check engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 827 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–45

ES

DTC CHECK / CLEAR

NOTICE:

All the stored DTCs and freeze frame data are erased if:

1) the ECM is changed from normal mode to check mode

or vice versa; or 2) the ignition switch is turned from ON

to ACC or off while in check mode.

Before changing modes, always check and make a note

of any DTCs and freeze frame data.

HINT:

• DTCs which are stored in the ECM can be displayed on an

intelligent tester. An intelligent tester can display current

and pending DTCs.

• Some DTCs are not set if the ECM does not detect the

same malfunction again during the second consecutive

driving cycle. However, such malfunctions, detected on

only one occasion, are stored as pending DTCs.

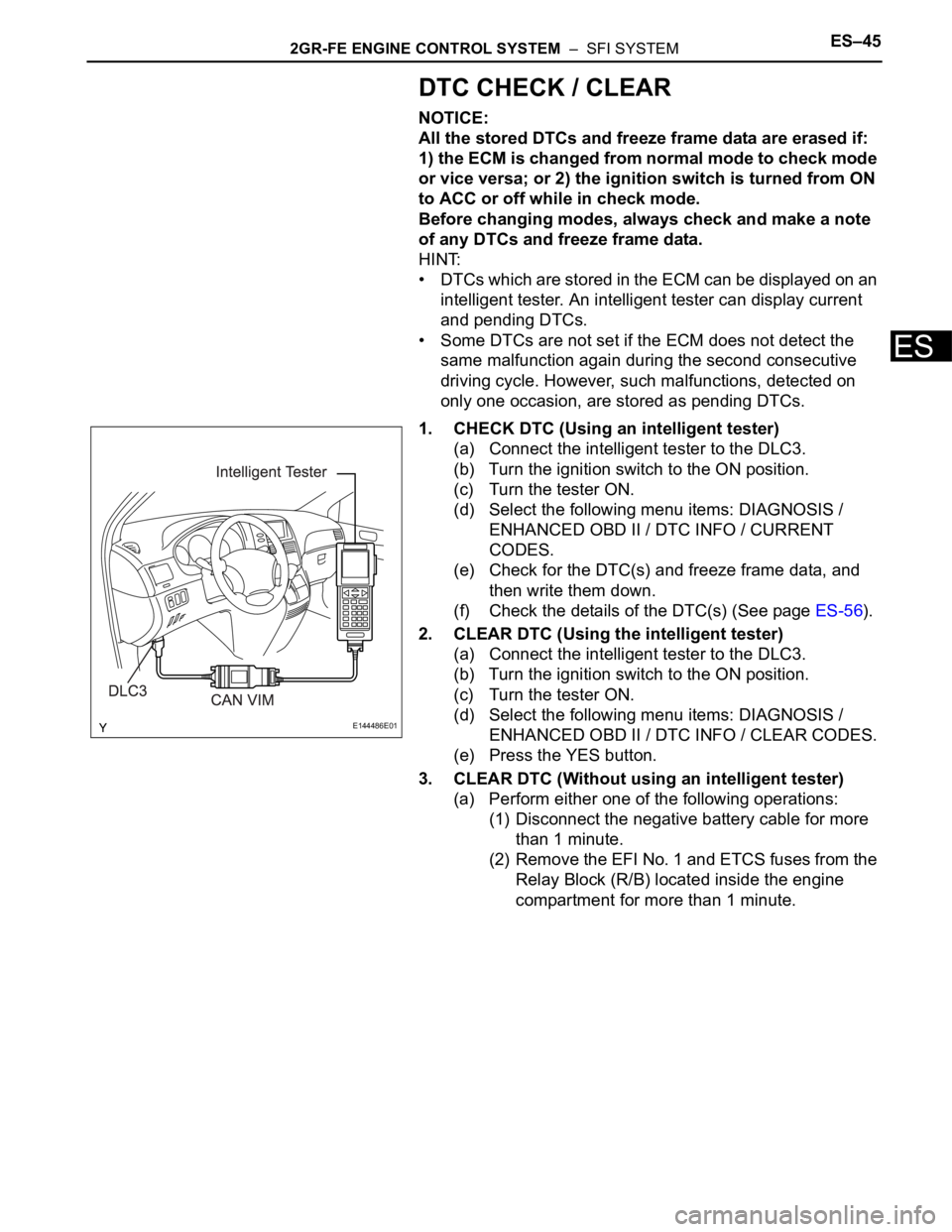

1. CHECK DTC (Using an intelligent tester)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester ON.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT

CODES.

(e) Check for the DTC(s) and freeze frame data, and

then write them down.

(f) Check the details of the DTC(s) (See page ES-56).

2. CLEAR DTC (Using the intelligent tester)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester ON.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CLEAR CODES.

(e) Press the YES button.

3. CLEAR DTC (Without using an intelligent tester)

(a) Perform either one of the following operations:

(1) Disconnect the negative battery cable for more

than 1 minute.

(2) Remove the EFI No. 1 and ETCS fuses from the

Relay Block (R/B) located inside the engine

compartment for more than 1 minute.

E144486E01

Page 830 of 3000

ES–462GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

FREEZE FRAME DATA

1. DESCRIPTION

(a) The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC

is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle

was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was

lean or rich, as well as other data recorded at the

time of a malfunction.

HINT:

If it is impossible to duplicate the problem even

though a DTC is detected, confirm the freeze frame

data.

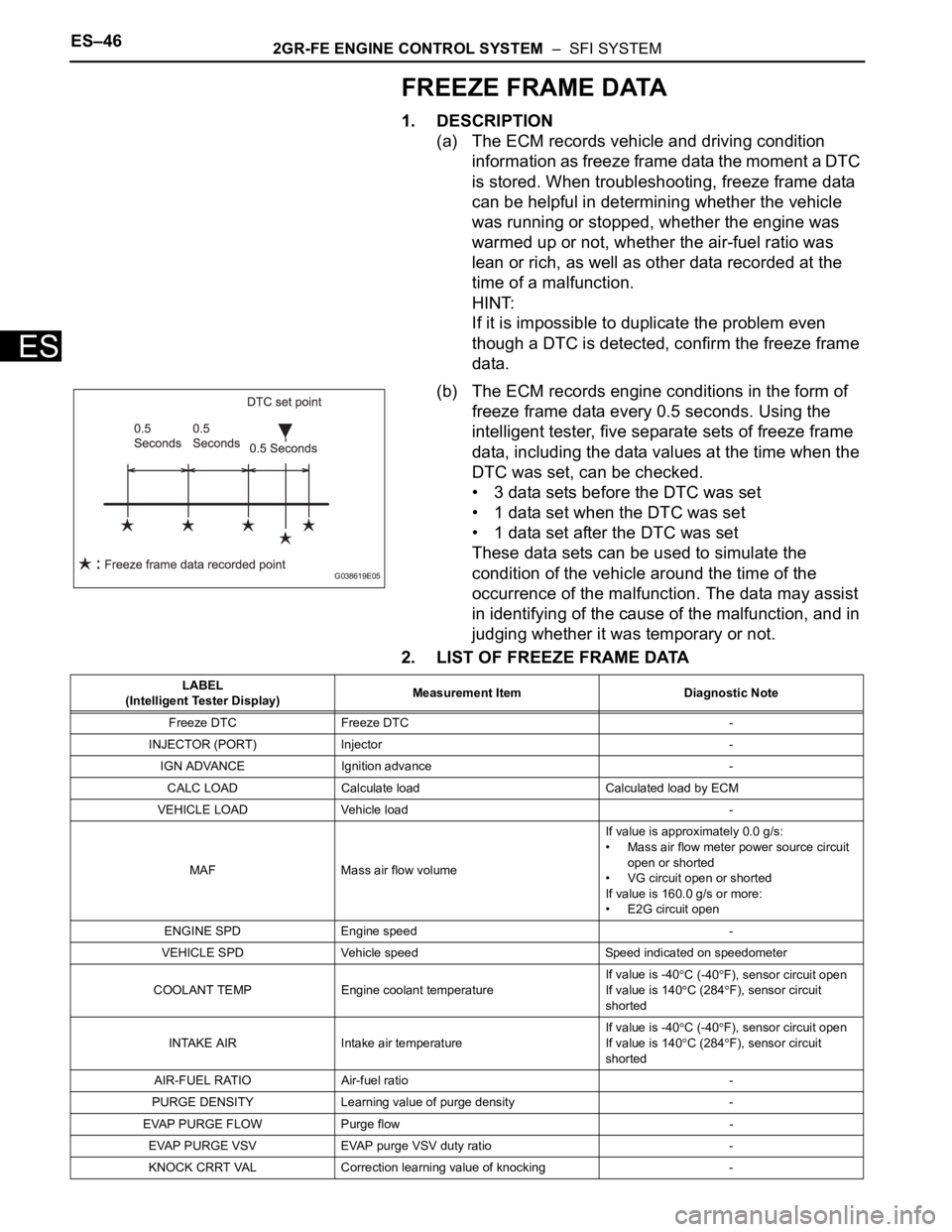

(b) The ECM records engine conditions in the form of

freeze frame data every 0.5 seconds. Using the

intelligent tester, five separate sets of freeze frame

data, including the data values at the time when the

DTC was set, can be checked.

• 3 data sets before the DTC was set

• 1 data set when the DTC was set

• 1 data set after the DTC was set

These data sets can be used to simulate the

condition of the vehicle around the time of the

occurrence of the malfunction. The data may assist

in identifying of the cause of the malfunction, and in

judging whether it was temporary or not.

2. LIST OF FREEZE FRAME DATA

G038619E05

LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Freeze DTC Freeze DTC -

INJECTOR (PORT) Injector -

IGN ADVANCE Ignition advance -

CALC LOAD Calculate load Calculated load by ECM

VEHICLE LOAD Vehicle load -

MAF Mass air flow volumeIf value is approximately 0.0 g/s:

• Mass air flow meter power source circuit

open or shorted

• VG circuit open or shorted

If value is 160.0 g/s or more:

• E2G circuit open

ENGINE SPD Engine speed -

VEHICLE SPD Vehicle speed Speed indicated on speedometer

COOLANT TEMP Engine coolant temperatureIf value is -40

C (-40F), sensor circuit open

If value is 140

C (284F), sensor circuit

shorted

INTAKE AIR Intake air temperatureIf value is -40

C (-40F), sensor circuit open

If value is 140C (284F), sensor circuit

shorted

AIR-FUEL RATIO Air-fuel ratio -

PURGE DENSITY Learning value of purge density -

EVAP PURGE FLOW Purge flow -

EVAP PURGE VSV EVAP purge VSV duty ratio -

KNOCK CRRT VAL Correction learning value of knocking -

Page 831 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–47

ES

KNOCK FB VAL Feedback value of knocking -

ACCEL POS #1Absolute Accelerator Pedal Position (APP)

No. 1-

ACCEL POS #2 Absolute APP No. 2 -

THROTTLE POS Throttle positionRead value with ignition switch on (Do not

start engine)

THROTTLE POS Throttle sensor positioningRead value with ignition switch on (Do not

start engine)

THROTTLE POS#2 Throttle sensor positioning #2Read value with ignition switch on (Do not

start engine)

THROTTLE MOT Throttle motor -

O2S B1 S2 Heated oxygen sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check voltage output of sensor

O2S B2 S2 Heated oxygen sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check voltage output of sensor

AFS B1 S1 A/F sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check voltage output of sensor

AFS B2 S1 A/F sensor outputPerforming INJ VOL or A/F CONTROL

function of ACTIVE TEST enables technician

to check voltage output of sensor

TOTAL FT #1 Total fuel trim of bank 1 -

TOTAL FT #2 Total fuel trim of bank 2 -

SHORT FT #1 Short-term fuel trim of bank 1Short-term fuel compensation used to

maintain air-fuel ratio at stoichiometric air-fuel

ratio

LONG FT #1 Long-term fuel trim of bank 1Overall fuel compensation carried out in long-

term to compensate for a continual deviation

of short-term fuel trim from central valve

SHORT FT #2 Short-term fuel trim of bank 2Short-term fuel compensation used to

maintain air-fuel ratio at stoichiometric air-fuel

ratio

LONG FT #2 Long-term fuel trim of bank 2Overall fuel compensation carried out in long-

term to compensate for a continual deviation

of short-term fuel trim from central valve

FUEL SYS #1 Fuel system status (bank 1)• OL (Open Loop): Has not yet satisfied

conditions to go closed loop

• CL (Closed Loop): Using heated oxygen

sensor as feedback for fuel control

• OL DRIVE: Open loop due to driving

conditions (fuel enrichment)

• OL FAULT: Open loop due to detected

system fault

• CL FAULT: Closed loop but heated

oxygen sensor, which used for fuel control

malfunctioning

FUEL SYS #2 Fuel system status (bank 2)• OL (Open Loop): Has not yet satisfied

conditions to go closed loop

• CL (Closed Loop): Using heated oxygen

sensor as feedback for fuel control

• OL DRIVE: Open loop due to driving

conditions (fuel enrichment)

• OL FAULT: Open loop due to detected

system fault

• CL FAULT: Closed loop but heated

oxygen sensor, which used for fuel control

malfunctioning

O2FT B1 S2 Fuel trim at heated oxygen sensor Same as SHORT FT #1LABEL

(Intelligent Tester Display)Measurement Item Diagnostic Note

Page 835 of 3000

ES–5162GR-FE ENGINE CONTROL SYSTEM – ENGINE COOLANT TEMPERATURE SENSOR

ES

REMOVAL

1. DRAIN ENGINE COOLANT (See page CO-6)

2. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

3. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

4. REMOVE NO. 1 AIR CLEANER INLET (See page EM-

28)

5. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-493)

6. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

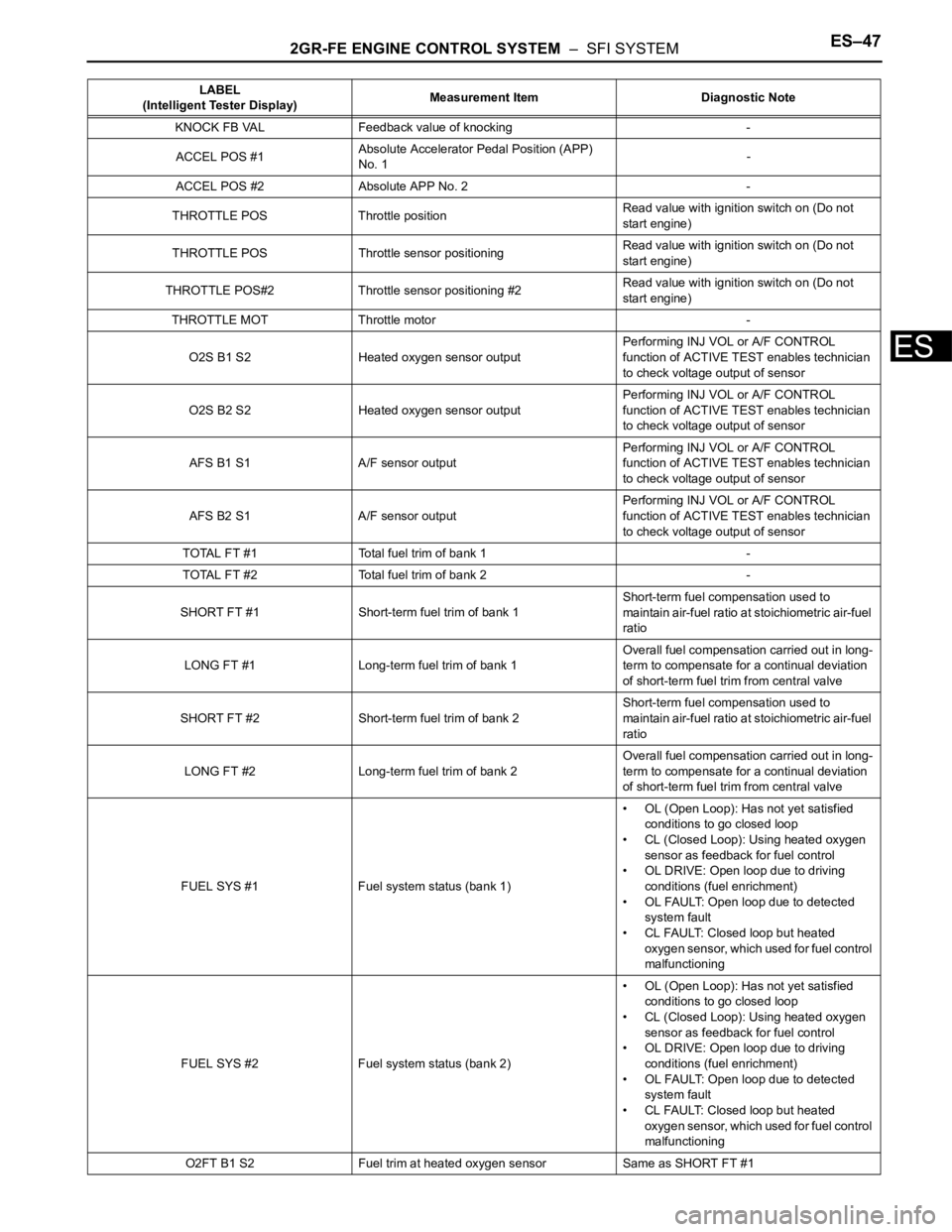

7. REMOVE ENGINE COOLANT TEMPERATURE

SENSOR

(a) Remove the engine coolant temperature sensor

connector.

(b) Remove the engine coolant temperature sensor.

INSPECTION

1. INSPECT ENGINE COOLANT TEMPERATURE

SENSOR

(a) Using an ohmmeter, measure the resistance

between the terminals.

Standard resistance

• If the result is as specified, do not replace the

engine coolant temperature sensor.

• If the result is not as specified, replace the

engine coolant temperature sensor.

NOTICE:

In case of checking the engine coolant

temperature sensor in water, do not allow water

to go into the terminals. After checking, dry the

engine coolant temperature sensor.

A162197

A164436E01

Condition Specified Condition

20

C (68F) 2.32 to 2.59 k

80C (176F) 0.310 to 0.326 k

Page 836 of 3000

2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–521

ES

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

(See page FU-13)

2. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-4)

5. REMOVE FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-27)

6. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-493)

7. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

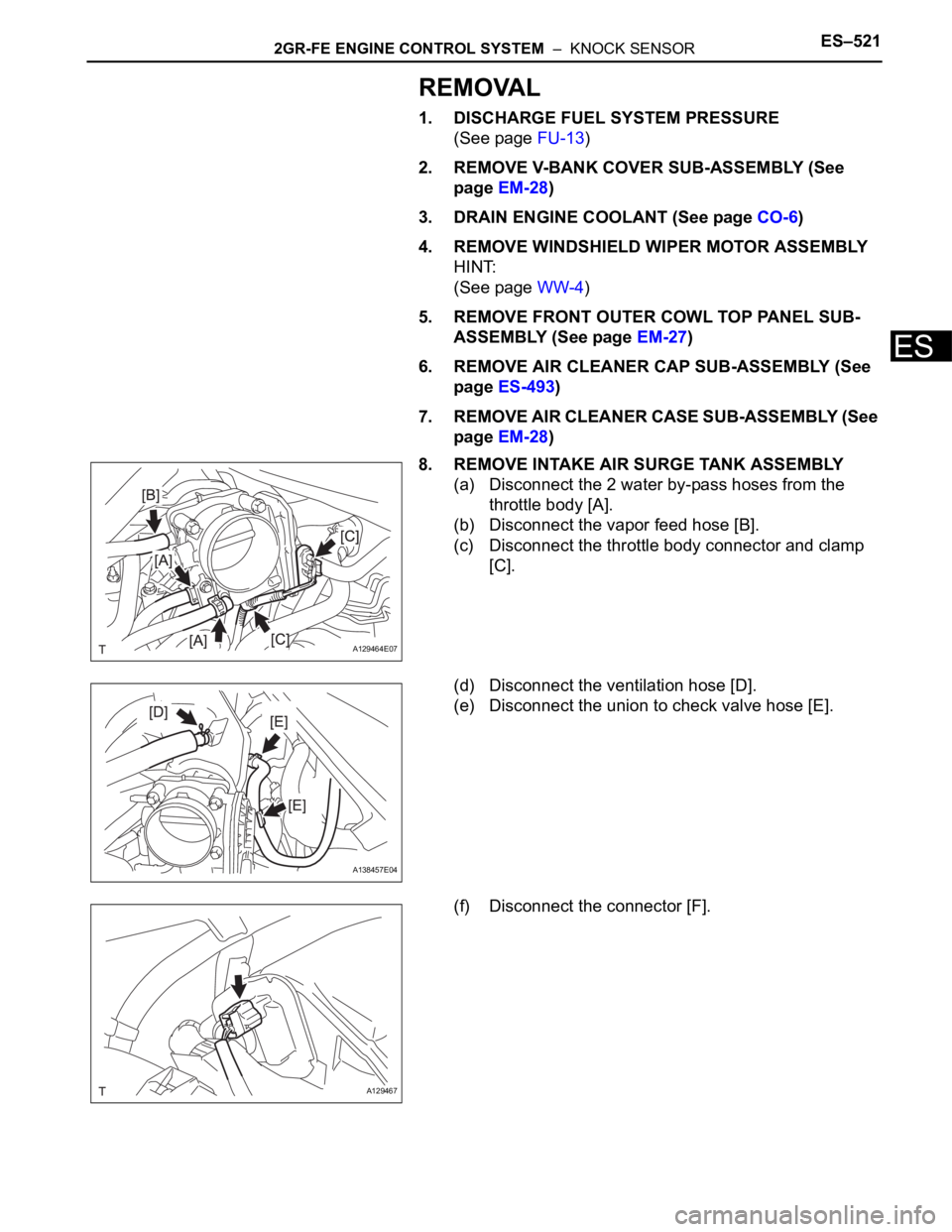

8. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

(a) Disconnect the 2 water by-pass hoses from the

throttle body [A].

(b) Disconnect the vapor feed hose [B].

(c) Disconnect the throttle body connector and clamp

[C].

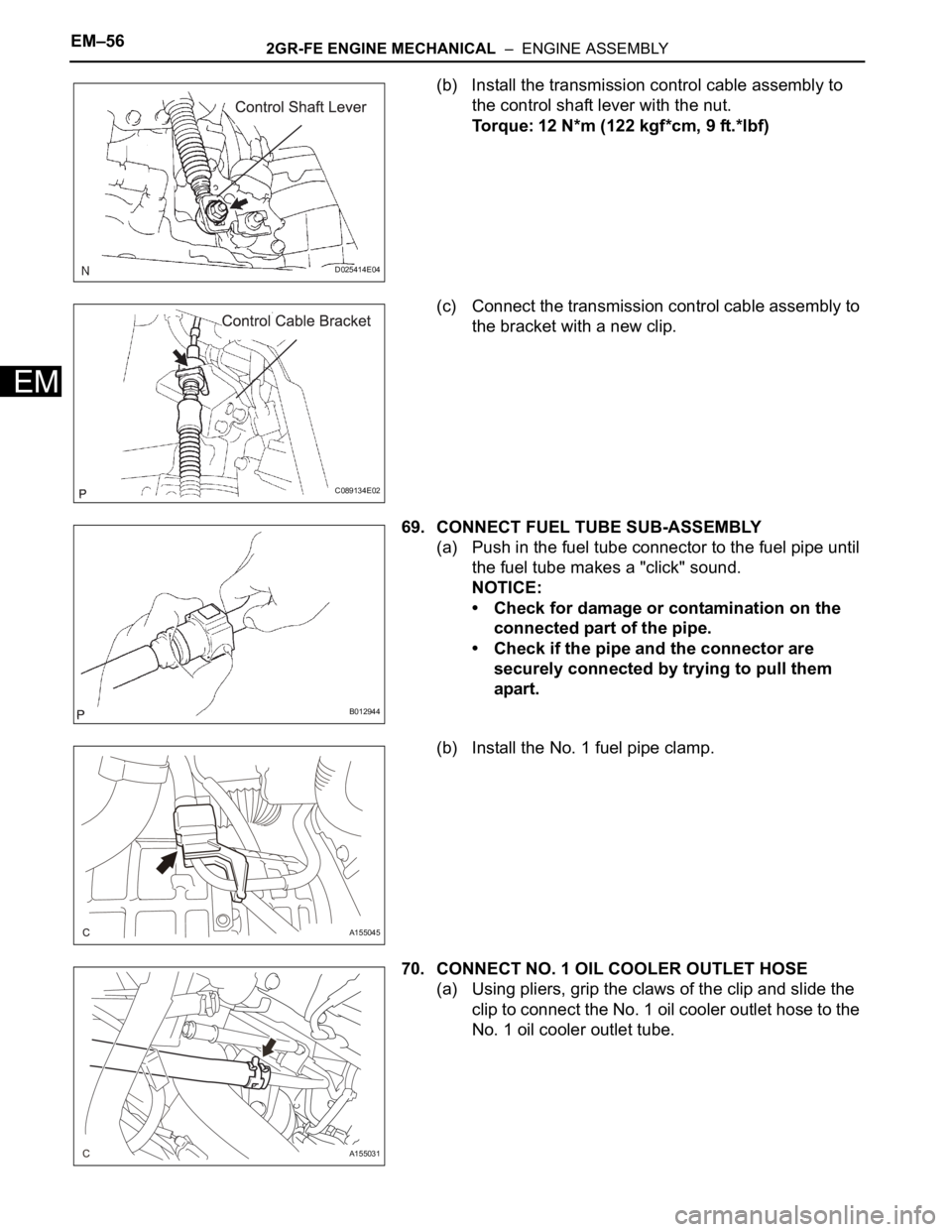

(d) Disconnect the ventilation hose [D].

(e) Disconnect the union to check valve hose [E].

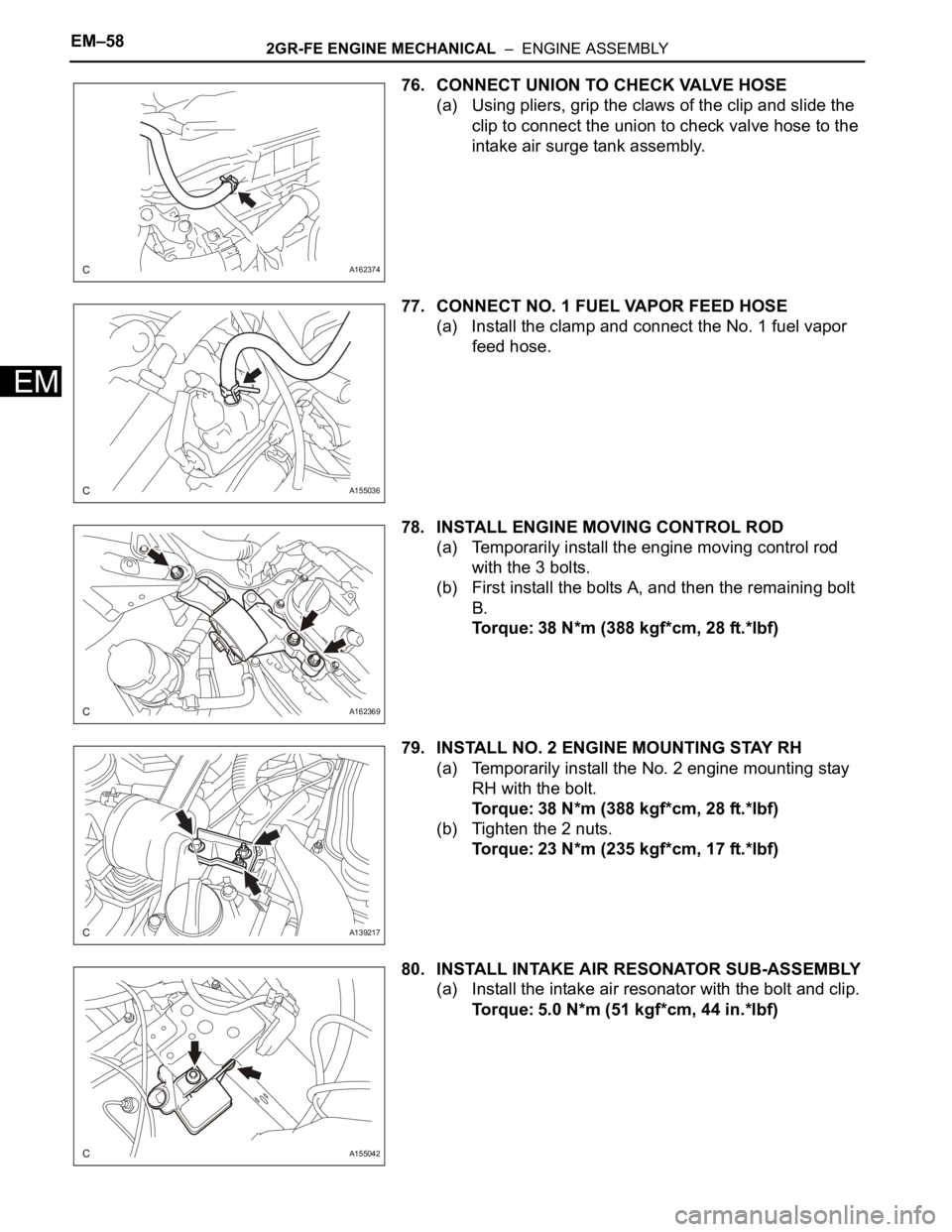

(f) Disconnect the connector [F].

A129464E07

A138457E04

A129467

Page 838 of 3000

![TOYOTA SIENNA 2007 Service Repair Manual 2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–523

ES

(a) Install a new gasket to the intake air surge tank [A].

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts [B].

Torque: 18 N*m ( TOYOTA SIENNA 2007 Service Repair Manual 2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–523

ES

(a) Install a new gasket to the intake air surge tank [A].

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts [B].

Torque: 18 N*m (](/img/14/57466/w960_57466-837.png)

2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–523

ES

(a) Install a new gasket to the intake air surge tank [A].

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts [B].

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

(c) Install the intake air surge tank with the 2 nuts and 2

bolts [C].

Torque: Nut

16 N*m (163 kgf*cm, 12 ft.*lbf)

Bolt

21 N*m (214 kgf*cm, 15 ft.*lbf)

(d) Connect the connector [D].

(e) Connect the union to check valve hose [E].

(f) Connect the ventilation hose No. 2 [F].

(g) Install the clamp and connect the throttle with motor

body assembly connector [G].

(h) Connect the vapor feed hose [H].

(i) Connect the 2 water by-pass hoses to the throttle

with motor body assembly [I].

5. INSTALL AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-59)

6. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-496)

7. ADD ENGINE COOLANT (See page CO-7)

8. INSPECT FOR ENGINE COOLANT LEAK (See page

CO-1)

9. INSPECT FOR FUEL LEAK (See page FU-7)

10. INSTALL FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-61)

11. INSTALL WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-5)

A129468E09

A129467

A138457E05

A129464E08

Page 873 of 3000

EM–562GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

(b) Install the transmission control cable assembly to

the control shaft lever with the nut.

Torque: 12 N*m (122 kgf*cm, 9 ft.*lbf)

(c) Connect the transmission control cable assembly to

the bracket with a new clip.

69. CONNECT FUEL TUBE SUB-ASSEMBLY

(a) Push in the fuel tube connector to the fuel pipe until

the fuel tube makes a "click" sound.

NOTICE:

• Check for damage or contamination on the

connected part of the pipe.

• Check if the pipe and the connector are

securely connected by trying to pull them

apart.

(b) Install the No. 1 fuel pipe clamp.

70. CONNECT NO. 1 OIL COOLER OUTLET HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the No. 1 oil cooler outlet hose to the

No. 1 oil cooler outlet tube.

D025414E04

C089134E02

B012944

A155045

A155031

Page 875 of 3000

EM–582GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

76. CONNECT UNION TO CHECK VALVE HOSE

(a) Using pliers, grip the claws of the clip and slide the

clip to connect the union to check valve hose to the

intake air surge tank assembly.

77. CONNECT NO. 1 FUEL VAPOR FEED HOSE

(a) Install the clamp and connect the No. 1 fuel vapor

feed hose.

78. INSTALL ENGINE MOVING CONTROL ROD

(a) Temporarily install the engine moving control rod

with the 3 bolts.

(b) First install the bolts A, and then the remaining bolt

B.

Torque: 38 N*m (388 kgf*cm, 28 ft.*lbf)

79. INSTALL NO. 2 ENGINE MOUNTING STAY RH

(a) Temporarily install the No. 2 engine mounting stay

RH with the bolt.

Torque: 38 N*m (388 kgf*cm, 28 ft.*lbf)

(b) Tighten the 2 nuts.

Torque: 23 N*m (235 kgf*cm, 17 ft.*lbf)

80. INSTALL INTAKE AIR RESONATOR SUB-ASSEMBLY

(a) Install the intake air resonator with the bolt and clip.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

A162374

A155036

A162369

A139217

A155042

Page 879 of 3000

EM–622GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

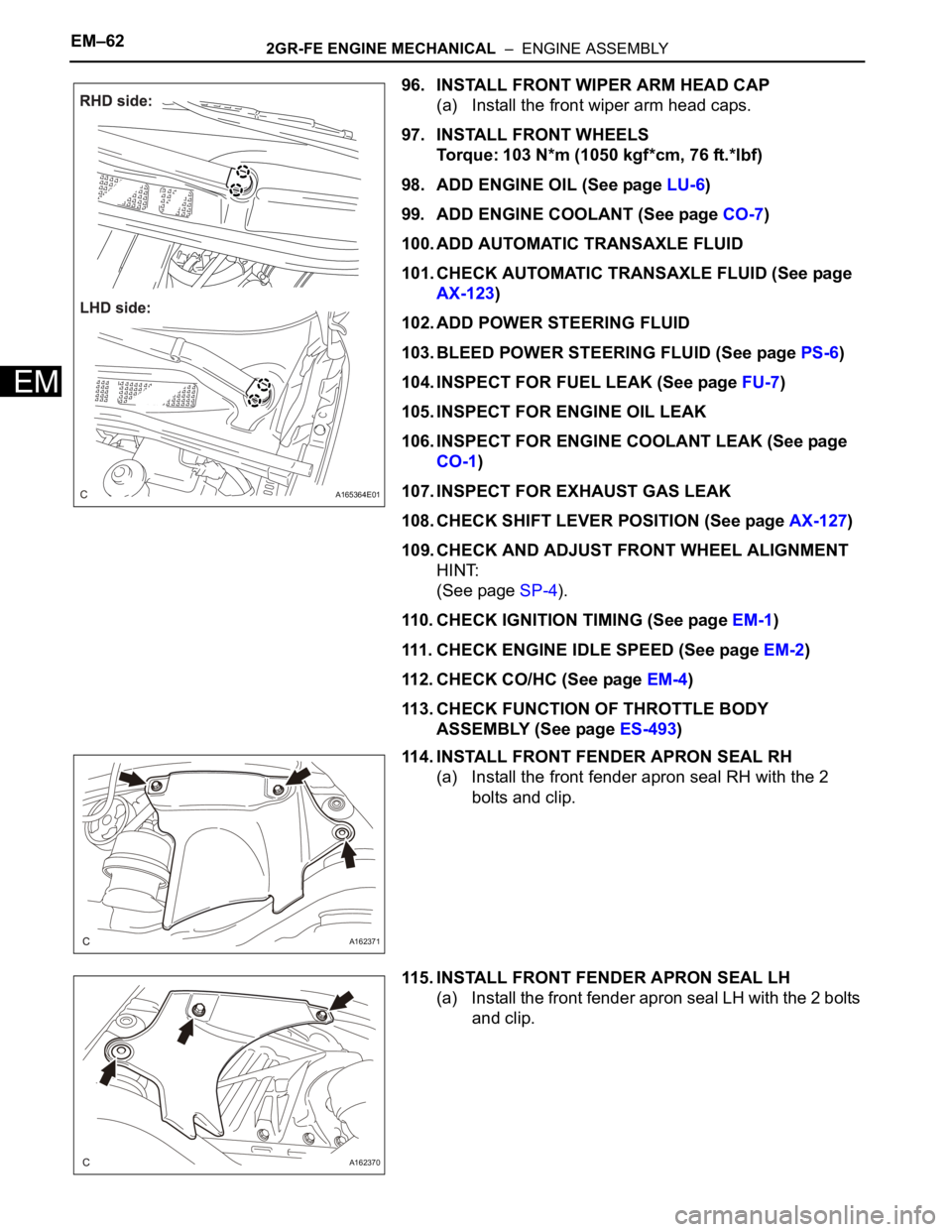

96. INSTALL FRONT WIPER ARM HEAD CAP

(a) Install the front wiper arm head caps.

97. INSTALL FRONT WHEELS

Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

98. ADD ENGINE OIL (See page LU-6)

99. ADD ENGINE COOLANT (See page CO-7)

100. ADD AUTOMATIC TRANSAXLE FLUID

101. CHECK AUTOMATIC TRANSAXLE FLUID (See page

AX-123)

102. ADD POWER STEERING FLUID

103. BLEED POWER STEERING FLUID (See page PS-6)

104. INSPECT FOR FUEL LEAK (See page FU-7)

105. INSPECT FOR ENGINE OIL LEAK

106. INSPECT FOR ENGINE COOLANT LEAK (See page

CO-1)

107. INSPECT FOR EXHAUST GAS LEAK

108. CHECK SHIFT LEVER POSITION (See page AX-127)

109. CHECK AND ADJUST FRONT WHEEL ALIGNMENT

HINT:

(See page SP-4).

110. CHECK IGNITION TIMING (See page EM-1)

111. CHECK ENGINE IDLE SPEED (See page EM-2)

112. CHECK CO/HC (See page EM-4)

113. CHECK FUNCTION OF THROTTLE BODY

ASSEMBLY (See page ES-493)

114. INSTALL FRONT FENDER APRON SEAL RH

(a) Install the front fender apron seal RH with the 2

bolts and clip.

115. INSTALL FRONT FENDER APRON SEAL LH

(a) Install the front fender apron seal LH with the 2 bolts

and clip.

A165364E01

A162371

A162370

Page 880 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–63

EM

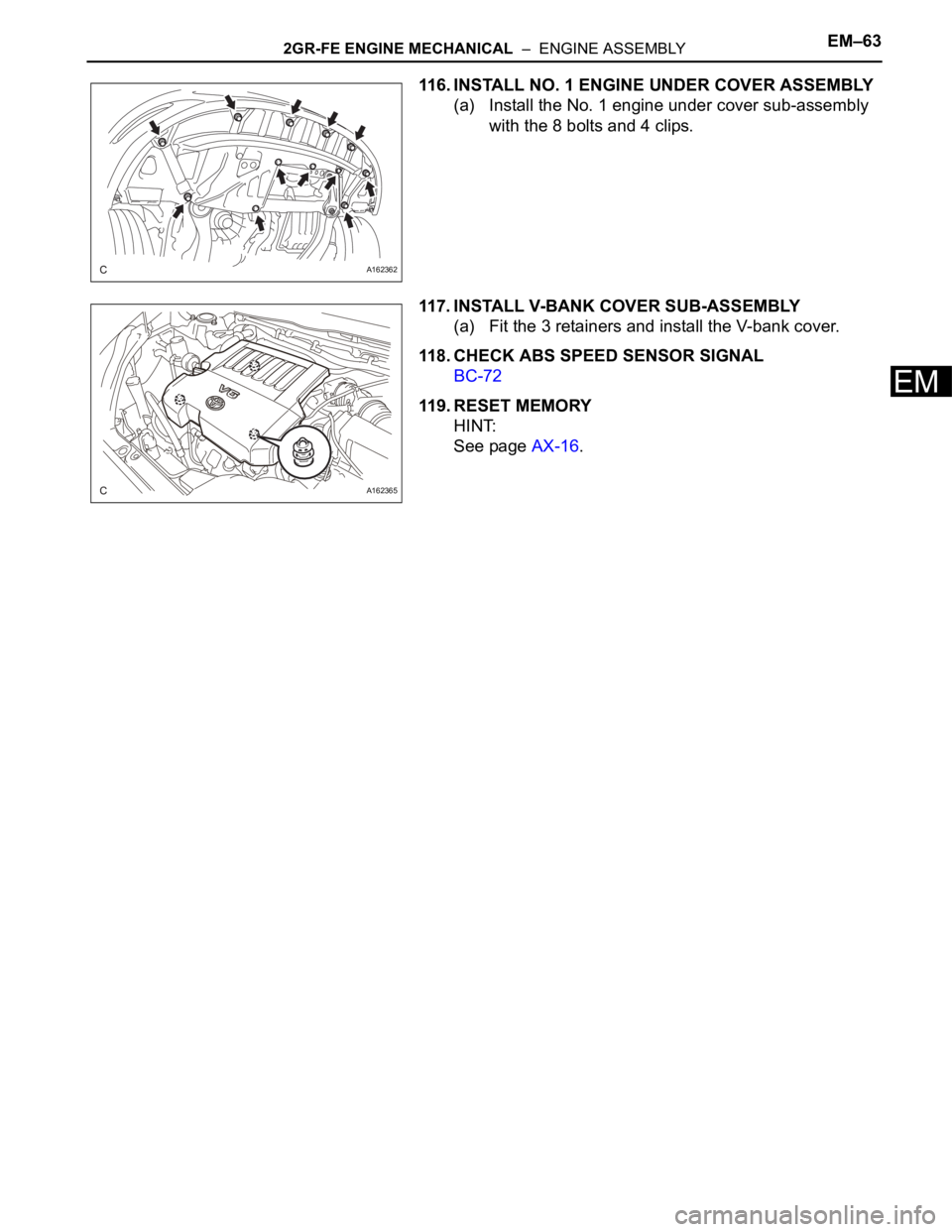

116. INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY

(a) Install the No. 1 engine under cover sub-assembly

with the 8 bolts and 4 clips.

117. INSTALL V-BANK COVER SUB-ASSEMBLY

(a) Fit the 3 retainers and install the V-bank cover.

118. CHECK ABS SPEED SENSOR SIGNAL

BC-72

119. RESET MEMORY

HINT:

See page AX-16.

A162362

A162365