ecu TOYOTA SIENNA 2007 Service Workshop Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 312 of 3000

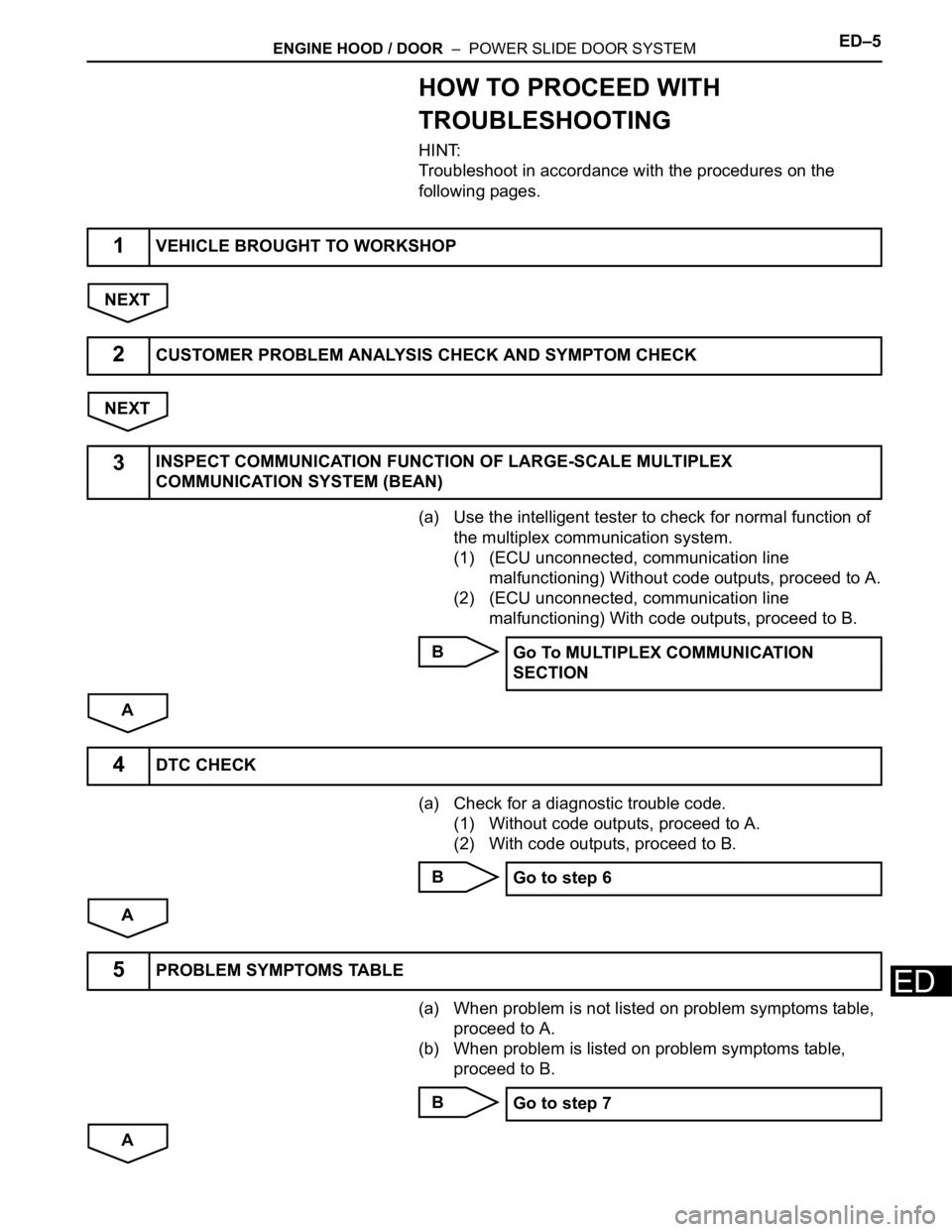

ENGINE HOOD / DOOR – POWER SLIDE DOOR SYSTEMED–5

ED

HOW TO PROCEED WITH

TROUBLESHOOTING

HINT:

Troubleshoot in accordance with the procedures on the

following pages.

NEXT

NEXT

(a) Use the intelligent tester to check for normal function of

the multiplex communication system.

(1) (ECU unconnected, communication line

malfunctioning) Without code outputs, proceed to A.

(2) (ECU unconnected, communication line

malfunctioning) With code outputs, proceed to B.

B

A

(a) Check for a diagnostic trouble code.

(1) Without code outputs, proceed to A.

(2) With code outputs, proceed to B.

B

A

(a) When problem is not listed on problem symptoms table,

proceed to A.

(b) When problem is listed on problem symptoms table,

proceed to B.

B

A

1VEHICLE BROUGHT TO WORKSHOP

2CUSTOMER PROBLEM ANALYSIS CHECK AND SYMPTOM CHECK

3INSPECT COMMUNICATION FUNCTION OF LARGE-SCALE MULTIPLEX

COMMUNICATION SYSTEM (BEAN)

Go To MULTIPLEX COMMUNICATION

SECTION

4DTC CHECK

Go to step 6

5PROBLEM SYMPTOMS TABLE

Go to step 7

Page 313 of 3000

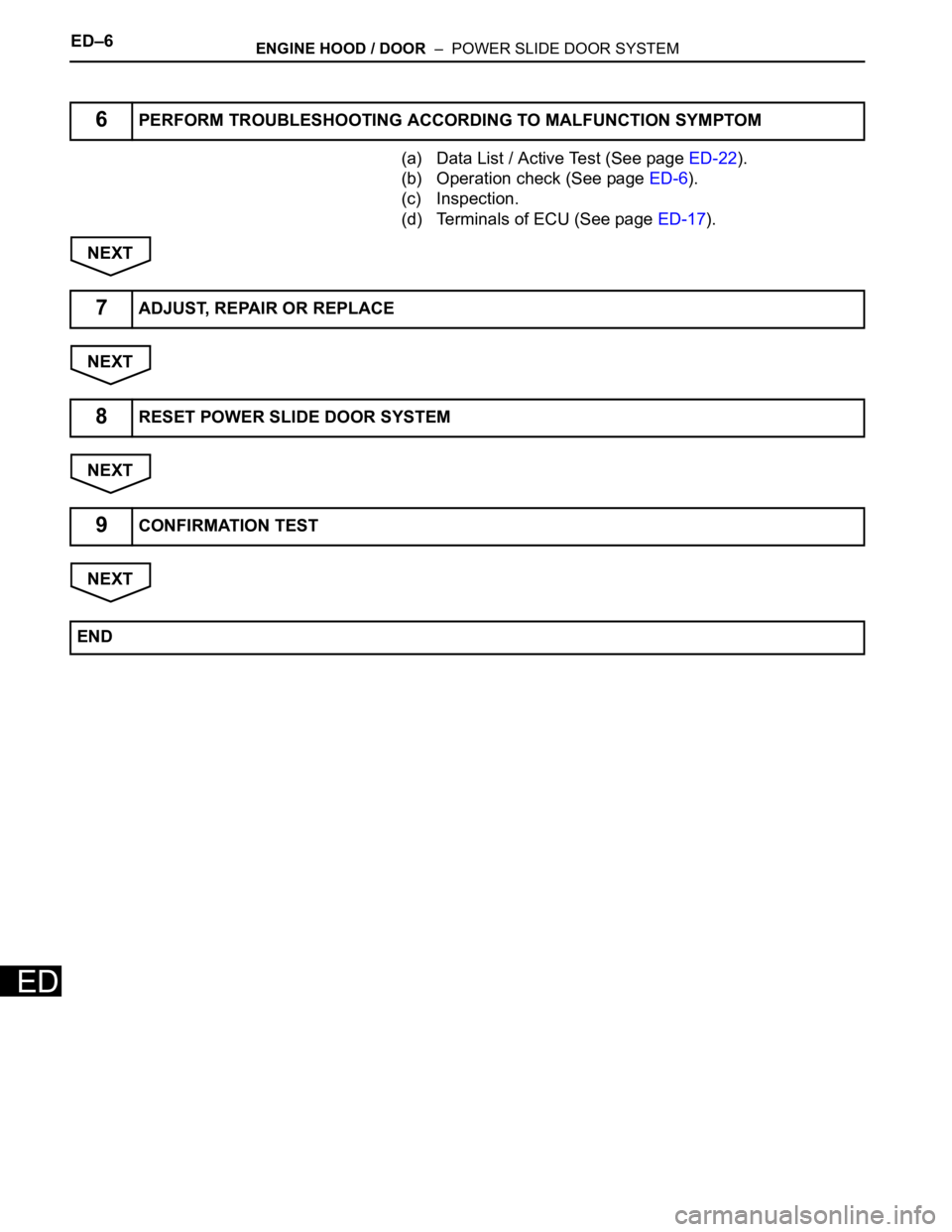

ED–6ENGINE HOOD / DOOR – POWER SLIDE DOOR SYSTEM

ED

(a) Data List / Active Test (See page ED-22).

(b) Operation check (See page ED-6).

(c) Inspection.

(d) Terminals of ECU (See page ED-17).

NEXT

NEXT

NEXT

NEXT

6PERFORM TROUBLESHOOTING ACCORDING TO MALFUNCTION SYMPTOM

7ADJUST, REPAIR OR REPLACE

8RESET POWER SLIDE DOOR SYSTEM

9CONFIRMATION TEST

END

Page 324 of 3000

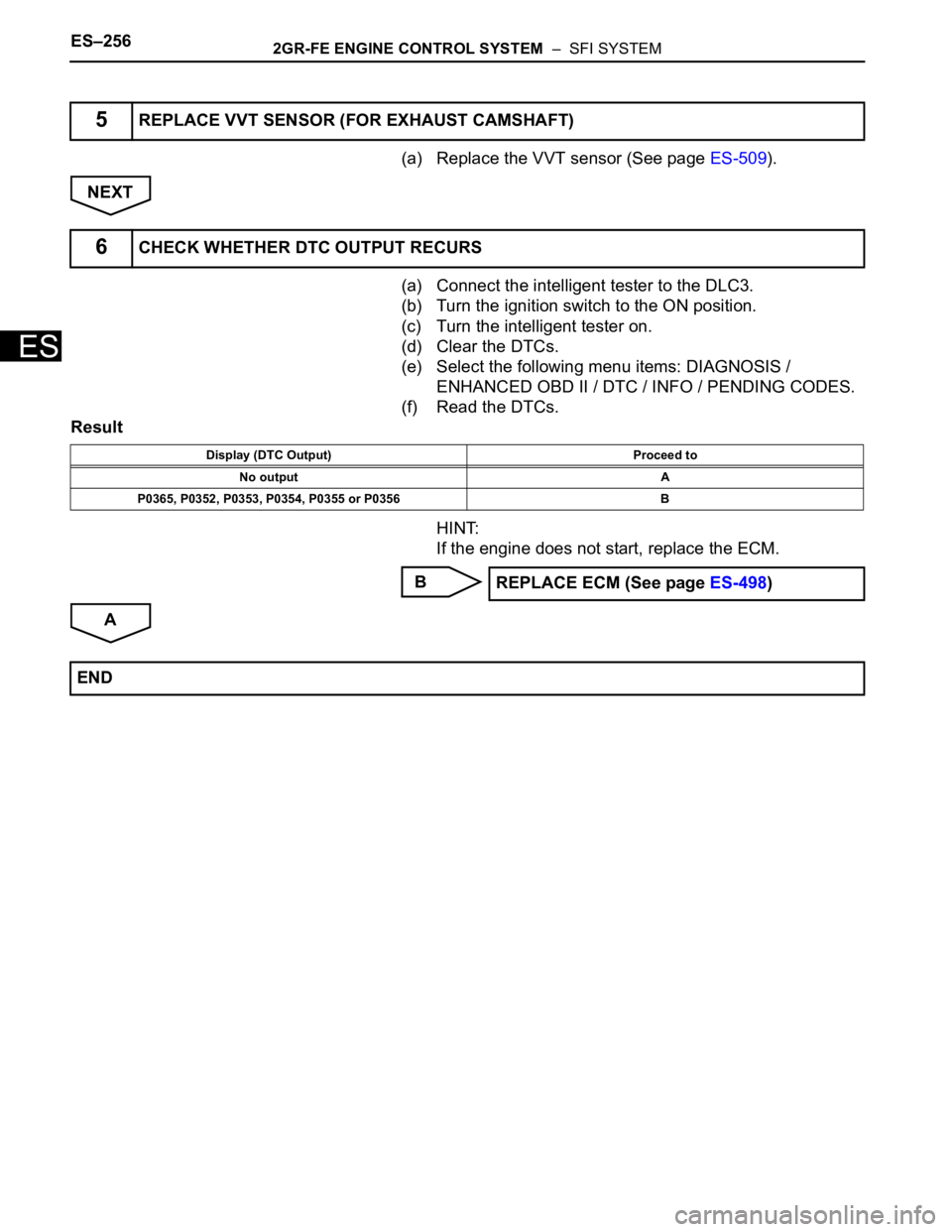

ES–2562GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

(a) Replace the VVT sensor (See page ES-509).

NEXT

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the intelligent tester on.

(d) Clear the DTCs.

(e) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC / INFO / PENDING CODES.

(f) Read the DTCs.

Result

HINT:

If the engine does not start, replace the ECM.

B

A

5REPLACE VVT SENSOR (FOR EXHAUST CAMSHAFT)

6CHECK WHETHER DTC OUTPUT RECURS

Display (DTC Output) Proceed to

No output A

P0365, P0352, P0353, P0354, P0355 or P0356 B

REPLACE ECM (See page ES-498)

END

Page 354 of 3000

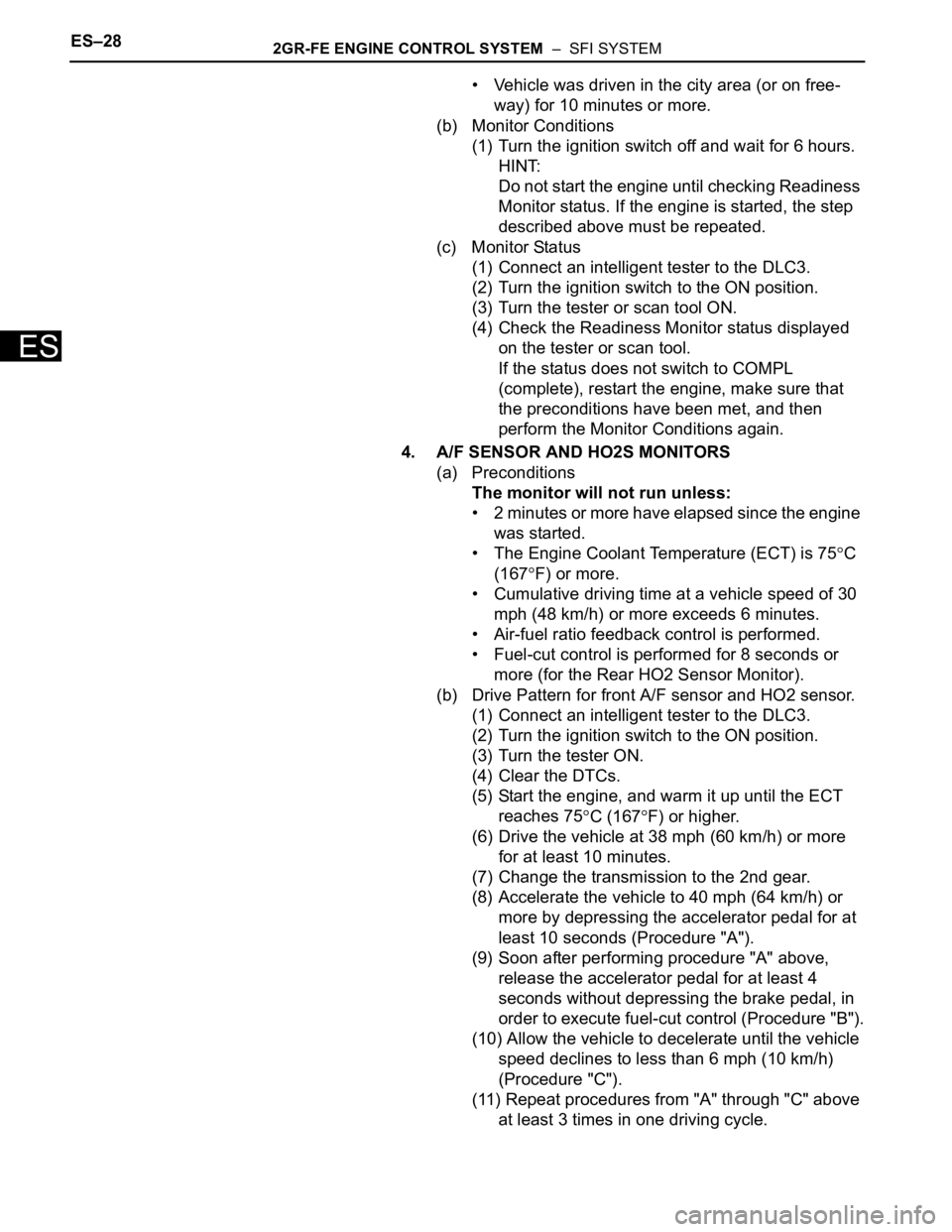

ES–282GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

• Vehicle was driven in the city area (or on free-

way) for 10 minutes or more.

(b) Monitor Conditions

(1) Turn the ignition switch off and wait for 6 hours.

HINT:

Do not start the engine until checking Readiness

Monitor status. If the engine is started, the step

described above must be repeated.

(c) Monitor Status

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester or scan tool ON.

(4) Check the Readiness Monitor status displayed

on the tester or scan tool.

If the status does not switch to COMPL

(complete), restart the engine, make sure that

the preconditions have been met, and then

perform the Monitor Conditions again.

4. A/F SENSOR AND HO2S MONITORS

(a) Preconditions

The monitor will not run unless:

• 2 minutes or more have elapsed since the engine

was started.

• The Engine Coolant Temperature (ECT) is 75

C

(167

F) or more.

• Cumulative driving time at a vehicle speed of 30

mph (48 km/h) or more exceeds 6 minutes.

• Air-fuel ratio feedback control is performed.

• Fuel-cut control is performed for 8 seconds or

more (for the Rear HO2 Sensor Monitor).

(b) Drive Pattern for front A/F sensor and HO2 sensor.

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester ON.

(4) Clear the DTCs.

(5) Start the engine, and warm it up until the ECT

reaches 75

C (167F) or higher.

(6) Drive the vehicle at 38 mph (60 km/h) or more

for at least 10 minutes.

(7) Change the transmission to the 2nd gear.

(8) Accelerate the vehicle to 40 mph (64 km/h) or

more by depressing the accelerator pedal for at

least 10 seconds (Procedure "A").

(9) Soon after performing procedure "A" above,

release the accelerator pedal for at least 4

seconds without depressing the brake pedal, in

order to execute fuel-cut control (Procedure "B").

(10) Allow the vehicle to decelerate until the vehicle

speed declines to less than 6 mph (10 km/h)

(Procedure "C").

(11) Repeat procedures from "A" through "C" above

at least 3 times in one driving cycle.

Page 359 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–41

ES

DIAGNOSIS SYSTEM

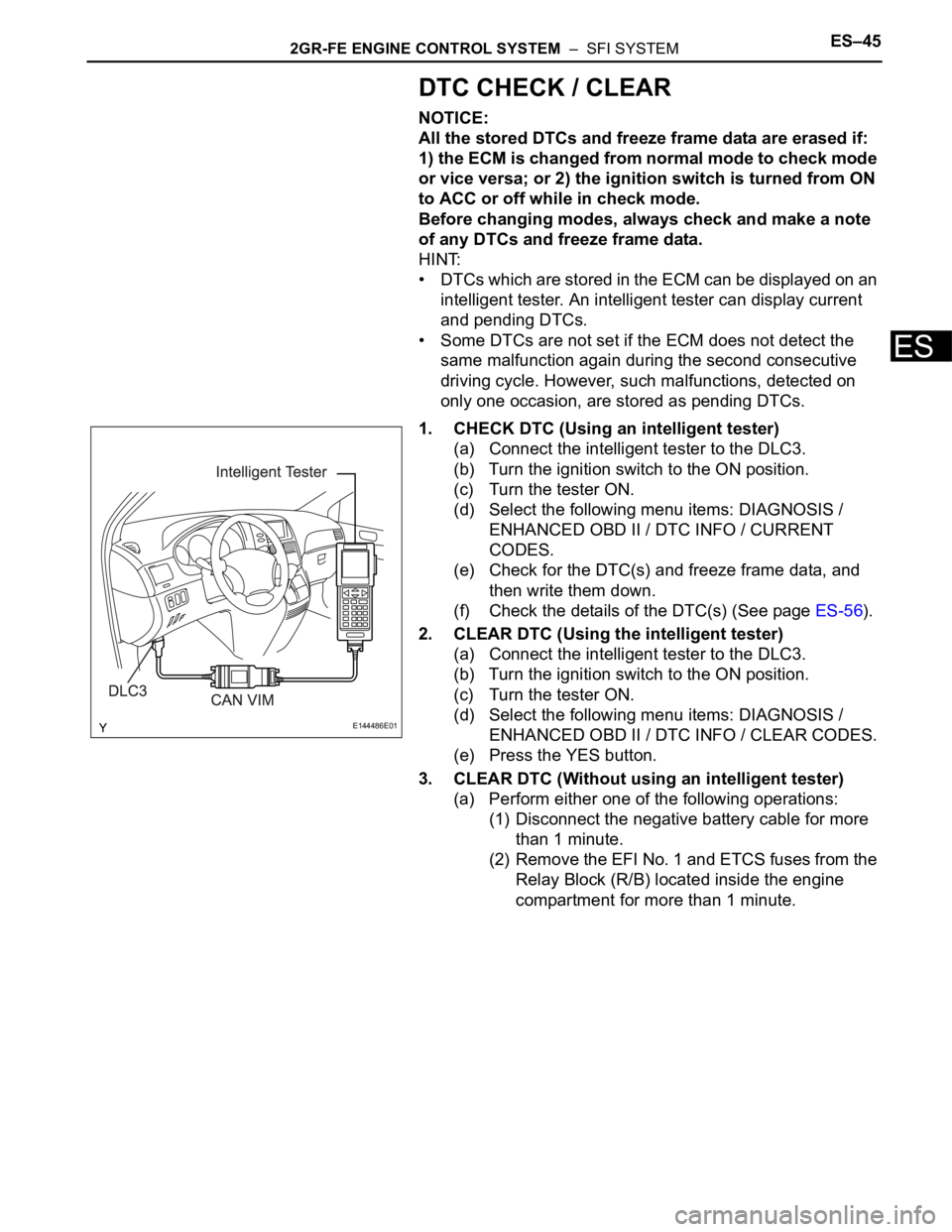

1. DESCRIPTION

(a) When troubleshooting OBD II (On-Board

Diagnostics) vehicles, an intelligent tester

(complying with SAE J1987) must be connected to

the DLC3 (Data Link Connector 3) of the vehicle.

Various data in the vehicle's ECM (Engine Control

Module) can be then read.

(b) OBD II regulations require that the vehicle's on-

board computer illuminates the MIL (Malfunction

Indicator Lamp) on the instrument panel when the

computer detects a malfunction in:

(1) The emission control systems and components

(2) The power train control components (which

affect vehicle emissions)

(3) The computer itself

In addition, the applicable DTCs (Diagnostic

Trouble Codes) prescribed by SAE J2012 are

recorded on 3 consecutive trips, the MIL turns

off automatically but the DTCs remain recorded

in the ECM memory.

(c) To check for DTCs, connect an intelligent tester to

the DLC3. The tester displays DTCs, freeze frame

data, and a variety of engine data. The DTCs and

freeze frame data can be erased with the tester

(See page ES-39).

FI00534

E144486E01

Page 363 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–45

ES

DTC CHECK / CLEAR

NOTICE:

All the stored DTCs and freeze frame data are erased if:

1) the ECM is changed from normal mode to check mode

or vice versa; or 2) the ignition switch is turned from ON

to ACC or off while in check mode.

Before changing modes, always check and make a note

of any DTCs and freeze frame data.

HINT:

• DTCs which are stored in the ECM can be displayed on an

intelligent tester. An intelligent tester can display current

and pending DTCs.

• Some DTCs are not set if the ECM does not detect the

same malfunction again during the second consecutive

driving cycle. However, such malfunctions, detected on

only one occasion, are stored as pending DTCs.

1. CHECK DTC (Using an intelligent tester)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester ON.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT

CODES.

(e) Check for the DTC(s) and freeze frame data, and

then write them down.

(f) Check the details of the DTC(s) (See page ES-56).

2. CLEAR DTC (Using the intelligent tester)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester ON.

(d) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CLEAR CODES.

(e) Press the YES button.

3. CLEAR DTC (Without using an intelligent tester)

(a) Perform either one of the following operations:

(1) Disconnect the negative battery cable for more

than 1 minute.

(2) Remove the EFI No. 1 and ETCS fuses from the

Relay Block (R/B) located inside the engine

compartment for more than 1 minute.

E144486E01

Page 382 of 3000

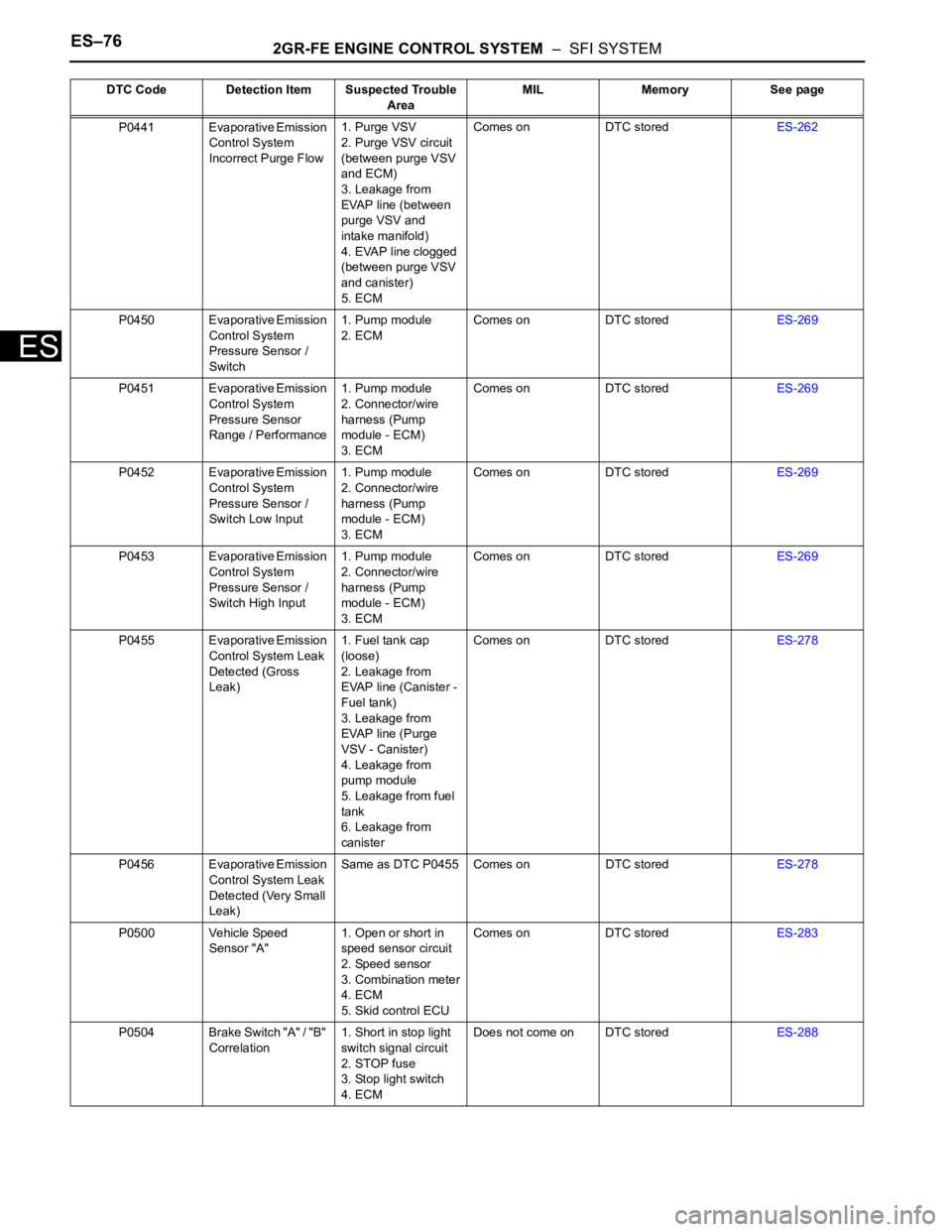

ES–762GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

P0441 Evaporative Emission

Control System

Incorrect Purge Flow1. Purge VSV

2. Purge VSV circuit

(between purge VSV

and ECM)

3. Leakage from

EVAP line (between

purge VSV and

intake manifold)

4. EVAP line clogged

(between purge VSV

and canister)

5. ECMComes on DTC storedES-262

P0450 Evaporative Emission

Control System

Pressure Sensor /

Switch1. Pump module

2. ECMComes on DTC storedES-269

P0451 Evaporative Emission

Control System

Pressure Sensor

Range / Performance1. Pump module

2. Connector/wire

harness (Pump

module - ECM)

3. ECMComes on DTC storedES-269

P0452 Evaporative Emission

Control System

Pressure Sensor /

Switch Low Input1. Pump module

2. Connector/wire

harness (Pump

module - ECM)

3. ECMComes on DTC storedES-269

P0453 Evaporative Emission

Control System

Pressure Sensor /

Switch High Input1. Pump module

2. Connector/wire

harness (Pump

module - ECM)

3. ECMComes on DTC storedES-269

P0455 Evaporative Emission

Control System Leak

Detected (Gross

Leak)1. Fuel tank cap

(loose)

2. Leakage from

EVAP line (Canister -

Fuel tank)

3. Leakage from

EVAP line (Purge

VSV - Canister)

4. Leakage from

pump module

5. Leakage from fuel

tank

6. Leakage from

canisterComes on DTC storedES-278

P0456 Evaporative Emission

Control System Leak

Detected (Very Small

Leak)Same as DTC P0455 Comes on DTC storedES-278

P0500 Vehicle Speed

Sensor "A"1. Open or short in

speed sensor circuit

2. Speed sensor

3. Combination meter

4. ECM

5. Skid control ECUComes on DTC storedES-283

P0504 Brake Switch "A" / "B"

Correlation1. Short in stop light

switch signal circuit

2. STOP fuse

3. Stop light switch

4. ECMDoes not come on DTC storedES-288 DTC Code Detection Item Suspected Trouble

AreaMIL Memory See page

Page 397 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–91

ES

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Clear the DTCs (See page ES-39).

(d) Start the engine and warm it up.

(e) Select the check mode using the tester (See page ES-

43).

(f) Drive the vehicle for more than 10 minutes.

(g) Read the DTCs using the tester.

OK:

No DTC outputs.

NG

OK

3CHECK WHETHER DTC OUTPUT RECURS (DTC P0011, P0012, P0021 OR P0022)

Go to step 4

SYSTEM IS OK

Page 399 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–93

ES

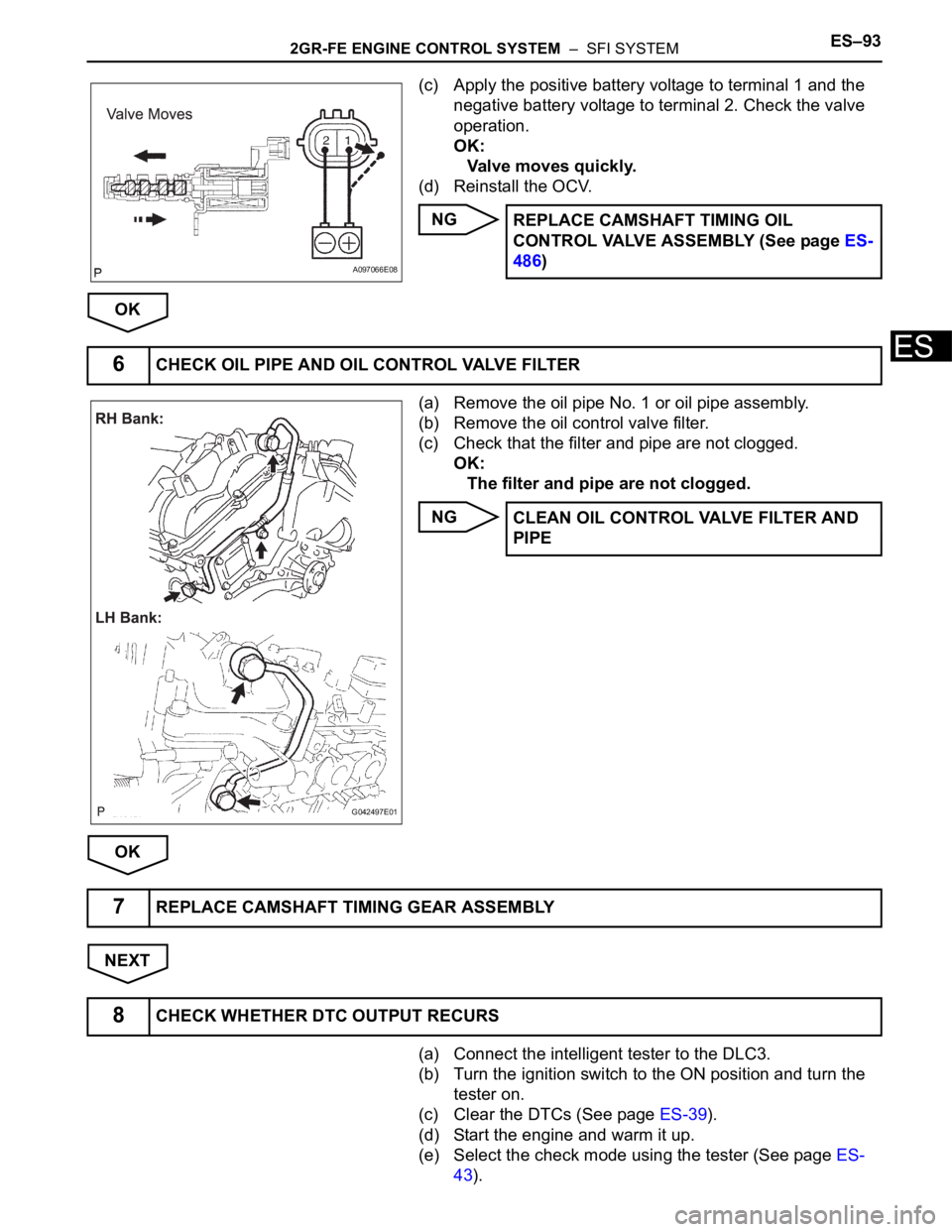

(c) Apply the positive battery voltage to terminal 1 and the

negative battery voltage to terminal 2. Check the valve

operation.

OK:

Valve moves quickly.

(d) Reinstall the OCV.

NG

OK

(a) Remove the oil pipe No. 1 or oil pipe assembly.

(b) Remove the oil control valve filter.

(c) Check that the filter and pipe are not clogged.

OK:

The filter and pipe are not clogged.

NG

OK

NEXT

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Clear the DTCs (See page ES-39).

(d) Start the engine and warm it up.

(e) Select the check mode using the tester (See page ES-

43).

A097066E08

REPLACE CAMSHAFT TIMING OIL

CONTROL VALVE ASSEMBLY (See page ES-

486)

6CHECK OIL PIPE AND OIL CONTROL VALVE FILTER

G042497E01

CLEAN OIL CONTROL VALVE FILTER AND

PIPE

7REPLACE CAMSHAFT TIMING GEAR ASSEMBLY

8CHECK WHETHER DTC OUTPUT RECURS

Page 408 of 3000

ES–1022GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the

time of a malfunction.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(d) Read the DTCs.

Result

HINT:

If any DTCs other than P0014, P0015, P0024 or P0025

are output, troubleshoot those DTCs first.

B

A

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and turn the tester on.

(c) Warm up the engine.

(d) Select the following menu items on the tester:

DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST /

VVT EX B1 or VVT EX B2.

(e) Check the engine speed while operating the Oil Control

Valve (OCV) using the tester.

OK

NG

OK

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Clear the DTCs (See page ES-39).

1CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0014, P0015, P0024 OR

P0025)

Display (DTC Output) Proceed to

P0014, P0015, P0024 or P0025 A

P0014, P0015, P0024 or P0025 and other DTCs B

GO TO DTC CHART (See page ES-56)

2PERFORM ACTIVE TEST BY INTELLIGENT TESTER (OPERATE OCV)

Tester Operation Specified Condition

OCV OFF Normal engine idle speed

OCV ON Engine idles roughly or stalls (soon after OCV switched from OFF to ON)

Go to step 4

3CHECK WHETHER DTC OUTPUT RECURS (DTC P0014, P0015, P0024 OR P0025)