steering wheel TOYOTA SIENNA 2007 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 289 of 3000

INSTRUMENT PANEL – INSTRUMENT PANEL SAFETY PADIP–5

IP

REMOVAL

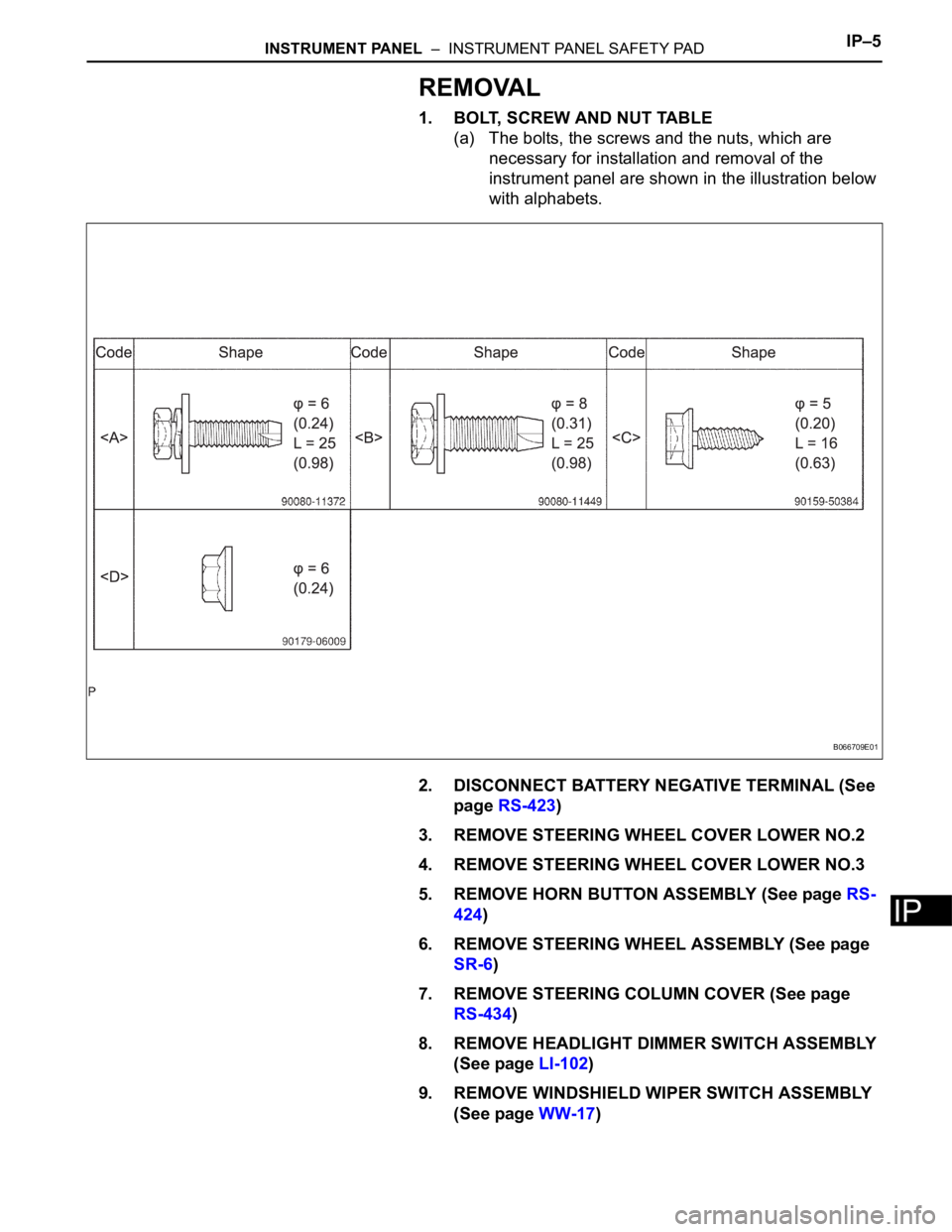

1. BOLT, SCREW AND NUT TABLE

(a) The bolts, the screws and the nuts, which are

necessary for installation and removal of the

instrument panel are shown in the illustration below

with alphabets.

2. DISCONNECT BATTERY NEGATIVE TERMINAL (See

page RS-423)

3. REMOVE STEERING WHEEL COVER LOWER NO.2

4. REMOVE STEERING WHEEL COVER LOWER NO.3

5. REMOVE HORN BUTTON ASSEMBLY (See page RS-

424)

6. REMOVE STEERING WHEEL ASSEMBLY (See page

SR-6)

7. REMOVE STEERING COLUMN COVER (See page

RS-434)

8. REMOVE HEADLIGHT DIMMER SWITCH ASSEMBLY

(See page LI-102)

9. REMOVE WINDSHIELD WIPER SWITCH ASSEMBLY

(See page WW-17)

B066709E01

Page 318 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–1

ES

SFI SYSTEM

PRECAUTION

1. INITIALIZATION

NOTICE:

• Perform RESET MEMORY (AT initialization) when

replacing the automatic transaxle assembly, engine

assembly or ECM (See page AX-16).

• Perform REGISTRATION (VIN registration) when

replacing the ECM (See page ES-15).

HINT:

Initialization cannot be completed by only removing the

battery.

2. FOR USING INTELLIGENT TESTER

CAUTION:

Observe the following items for safety reasons:

• Before using the tester, read the instruction

manual.

• Prevent the tester cable from being caught on the

pedals, shift lever and steering wheel when

driving with the tester connected to the vehicle.

• When driving the vehicle for testing purposes

using the tester, two persons are required. One is

for driving the vehicle, and the other operates the

tester.

3. FOR USING BATTERY DURING INSPECTION

(a) While using the battery during inspection, do not

bring the positive and negative tester probes too

close to each other as a short circuit may occur.

4. COOLING FAN SYSTEM

NOTICE:

• When the ignition switch is turned off and the engine

temperature is high, the cooling fans may operate for

approximately 3 minutes.

• After turning the ignition switch off, keep hands and

objects away from the fans when they are operating.

HINT:

If all of the following are met for a certain period of time during

a few minute period immediately before the engine is

stopped, the electric fans will continue to operate for 3

minutes after the engine is stopped. This is performed to

ensure restartability and stabilize idle speed.

– The intelligent tester indicates a very high coolant

temperature.

– The intelligent tester indicates a high outside air

temperature.

– The vehicle has been driven under high load (driving on an

uphill or equivalent).

The following sensors are used for this control:

– Coolant temperature sensor

– Outside air temperature sensor

–MAF sensor

– Vehicle speed sensors

Page 879 of 3000

EM–622GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

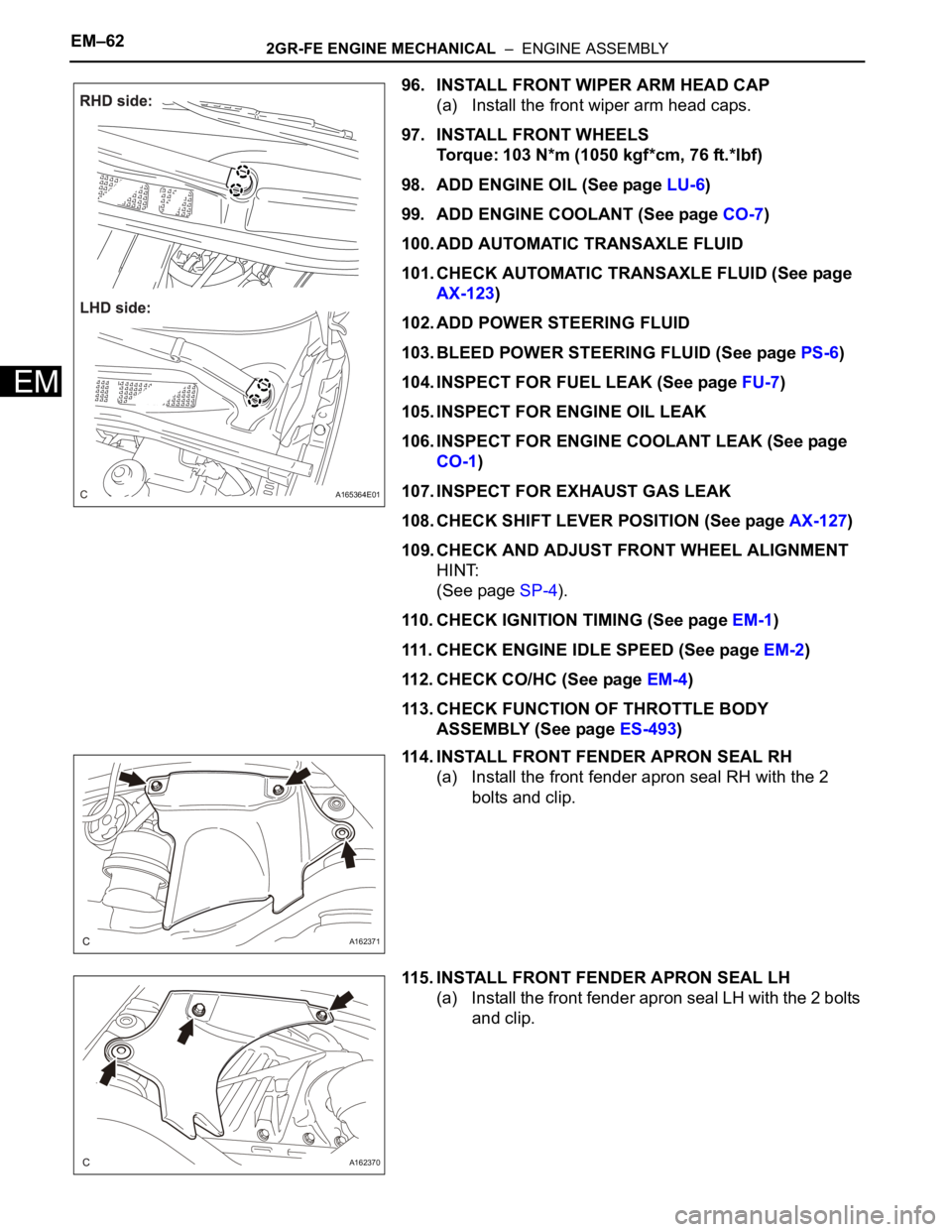

96. INSTALL FRONT WIPER ARM HEAD CAP

(a) Install the front wiper arm head caps.

97. INSTALL FRONT WHEELS

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

98. ADD ENGINE OIL (See page LU-6)

99. ADD ENGINE COOLANT (See page CO-7)

100. ADD AUTOMATIC TRANSAXLE FLUID

101. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

102. ADD POWER STEERING FLUID

103. BLEED POWER STEERING FLUID (See page PS-6)

104. INSPECT FOR FUEL LEAK (See page FU-7)

105. INSPECT FOR ENGINE OIL LEAK

106. INSPECT FOR ENGINE COOLANT LEAK (See page

CO-1)

107. INSPECT FOR EXHAUST GAS LEAK

108. CHECK SHIFT LEVER POSITION (See page AX-127)

109. CHECK AND ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page SP-4).

110. CHECK IGNITION TIMING (See page EM-1)

111. CHECK ENGINE IDLE SPEED (See page EM-2)

112. CHECK CO/HC (See page EM-4)

113. CHECK FUNCTION OF THROTTLE BODY

ASSEMBLY (See page ES-493)

114. INSTALL FRONT FENDER APRON SEAL RH

(a) Install the front fender apron seal RH with the 2

bolts and clip.

115. INSTALL FRONT FENDER APRON SEAL LH

(a) Install the front fender apron seal LH with the 2 bolts

and clip.

A165364E01

A162371

A162370

Page 1021 of 3000

EM–622GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

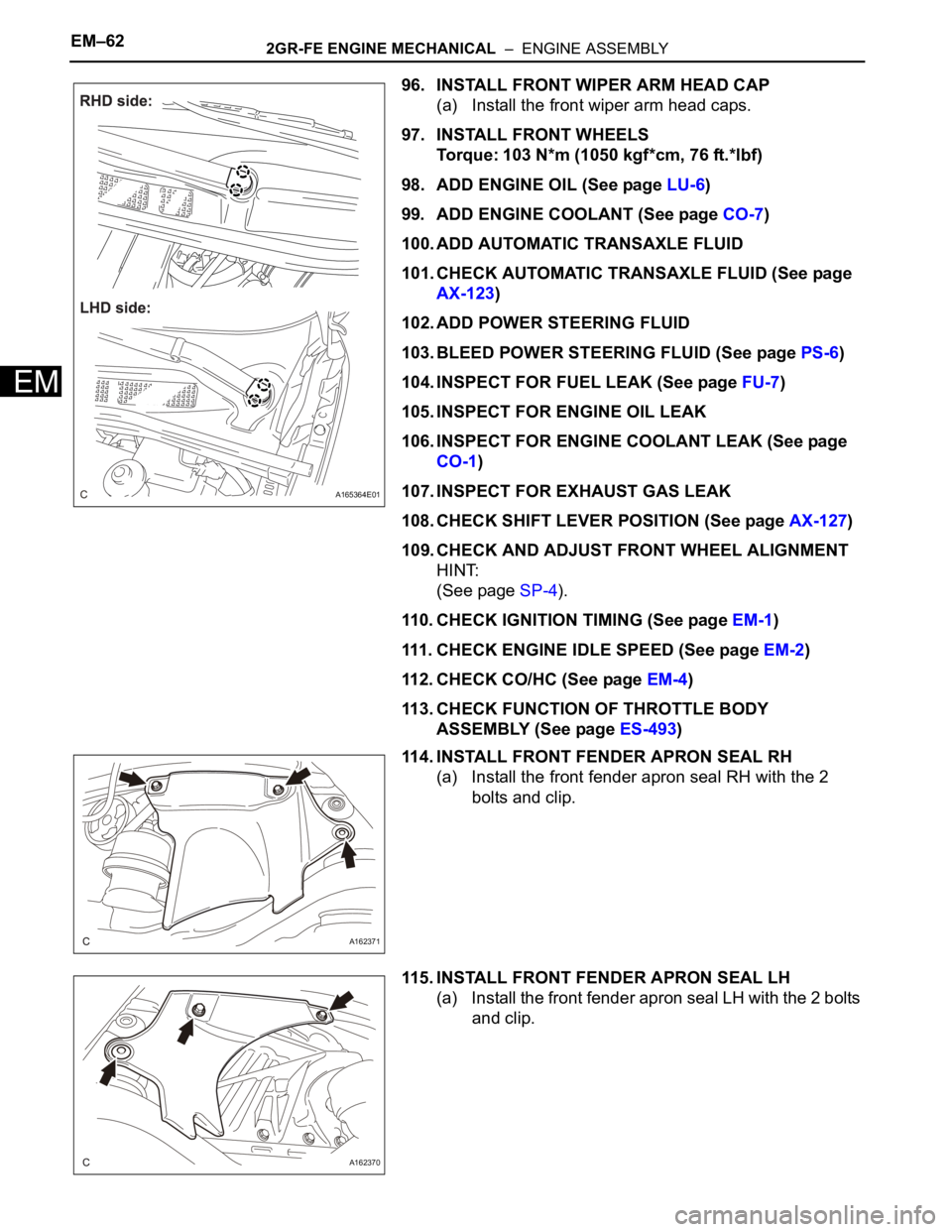

96. INSTALL FRONT WIPER ARM HEAD CAP

(a) Install the front wiper arm head caps.

97. INSTALL FRONT WHEELS

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

98. ADD ENGINE OIL (See page LU-6)

99. ADD ENGINE COOLANT (See page CO-7)

100. ADD AUTOMATIC TRANSAXLE FLUID

101. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

102. ADD POWER STEERING FLUID

103. BLEED POWER STEERING FLUID (See page PS-6)

104. INSPECT FOR FUEL LEAK (See page FU-7)

105. INSPECT FOR ENGINE OIL LEAK

106. INSPECT FOR ENGINE COOLANT LEAK (See page

CO-1)

107. INSPECT FOR EXHAUST GAS LEAK

108. CHECK SHIFT LEVER POSITION (See page AX-127)

109. CHECK AND ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page SP-4).

110. CHECK IGNITION TIMING (See page EM-1)

111. CHECK ENGINE IDLE SPEED (See page EM-2)

112. CHECK CO/HC (See page EM-4)

113. CHECK FUNCTION OF THROTTLE BODY

ASSEMBLY (See page ES-493)

114. INSTALL FRONT FENDER APRON SEAL RH

(a) Install the front fender apron seal RH with the 2

bolts and clip.

115. INSTALL FRONT FENDER APRON SEAL LH

(a) Install the front fender apron seal LH with the 2 bolts

and clip.

A165364E01

A162371

A162370

Page 1339 of 3000

ST–162GR-FE STARTING – IGNITION SWITCH

ST

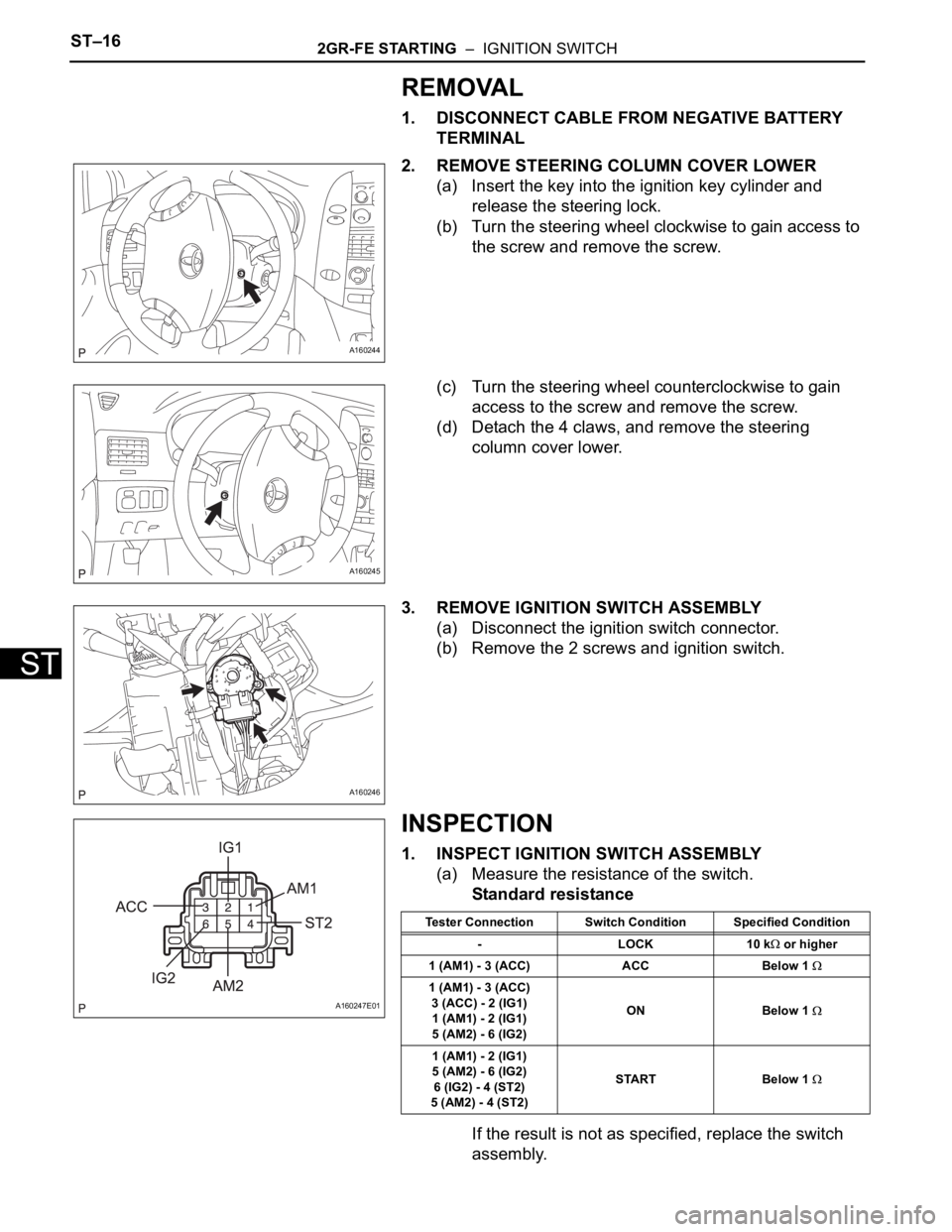

REMOVAL

1. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

2. REMOVE STEERING COLUMN COVER LOWER

(a) Insert the key into the ignition key cylinder and

release the steering lock.

(b) Turn the steering wheel clockwise to gain access to

the screw and remove the screw.

(c) Turn the steering wheel counterclockwise to gain

access to the screw and remove the screw.

(d) Detach the 4 claws, and remove the steering

column cover lower.

3. REMOVE IGNITION SWITCH ASSEMBLY

(a) Disconnect the ignition switch connector.

(b) Remove the 2 screws and ignition switch.

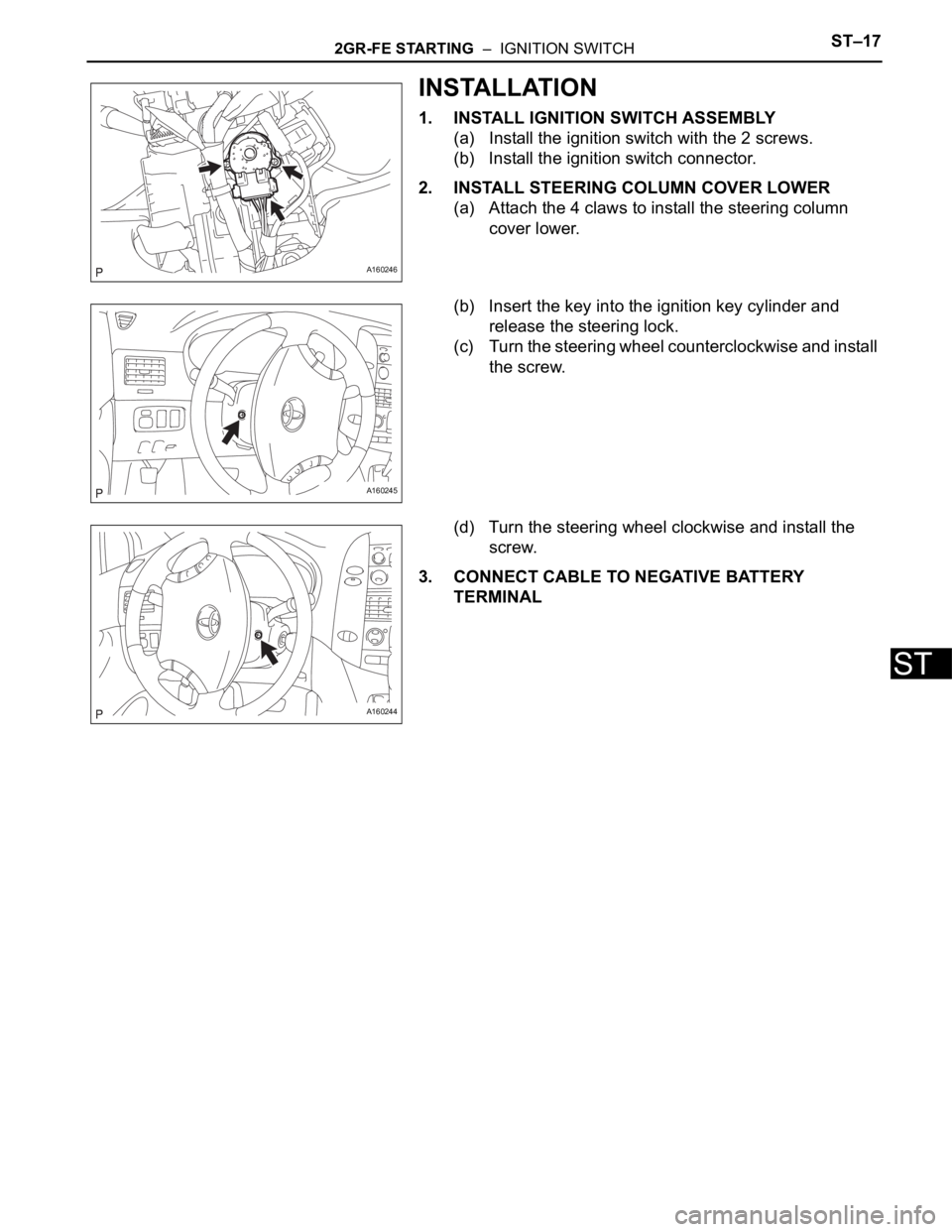

INSPECTION

1. INSPECT IGNITION SWITCH ASSEMBLY

(a) Measure the resistance of the switch.

Standard resistance

If the result is not as specified, replace the switch

assembly.

A160244

A160245

A160246

A160247E01

Tester Connection Switch Condition Specified Condition

-LOCK10 k

or higher

1 (AM1) - 3 (ACC) ACC Below 1

1 (AM1) - 3 (ACC)

3 (ACC) - 2 (IG1)

1 (AM1) - 2 (IG1)

5 (AM2) - 6 (IG2)ON Below 1

1 (AM1) - 2 (IG1)

5 (AM2) - 6 (IG2)

6 (IG2) - 4 (ST2)

5 (AM2) - 4 (ST2)START Below 1

Page 1340 of 3000

2GR-FE STARTING – IGNITION SWITCHST–17

ST

INSTALLATION

1. INSTALL IGNITION SWITCH ASSEMBLY

(a) Install the ignition switch with the 2 screws.

(b) Install the ignition switch connector.

2. INSTALL STEERING COLUMN COVER LOWER

(a) Attach the 4 claws to install the steering column

cover lower.

(b) Insert the key into the ignition key cylinder and

release the steering lock.

(c) Turn the steering wheel counterclockwise and install

the screw.

(d) Turn the steering wheel clockwise and install the

screw.

3. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

A160246

A160245

A160244

Page 2080 of 3000

DRIVE SHAFT – FRONT DRIVE SHAFTDS–5

DS

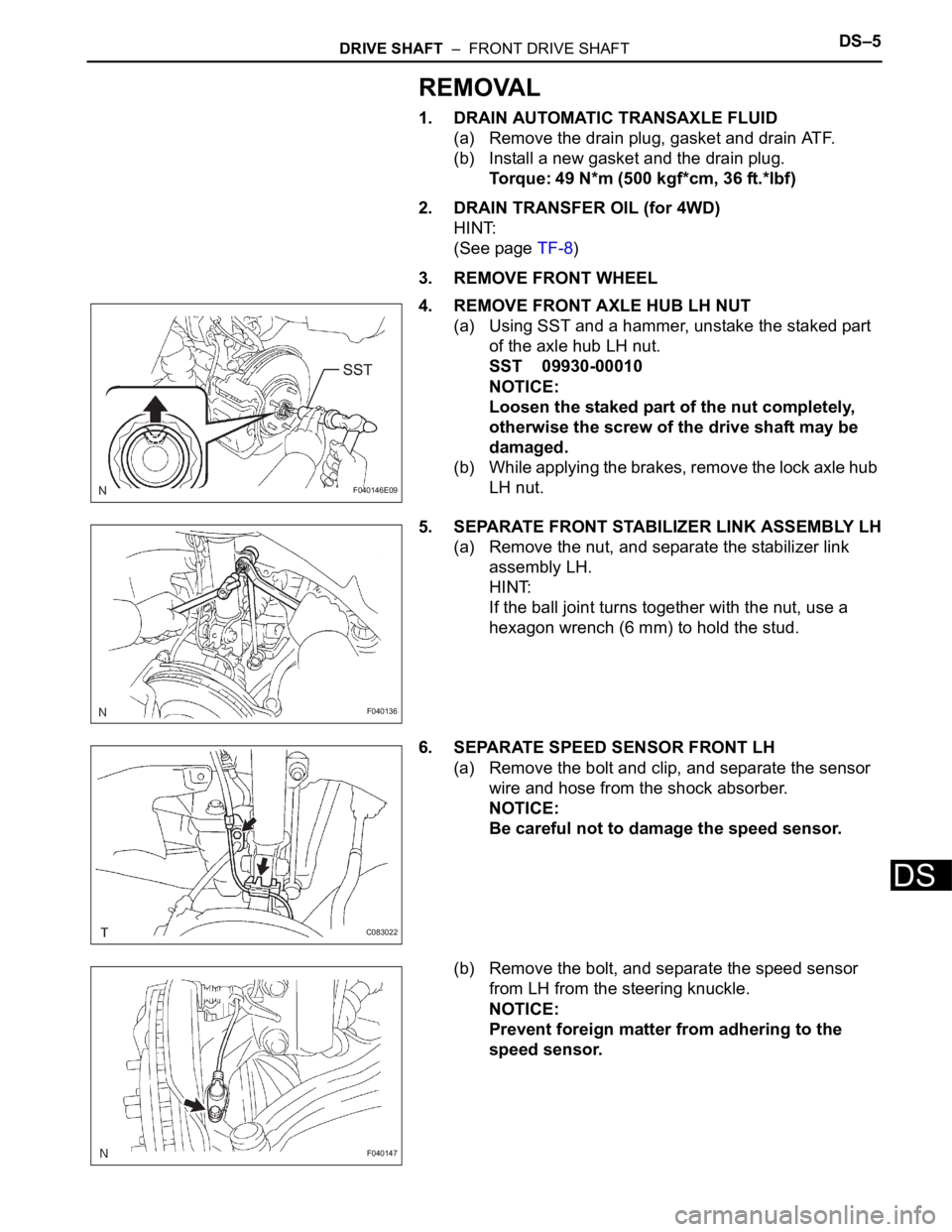

REMOVAL

1. DRAIN AUTOMATIC TRANSAXLE FLUID

(a) Remove the drain plug, gasket and drain ATF.

(b) Install a new gasket and the drain plug.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

2. DRAIN TRANSFER OIL (for 4WD)

HINT:

(See page TF-8)

3. REMOVE FRONT WHEEL

4. REMOVE FRONT AXLE HUB LH NUT

(a) Using SST and a hammer, unstake the staked part

of the axle hub LH nut.

SST 09930-00010

NOTICE:

Loosen the staked part of the nut completely,

otherwise the screw of the drive shaft may be

damaged.

(b) While applying the brakes, remove the lock axle hub

LH nut.

5. SEPARATE FRONT STABILIZER LINK ASSEMBLY LH

(a) Remove the nut, and separate the stabilizer link

assembly LH.

HINT:

If the ball joint turns together with the nut, use a

hexagon wrench (6 mm) to hold the stud.

6. SEPARATE SPEED SENSOR FRONT LH

(a) Remove the bolt and clip, and separate the sensor

wire and hose from the shock absorber.

NOTICE:

Be careful not to damage the speed sensor.

(b) Remove the bolt, and separate the speed sensor

from LH from the steering knuckle.

NOTICE:

Prevent foreign matter from adhering to the

speed sensor.

F040146E09

F040136

C083022

F040147

Page 2165 of 3000

AH–6AXLE – FRONT AXLE HUB

AH

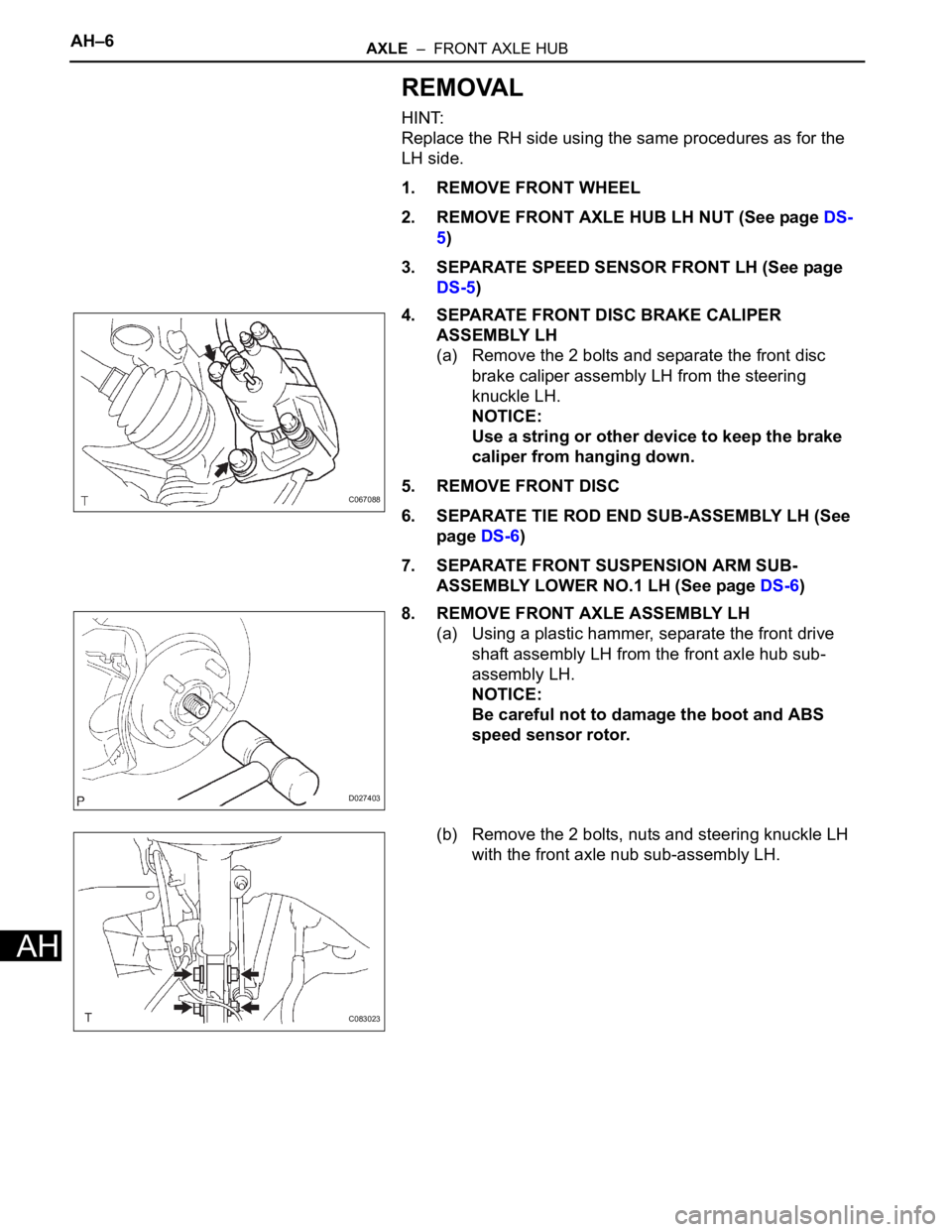

REMOVAL

HINT:

Replace the RH side using the same procedures as for the

LH side.

1. REMOVE FRONT WHEEL

2. REMOVE FRONT AXLE HUB LH NUT (See page DS-

5)

3. SEPARATE SPEED SENSOR FRONT LH (See page

DS-5)

4. SEPARATE FRONT DISC BRAKE CALIPER

ASSEMBLY LH

(a) Remove the 2 bolts and separate the front disc

brake caliper assembly LH from the steering

knuckle LH.

NOTICE:

Use a string or other device to keep the brake

caliper from hanging down.

5. REMOVE FRONT DISC

6. SEPARATE TIE ROD END SUB-ASSEMBLY LH (See

page DS-6)

7. SEPARATE FRONT SUSPENSION ARM SUB-

ASSEMBLY LOWER NO.1 LH (See page DS-6)

8. REMOVE FRONT AXLE ASSEMBLY LH

(a) Using a plastic hammer, separate the front drive

shaft assembly LH from the front axle hub sub-

assembly LH.

NOTICE:

Be careful not to damage the boot and ABS

speed sensor rotor.

(b) Remove the 2 bolts, nuts and steering knuckle LH

with the front axle nub sub-assembly LH.

C067088

D027403

C083023

Page 2168 of 3000

AXLE – FRONT AXLE HUBAH–9

AH

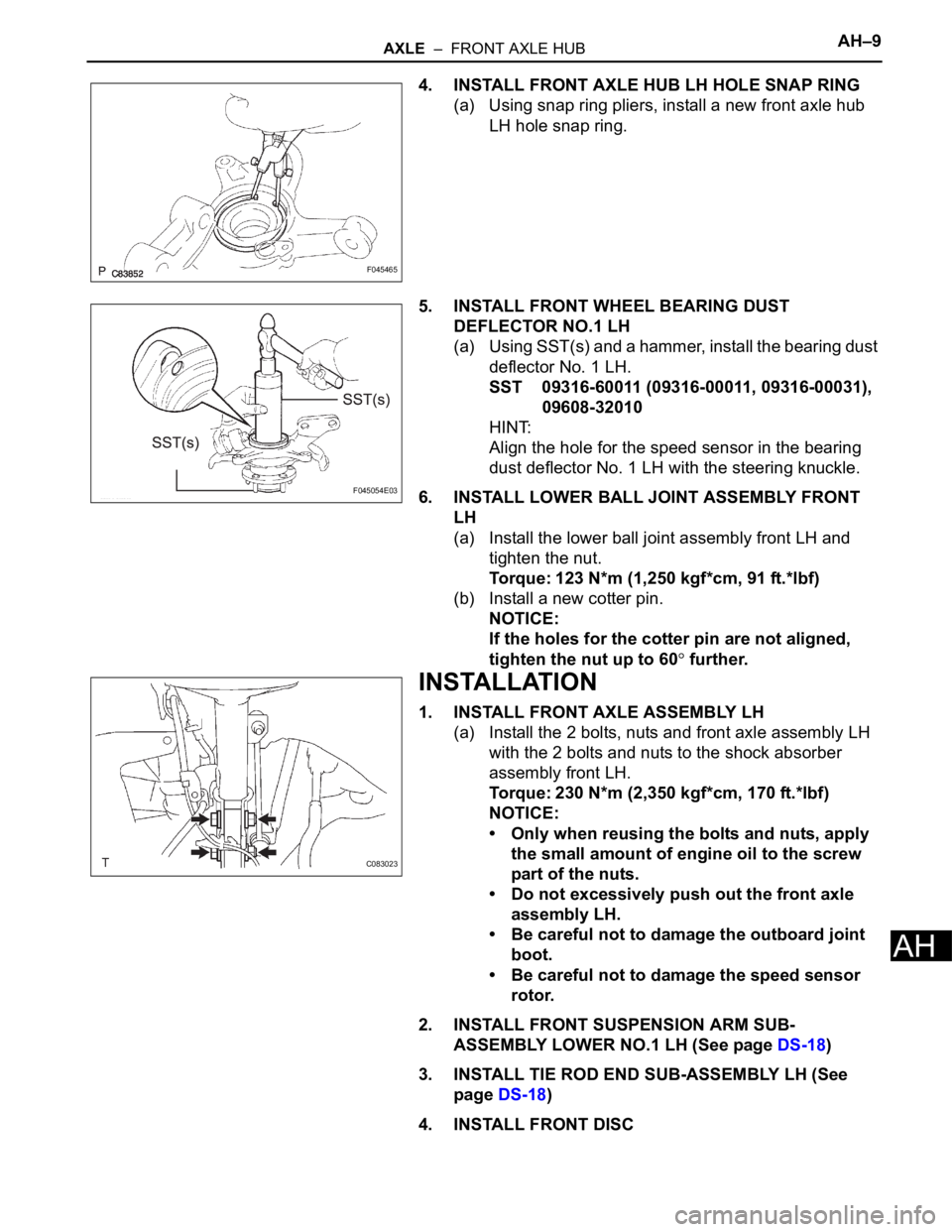

4. INSTALL FRONT AXLE HUB LH HOLE SNAP RING

(a) Using snap ring pliers, install a new front axle hub

LH hole snap ring.

5. INSTALL FRONT WHEEL BEARING DUST

DEFLECTOR NO.1 LH

(a) Using SST(s) and a hammer, install the bearing dust

deflector No. 1 LH.

SST 09316-60011 (09316-00011, 09316-00031),

09608-32010

HINT:

Align the hole for the speed sensor in the bearing

dust deflector No. 1 LH with the steering knuckle.

6. INSTALL LOWER BALL JOINT ASSEMBLY FRONT

LH

(a) Install the lower ball joint assembly front LH and

tighten the nut.

Torque: 123 N*m (1,250 kgf*cm, 91 ft.*lbf)

(b) Install a new cotter pin.

NOTICE:

If the holes for the cotter pin are not aligned,

tighten the nut up to 60

further.

INSTALLATION

1. INSTALL FRONT AXLE ASSEMBLY LH

(a) Install the 2 bolts, nuts and front axle assembly LH

with the 2 bolts and nuts to the shock absorber

assembly front LH.

Torque: 230 N*m (2,350 kgf*cm, 170 ft.*lbf)

NOTICE:

• Only when reusing the bolts and nuts, apply

the small amount of engine oil to the screw

part of the nuts.

• Do not excessively push out the front axle

assembly LH.

• Be careful not to damage the outboard joint

boot.

• Be careful not to damage the speed sensor

rotor.

2. INSTALL FRONT SUSPENSION ARM SUB-

ASSEMBLY LOWER NO.1 LH (See page DS-18)

3. INSTALL TIE ROD END SUB-ASSEMBLY LH (See

page DS-18)

4. INSTALL FRONT DISC

F045465

F045054E03

C083023

Page 2169 of 3000

AH–10AXLE – FRONT AXLE HUB

AH

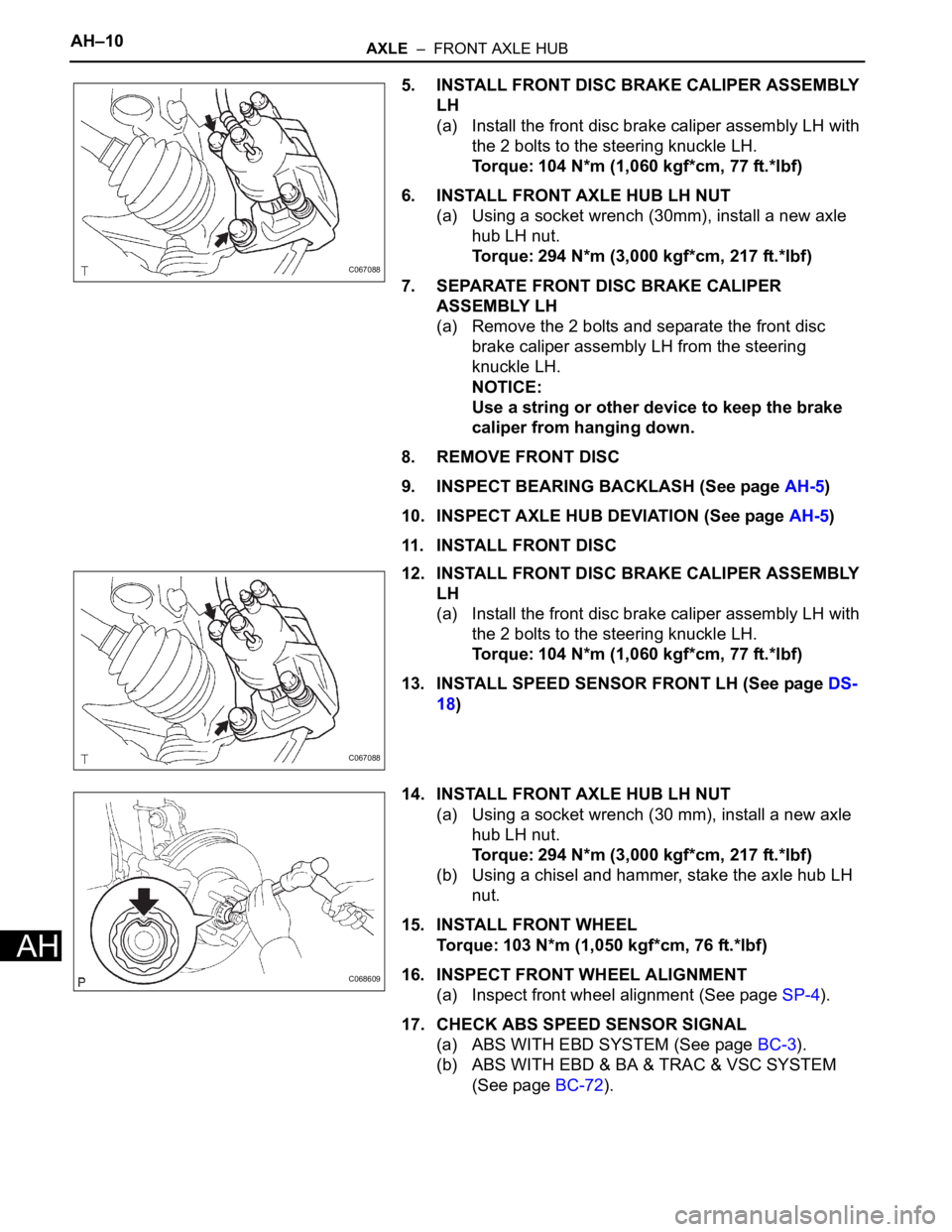

5. INSTALL FRONT DISC BRAKE CALIPER ASSEMBLY

LH

(a) Install the front disc brake caliper assembly LH with

the 2 bolts to the steering knuckle LH.

Torque: 104 N*m (1,060 kgf*cm, 77 ft.*lbf)

6. INSTALL FRONT AXLE HUB LH NUT

(a) Using a socket wrench (30mm), install a new axle

hub LH nut.

Torque: 294 N*m (3,000 kgf*cm, 217 ft.*lbf)

7. SEPARATE FRONT DISC BRAKE CALIPER

ASSEMBLY LH

(a) Remove the 2 bolts and separate the front disc

brake caliper assembly LH from the steering

knuckle LH.

NOTICE:

Use a string or other device to keep the brake

caliper from hanging down.

8. REMOVE FRONT DISC

9. INSPECT BEARING BACKLASH (See page AH-5)

10. INSPECT AXLE HUB DEVIATION (See page AH-5)

11. INSTALL FRONT DISC

12. INSTALL FRONT DISC BRAKE CALIPER ASSEMBLY

LH

(a) Install the front disc brake caliper assembly LH with

the 2 bolts to the steering knuckle LH.

Torque: 104 N*m (1,060 kgf*cm, 77 ft.*lbf)

13. INSTALL SPEED SENSOR FRONT LH (See page DS-

18)

14. INSTALL FRONT AXLE HUB LH NUT

(a) Using a socket wrench (30 mm), install a new axle

hub LH nut.

Torque: 294 N*m (3,000 kgf*cm, 217 ft.*lbf)

(b) Using a chisel and hammer, stake the axle hub LH

nut.

15. INSTALL FRONT WHEEL

Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

16. INSPECT FRONT WHEEL ALIGNMENT

(a) Inspect front wheel alignment (See page SP-4).

17. CHECK ABS SPEED SENSOR SIGNAL

(a) ABS WITH EBD SYSTEM (See page BC-3).

(b) ABS WITH EBD & BA & TRAC & VSC SYSTEM

(See page BC-72).

C067088

C067088

C068609