fuel cap TOYOTA SIENNA 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1144 of 3000

FU–262GR-FE FUEL – FUEL PRESSURE PULSATION DAMPER

FU

2. INSTALL INTAKE AIR SURGE TANK ASSEMBLY (See

page FU-19)

3. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (See

page FU-20)

4. ADD ENGINE COOLANT (See page CO-7)

5. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

6. INSPECT FOR ENGINE COOLANT LEAK (See page

CO-1)

7. INSTALL NO. 1 ENGINE UNDER COVER

8. INSPECT FOR FUEL LEAK (See page FU-7)

9. INSTALL V-BANK COVER SUB-ASSEMBLY (See

page EM-63)

10. INSTALL COWL TOP PANEL SUB-ASSEMBLY

OUTER FRONT (See page FU-21)

11. INSTALL NO. 1 COWL TOP TO COWL BRACE INNER

(See page FU-21)

12. INSTALL WINDSHIELD WIPER MOTOR AND LINK

ASSEMBLY (See page WW-6)

13. INSTALL FRONT WIPER ARM LH (See page WW-6)

14. INSTALL FRONT WIPER ARM RH (See page WW-7)

Page 1175 of 3000

2GR-FE EMISSION CONTROL – EMISSION CONTROL SYSTEMEC–5

EC

ON-VEHICLE INSPECTION

1. INSPECT FUEL CUT RPM

(a) Increase the engine speed to at least 3500 rpm.

(b) Use a sound scope to check for injector operating

sounds.

(c) Check that when the throttle lever is released,

injector operating sounds stop momentarily (at 2500

rpm) and then resume (at 1400 rpm).

Standard

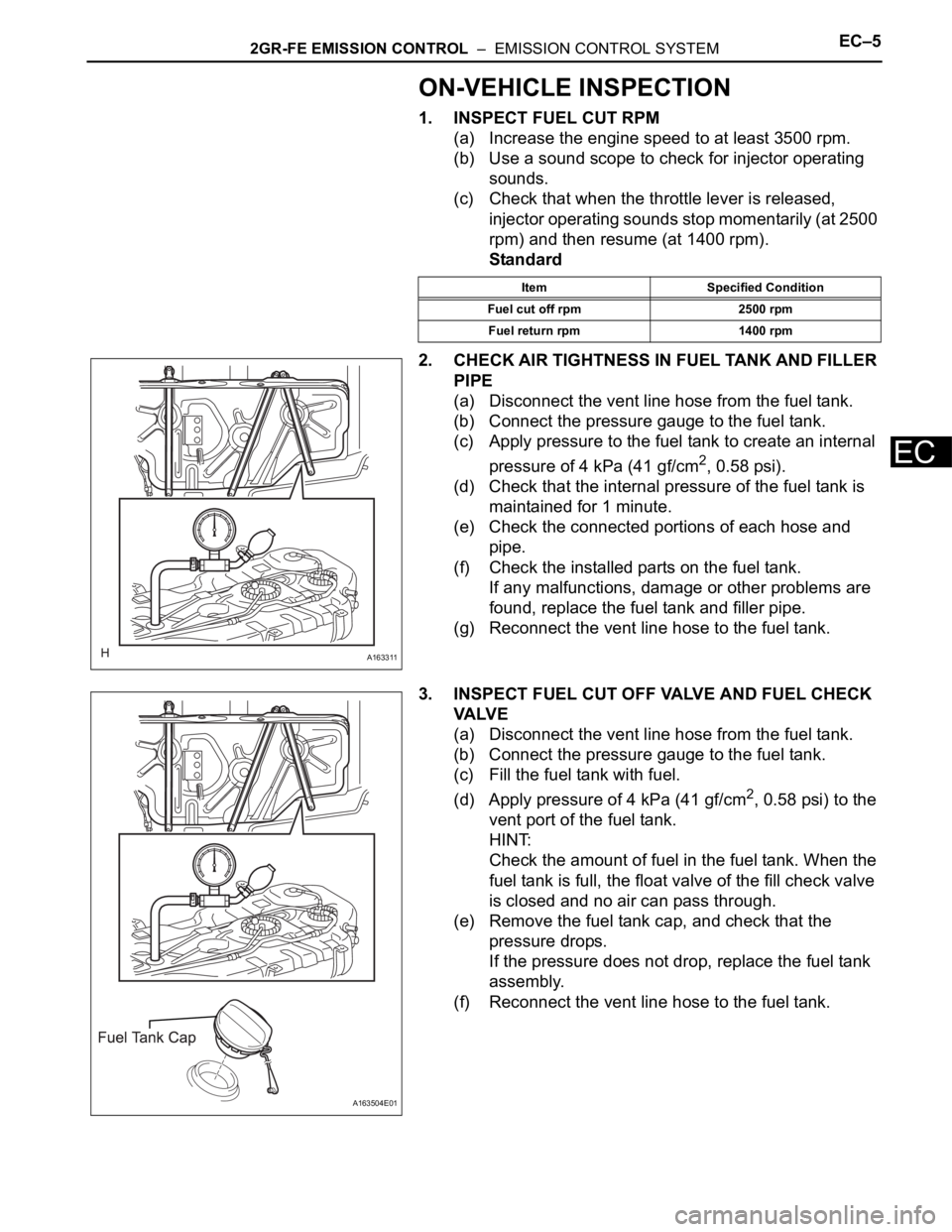

2. CHECK AIR TIGHTNESS IN FUEL TANK AND FILLER

PIPE

(a) Disconnect the vent line hose from the fuel tank.

(b) Connect the pressure gauge to the fuel tank.

(c) Apply pressure to the fuel tank to create an internal

pressure of 4 kPa (41 gf/cm

2, 0.58 psi).

(d) Check that the internal pressure of the fuel tank is

maintained for 1 minute.

(e) Check the connected portions of each hose and

pipe.

(f) Check the installed parts on the fuel tank.

If any malfunctions, damage or other problems are

found, replace the fuel tank and filler pipe.

(g) Reconnect the vent line hose to the fuel tank.

3. INSPECT FUEL CUT OFF VALVE AND FUEL CHECK

VA LV E

(a) Disconnect the vent line hose from the fuel tank.

(b) Connect the pressure gauge to the fuel tank.

(c) Fill the fuel tank with fuel.

(d) Apply pressure of 4 kPa (41 gf/cm

2, 0.58 psi) to the

vent port of the fuel tank.

HINT:

Check the amount of fuel in the fuel tank. When the

fuel tank is full, the float valve of the fill check valve

is closed and no air can pass through.

(e) Remove the fuel tank cap, and check that the

pressure drops.

If the pressure does not drop, replace the fuel tank

assembly.

(f) Reconnect the vent line hose to the fuel tank.

Item Specified Condition

Fuel cut off rpm 2500 rpm

Fuel return rpm 1400 rpm

A163311

A163504E01

Page 1210 of 3000

EC–422GR-FE EMISSION CONTROL – FUEL TANK CAP

EC

FUEL TANK CAP

INSPECTION

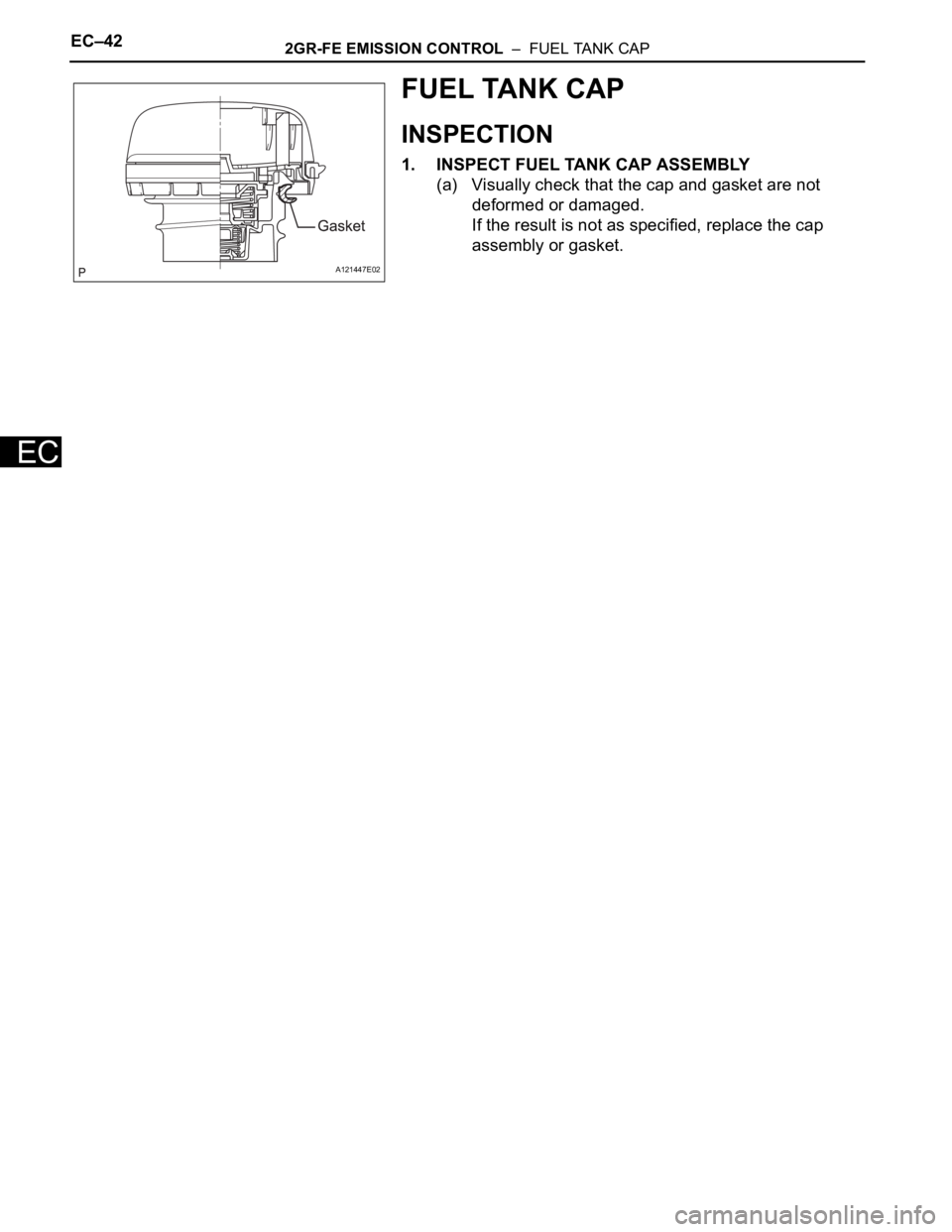

1. INSPECT FUEL TANK CAP ASSEMBLY

(a) Visually check that the cap and gasket are not

deformed or damaged.

If the result is not as specified, replace the cap

assembly or gasket.

A121447E02

Page 2994 of 3000

SUPPLEMENTAL RESTRAINT SYSTEM – AIRBAG SYSTEMRS–17

RS

• The center airbag sensor assembly receives

signals from the deceleration sensor and the

safing sensor built into the center airbag

sensor assembly and the side airbag sensor

and the rear airbag sensor, and determines

whether or not the front seat side airbag and

curtain shield airbag assemblies should be

activated, and diagnoses system

malfunctions.

• The center airbag sensor assembly sends the

airbag deployment signal to the ECM through

BEAN and CAN to operate fuel pump control.

• The center airbag sensor assembly sends the

airbag deployment signal to the main body

ECU through a discrete line to operate

collision door lock release control.

(2) Deceleration sensor and ignition control circuit

• The deceleration sensor is built into the

center airbag sensor assembly, front airbag

sensor, side airbag sensor and rear airbag

sensor, and the distortion created based on

the deceleration of the vehicle during a

frontal, front side or rear side collision is

converted into an electric signal.

• The ignition control circuit performs

calculations based on the signal output from

the deceleration sensors of the center airbag

sensor assembly, front airbag sensor, side

airbag sensor and rear airbag sensor. If the

calculated values are greater than the

specified values, it activates an ignition

operation.

(3) Safing sensor

• The safing sensor is built into the center

airbag sensor assembly. During a frontal

collision, the sensor turns on and outputs an

ON signal to the center airbag sensor

assembly if a deceleration rate greater than

the specified value is applied to the safing

sensor.

(4) Backup power source

• The backup power source consists of a

power supply capacitor and a DC-DC

converter. If the power system does not

function during a collision, the power supply

capacitor discharges and supplies electric

power to the system. The DC-DC converter

operates as a boosting transformer when the

battery voltage falls below a predetermined

level.