engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 1112 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–165

EM

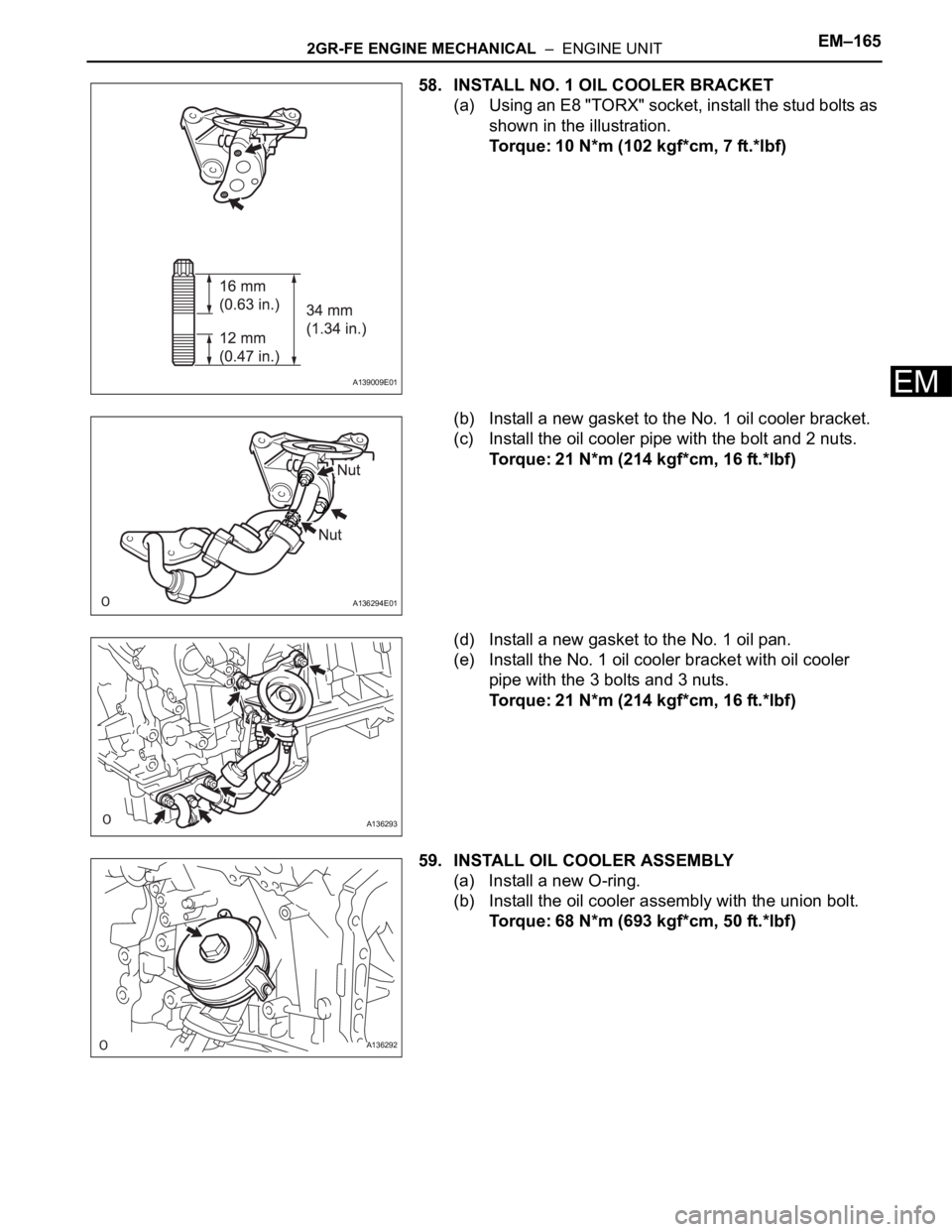

58. INSTALL NO. 1 OIL COOLER BRACKET

(a) Using an E8 "TORX" socket, install the stud bolts as

shown in the illustration.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(b) Install a new gasket to the No. 1 oil cooler bracket.

(c) Install the oil cooler pipe with the bolt and 2 nuts.

Torque: 21 N*m (214 kgf*cm, 16 ft.*lbf)

(d) Install a new gasket to the No. 1 oil pan.

(e) Install the No. 1 oil cooler bracket with oil cooler

pipe with the 3 bolts and 3 nuts.

Torque: 21 N*m (214 kgf*cm, 16 ft.*lbf)

59. INSTALL OIL COOLER ASSEMBLY

(a) Install a new O-ring.

(b) Install the oil cooler assembly with the union bolt.

Torque: 68 N*m (693 kgf*cm, 50 ft.*lbf)

A139009E01

A136294E01

A136293

A136292

Page 1113 of 3000

EM–1662GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

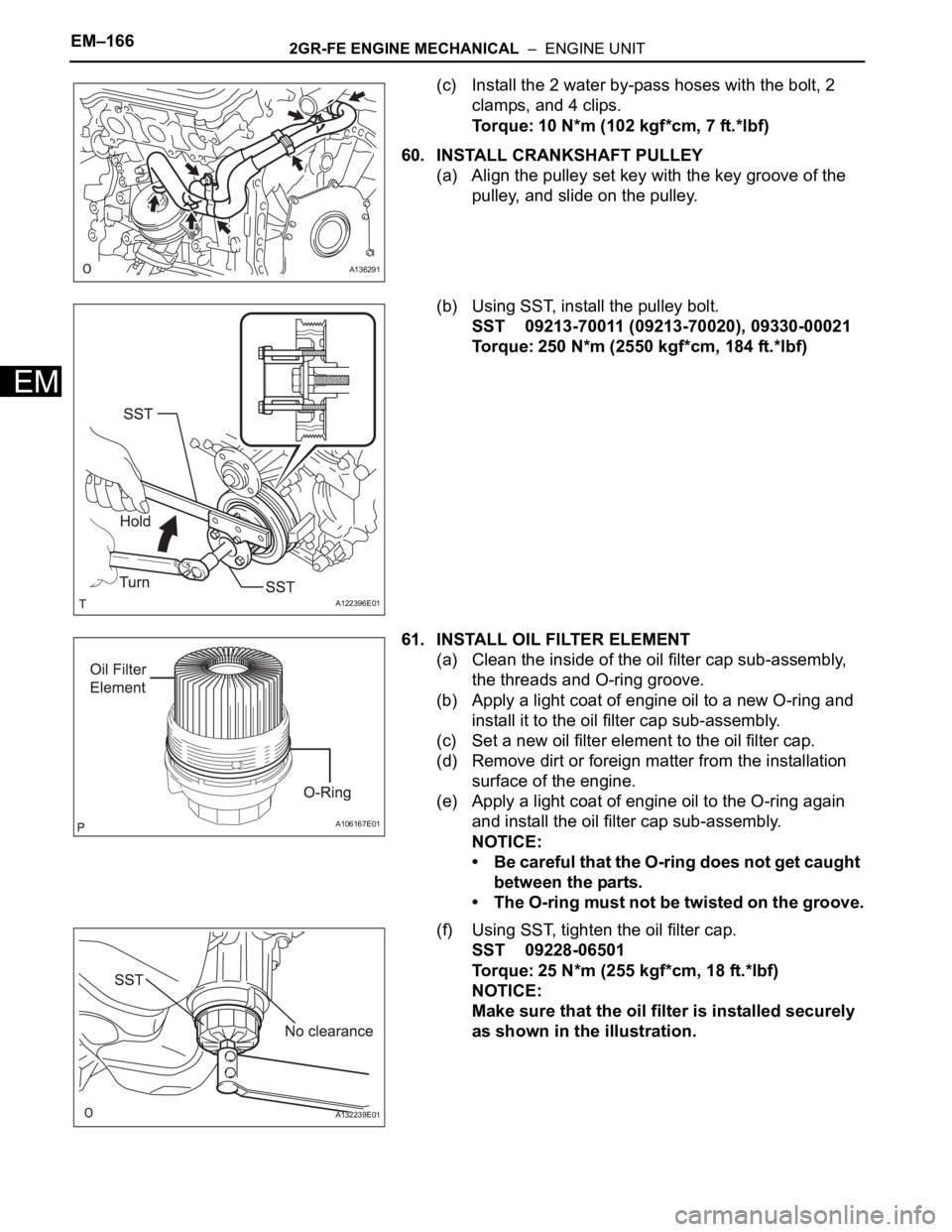

(c) Install the 2 water by-pass hoses with the bolt, 2

clamps, and 4 clips.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

60. INSTALL CRANKSHAFT PULLEY

(a) Align the pulley set key with the key groove of the

pulley, and slide on the pulley.

(b) Using SST, install the pulley bolt.

SST 09213-70011 (09213-70020), 09330-00021

Torque: 250 N*m (2550 kgf*cm, 184 ft.*lbf)

61. INSTALL OIL FILTER ELEMENT

(a) Clean the inside of the oil filter cap sub-assembly,

the threads and O-ring groove.

(b) Apply a light coat of engine oil to a new O-ring and

install it to the oil filter cap sub-assembly.

(c) Set a new oil filter element to the oil filter cap.

(d) Remove dirt or foreign matter from the installation

surface of the engine.

(e) Apply a light coat of engine oil to the O-ring again

and install the oil filter cap sub-assembly.

NOTICE:

• Be careful that the O-ring does not get caught

between the parts.

• The O-ring must not be twisted on the groove.

(f) Using SST, tighten the oil filter cap.

SST 09228-06501

Torque: 25 N*m (255 kgf*cm, 18 ft.*lbf)

NOTICE:

Make sure that the oil filter is installed securely

as shown in the illustration.

A136291

A122396E01

A106167E01

A132239E01

Page 1114 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–167

EM

(g) Apply a light coat of engine oil to a new O-ring and

install it to the oil filter cap.

NOTICE:

Remove all dirt and foreign matter from the

installation surface.

(h) Install the oil filter drain plug to the oil filter cap.

Torque: 13 N*m (127 kgf*cm, 9 ft.*lbf)

NOTICE:

Make sure that the O-ring does not get caught

between the parts.

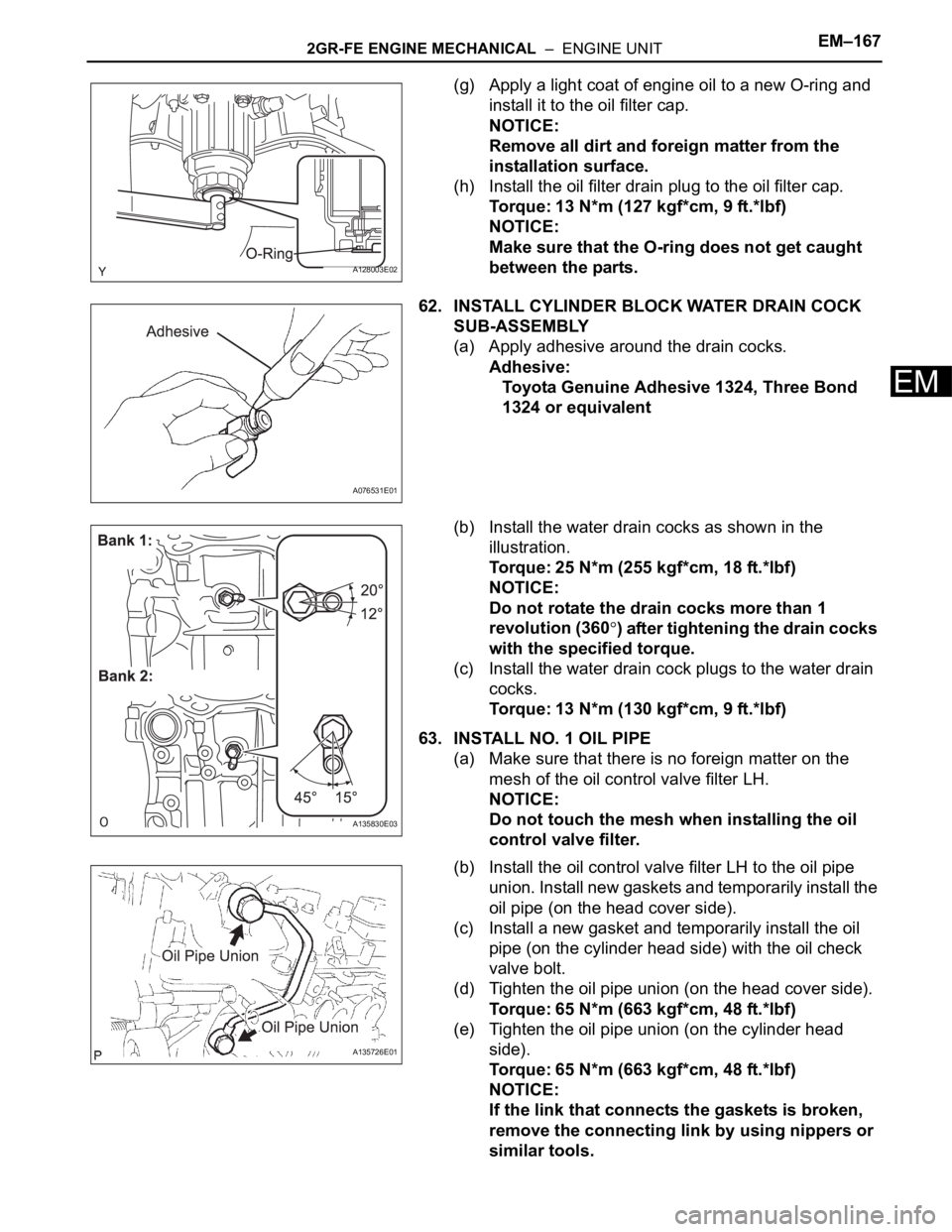

62. INSTALL CYLINDER BLOCK WATER DRAIN COCK

SUB-ASSEMBLY

(a) Apply adhesive around the drain cocks.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond

1324 or equivalent

(b) Install the water drain cocks as shown in the

illustration.

Torque: 25 N*m (255 kgf*cm, 18 ft.*lbf)

NOTICE:

Do not rotate the drain cocks more than 1

revolution (360

) after tightening the drain cocks

with the specified torque.

(c) Install the water drain cock plugs to the water drain

cocks.

Torque: 13 N*m (130 kgf*cm, 9 ft.*lbf)

63. INSTALL NO. 1 OIL PIPE

(a) Make sure that there is no foreign matter on the

mesh of the oil control valve filter LH.

NOTICE:

Do not touch the mesh when installing the oil

control valve filter.

(b) Install the oil control valve filter LH to the oil pipe

union. Install new gaskets and temporarily install the

oil pipe (on the head cover side).

(c) Install a new gasket and temporarily install the oil

pipe (on the cylinder head side) with the oil check

valve bolt.

(d) Tighten the oil pipe union (on the head cover side).

Torque: 65 N*m (663 kgf*cm, 48 ft.*lbf)

(e) Tighten the oil pipe union (on the cylinder head

side).

Torque: 65 N*m (663 kgf*cm, 48 ft.*lbf)

NOTICE:

If the link that connects the gaskets is broken,

remove the connecting link by using nippers or

similar tools.

A128003E02

A076531E01

A135830E03

A135726E01

Page 1115 of 3000

EM–1682GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

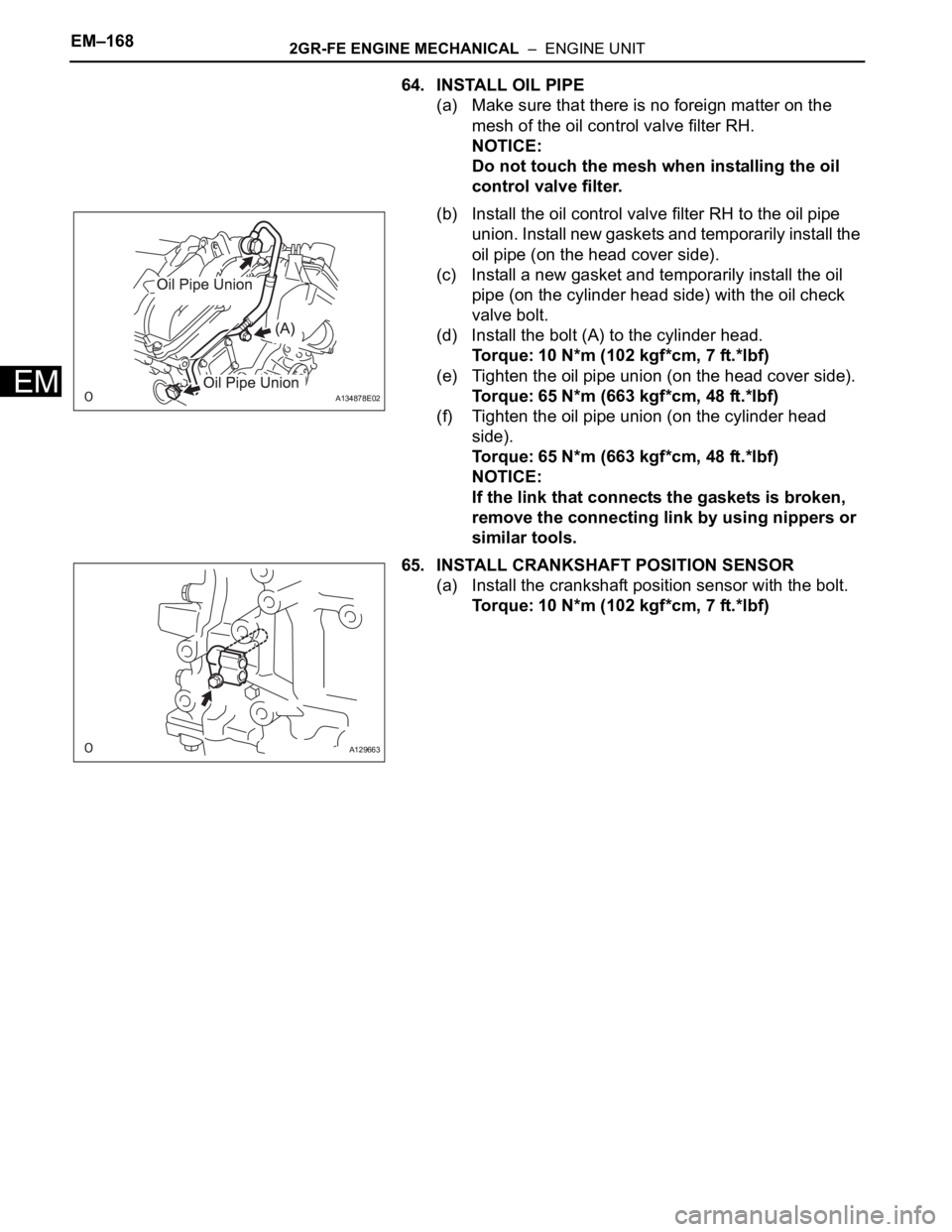

64. INSTALL OIL PIPE

(a) Make sure that there is no foreign matter on the

mesh of the oil control valve filter RH.

NOTICE:

Do not touch the mesh when installing the oil

control valve filter.

(b) Install the oil control valve filter RH to the oil pipe

union. Install new gaskets and temporarily install the

oil pipe (on the head cover side).

(c) Install a new gasket and temporarily install the oil

pipe (on the cylinder head side) with the oil check

valve bolt.

(d) Install the bolt (A) to the cylinder head.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(e) Tighten the oil pipe union (on the head cover side).

Torque: 65 N*m (663 kgf*cm, 48 ft.*lbf)

(f) Tighten the oil pipe union (on the cylinder head

side).

Torque: 65 N*m (663 kgf*cm, 48 ft.*lbf)

NOTICE:

If the link that connects the gaskets is broken,

remove the connecting link by using nippers or

similar tools.

65. INSTALL CRANKSHAFT POSITION SENSOR

(a) Install the crankshaft position sensor with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

A134878E02

A129663

Page 1116 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–169

EM

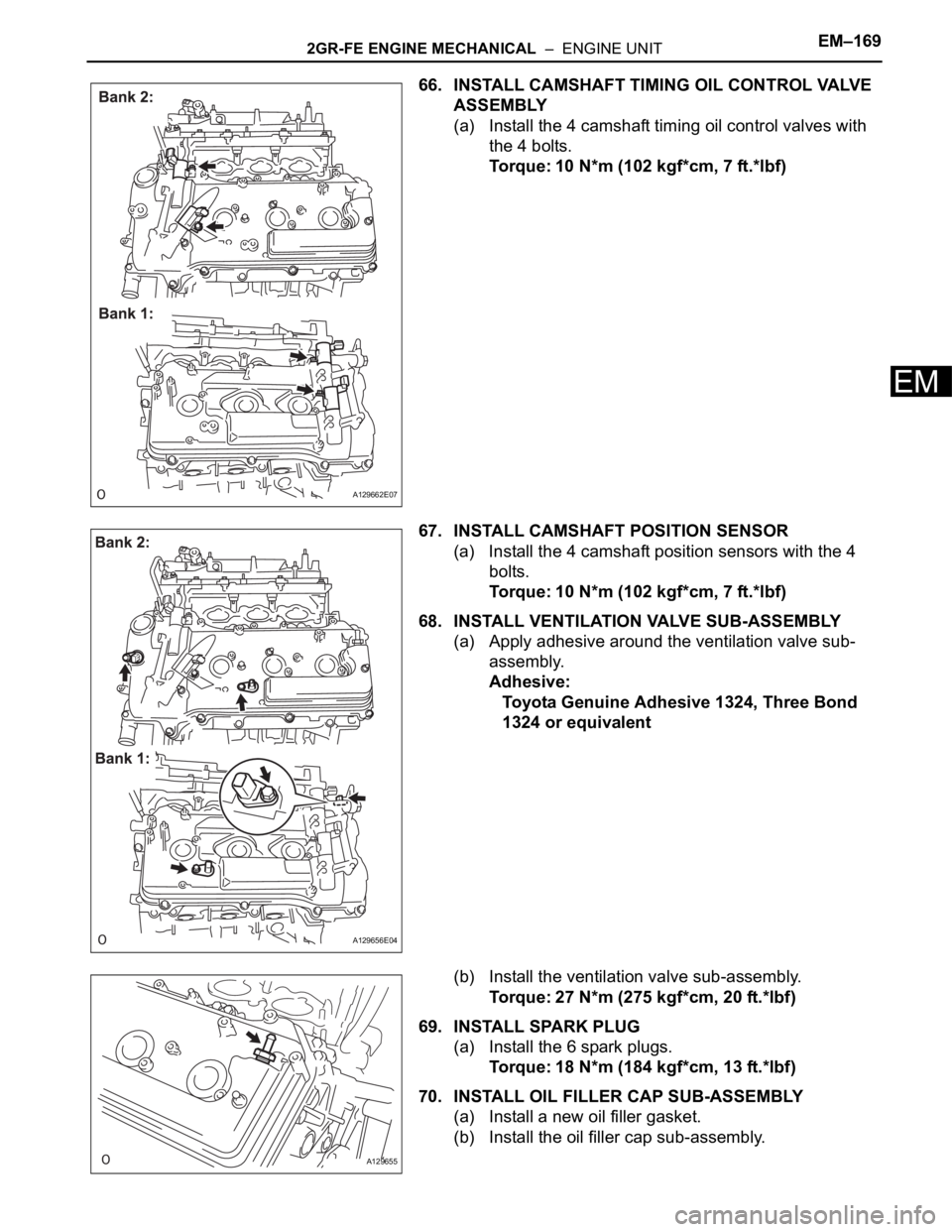

66. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY

(a) Install the 4 camshaft timing oil control valves with

the 4 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

67. INSTALL CAMSHAFT POSITION SENSOR

(a) Install the 4 camshaft position sensors with the 4

bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

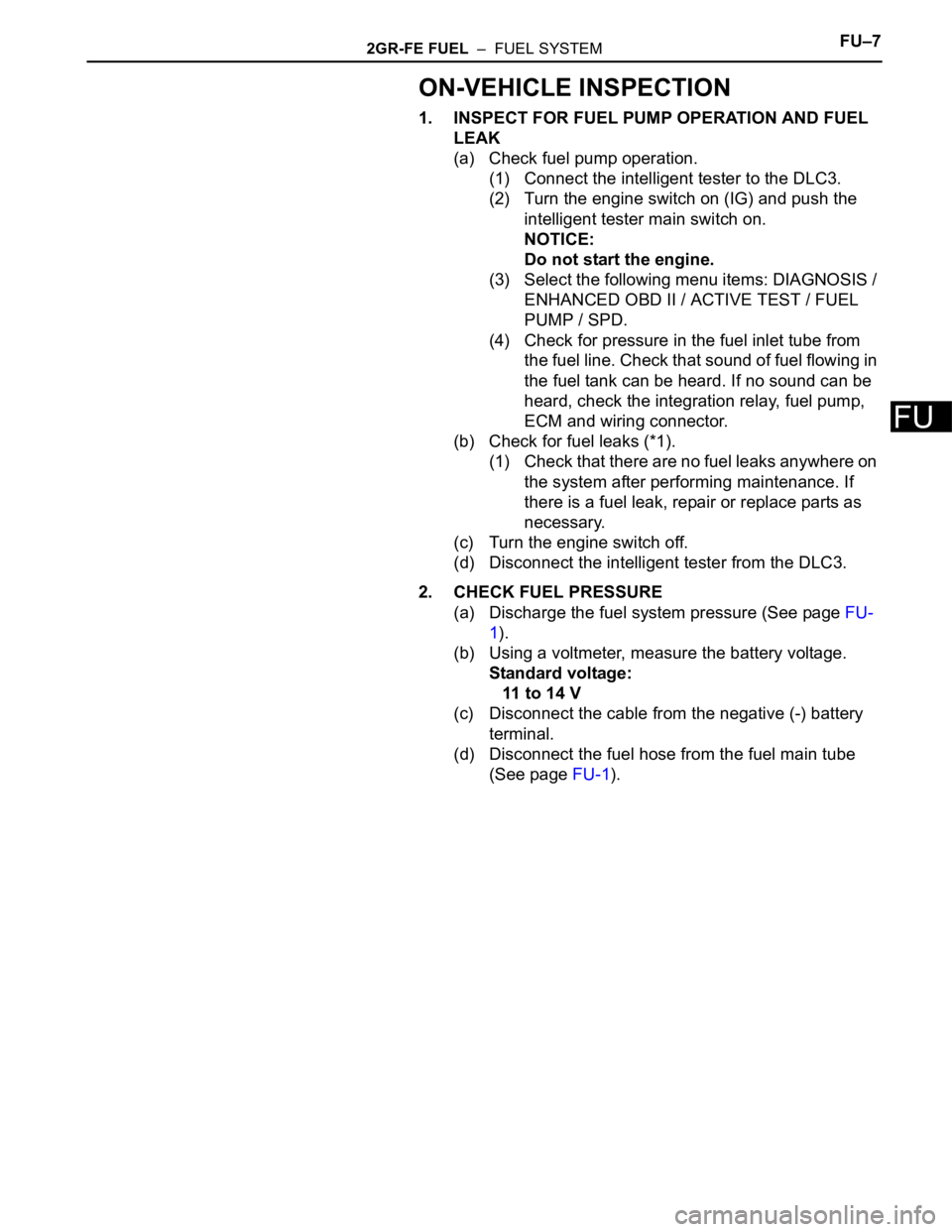

68. INSTALL VENTILATION VALVE SUB-ASSEMBLY

(a) Apply adhesive around the ventilation valve sub-

assembly.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond

1324 or equivalent

(b) Install the ventilation valve sub-assembly.

Torque: 27 N*m (275 kgf*cm, 20 ft.*lbf)

69. INSTALL SPARK PLUG

(a) Install the 6 spark plugs.

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

70. INSTALL OIL FILLER CAP SUB-ASSEMBLY

(a) Install a new oil filler gasket.

(b) Install the oil filler cap sub-assembly.

A129662E07

A129656E04

A129655

Page 1117 of 3000

2GR-FE FUEL – FUEL SYSTEMFU–7

FU

ON-VEHICLE INSPECTION

1. INSPECT FOR FUEL PUMP OPERATION AND FUEL

LEAK

(a) Check fuel pump operation.

(1) Connect the intelligent tester to the DLC3.

(2) Turn the engine switch on (IG) and push the

intelligent tester main switch on.

NOTICE:

Do not start the engine.

(3) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / ACTIVE TEST / FUEL

PUMP / SPD.

(4) Check for pressure in the fuel inlet tube from

the fuel line. Check that sound of fuel flowing in

the fuel tank can be heard. If no sound can be

heard, check the integration relay, fuel pump,

ECM and wiring connector.

(b) Check for fuel leaks (*1).

(1) Check that there are no fuel leaks anywhere on

the system after performing maintenance. If

there is a fuel leak, repair or replace parts as

necessary.

(c) Turn the engine switch off.

(d) Disconnect the intelligent tester from the DLC3.

2. CHECK FUEL PRESSURE

(a) Discharge the fuel system pressure (See page FU-

1).

(b) Using a voltmeter, measure the battery voltage.

Standard voltage:

11 to 14 V

(c) Disconnect the cable from the negative (-) battery

terminal.

(d) Disconnect the fuel hose from the fuel main tube

(See page FU-1).

Page 1118 of 3000

FU–82GR-FE FUEL – FUEL SYSTEM

FU

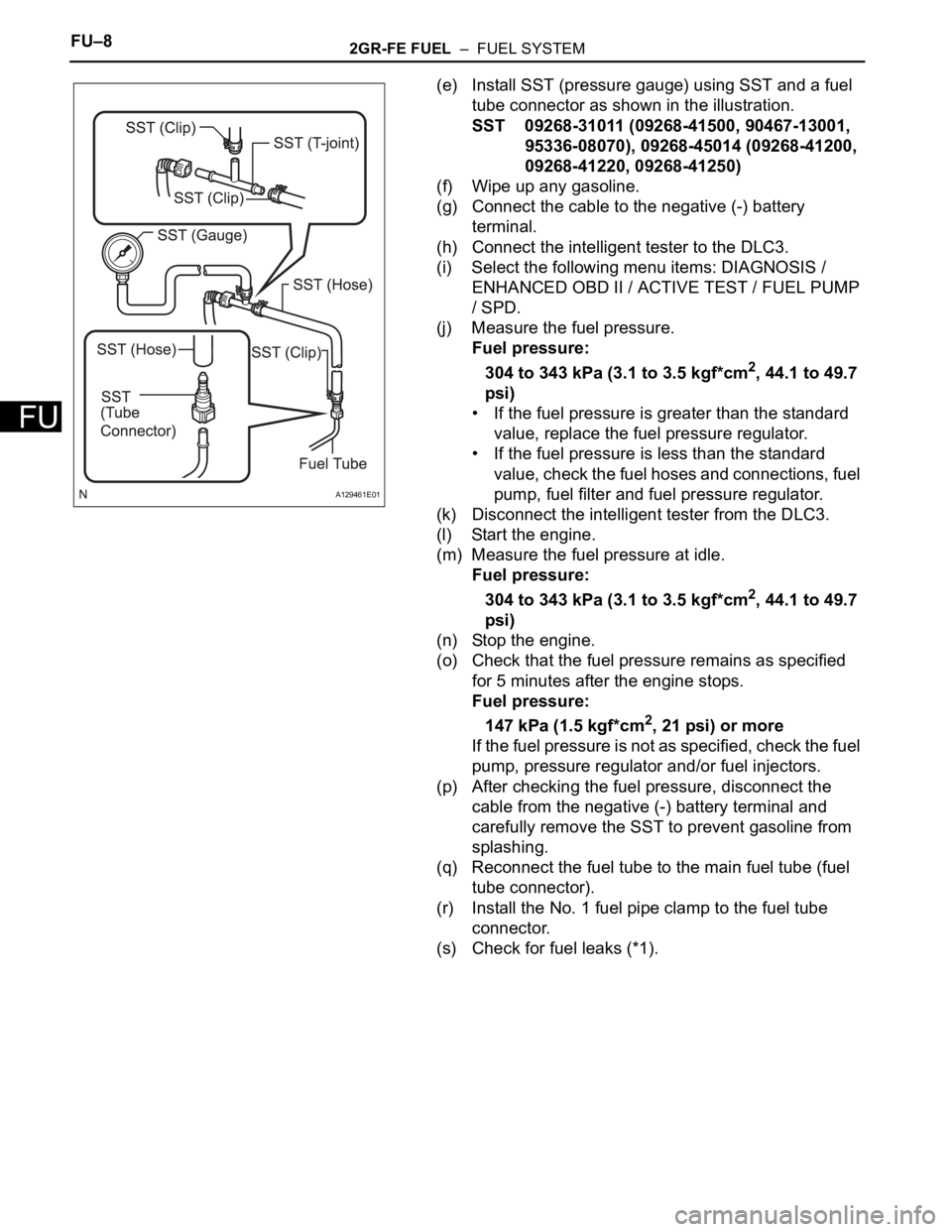

(e) Install SST (pressure gauge) using SST and a fuel

tube connector as shown in the illustration.

SST 09268-31011 (09268-41500, 90467-13001,

95336-08070), 09268-45014 (09268-41200,

09268-41220, 09268-41250)

(f) Wipe up any gasoline.

(g) Connect the cable to the negative (-) battery

terminal.

(h) Connect the intelligent tester to the DLC3.

(i) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / ACTIVE TEST / FUEL PUMP

/ SPD.

(j) Measure the fuel pressure.

Fuel pressure:

304 to 343 kPa (3.1 to 3.5 kgf*cm

2, 44.1 to 49.7

psi)

• If the fuel pressure is greater than the standard

value, replace the fuel pressure regulator.

• If the fuel pressure is less than the standard

value, check the fuel hoses and connections, fuel

pump, fuel filter and fuel pressure regulator.

(k) Disconnect the intelligent tester from the DLC3.

(l) Start the engine.

(m) Measure the fuel pressure at idle.

Fuel pressure:

304 to 343 kPa (3.1 to 3.5 kgf*cm

2, 44.1 to 49.7

psi)

(n) Stop the engine.

(o) Check that the fuel pressure remains as specified

for 5 minutes after the engine stops.

Fuel pressure:

147 kPa (1.5 kgf*cm

2, 21 psi) or more

If the fuel pressure is not as specified, check the fuel

pump, pressure regulator and/or fuel injectors.

(p) After checking the fuel pressure, disconnect the

cable from the negative (-) battery terminal and

carefully remove the SST to prevent gasoline from

splashing.

(q) Reconnect the fuel tube to the main fuel tube (fuel

tube connector).

(r) Install the No. 1 fuel pipe clamp to the fuel tube

connector.

(s) Check for fuel leaks (*1).

A129461E01

Page 1119 of 3000

2GR-FE FUEL – FUEL INJECTORFU–13

FU

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

HINT:

See page FU-1.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

3. REMOVE NO. 1 ENGINE UNDER COVER

4. DRAIN ENGINE COOLANT (See page CO-6)

5. REMOVE FRONT WIPER ARM HEAD CAP (See page

WW-4)

6. REMOVE FRONT WIPER ARM RH (See page WW-4)

7. REMOVE FRONT WIPER ARM LH (See page WW-4)

8. REMOVE COWL TOP VENTILATOR LOUVER SUB-

ASSEMBLY (See page WW-4)

9. REMOVE WINDSHIELD WIPER MOTOR AND LINK

ASSEMBLY (See page WW-4)

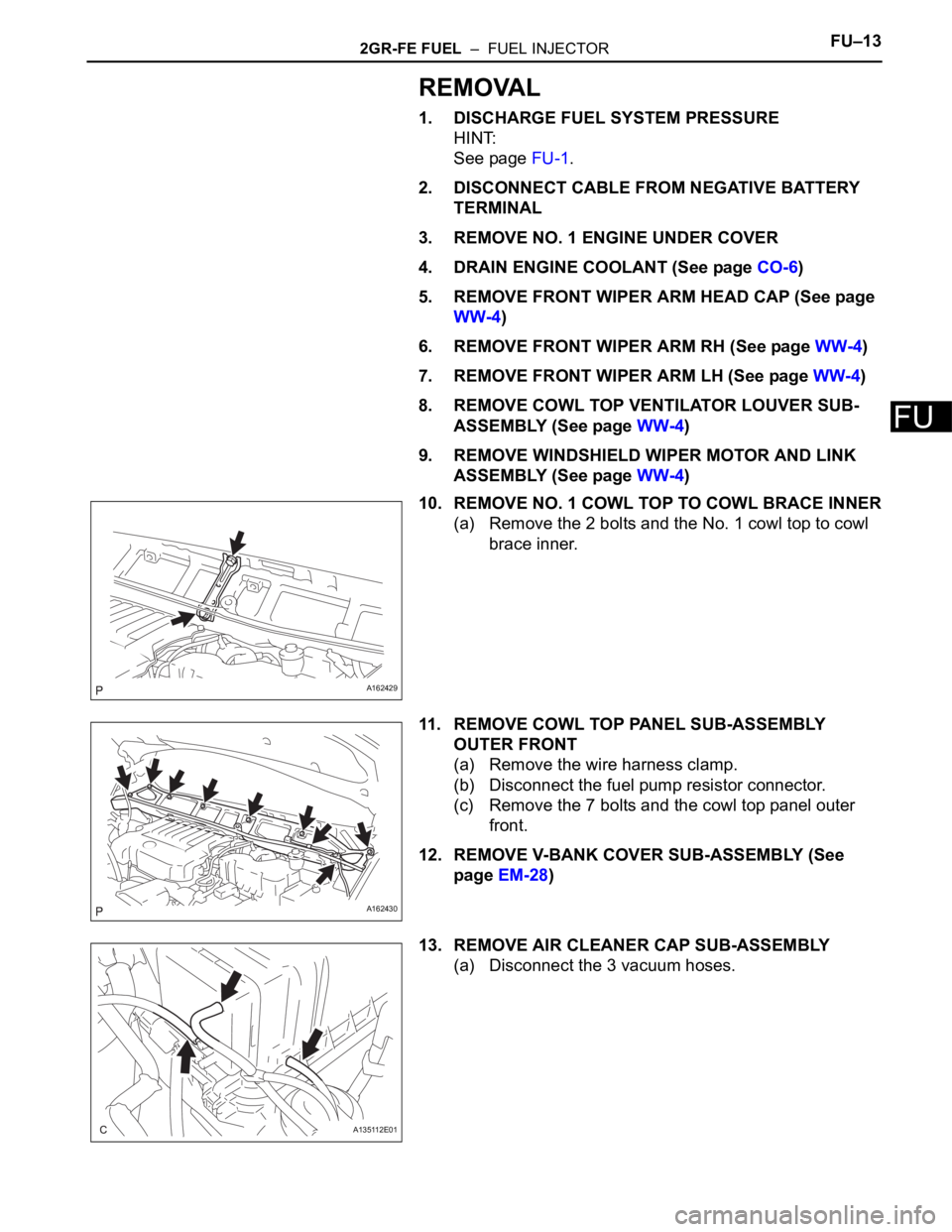

10. REMOVE NO. 1 COWL TOP TO COWL BRACE INNER

(a) Remove the 2 bolts and the No. 1 cowl top to cowl

brace inner.

11. REMOVE COWL TOP PANEL SUB-ASSEMBLY

OUTER FRONT

(a) Remove the wire harness clamp.

(b) Disconnect the fuel pump resistor connector.

(c) Remove the 7 bolts and the cowl top panel outer

front.

12. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

13. REMOVE AIR CLEANER CAP SUB-ASSEMBLY

(a) Disconnect the 3 vacuum hoses.

A162429

A162430

A135112E01

Page 1122 of 3000

2GR-FE FUEL – FUEL SYSTEMFU–1

FU

FUEL SYSTEM

PRECAUTION

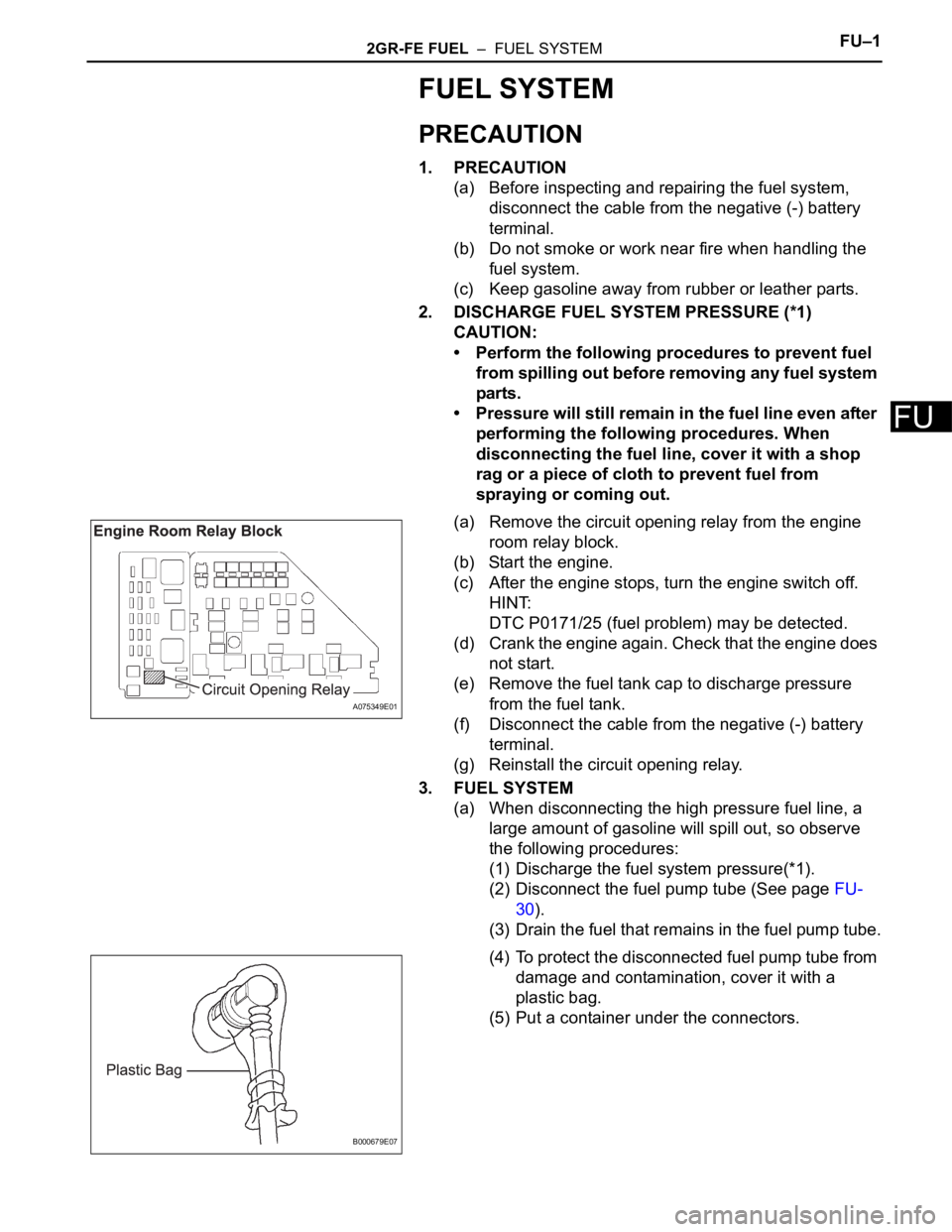

1. PRECAUTION

(a) Before inspecting and repairing the fuel system,

disconnect the cable from the negative (-) battery

terminal.

(b) Do not smoke or work near fire when handling the

fuel system.

(c) Keep gasoline away from rubber or leather parts.

2. DISCHARGE FUEL SYSTEM PRESSURE (*1)

CAUTION:

• Perform the following procedures to prevent fuel

from spilling out before removing any fuel system

parts.

• Pressure will still remain in the fuel line even after

performing the following procedures. When

disconnecting the fuel line, cover it with a shop

rag or a piece of cloth to prevent fuel from

spraying or coming out.

(a) Remove the circuit opening relay from the engine

room relay block.

(b) Start the engine.

(c) After the engine stops, turn the engine switch off.

HINT:

DTC P0171/25 (fuel problem) may be detected.

(d) Crank the engine again. Check that the engine does

not start.

(e) Remove the fuel tank cap to discharge pressure

from the fuel tank.

(f) Disconnect the cable from the negative (-) battery

terminal.

(g) Reinstall the circuit opening relay.

3. FUEL SYSTEM

(a) When disconnecting the high pressure fuel line, a

large amount of gasoline will spill out, so observe

the following procedures:

(1) Discharge the fuel system pressure(*1).

(2) Disconnect the fuel pump tube (See page FU-

30).

(3) Drain the fuel that remains in the fuel pump tube.

(4) To protect the disconnected fuel pump tube from

damage and contamination, cover it with a

plastic bag.

(5) Put a container under the connectors.

A075349E01

B000679E07

Page 1123 of 3000

FU–22GR-FE FUEL – FUEL SYSTEM

FU

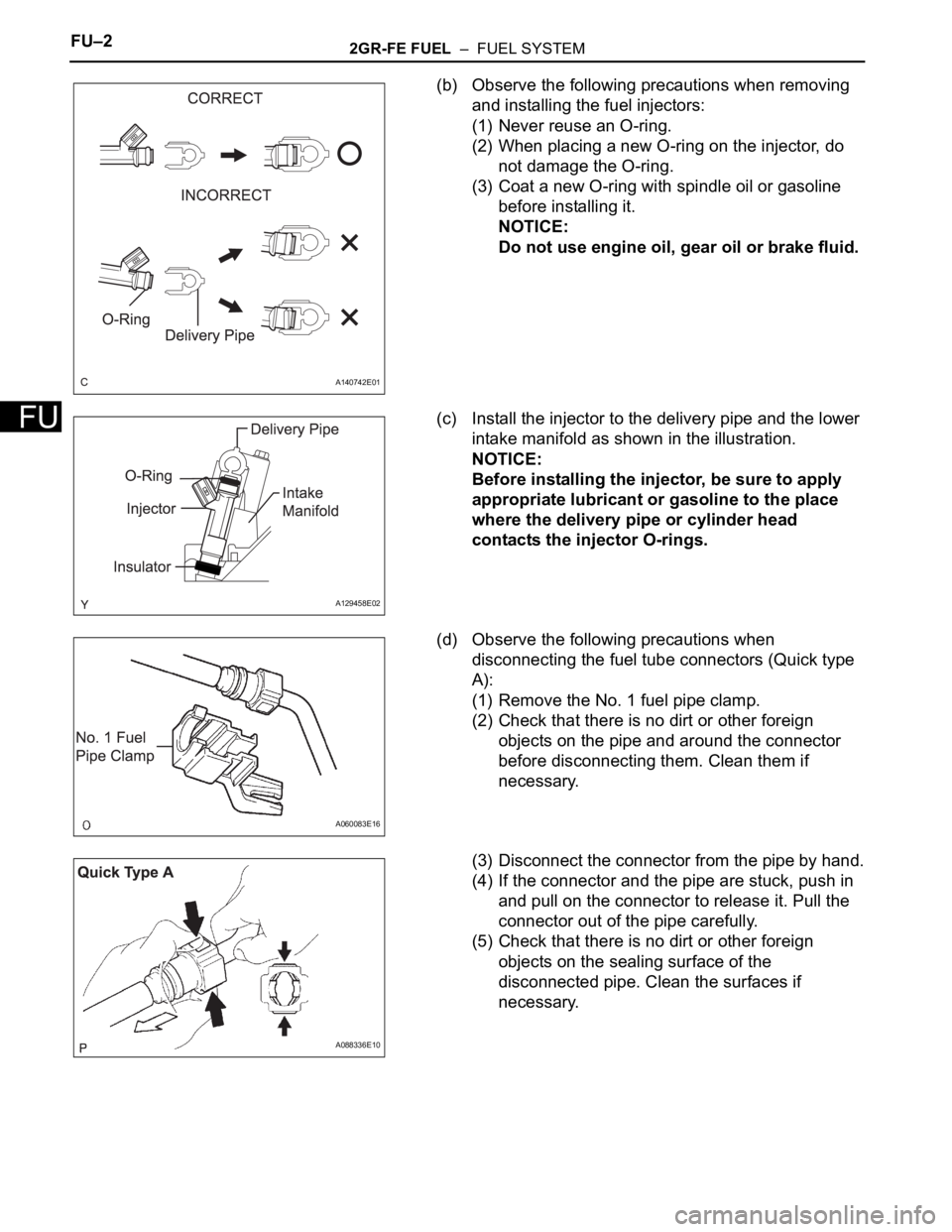

(b) Observe the following precautions when removing

and installing the fuel injectors:

(1) Never reuse an O-ring.

(2) When placing a new O-ring on the injector, do

not damage the O-ring.

(3) Coat a new O-ring with spindle oil or gasoline

before installing it.

NOTICE:

Do not use engine oil, gear oil or brake fluid.

(c) Install the injector to the delivery pipe and the lower

intake manifold as shown in the illustration.

NOTICE:

Before installing the injector, be sure to apply

appropriate lubricant or gasoline to the place

where the delivery pipe or cylinder head

contacts the injector O-rings.

(d) Observe the following precautions when

disconnecting the fuel tube connectors (Quick type

A):

(1) Remove the No. 1 fuel pipe clamp.

(2) Check that there is no dirt or other foreign

objects on the pipe and around the connector

before disconnecting them. Clean them if

necessary.

(3) Disconnect the connector from the pipe by hand.

(4) If the connector and the pipe are stuck, push in

and pull on the connector to release it. Pull the

connector out of the pipe carefully.

(5) Check that there is no dirt or other foreign

objects on the sealing surface of the

disconnected pipe. Clean the surfaces if

necessary.

A140742E01

A129458E02

A060083E16

A088336E10