coolant TOYOTA SIENNA 2007 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 328 of 3000

ES–2602GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

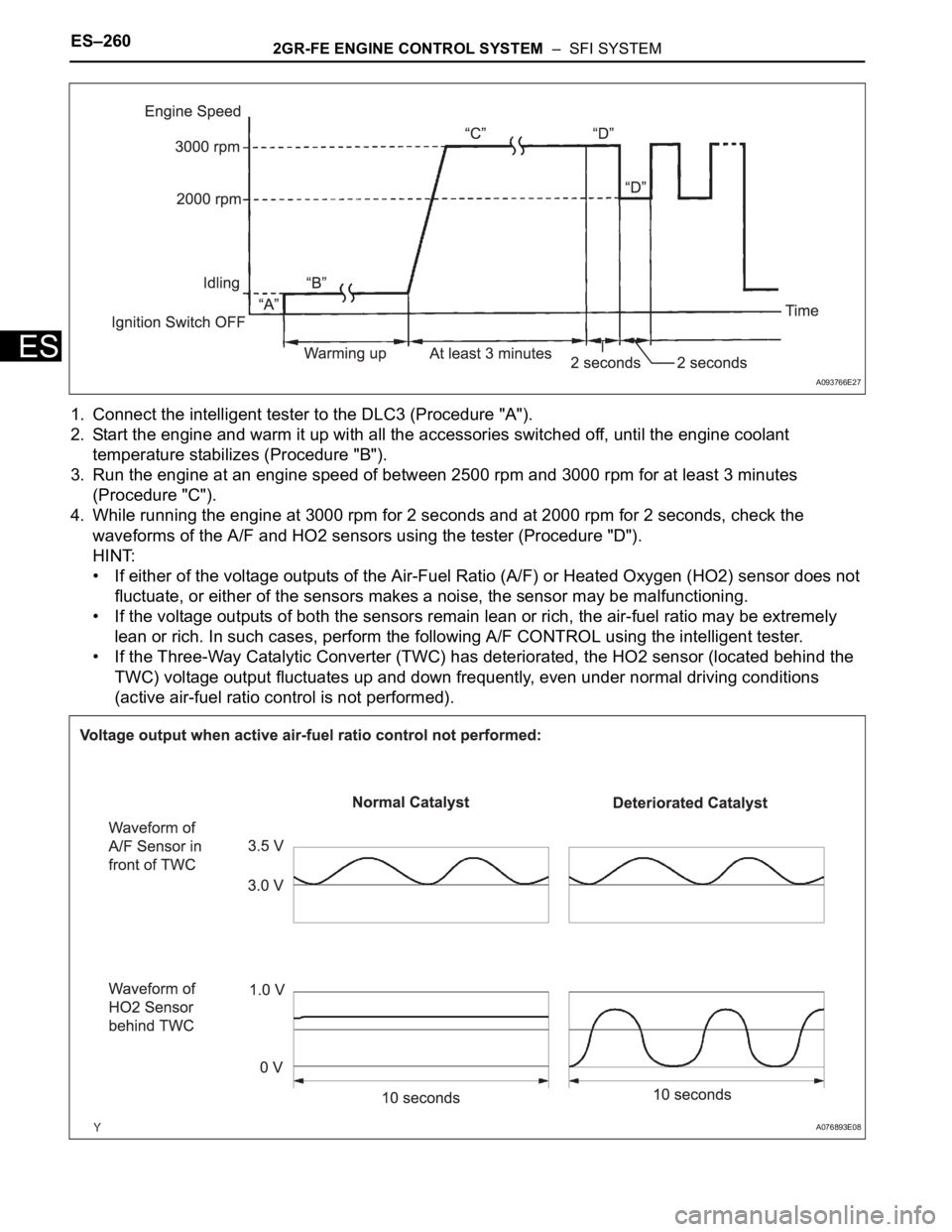

1. Connect the intelligent tester to the DLC3 (Procedure "A").

2. Start the engine and warm it up with all the accessories switched off, until the engine coolant

temperature stabilizes (Procedure "B").

3. Run the engine at an engine speed of between 2500 rpm and 3000 rpm for at least 3 minutes

(Procedure "C").

4. While running the engine at 3000 rpm for 2 seconds and at 2000 rpm for 2 seconds, check the

waveforms of the A/F and HO2 sensors using the tester (Procedure "D").

HINT:

• If either of the voltage outputs of the Air-Fuel Ratio (A/F) or Heated Oxygen (HO2) sensor does not

fluctuate, or either of the sensors makes a noise, the sensor may be malfunctioning.

• If the voltage outputs of both the sensors remain lean or rich, the air-fuel ratio may be extremely

lean or rich. In such cases, perform the following A/F CONTROL using the intelligent tester.

• If the Three-Way Catalytic Converter (TWC) has deteriorated, the HO2 sensor (located behind the

TWC) voltage output fluctuates up and down frequently, even under normal driving conditions

(active air-fuel ratio control is not performed).

A093766E27

A076893E08

Page 353 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–27

ES

Contents:

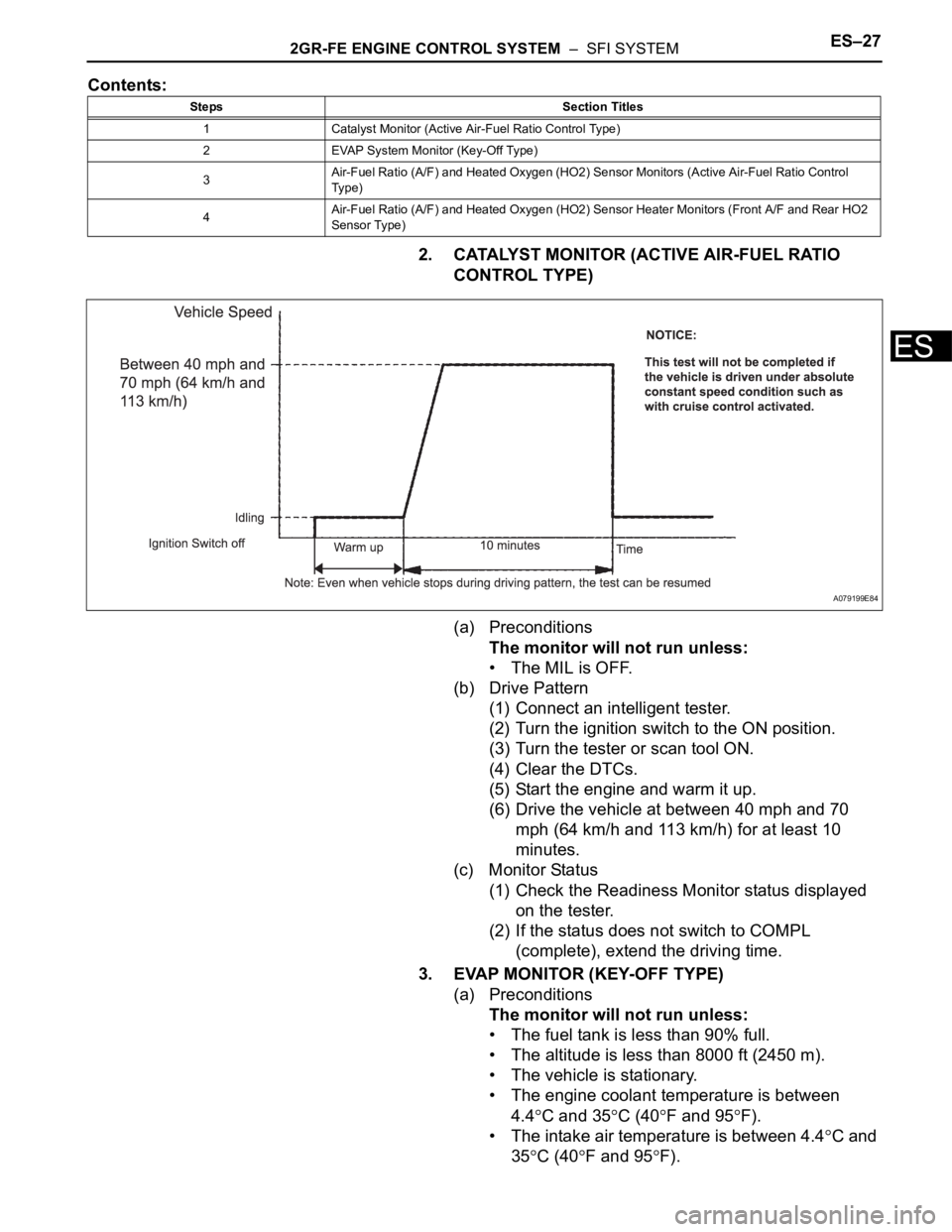

2. CATALYST MONITOR (ACTIVE AIR-FUEL RATIO

CONTROL TYPE)

(a) Preconditions

The monitor will not run unless:

• The MIL is OFF.

(b) Drive Pattern

(1) Connect an intelligent tester.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester or scan tool ON.

(4) Clear the DTCs.

(5) Start the engine and warm it up.

(6) Drive the vehicle at between 40 mph and 70

mph (64 km/h and 113 km/h) for at least 10

minutes.

(c) Monitor Status

(1) Check the Readiness Monitor status displayed

on the tester.

(2) If the status does not switch to COMPL

(complete), extend the driving time.

3. EVAP MONITOR (KEY-OFF TYPE)

(a) Preconditions

The monitor will not run unless:

• The fuel tank is less than 90% full.

• The altitude is less than 8000 ft (2450 m).

• The vehicle is stationary.

• The engine coolant temperature is between

4.4

C and 35C (40F and 95F).

• The intake air temperature is between 4.4

C and

35

C (40F and 95F).

Steps Section Titles

1 Catalyst Monitor (Active Air-Fuel Ratio Control Type)

2 EVAP System Monitor (Key-Off Type)

3Air-Fuel Ratio (A/F) and Heated Oxygen (HO2) Sensor Monitors (Active Air-Fuel Ratio Control

Ty p e )

4Air-Fuel Ratio (A/F) and Heated Oxygen (HO2) Sensor Heater Monitors (Front A/F and Rear HO2

Sensor Type)

A079199E84

Page 354 of 3000

ES–282GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

• Vehicle was driven in the city area (or on free-

way) for 10 minutes or more.

(b) Monitor Conditions

(1) Turn the ignition switch off and wait for 6 hours.

HINT:

Do not start the engine until checking Readiness

Monitor status. If the engine is started, the step

described above must be repeated.

(c) Monitor Status

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester or scan tool ON.

(4) Check the Readiness Monitor status displayed

on the tester or scan tool.

If the status does not switch to COMPL

(complete), restart the engine, make sure that

the preconditions have been met, and then

perform the Monitor Conditions again.

4. A/F SENSOR AND HO2S MONITORS

(a) Preconditions

The monitor will not run unless:

• 2 minutes or more have elapsed since the engine

was started.

• The Engine Coolant Temperature (ECT) is 75

C

(167

F) or more.

• Cumulative driving time at a vehicle speed of 30

mph (48 km/h) or more exceeds 6 minutes.

• Air-fuel ratio feedback control is performed.

• Fuel-cut control is performed for 8 seconds or

more (for the Rear HO2 Sensor Monitor).

(b) Drive Pattern for front A/F sensor and HO2 sensor.

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester ON.

(4) Clear the DTCs.

(5) Start the engine, and warm it up until the ECT

reaches 75

C (167F) or higher.

(6) Drive the vehicle at 38 mph (60 km/h) or more

for at least 10 minutes.

(7) Change the transmission to the 2nd gear.

(8) Accelerate the vehicle to 40 mph (64 km/h) or

more by depressing the accelerator pedal for at

least 10 seconds (Procedure "A").

(9) Soon after performing procedure "A" above,

release the accelerator pedal for at least 4

seconds without depressing the brake pedal, in

order to execute fuel-cut control (Procedure "B").

(10) Allow the vehicle to decelerate until the vehicle

speed declines to less than 6 mph (10 km/h)

(Procedure "C").

(11) Repeat procedures from "A" through "C" above

at least 3 times in one driving cycle.

Page 357 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–31

ES

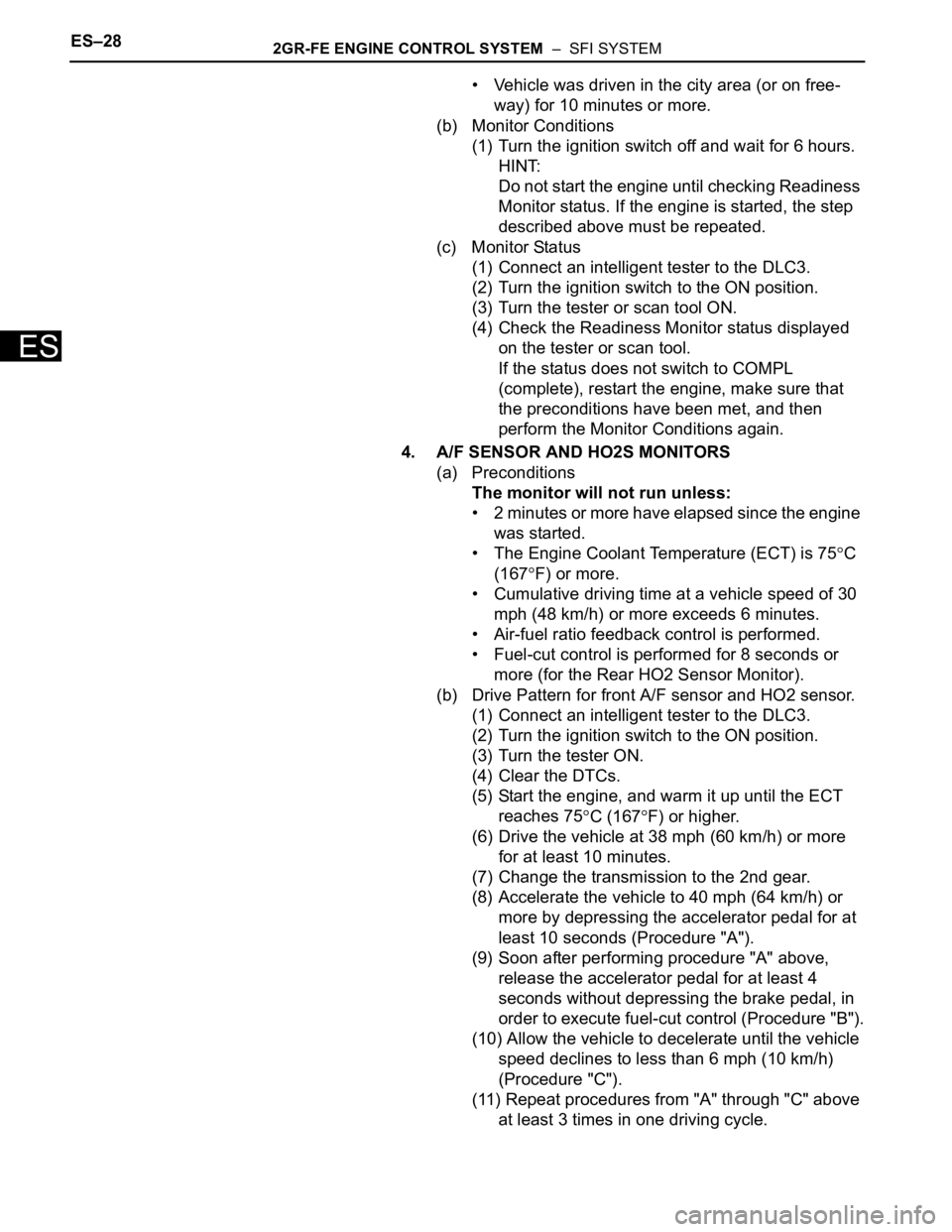

PROBLEM SYMPTOMS TABLE

HINT:

When a malfunction is not confirmed by a DTC (Diagnostic

Trouble Code) check and the cause of problem cannot be

identified through a basic inspection, troubleshoot according

to the priority order indicated in the table below.

SFI SYSTEM

Symptom Suspected Area See page

Engine does not crank (does not start)1. Immobilizer systemEI-2

2. StarterST-7

3. STARTER RelayST-14

4. Cranking holding function circuitES-461

No initial combustion (does not start)1. ECM power source circuitES-437

2. Ignition systemIG-5

3. Fuel pump control circuitES-451

4. InjectorFU-16

5. VC output circuitES-444

6. ECMES-498

Difficult to start (engine cranks normally)1. Electronic Throttle Control System (ETCS)ES-329

2. Fuel pump control circuitES-451

3. Ignition systemIG-5

4. Spark plugIG-7

5. CompressionEM-3

6. InjectorFU-16

7. VC output circuitES-444

Difficult to start with cold engine1. Cranking holding function circuitES-461

2. Electronic Throttle Control System (ETCS)ES-329

3. Fuel pump control circuitES-451

4. Spark plugIG-7

5. Ignition systemIG-6

6. InjectorFU-16

7. Engine coolant temperature sensorES-516

Difficult to start with hot engine1. Cooling fan systemCO-4

2. Cranking holding function circuitES-461

3. Electronic Throttle Control System (ETCS)ES-329

4. Fuel pump control circuitES-451

5. Spark plugIG-7

6. Ignition systemIG-5

7. InjectorFU-16

8. Engine coolant temperature sensorES-516

High engine idle speed (poor idling)1. Electronic Throttle Control System (ETCS)ES-329

2. ECM power source circuitES-437

3. A/C signal circuit (Compressor circuit) -

4. Acoustic Control Induction System (ACIS)ES-470

5. PCV hoseEC-15

6. ECMES-498

Page 364 of 3000

ES–462GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

FREEZE FRAME DATA

1. DESCRIPTION

(a) The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC

is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle

was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was

lean or rich, as well as other data recorded at the

time of a malfunction.

HINT:

If it is impossible to duplicate the problem even

though a DTC is detected, confirm the freeze frame

data.

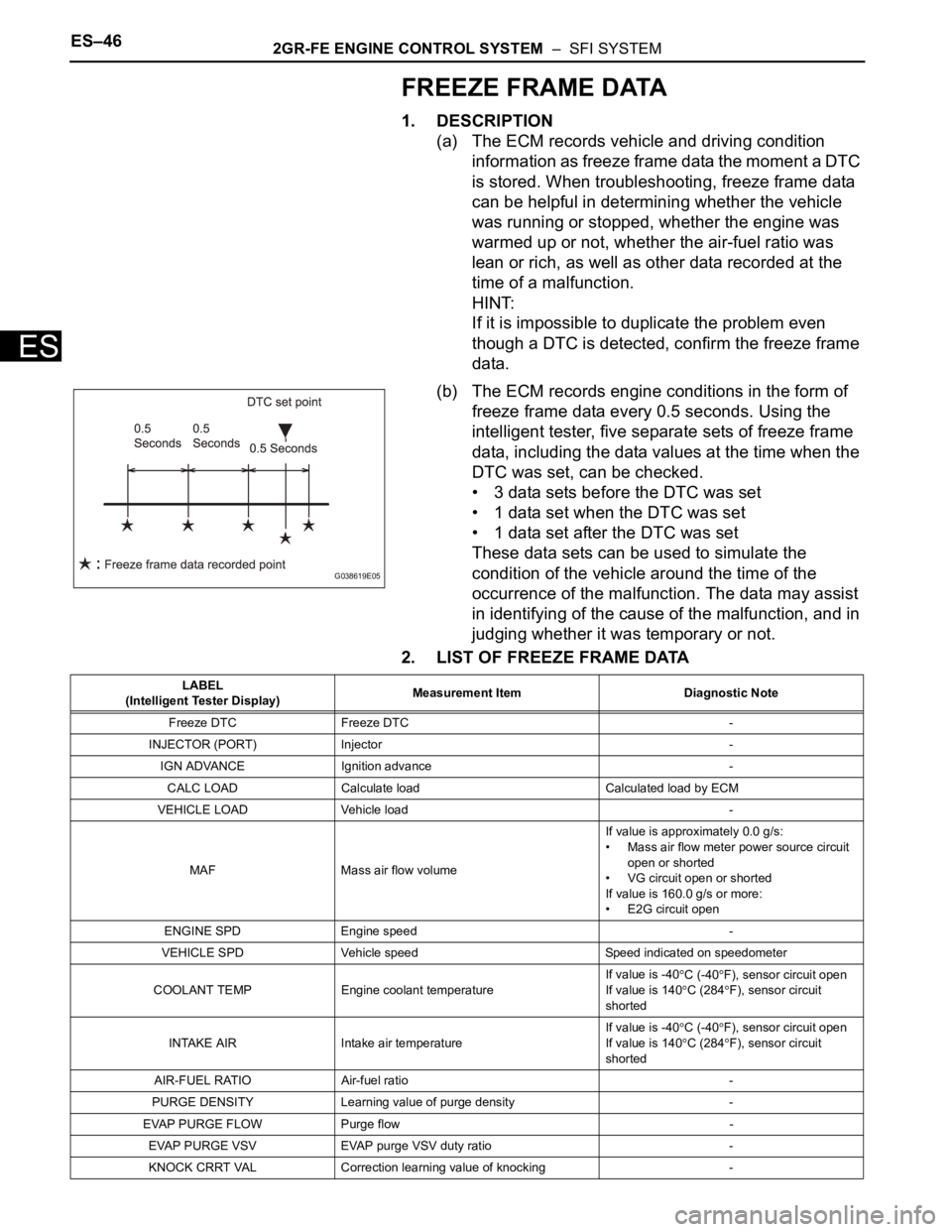

(b) The ECM records engine conditions in the form of

freeze frame data every 0.5 seconds. Using the

intelligent tester, five separate sets of freeze frame

data, including the data values at the time when the

DTC was set, can be checked.

• 3 data sets before the DTC was set

• 1 data set when the DTC was set

• 1 data set after the DTC was set

These data sets can be used to simulate the

condition of the vehicle around the time of the

occurrence of the malfunction. The data may assist

in identifying of the cause of the malfunction, and in

judging whether it was temporary or not.

2. LIST OF FREEZE FRAME DATA

G038619E05

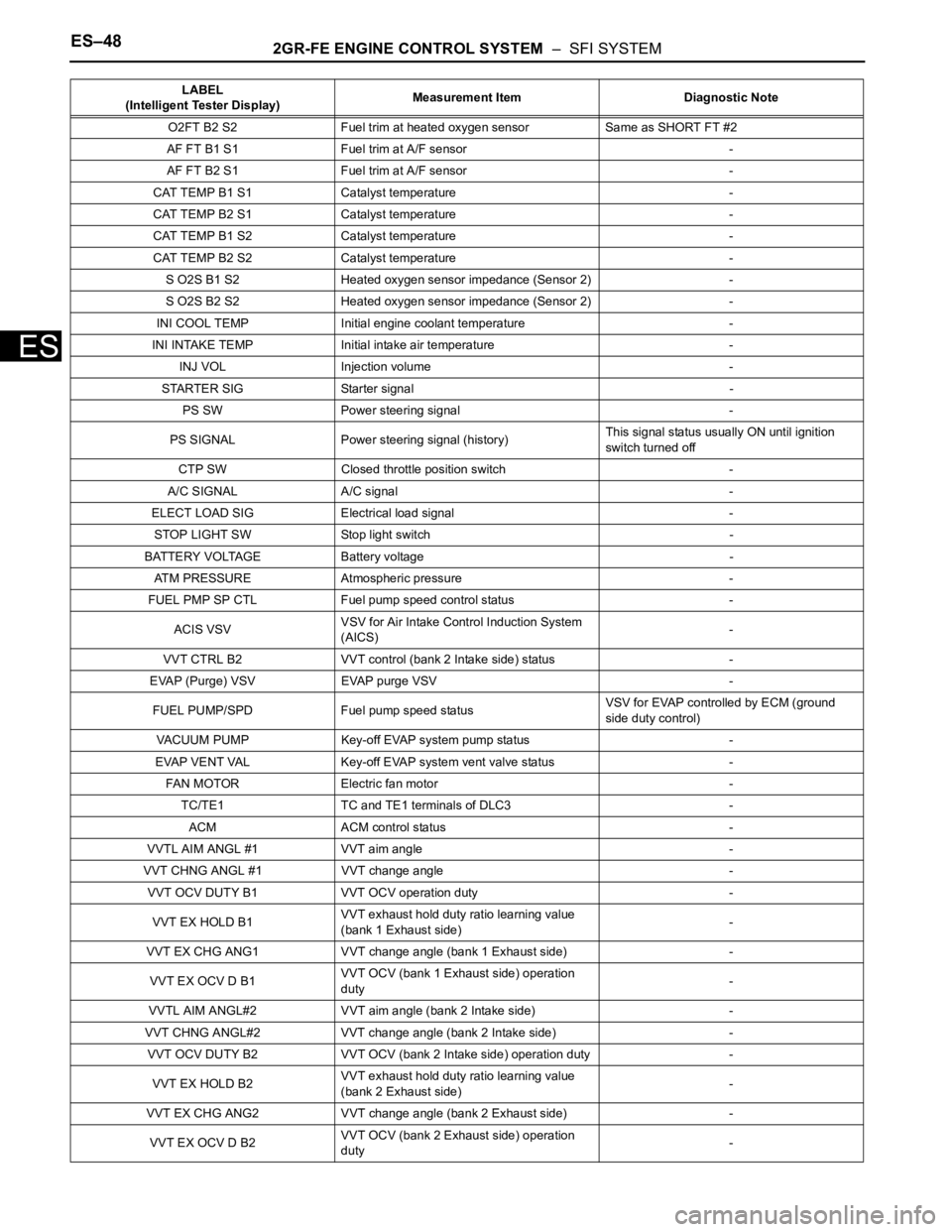

LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Freeze DTC Freeze DTC -

INJECTOR (PORT) Injector -

IGN ADVANCE Ignition advance -

CALC LOAD Calculate load Calculated load by ECM

VEHICLE LOAD Vehicle load -

MAF Mass air flow volumeIf value is approximately 0.0 g/s:

• Mass air flow meter power source circuit

open or shorted

• VG circuit open or shorted

If value is 160.0 g/s or more:

• E2G circuit open

ENGINE SPD Engine speed -

VEHICLE SPD Vehicle speed Speed indicated on speedometer

COOLANT TEMP Engine coolant temperatureIf value is -40

C (-40F), sensor circuit open

If value is 140

C (284F), sensor circuit

shorted

INTAKE AIR Intake air temperatureIf value is -40

C (-40F), sensor circuit open

If value is 140C (284F), sensor circuit

shorted

AIR-FUEL RATIO Air-fuel ratio -

PURGE DENSITY Learning value of purge density -

EVAP PURGE FLOW Purge flow -

EVAP PURGE VSV EVAP purge VSV duty ratio -

KNOCK CRRT VAL Correction learning value of knocking -

Page 366 of 3000

ES–482GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

O2FT B2 S2 Fuel trim at heated oxygen sensor Same as SHORT FT #2

AF FT B1 S1 Fuel trim at A/F sensor -

AF FT B2 S1 Fuel trim at A/F sensor -

CAT TEMP B1 S1 Catalyst temperature -

CAT TEMP B2 S1 Catalyst temperature -

CAT TEMP B1 S2 Catalyst temperature -

CAT TEMP B2 S2 Catalyst temperature -

S O2S B1 S2 Heated oxygen sensor impedance (Sensor 2) -

S O2S B2 S2 Heated oxygen sensor impedance (Sensor 2) -

INI COOL TEMP Initial engine coolant temperature -

INI INTAKE TEMP Initial intake air temperature -

INJ VOL Injection volume -

STARTER SIG Starter signal -

PS SW Power steering signal -

PS SIGNAL Power steering signal (history)This signal status usually ON until ignition

switch turned off

CTP SW Closed throttle position switch -

A/C SIGNAL A/C signal -

ELECT LOAD SIG Electrical load signal -

STOP LIGHT SW Stop light switch -

BATTERY VOLTAGE Battery voltage -

ATM PRESSURE Atmospheric pressure -

FUEL PMP SP CTL Fuel pump speed control status -

ACIS VSVVSV for Air Intake Control Induction System

(AICS)-

VVT CTRL B2 VVT control (bank 2 Intake side) status -

EVAP (Purge) VSV EVAP purge VSV -

FUEL PUMP/SPD Fuel pump speed statusVSV for EVAP controlled by ECM (ground

side duty control)

VACUUM PUMP Key-off EVAP system pump status -

EVAP VENT VAL Key-off EVAP system vent valve status -

FAN MOTOR Electric fan motor -

TC/TE1 TC and TE1 terminals of DLC3 -

ACM ACM control status -

VVTL AIM ANGL #1 VVT aim angle -

VVT CHNG ANGL #1 VVT change angle -

VVT OCV DUTY B1 VVT OCV operation duty -

VVT EX HOLD B1VVT exhaust hold duty ratio learning value

(bank 1 Exhaust side)-

VVT EX CHG ANG1 VVT change angle (bank 1 Exhaust side) -

VVT EX OCV D B1VVT OCV (bank 1 Exhaust side) operation

duty-

VVTL AIM ANGL#2 VVT aim angle (bank 2 Intake side) -

VVT CHNG ANGL#2 VVT change angle (bank 2 Intake side) -

VVT OCV DUTY B2 VVT OCV (bank 2 Intake side) operation duty -

VVT EX HOLD B2VVT exhaust hold duty ratio learning value

(bank 2 Exhaust side)-

VVT EX CHG ANG2 VVT change angle (bank 2 Exhaust side) -

VVT EX OCV D B2VVT OCV (bank 2 Exhaust side) operation

duty- LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Page 369 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–51

ES

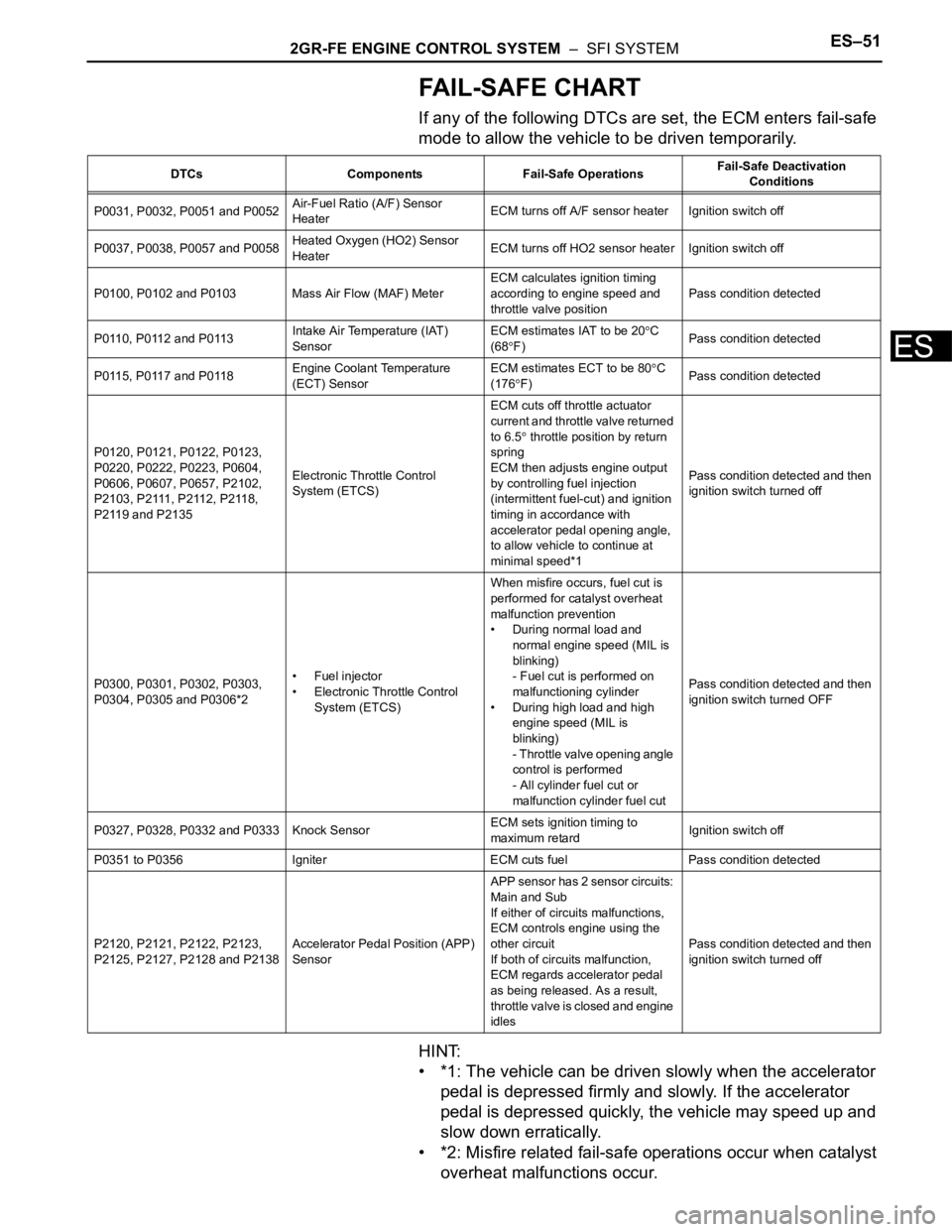

FAIL-SAFE CHART

If any of the following DTCs are set, the ECM enters fail-safe

mode to allow the vehicle to be driven temporarily.

HINT:

• *1: The vehicle can be driven slowly when the accelerator

pedal is depressed firmly and slowly. If the accelerator

pedal is depressed quickly, the vehicle may speed up and

slow down erratically.

• *2: Misfire related fail-safe operations occur when catalyst

overheat malfunctions occur.

DTCs Components Fail-Safe OperationsFail-Safe Deactivation

Conditions

P0031, P0032, P0051 and P0052Air-Fuel Ratio (A/F) Sensor

HeaterECM turns off A/F sensor heater Ignition switch off

P0037, P0038, P0057 and P0058Heated Oxygen (HO2) Sensor

HeaterECM turns off HO2 sensor heater Ignition switch off

P0100, P0102 and P0103 Mass Air Flow (MAF) MeterECM calculates ignition timing

according to engine speed and

throttle valve positionPass condition detected

P0110, P0112 and P0113Intake Air Temperature (IAT)

SensorECM estimates IAT to be 20

C

(68

F)Pass condition detected

P0115, P0117 and P0118Engine Coolant Temperature

(ECT) SensorECM estimates ECT to be 80

C

(176

F)Pass condition detected

P0120, P0121, P0122, P0123,

P0220, P0222, P0223, P0604,

P0606, P0607, P0657, P2102,

P2103, P2111, P2112, P2118,

P2119 and P2135Electronic Throttle Control

System (ETCS)ECM cuts off throttle actuator

current and throttle valve returned

to 6.5

throttle position by return

spring

ECM then adjusts engine output

by controlling fuel injection

(intermittent fuel-cut) and ignition

timing in accordance with

accelerator pedal opening angle,

to allow vehicle to continue at

minimal speed*1Pass condition detected and then

ignition switch turned off

P0300, P0301, P0302, P0303,

P0304, P0305 and P0306*2• Fuel injector

• Electronic Throttle Control

System (ETCS)When misfire occurs, fuel cut is

performed for catalyst overheat

malfunction prevention

• During normal load and

normal engine speed (MIL is

blinking)

- Fuel cut is performed on

malfunctioning cylinder

• During high load and high

engine speed (MIL is

blinking)

- Throttle valve opening angle

control is performed

- All cylinder fuel cut or

malfunction cylinder fuel cutPass condition detected and then

ignition switch turned OFF

P0327, P0328, P0332 and P0333 Knock SensorECM sets ignition timing to

maximum retardIgnition switch off

P0351 to P0356 Igniter ECM cuts fuel Pass condition detected

P2120, P2121, P2122, P2123,

P2125, P2127, P2128 and P2138Accelerator Pedal Position (APP)

SensorAPP sensor has 2 sensor circuits:

Main and Sub

If either of circuits malfunctions,

ECM controls engine using the

other circuit

If both of circuits malfunction,

ECM regards accelerator pedal

as being released. As a result,

throttle valve is closed and engine

idlesPass condition detected and then

ignition switch turned off

Page 373 of 3000

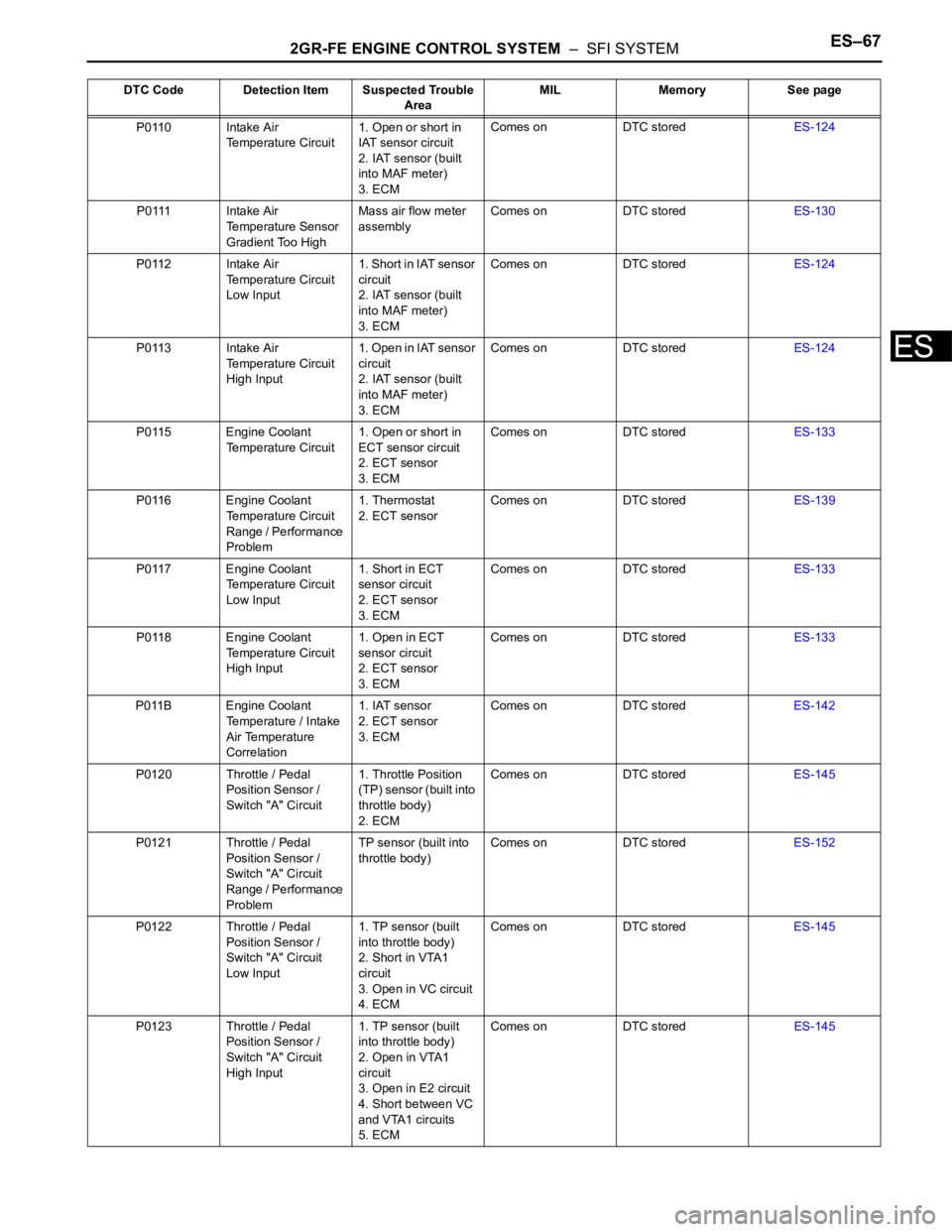

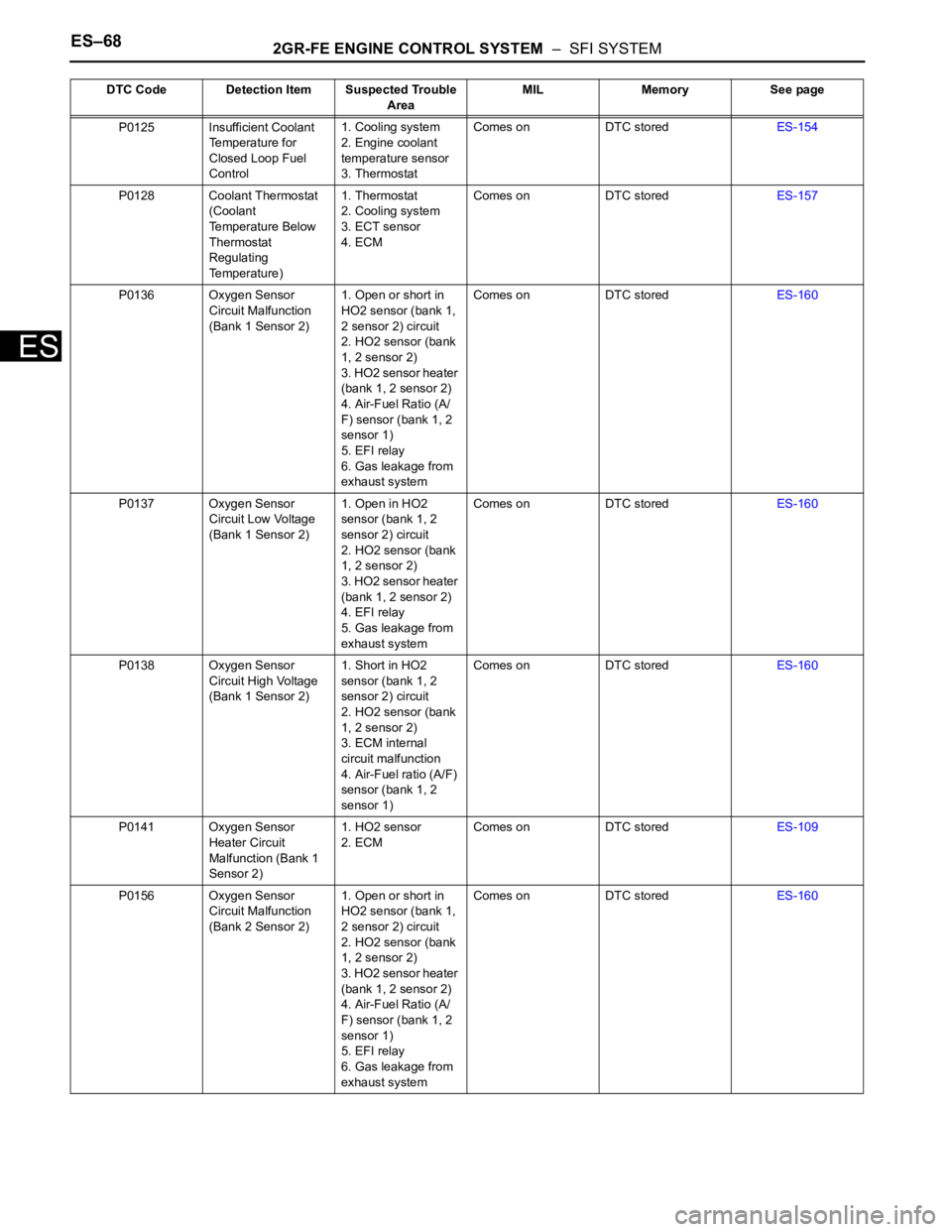

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–67

ES

P0110 Intake Air

Temperature Circuit1. Open or short in

IAT sensor circuit

2. IAT sensor (built

into MAF meter)

3. ECMComes on DTC storedES-124

P0111 Intake Air

Temperature Sensor

Gradient Too HighMass air flow meter

assemblyComes on DTC storedES-130

P0112 Intake Air

Temperature Circuit

Low Input1. Short in IAT sensor

circuit

2. IAT sensor (built

into MAF meter)

3. ECMComes on DTC storedES-124

P0113 Intake Air

Temperature Circuit

High Input1 . O p e n i n I AT s e n s o r

circuit

2. IAT sensor (built

into MAF meter)

3. ECMComes on DTC storedES-124

P0115 Engine Coolant

Temperature Circuit1. Open or short in

ECT sensor circuit

2. ECT sensor

3. ECMComes on DTC storedES-133

P0116 Engine Coolant

Temperature Circuit

Range / Performance

Problem1. Thermostat

2. ECT sensorComes on DTC storedES-139

P0117 Engine Coolant

Temperature Circuit

Low Input1. Short in ECT

sensor circuit

2. ECT sensor

3. ECMComes on DTC storedES-133

P0118 Engine Coolant

Temperature Circuit

High Input1. Open in ECT

sensor circuit

2. ECT sensor

3. ECMComes on DTC storedES-133

P011B Engine Coolant

Temperature / Intake

Air Temperature

Correlation1. IAT sensor

2. ECT sensor

3. ECMComes on DTC storedES-142

P0120 Throttle / Pedal

Position Sensor /

Switch "A" Circuit1. Throttle Position

(TP) sensor (built into

throttle body)

2. ECMComes on DTC storedES-145

P0121 Throttle / Pedal

Position Sensor /

Switch "A" Circuit

Range / Performance

ProblemTP sensor (built into

throttle body)Comes on DTC storedES-152

P0122 Throttle / Pedal

Position Sensor /

Switch "A" Circuit

Low Input1. TP sensor (built

into throttle body)

2. Short in VTA1

circuit

3. Open in VC circuit

4. ECMComes on DTC storedES-145

P0123 Throttle / Pedal

Position Sensor /

Switch "A" Circuit

High Input1. TP sensor (built

into throttle body)

2. Open in VTA1

circuit

3. Open in E2 circuit

4. Short between VC

and VTA1 circuits

5. ECMComes on DTC storedES-145 DTC Code Detection Item Suspected Trouble

AreaMIL Memory See page

Page 374 of 3000

ES–682GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

P0125 Insufficient Coolant

Temperature for

Closed Loop Fuel

Control1. Cooling system

2. Engine coolant

temperature sensor

3. ThermostatComes on DTC storedES-154

P0128 Coolant Thermostat

(Coolant

Temperature Below

Thermostat

Regulating

Temperature)1. Thermostat

2. Cooling system

3. ECT sensor

4. ECMComes on DTC storedES-157

P0136 Oxygen Sensor

Circuit Malfunction

(Bank 1 Sensor 2)1. Open or short in

HO2 sensor (bank 1,

2 sensor 2) circuit

2. HO2 sensor (bank

1, 2 sensor 2)

3. HO2 sensor heater

(bank 1, 2 sensor 2)

4. Air-Fuel Ratio (A/

F) sensor (bank 1, 2

sensor 1)

5. EFI relay

6. Gas leakage from

exhaust systemComes on DTC storedES-160

P0137 Oxygen Sensor

Circuit Low Voltage

(Bank 1 Sensor 2)1. Open in HO2

sensor (bank 1, 2

sensor 2) circuit

2. HO2 sensor (bank

1, 2 sensor 2)

3. HO2 sensor heater

(bank 1, 2 sensor 2)

4. EFI relay

5. Gas leakage from

exhaust systemComes on DTC storedES-160

P0138 Oxygen Sensor

Circuit High Voltage

(Bank 1 Sensor 2)1. Short in HO2

sensor (bank 1, 2

sensor 2) circuit

2. HO2 sensor (bank

1, 2 sensor 2)

3. ECM internal

circuit malfunction

4. Air-Fuel ratio (A/F)

sensor (bank 1, 2

sensor 1)Comes on DTC storedES-160

P0141 Oxygen Sensor

Heater Circuit

Malfunction (Bank 1

Sensor 2)1. HO2 sensor

2. ECMComes on DTC storedES-109

P0156 Oxygen Sensor

Circuit Malfunction

(Bank 2 Sensor 2)1. Open or short in

HO2 sensor (bank 1,

2 sensor 2) circuit

2. HO2 sensor (bank

1, 2 sensor 2)

3. HO2 sensor heater

(bank 1, 2 sensor 2)

4. Air-Fuel Ratio (A/

F) sensor (bank 1, 2

sensor 1)

5. EFI relay

6. Gas leakage from

exhaust systemComes on DTC storedES-160 DTC Code Detection Item Suspected Trouble

AreaMIL Memory See page

Page 375 of 3000

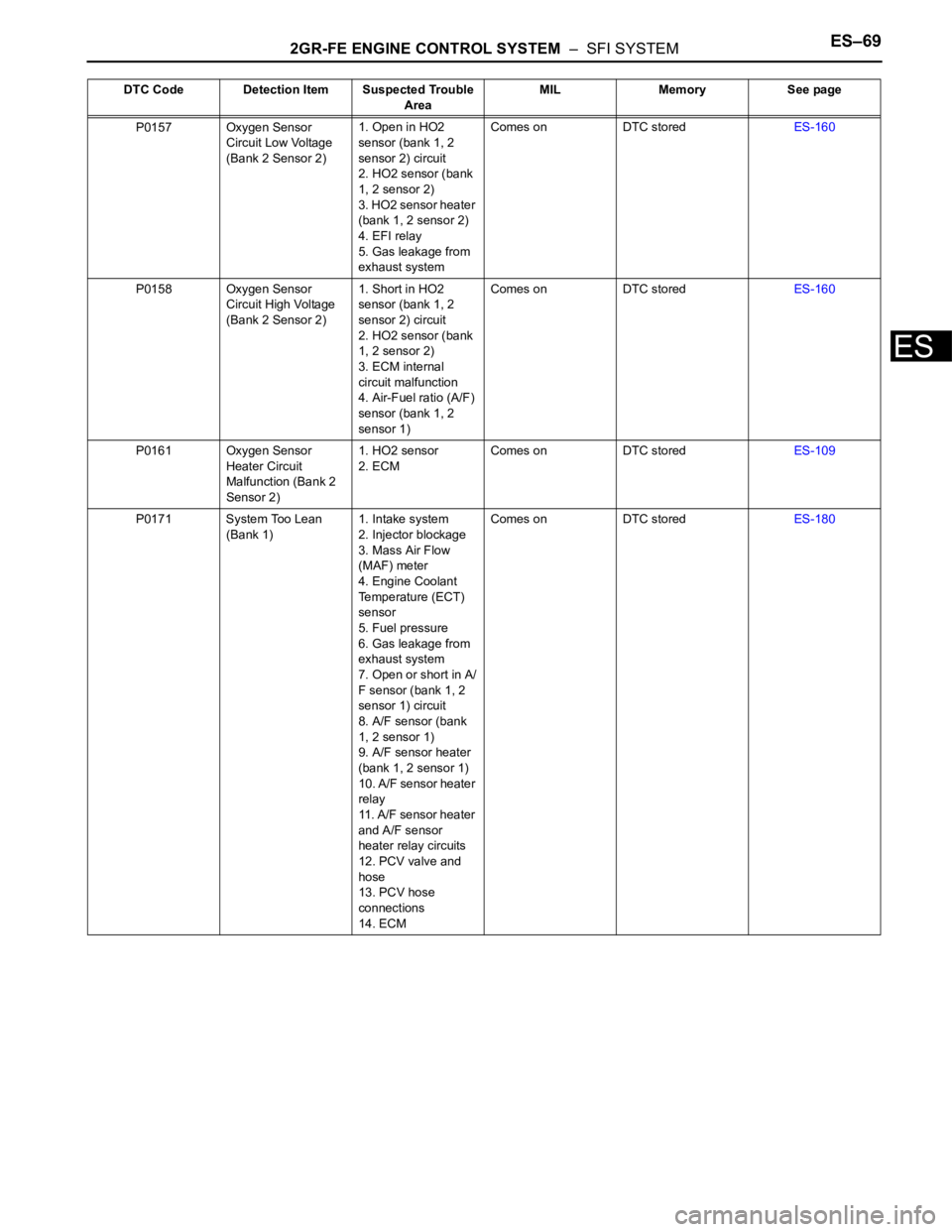

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–69

ES

P0157 Oxygen Sensor

Circuit Low Voltage

(Bank 2 Sensor 2)1. Open in HO2

sensor (bank 1, 2

sensor 2) circuit

2. HO2 sensor (bank

1, 2 sensor 2)

3. HO2 sensor heater

(bank 1, 2 sensor 2)

4. EFI relay

5. Gas leakage from

exhaust systemComes on DTC storedES-160

P0158 Oxygen Sensor

Circuit High Voltage

(Bank 2 Sensor 2)1. Short in HO2

sensor (bank 1, 2

sensor 2) circuit

2. HO2 sensor (bank

1, 2 sensor 2)

3. ECM internal

circuit malfunction

4. Air-Fuel ratio (A/F)

sensor (bank 1, 2

sensor 1)Comes on DTC storedES-160

P0161 Oxygen Sensor

Heater Circuit

Malfunction (Bank 2

Sensor 2)1. HO2 sensor

2. ECMComes on DTC storedES-109

P0171 System Too Lean

(Bank 1)1. Intake system

2. Injector blockage

3. Mass Air Flow

(MAF) meter

4. Engine Coolant

Temperature (ECT)

sensor

5. Fuel pressure

6. Gas leakage from

exhaust system

7. Open or short in A/

F sensor (bank 1, 2

sensor 1) circuit

8. A/F sensor (bank

1, 2 sensor 1)

9. A/F sensor heater

(bank 1, 2 sensor 1)

10. A/F sensor heater

relay

11. A/F sensor heater

and A/F sensor

heater relay circuits

12. PCV valve and

hose

13. PCV hose

connections

14. ECMComes on DTC storedES-180 DTC Code Detection Item Suspected Trouble

AreaMIL Memory See page