27CORRECTLY REINSTALL OR REPLACE FUEL TANK CAP

Go to step 37

Page 726 of 3000

ES–4402GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

HINT:

When installing the fuel tank cap, tighten it until a few click

sounds are heard.

NEXT

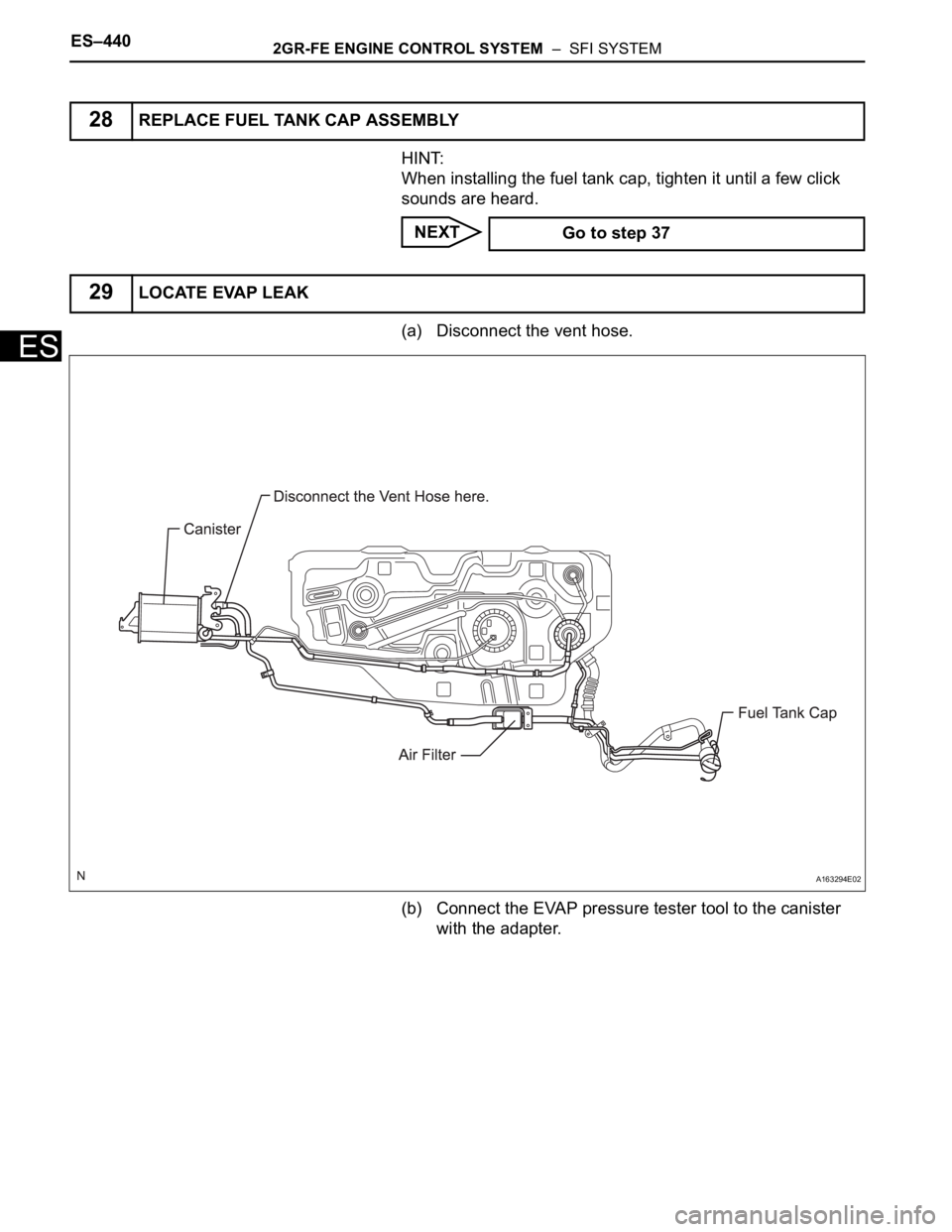

(a) Disconnect the vent hose.

(b) Connect the EVAP pressure tester tool to the canister

with the adapter.

28REPLACE FUEL TANK CAP ASSEMBLY

Go to step 37

29LOCATE EVAP LEAK

A163294E02

Page 836 of 3000

2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–521

ES

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

(See page FU-13)

2. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-4)

5. REMOVE FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-27)

6. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-493)

7. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

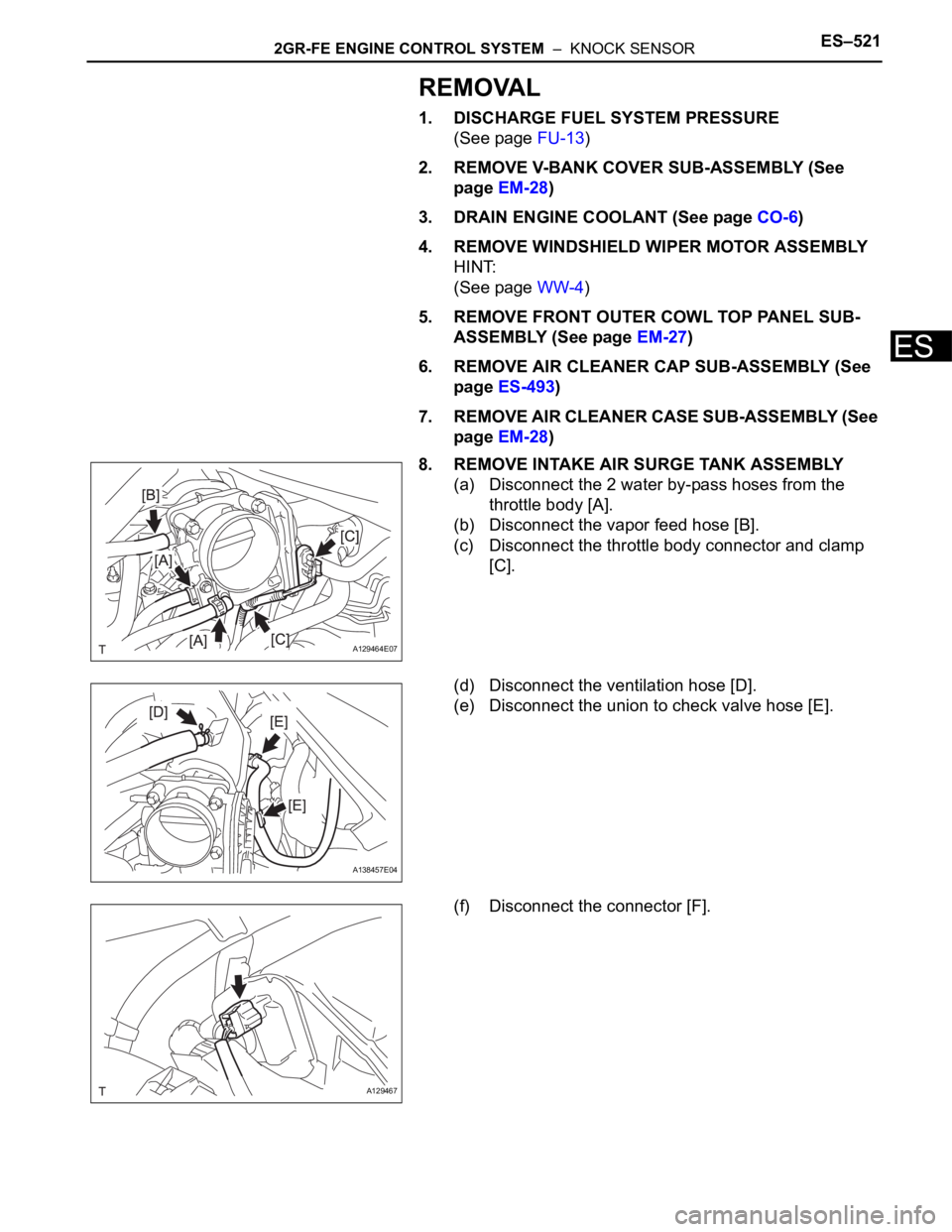

8. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

(a) Disconnect the 2 water by-pass hoses from the

throttle body [A].

(b) Disconnect the vapor feed hose [B].

(c) Disconnect the throttle body connector and clamp

[C].

(d) Disconnect the ventilation hose [D].

(e) Disconnect the union to check valve hose [E].

(f) Disconnect the connector [F].

A129464E07

A138457E04

A129467

Page 838 of 3000

![TOYOTA SIENNA 2007 Service User Guide 2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–523

ES

(a) Install a new gasket to the intake air surge tank [A].

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts [B].

Torque: 18 N*m ( TOYOTA SIENNA 2007 Service User Guide 2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–523

ES

(a) Install a new gasket to the intake air surge tank [A].

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts [B].

Torque: 18 N*m (](/img/14/57466/w960_57466-837.png)

2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–523

ES

(a) Install a new gasket to the intake air surge tank [A].

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts [B].

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

(c) Install the intake air surge tank with the 2 nuts and 2

bolts [C].

Torque: Nut

16 N*m (163 kgf*cm, 12 ft.*lbf)

Bolt

21 N*m (214 kgf*cm, 15 ft.*lbf)

(d) Connect the connector [D].

(e) Connect the union to check valve hose [E].

(f) Connect the ventilation hose No. 2 [F].

(g) Install the clamp and connect the throttle with motor

body assembly connector [G].

(h) Connect the vapor feed hose [H].

(i) Connect the 2 water by-pass hoses to the throttle

with motor body assembly [I].

5. INSTALL AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-59)

6. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-496)

7. ADD ENGINE COOLANT (See page CO-7)

8. INSPECT FOR ENGINE COOLANT LEAK (See page

CO-1)

9. INSPECT FOR FUEL LEAK (See page FU-7)

10. INSTALL FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-61)

11. INSTALL WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-5)

A129468E09

A129467

A138457E05

A129464E08

Page 879 of 3000

EM–622GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

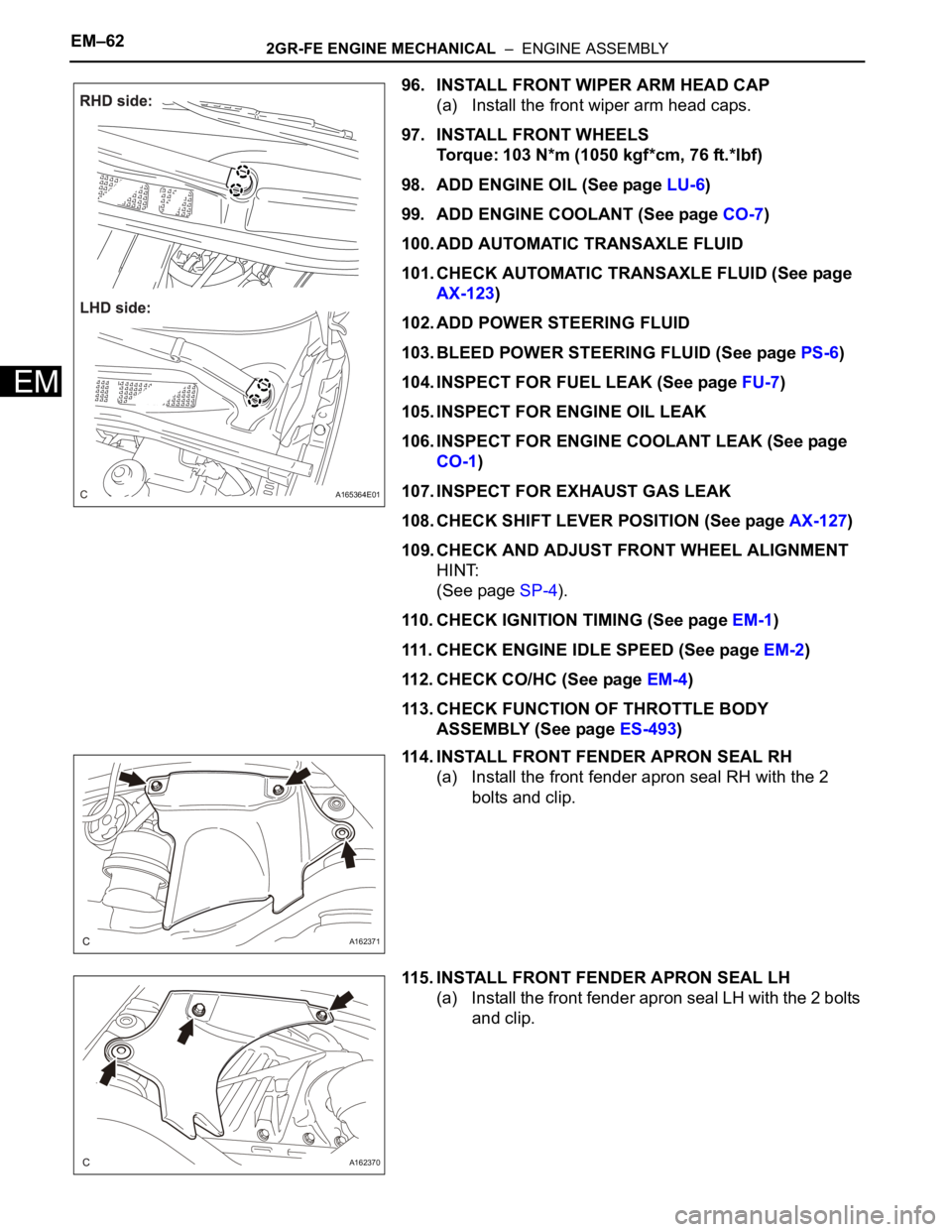

96. INSTALL FRONT WIPER ARM HEAD CAP

(a) Install the front wiper arm head caps.

97. INSTALL FRONT WHEELS

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

98. ADD ENGINE OIL (See page LU-6)

99. ADD ENGINE COOLANT (See page CO-7)

100. ADD AUTOMATIC TRANSAXLE FLUID

101. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

102. ADD POWER STEERING FLUID

103. BLEED POWER STEERING FLUID (See page PS-6)

104. INSPECT FOR FUEL LEAK (See page FU-7)

105. INSPECT FOR ENGINE OIL LEAK

106. INSPECT FOR ENGINE COOLANT LEAK (See page

CO-1)

107. INSPECT FOR EXHAUST GAS LEAK

108. CHECK SHIFT LEVER POSITION (See page AX-127)

109. CHECK AND ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page SP-4).

110. CHECK IGNITION TIMING (See page EM-1)

111. CHECK ENGINE IDLE SPEED (See page EM-2)

112. CHECK CO/HC (See page EM-4)

113. CHECK FUNCTION OF THROTTLE BODY

ASSEMBLY (See page ES-493)

114. INSTALL FRONT FENDER APRON SEAL RH

(a) Install the front fender apron seal RH with the 2

bolts and clip.

115. INSTALL FRONT FENDER APRON SEAL LH

(a) Install the front fender apron seal LH with the 2 bolts

and clip.

A165364E01

A162371

A162370