check oil TOYOTA SIENNA 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 408 of 3000

ES–1022GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the

time of a malfunction.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(d) Read the DTCs.

Result

HINT:

If any DTCs other than P0014, P0015, P0024 or P0025

are output, troubleshoot those DTCs first.

B

A

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and turn the tester on.

(c) Warm up the engine.

(d) Select the following menu items on the tester:

DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST /

VVT EX B1 or VVT EX B2.

(e) Check the engine speed while operating the Oil Control

Valve (OCV) using the tester.

OK

NG

OK

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Clear the DTCs (See page ES-39).

1CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0014, P0015, P0024 OR

P0025)

Display (DTC Output) Proceed to

P0014, P0015, P0024 or P0025 A

P0014, P0015, P0024 or P0025 and other DTCs B

GO TO DTC CHART (See page ES-56)

2PERFORM ACTIVE TEST BY INTELLIGENT TESTER (OPERATE OCV)

Tester Operation Specified Condition

OCV OFF Normal engine idle speed

OCV ON Engine idles roughly or stalls (soon after OCV switched from OFF to ON)

Go to step 4

3CHECK WHETHER DTC OUTPUT RECURS (DTC P0014, P0015, P0024 OR P0025)

Page 410 of 3000

ES–1042GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

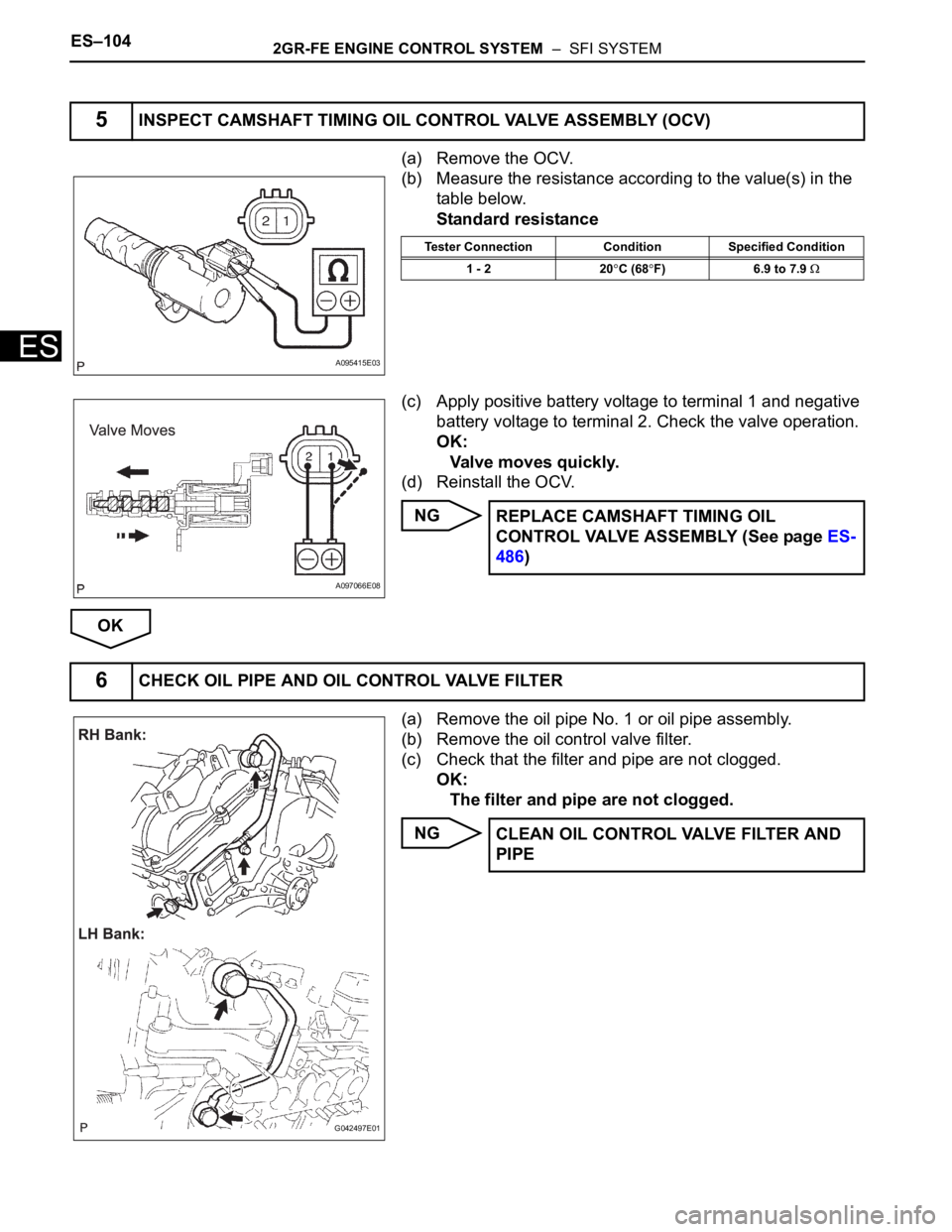

(a) Remove the OCV.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Apply positive battery voltage to terminal 1 and negative

battery voltage to terminal 2. Check the valve operation.

OK:

Valve moves quickly.

(d) Reinstall the OCV.

NG

OK

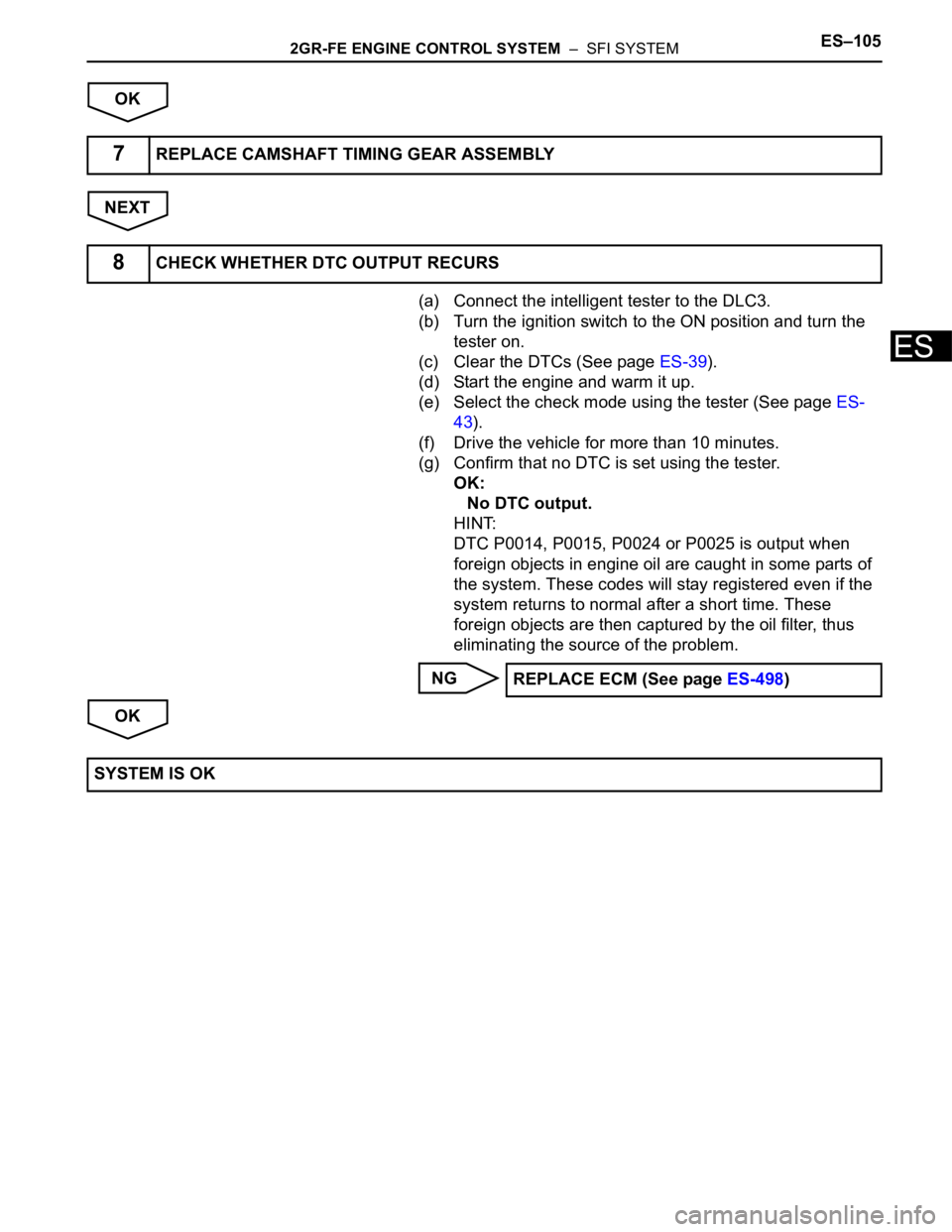

(a) Remove the oil pipe No. 1 or oil pipe assembly.

(b) Remove the oil control valve filter.

(c) Check that the filter and pipe are not clogged.

OK:

The filter and pipe are not clogged.

NG

5INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (OCV)

A095415E03

Tester Connection Condition Specified Condition

1 - 2 20

C (68F) 6.9 to 7.9

A097066E08

REPLACE CAMSHAFT TIMING OIL

CONTROL VALVE ASSEMBLY (See page ES-

486)

6CHECK OIL PIPE AND OIL CONTROL VALVE FILTER

G042497E01

CLEAN OIL CONTROL VALVE FILTER AND

PIPE

Page 411 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–105

ES

OK

NEXT

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Clear the DTCs (See page ES-39).

(d) Start the engine and warm it up.

(e) Select the check mode using the tester (See page ES-

43).

(f) Drive the vehicle for more than 10 minutes.

(g) Confirm that no DTC is set using the tester.

OK:

No DTC output.

HINT:

DTC P0014, P0015, P0024 or P0025 is output when

foreign objects in engine oil are caught in some parts of

the system. These codes will stay registered even if the

system returns to normal after a short time. These

foreign objects are then captured by the oil filter, thus

eliminating the source of the problem.

NG

OK

7REPLACE CAMSHAFT TIMING GEAR ASSEMBLY

8CHECK WHETHER DTC OUTPUT RECURS

REPLACE ECM (See page ES-498)

SYSTEM IS OK

Page 412 of 3000

ES–1062GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

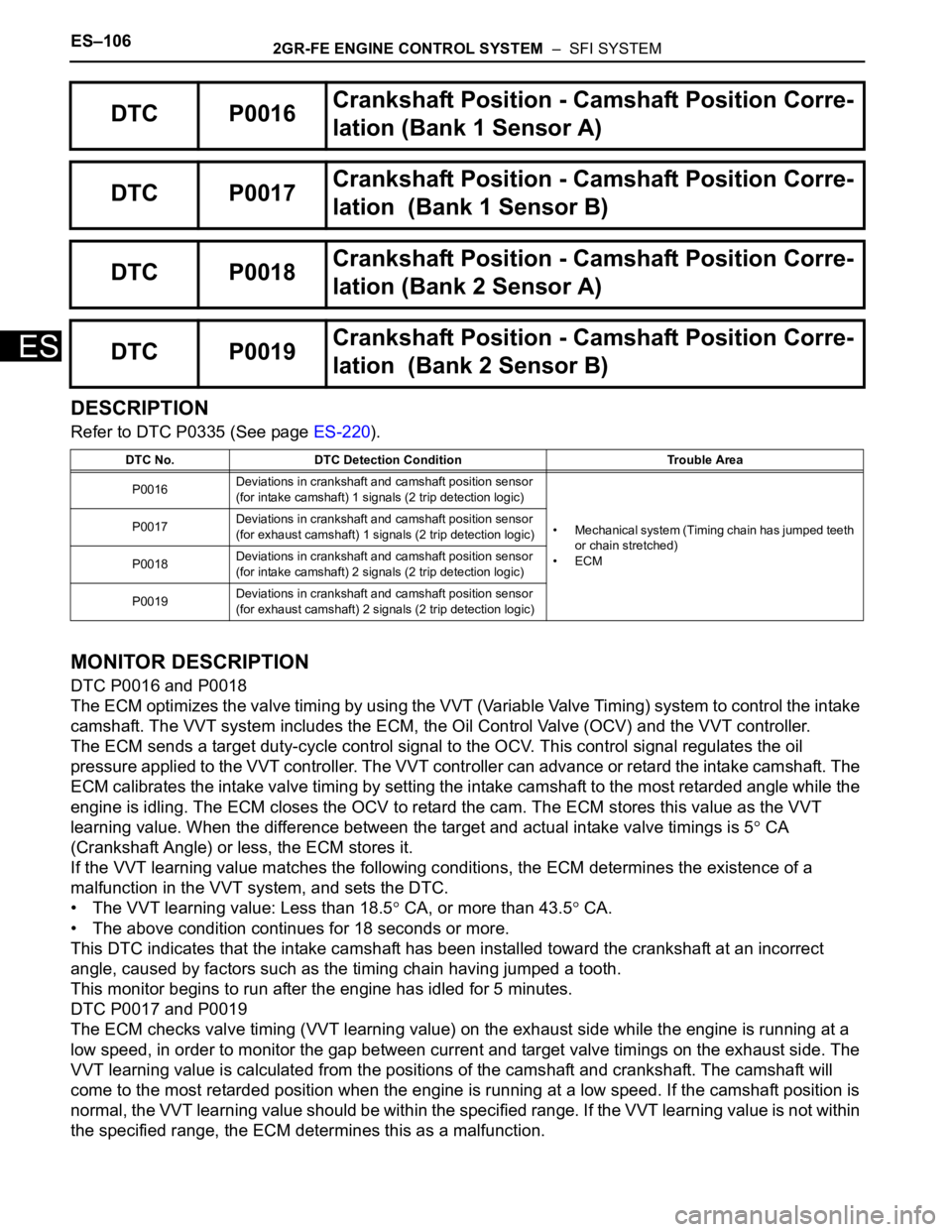

DESCRIPTION

Refer to DTC P0335 (See page ES-220).

MONITOR DESCRIPTION

DTC P0016 and P0018

The ECM optimizes the valve timing by using the VVT (Variable Valve Timing) system to control the intake

camshaft. The VVT system includes the ECM, the Oil Control Valve (OCV) and the VVT controller.

The ECM sends a target duty-cycle control signal to the OCV. This control signal regulates the oil

pressure applied to the VVT controller. The VVT controller can advance or retard the intake camshaft. The

ECM calibrates the intake valve timing by setting the intake camshaft to the most retarded angle while the

engine is idling. The ECM closes the OCV to retard the cam. The ECM stores this value as the VVT

learning value. When the difference between the target and actual intake valve timings is 5

CA

(Crankshaft Angle) or less, the ECM stores it.

If the VVT learning value matches the following conditions, the ECM determines the existence of a

malfunction in the VVT system, and sets the DTC.

• The VVT learning value: Less than 18.5

CA, or more than 43.5 CA.

• The above condition continues for 18 seconds or more.

This DTC indicates that the intake camshaft has been installed toward the crankshaft at an incorrect

angle, caused by factors such as the timing chain having jumped a tooth.

This monitor begins to run after the engine has idled for 5 minutes.

DTC P0017 and P0019

The ECM checks valve timing (VVT learning value) on the exhaust side while the engine is running at a

low speed, in order to monitor the gap between current and target valve timings on the exhaust side. The

VVT learning value is calculated from the positions of the camshaft and crankshaft. The camshaft will

come to the most retarded position when the engine is running at a low speed. If the camshaft position is

normal, the VVT learning value should be within the specified range. If the VVT learning value is not within

the specified range, the ECM determines this as a malfunction.

DTC P0016Crankshaft Position - Camshaft Position Corre-

lation (Bank 1 Sensor A)

DTC P0017Crankshaft Position - Camshaft Position Corre-

lation (Bank 1 Sensor B)

DTC P0018Crankshaft Position - Camshaft Position Corre-

lation (Bank 2 Sensor A)

DTC P0019Crankshaft Position - Camshaft Position Corre-

lation (Bank 2 Sensor B)

DTC No. DTC Detection Condition Trouble Area

P0016Deviations in crankshaft and camshaft position sensor

(for intake camshaft) 1 signals (2 trip detection logic)

• Mechanical system (Timing chain has jumped teeth

or chain stretched)

•ECM P0017Deviations in crankshaft and camshaft position sensor

(for exhaust camshaft) 1 signals (2 trip detection logic)

P0018Deviations in crankshaft and camshaft position sensor

(for intake camshaft) 2 signals (2 trip detection logic)

P0019Deviations in crankshaft and camshaft position sensor

(for exhaust camshaft) 2 signals (2 trip detection logic)

Page 511 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–205

ES

When multiple DTCs for misfiring cylinders are set, but DTC P0300 is not set, it indicates that misfires

have been detected in different cylinders at different times. DTC P0300 is only set when several misfiring

cylinders are detected at the same time.

MONITOR DESCRIPTION

The ECM illuminates the MIL and sets a DTC when either one of the following conditions, which could

cause emission deterioration, is detected (2 trip detection logic).

• Within the first 1000 crankshaft revolutions of the engine starting, an excessive misfiring rate

(approximately 20 to 50 misfires per 1000 crankshaft revolutions) occurs once.

• An excessive misfiring rate (approximately 20 to 50 misfires per 1,000 crankshaft revolutions) occurs a

total of 4 times.

The ECM flashes the MIL and sets a DTC when either one of the following conditions, which could cause

the Three-Way Catalytic Converter (TWC) damage, is detected (2 trip detection logic).

• At a high engine rpm, a catalyst damage misfire, which monitored every 200 crankshaft revolutions,

occurs once.

• At a normal engine rpm, a catalyst damage misfire, which monitored every 200 crankshaft revolutions,

occurs 3 times.

HINT:

If a catalyst damage misfire occurs, the ECM informs the driver by flashing the MIL.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

Misfire:

Monitor period of emission-related-misfire:

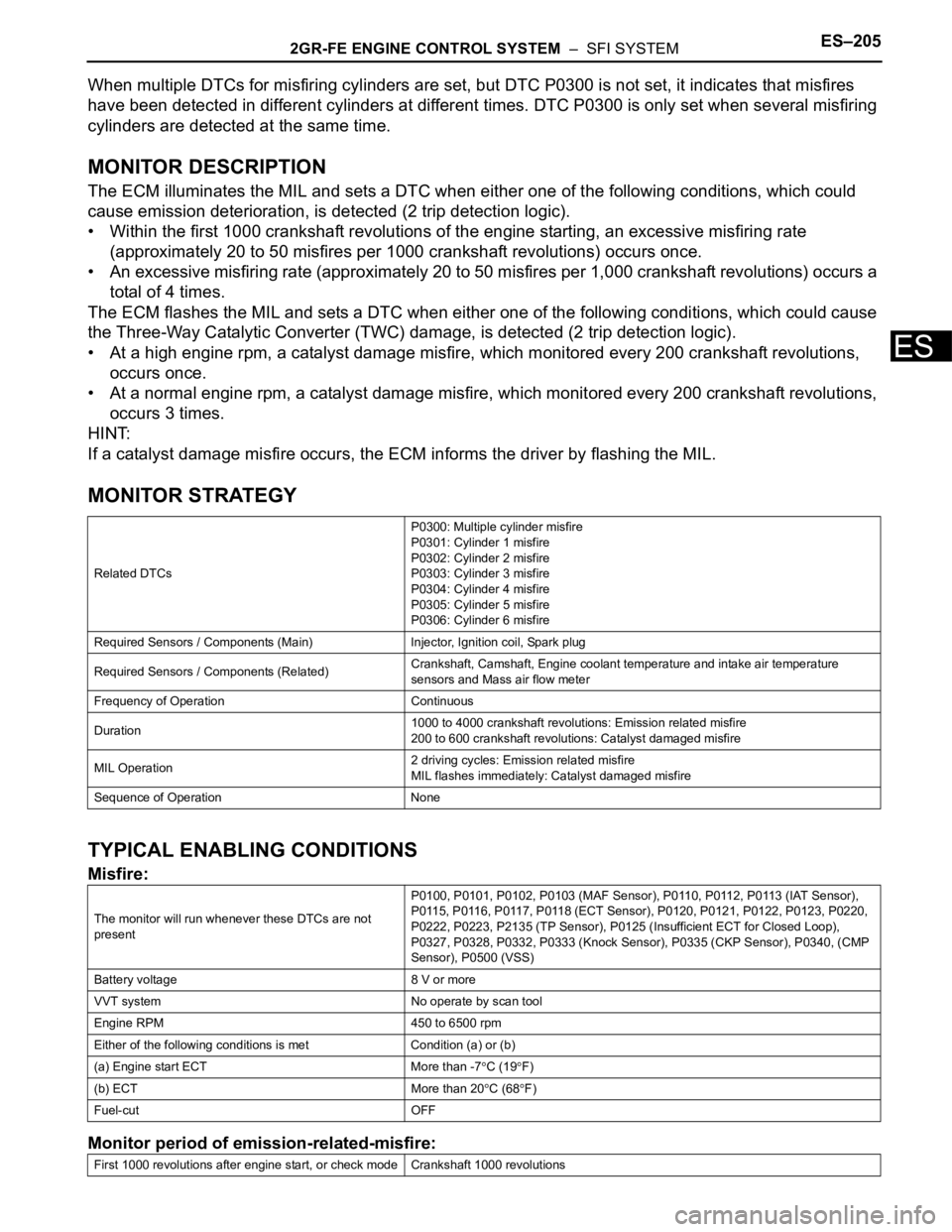

Related DTCsP0300: Multiple cylinder misfire

P0301: Cylinder 1 misfire

P0302: Cylinder 2 misfire

P0303: Cylinder 3 misfire

P0304: Cylinder 4 misfire

P0305: Cylinder 5 misfire

P0306: Cylinder 6 misfire

Required Sensors / Components (Main) Injector, Ignition coil, Spark plug

Required Sensors / Components (Related)Crankshaft, Camshaft, Engine coolant temperature and intake air temperature

sensors and Mass air flow meter

Frequency of Operation Continuous

Duration1000 to 4000 crankshaft revolutions: Emission related misfire

200 to 600 crankshaft revolutions: Catalyst damaged misfire

MIL Operation2 driving cycles: Emission related misfire

MIL flashes immediately: Catalyst damaged misfire

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentP0100, P0101, P0102, P0103 (MAF Sensor), P0110, P0112, P0113 (IAT Sensor),

P0115, P0116, P0117, P0118 (ECT Sensor), P0120, P0121, P0122, P0123, P0220,

P0222, P0223, P2135 (TP Sensor), P0125 (Insufficient ECT for Closed Loop),

P0327, P0328, P0332, P0333 (Knock Sensor), P0335 (CKP Sensor), P0340, (CMP

Sensor), P0500 (VSS)

Battery voltage 8 V or more

VVT system No operate by scan tool

Engine RPM 450 to 6500 rpm

Either of the following conditions is met Condition (a) or (b)

(a) Engine start ECT More than -7

C (19F)

(b) ECT More than 20

C (68F)

Fuel-cut OFF

First 1000 revolutions after engine start, or check mode Crankshaft 1000 revolutions

Page 517 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–211

ES

(d) Read the CYL #1 to #6 or DTCs displayed on the tester.

Result

HINT:

• If it is difficult to reproduce misfires for each cylinder, check

the Data List item called MISFIRE MARGIN. Try to find

vehicle driving conditions that lower the MISFIRE

MARGIN value. Values above 30% are considered normal.

• If the freeze frame data's record of the ECT is below 75

C

(167

F), the misfire may be detected only when the engine

is cold.

• If the freeze frame data's record of the ENG RUN TIME is

below 120 seconds, the misfire may be detected

immediately after the engine is started.

B

A

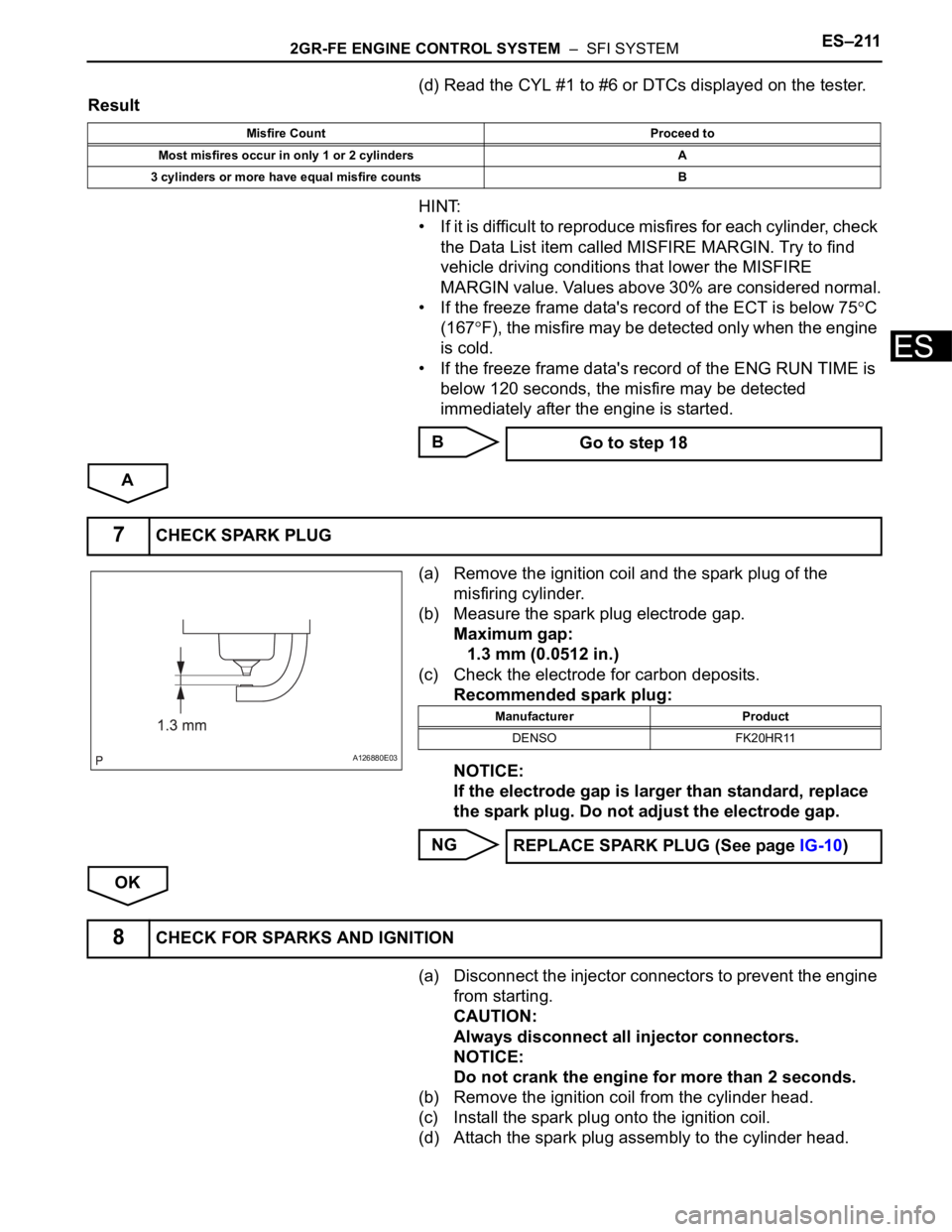

(a) Remove the ignition coil and the spark plug of the

misfiring cylinder.

(b) Measure the spark plug electrode gap.

Maximum gap:

1.3 mm (0.0512 in.)

(c) Check the electrode for carbon deposits.

Recommended spark plug:

NOTICE:

If the electrode gap is larger than standard, replace

the spark plug. Do not adjust the electrode gap.

NG

OK

(a) Disconnect the injector connectors to prevent the engine

from starting.

CAUTION:

Always disconnect all injector connectors.

NOTICE:

Do not crank the engine for more than 2 seconds.

(b) Remove the ignition coil from the cylinder head.

(c) Install the spark plug onto the ignition coil.

(d) Attach the spark plug assembly to the cylinder head.

Misfire Count Proceed to

Most misfires occur in only 1 or 2 cylinders A

3 cylinders or more have equal misfire counts B

Go to step 18

7CHECK SPARK PLUG

A126880E03

Manufacturer Product

DENSO FK20HR11

REPLACE SPARK PLUG (See page IG-10)

8CHECK FOR SPARKS AND IGNITION

Page 518 of 3000

ES–2122GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

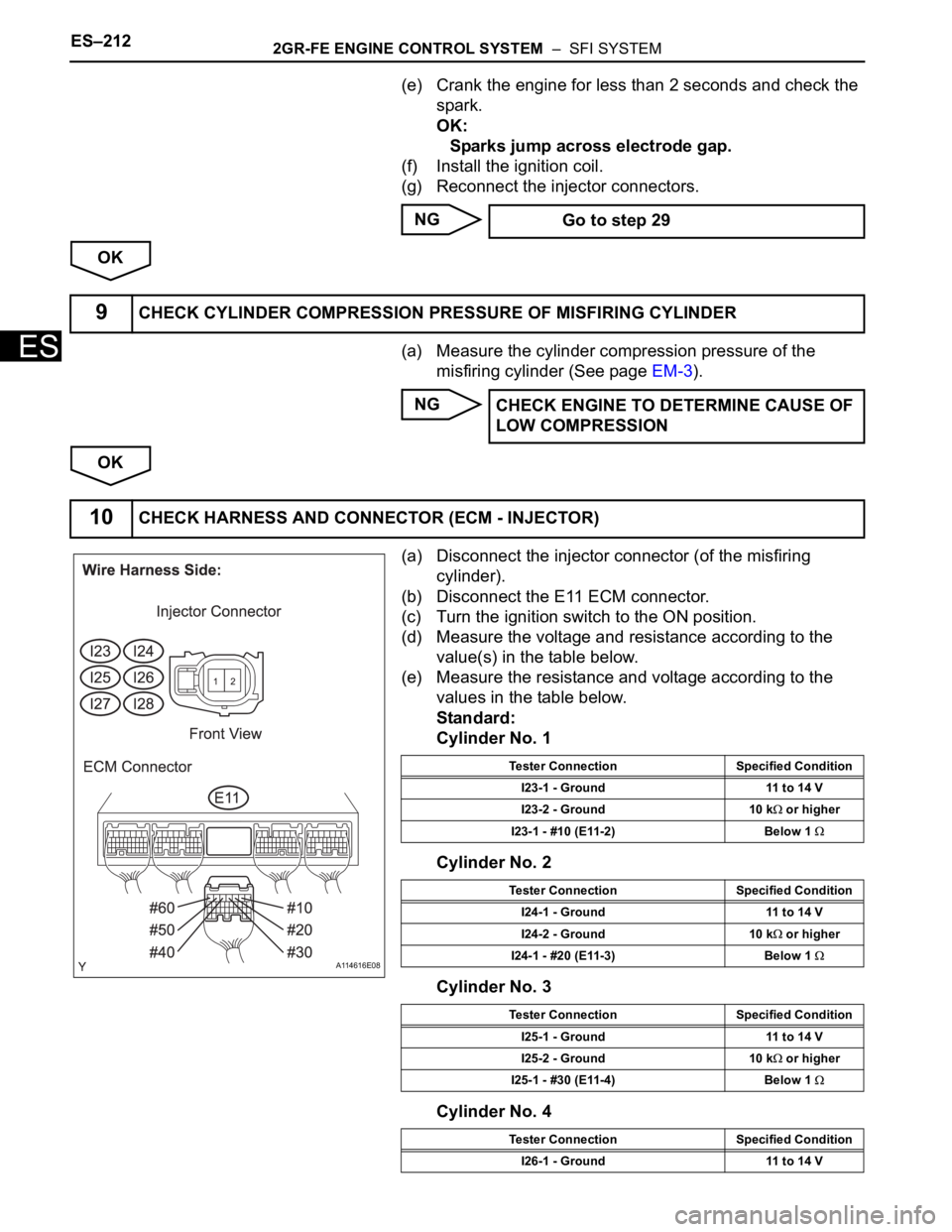

(e) Crank the engine for less than 2 seconds and check the

spark.

OK:

Sparks jump across electrode gap.

(f) Install the ignition coil.

(g) Reconnect the injector connectors.

NG

OK

(a) Measure the cylinder compression pressure of the

misfiring cylinder (See page EM-3).

NG

OK

(a) Disconnect the injector connector (of the misfiring

cylinder).

(b) Disconnect the E11 ECM connector.

(c) Turn the ignition switch to the ON position.

(d) Measure the voltage and resistance according to the

value(s) in the table below.

(e) Measure the resistance and voltage according to the

values in the table below.

Standard:

Cylinder No. 1

Cylinder No. 2

Cylinder No. 3

Cylinder No. 4 Go to step 29

9CHECK CYLINDER COMPRESSION PRESSURE OF MISFIRING CYLINDER

CHECK ENGINE TO DETERMINE CAUSE OF

LOW COMPRESSION

10CHECK HARNESS AND CONNECTOR (ECM - INJECTOR)

A114616E08

Tester Connection Specified Condition

I23-1 - Ground 11 to 14 V

I23-2 - Ground 10 k

or higher

I23-1 - #10 (E11-2) Below 1

Tester Connection Specified Condition

I24-1 - Ground 11 to 14 V

I24-2 - Ground 10 k

or higher

I24-1 - #20 (E11-3) Below 1

Tester Connection Specified Condition

I25-1 - Ground 11 to 14 V

I25-2 - Ground 10 k

or higher

I25-1 - #30 (E11-4) Below 1

Tester Connection Specified Condition

I26-1 - Ground 11 to 14 V

Page 523 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–217

ES

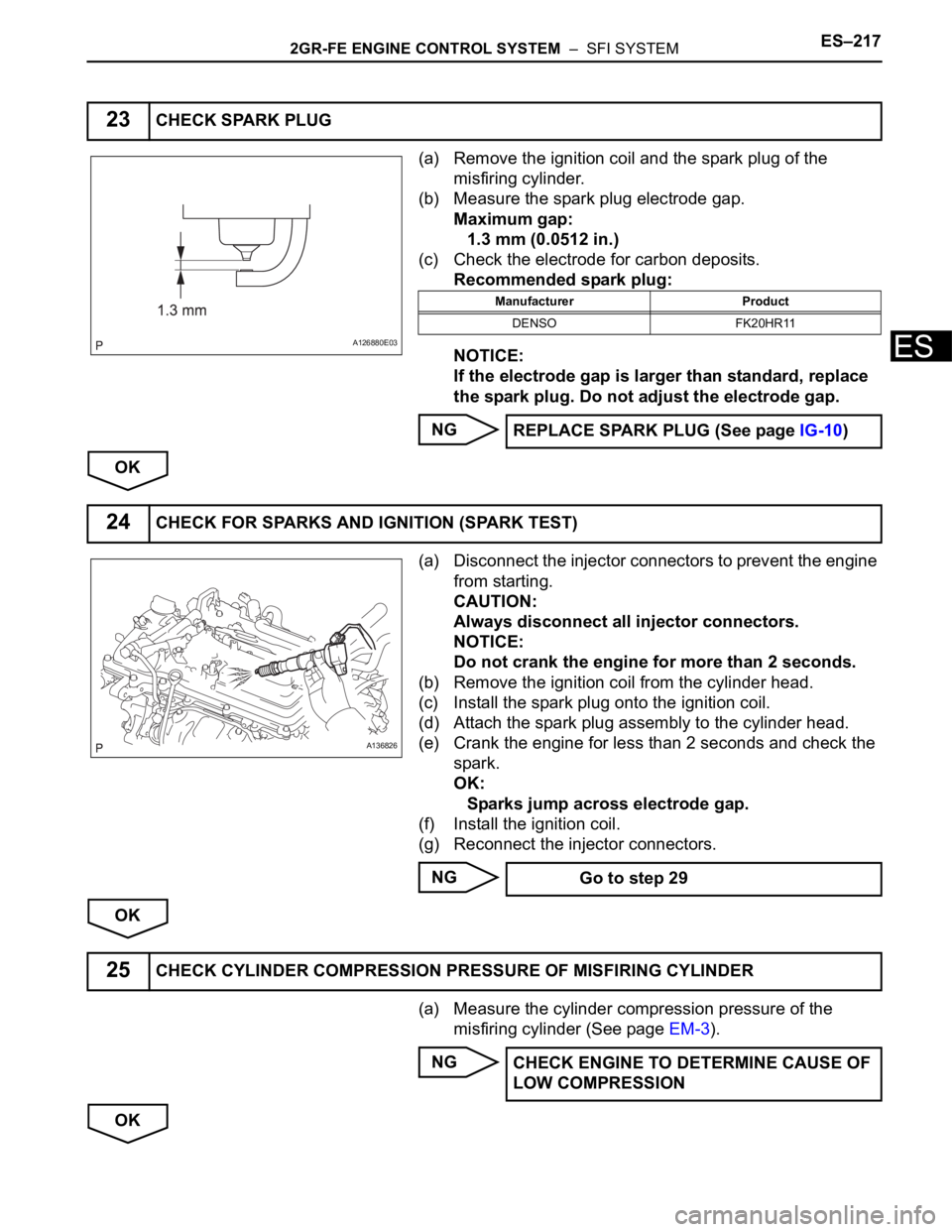

(a) Remove the ignition coil and the spark plug of the

misfiring cylinder.

(b) Measure the spark plug electrode gap.

Maximum gap:

1.3 mm (0.0512 in.)

(c) Check the electrode for carbon deposits.

Recommended spark plug:

NOTICE:

If the electrode gap is larger than standard, replace

the spark plug. Do not adjust the electrode gap.

NG

OK

(a) Disconnect the injector connectors to prevent the engine

from starting.

CAUTION:

Always disconnect all injector connectors.

NOTICE:

Do not crank the engine for more than 2 seconds.

(b) Remove the ignition coil from the cylinder head.

(c) Install the spark plug onto the ignition coil.

(d) Attach the spark plug assembly to the cylinder head.

(e) Crank the engine for less than 2 seconds and check the

spark.

OK:

Sparks jump across electrode gap.

(f) Install the ignition coil.

(g) Reconnect the injector connectors.

NG

OK

(a) Measure the cylinder compression pressure of the

misfiring cylinder (See page EM-3).

NG

OK

23CHECK SPARK PLUG

A126880E03

Manufacturer Product

DENSO FK20HR11

REPLACE SPARK PLUG (See page IG-10)

24CHECK FOR SPARKS AND IGNITION (SPARK TEST)

A136826

Go to step 29

25CHECK CYLINDER COMPRESSION PRESSURE OF MISFIRING CYLINDER

CHECK ENGINE TO DETERMINE CAUSE OF

LOW COMPRESSION

Page 525 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–219

ES

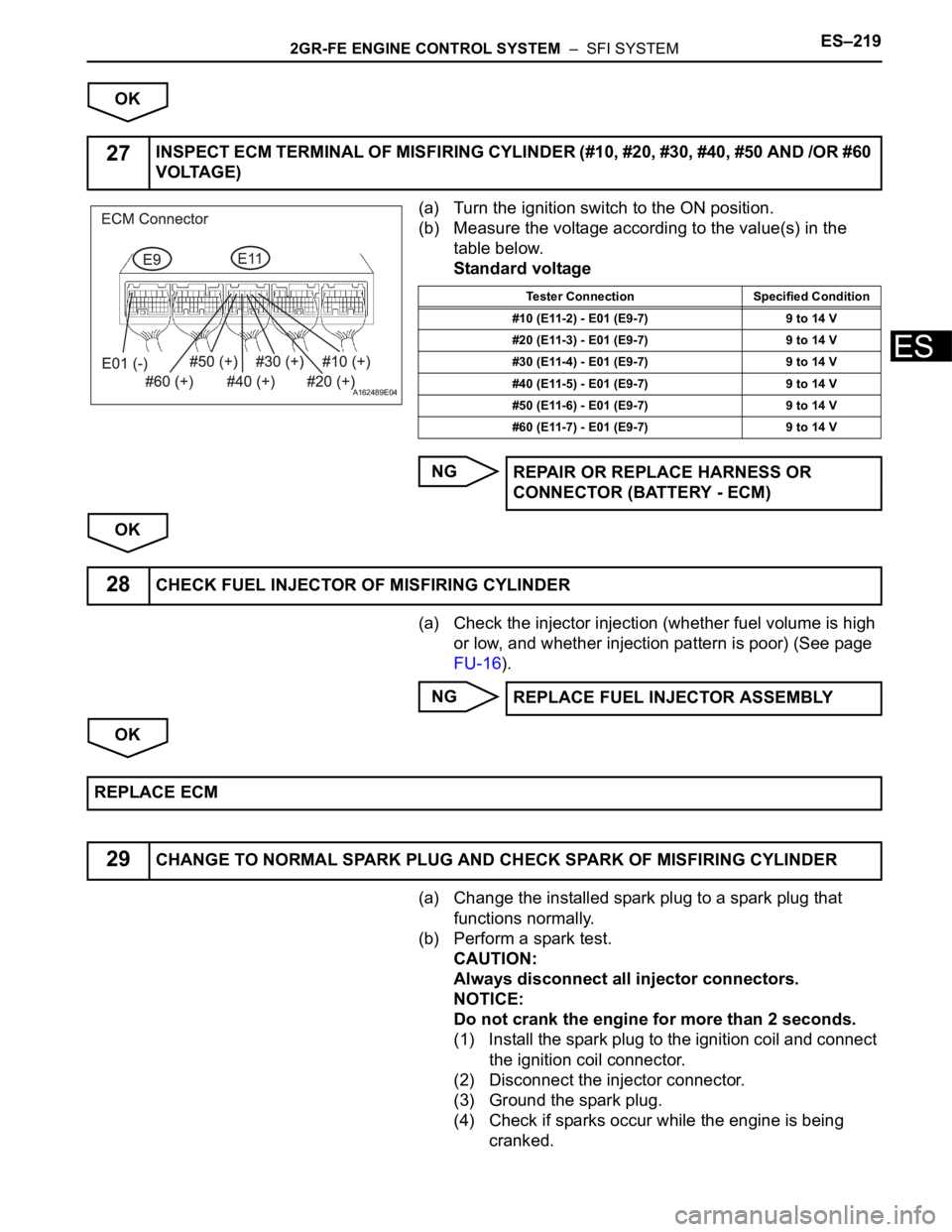

OK

(a) Turn the ignition switch to the ON position.

(b) Measure the voltage according to the value(s) in the

table below.

Standard voltage

NG

OK

(a) Check the injector injection (whether fuel volume is high

or low, and whether injection pattern is poor) (See page

FU-16).

NG

OK

(a) Change the installed spark plug to a spark plug that

functions normally.

(b) Perform a spark test.

CAUTION:

Always disconnect all injector connectors.

NOTICE:

Do not crank the engine for more than 2 seconds.

(1) Install the spark plug to the ignition coil and connect

the ignition coil connector.

(2) Disconnect the injector connector.

(3) Ground the spark plug.

(4) Check if sparks occur while the engine is being

cranked.

27INSPECT ECM TERMINAL OF MISFIRING CYLINDER (#10, #20, #30, #40, #50 AND /OR #60

VOLTAGE)

A162489E04

Tester Connection Specified Condition

#10 (E11-2) - E01 (E9-7) 9 to 14 V

#20 (E11-3) - E01 (E9-7) 9 to 14 V

#30 (E11-4) - E01 (E9-7) 9 to 14 V

#40 (E11-5) - E01 (E9-7) 9 to 14 V

#50 (E11-6) - E01 (E9-7) 9 to 14 V

#60 (E11-7) - E01 (E9-7) 9 to 14 V

REPAIR OR REPLACE HARNESS OR

CONNECTOR (BATTERY - ECM)

28CHECK FUEL INJECTOR OF MISFIRING CYLINDER

REPLACE FUEL INJECTOR ASSEMBLY

REPLACE ECM

29CHANGE TO NORMAL SPARK PLUG AND CHECK SPARK OF MISFIRING CYLINDER

Page 526 of 3000

ES–2202GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

OK:

Sparks jump across electrode gap.

NG

OK

NG

OK Go to step 30

REPLACE SPARK PLUG (See page IG-10)

30CHANGE TO NORMAL IGNITION COIL AND CHECK SPARK OF MISFIRING CYLINDER

REPLACE ECM

REPLACE IGNITION COIL