fuel pressure TOYOTA SIENNA 2007 Service Manual PDF

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1151 of 3000

2GR-FE FUEL – FUEL PUMPFU–33

FU

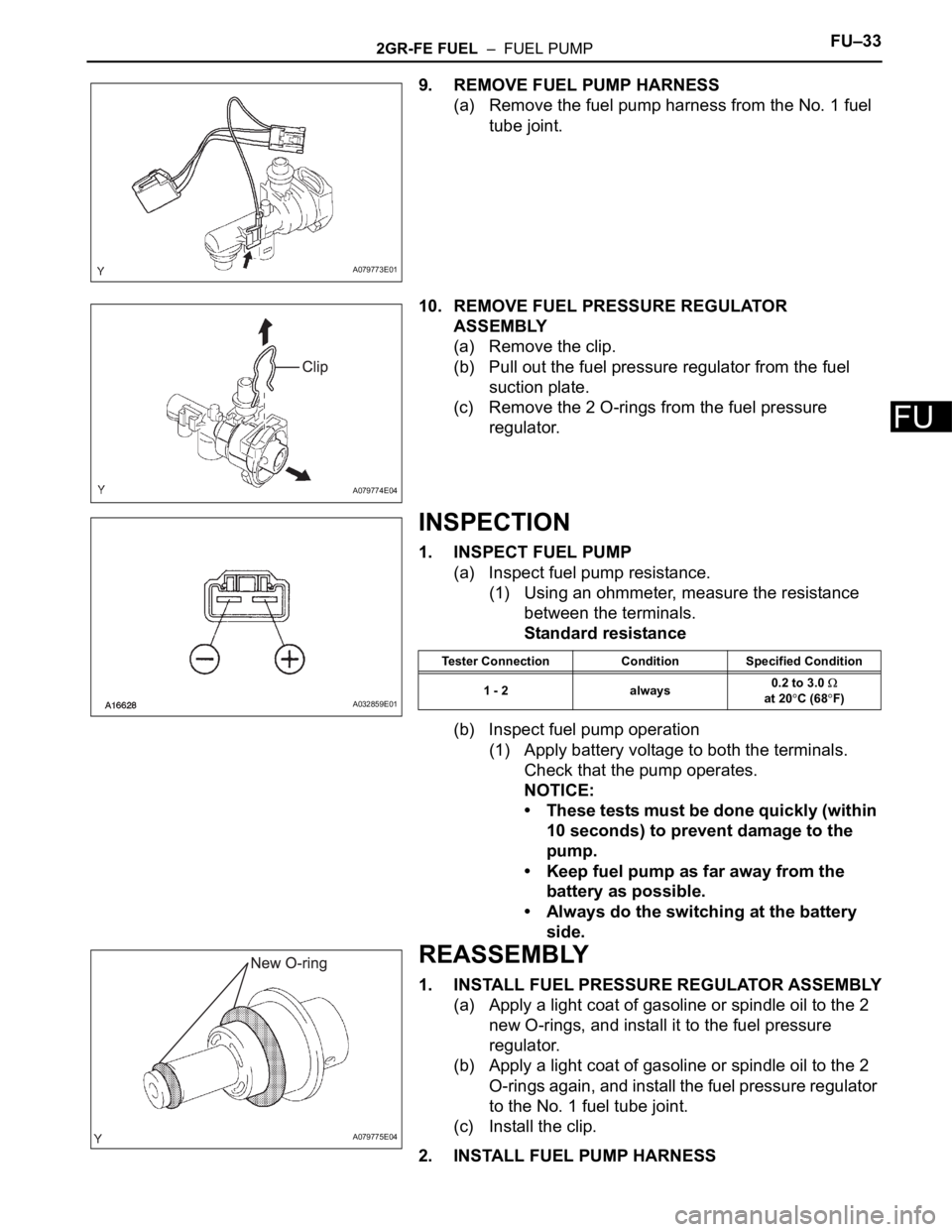

9. REMOVE FUEL PUMP HARNESS

(a) Remove the fuel pump harness from the No. 1 fuel

tube joint.

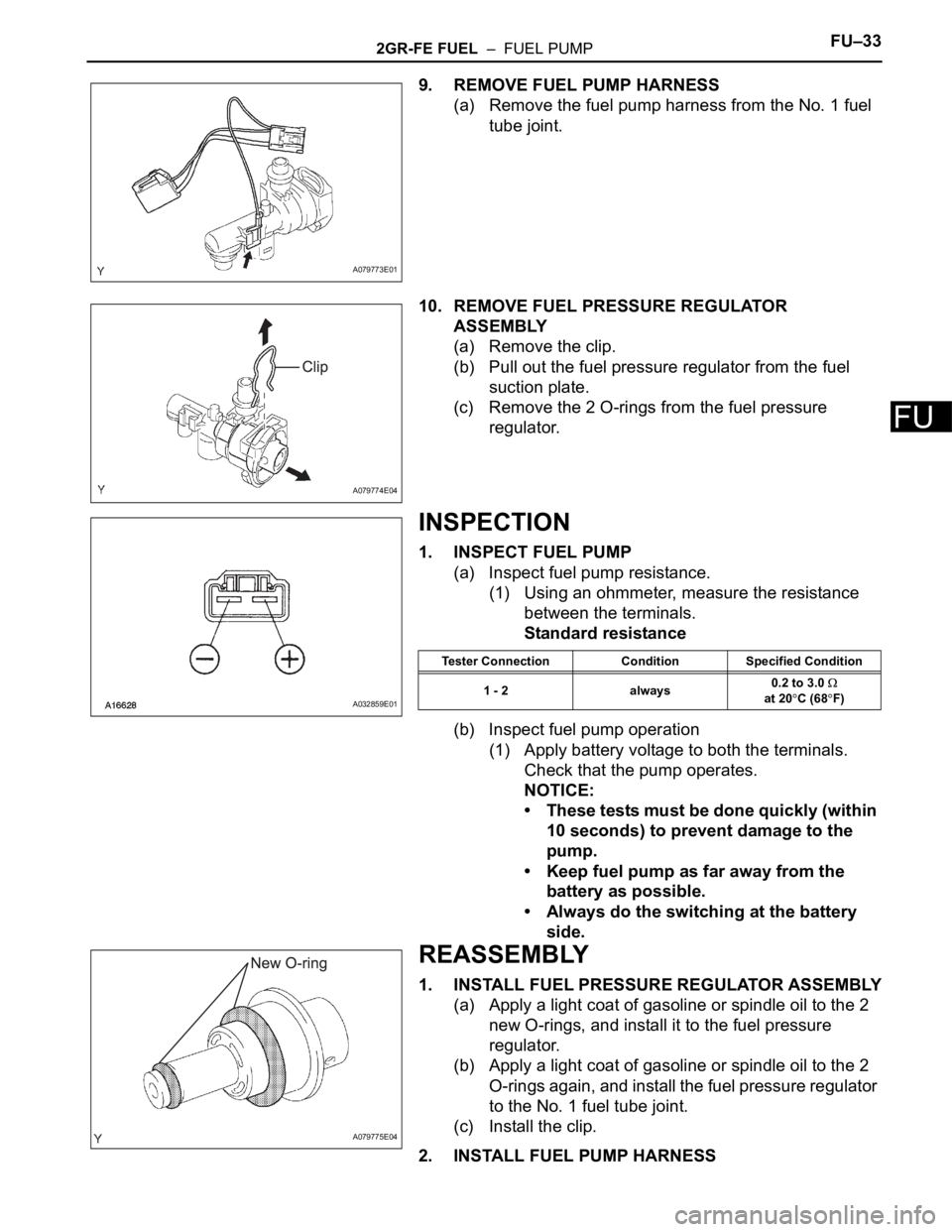

10. REMOVE FUEL PRESSURE REGULATOR

ASSEMBLY

(a) Remove the clip.

(b) Pull out the fuel pressure regulator from the fuel

suction plate.

(c) Remove the 2 O-rings from the fuel pressure

regulator.

INSPECTION

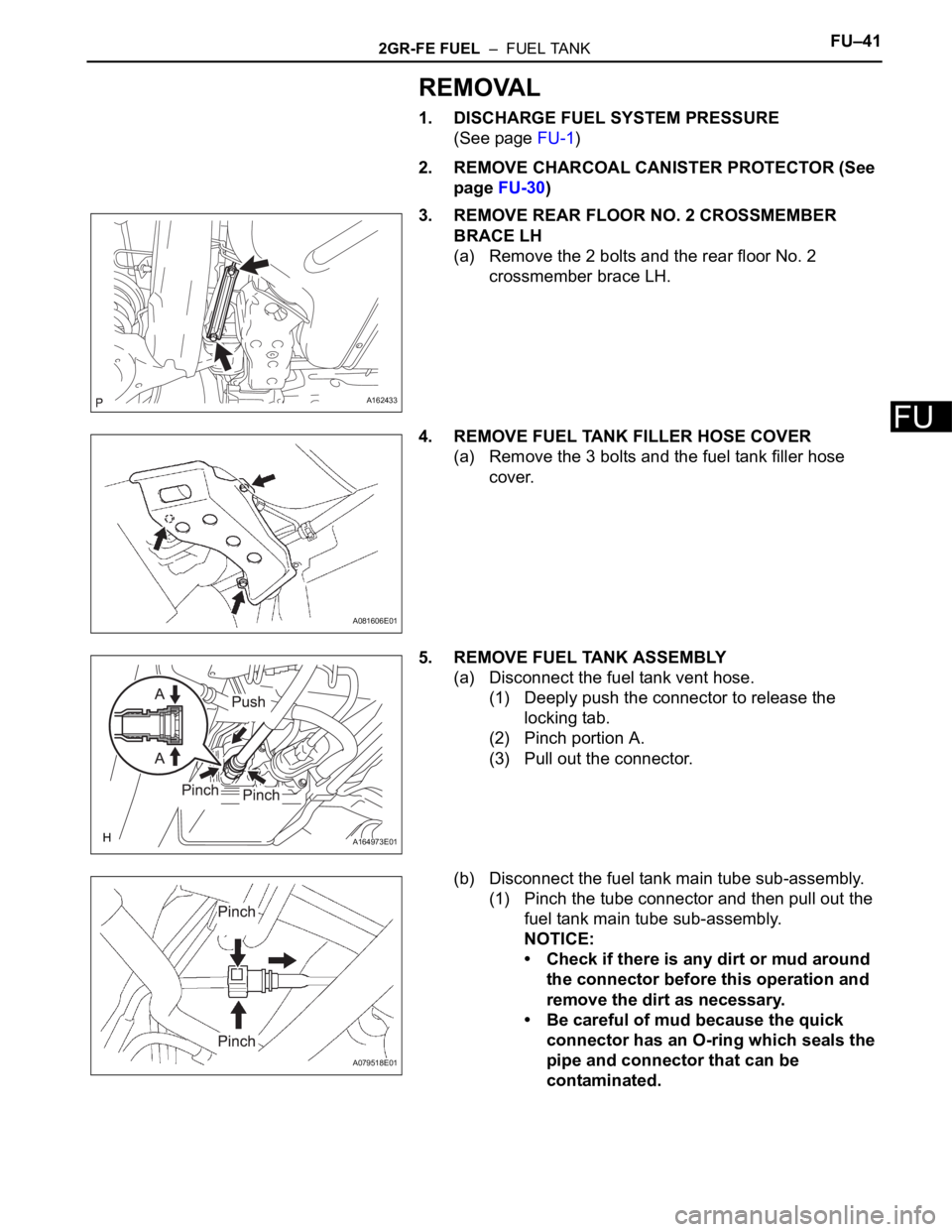

1. INSPECT FUEL PUMP

(a) Inspect fuel pump resistance.

(1) Using an ohmmeter, measure the resistance

between the terminals.

Standard resistance

(b) Inspect fuel pump operation

(1) Apply battery voltage to both the terminals.

Check that the pump operates.

NOTICE:

• These tests must be done quickly (within

10 seconds) to prevent damage to the

pump.

• Keep fuel pump as far away from the

battery as possible.

• Always do the switching at the battery

side.

REASSEMBLY

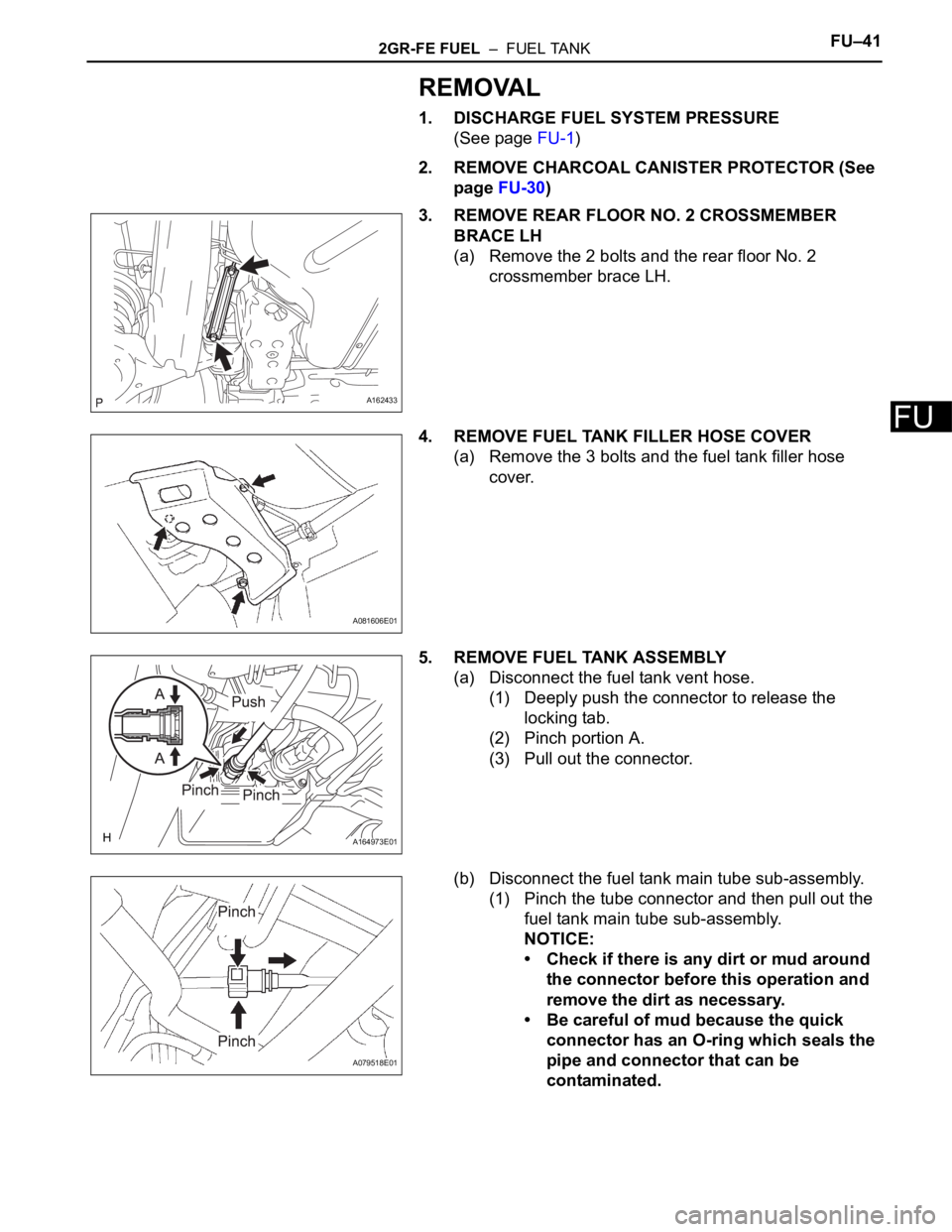

1. INSTALL FUEL PRESSURE REGULATOR ASSEMBLY

(a) Apply a light coat of gasoline or spindle oil to the 2

new O-rings, and install it to the fuel pressure

regulator.

(b) Apply a light coat of gasoline or spindle oil to the 2

O-rings again, and install the fuel pressure regulator

to the No. 1 fuel tube joint.

(c) Install the clip.

2. INSTALL FUEL PUMP HARNESS

A079773E01

A079774E04

A032859E01

Tester Connection Condition Specified Condition

1 - 2 always0.2 to 3.0

at 20

C (68F)

A079775E04

Page 1156 of 3000

2GR-FE FUEL – FUEL PUMPFU–33

FU

9. REMOVE FUEL PUMP HARNESS

(a) Remove the fuel pump harness from the No. 1 fuel

tube joint.

10. REMOVE FUEL PRESSURE REGULATOR

ASSEMBLY

(a) Remove the clip.

(b) Pull out the fuel pressure regulator from the fuel

suction plate.

(c) Remove the 2 O-rings from the fuel pressure

regulator.

INSPECTION

1. INSPECT FUEL PUMP

(a) Inspect fuel pump resistance.

(1) Using an ohmmeter, measure the resistance

between the terminals.

Standard resistance

(b) Inspect fuel pump operation

(1) Apply battery voltage to both the terminals.

Check that the pump operates.

NOTICE:

• These tests must be done quickly (within

10 seconds) to prevent damage to the

pump.

• Keep fuel pump as far away from the

battery as possible.

• Always do the switching at the battery

side.

REASSEMBLY

1. INSTALL FUEL PRESSURE REGULATOR ASSEMBLY

(a) Apply a light coat of gasoline or spindle oil to the 2

new O-rings, and install it to the fuel pressure

regulator.

(b) Apply a light coat of gasoline or spindle oil to the 2

O-rings again, and install the fuel pressure regulator

to the No. 1 fuel tube joint.

(c) Install the clip.

2. INSTALL FUEL PUMP HARNESS

A079773E01

A079774E04

A032859E01

Tester Connection Condition Specified Condition

1 - 2 always0.2 to 3.0

at 20

C (68F)

A079775E04

Page 1161 of 3000

2GR-FE FUEL – FUEL TANKFU–41

FU

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

(See page FU-1)

2. REMOVE CHARCOAL CANISTER PROTECTOR (See

page FU-30)

3. REMOVE REAR FLOOR NO. 2 CROSSMEMBER

BRACE LH

(a) Remove the 2 bolts and the rear floor No. 2

crossmember brace LH.

4. REMOVE FUEL TANK FILLER HOSE COVER

(a) Remove the 3 bolts and the fuel tank filler hose

cover.

5. REMOVE FUEL TANK ASSEMBLY

(a) Disconnect the fuel tank vent hose.

(1) Deeply push the connector to release the

locking tab.

(2) Pinch portion A.

(3) Pull out the connector.

(b) Disconnect the fuel tank main tube sub-assembly.

(1) Pinch the tube connector and then pull out the

fuel tank main tube sub-assembly.

NOTICE:

• Check if there is any dirt or mud around

the connector before this operation and

remove the dirt as necessary.

• Be careful of mud because the quick

connector has an O-ring which seals the

pipe and connector that can be

contaminated.

A162433

A081606E01

A164973E01

A079518E01

Page 1164 of 3000

2GR-FE FUEL – FUEL TANKFU–41

FU

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

(See page FU-1)

2. REMOVE CHARCOAL CANISTER PROTECTOR (See

page FU-30)

3. REMOVE REAR FLOOR NO. 2 CROSSMEMBER

BRACE LH

(a) Remove the 2 bolts and the rear floor No. 2

crossmember brace LH.

4. REMOVE FUEL TANK FILLER HOSE COVER

(a) Remove the 3 bolts and the fuel tank filler hose

cover.

5. REMOVE FUEL TANK ASSEMBLY

(a) Disconnect the fuel tank vent hose.

(1) Deeply push the connector to release the

locking tab.

(2) Pinch portion A.

(3) Pull out the connector.

(b) Disconnect the fuel tank main tube sub-assembly.

(1) Pinch the tube connector and then pull out the

fuel tank main tube sub-assembly.

NOTICE:

• Check if there is any dirt or mud around

the connector before this operation and

remove the dirt as necessary.

• Be careful of mud because the quick

connector has an O-ring which seals the

pipe and connector that can be

contaminated.

A162433

A081606E01

A164973E01

A079518E01

Page 1173 of 3000

EC–102GR-FE EMISSION CONTROL – CANISTER

EC

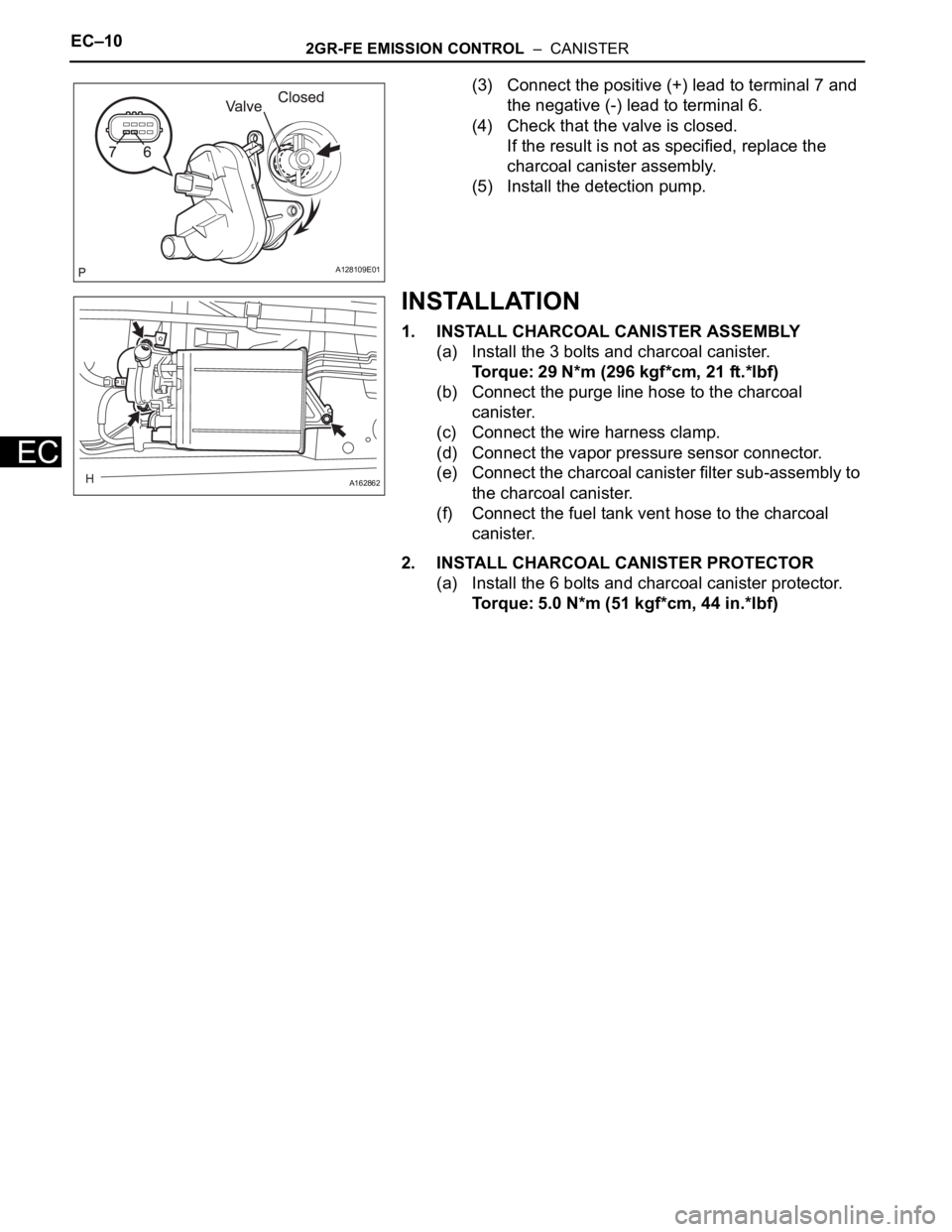

(3) Connect the positive (+) lead to terminal 7 and

the negative (-) lead to terminal 6.

(4) Check that the valve is closed.

If the result is not as specified, replace the

charcoal canister assembly.

(5) Install the detection pump.

INSTALLATION

1. INSTALL CHARCOAL CANISTER ASSEMBLY

(a) Install the 3 bolts and charcoal canister.

Torque: 29 N*m (296 kgf*cm, 21 ft.*lbf)

(b) Connect the purge line hose to the charcoal

canister.

(c) Connect the wire harness clamp.

(d) Connect the vapor pressure sensor connector.

(e) Connect the charcoal canister filter sub-assembly to

the charcoal canister.

(f) Connect the fuel tank vent hose to the charcoal

canister.

2. INSTALL CHARCOAL CANISTER PROTECTOR

(a) Install the 6 bolts and charcoal canister protector.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*lbf)

A128109E01

A162862

Page 1175 of 3000

2GR-FE EMISSION CONTROL – EMISSION CONTROL SYSTEMEC–5

EC

ON-VEHICLE INSPECTION

1. INSPECT FUEL CUT RPM

(a) Increase the engine speed to at least 3500 rpm.

(b) Use a sound scope to check for injector operating

sounds.

(c) Check that when the throttle lever is released,

injector operating sounds stop momentarily (at 2500

rpm) and then resume (at 1400 rpm).

Standard

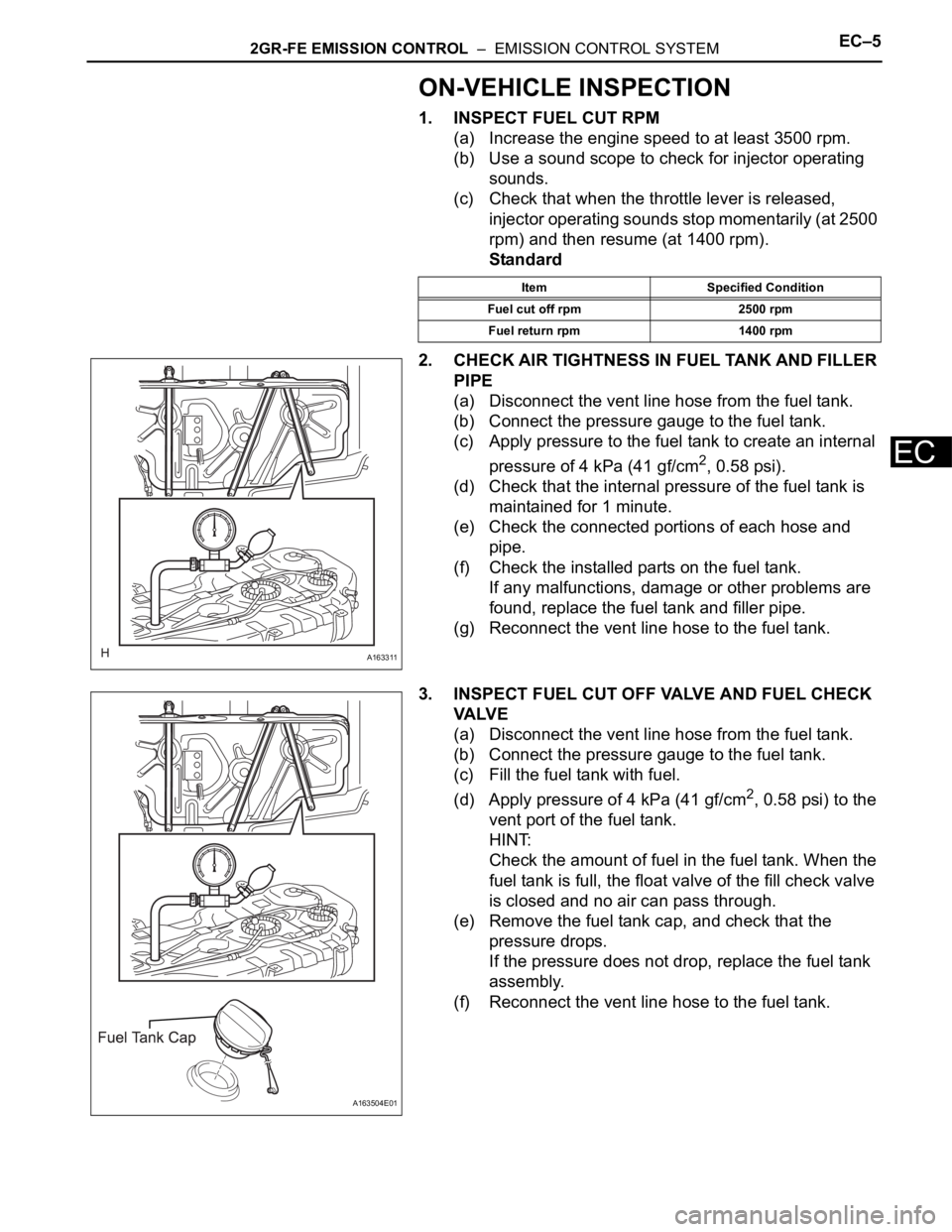

2. CHECK AIR TIGHTNESS IN FUEL TANK AND FILLER

PIPE

(a) Disconnect the vent line hose from the fuel tank.

(b) Connect the pressure gauge to the fuel tank.

(c) Apply pressure to the fuel tank to create an internal

pressure of 4 kPa (41 gf/cm

2, 0.58 psi).

(d) Check that the internal pressure of the fuel tank is

maintained for 1 minute.

(e) Check the connected portions of each hose and

pipe.

(f) Check the installed parts on the fuel tank.

If any malfunctions, damage or other problems are

found, replace the fuel tank and filler pipe.

(g) Reconnect the vent line hose to the fuel tank.

3. INSPECT FUEL CUT OFF VALVE AND FUEL CHECK

VA LV E

(a) Disconnect the vent line hose from the fuel tank.

(b) Connect the pressure gauge to the fuel tank.

(c) Fill the fuel tank with fuel.

(d) Apply pressure of 4 kPa (41 gf/cm

2, 0.58 psi) to the

vent port of the fuel tank.

HINT:

Check the amount of fuel in the fuel tank. When the

fuel tank is full, the float valve of the fill check valve

is closed and no air can pass through.

(e) Remove the fuel tank cap, and check that the

pressure drops.

If the pressure does not drop, replace the fuel tank

assembly.

(f) Reconnect the vent line hose to the fuel tank.

Item Specified Condition

Fuel cut off rpm 2500 rpm

Fuel return rpm 1400 rpm

A163311

A163504E01

Page 1181 of 3000

EC–82GR-FE EMISSION CONTROL – CANISTER

EC

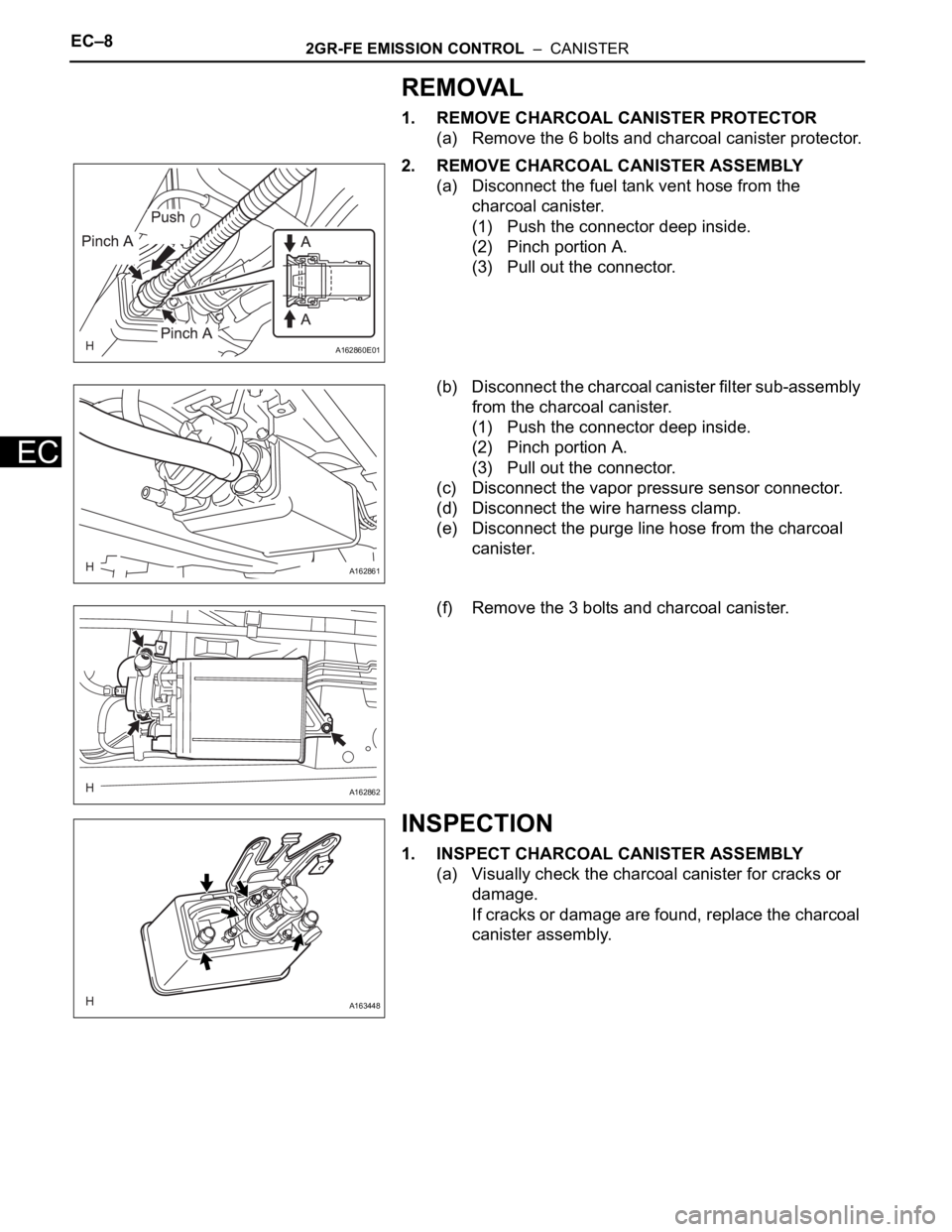

REMOVAL

1. REMOVE CHARCOAL CANISTER PROTECTOR

(a) Remove the 6 bolts and charcoal canister protector.

2. REMOVE CHARCOAL CANISTER ASSEMBLY

(a) Disconnect the fuel tank vent hose from the

charcoal canister.

(1) Push the connector deep inside.

(2) Pinch portion A.

(3) Pull out the connector.

(b) Disconnect the charcoal canister filter sub-assembly

from the charcoal canister.

(1) Push the connector deep inside.

(2) Pinch portion A.

(3) Pull out the connector.

(c) Disconnect the vapor pressure sensor connector.

(d) Disconnect the wire harness clamp.

(e) Disconnect the purge line hose from the charcoal

canister.

(f) Remove the 3 bolts and charcoal canister.

INSPECTION

1. INSPECT CHARCOAL CANISTER ASSEMBLY

(a) Visually check the charcoal canister for cracks or

damage.

If cracks or damage are found, replace the charcoal

canister assembly.

A162860E01

A162861

A162862

A163448