check oil TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 2657 of 3000

PB–18PARKING BRAKE – PARKING BRAKE ASSEMBLY

PB

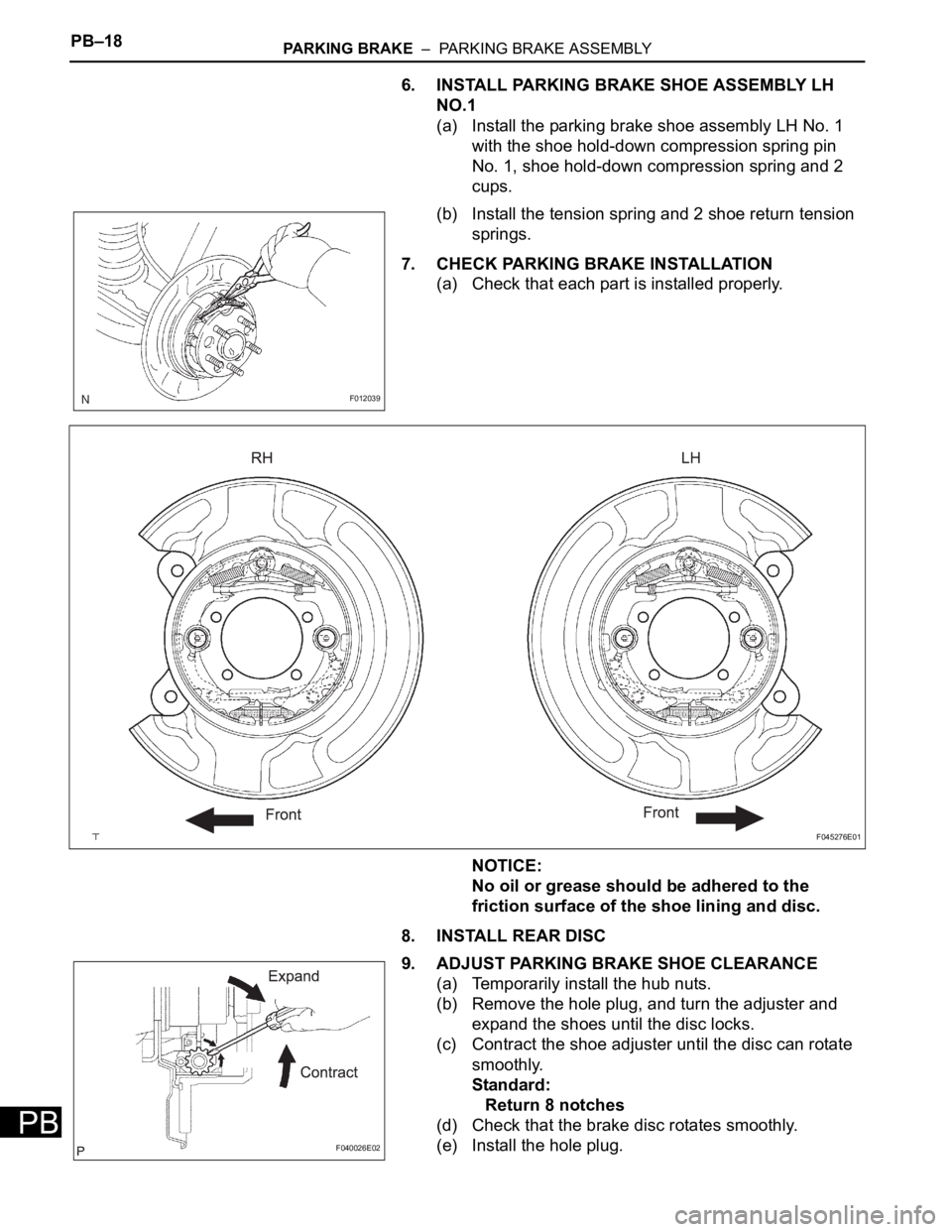

6. INSTALL PARKING BRAKE SHOE ASSEMBLY LH

NO.1

(a) Install the parking brake shoe assembly LH No. 1

with the shoe hold-down compression spring pin

No. 1, shoe hold-down compression spring and 2

cups.

(b) Install the tension spring and 2 shoe return tension

springs.

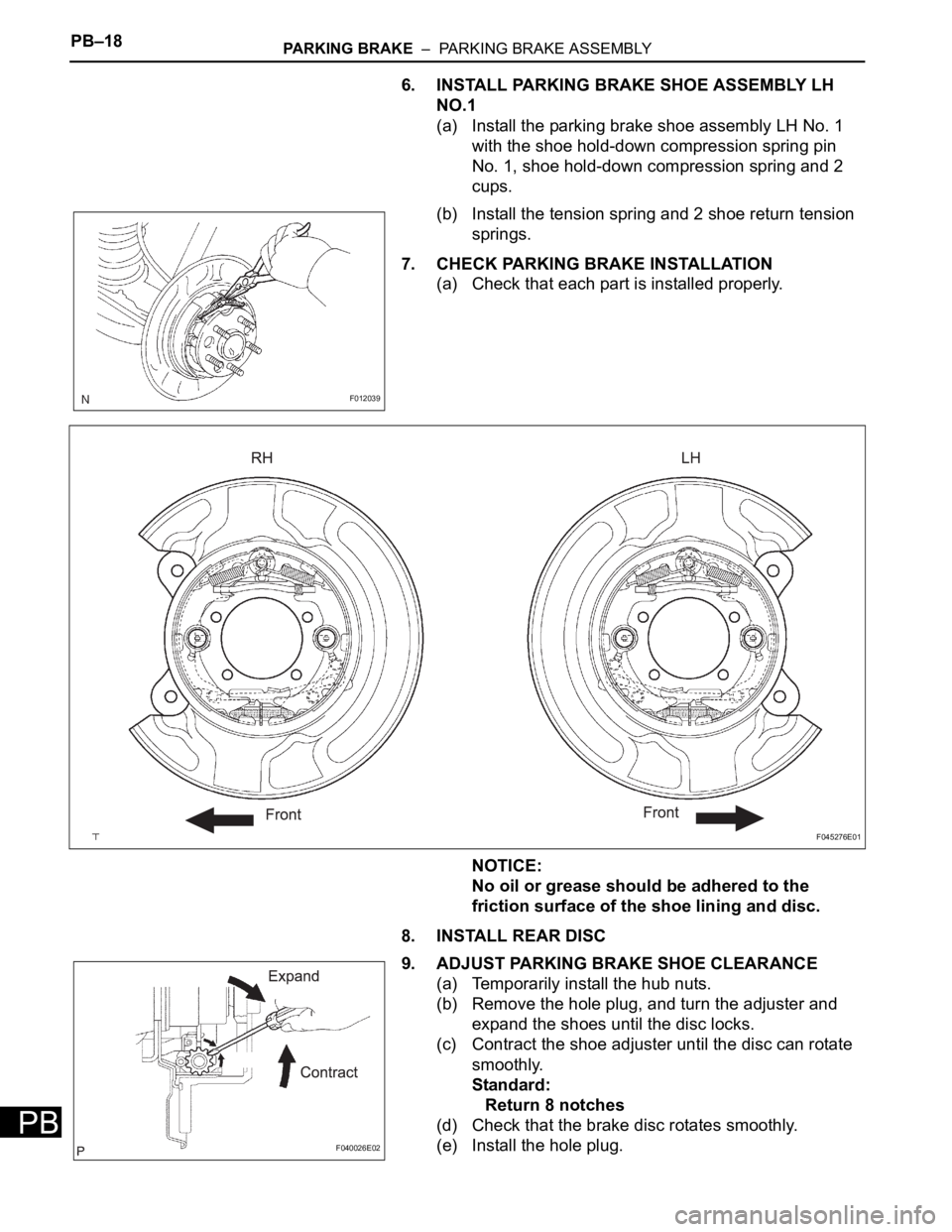

7. CHECK PARKING BRAKE INSTALLATION

(a) Check that each part is installed properly.

NOTICE:

No oil or grease should be adhered to the

friction surface of the shoe lining and disc.

8. INSTALL REAR DISC

9. ADJUST PARKING BRAKE SHOE CLEARANCE

(a) Temporarily install the hub nuts.

(b) Remove the hole plug, and turn the adjuster and

expand the shoes until the disc locks.

(c) Contract the shoe adjuster until the disc can rotate

smoothly.

Standard:

Return 8 notches

(d) Check that the brake disc rotates smoothly.

(e) Install the hole plug.

F012039

F045276E01

F040026E02

Page 2668 of 3000

PB–18PARKING BRAKE – PARKING BRAKE ASSEMBLY

PB

6. INSTALL PARKING BRAKE SHOE ASSEMBLY LH

NO.1

(a) Install the parking brake shoe assembly LH No. 1

with the shoe hold-down compression spring pin

No. 1, shoe hold-down compression spring and 2

cups.

(b) Install the tension spring and 2 shoe return tension

springs.

7. CHECK PARKING BRAKE INSTALLATION

(a) Check that each part is installed properly.

NOTICE:

No oil or grease should be adhered to the

friction surface of the shoe lining and disc.

8. INSTALL REAR DISC

9. ADJUST PARKING BRAKE SHOE CLEARANCE

(a) Temporarily install the hub nuts.

(b) Remove the hole plug, and turn the adjuster and

expand the shoes until the disc locks.

(c) Contract the shoe adjuster until the disc can rotate

smoothly.

Standard:

Return 8 notches

(d) Check that the brake disc rotates smoothly.

(e) Install the hole plug.

F012039

F045276E01

F040026E02

Page 2701 of 3000

POWER STEERING – RACK AND PINION POWER STEERING GEARPS–33

PS

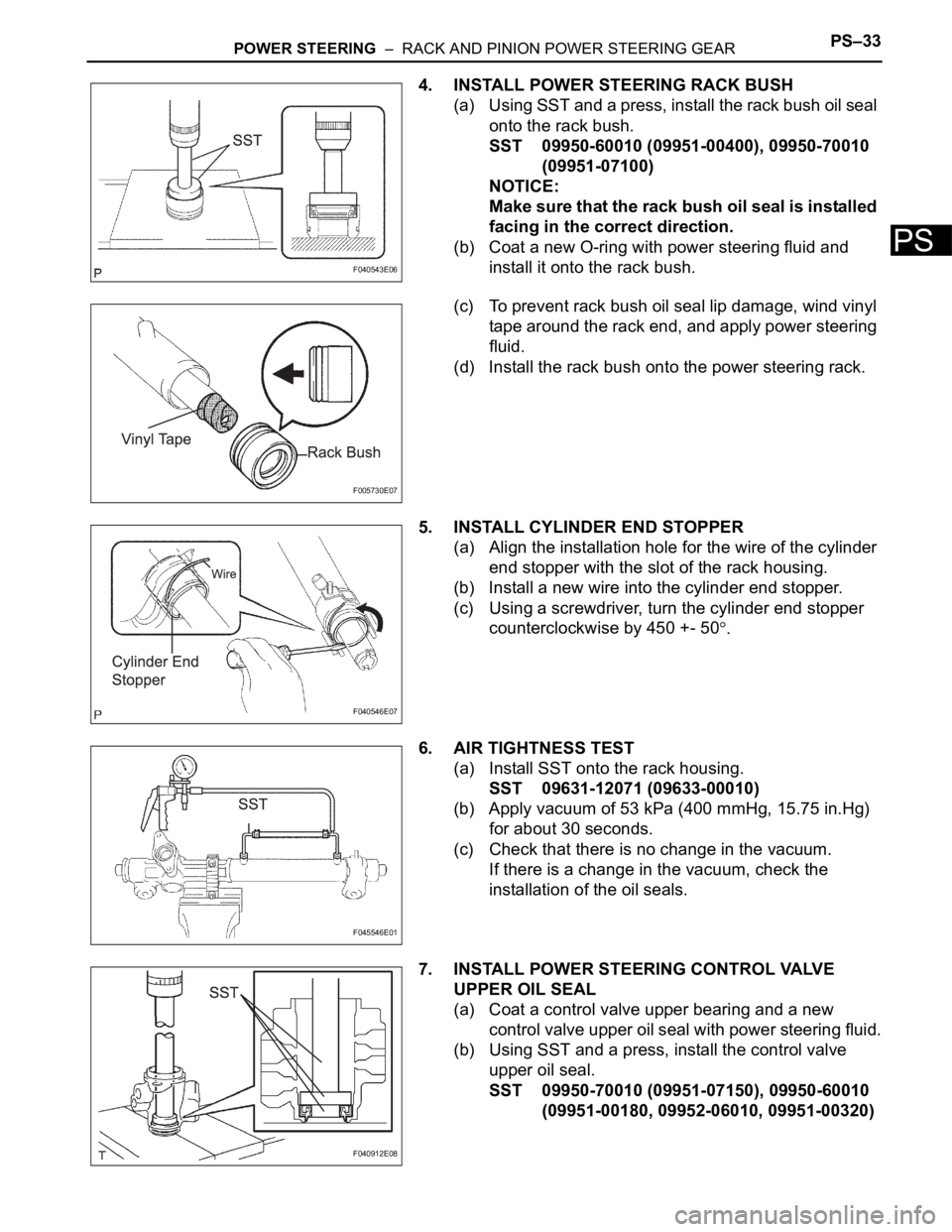

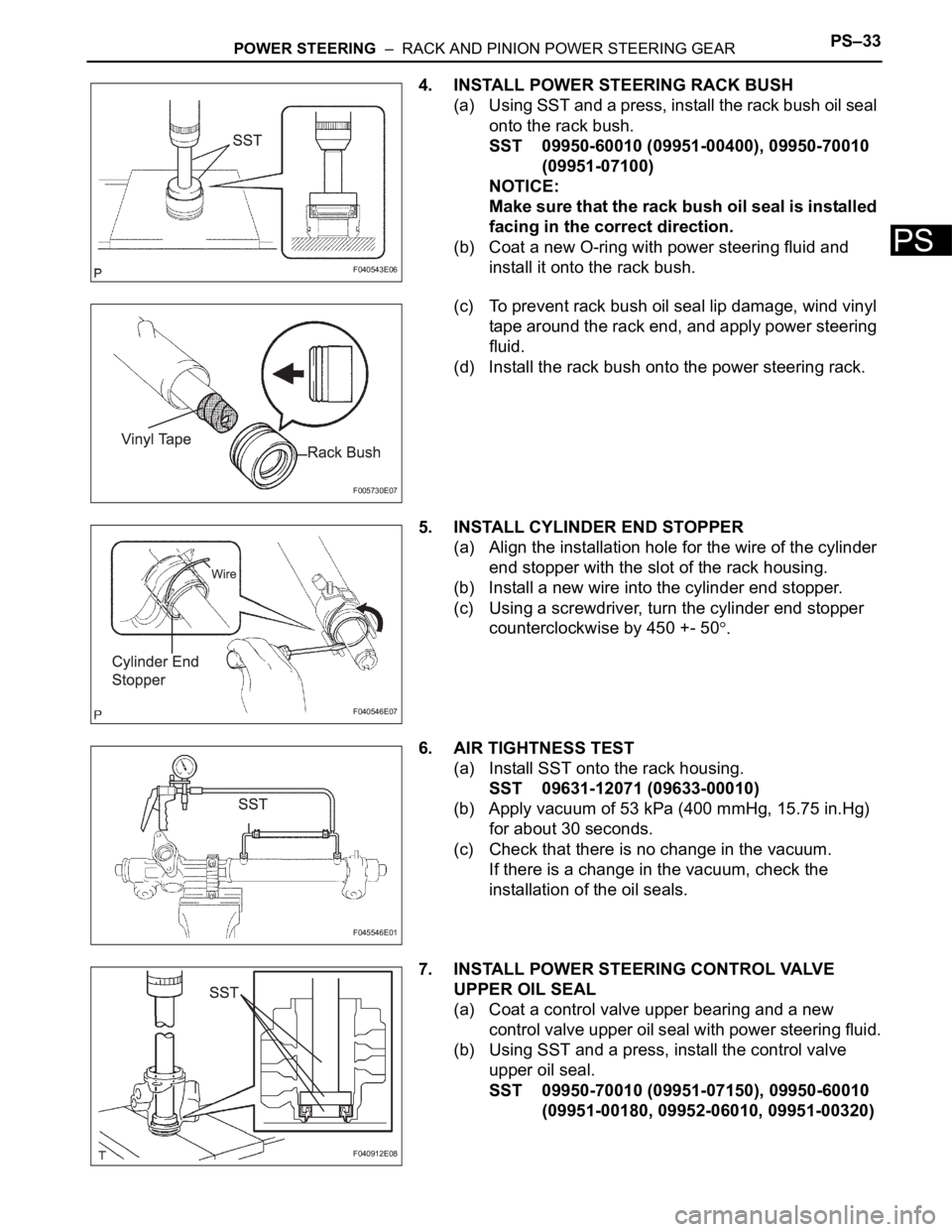

4. INSTALL POWER STEERING RACK BUSH

(a) Using SST and a press, install the rack bush oil seal

onto the rack bush.

SST 09950-60010 (09951-00400), 09950-70010

(09951-07100)

NOTICE:

Make sure that the rack bush oil seal is installed

facing in the correct direction.

(b) Coat a new O-ring with power steering fluid and

install it onto the rack bush.

(c) To prevent rack bush oil seal lip damage, wind vinyl

tape around the rack end, and apply power steering

fluid.

(d) Install the rack bush onto the power steering rack.

5. INSTALL CYLINDER END STOPPER

(a) Align the installation hole for the wire of the cylinder

end stopper with the slot of the rack housing.

(b) Install a new wire into the cylinder end stopper.

(c) Using a screwdriver, turn the cylinder end stopper

counterclockwise by 450 +- 50

.

6. AIR TIGHTNESS TEST

(a) Install SST onto the rack housing.

SST 09631-12071 (09633-00010)

(b) Apply vacuum of 53 kPa (400 mmHg, 15.75 in.Hg)

for about 30 seconds.

(c) Check that there is no change in the vacuum.

If there is a change in the vacuum, check the

installation of the oil seals.

7. INSTALL POWER STEERING CONTROL VALVE

UPPER OIL SEAL

(a) Coat a control valve upper bearing and a new

control valve upper oil seal with power steering fluid.

(b) Using SST and a press, install the control valve

upper oil seal.

SST 09950-70010 (09951-07150), 09950-60010

(09951-00180, 09952-06010, 09951-00320)

F040543E06

F005730E07

F040546E07

F045546E01

F040912E08

Page 2725 of 3000

PS–14POWER STEERING – VANE PUMP

PS

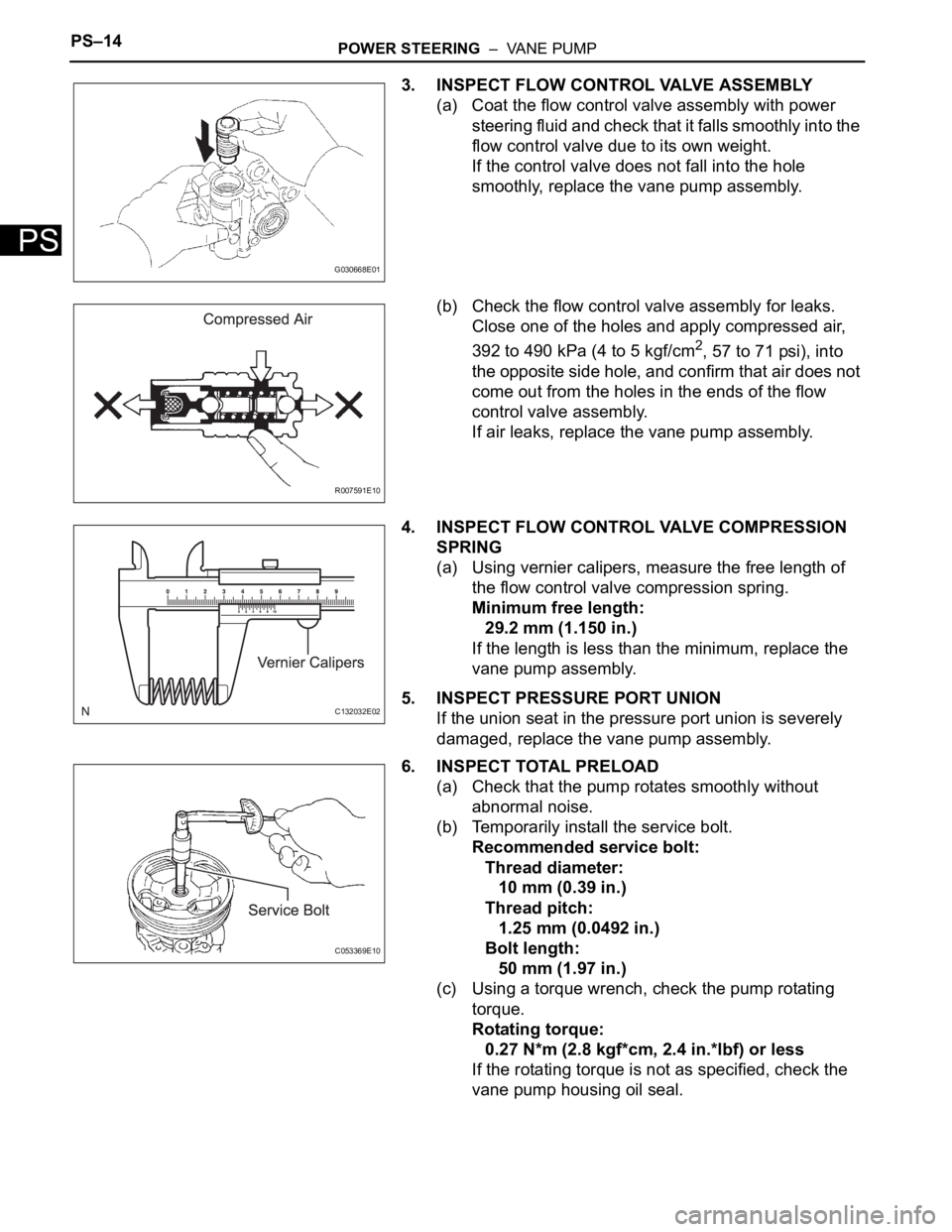

3. INSPECT FLOW CONTROL VALVE ASSEMBLY

(a) Coat the flow control valve assembly with power

steering fluid and check that it falls smoothly into the

flow control valve due to its own weight.

If the control valve does not fall into the hole

smoothly, replace the vane pump assembly.

(b) Check the flow control valve assembly for leaks.

Close one of the holes and apply compressed air,

392 to 490 kPa (4 to 5 kgf/cm

2, 57 to 71 psi), into

the opposite side hole, and confirm that air does not

come out from the holes in the ends of the flow

control valve assembly.

If air leaks, replace the vane pump assembly.

4. INSPECT FLOW CONTROL VALVE COMPRESSION

SPRING

(a) Using vernier calipers, measure the free length of

the flow control valve compression spring.

Minimum free length:

29.2 mm (1.150 in.)

If the length is less than the minimum, replace the

vane pump assembly.

5. INSPECT PRESSURE PORT UNION

If the union seat in the pressure port union is severely

damaged, replace the vane pump assembly.

6. INSPECT TOTAL PRELOAD

(a) Check that the pump rotates smoothly without

abnormal noise.

(b) Temporarily install the service bolt.

Recommended service bolt:

Thread diameter:

10 mm (0.39 in.)

Thread pitch:

1.25 mm (0.0492 in.)

Bolt length:

50 mm (1.97 in.)

(c) Using a torque wrench, check the pump rotating

torque.

Rotating torque:

0.27 N*m (2.8 kgf*cm, 2.4 in.*lbf) or less

If the rotating torque is not as specified, check the

vane pump housing oil seal.

G030668E01

R007591E10

C132032E02

C053369E10

Page 2744 of 3000

POWER STEERING – RACK AND PINION POWER STEERING GEARPS–33

PS

4. INSTALL POWER STEERING RACK BUSH

(a) Using SST and a press, install the rack bush oil seal

onto the rack bush.

SST 09950-60010 (09951-00400), 09950-70010

(09951-07100)

NOTICE:

Make sure that the rack bush oil seal is installed

facing in the correct direction.

(b) Coat a new O-ring with power steering fluid and

install it onto the rack bush.

(c) To prevent rack bush oil seal lip damage, wind vinyl

tape around the rack end, and apply power steering

fluid.

(d) Install the rack bush onto the power steering rack.

5. INSTALL CYLINDER END STOPPER

(a) Align the installation hole for the wire of the cylinder

end stopper with the slot of the rack housing.

(b) Install a new wire into the cylinder end stopper.

(c) Using a screwdriver, turn the cylinder end stopper

counterclockwise by 450 +- 50

.

6. AIR TIGHTNESS TEST

(a) Install SST onto the rack housing.

SST 09631-12071 (09633-00010)

(b) Apply vacuum of 53 kPa (400 mmHg, 15.75 in.Hg)

for about 30 seconds.

(c) Check that there is no change in the vacuum.

If there is a change in the vacuum, check the

installation of the oil seals.

7. INSTALL POWER STEERING CONTROL VALVE

UPPER OIL SEAL

(a) Coat a control valve upper bearing and a new

control valve upper oil seal with power steering fluid.

(b) Using SST and a press, install the control valve

upper oil seal.

SST 09950-70010 (09951-07150), 09950-60010

(09951-00180, 09952-06010, 09951-00320)

F040543E06

F005730E07

F040546E07

F045546E01

F040912E08

Page 2915 of 3000

AIR CONDITIONING – REFRIGERANTAC–171

AC

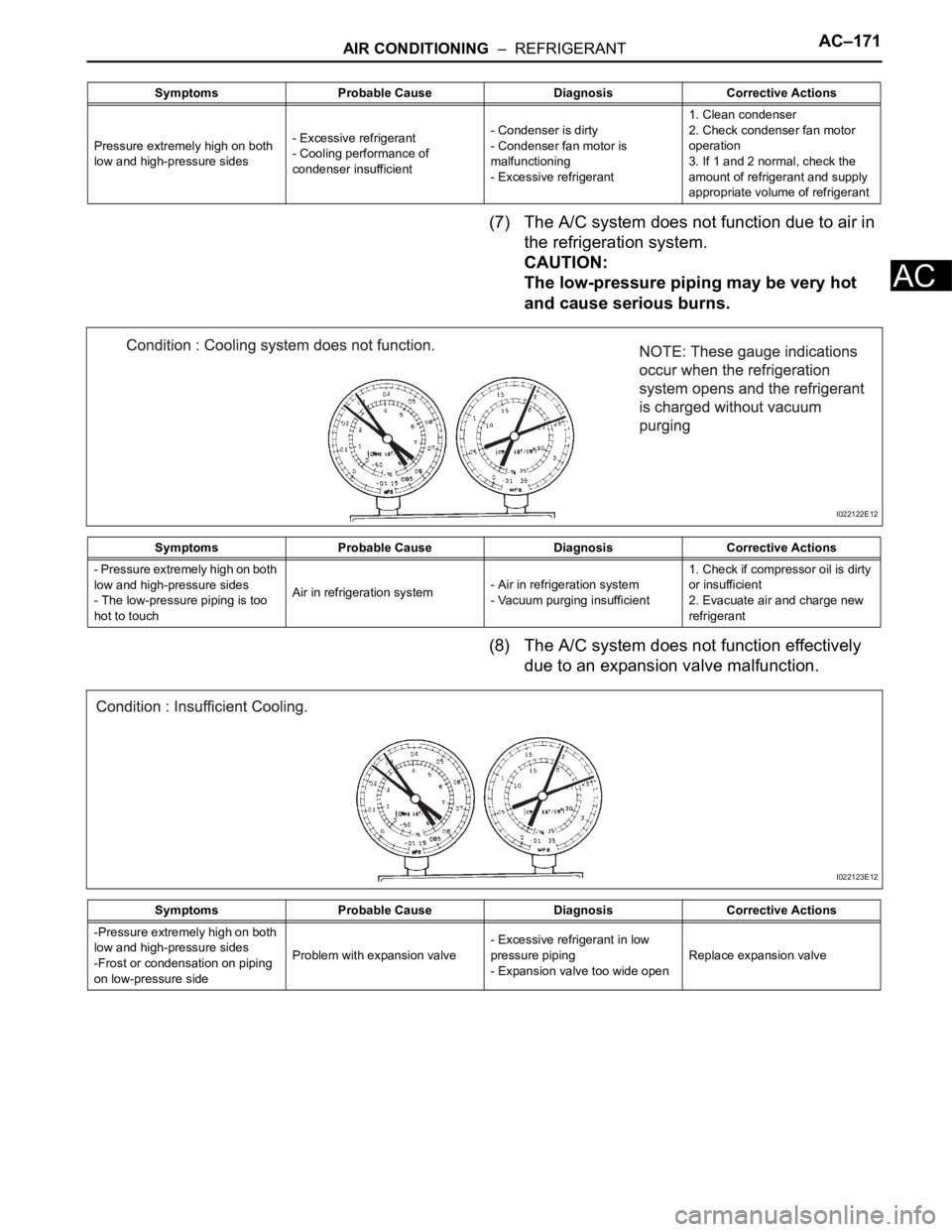

(7) The A/C system does not function due to air in

the refrigeration system.

CAUTION:

The low-pressure piping may be very hot

and cause serious burns.

(8) The A/C system does not function effectively

due to an expansion valve malfunction.

Symptoms Probable Cause Diagnosis Corrective Actions

Pressure extremely high on both

low and high-pressure sides- Excessive refrigerant

- Cooling performance of

condenser insufficient- Condenser is dirty

- Condenser fan motor is

malfunctioning

- Excessive refrigerant1. Clean condenser

2. Check condenser fan motor

operation

3. If 1 and 2 normal, check the

amount of refrigerant and supply

appropriate volume of refrigerant

Symptoms Probable Cause Diagnosis Corrective Actions

- Pressure extremely high on both

low and high-pressure sides

- The low-pressure piping is too

hot to touchAir in refrigeration system- Air in refrigeration system

- Vacuum purging insufficient1. Check if compressor oil is dirty

or insufficient

2. Evacuate air and charge new

refrigerant

I022122E12

Symptoms Probable Cause Diagnosis Corrective Actions

-Pressure extremely high on both

low and high-pressure sides

-Frost or condensation on piping

on low-pressure sideProblem with expansion valve- Excessive refrigerant in low

pressure piping

- Expansion valve too wide openReplace expansion valve

I022123E12

Page 2917 of 3000

AIR CONDITIONING – REFRIGERANTAC–173

AC

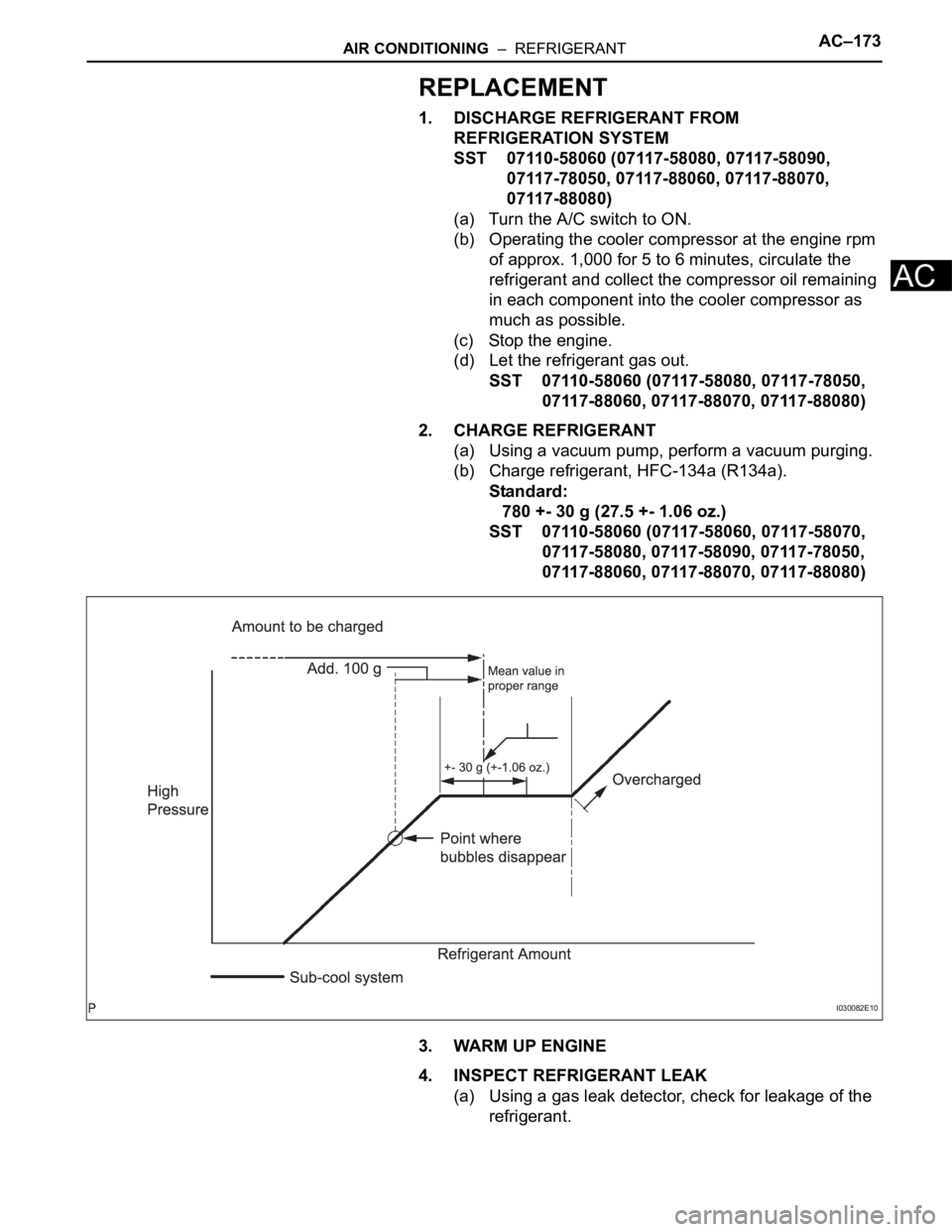

REPLACEMENT

1. DISCHARGE REFRIGERANT FROM

REFRIGERATION SYSTEM

SST 07110-58060 (07117-58080, 07117-58090,

07117-78050, 07117-88060, 07117-88070,

07117-88080)

(a) Turn the A/C switch to ON.

(b) Operating the cooler compressor at the engine rpm

of approx. 1,000 for 5 to 6 minutes, circulate the

refrigerant and collect the compressor oil remaining

in each component into the cooler compressor as

much as possible.

(c) Stop the engine.

(d) Let the refrigerant gas out.

SST 07110-58060 (07117-58080, 07117-78050,

07117-88060, 07117-88070, 07117-88080)

2. CHARGE REFRIGERANT

(a) Using a vacuum pump, perform a vacuum purging.

(b) Charge refrigerant, HFC-134a (R134a).

Standard:

780 +- 30 g (27.5 +- 1.06 oz.)

SST 07110-58060 (07117-58060, 07117-58070,

07117-58080, 07117-58090, 07117-78050,

07117-88060, 07117-88070, 07117-88080)

3. WARM UP ENGINE

4. INSPECT REFRIGERANT LEAK

(a) Using a gas leak detector, check for leakage of the

refrigerant.

I030082E10

Page 2956 of 3000

AC–230AIR CONDITIONING – COMPRESSOR AND MAGNETIC CLUTCH

AC

2. INSPECT COMPRESSOR OIL

(a) When replacing the compressor and magnetic

clutch with a new one, after gradually removing the

refrigerant gas from the service valve, drain the

following amount of oil from the new compressor

and magnetic clutch before installation.

Standard:

(Oil capacity inside new compressor and

magnetic clutch:

225 + 15 cc (7.6 + 0.5 fl.oz.)) - (Remaining oil

amount in the removed compressor and

magnetic clutch) = (Oil amount to be

removed when replacing)

NOTICE:

• When checking the compressor oil level,

observe the precautions on the cooler

removal / installation.

• Because compressor oil remains in the pipes

of the vehicle, if a new compressor and

magnetic clutch is installed without removing

some oil inside, the oil amount becomes

excessive, preventing heat exchange in the

refrigerant cycle and causing refrigerant

failure.

• If the remaining oil in the removed

compressor and magnetic clutch is too small

in volume, check for oil leakage.

• Be sure to use ND-OIL 8 for compressor oil.

3. INSPECT COMPRESSOR AND MAGNETIC CLUTCH

(a) Disconnect the connector from the compressor and

magnetic clutch.

E145186E03

Page 2970 of 3000

AC–230AIR CONDITIONING – COMPRESSOR AND MAGNETIC CLUTCH

AC

2. INSPECT COMPRESSOR OIL

(a) When replacing the compressor and magnetic

clutch with a new one, after gradually removing the

refrigerant gas from the service valve, drain the

following amount of oil from the new compressor

and magnetic clutch before installation.

Standard:

(Oil capacity inside new compressor and

magnetic clutch:

225 + 15 cc (7.6 + 0.5 fl.oz.)) - (Remaining oil

amount in the removed compressor and

magnetic clutch) = (Oil amount to be

removed when replacing)

NOTICE:

• When checking the compressor oil level,

observe the precautions on the cooler

removal / installation.

• Because compressor oil remains in the pipes

of the vehicle, if a new compressor and

magnetic clutch is installed without removing

some oil inside, the oil amount becomes

excessive, preventing heat exchange in the

refrigerant cycle and causing refrigerant

failure.

• If the remaining oil in the removed

compressor and magnetic clutch is too small

in volume, check for oil leakage.

• Be sure to use ND-OIL 8 for compressor oil.

3. INSPECT COMPRESSOR AND MAGNETIC CLUTCH

(a) Disconnect the connector from the compressor and

magnetic clutch.

E145186E03