transmission oil TOYOTA SIENNA 2007 Service Owner's Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1520 of 3000

U151E AUTOMATIC TRANSAXLE – VALVE BODY ASSEMBLYAX–137

AX

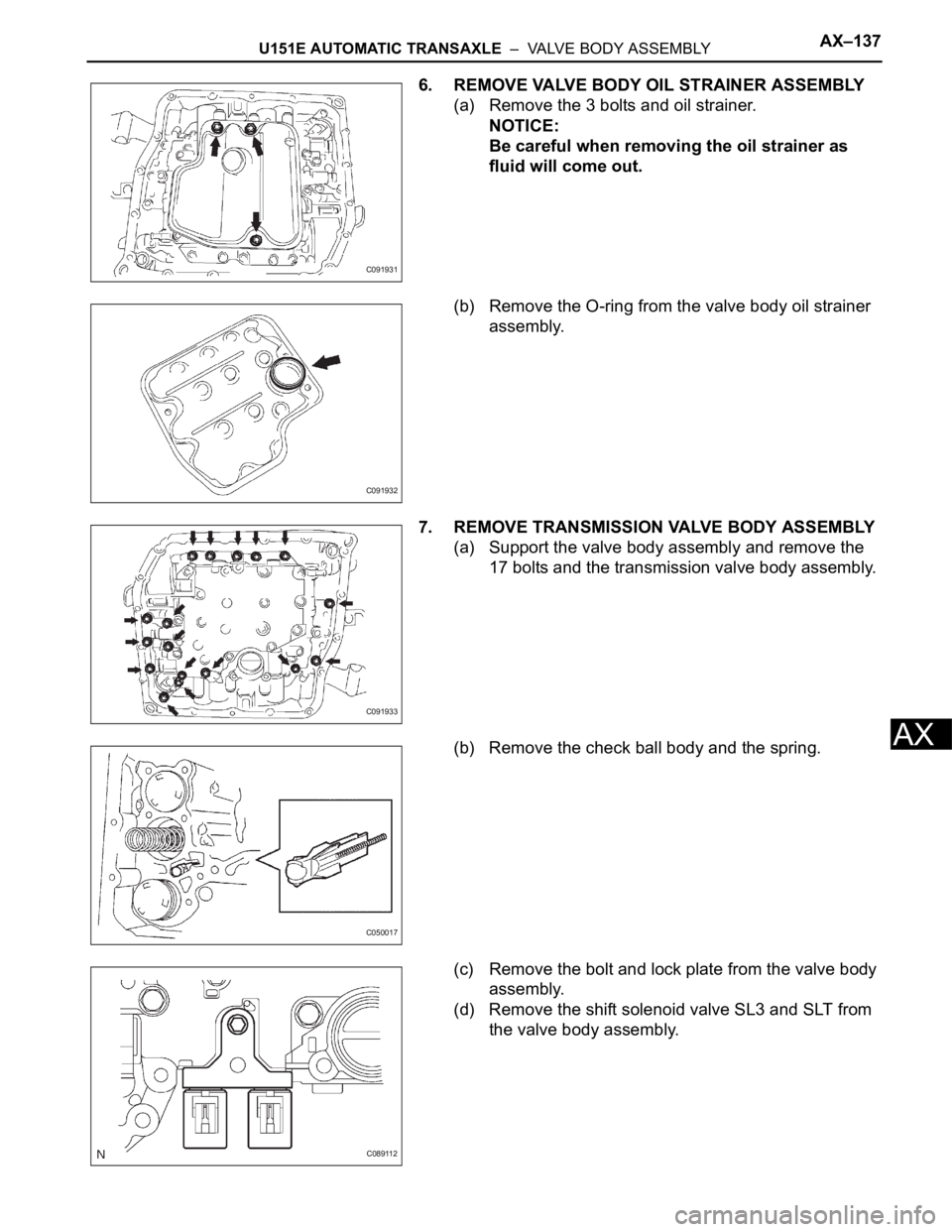

6. REMOVE VALVE BODY OIL STRAINER ASSEMBLY

(a) Remove the 3 bolts and oil strainer.

NOTICE:

Be careful when removing the oil strainer as

fluid will come out.

(b) Remove the O-ring from the valve body oil strainer

assembly.

7. REMOVE TRANSMISSION VALVE BODY ASSEMBLY

(a) Support the valve body assembly and remove the

17 bolts and the transmission valve body assembly.

(b) Remove the check ball body and the spring.

(c) Remove the bolt and lock plate from the valve body

assembly.

(d) Remove the shift solenoid valve SL3 and SLT from

the valve body assembly.

C091931

C091932

C091933

C050017

C089112

Page 1524 of 3000

U151E AUTOMATIC TRANSAXLE – VALVE BODY ASSEMBLYAX–141

AX

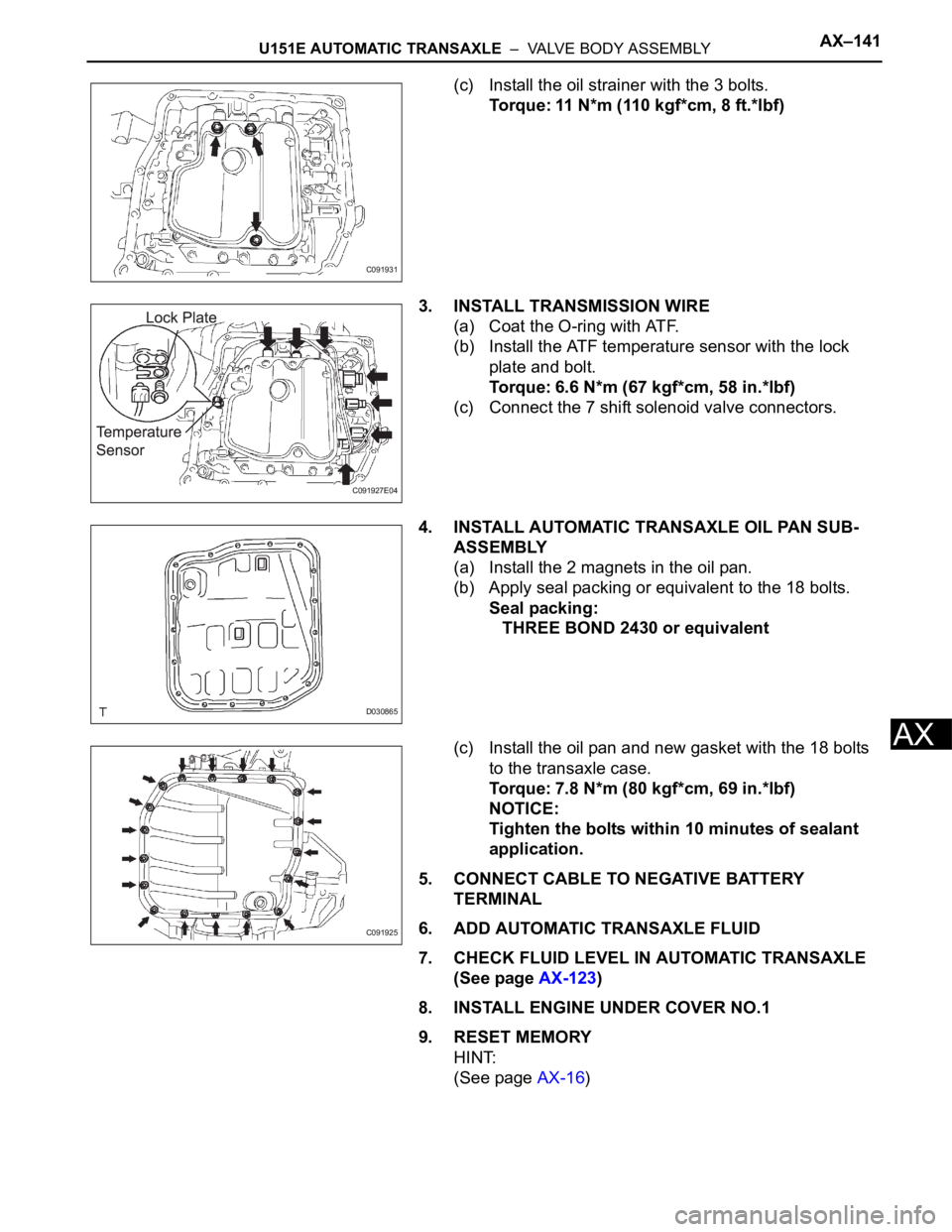

(c) Install the oil strainer with the 3 bolts.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

3. INSTALL TRANSMISSION WIRE

(a) Coat the O-ring with ATF.

(b) Install the ATF temperature sensor with the lock

plate and bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

(c) Connect the 7 shift solenoid valve connectors.

4. INSTALL AUTOMATIC TRANSAXLE OIL PAN SUB-

ASSEMBLY

(a) Install the 2 magnets in the oil pan.

(b) Apply seal packing or equivalent to the 18 bolts.

Seal packing:

THREE BOND 2430 or equivalent

(c) Install the oil pan and new gasket with the 18 bolts

to the transaxle case.

Torque: 7.8 N*m (80 kgf*cm, 69 in.*lbf)

NOTICE:

Tighten the bolts within 10 minutes of sealant

application.

5. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

6. ADD AUTOMATIC TRANSAXLE FLUID

7. CHECK FLUID LEVEL IN AUTOMATIC TRANSAXLE

(See page AX-123)

8. INSTALL ENGINE UNDER COVER NO.1

9. RESET MEMORY

HINT:

(See page AX-16)

C091931

C091927E04

D030865

C091925

Page 1553 of 3000

AX–158U151E AUTOMATIC TRANSAXLE – DIFFERENTIAL OIL SEAL

AX

TRANSMISSION

U151E AUTOMATIC TRANSAXLE

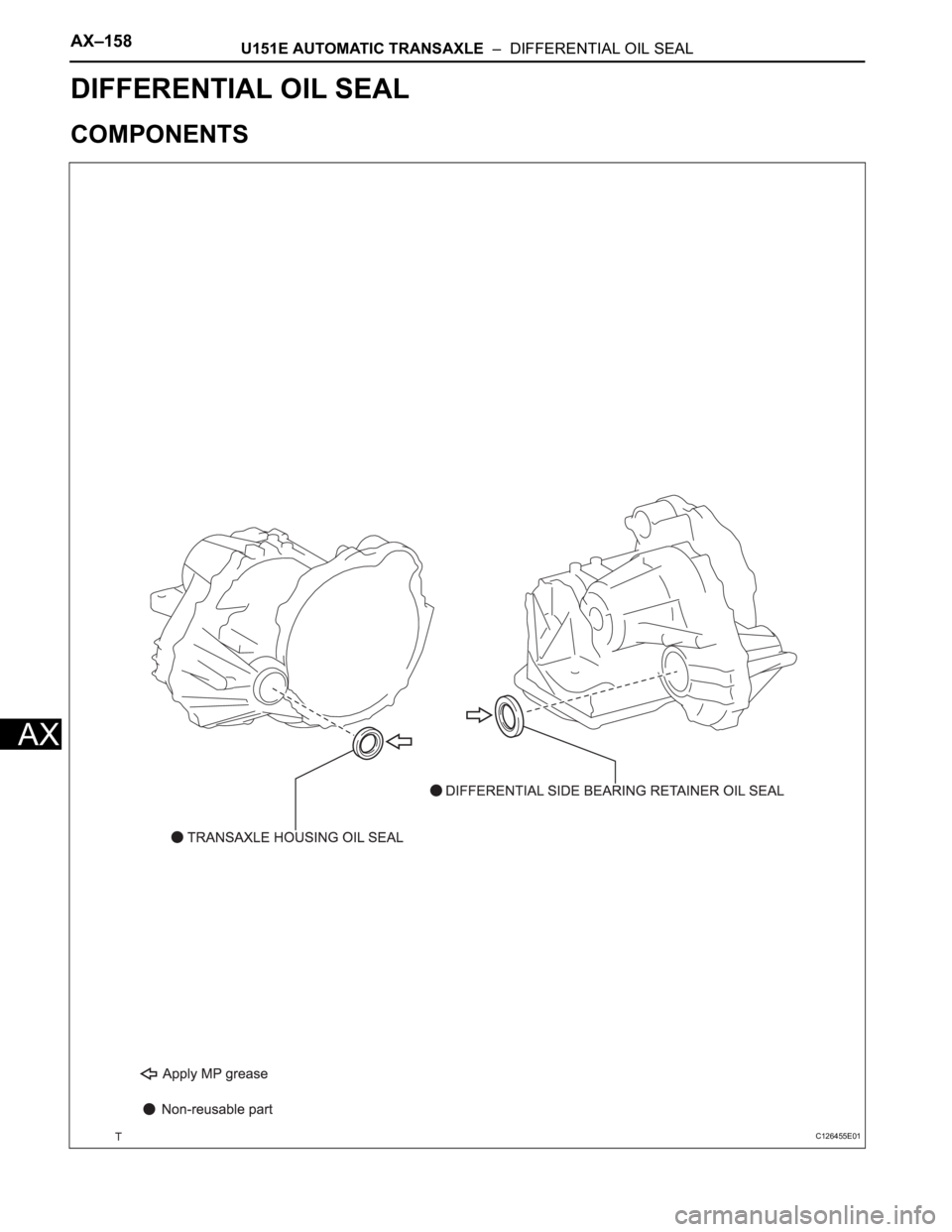

DIFFERENTIAL OIL SEAL

COMPONENTS

C126455E01

Page 1558 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–179

AX

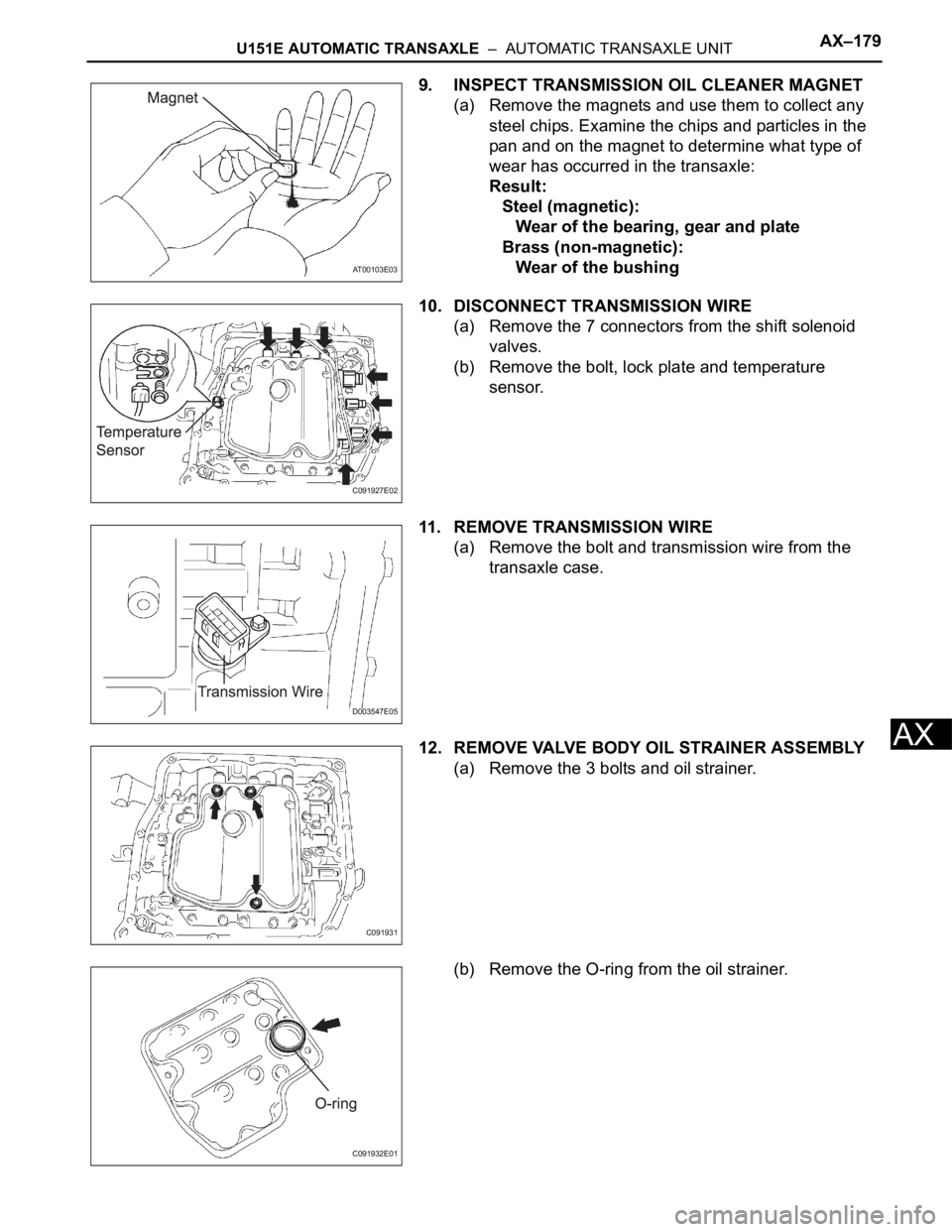

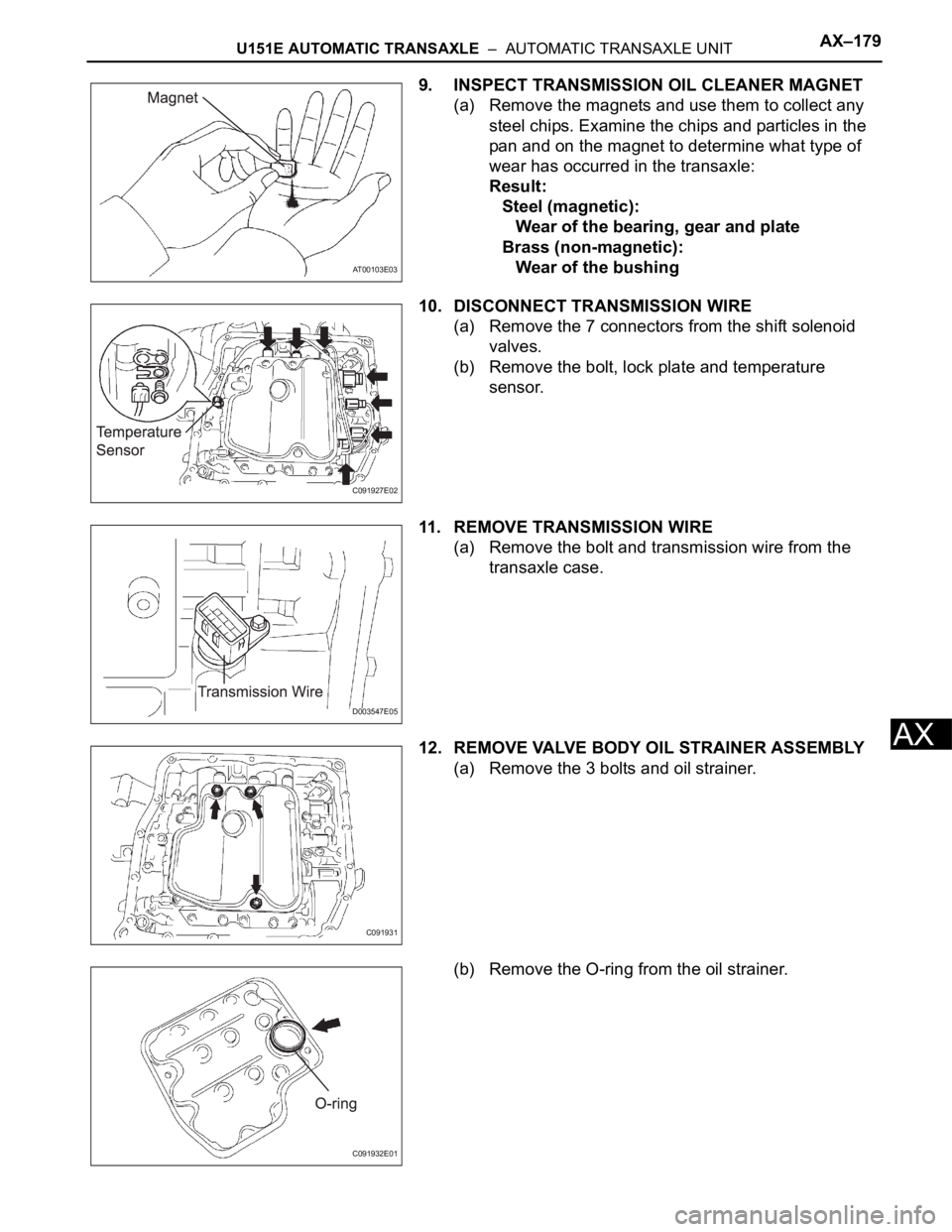

9. INSPECT TRANSMISSION OIL CLEANER MAGNET

(a) Remove the magnets and use them to collect any

steel chips. Examine the chips and particles in the

pan and on the magnet to determine what type of

wear has occurred in the transaxle:

Result:

Steel (magnetic):

Wear of the bearing, gear and plate

Brass (non-magnetic):

Wear of the bushing

10. DISCONNECT TRANSMISSION WIRE

(a) Remove the 7 connectors from the shift solenoid

valves.

(b) Remove the bolt, lock plate and temperature

sensor.

11. REMOVE TRANSMISSION WIRE

(a) Remove the bolt and transmission wire from the

transaxle case.

12. REMOVE VALVE BODY OIL STRAINER ASSEMBLY

(a) Remove the 3 bolts and oil strainer.

(b) Remove the O-ring from the oil strainer.

AT00103E03

C091927E02

D003547E05

C091931

C091932E01

Page 1581 of 3000

AX–164U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLY

AX

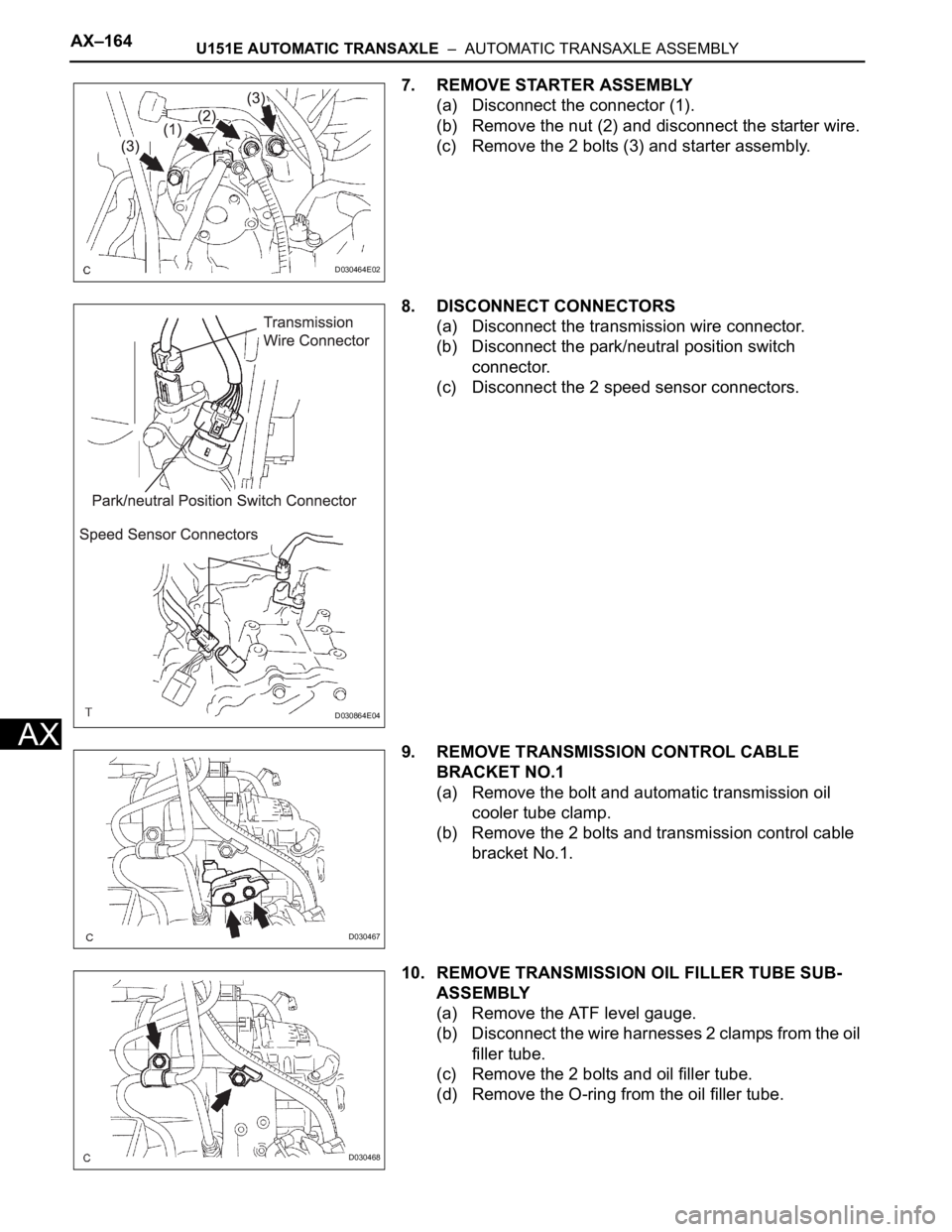

7. REMOVE STARTER ASSEMBLY

(a) Disconnect the connector (1).

(b) Remove the nut (2) and disconnect the starter wire.

(c) Remove the 2 bolts (3) and starter assembly.

8. DISCONNECT CONNECTORS

(a) Disconnect the transmission wire connector.

(b) Disconnect the park/neutral position switch

connector.

(c) Disconnect the 2 speed sensor connectors.

9. REMOVE TRANSMISSION CONTROL CABLE

BRACKET NO.1

(a) Remove the bolt and automatic transmission oil

cooler tube clamp.

(b) Remove the 2 bolts and transmission control cable

bracket No.1.

10. REMOVE TRANSMISSION OIL FILLER TUBE SUB-

ASSEMBLY

(a) Remove the ATF level gauge.

(b) Disconnect the wire harnesses 2 clamps from the oil

filler tube.

(c) Remove the 2 bolts and oil filler tube.

(d) Remove the O-ring from the oil filler tube.

D030464E02

D030864E04

D030467

D030468

Page 1584 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE ASSEMBLYAX–167

AX

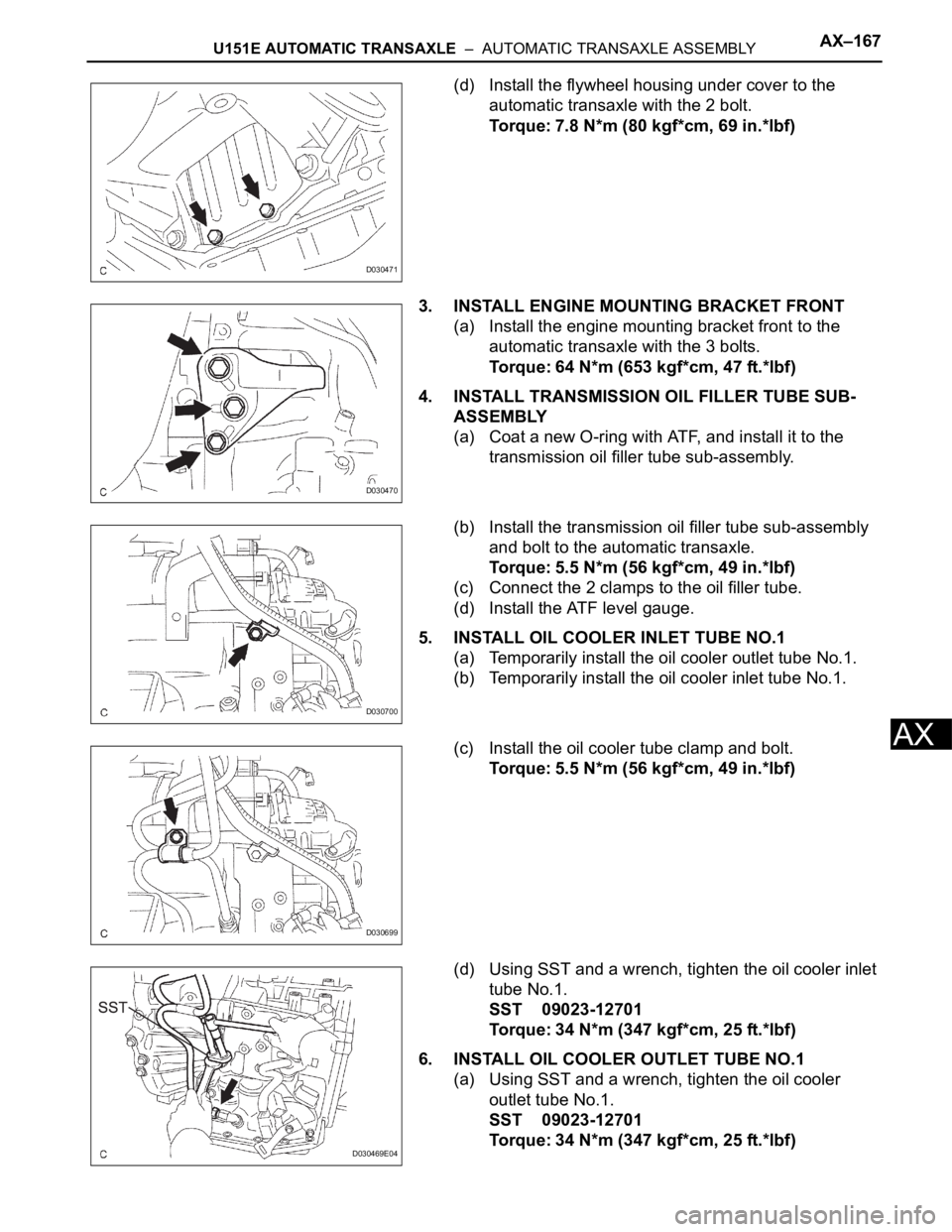

(d) Install the flywheel housing under cover to the

automatic transaxle with the 2 bolt.

Torque: 7.8 N*m (80 kgf*cm, 69 in.*lbf)

3. INSTALL ENGINE MOUNTING BRACKET FRONT

(a) Install the engine mounting bracket front to the

automatic transaxle with the 3 bolts.

Torque: 64 N*m (653 kgf*cm, 47 ft.*lbf)

4. INSTALL TRANSMISSION OIL FILLER TUBE SUB-

ASSEMBLY

(a) Coat a new O-ring with ATF, and install it to the

transmission oil filler tube sub-assembly.

(b) Install the transmission oil filler tube sub-assembly

and bolt to the automatic transaxle.

Torque: 5.5 N*m (56 kgf*cm, 49 in.*lbf)

(c) Connect the 2 clamps to the oil filler tube.

(d) Install the ATF level gauge.

5. INSTALL OIL COOLER INLET TUBE NO.1

(a) Temporarily install the oil cooler outlet tube No.1.

(b) Temporarily install the oil cooler inlet tube No.1.

(c) Install the oil cooler tube clamp and bolt.

Torque: 5.5 N*m (56 kgf*cm, 49 in.*lbf)

(d) Using SST and a wrench, tighten the oil cooler inlet

tube No.1.

SST 09023-12701

Torque: 34 N*m (347 kgf*cm, 25 ft.*lbf)

6. INSTALL OIL COOLER OUTLET TUBE NO.1

(a) Using SST and a wrench, tighten the oil cooler

outlet tube No.1.

SST 09023-12701

Torque: 34 N*m (347 kgf*cm, 25 ft.*lbf)

D030471

D030470

D030700

D030699

D030469E04

Page 1614 of 3000

AX–228U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNIT

AX

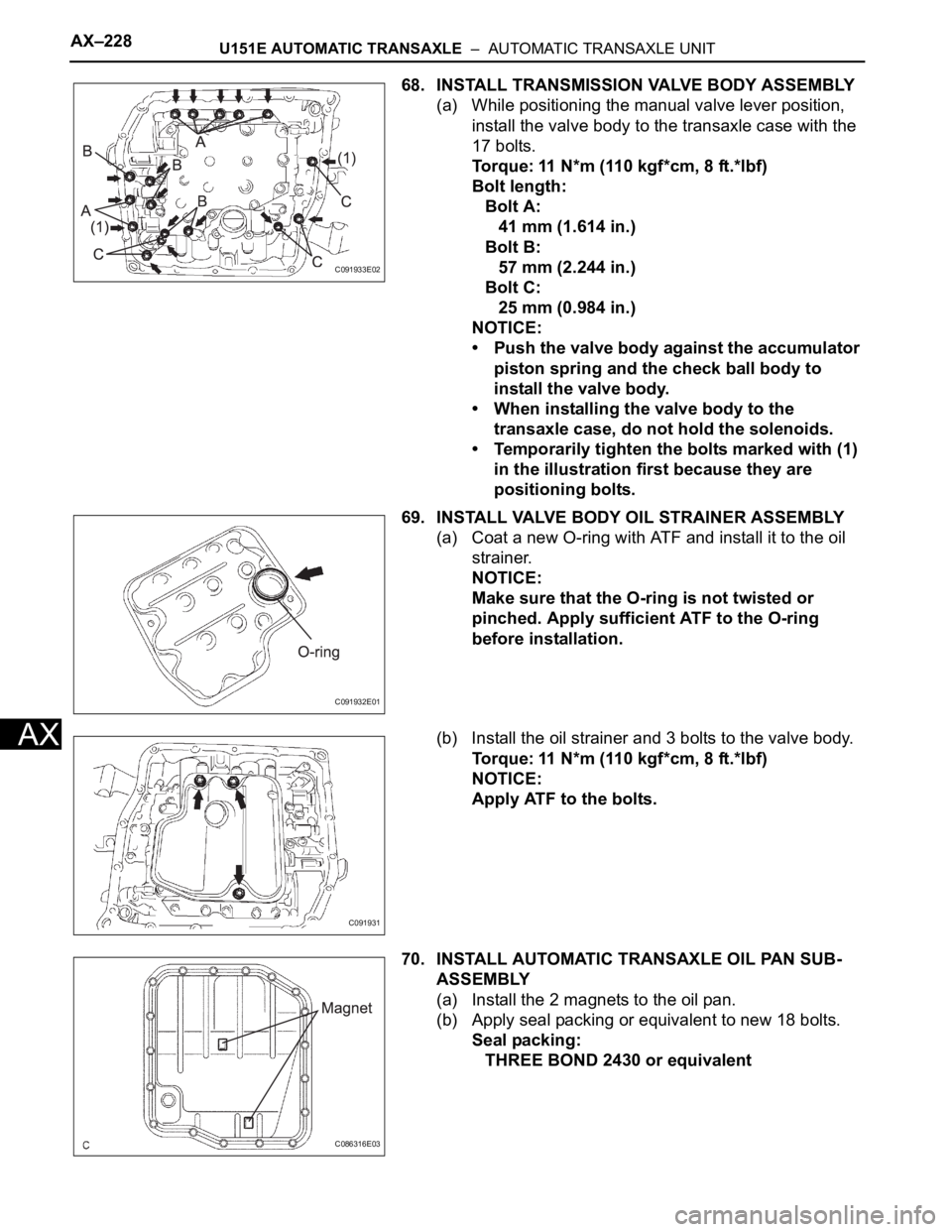

68. INSTALL TRANSMISSION VALVE BODY ASSEMBLY

(a) While positioning the manual valve lever position,

install the valve body to the transaxle case with the

17 bolts.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

Bolt length:

Bolt A:

41 mm (1.614 in.)

Bolt B:

57 mm (2.244 in.)

Bolt C:

25 mm (0.984 in.)

NOTICE:

• Push the valve body against the accumulator

piston spring and the check ball body to

install the valve body.

• When installing the valve body to the

transaxle case, do not hold the solenoids.

• Temporarily tighten the bolts marked with (1)

in the illustration first because they are

positioning bolts.

69. INSTALL VALVE BODY OIL STRAINER ASSEMBLY

(a) Coat a new O-ring with ATF and install it to the oil

strainer.

NOTICE:

Make sure that the O-ring is not twisted or

pinched. Apply sufficient ATF to the O-ring

before installation.

(b) Install the oil strainer and 3 bolts to the valve body.

Torque: 11 N*m (110 kgf*cm, 8 ft.*lbf)

NOTICE:

Apply ATF to the bolts.

70. INSTALL AUTOMATIC TRANSAXLE OIL PAN SUB-

ASSEMBLY

(a) Install the 2 magnets to the oil pan.

(b) Apply seal packing or equivalent to new 18 bolts.

Seal packing:

THREE BOND 2430 or equivalent

C091933E02

C091932E01

C091931

C086316E03

Page 1623 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE UNITAX–179

AX

9. INSPECT TRANSMISSION OIL CLEANER MAGNET

(a) Remove the magnets and use them to collect any

steel chips. Examine the chips and particles in the

pan and on the magnet to determine what type of

wear has occurred in the transaxle:

Result:

Steel (magnetic):

Wear of the bearing, gear and plate

Brass (non-magnetic):

Wear of the bushing

10. DISCONNECT TRANSMISSION WIRE

(a) Remove the 7 connectors from the shift solenoid

valves.

(b) Remove the bolt, lock plate and temperature

sensor.

11. REMOVE TRANSMISSION WIRE

(a) Remove the bolt and transmission wire from the

transaxle case.

12. REMOVE VALVE BODY OIL STRAINER ASSEMBLY

(a) Remove the 3 bolts and oil strainer.

(b) Remove the O-ring from the oil strainer.

AT00103E03

C091927E02

D003547E05

C091931

C091932E01

Page 1647 of 3000

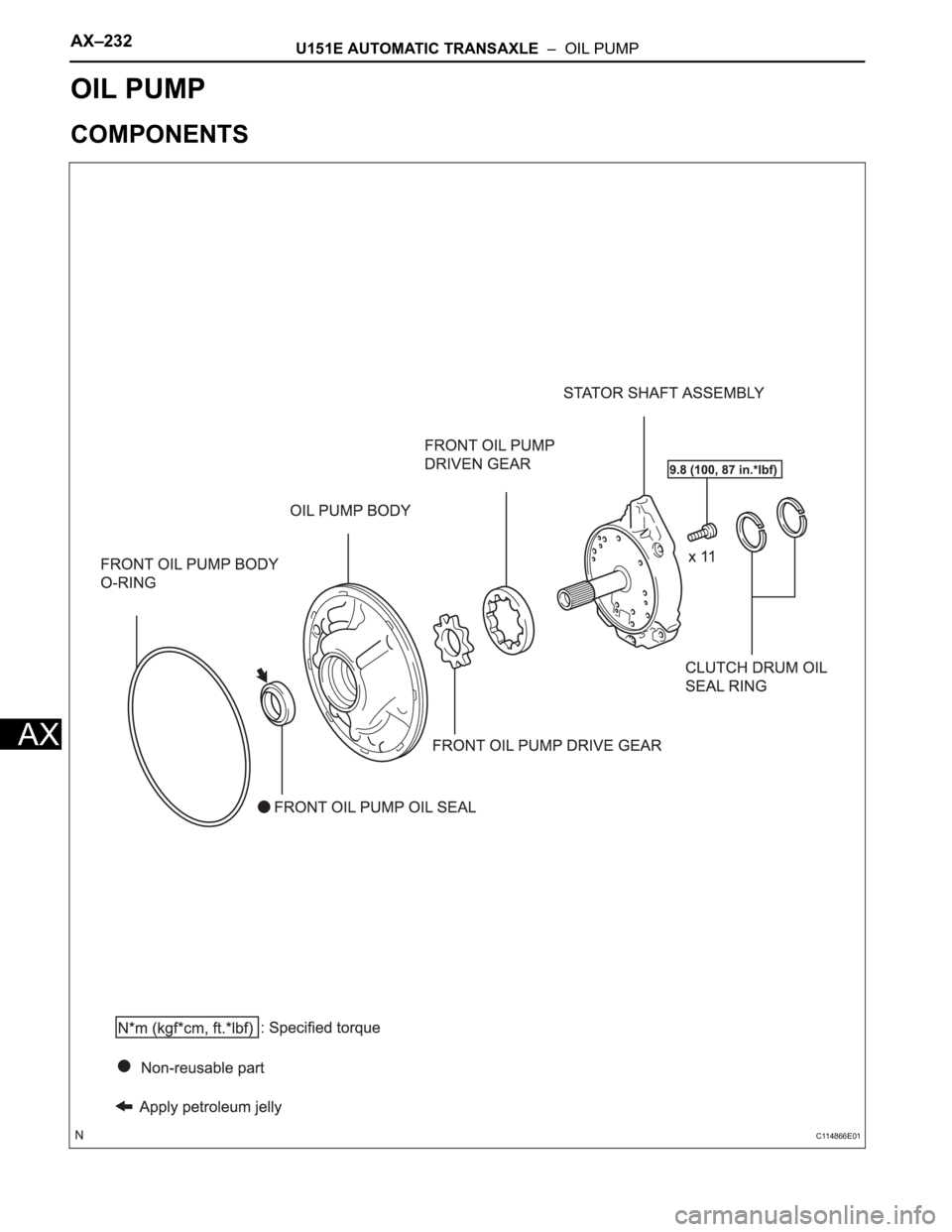

AX–232U151E AUTOMATIC TRANSAXLE – OIL PUMP

AX

TRANSMISSION

U151E AUTOMATIC TRANSAXLE

OIL PUMP

COMPONENTS

C114866E01

Page 1699 of 3000

AX–16U151F AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

(9) Disconnect the connector of the transmission

wire.

HINT:

Disconnect the connector only when performing

the D position stall test.

(10)Start the engine.

(11)Firmly depress the brake pedal, shift to the D

position, depress the accelerator pedal all the

way down and check the line pressure while the

stall test is performed.

Specified line pressure:

(12)Turn the ignition switch off.

(13)Remove the SST, install the test plug A.

(14)Remove the test plug B, install the SST and

start engine.

SST 09992-00095 (09992-00231, 09992-

00271)

(15)Connect the transmission wire connector,

depress the brake pedal firmly, shift to the R

position and check that the line pressure while

the engine is idling and during the stall test.

Specified line pressure:

(16)Remove the SST, install the test plug B.

(17)Clear the DTC.

Evaluation:

C160154E01

Condition

D position kPa (kgf / cm2, psi)

Stall test931 to 1,031 kPa

(9.5 to 10.5 kgf/cm

2, 135 to 150 psi)

Condition

R position kPa (kgf / cm

2, psi)

Idling672 to 742 kPa

(6.9 to 7.6 kgf/cm

2, 97 to 108 psi)

Stall test1,768 to 1,968 kPa

(18.0 to 20.1 kgf/cm

2, 256 to 285 psi)

Problem Possible cause

Measured values are higher than specified in all positions• Shift solenoid valve SLT defective

• Regulator valve defective

Measured values are lower than specified in all positions• Shift solenoid valve SLT defective

• Regulator valve defective

• Oil pump defective

• U/D (Underdrive) direct clutch defective

Pressure is low in the D position only• D position circuit fluid leak

• Forward clutch defective

Pressure is low in the R position only• R position circuit fluid leak

• Reverse clutch defective

• 1st and reverse brake defective