coolant TOYOTA SIENNA 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 376 of 3000

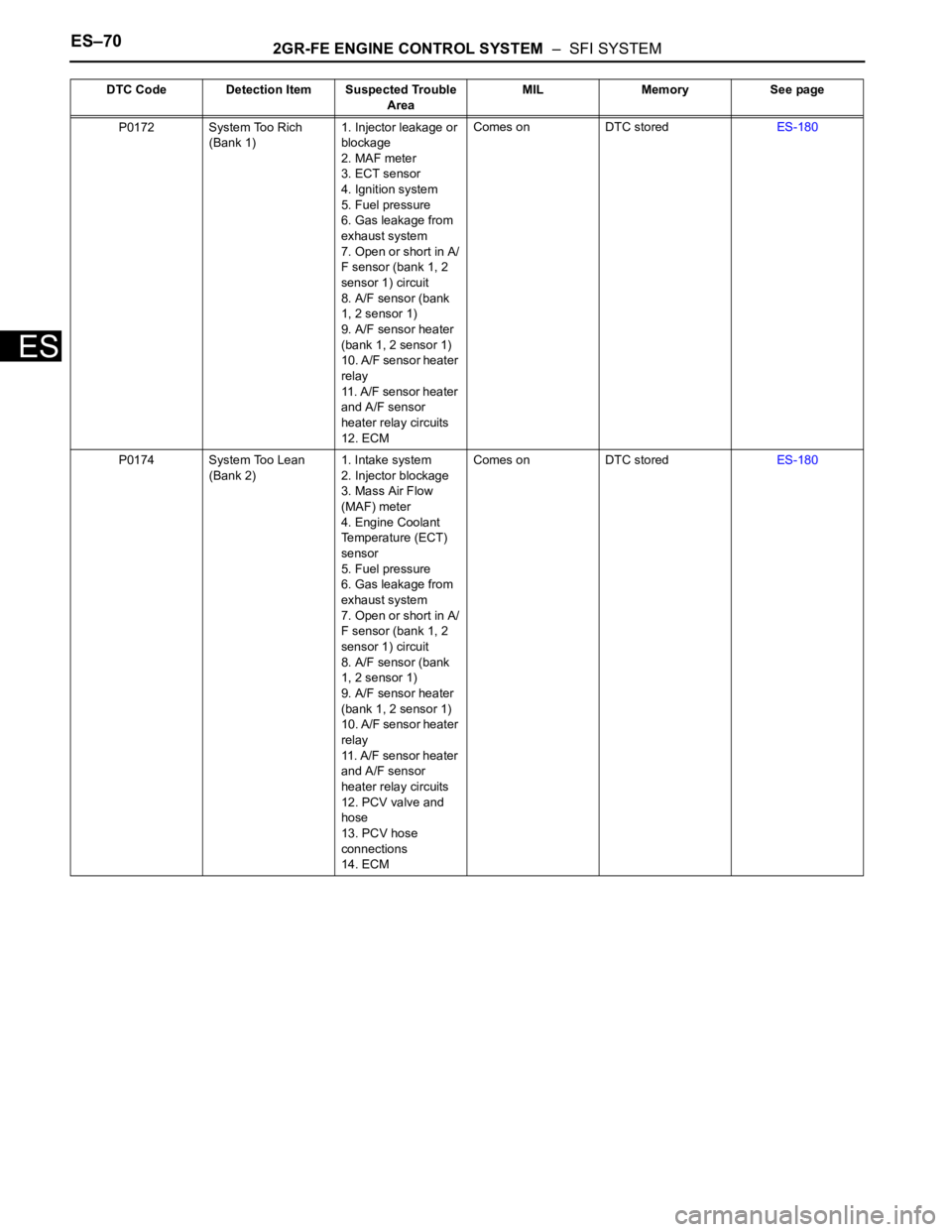

ES–702GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

P0172 System Too Rich

(Bank 1)1. Injector leakage or

blockage

2. MAF meter

3. ECT sensor

4. Ignition system

5. Fuel pressure

6. Gas leakage from

exhaust system

7. Open or short in A/

F sensor (bank 1, 2

sensor 1) circuit

8. A/F sensor (bank

1, 2 sensor 1)

9. A/F sensor heater

(bank 1, 2 sensor 1)

10. A/F sensor heater

relay

11. A/F sensor heater

and A/F sensor

heater relay circuits

12. ECMComes on DTC storedES-180

P0174 System Too Lean

(Bank 2)1. Intake system

2. Injector blockage

3. Mass Air Flow

(MAF) meter

4. Engine Coolant

Temperature (ECT)

sensor

5. Fuel pressure

6. Gas leakage from

exhaust system

7. Open or short in A/

F sensor (bank 1, 2

sensor 1) circuit

8. A/F sensor (bank

1, 2 sensor 1)

9. A/F sensor heater

(bank 1, 2 sensor 1)

10. A/F sensor heater

relay

11. A/F sensor heater

and A/F sensor

heater relay circuits

12. PCV valve and

hose

13. PCV hose

connections

14. ECMComes on DTC storedES-180 DTC Code Detection Item Suspected Trouble

AreaMIL Memory See page

Page 378 of 3000

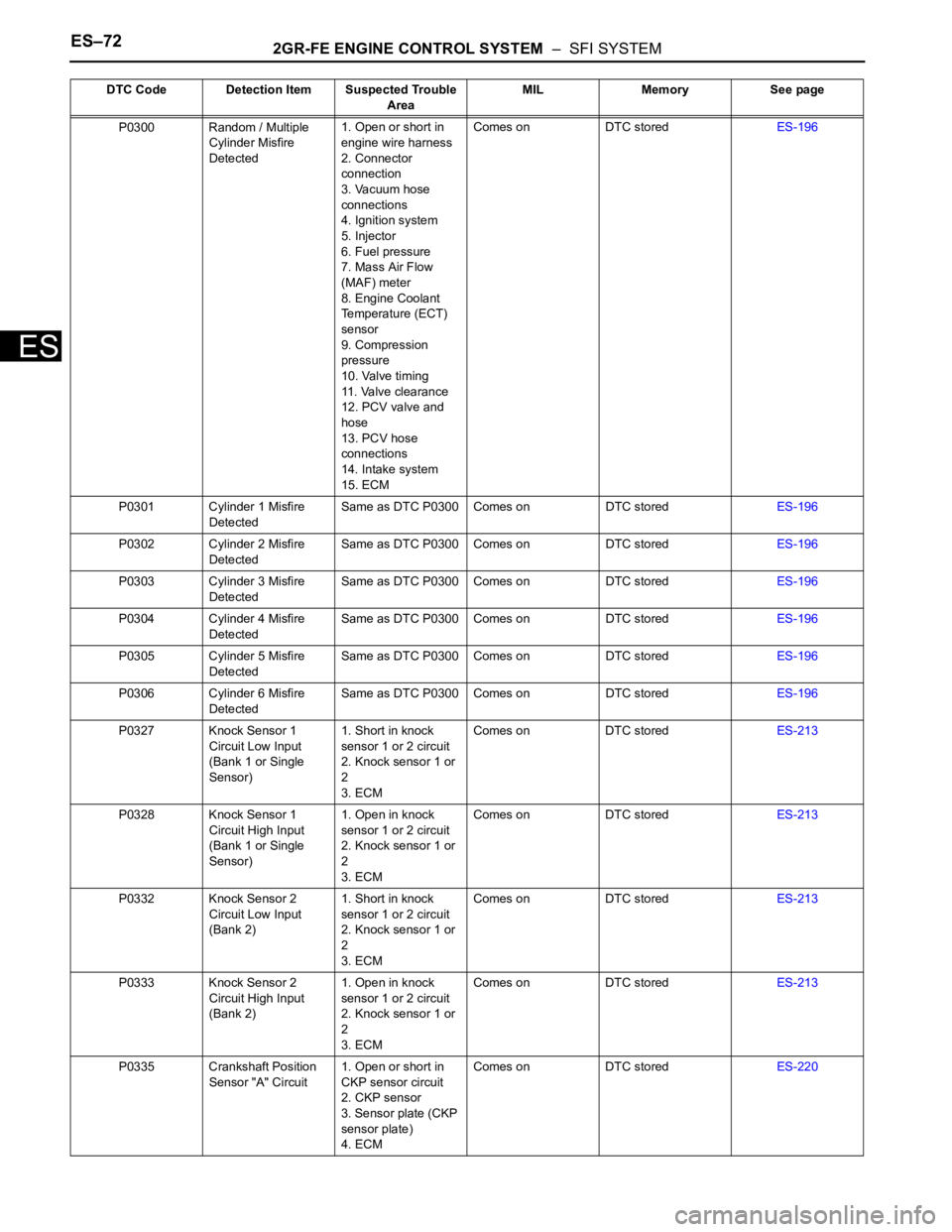

ES–722GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

P0300 Random / Multiple

Cylinder Misfire

Detected1. Open or short in

engine wire harness

2. Connector

connection

3. Vacuum hose

connections

4. Ignition system

5. Injector

6. Fuel pressure

7. Mass Air Flow

(MAF) meter

8. Engine Coolant

Temperature (ECT)

sensor

9. Compression

pressure

10. Valve timing

11. Valve clearance

12. PCV valve and

hose

13. PCV hose

connections

14. Intake system

15. ECMComes on DTC storedES-196

P0301 Cylinder 1 Misfire

DetectedSame as DTC P0300 Comes on DTC storedES-196

P0302 Cylinder 2 Misfire

DetectedSame as DTC P0300 Comes on DTC storedES-196

P0303 Cylinder 3 Misfire

DetectedSame as DTC P0300 Comes on DTC storedES-196

P0304 Cylinder 4 Misfire

DetectedSame as DTC P0300 Comes on DTC storedES-196

P0305 Cylinder 5 Misfire

DetectedSame as DTC P0300 Comes on DTC storedES-196

P0306 Cylinder 6 Misfire

DetectedSame as DTC P0300 Comes on DTC storedES-196

P0327 Knock Sensor 1

Circuit Low Input

(Bank 1 or Single

Sensor)1. Short in knock

sensor 1 or 2 circuit

2. Knock sensor 1 or

2

3. ECMComes on DTC storedES-213

P0328 Knock Sensor 1

Circuit High Input

(Bank 1 or Single

Sensor)1. Open in knock

sensor 1 or 2 circuit

2. Knock sensor 1 or

2

3. ECMComes on DTC storedES-213

P0332 Knock Sensor 2

Circuit Low Input

(Bank 2)1. Short in knock

sensor 1 or 2 circuit

2. Knock sensor 1 or

2

3. ECMComes on DTC storedES-213

P0333 Knock Sensor 2

Circuit High Input

(Bank 2)1. Open in knock

sensor 1 or 2 circuit

2. Knock sensor 1 or

2

3. ECMComes on DTC storedES-213

P0335 Crankshaft Position

Sensor "A" Circuit1. Open or short in

CKP sensor circuit

2. CKP sensor

3. Sensor plate (CKP

sensor plate)

4. ECMComes on DTC storedES-220 DTC Code Detection Item Suspected Trouble

AreaMIL Memory See page

Page 389 of 3000

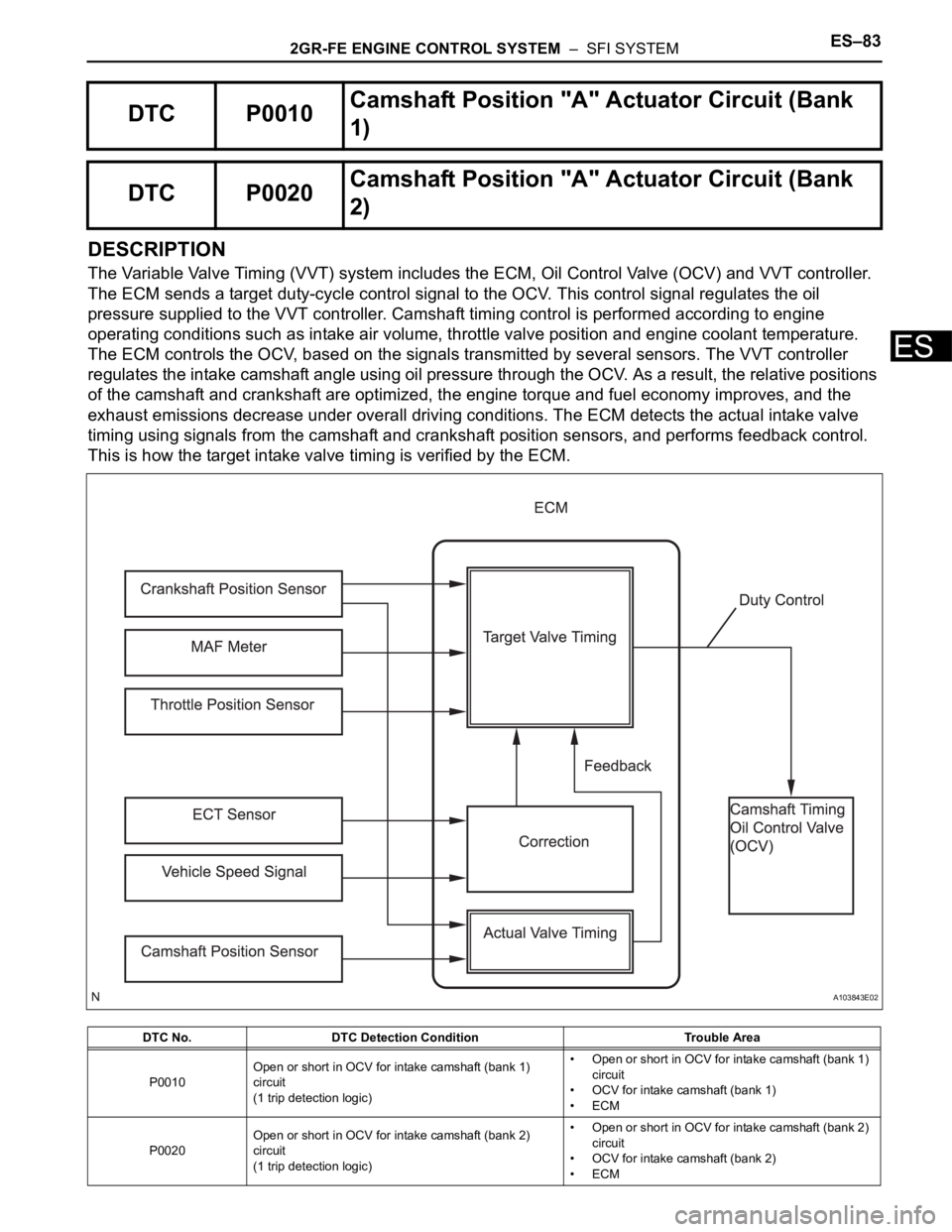

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–83

ES

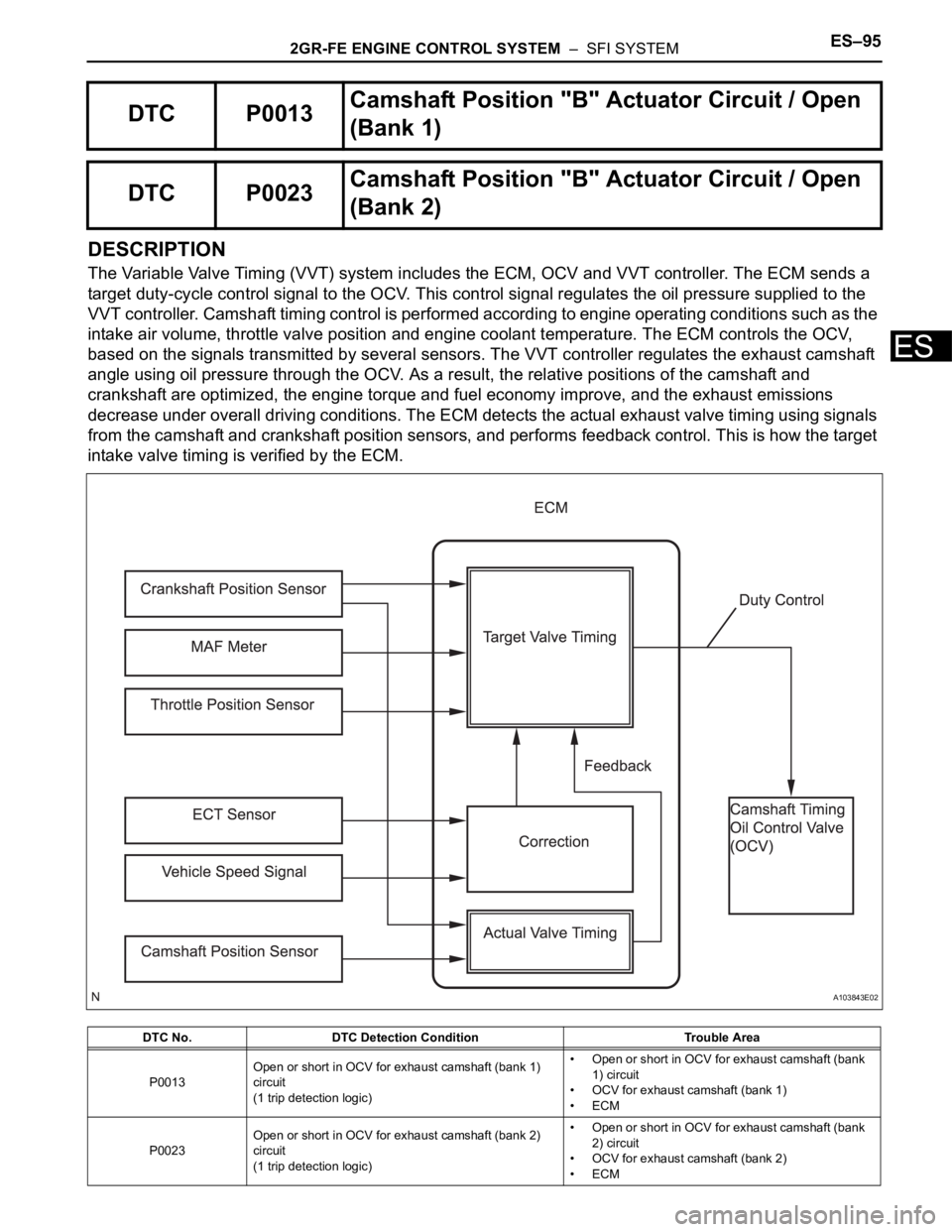

DESCRIPTION

The Variable Valve Timing (VVT) system includes the ECM, Oil Control Valve (OCV) and VVT controller.

The ECM sends a target duty-cycle control signal to the OCV. This control signal regulates the oil

pressure supplied to the VVT controller. Camshaft timing control is performed according to engine

operating conditions such as intake air volume, throttle valve position and engine coolant temperature.

The ECM controls the OCV, based on the signals transmitted by several sensors. The VVT controller

regulates the intake camshaft angle using oil pressure through the OCV. As a result, the relative positions

of the camshaft and crankshaft are optimized, the engine torque and fuel economy improves, and the

exhaust emissions decrease under overall driving conditions. The ECM detects the actual intake valve

timing using signals from the camshaft and crankshaft position sensors, and performs feedback control.

This is how the target intake valve timing is verified by the ECM.

DTC P0010Camshaft Position "A" Actuator Circuit (Bank

1)

DTC P0020Camshaft Position "A" Actuator Circuit (Bank

2)

DTC No. DTC Detection Condition Trouble Area

P0010Open or short in OCV for intake camshaft (bank 1)

circuit

(1 trip detection logic)• Open or short in OCV for intake camshaft (bank 1)

circuit

• OCV for intake camshaft (bank 1)

•ECM

P0020Open or short in OCV for intake camshaft (bank 2)

circuit

(1 trip detection logic)• Open or short in OCV for intake camshaft (bank 2)

circuit

• OCV for intake camshaft (bank 2)

•ECM

A103843E02

Page 395 of 3000

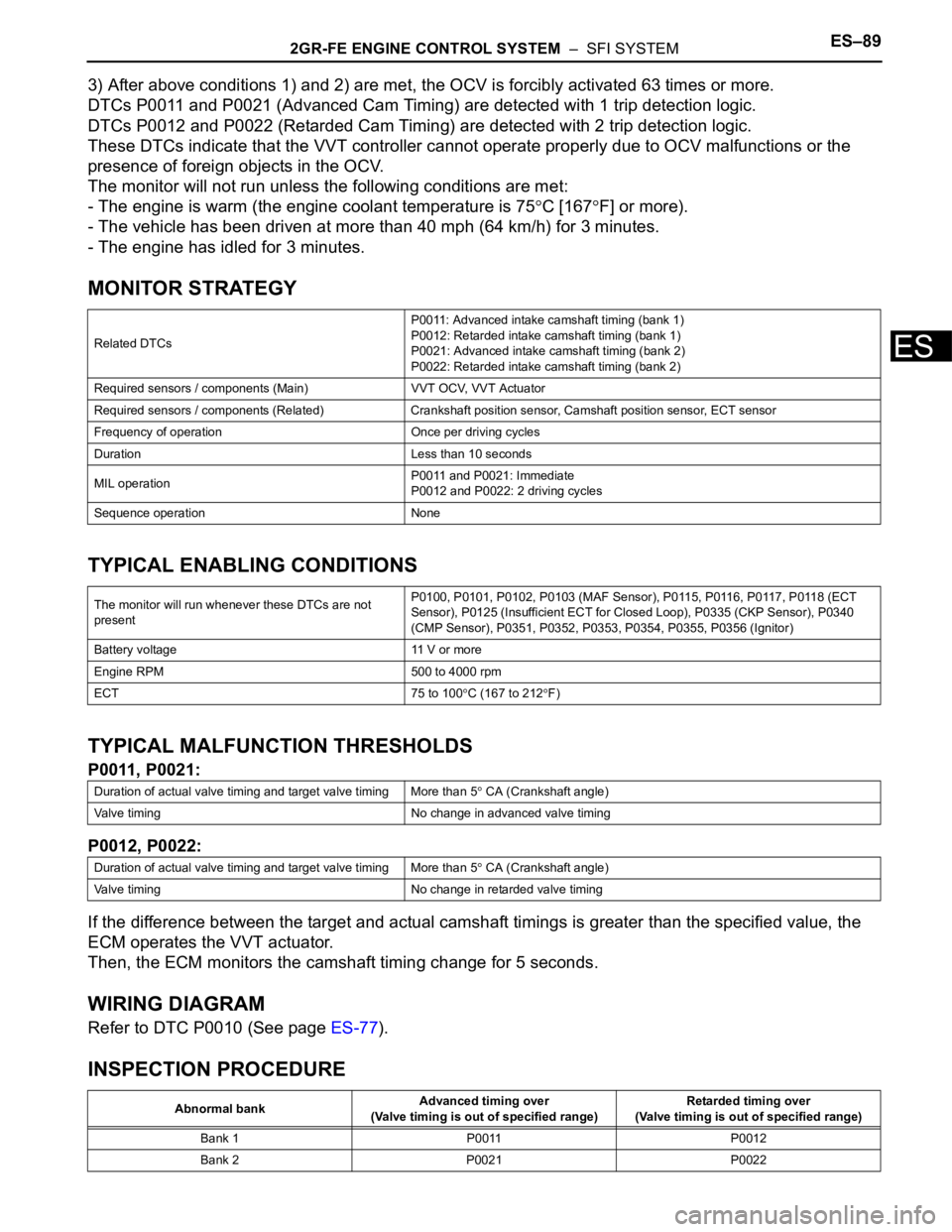

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–89

ES

3) After above conditions 1) and 2) are met, the OCV is forcibly activated 63 times or more.

DTCs P0011 and P0021 (Advanced Cam Timing) are detected with 1 trip detection logic.

DTCs P0012 and P0022 (Retarded Cam Timing) are detected with 2 trip detection logic.

These DTCs indicate that the VVT controller cannot operate properly due to OCV malfunctions or the

presence of foreign objects in the OCV.

The monitor will not run unless the following conditions are met:

- The engine is warm (the engine coolant temperature is 75

C [167F] or more).

- The vehicle has been driven at more than 40 mph (64 km/h) for 3 minutes.

- The engine has idled for 3 minutes.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

P0011, P0021:

P0012, P0022:

If the difference between the target and actual camshaft timings is greater than the specified value, the

ECM operates the VVT actuator.

Then, the ECM monitors the camshaft timing change for 5 seconds.

WIRING DIAGRAM

Refer to DTC P0010 (See page ES-77).

INSPECTION PROCEDURE

Related DTCsP0011: Advanced intake camshaft timing (bank 1)

P0012: Retarded intake camshaft timing (bank 1)

P0021: Advanced intake camshaft timing (bank 2)

P0022: Retarded intake camshaft timing (bank 2)

Required sensors / components (Main) VVT OCV, VVT Actuator

Required sensors / components (Related) Crankshaft position sensor, Camshaft position sensor, ECT sensor

Frequency of operation Once per driving cycles

Duration Less than 10 seconds

MIL operationP0011 and P0021: Immediate

P0012 and P0022: 2 driving cycles

Sequence operation None

The monitor will run whenever these DTCs are not

presentP0100, P0101, P0102, P0103 (MAF Sensor), P0115, P0116, P0117, P0118 (ECT

Sensor), P0125 (Insufficient ECT for Closed Loop), P0335 (CKP Sensor), P0340

(CMP Sensor), P0351, P0352, P0353, P0354, P0355, P0356 (Ignitor)

Battery voltage 11 V or more

Engine RPM 500 to 4000 rpm

ECT 75 to 100

C (167 to 212F)

Duration of actual valve timing and target valve timing More than 5

CA (Crankshaft angle)

Valve timing No change in advanced valve timing

Duration of actual valve timing and target valve timing More than 5

CA (Crankshaft angle)

Valve timing No change in retarded valve timing

Abnormal bankAdvanced timing over

(Valve timing is out of specified range)Retarded timing over

(Valve timing is out of specified range)

Bank 1 P0011 P0012

Bank 2 P0021 P0022

Page 401 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–95

ES

DESCRIPTION

The Variable Valve Timing (VVT) system includes the ECM, OCV and VVT controller. The ECM sends a

target duty-cycle control signal to the OCV. This control signal regulates the oil pressure supplied to the

VVT controller. Camshaft timing control is performed according to engine operating conditions such as the

intake air volume, throttle valve position and engine coolant temperature. The ECM controls the OCV,

based on the signals transmitted by several sensors. The VVT controller regulates the exhaust camshaft

angle using oil pressure through the OCV. As a result, the relative positions of the camshaft and

crankshaft are optimized, the engine torque and fuel economy improve, and the exhaust emissions

decrease under overall driving conditions. The ECM detects the actual exhaust valve timing using signals

from the camshaft and crankshaft position sensors, and performs feedback control. This is how the target

intake valve timing is verified by the ECM.

DTC P0013Camshaft Position "B" Actuator Circuit / Open

(Bank 1)

DTC P0023Camshaft Position "B" Actuator Circuit / Open

(Bank 2)

DTC No. DTC Detection Condition Trouble Area

P0013Open or short in OCV for exhaust camshaft (bank 1)

circuit

(1 trip detection logic)• Open or short in OCV for exhaust camshaft (bank

1) circuit

• OCV for exhaust camshaft (bank 1)

•ECM

P0023Open or short in OCV for exhaust camshaft (bank 2)

circuit

(1 trip detection logic)• Open or short in OCV for exhaust camshaft (bank

2) circuit

• OCV for exhaust camshaft (bank 2)

•ECM

A103843E02

Page 407 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–101

ES

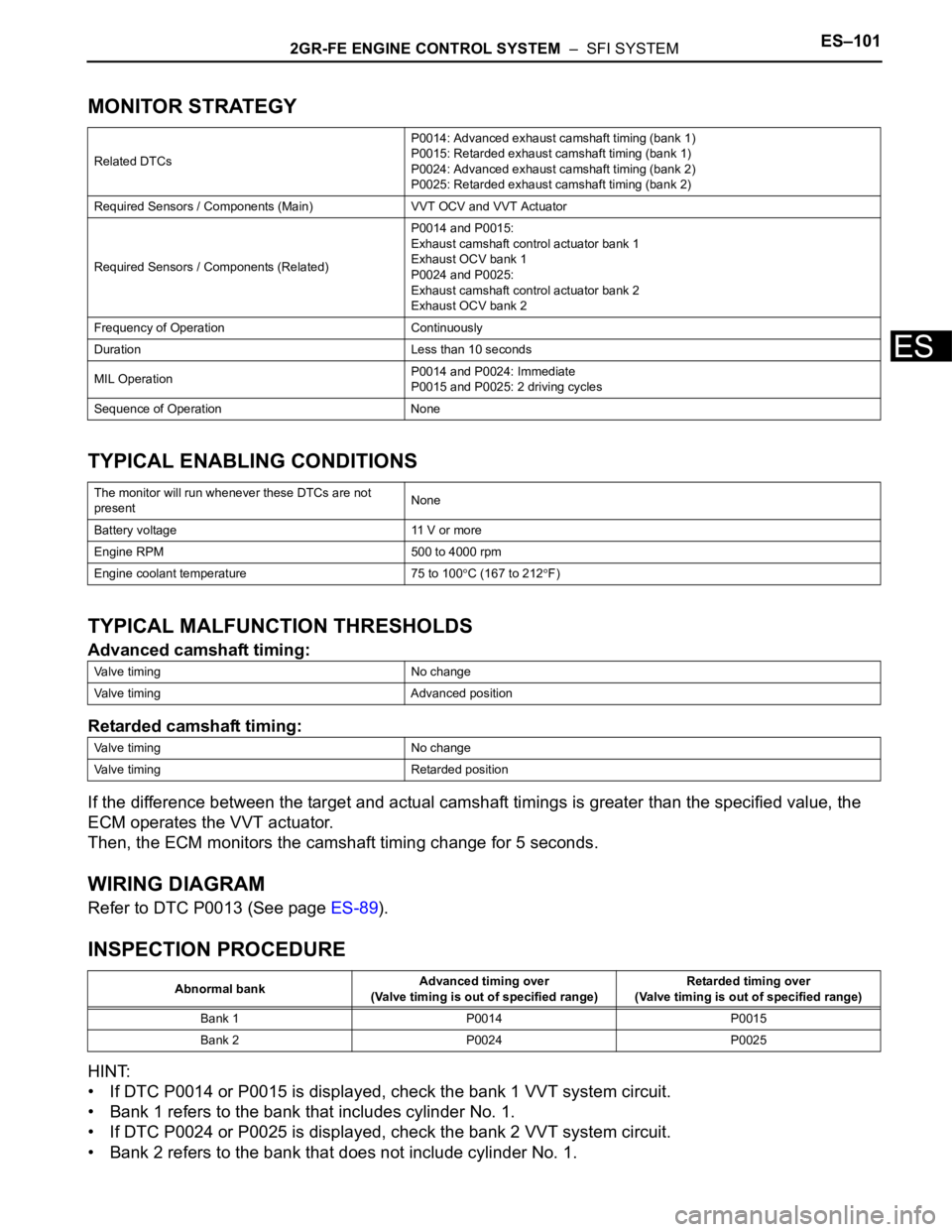

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

Advanced camshaft timing:

Retarded camshaft timing:

If the difference between the target and actual camshaft timings is greater than the specified value, the

ECM operates the VVT actuator.

Then, the ECM monitors the camshaft timing change for 5 seconds.

WIRING DIAGRAM

Refer to DTC P0013 (See page ES-89).

INSPECTION PROCEDURE

HINT:

• If DTC P0014 or P0015 is displayed, check the bank 1 VVT system circuit.

• Bank 1 refers to the bank that includes cylinder No. 1.

• If DTC P0024 or P0025 is displayed, check the bank 2 VVT system circuit.

• Bank 2 refers to the bank that does not include cylinder No. 1.

Related DTCsP0014: Advanced exhaust camshaft timing (bank 1)

P0015: Retarded exhaust camshaft timing (bank 1)

P0024: Advanced exhaust camshaft timing (bank 2)

P0025: Retarded exhaust camshaft timing (bank 2)

Required Sensors / Components (Main) VVT OCV and VVT Actuator

Required Sensors / Components (Related)P0014 and P0015:

Exhaust camshaft control actuator bank 1

Exhaust OCV bank 1

P0024 and P0025:

Exhaust camshaft control actuator bank 2

Exhaust OCV bank 2

Frequency of Operation Continuously

Duration Less than 10 seconds

MIL OperationP0014 and P0024: Immediate

P0015 and P0025: 2 driving cycles

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone

Battery voltage 11 V or more

Engine RPM 500 to 4000 rpm

Engine coolant temperature 75 to 100

C (167 to 212F)

Valve timing No change

Valve timing Advanced position

Valve timing No change

Valve timing Retarded position

Abnormal bankAdvanced timing over

(Valve timing is out of specified range)Retarded timing over

(Valve timing is out of specified range)

Bank 1 P0014 P0015

Bank 2 P0024 P0025

Page 436 of 3000

ES–1302GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

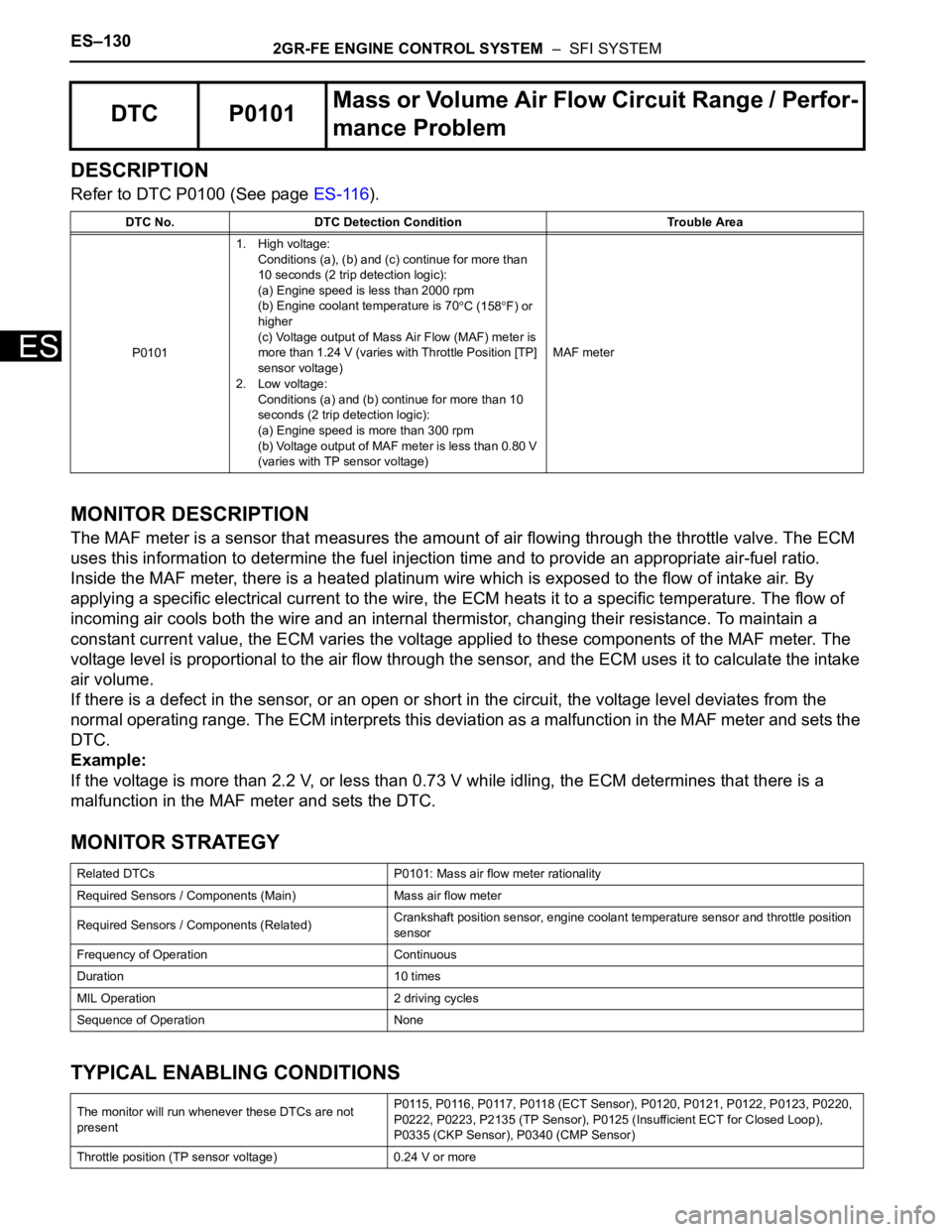

DESCRIPTION

Refer to DTC P0100 (See page ES-116).

MONITOR DESCRIPTION

The MAF meter is a sensor that measures the amount of air flowing through the throttle valve. The ECM

uses this information to determine the fuel injection time and to provide an appropriate air-fuel ratio.

Inside the MAF meter, there is a heated platinum wire which is exposed to the flow of intake air. By

applying a specific electrical current to the wire, the ECM heats it to a specific temperature. The flow of

incoming air cools both the wire and an internal thermistor, changing their resistance. To maintain a

constant current value, the ECM varies the voltage applied to these components of the MAF meter. The

voltage level is proportional to the air flow through the sensor, and the ECM uses it to calculate the intake

air volume.

If there is a defect in the sensor, or an open or short in the circuit, the voltage level deviates from the

normal operating range. The ECM interprets this deviation as a malfunction in the MAF meter and sets the

DTC.

Example:

If the voltage is more than 2.2 V, or less than 0.73 V while idling, the ECM determines that there is a

malfunction in the MAF meter and sets the DTC.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

DTC P0101Mass or Volume Air Flow Circuit Range / Perfor-

mance Problem

DTC No. DTC Detection Condition Trouble Area

P01011. High voltage:

Conditions (a), (b) and (c) continue for more than

10 seconds (2 trip detection logic):

(a) Engine speed is less than 2000 rpm

(b) Engine coolant temperature is 70

C (158F) or

higher

(c) Voltage output of Mass Air Flow (MAF) meter is

more than 1.24 V (varies with Throttle Position [TP]

sensor voltage)

2. Low voltage:

Conditions (a) and (b) continue for more than 10

seconds (2 trip detection logic):

(a) Engine speed is more than 300 rpm

(b) Voltage output of MAF meter is less than 0.80 V

(varies with TP sensor voltage)MAF meter

Related DTCs P0101: Mass air flow meter rationality

Required Sensors / Components (Main) Mass air flow meter

Required Sensors / Components (Related)Crankshaft position sensor, engine coolant temperature sensor and throttle position

sensor

Frequency of Operation Continuous

Duration 10 times

MIL Operation 2 driving cycles

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentP0115, P0116, P0117, P0118 (ECT Sensor), P0120, P0121, P0122, P0123, P0220,

P0222, P0223, P2135 (TP Sensor), P0125 (Insufficient ECT for Closed Loop),

P0335 (CKP Sensor), P0340 (CMP Sensor)

Throttle position (TP sensor voltage) 0.24 V or more

Page 447 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–141

ES

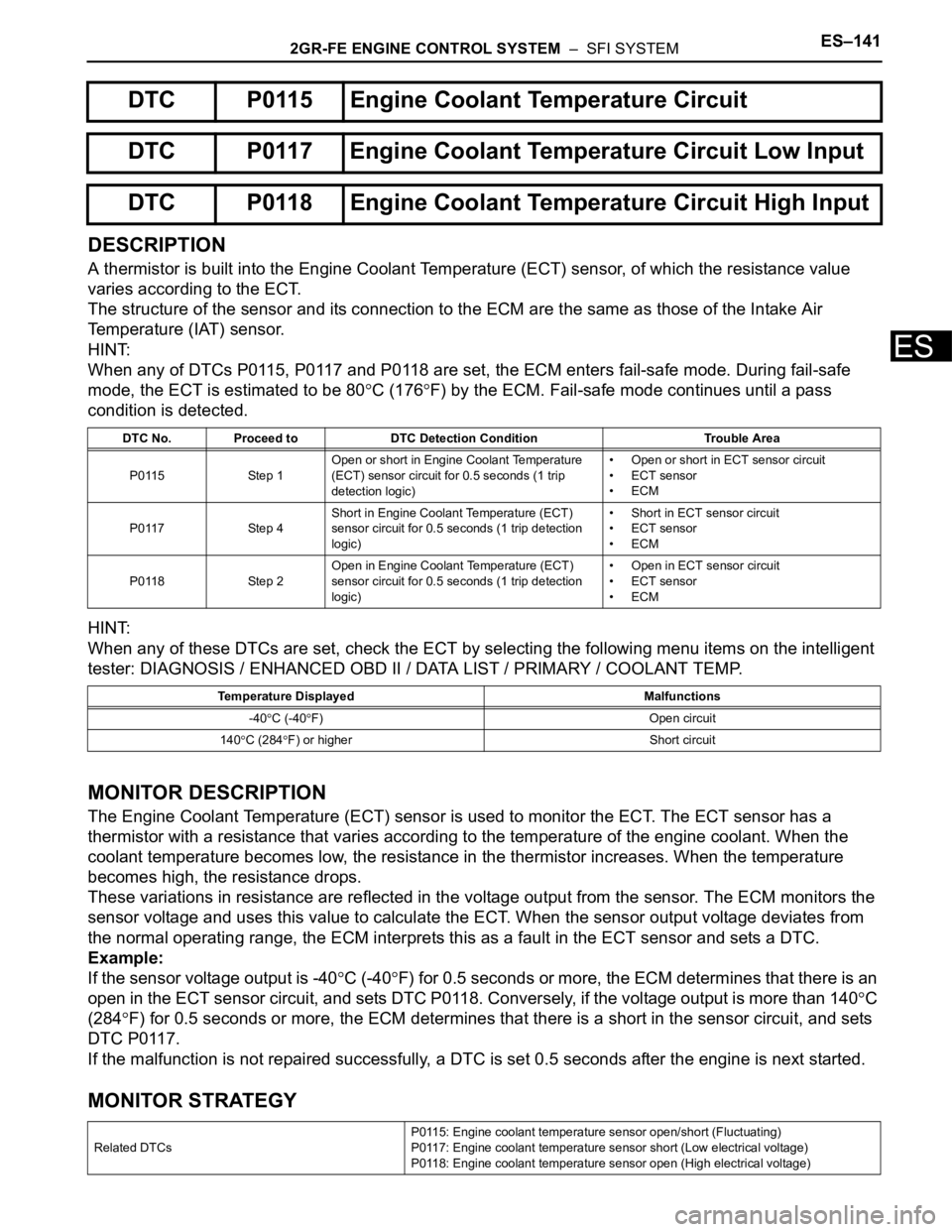

DESCRIPTION

A thermistor is built into the Engine Coolant Temperature (ECT) sensor, of which the resistance value

varies according to the ECT.

The structure of the sensor and its connection to the ECM are the same as those of the Intake Air

Temperature (IAT) sensor.

HINT:

When any of DTCs P0115, P0117 and P0118 are set, the ECM enters fail-safe mode. During fail-safe

mode, the ECT is estimated to be 80

C (176F) by the ECM. Fail-safe mode continues until a pass

condition is detected.

HINT:

When any of these DTCs are set, check the ECT by selecting the following menu items on the intelligent

tester: DIAGNOSIS / ENHANCED OBD II / DATA LIST / PRIMARY / COOLANT TEMP.

MONITOR DESCRIPTION

The Engine Coolant Temperature (ECT) sensor is used to monitor the ECT. The ECT sensor has a

thermistor with a resistance that varies according to the temperature of the engine coolant. When the

coolant temperature becomes low, the resistance in the thermistor increases. When the temperature

becomes high, the resistance drops.

These variations in resistance are reflected in the voltage output from the sensor. The ECM monitors the

sensor voltage and uses this value to calculate the ECT. When the sensor output voltage deviates from

the normal operating range, the ECM interprets this as a fault in the ECT sensor and sets a DTC.

Example:

If the sensor voltage output is -40

C (-40F) for 0.5 seconds or more, the ECM determines that there is an

open in the ECT sensor circuit, and sets DTC P0118. Conversely, if the voltage output is more than 140

C

(284

F) for 0.5 seconds or more, the ECM determines that there is a short in the sensor circuit, and sets

DTC P0117.

If the malfunction is not repaired successfully, a DTC is set 0.5 seconds after the engine is next started.

MONITOR STRATEGY

DTC P0115 Engine Coolant Temperature Circuit

DTC P0117 Engine Coolant Temperature Circuit Low Input

DTC P0118 Engine Coolant Temperature Circuit High Input

DTC No. Proceed to DTC Detection Condition Trouble Area

P0115 Step 1Open or short in Engine Coolant Temperature

(ECT) sensor circuit for 0.5 seconds (1 trip

detection logic)• Open or short in ECT sensor circuit

• ECT sensor

•ECM

P0117 Step 4Short in Engine Coolant Temperature (ECT)

sensor circuit for 0.5 seconds (1 trip detection

logic)• Short in ECT sensor circuit

• ECT sensor

•ECM

P0118 Step 2Open in Engine Coolant Temperature (ECT)

sensor circuit for 0.5 seconds (1 trip detection

logic)• Open in ECT sensor circuit

• ECT sensor

•ECM

Temperature Displayed Malfunctions

-40

C (-40F) Open circuit

140

C (284F) or higher Short circuit

Related DTCsP0115: Engine coolant temperature sensor open/short (Fluctuating)

P0117: Engine coolant temperature sensor short (Low electrical voltage)

P0118: Engine coolant temperature sensor open (High electrical voltage)

Page 448 of 3000

ES–1422GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

P0115:

P0117:

P0118:

COMPONENT OPERATING RANGE

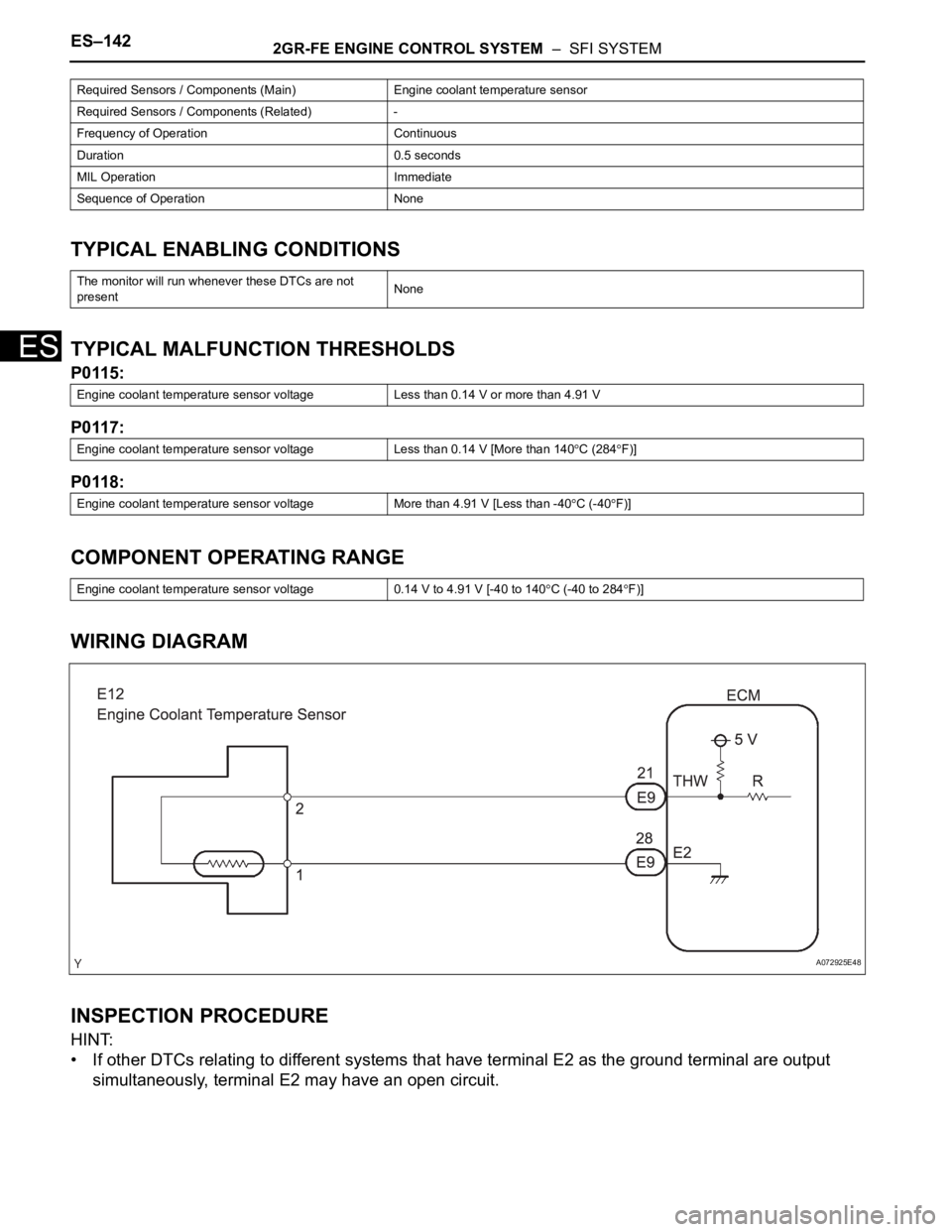

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

• If other DTCs relating to different systems that have terminal E2 as the ground terminal are output

simultaneously, terminal E2 may have an open circuit.

Required Sensors / Components (Main) Engine coolant temperature sensor

Required Sensors / Components (Related) -

Frequency of Operation Continuous

Duration 0.5 seconds

MIL Operation Immediate

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone

Engine coolant temperature sensor voltage Less than 0.14 V or more than 4.91 V

Engine coolant temperature sensor voltage Less than 0.14 V [More than 140

C (284F)]

Engine coolant temperature sensor voltage More than 4.91 V [Less than -40

C (-40F)]

Engine coolant temperature sensor voltage 0.14 V to 4.91 V [-40 to 140

C (-40 to 284F)]

A072925E48

Page 449 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–143

ES

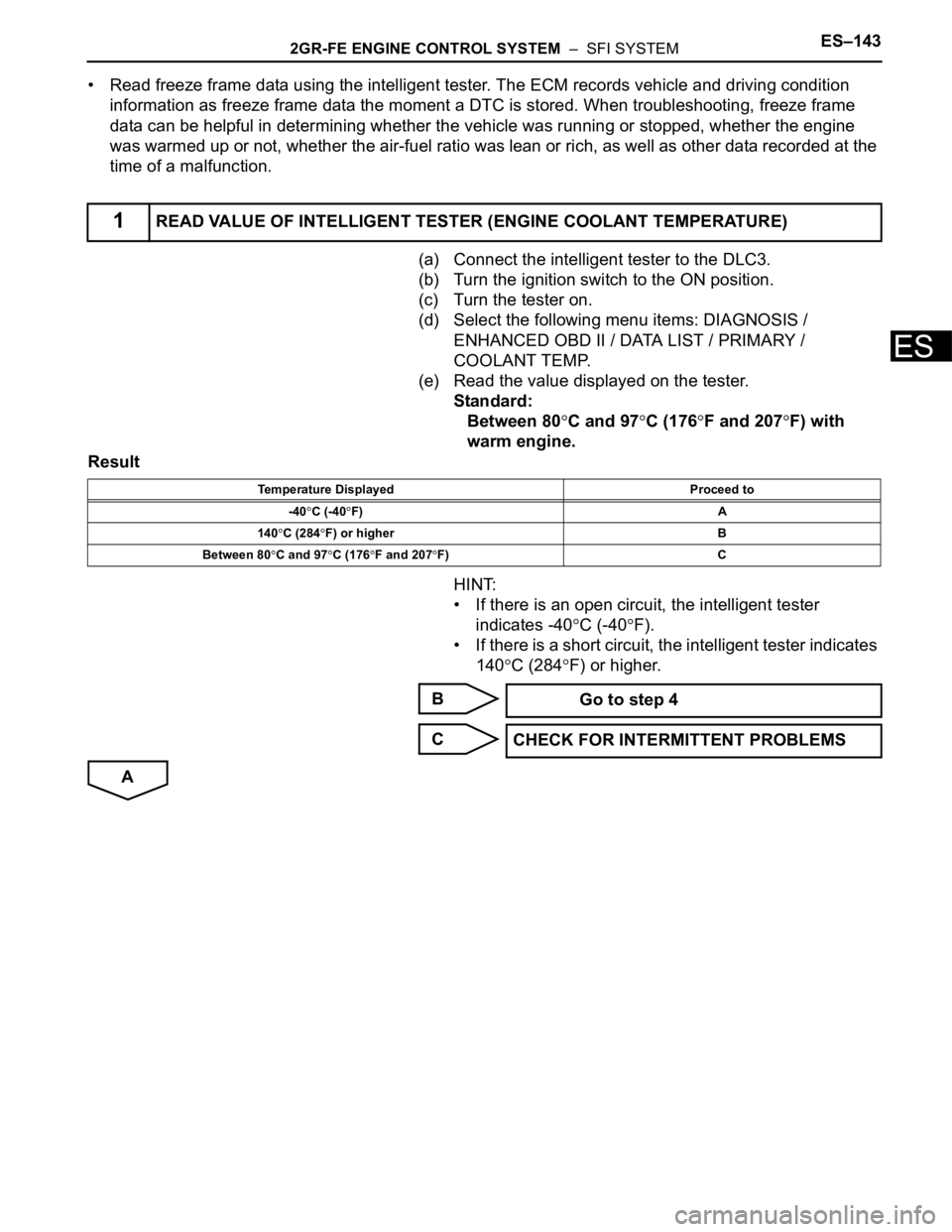

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the

time of a malfunction.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DATA LIST / PRIMARY /

COOLANT TEMP.

(e) Read the value displayed on the tester.

Standard:

Between 80

C and 97C (176F and 207F) with

warm engine.

Result

HINT:

• If there is an open circuit, the intelligent tester

indicates -40

C (-40F).

• If there is a short circuit, the intelligent tester indicates

140

C (284F) or higher.

B

C

A

1READ VALUE OF INTELLIGENT TESTER (ENGINE COOLANT TEMPERATURE)

Temperature Displayed Proceed to

-40

C (-40F) A

140

C (284F) or higher B

Between 80

C and 97C (176F and 207F) C

Go to step 4

CHECK FOR INTERMITTENT PROBLEMS