air bleeding TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 906 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–101

EM

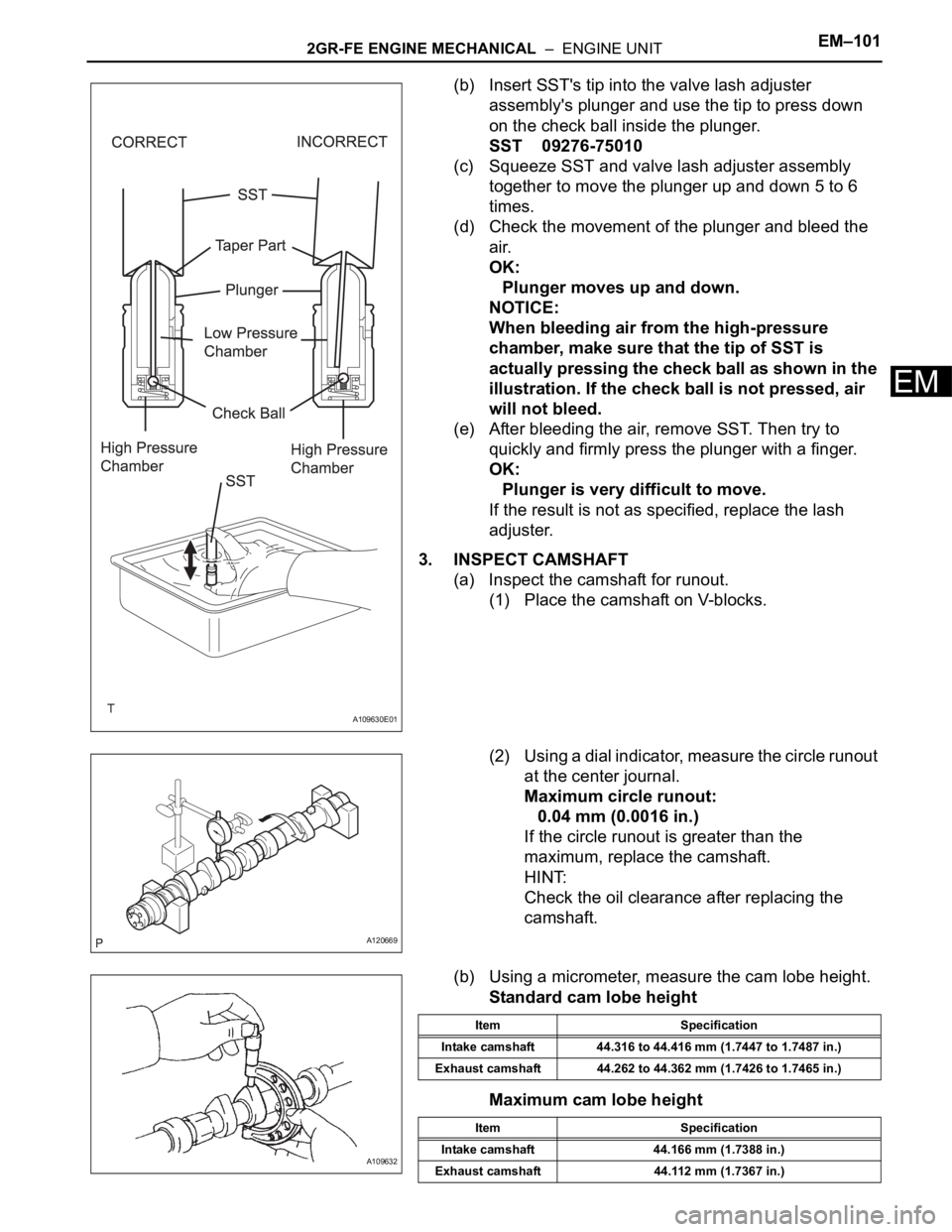

(b) Insert SST's tip into the valve lash adjuster

assembly's plunger and use the tip to press down

on the check ball inside the plunger.

SST 09276-75010

(c) Squeeze SST and valve lash adjuster assembly

together to move the plunger up and down 5 to 6

times.

(d) Check the movement of the plunger and bleed the

air.

OK:

Plunger moves up and down.

NOTICE:

When bleeding air from the high-pressure

chamber, make sure that the tip of SST is

actually pressing the check ball as shown in the

illustration. If the check ball is not pressed, air

will not bleed.

(e) After bleeding the air, remove SST. Then try to

quickly and firmly press the plunger with a finger.

OK:

Plunger is very difficult to move.

If the result is not as specified, replace the lash

adjuster.

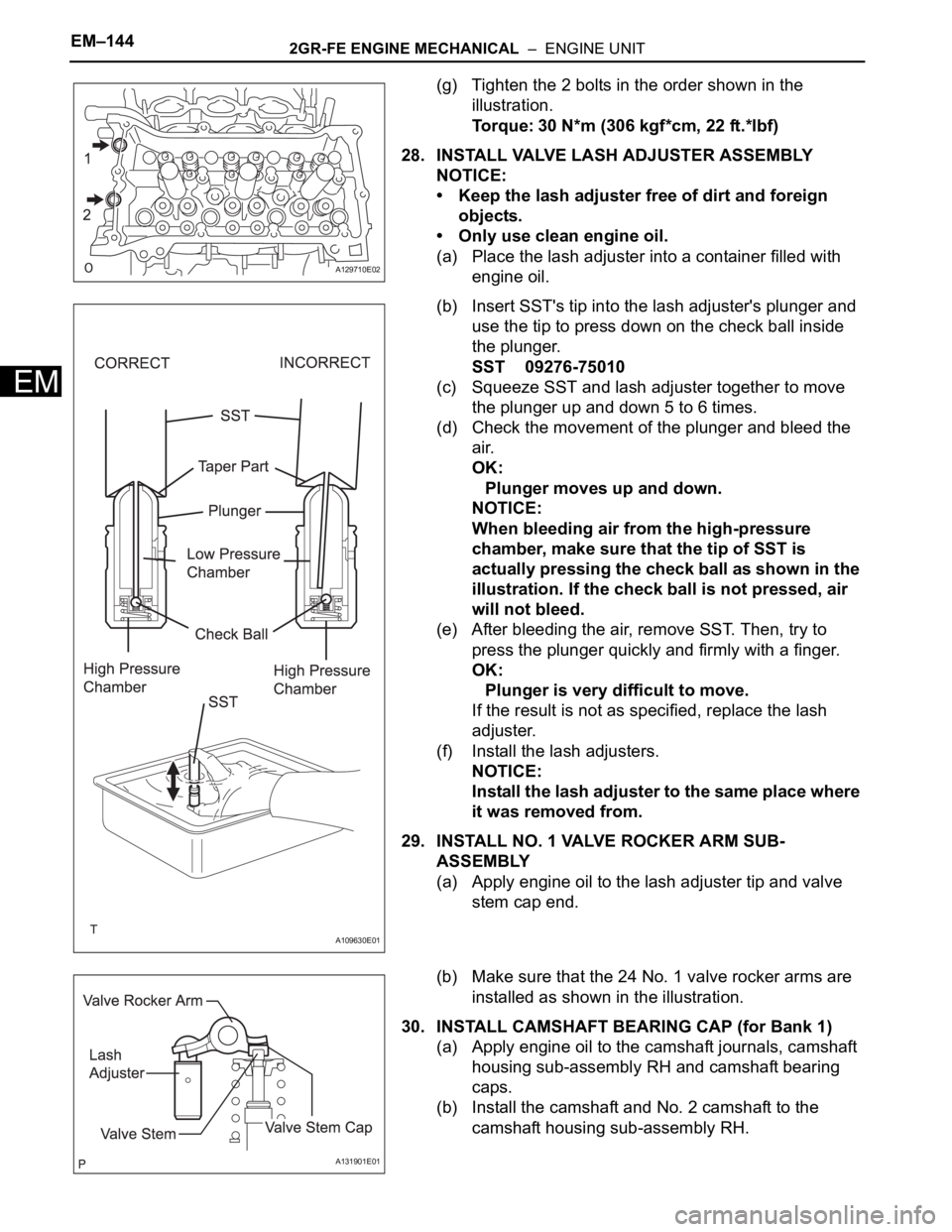

3. INSPECT CAMSHAFT

(a) Inspect the camshaft for runout.

(1) Place the camshaft on V-blocks.

(2) Using a dial indicator, measure the circle runout

at the center journal.

Maximum circle runout:

0.04 mm (0.0016 in.)

If the circle runout is greater than the

maximum, replace the camshaft.

HINT:

Check the oil clearance after replacing the

camshaft.

(b) Using a micrometer, measure the cam lobe height.

Standard cam lobe height

Maximum cam lobe height

A109630E01

A120669

A109632

Item Specification

Intake camshaft 44.316 to 44.416 mm (1.7447 to 1.7487 in.)

Exhaust camshaft 44.262 to 44.362 mm (1.7426 to 1.7465 in.)

Item Specification

Intake camshaft 44.166 mm (1.7388 in.)

Exhaust camshaft 44.112 mm (1.7367 in.)

Page 953 of 3000

EM–1442GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

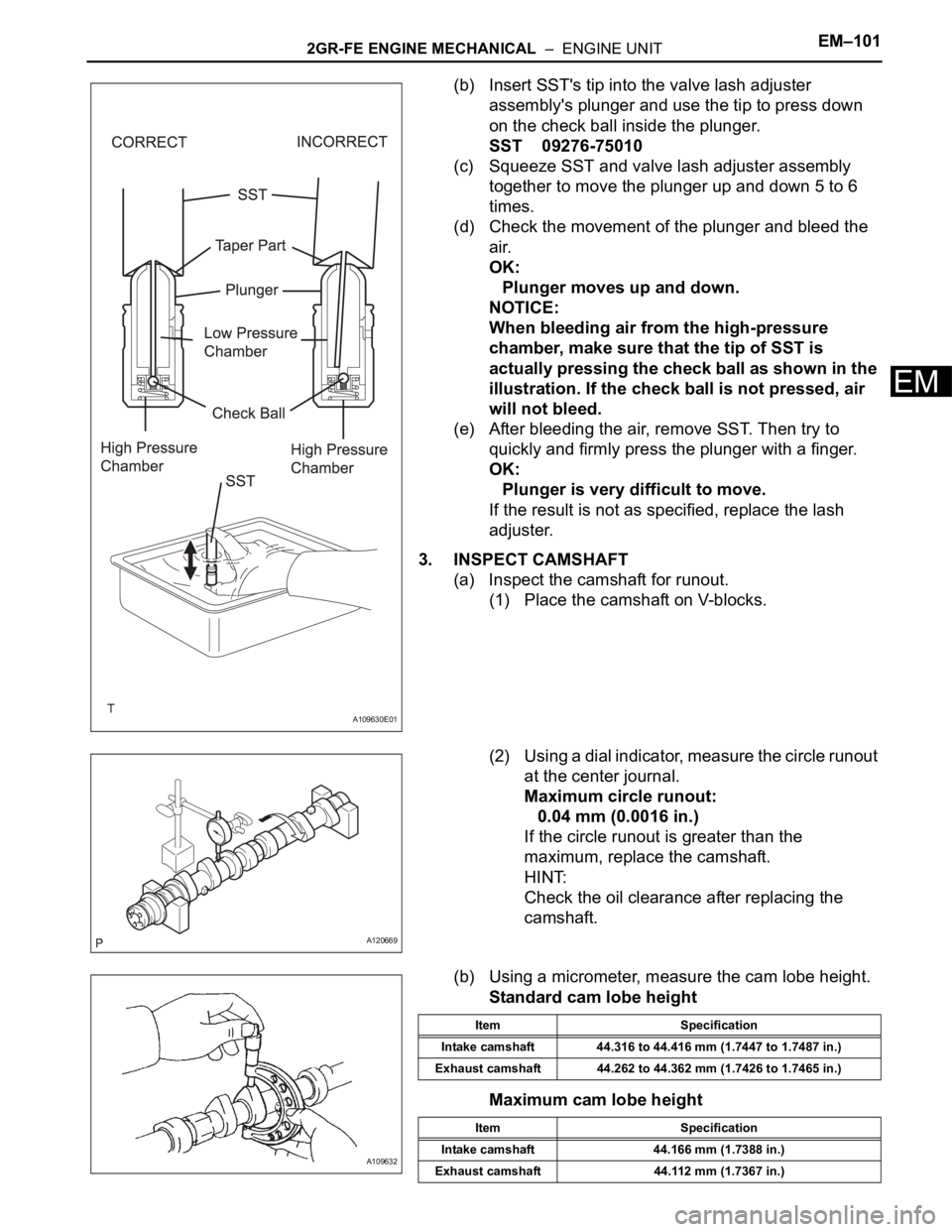

(g) Tighten the 2 bolts in the order shown in the

illustration.

Torque: 30 N*m (306 kgf*cm, 22 ft.*lbf)

28. INSTALL VALVE LASH ADJUSTER ASSEMBLY

NOTICE:

• Keep the lash adjuster free of dirt and foreign

objects.

• Only use clean engine oil.

(a) Place the lash adjuster into a container filled with

engine oil.

(b) Insert SST's tip into the lash adjuster's plunger and

use the tip to press down on the check ball inside

the plunger.

SST 09276-75010

(c) Squeeze SST and lash adjuster together to move

the plunger up and down 5 to 6 times.

(d) Check the movement of the plunger and bleed the

air.

OK:

Plunger moves up and down.

NOTICE:

When bleeding air from the high-pressure

chamber, make sure that the tip of SST is

actually pressing the check ball as shown in the

illustration. If the check ball is not pressed, air

will not bleed.

(e) After bleeding the air, remove SST. Then, try to

press the plunger quickly and firmly with a finger.

OK:

Plunger is very difficult to move.

If the result is not as specified, replace the lash

adjuster.

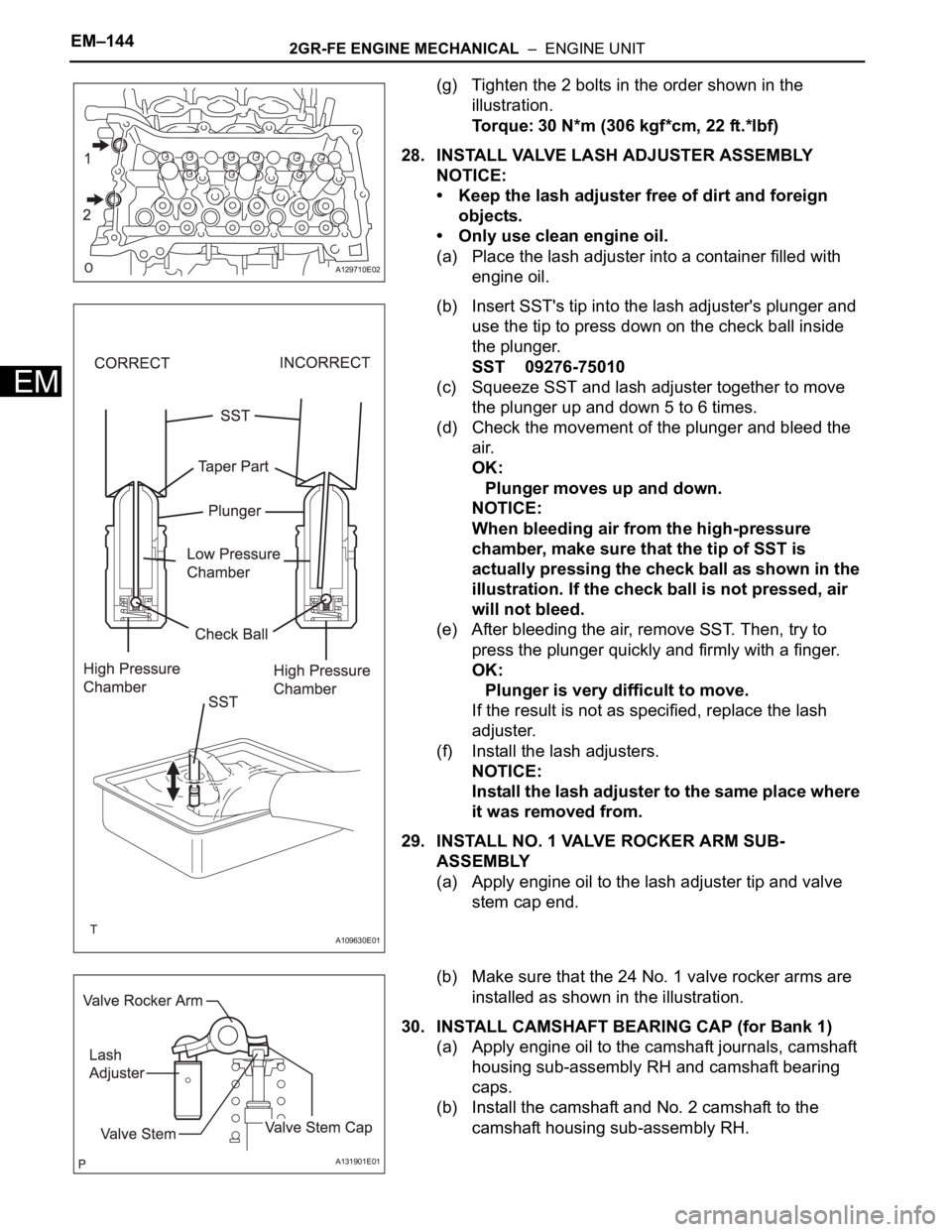

(f) Install the lash adjusters.

NOTICE:

Install the lash adjuster to the same place where

it was removed from.

29. INSTALL NO. 1 VALVE ROCKER ARM SUB-

ASSEMBLY

(a) Apply engine oil to the lash adjuster tip and valve

stem cap end.

(b) Make sure that the 24 No. 1 valve rocker arms are

installed as shown in the illustration.

30. INSTALL CAMSHAFT BEARING CAP (for Bank 1)

(a) Apply engine oil to the camshaft journals, camshaft

housing sub-assembly RH and camshaft bearing

caps.

(b) Install the camshaft and No. 2 camshaft to the

camshaft housing sub-assembly RH.

A129710E02

A109630E01

A131901E01

Page 1048 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–101

EM

(b) Insert SST's tip into the valve lash adjuster

assembly's plunger and use the tip to press down

on the check ball inside the plunger.

SST 09276-75010

(c) Squeeze SST and valve lash adjuster assembly

together to move the plunger up and down 5 to 6

times.

(d) Check the movement of the plunger and bleed the

air.

OK:

Plunger moves up and down.

NOTICE:

When bleeding air from the high-pressure

chamber, make sure that the tip of SST is

actually pressing the check ball as shown in the

illustration. If the check ball is not pressed, air

will not bleed.

(e) After bleeding the air, remove SST. Then try to

quickly and firmly press the plunger with a finger.

OK:

Plunger is very difficult to move.

If the result is not as specified, replace the lash

adjuster.

3. INSPECT CAMSHAFT

(a) Inspect the camshaft for runout.

(1) Place the camshaft on V-blocks.

(2) Using a dial indicator, measure the circle runout

at the center journal.

Maximum circle runout:

0.04 mm (0.0016 in.)

If the circle runout is greater than the

maximum, replace the camshaft.

HINT:

Check the oil clearance after replacing the

camshaft.

(b) Using a micrometer, measure the cam lobe height.

Standard cam lobe height

Maximum cam lobe height

A109630E01

A120669

A109632

Item Specification

Intake camshaft 44.316 to 44.416 mm (1.7447 to 1.7487 in.)

Exhaust camshaft 44.262 to 44.362 mm (1.7426 to 1.7465 in.)

Item Specification

Intake camshaft 44.166 mm (1.7388 in.)

Exhaust camshaft 44.112 mm (1.7367 in.)

Page 1091 of 3000

EM–1442GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

(g) Tighten the 2 bolts in the order shown in the

illustration.

Torque: 30 N*m (306 kgf*cm, 22 ft.*lbf)

28. INSTALL VALVE LASH ADJUSTER ASSEMBLY

NOTICE:

• Keep the lash adjuster free of dirt and foreign

objects.

• Only use clean engine oil.

(a) Place the lash adjuster into a container filled with

engine oil.

(b) Insert SST's tip into the lash adjuster's plunger and

use the tip to press down on the check ball inside

the plunger.

SST 09276-75010

(c) Squeeze SST and lash adjuster together to move

the plunger up and down 5 to 6 times.

(d) Check the movement of the plunger and bleed the

air.

OK:

Plunger moves up and down.

NOTICE:

When bleeding air from the high-pressure

chamber, make sure that the tip of SST is

actually pressing the check ball as shown in the

illustration. If the check ball is not pressed, air

will not bleed.

(e) After bleeding the air, remove SST. Then, try to

press the plunger quickly and firmly with a finger.

OK:

Plunger is very difficult to move.

If the result is not as specified, replace the lash

adjuster.

(f) Install the lash adjusters.

NOTICE:

Install the lash adjuster to the same place where

it was removed from.

29. INSTALL NO. 1 VALVE ROCKER ARM SUB-

ASSEMBLY

(a) Apply engine oil to the lash adjuster tip and valve

stem cap end.

(b) Make sure that the 24 No. 1 valve rocker arms are

installed as shown in the illustration.

30. INSTALL CAMSHAFT BEARING CAP (for Bank 1)

(a) Apply engine oil to the camshaft journals, camshaft

housing sub-assembly RH and camshaft bearing

caps.

(b) Install the camshaft and No. 2 camshaft to the

camshaft housing sub-assembly RH.

A129710E02

A109630E01

A131901E01

Page 2595 of 3000

BRAKE – BRAKE FLUIDBR–3

BR

BRAKE FLUID

BLEEDING

HINT:

If any work is performed on the brake system or if air in the

brake lines is suspected, bleed the air out of the brake

system.

NOTICE:

Wash the brake fluid off immediately if it adheres to any

painted surfaces.

1. REMOVE COWL TOP PANEL SUB-ASSEMBLY

OUTER FRONT (See page SP-13)

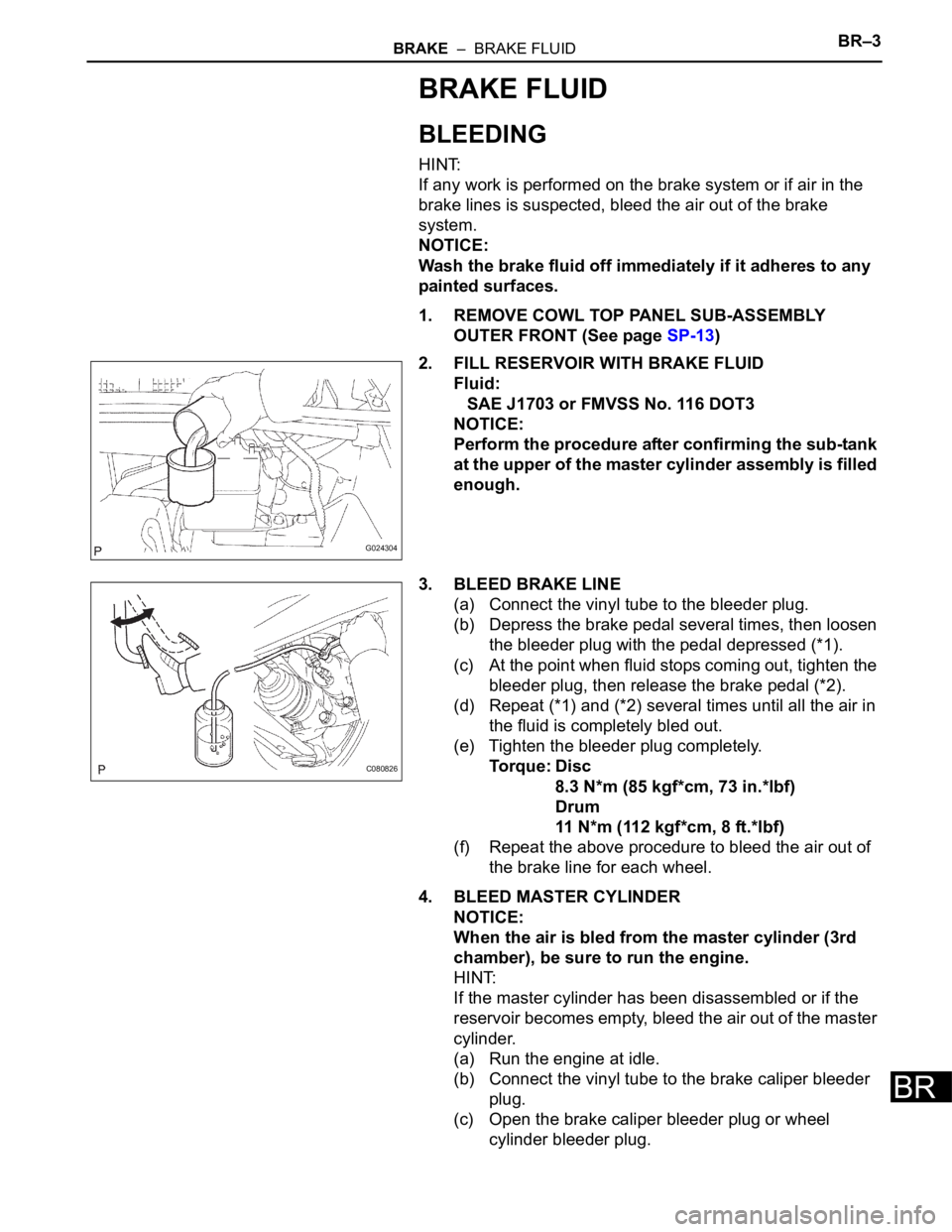

2. FILL RESERVOIR WITH BRAKE FLUID

Fluid:

SAE J1703 or FMVSS No. 116 DOT3

NOTICE:

Perform the procedure after confirming the sub-tank

at the upper of the master cylinder assembly is filled

enough.

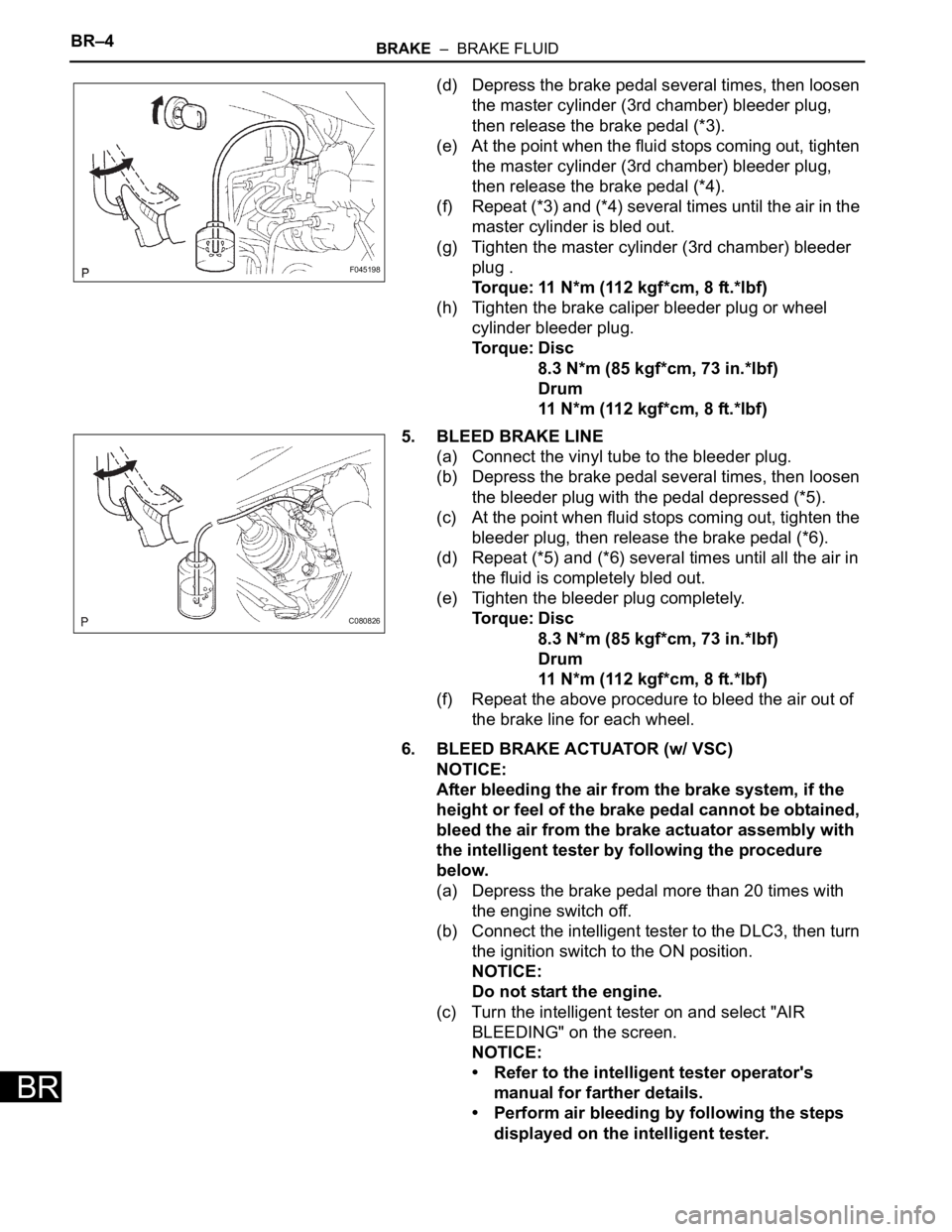

3. BLEED BRAKE LINE

(a) Connect the vinyl tube to the bleeder plug.

(b) Depress the brake pedal several times, then loosen

the bleeder plug with the pedal depressed (*1).

(c) At the point when fluid stops coming out, tighten the

bleeder plug, then release the brake pedal (*2).

(d) Repeat (*1) and (*2) several times until all the air in

the fluid is completely bled out.

(e) Tighten the bleeder plug completely.

Torque: Disc

8.3 N*m (85 kgf*cm, 73 in.*lbf)

Drum

11 N*m (112 kgf*cm, 8 ft.*lbf)

(f) Repeat the above procedure to bleed the air out of

the brake line for each wheel.

4. BLEED MASTER CYLINDER

NOTICE:

When the air is bled from the master cylinder (3rd

chamber), be sure to run the engine.

HINT:

If the master cylinder has been disassembled or if the

reservoir becomes empty, bleed the air out of the master

cylinder.

(a) Run the engine at idle.

(b) Connect the vinyl tube to the brake caliper bleeder

plug.

(c) Open the brake caliper bleeder plug or wheel

cylinder bleeder plug.

G024304

C080826

Page 2596 of 3000

BR–4BRAKE – BRAKE FLUID

BR

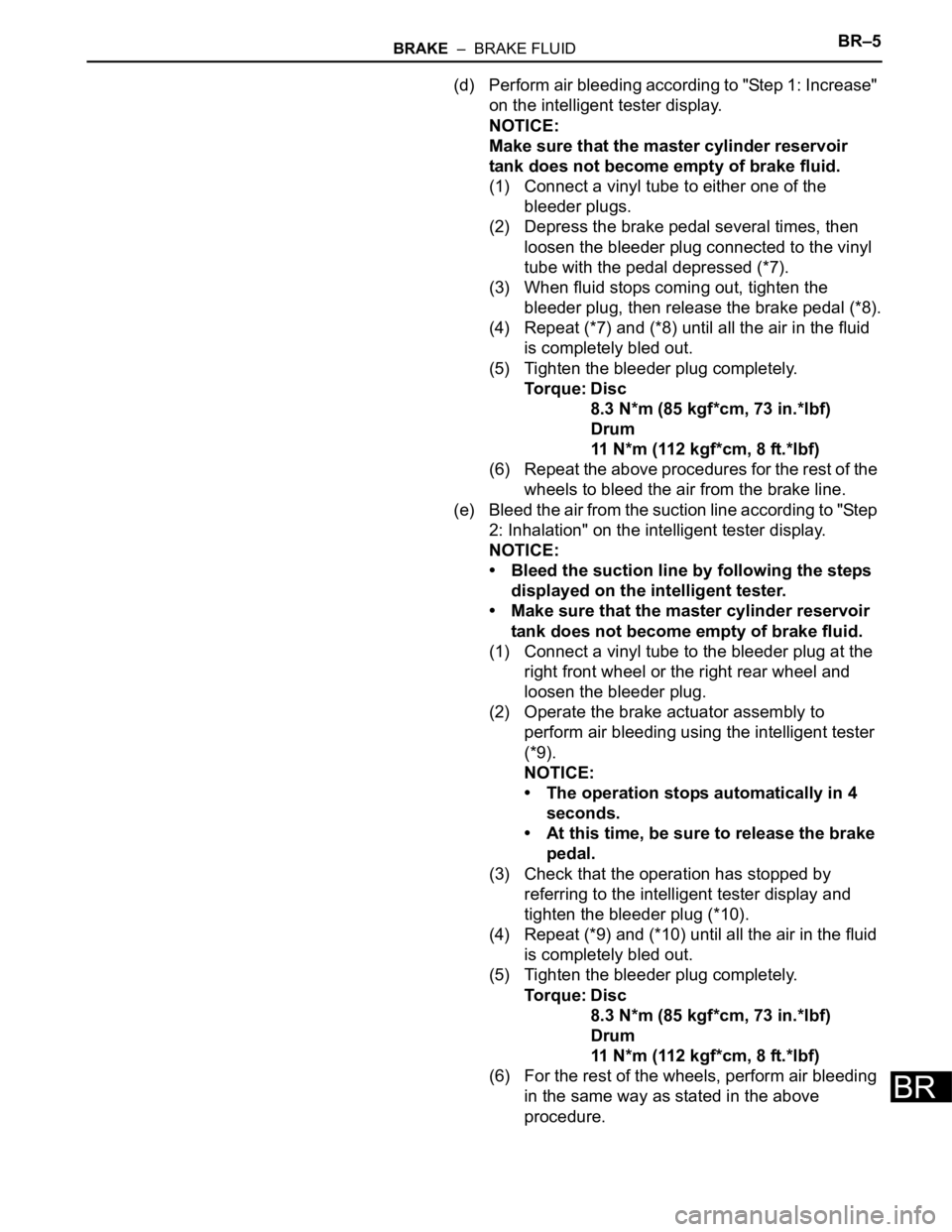

(d) Depress the brake pedal several times, then loosen

the master cylinder (3rd chamber) bleeder plug,

then release the brake pedal (*3).

(e) At the point when the fluid stops coming out, tighten

the master cylinder (3rd chamber) bleeder plug,

then release the brake pedal (*4).

(f) Repeat (*3) and (*4) several times until the air in the

master cylinder is bled out.

(g) Tighten the master cylinder (3rd chamber) bleeder

plug .

Torque: 11 N*m (112 kgf*cm, 8 ft.*lbf)

(h) Tighten the brake caliper bleeder plug or wheel

cylinder bleeder plug.

Torque: Disc

8.3 N*m (85 kgf*cm, 73 in.*lbf)

Drum

11 N*m (112 kgf*cm, 8 ft.*lbf)

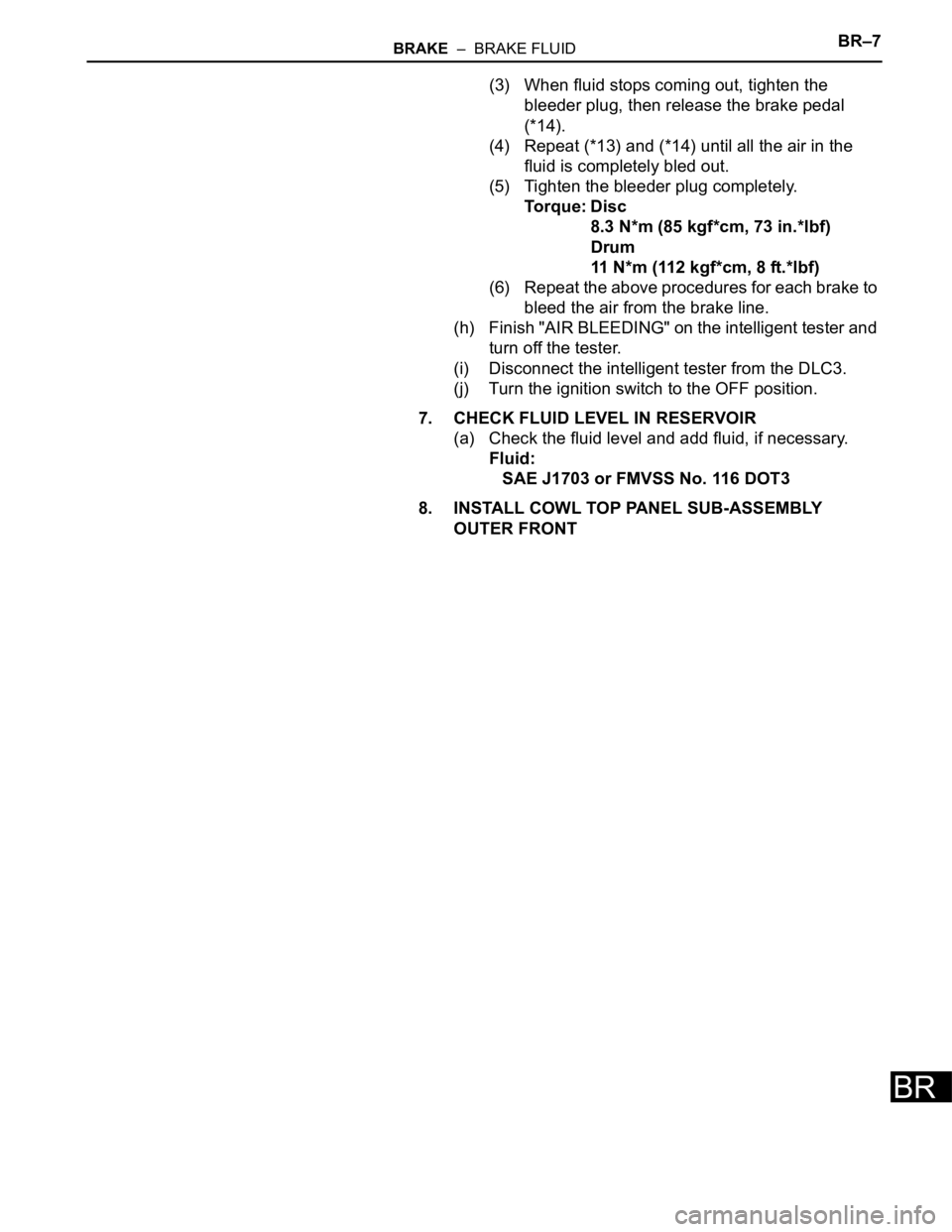

5. BLEED BRAKE LINE

(a) Connect the vinyl tube to the bleeder plug.

(b) Depress the brake pedal several times, then loosen

the bleeder plug with the pedal depressed (*5).

(c) At the point when fluid stops coming out, tighten the

bleeder plug, then release the brake pedal (*6).

(d) Repeat (*5) and (*6) several times until all the air in

the fluid is completely bled out.

(e) Tighten the bleeder plug completely.

Torque: Disc

8.3 N*m (85 kgf*cm, 73 in.*lbf)

Drum

11 N*m (112 kgf*cm, 8 ft.*lbf)

(f) Repeat the above procedure to bleed the air out of

the brake line for each wheel.

6. BLEED BRAKE ACTUATOR (w/ VSC)

NOTICE:

After bleeding the air from the brake system, if the

height or feel of the brake pedal cannot be obtained,

bleed the air from the brake actuator assembly with

the intelligent tester by following the procedure

below.

(a) Depress the brake pedal more than 20 times with

the engine switch off.

(b) Connect the intelligent tester to the DLC3, then turn

the ignition switch to the ON position.

NOTICE:

Do not start the engine.

(c) Turn the intelligent tester on and select "AIR

BLEEDING" on the screen.

NOTICE:

• Refer to the intelligent tester operator's

manual for farther details.

• Perform air bleeding by following the steps

displayed on the intelligent tester.

F045198

C080826

Page 2597 of 3000

BRAKE – BRAKE FLUIDBR–5

BR

(d) Perform air bleeding according to "Step 1: Increase"

on the intelligent tester display.

NOTICE:

Make sure that the master cylinder reservoir

tank does not become empty of brake fluid.

(1) Connect a vinyl tube to either one of the

bleeder plugs.

(2) Depress the brake pedal several times, then

loosen the bleeder plug connected to the vinyl

tube with the pedal depressed (*7).

(3) When fluid stops coming out, tighten the

bleeder plug, then release the brake pedal (*8).

(4) Repeat (*7) and (*8) until all the air in the fluid

is completely bled out.

(5) Tighten the bleeder plug completely.

To r q u e : D i s c

8.3 N*m (85 kgf*cm, 73 in.*lbf)

Drum

11 N*m (112 kgf*cm, 8 ft.*lbf)

(6) Repeat the above procedures for the rest of the

wheels to bleed the air from the brake line.

(e) Bleed the air from the suction line according to "Step

2: Inhalation" on the intelligent tester display.

NOTICE:

• Bleed the suction line by following the steps

displayed on the intelligent tester.

• Make sure that the master cylinder reservoir

tank does not become empty of brake fluid.

(1) Connect a vinyl tube to the bleeder plug at the

right front wheel or the right rear wheel and

loosen the bleeder plug.

(2) Operate the brake actuator assembly to

perform air bleeding using the intelligent tester

(*9).

NOTICE:

• The operation stops automatically in 4

seconds.

• At this time, be sure to release the brake

pedal.

(3) Check that the operation has stopped by

referring to the intelligent tester display and

tighten the bleeder plug (*10).

(4) Repeat (*9) and (*10) until all the air in the fluid

is completely bled out.

(5) Tighten the bleeder plug completely.

To r q u e : D i s c

8.3 N*m (85 kgf*cm, 73 in.*lbf)

Drum

11 N*m (112 kgf*cm, 8 ft.*lbf)

(6) For the rest of the wheels, perform air bleeding

in the same way as stated in the above

procedure.

Page 2599 of 3000

BRAKE – BRAKE FLUIDBR–7

BR

(3) When fluid stops coming out, tighten the

bleeder plug, then release the brake pedal

(*14).

(4) Repeat (*13) and (*14) until all the air in the

fluid is completely bled out.

(5) Tighten the bleeder plug completely.

To r q u e : D i s c

8.3 N*m (85 kgf*cm, 73 in.*lbf)

Drum

11 N*m (112 kgf*cm, 8 ft.*lbf)

(6) Repeat the above procedures for each brake to

bleed the air from the brake line.

(h) Finish "AIR BLEEDING" on the intelligent tester and

turn off the tester.

(i) Disconnect the intelligent tester from the DLC3.

(j) Turn the ignition switch to the OFF position.

7. CHECK FLUID LEVEL IN RESERVOIR

(a) Check the fluid level and add fluid, if necessary.

Fluid:

SAE J1703 or FMVSS No. 116 DOT3

8. INSTALL COWL TOP PANEL SUB-ASSEMBLY

OUTER FRONT