Hoses TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 21 of 3000

2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–521

ES

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

(See page FU-13)

2. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-4)

5. REMOVE FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-27)

6. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-493)

7. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-28)

8. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

(a) Disconnect the 2 water by-pass hoses from the

throttle body [A].

(b) Disconnect the vapor feed hose [B].

(c) Disconnect the throttle body connector and clamp

[C].

(d) Disconnect the ventilation hose [D].

(e) Disconnect the union to check valve hose [E].

(f) Disconnect the connector [F].

A129464E07

A138457E04

A129467

Page 23 of 3000

![TOYOTA SIENNA 2007 Service Repair Manual 2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–523

ES

(a) Install a new gasket to the intake air surge tank [A].

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts [B].

Torque: 18 N*m ( TOYOTA SIENNA 2007 Service Repair Manual 2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–523

ES

(a) Install a new gasket to the intake air surge tank [A].

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts [B].

Torque: 18 N*m (](/img/14/57466/w960_57466-22.png)

2GR-FE ENGINE CONTROL SYSTEM – KNOCK SENSORES–523

ES

(a) Install a new gasket to the intake air surge tank [A].

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts [B].

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

(c) Install the intake air surge tank with the 2 nuts and 2

bolts [C].

Torque: Nut

16 N*m (163 kgf*cm, 12 ft.*lbf)

Bolt

21 N*m (214 kgf*cm, 15 ft.*lbf)

(d) Connect the connector [D].

(e) Connect the union to check valve hose [E].

(f) Connect the ventilation hose No. 2 [F].

(g) Install the clamp and connect the throttle with motor

body assembly connector [G].

(h) Connect the vapor feed hose [H].

(i) Connect the 2 water by-pass hoses to the throttle

with motor body assembly [I].

5. INSTALL AIR CLEANER CASE SUB-ASSEMBLY (See

page EM-59)

6. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-496)

7. ADD ENGINE COOLANT (See page CO-7)

8. INSPECT FOR ENGINE COOLANT LEAK (See page

CO-1)

9. INSPECT FOR FUEL LEAK (See page FU-7)

10. INSTALL FRONT OUTER COWL TOP PANEL SUB-

ASSEMBLY (See page EM-61)

11. INSTALL WINDSHIELD WIPER MOTOR ASSEMBLY

HINT:

(See page WW-5)

A129468E09

A129467

A138457E05

A129464E08

Page 27 of 3000

EM–282GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

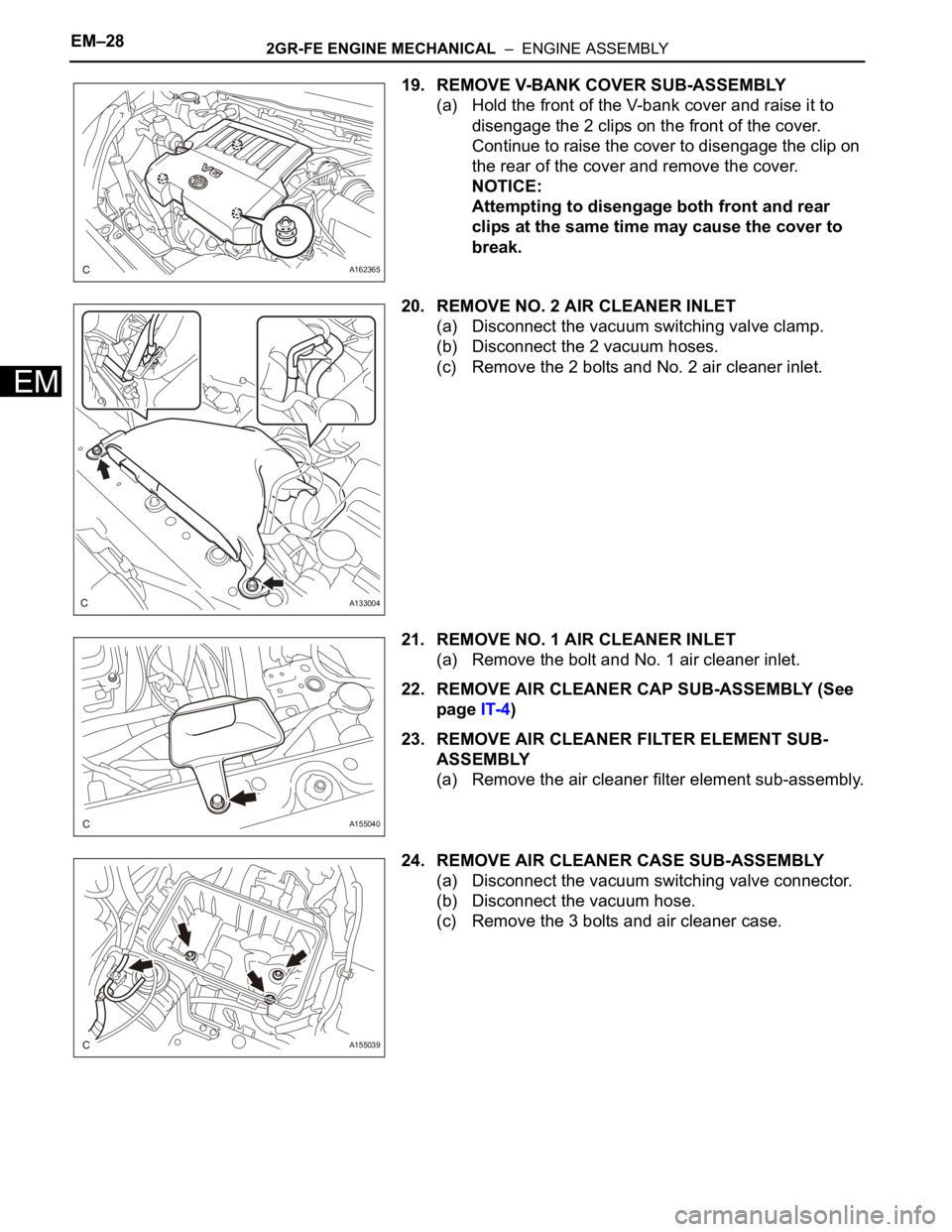

19. REMOVE V-BANK COVER SUB-ASSEMBLY

(a) Hold the front of the V-bank cover and raise it to

disengage the 2 clips on the front of the cover.

Continue to raise the cover to disengage the clip on

the rear of the cover and remove the cover.

NOTICE:

Attempting to disengage both front and rear

clips at the same time may cause the cover to

break.

20. REMOVE NO. 2 AIR CLEANER INLET

(a) Disconnect the vacuum switching valve clamp.

(b) Disconnect the 2 vacuum hoses.

(c) Remove the 2 bolts and No. 2 air cleaner inlet.

21. REMOVE NO. 1 AIR CLEANER INLET

(a) Remove the bolt and No. 1 air cleaner inlet.

22. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page IT-4)

23. REMOVE AIR CLEANER FILTER ELEMENT SUB-

ASSEMBLY

(a) Remove the air cleaner filter element sub-assembly.

24. REMOVE AIR CLEANER CASE SUB-ASSEMBLY

(a) Disconnect the vacuum switching valve connector.

(b) Disconnect the vacuum hose.

(c) Remove the 3 bolts and air cleaner case.

A162365

A133004

A155040

A155039

Page 34 of 3000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–35

EM

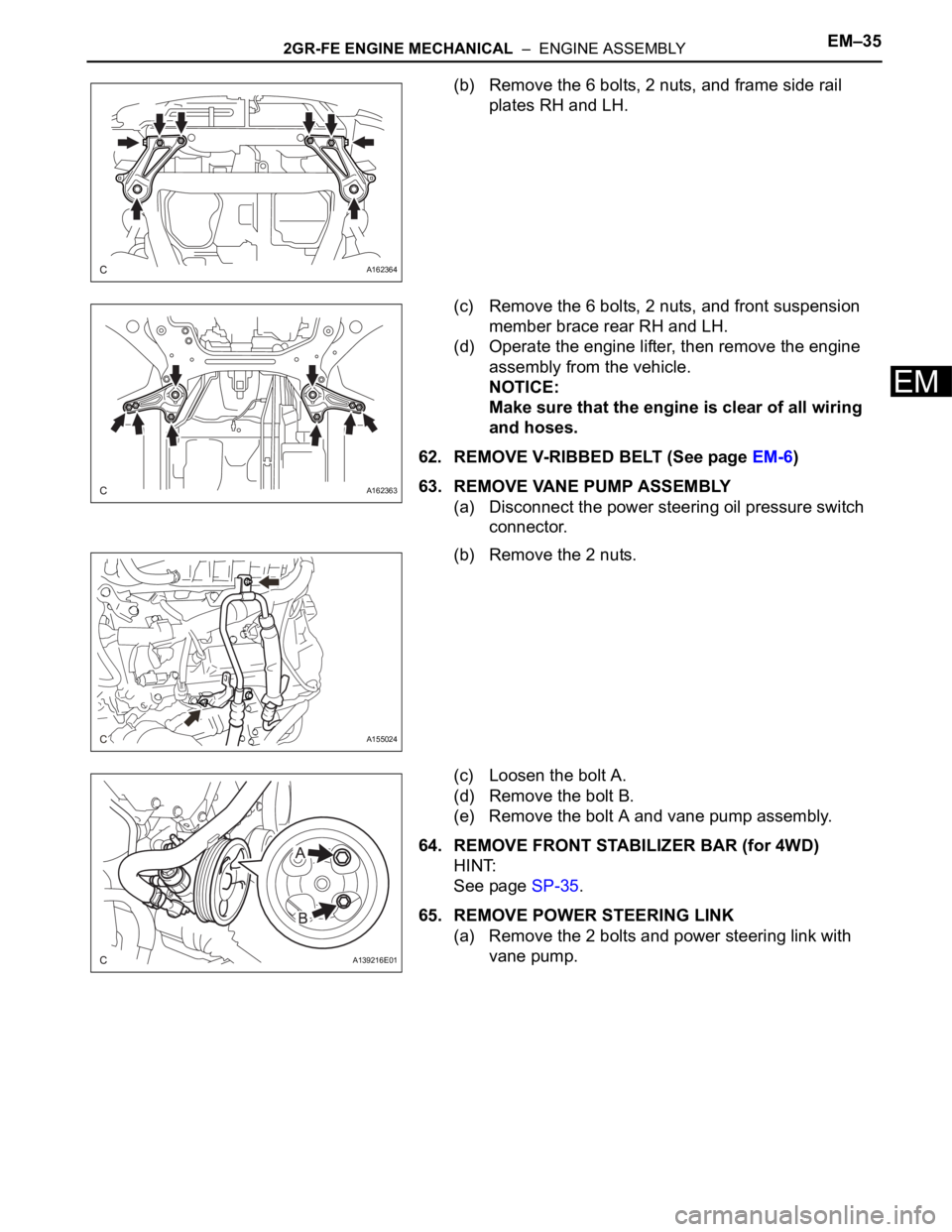

(b) Remove the 6 bolts, 2 nuts, and frame side rail

plates RH and LH.

(c) Remove the 6 bolts, 2 nuts, and front suspension

member brace rear RH and LH.

(d) Operate the engine lifter, then remove the engine

assembly from the vehicle.

NOTICE:

Make sure that the engine is clear of all wiring

and hoses.

62. REMOVE V-RIBBED BELT (See page EM-6)

63. REMOVE VANE PUMP ASSEMBLY

(a) Disconnect the power steering oil pressure switch

connector.

(b) Remove the 2 nuts.

(c) Loosen the bolt A.

(d) Remove the bolt B.

(e) Remove the bolt A and vane pump assembly.

64. REMOVE FRONT STABILIZER BAR (for 4WD)

HINT:

See page SP-35.

65. REMOVE POWER STEERING LINK

(a) Remove the 2 bolts and power steering link with

vane pump.

A162364

A162363

A155024

A139216E01

Page 37 of 3000

EM–382GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

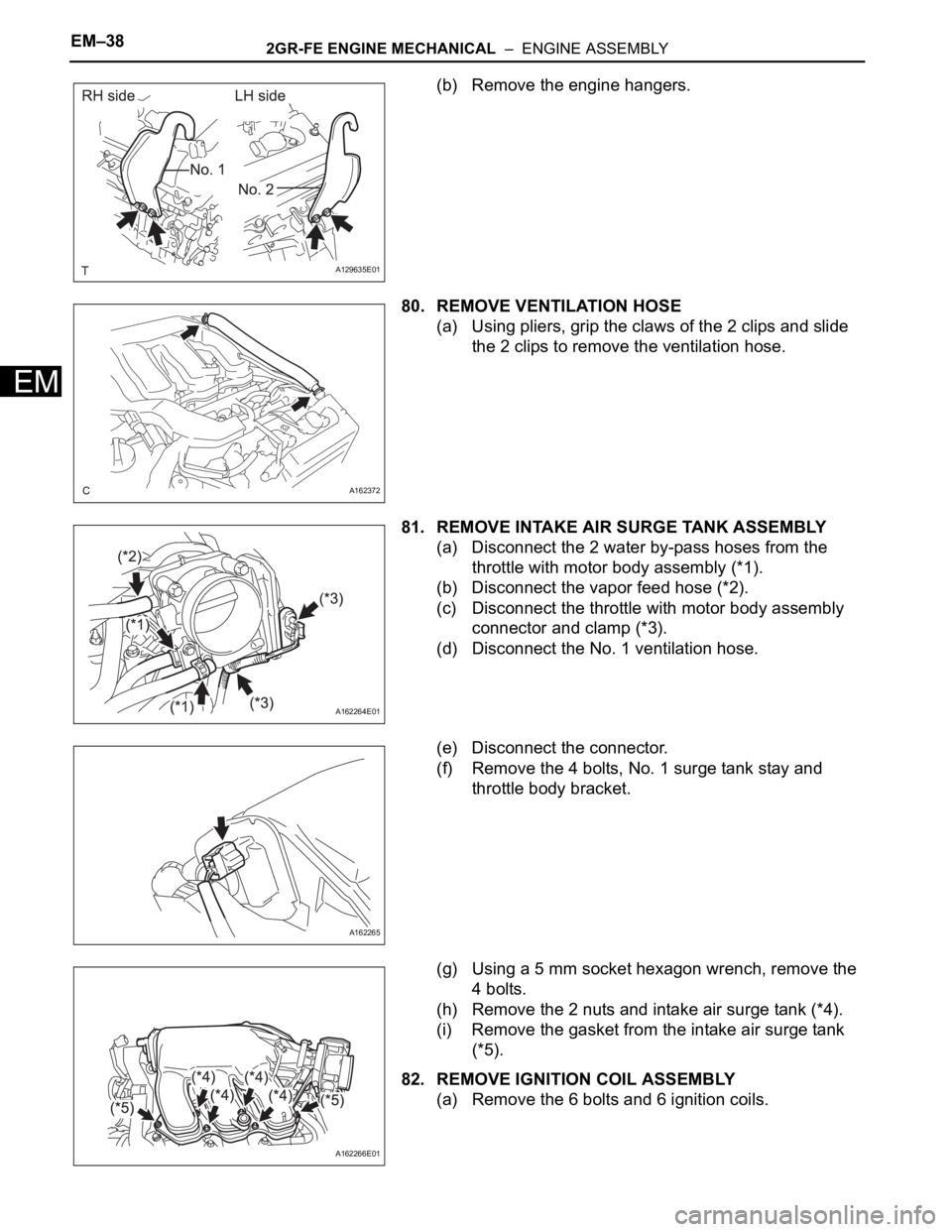

(b) Remove the engine hangers.

80. REMOVE VENTILATION HOSE

(a) Using pliers, grip the claws of the 2 clips and slide

the 2 clips to remove the ventilation hose.

81. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

(a) Disconnect the 2 water by-pass hoses from the

throttle with motor body assembly (*1).

(b) Disconnect the vapor feed hose (*2).

(c) Disconnect the throttle with motor body assembly

connector and clamp (*3).

(d) Disconnect the No. 1 ventilation hose.

(e) Disconnect the connector.

(f) Remove the 4 bolts, No. 1 surge tank stay and

throttle body bracket.

(g) Using a 5 mm socket hexagon wrench, remove the

4 bolts.

(h) Remove the 2 nuts and intake air surge tank (*4).

(i) Remove the gasket from the intake air surge tank

(*5).

82. REMOVE IGNITION COIL ASSEMBLY

(a) Remove the 6 bolts and 6 ignition coils.

A129635E01

A162372

A162264E01

A162265

A162266E01

Page 45 of 3000

EC–62GR-FE EMISSION CONTROL – EMISSION CONTROL SYSTEM

EC

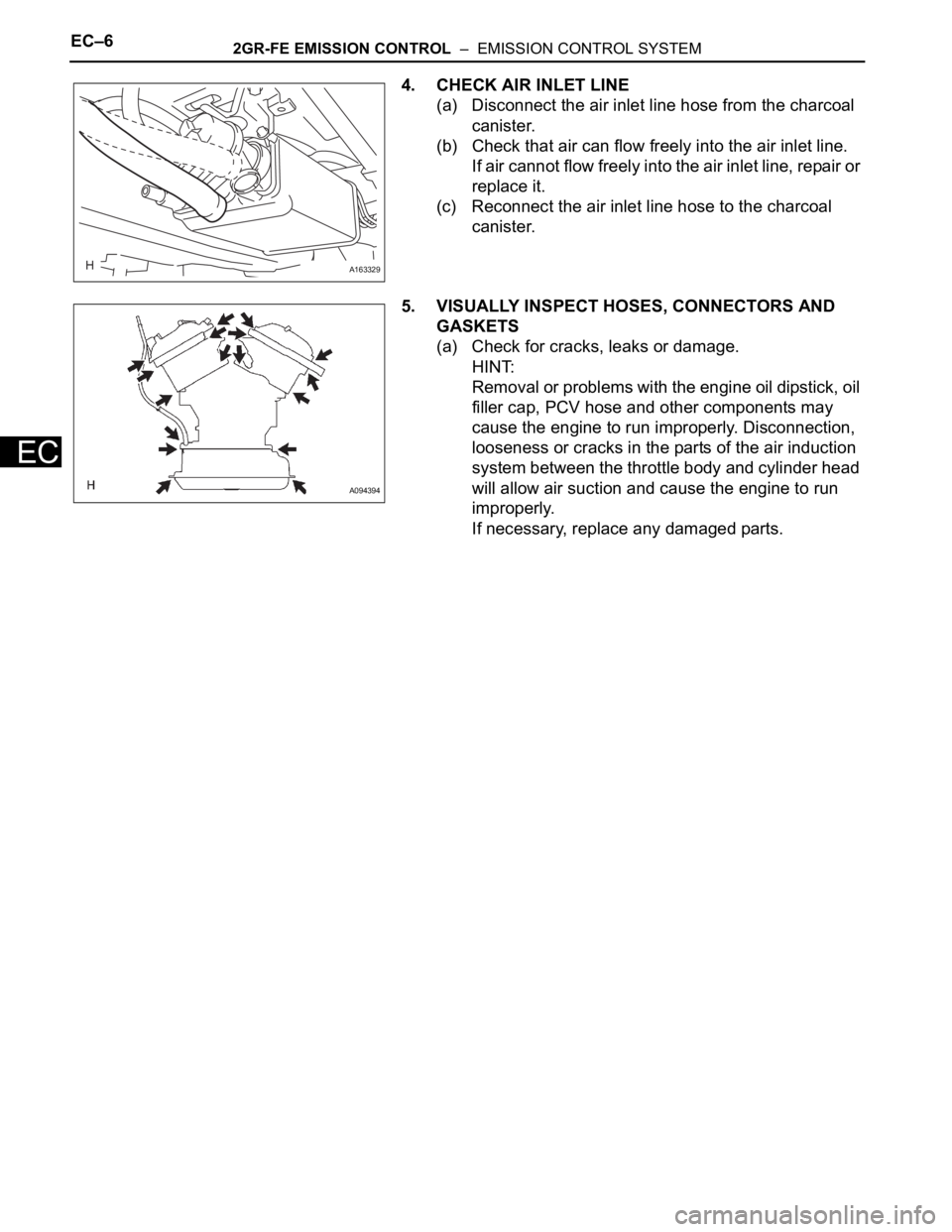

4. CHECK AIR INLET LINE

(a) Disconnect the air inlet line hose from the charcoal

canister.

(b) Check that air can flow freely into the air inlet line.

If air cannot flow freely into the air inlet line, repair or

replace it.

(c) Reconnect the air inlet line hose to the charcoal

canister.

5. VISUALLY INSPECT HOSES, CONNECTORS AND

GASKETS

(a) Check for cracks, leaks or damage.

HINT:

Removal or problems with the engine oil dipstick, oil

filler cap, PCV hose and other components may

cause the engine to run improperly. Disconnection,

looseness or cracks in the parts of the air induction

system between the throttle body and cylinder head

will allow air suction and cause the engine to run

improperly.

If necessary, replace any damaged parts.

A163329

A094394

Page 46 of 3000

2GR-FE INTAKE – INTAKE AIR CONTROL VALVEIT–5

IT

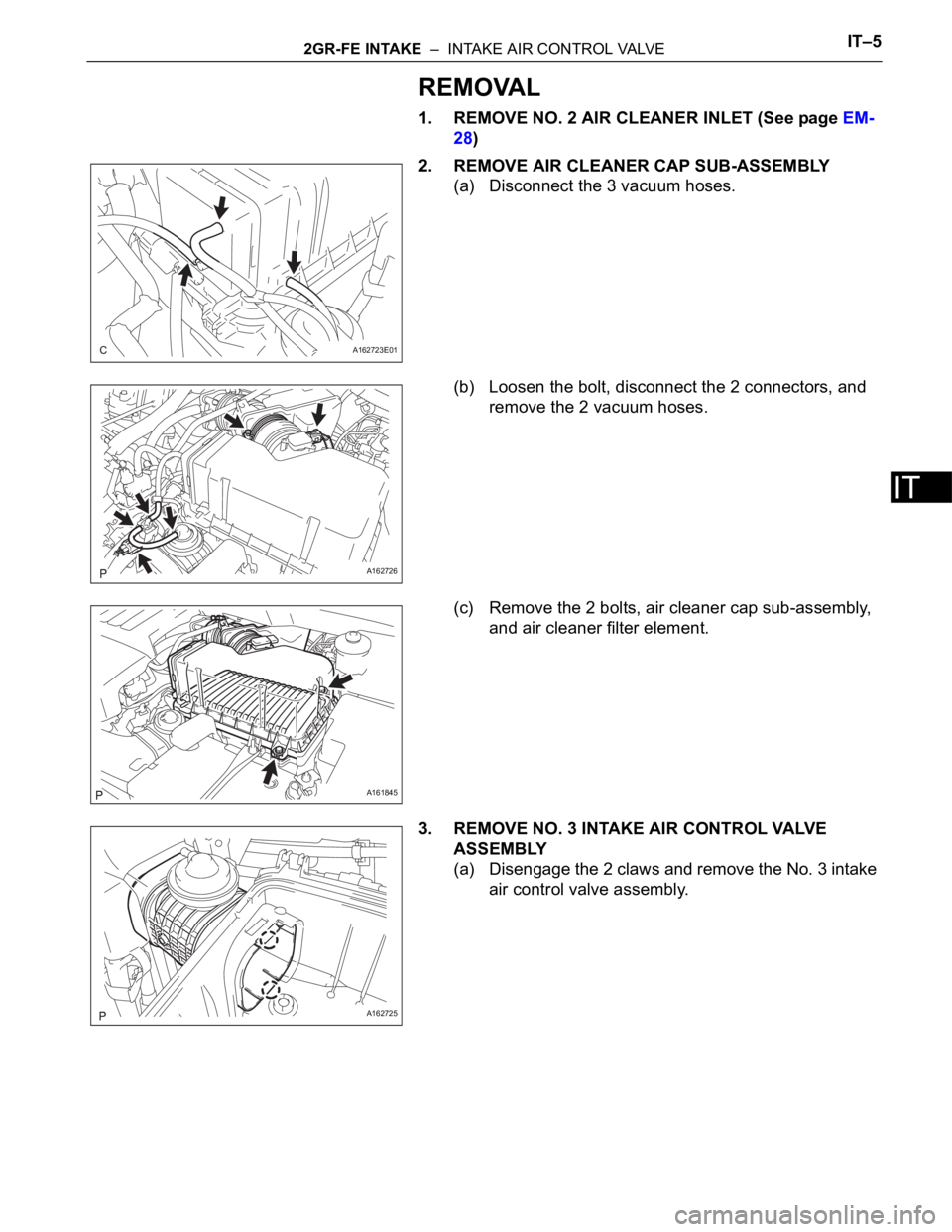

REMOVAL

1. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

2. REMOVE AIR CLEANER CAP SUB-ASSEMBLY

(a) Disconnect the 3 vacuum hoses.

(b) Loosen the bolt, disconnect the 2 connectors, and

remove the 2 vacuum hoses.

(c) Remove the 2 bolts, air cleaner cap sub-assembly,

and air cleaner filter element.

3. REMOVE NO. 3 INTAKE AIR CONTROL VALVE

ASSEMBLY

(a) Disengage the 2 claws and remove the No. 3 intake

air control valve assembly.

A162723E01

A162726

A161845

A162725

Page 47 of 3000

IT–62GR-FE INTAKE – INTAKE AIR CONTROL VALVE

IT

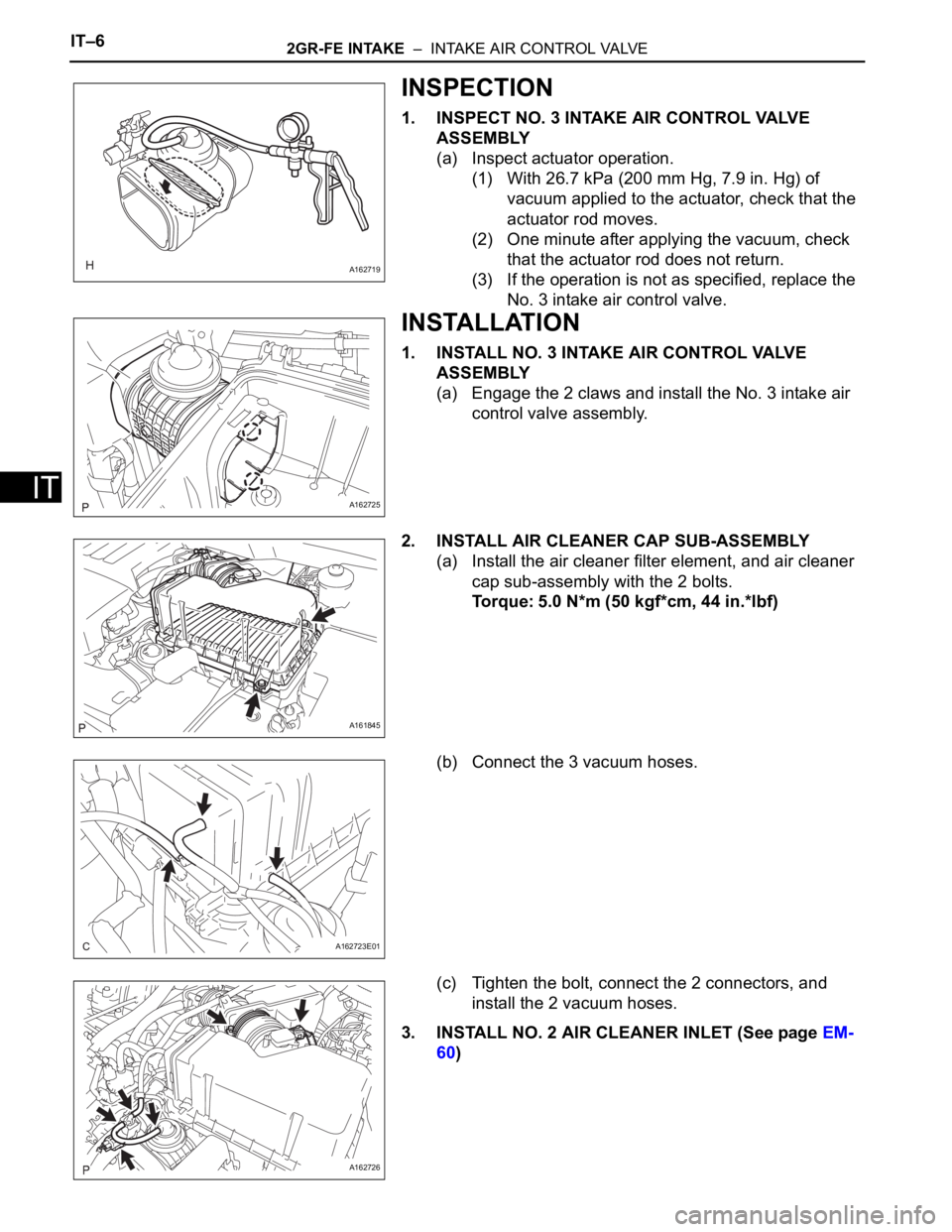

INSPECTION

1. INSPECT NO. 3 INTAKE AIR CONTROL VALVE

ASSEMBLY

(a) Inspect actuator operation.

(1) With 26.7 kPa (200 mm Hg, 7.9 in. Hg) of

vacuum applied to the actuator, check that the

actuator rod moves.

(2) One minute after applying the vacuum, check

that the actuator rod does not return.

(3) If the operation is not as specified, replace the

No. 3 intake air control valve.

INSTALLATION

1. INSTALL NO. 3 INTAKE AIR CONTROL VALVE

ASSEMBLY

(a) Engage the 2 claws and install the No. 3 intake air

control valve assembly.

2. INSTALL AIR CLEANER CAP SUB-ASSEMBLY

(a) Install the air cleaner filter element, and air cleaner

cap sub-assembly with the 2 bolts.

Torque: 5.0 N*m (50 kgf*cm, 44 in.*lbf)

(b) Connect the 3 vacuum hoses.

(c) Tighten the bolt, connect the 2 connectors, and

install the 2 vacuum hoses.

3. INSTALL NO. 2 AIR CLEANER INLET (See page EM-

60)

A162719

A162725

A161845

A162723E01

A162726

Page 199 of 3000

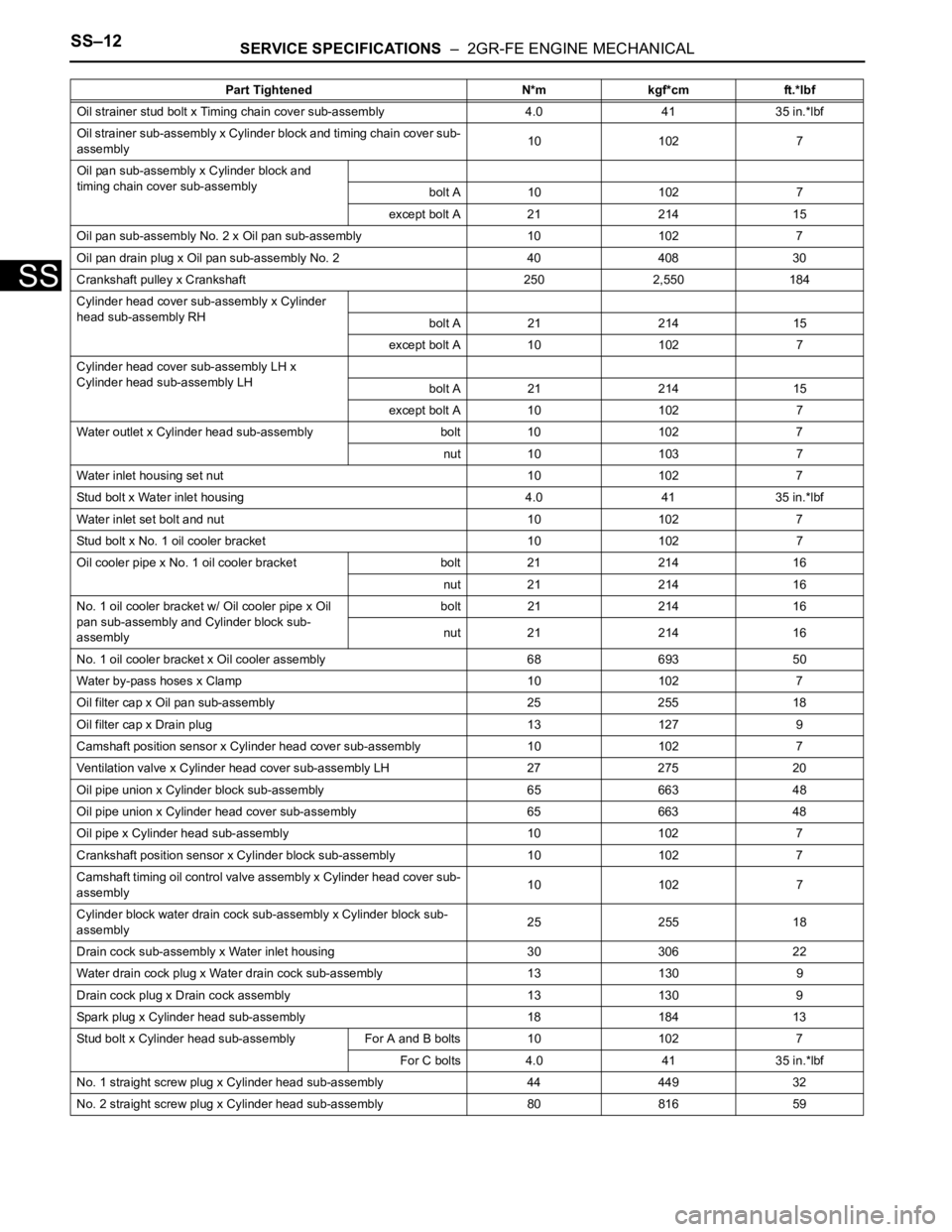

SS–12SERVICE SPECIFICATIONS – 2GR-FE ENGINE MECHANICAL

SS

Oil strainer stud bolt x Timing chain cover sub-assembly 4.0 41 35 in.*lbf

Oil strainer sub-assembly x Cylinder block and timing chain cover sub-

assembly10 102 7

Oil pan sub-assembly x Cylinder block and

timing chain cover sub-assembly

bolt A 10 102 7

except bolt A 21 214 15

Oil pan sub-assembly No. 2 x Oil pan sub-assembly 10 102 7

Oil pan drain plug x Oil pan sub-assembly No. 2 40 408 30

Crankshaft pulley x Crankshaft 250 2,550 184

Cylinder head cover sub-assembly x Cylinder

head sub-assembly RH

bolt A 21 214 15

except bolt A 10 102 7

Cylinder head cover sub-assembly LH x

Cylinder head sub-assembly LH

bolt A 21 214 15

except bolt A 10 102 7

Water outlet x Cylinder head sub-assembly bolt 10 102 7

nut 10 103 7

Water inlet housing set nut 10 102 7

Stud bolt x Water inlet housing 4.0 41 35 in.*lbf

Water inlet set bolt and nut 10 102 7

Stud bolt x No. 1 oil cooler bracket 10 102 7

Oil cooler pipe x No. 1 oil cooler bracket bolt 21 214 16

nut 21 214 16

No. 1 oil cooler bracket w/ Oil cooler pipe x Oil

pan sub-assembly and Cylinder block sub-

assemblybolt 21 214 16

nut 21 214 16

No. 1 oil cooler bracket x Oil cooler assembly 68 693 50

Water by-pass hoses x Clamp 10 102 7

Oil filter cap x Oil pan sub-assembly 25 255 18

Oil filter cap x Drain plug 13 127 9

Camshaft position sensor x Cylinder head cover sub-assembly 10 1027

Ventilation valve x Cylinder head cover sub-assembly LH 27 275 20

Oil pipe union x Cylinder block sub-assembly 65 663 48

Oil pipe union x Cylinder head cover sub-assembly 65 663 48

Oil pipe x Cylinder head sub-assembly 10 102 7

Crankshaft position sensor x Cylinder block sub-assembly 10 102 7

Camshaft timing oil control valve assembly x Cylinder head cover sub-

assembly10 102 7

Cylinder block water drain cock sub-assembly x Cylinder block sub-

assembly25 255 18

Drain cock sub-assembly x Water inlet housing 30 306 22

Water drain cock plug x Water drain cock sub-assembly 13 130 9

Drain cock plug x Drain cock assembly 13 130 9

Spark plug x Cylinder head sub-assembly 18 184 13

Stud bolt x Cylinder head sub-assembly For A and B bolts 10 102 7

For C bolts 4.0 41 35 in.*lbf

No. 1 straight screw plug x Cylinder head sub-assembly 44 449 32

No. 2 straight screw plug x Cylinder head sub-assembly 80 816 59Part Tightened N*m kgf*cm ft.*lbf

Page 334 of 3000

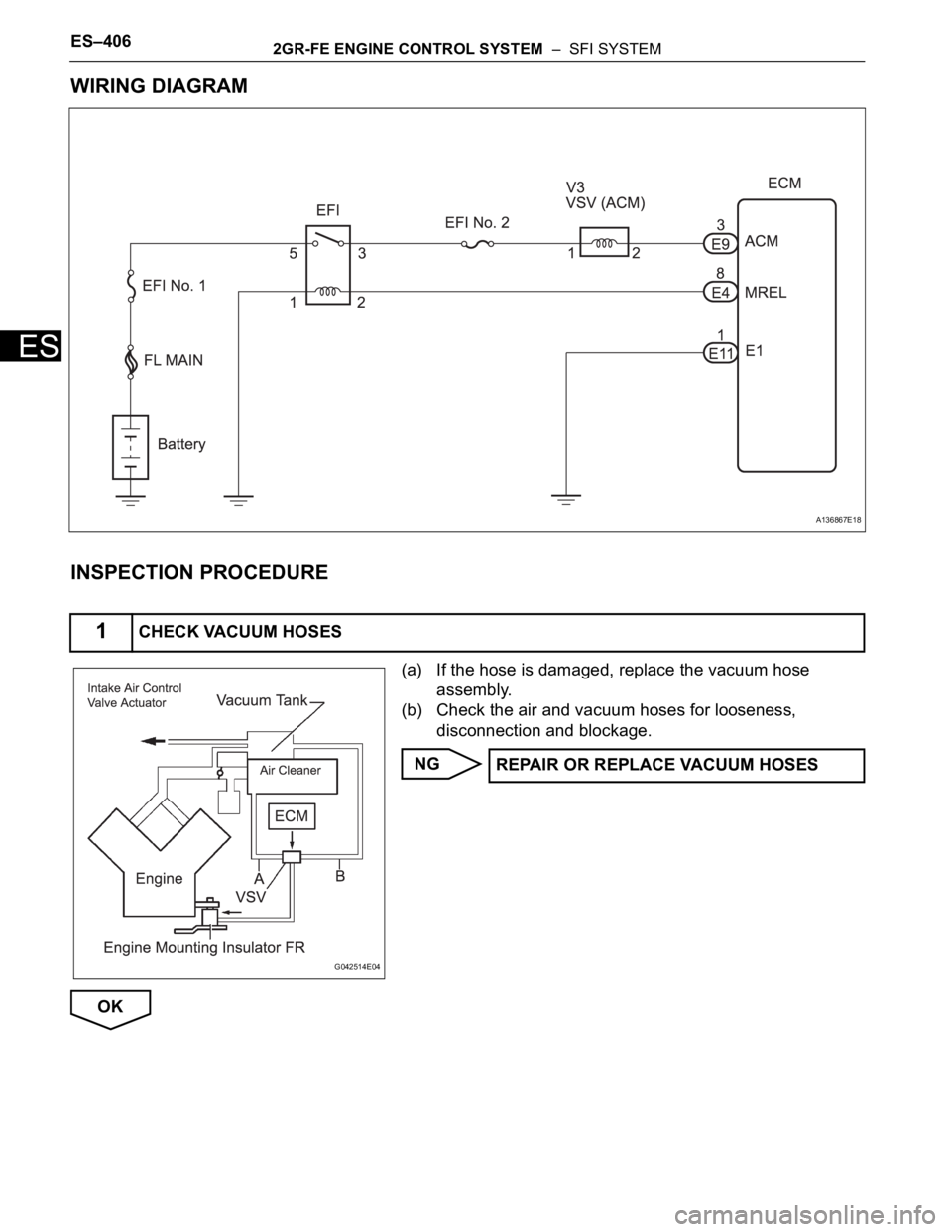

ES–4062GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

WIRING DIAGRAM

INSPECTION PROCEDURE

(a) If the hose is damaged, replace the vacuum hose

assembly.

(b) Check the air and vacuum hoses for looseness,

disconnection and blockage.

NG

OK

1CHECK VACUUM HOSES

A136867E18

G042514E04

REPAIR OR REPLACE VACUUM HOSES