door TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 51 of 3000

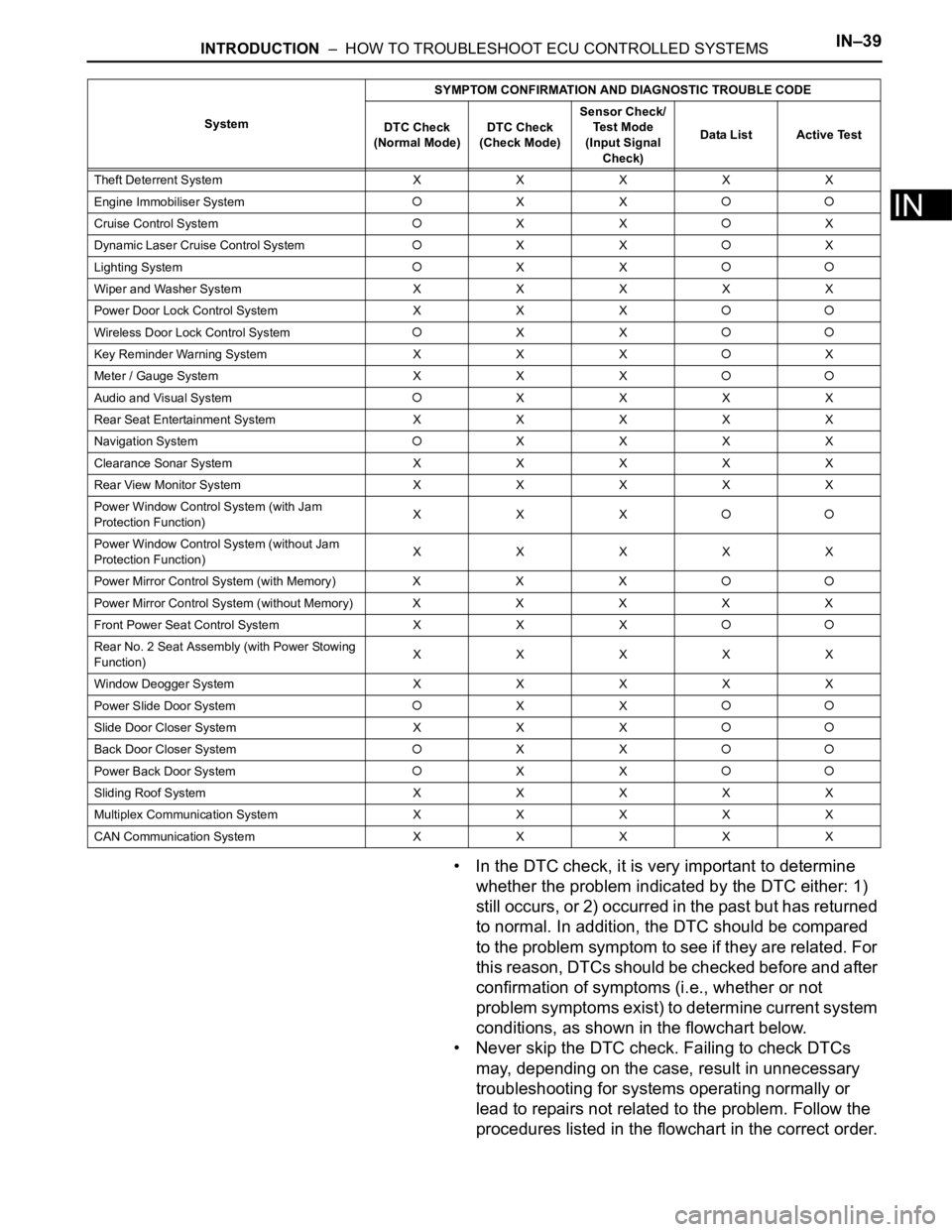

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMSIN–39

IN

• In the DTC check, it is very important to determine

whether the problem indicated by the DTC either: 1)

still occurs, or 2) occurred in the past but has returned

to normal. In addition, the DTC should be compared

to the problem symptom to see if they are related. For

this reason, DTCs should be checked before and after

confirmation of symptoms (i.e., whether or not

problem symptoms exist) to determine current system

conditions, as shown in the flowchart below.

• Never skip the DTC check. Failing to check DTCs

may, depending on the case, result in unnecessary

troubleshooting for systems operating normally or

lead to repairs not related to the problem. Follow the

procedures listed in the flowchart in the correct order.

Theft Deterrent System XXXXX

Engine Immobiliser System

XX

Cruise Control SystemXXX

Dynamic Laser Cruise Control System

XXX

Lighting System

XX

Wiper and Washer SystemXXXXX

Power Door Lock Control System X X X

Wireless Door Lock Control SystemXX

Key Reminder Warning System X X XX

Meter / Gauge System X X X

Audio and Visual SystemXXXX

Rear Seat Entertainment System XXXXX

Navigation System

XXXX

Clearance Sonar SystemXXXXX

Rear View Monitor System XXXXX

Power Window Control System (with Jam

Protection Function)XXX

Power Window Control System (without Jam

Protection Function)XXXXX

Power Mirror Control System (with Memory) X X X

Power Mirror Control System (without Memory)XXXXX

Front Power Seat Control System X X X

Rear No. 2 Seat Assembly (with Power Stowing

Function)XXXXX

Window Deogger SystemXXXXX

Power Slide Door System

XX

Slide Door Closer System X X X

Back Door Closer SystemXX

Power Back Door SystemXX

Sliding Roof System XXXXX

Multiplex Communication System XXXXX

CAN Communication System XXXXXSystemSYMPTOM CONFIRMATION AND DIAGNOSTIC TROUBLE CODE

DTC Check

(Normal Mode)DTC Check

(Check Mode)Sensor Check/

Test Mode

(Input Signal

Check)Data List Active Test

Page 69 of 3000

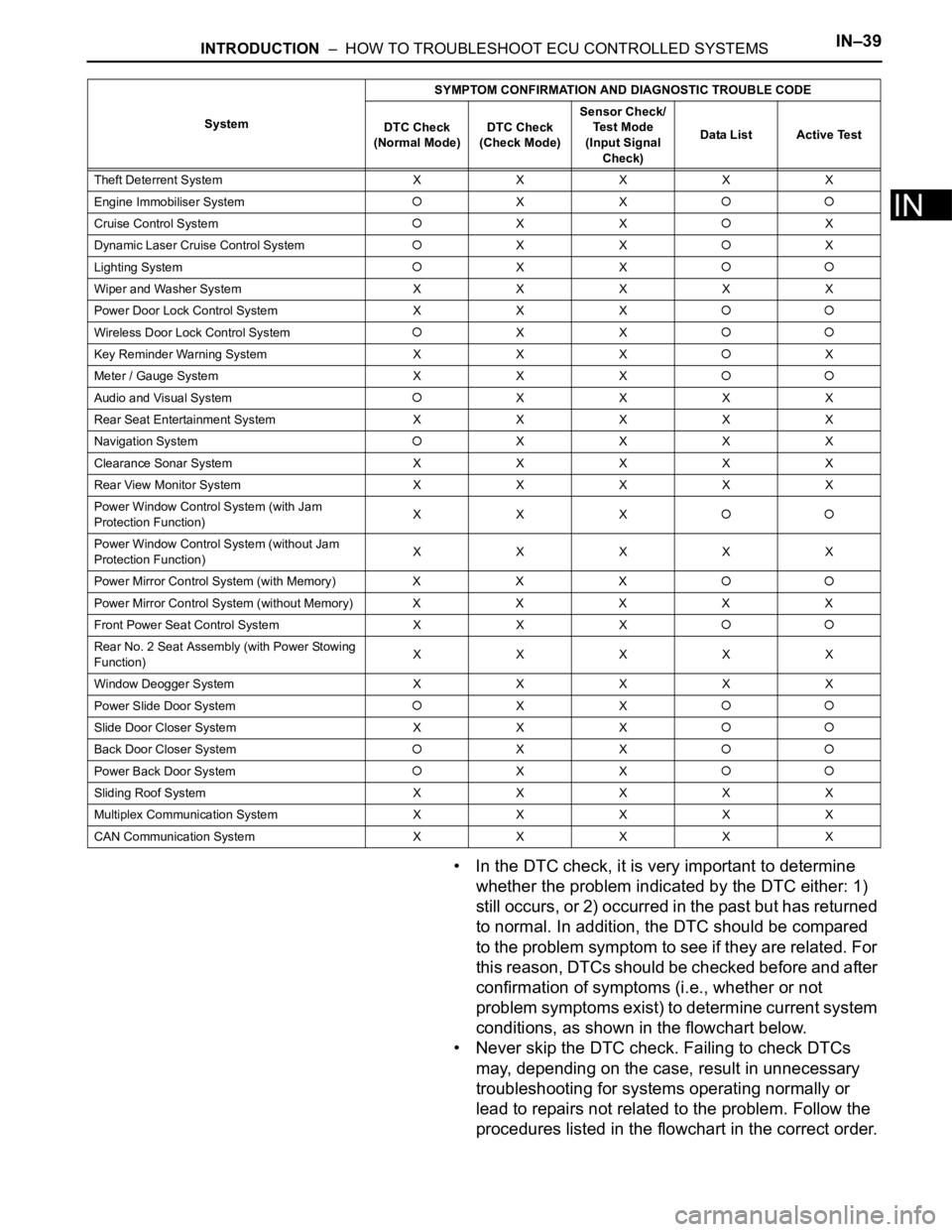

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMSIN–39

IN

• In the DTC check, it is very important to determine

whether the problem indicated by the DTC either: 1)

still occurs, or 2) occurred in the past but has returned

to normal. In addition, the DTC should be compared

to the problem symptom to see if they are related. For

this reason, DTCs should be checked before and after

confirmation of symptoms (i.e., whether or not

problem symptoms exist) to determine current system

conditions, as shown in the flowchart below.

• Never skip the DTC check. Failing to check DTCs

may, depending on the case, result in unnecessary

troubleshooting for systems operating normally or

lead to repairs not related to the problem. Follow the

procedures listed in the flowchart in the correct order.

Theft Deterrent System XXXXX

Engine Immobiliser System

XX

Cruise Control SystemXXX

Dynamic Laser Cruise Control System

XXX

Lighting System

XX

Wiper and Washer SystemXXXXX

Power Door Lock Control System X X X

Wireless Door Lock Control SystemXX

Key Reminder Warning System X X XX

Meter / Gauge System X X X

Audio and Visual SystemXXXX

Rear Seat Entertainment System XXXXX

Navigation System

XXXX

Clearance Sonar SystemXXXXX

Rear View Monitor System XXXXX

Power Window Control System (with Jam

Protection Function)XXX

Power Window Control System (without Jam

Protection Function)XXXXX

Power Mirror Control System (with Memory) X X X

Power Mirror Control System (without Memory)XXXXX

Front Power Seat Control System X X X

Rear No. 2 Seat Assembly (with Power Stowing

Function)XXXXX

Window Deogger SystemXXXXX

Power Slide Door System

XX

Slide Door Closer System X X X

Back Door Closer SystemXX

Power Back Door SystemXX

Sliding Roof System XXXXX

Multiplex Communication System XXXXX

CAN Communication System XXXXXSystemSYMPTOM CONFIRMATION AND DIAGNOSTIC TROUBLE CODE

DTC Check

(Normal Mode)DTC Check

(Check Mode)Sensor Check/

Test Mode

(Input Signal

Check)Data List Active Test

Page 159 of 3000

PP–86PREPARATION – ENGINE HOOD / DOOR

PP

EQUIPMENT

Clip remover

Plastic-faced hammer

Tape To avoid surface damage

Tire

To r q u e w r e n c h

Page 160 of 3000

PREPARATION – ENGINE HOOD / DOORPP–87

PP

SSM

08833-00070 Adhesive 1324,

THREE BOND 1324 or equivalent

Page 185 of 3000

BRAKE – BRAKE PEDALBR–11

BR

REMOVAL

1. SEPARATE BATTERY NEGATIVE TERMINAL

2. REMOVE FRONT DOOR SCUFF PLATE LH

3. REMOVE COWL SIDE TRIM BOARD LH

4. REMOVE INSTRUMENT PANEL FINISH PANEL SUB-

ASSEMBLY LOWER LH

(a) Remove the 2 bolts and instrument panel finish

panel sub-assembly lower LH.

5. REMOVE INSTRUMENT PANEL SAFETY PAD

INSERT SUB-ASSEMBLY NO. 1

(a) Remove the 4 bolts and instrument panel safety pad

insert sub-assembly No. 1.

6. LOOSEN BRAKE PEDAL SHAFT

(a) Loosen the 2 brake pedal shafts.

7. REMOVE BRAKE PEDAL SUPPORT ASSEMBLY

(a) Remove the 4 nuts and brake pedal support sub-

assembly.

(b) Using needle-nose pliers, remove the tension

spring.

(c) Remove the clip and clevis pin from the brake pedal

lever.

(d) Remove the 2 bolts from the brake pedal bracket

No. 3.

(e) Remove the stop light switch harness clamp from

the brake pedal support sub-assembly.

(f) Disconnect the stop light switch connector.

F045360E01

G024262

G024263

Page 187 of 3000

PARKING BRAKE – PARKING BRAKE PEDALPB–5

PB

REMOVAL

1. DISCONNECT BATTERY NEGATIVE TERMINAL

2. REMOVE FRONT DOOR SCUFF PLATE LH

3. REMOVE COWL SIDE TRIM BOARD LH

4. REMOVE INSTRUMENT PANEL FINISH PANEL SUB-

ASSEMBLY LOWER LH (See page IP-6)

5. REMOVE REAR DOOR SCUFF PLATE RH

6. REMOVE REAR DOOR SCUFF PLATE LH

7. REMOVE FRONT SEAT ASSEMBLY LH

HINT:

• Manual Seat Type (See page SE-48)

• Power Seat Type (See page SE-58)

• Fold Flat Type (See page SE-40)

8. REMOVE REAR SEAT NO.1 ASSEMBLY

HINT:

• Captain Seat Type (See page SE-68)

• Center Seat Type (See page SE-77)

9. REMOVE REAR FLOOR SEAT LOCK COVER

10. REMOVE REAR FLOOR SEAT LOCK COVER

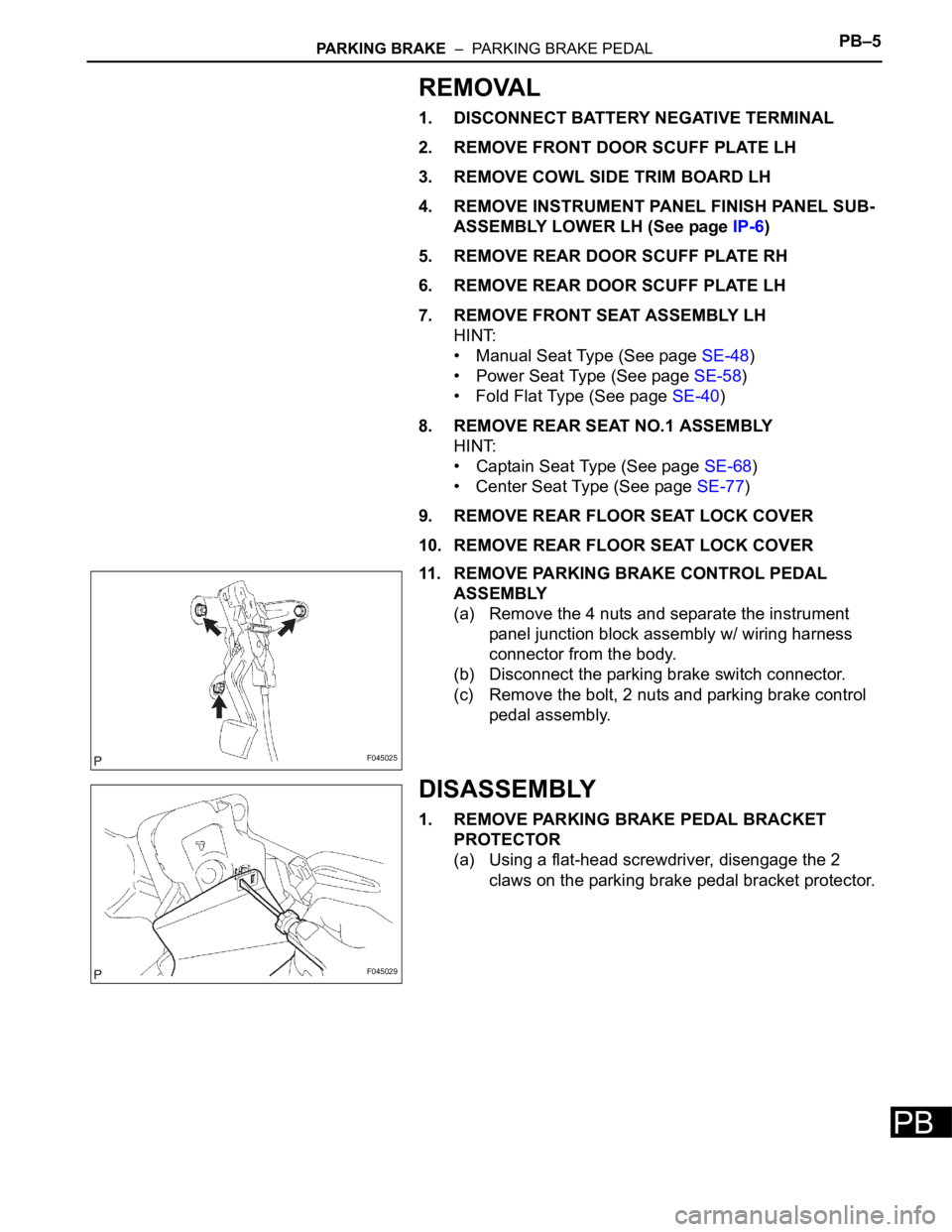

11. REMOVE PARKING BRAKE CONTROL PEDAL

ASSEMBLY

(a) Remove the 4 nuts and separate the instrument

panel junction block assembly w/ wiring harness

connector from the body.

(b) Disconnect the parking brake switch connector.

(c) Remove the bolt, 2 nuts and parking brake control

pedal assembly.

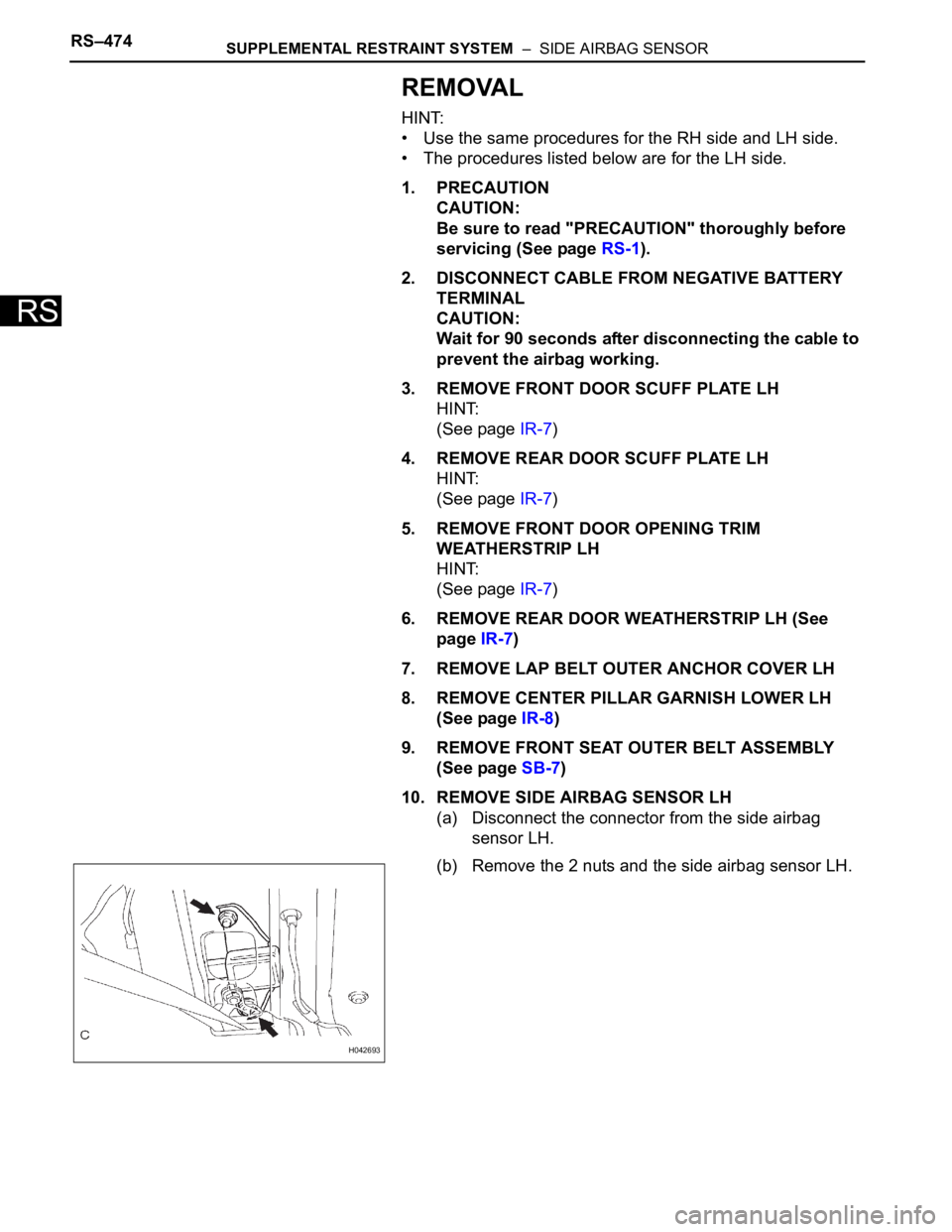

DISASSEMBLY

1. REMOVE PARKING BRAKE PEDAL BRACKET

PROTECTOR

(a) Using a flat-head screwdriver, disengage the 2

claws on the parking brake pedal bracket protector.

F045025

F045029

Page 232 of 3000

RS–474SUPPLEMENTAL RESTRAINT SYSTEM – SIDE AIRBAG SENSOR

RS

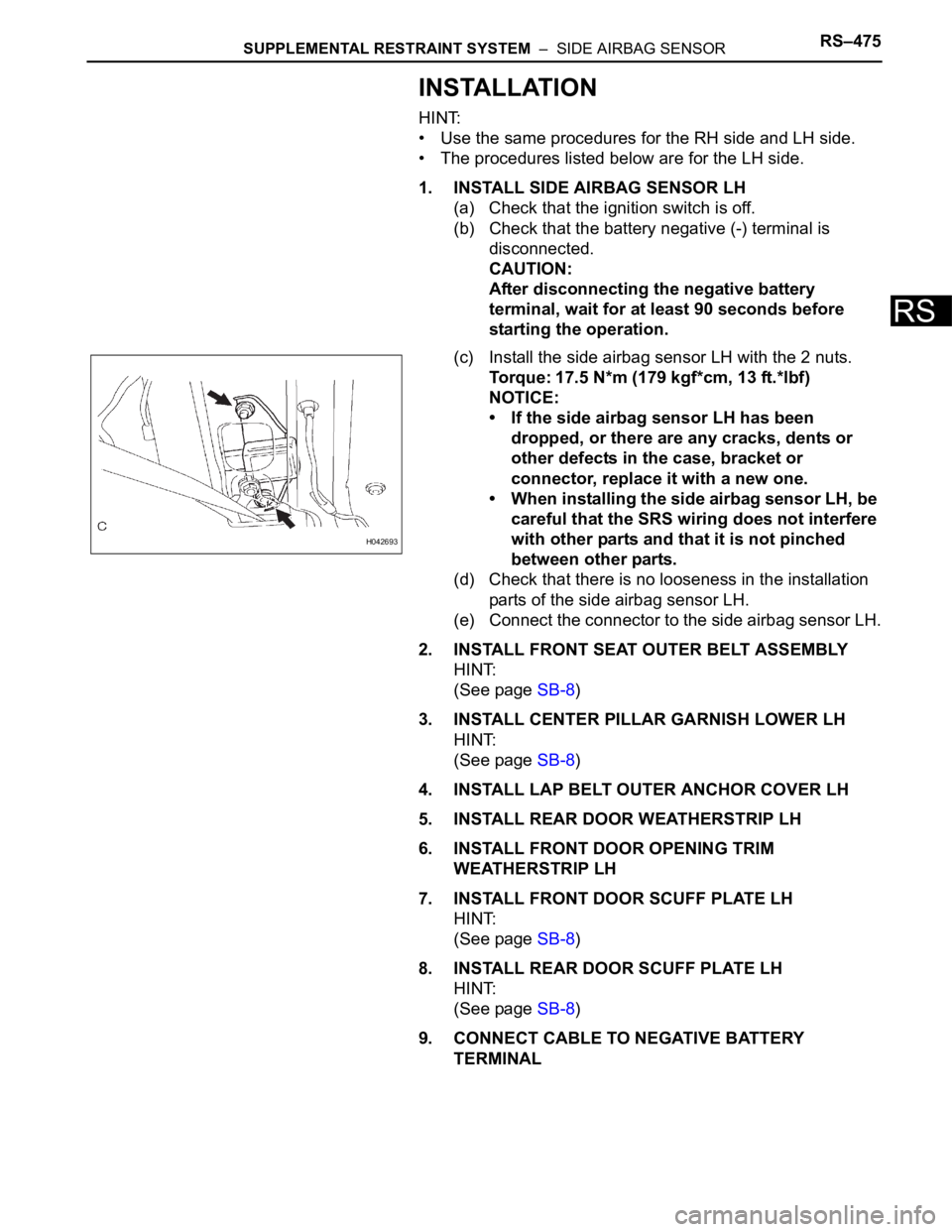

REMOVAL

HINT:

• Use the same procedures for the RH side and LH side.

• The procedures listed below are for the LH side.

1. PRECAUTION

CAUTION:

Be sure to read "PRECAUTION" thoroughly before

servicing (See page RS-1).

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait for 90 seconds after disconnecting the cable to

prevent the airbag working.

3. REMOVE FRONT DOOR SCUFF PLATE LH

HINT:

(See page IR-7)

4. REMOVE REAR DOOR SCUFF PLATE LH

HINT:

(See page IR-7)

5. REMOVE FRONT DOOR OPENING TRIM

WEATHERSTRIP LH

HINT:

(See page IR-7)

6. REMOVE REAR DOOR WEATHERSTRIP LH (See

page IR-7)

7. REMOVE LAP BELT OUTER ANCHOR COVER LH

8. REMOVE CENTER PILLAR GARNISH LOWER LH

(See page IR-8)

9. REMOVE FRONT SEAT OUTER BELT ASSEMBLY

(See page SB-7)

10. REMOVE SIDE AIRBAG SENSOR LH

(a) Disconnect the connector from the side airbag

sensor LH.

(b) Remove the 2 nuts and the side airbag sensor LH.

H042693

Page 233 of 3000

SUPPLEMENTAL RESTRAINT SYSTEM – SIDE AIRBAG SENSORRS–475

RS

INSTALLATION

HINT:

• Use the same procedures for the RH side and LH side.

• The procedures listed below are for the LH side.

1. INSTALL SIDE AIRBAG SENSOR LH

(a) Check that the ignition switch is off.

(b) Check that the battery negative (-) terminal is

disconnected.

CAUTION:

After disconnecting the negative battery

terminal, wait for at least 90 seconds before

starting the operation.

(c) Install the side airbag sensor LH with the 2 nuts.

Torque: 17.5 N*m (179 kgf*cm, 13 ft.*lbf)

NOTICE:

• If the side airbag sensor LH has been

dropped, or there are any cracks, dents or

other defects in the case, bracket or

connector, replace it with a new one.

• When installing the side airbag sensor LH, be

careful that the SRS wiring does not interfere

with other parts and that it is not pinched

between other parts.

(d) Check that there is no looseness in the installation

parts of the side airbag sensor LH.

(e) Connect the connector to the side airbag sensor LH.

2. INSTALL FRONT SEAT OUTER BELT ASSEMBLY

HINT:

(See page SB-8)

3. INSTALL CENTER PILLAR GARNISH LOWER LH

HINT:

(See page SB-8)

4. INSTALL LAP BELT OUTER ANCHOR COVER LH

5. INSTALL REAR DOOR WEATHERSTRIP LH

6. INSTALL FRONT DOOR OPENING TRIM

WEATHERSTRIP LH

7. INSTALL FRONT DOOR SCUFF PLATE LH

HINT:

(See page SB-8)

8. INSTALL REAR DOOR SCUFF PLATE LH

HINT:

(See page SB-8)

9. CONNECT CABLE TO NEGATIVE BATTERY

TERMINAL

H042693

Page 236 of 3000

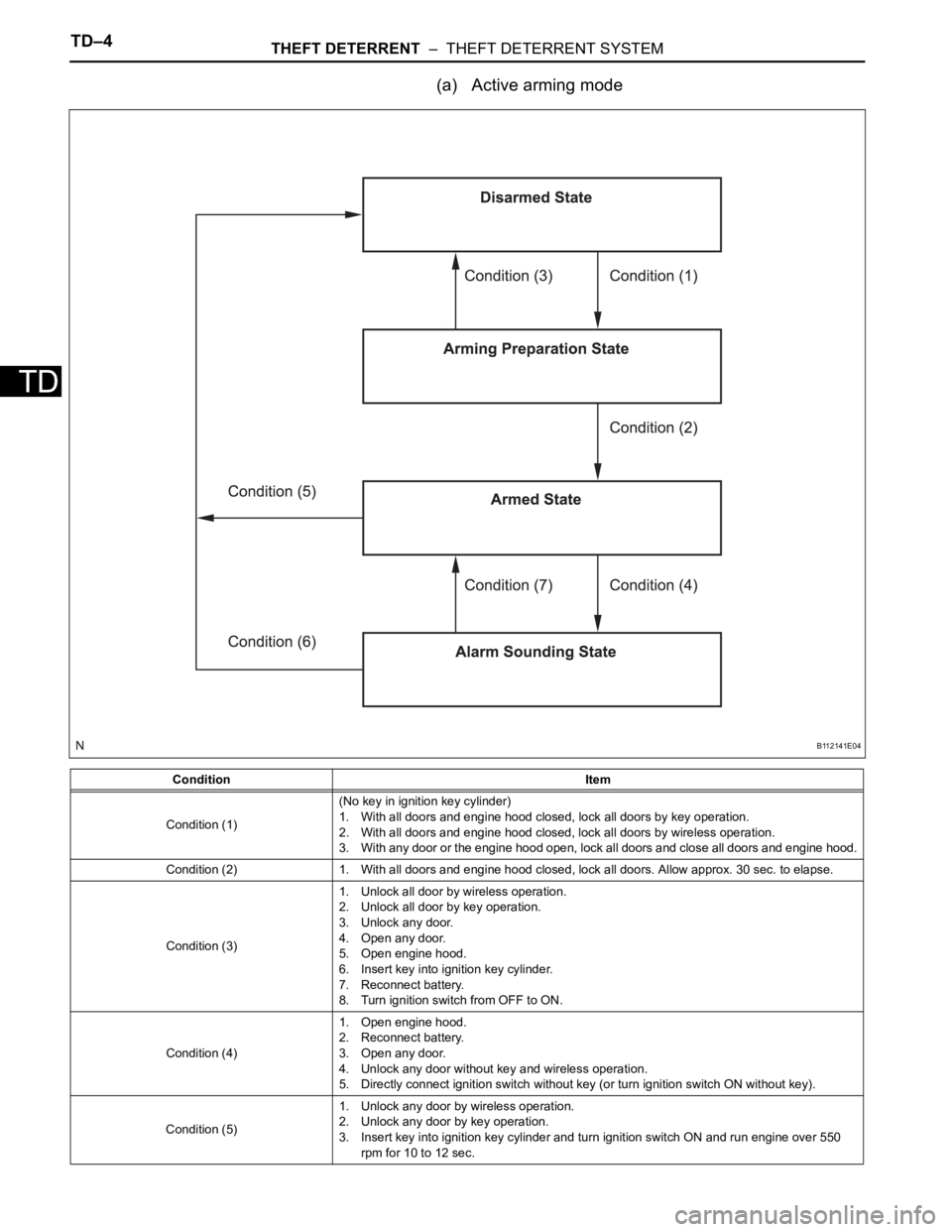

THEFT DETERRENT – THEFT DETERRENT SYSTEMTD–3

TD

SYSTEM DESCRIPTION

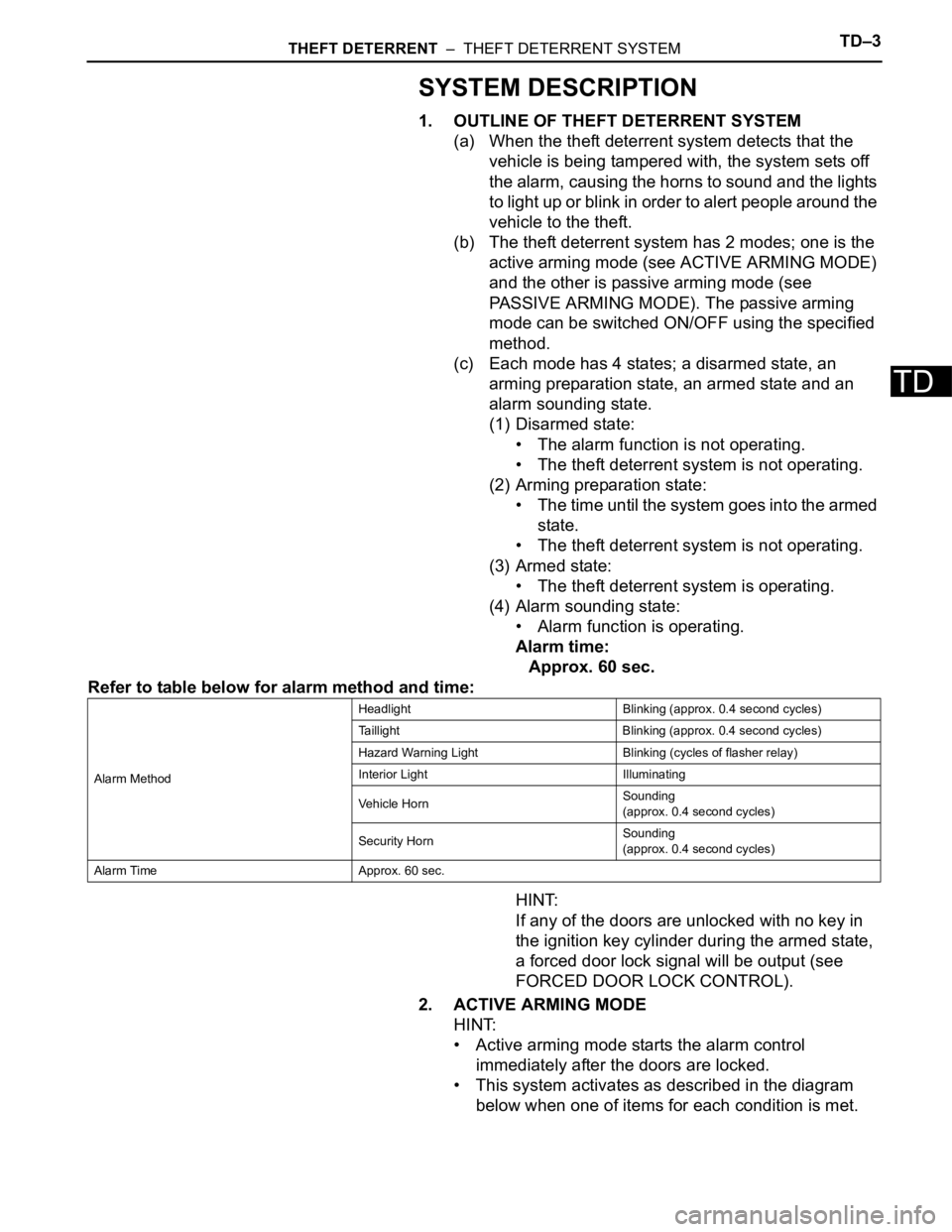

1. OUTLINE OF THEFT DETERRENT SYSTEM

(a) When the theft deterrent system detects that the

vehicle is being tampered with, the system sets off

the alarm, causing the horns to sound and the lights

to light up or blink in order to alert people around the

vehicle to the theft.

(b) The theft deterrent system has 2 modes; one is the

active arming mode (see ACTIVE ARMING MODE)

and the other is passive arming mode (see

PASSIVE ARMING MODE). The passive arming

mode can be switched ON/OFF using the specified

method.

(c) Each mode has 4 states; a disarmed state, an

arming preparation state, an armed state and an

alarm sounding state.

(1) Disarmed state:

• The alarm function is not operating.

• The theft deterrent system is not operating.

(2) Arming preparation state:

• The time until the system goes into the armed

state.

• The theft deterrent system is not operating.

(3) Armed state:

• The theft deterrent system is operating.

(4) Alarm sounding state:

• Alarm function is operating.

Alarm time:

Approx. 60 sec.

Refer to table below for alarm method and time:

HINT:

If any of the doors are unlocked with no key in

the ignition key cylinder during the armed state,

a forced door lock signal will be output (see

FORCED DOOR LOCK CONTROL).

2. ACTIVE ARMING MODE

HINT:

• Active arming mode starts the alarm control

immediately after the doors are locked.

• This system activates as described in the diagram

below when one of items for each condition is met.

Alarm MethodHeadlight Blinking (approx. 0.4 second cycles)

Taillight Blinking (approx. 0.4 second cycles)

Hazard Warning Light Blinking (cycles of flasher relay)

Interior Light Illuminating

Vehicle HornSounding

(approx. 0.4 second cycles)

Security HornSounding

(approx. 0.4 second cycles)

Alarm Time Approx. 60 sec.

Page 237 of 3000

TD–4THEFT DETERRENT – THEFT DETERRENT SYSTEM

TD

(a) Active arming mode

Condition Item

Condition (1)(No key in ignition key cylinder)

1. With all doors and engine hood closed, lock all doors by key operation.

2. With all doors and engine hood closed, lock all doors by wireless operation.

3. With any door or the engine hood open, lock all doors and close all doors and engine hood.

Condition (2) 1. With all doors and engine hood closed, lock all doors. Allow approx. 30 sec. to elapse.

Condition (3)1. Unlock all door by wireless operation.

2. Unlock all door by key operation.

3. Unlock any door.

4. Open any door.

5. Open engine hood.

6. Insert key into ignition key cylinder.

7. Reconnect battery.

8. Turn ignition switch from OFF to ON.

Condition (4)1. Open engine hood.

2. Reconnect battery.

3. Open any door.

4. Unlock any door without key and wireless operation.

5. Directly connect ignition switch without key (or turn ignition switch ON without key).

Condition (5)1. Unlock any door by wireless operation.

2. Unlock any door by key operation.

3. Insert key into ignition key cylinder and turn ignition switch ON and run engine over 550

rpm for 10 to 12 sec.

B112141E04