TOYOTA SUPRA 1995 Service Repair Manual

SUPRA 1995

TOYOTA

TOYOTA

https://www.carmanualsonline.info/img/14/57468/w960_57468-0.png

TOYOTA SUPRA 1995 Service Repair Manual

Trending: brake light, fuse diagram, tire type, wheel alignment, coolant, light, fog light

Page 581 of 2543

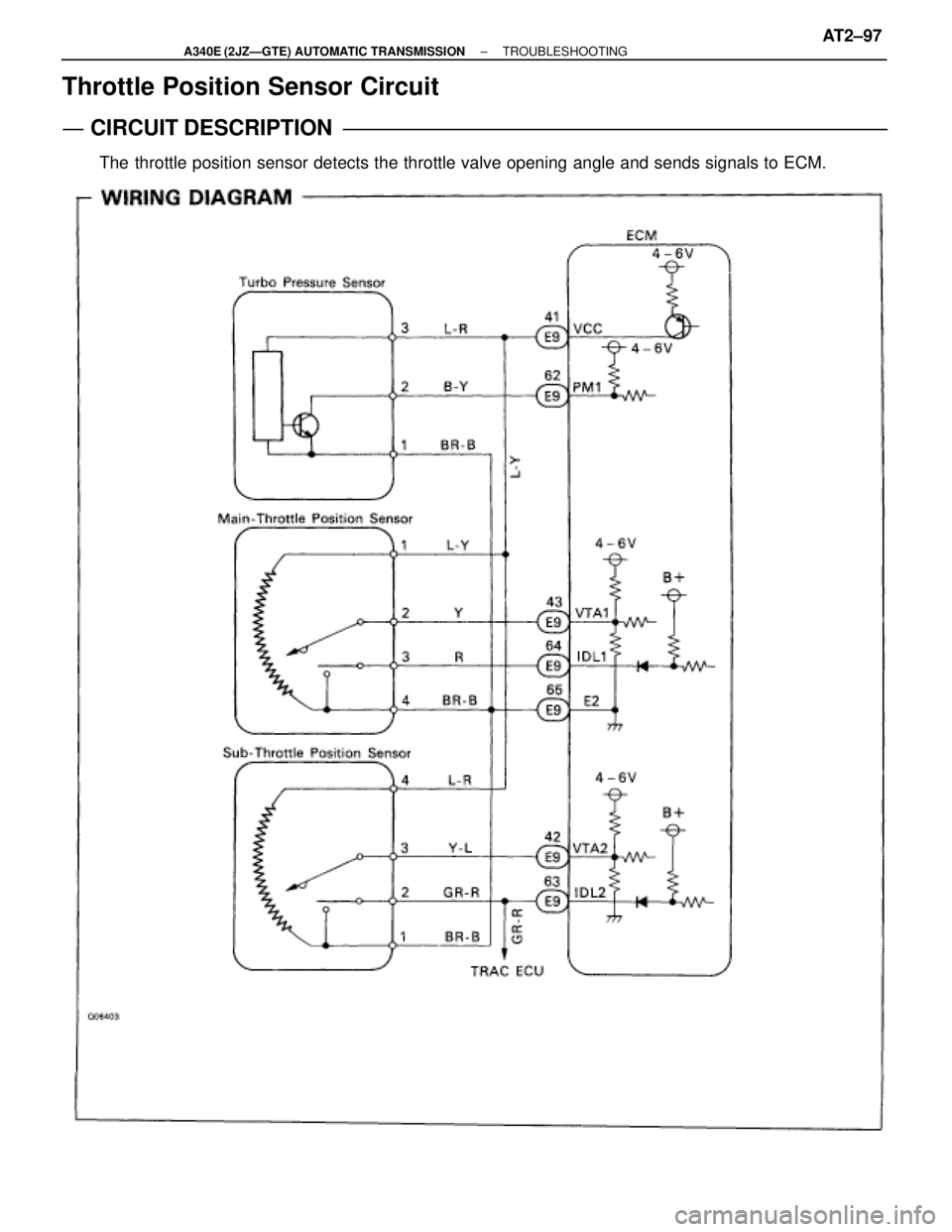

Throttle Position Sensor Circuit

CIRCUIT DESCRIPTION

The throttle position sensor detects the throttle valve opening angle and sends signals to ECM.

± A340E (2JZÐGTE) AUTOMATIC TRANSMISSIONTROUBLESHOOTINGAT2±97

Page 582 of 2543

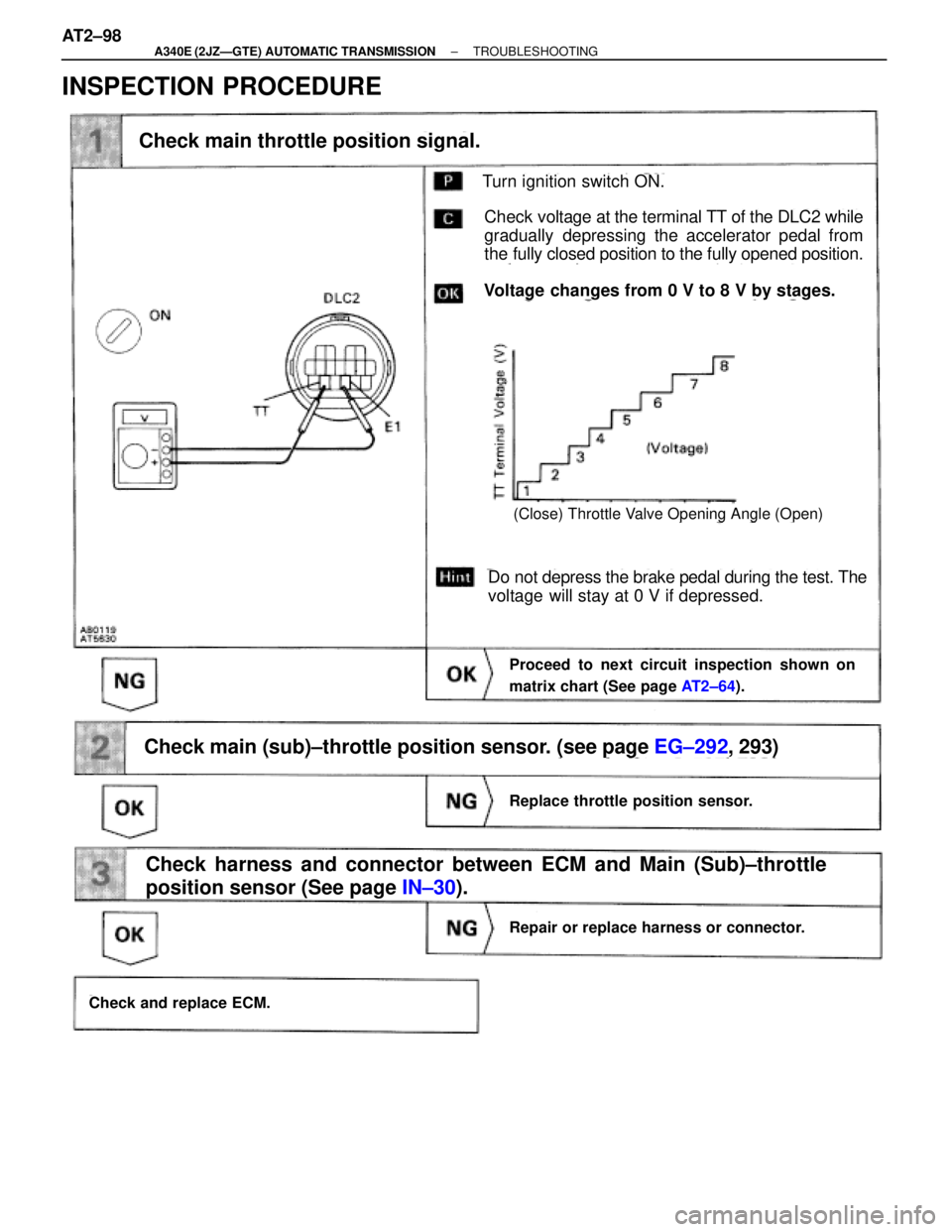

INSPECTION PROCEDURE

Check main throttle position signal.

Voltage changes from 0 V to 8 V by stages.

Turn ignition switch ON.

Do not depress the brake pedal during the test. The

voltage will stay at 0 V if depressed.

Check voltage at the terminal TT of the DLC2 while

gradually depressing the accelerator pedal from

the fully closed position to the fully opened position.

(Close) Throttle Valve Opening Angle (Open)

Proceed to next circuit inspection shown on

matrix chart (See page AT2±64).

Replace throttle position sensor.

Repair or replace harness or connector.

Check main (sub)±throttle position sensor. (see page EG±292, 293)

Check harness and connector between ECM and Main (Sub)±throttle

position sensor (See page IN±30).

Check and replace ECM.

AT2±98± A340E (2JZÐGTE) AUTOMATIC TRANSMISSIONTROUBLESHOOTING

Page 583 of 2543

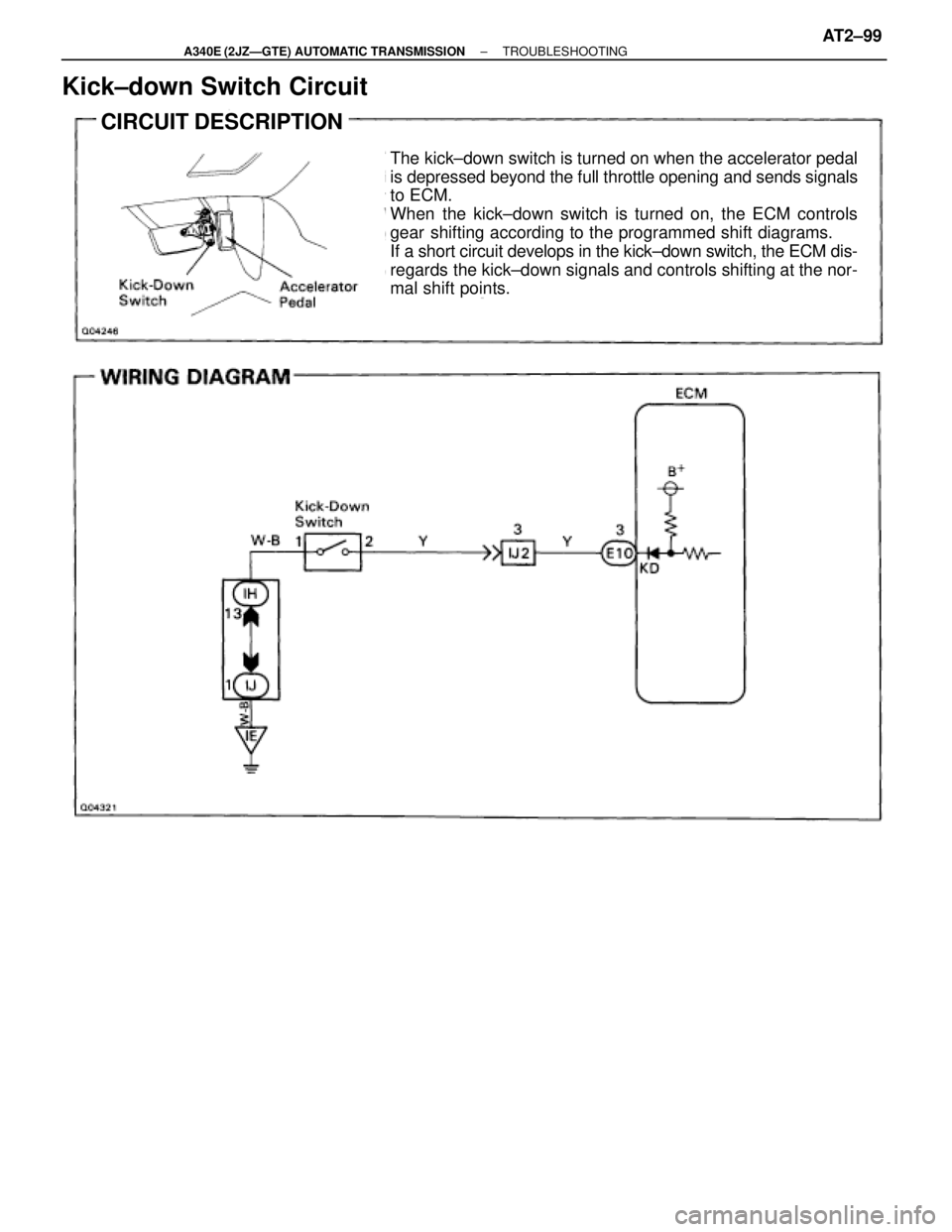

Kick±down Switch Circuit

The kick±down switch is turned on when the accelerator pedal

is depressed beyond the full throttle opening and sends signals

to ECM.

When the kick±down switch is turned on, the ECM controls

gear shifting according to the programmed shift diagrams.

If a short circuit develops in the kick±down switch, the ECM dis-

regards the kick±down signals and controls shifting at the nor-

mal shift points.

CIRCUIT DESCRIPTION

± A340E (2JZÐGTE) AUTOMATIC TRANSMISSIONTROUBLESHOOTINGAT2±99

Page 584 of 2543

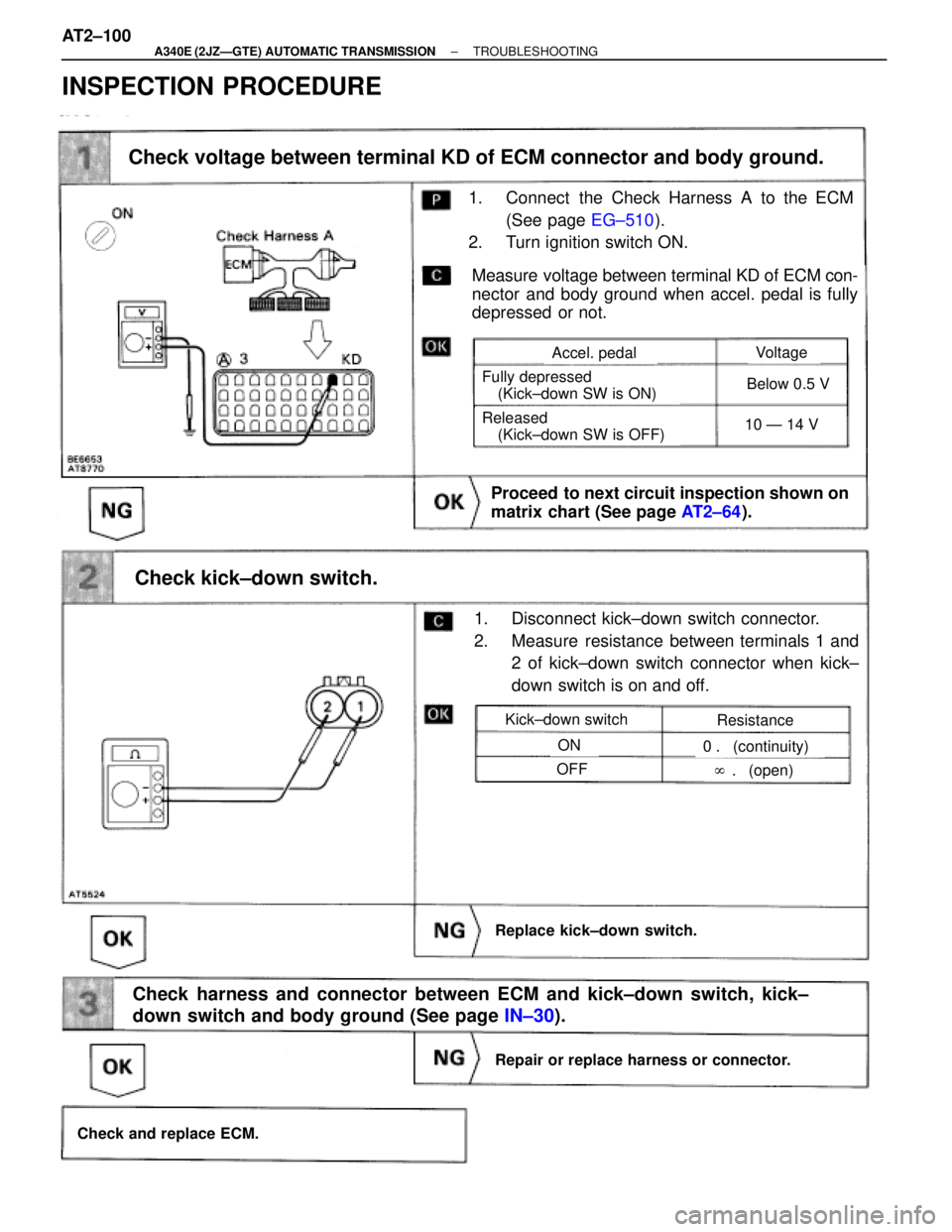

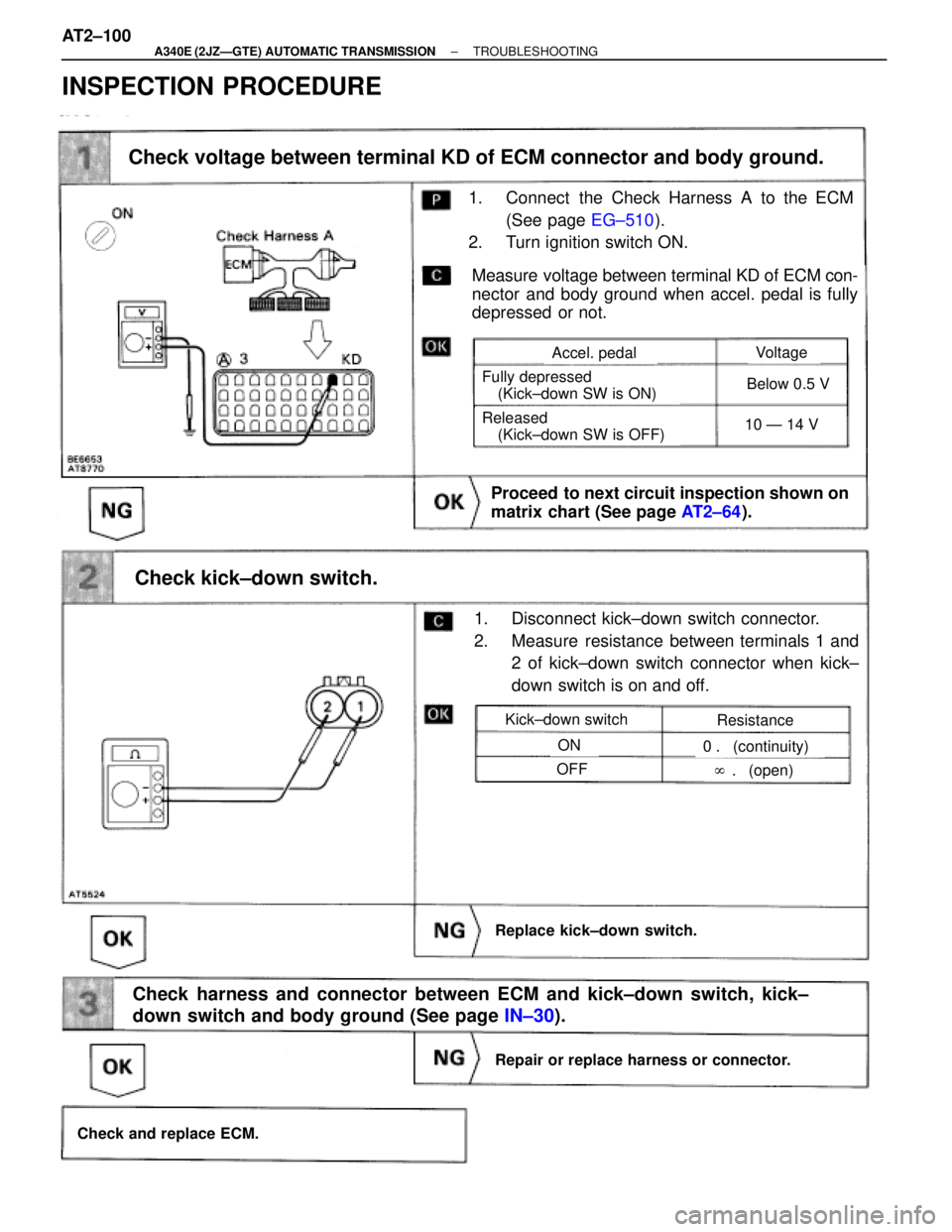

Check voltage between terminal KD of ECM connector and body ground.

1. Connect the Check Harness A to the ECM

(See page EG±510).

2. Turn ignition switch ON.

Measure voltage between terminal KD of ECM con-

nector and body ground when accel. pedal is fully

depressed or not.

Fully depressed

(Kick±down SW is ON)

Released

(Kick±down SW is OFF)

Accel. pedalVoltage

Below 0.5 V

10 Ð 14 V

Proceed to next circuit inspection shown on

matrix chart (See page AT2±64).

1. Disconnect kick±down switch connector.

2. Measure resistance between terminals 1 and

2 of kick±down switch connector when kick±

down switch is on and off.

Kick±down switchResistance

ON0 � (continuity)

� ��(open)OFF

Replace kick±down switch.

Repair or replace harness or connector.

Check kick±down switch.

Check harness and connector between ECM and kick±down switch, kick±

down switch and body ground (See page IN±30).

Check and replace ECM.

INSPECTION PROCEDURE

AT2±100± A340E (2JZÐGTE) AUTOMATIC TRANSMISSIONTROUBLESHOOTING

Page 585 of 2543

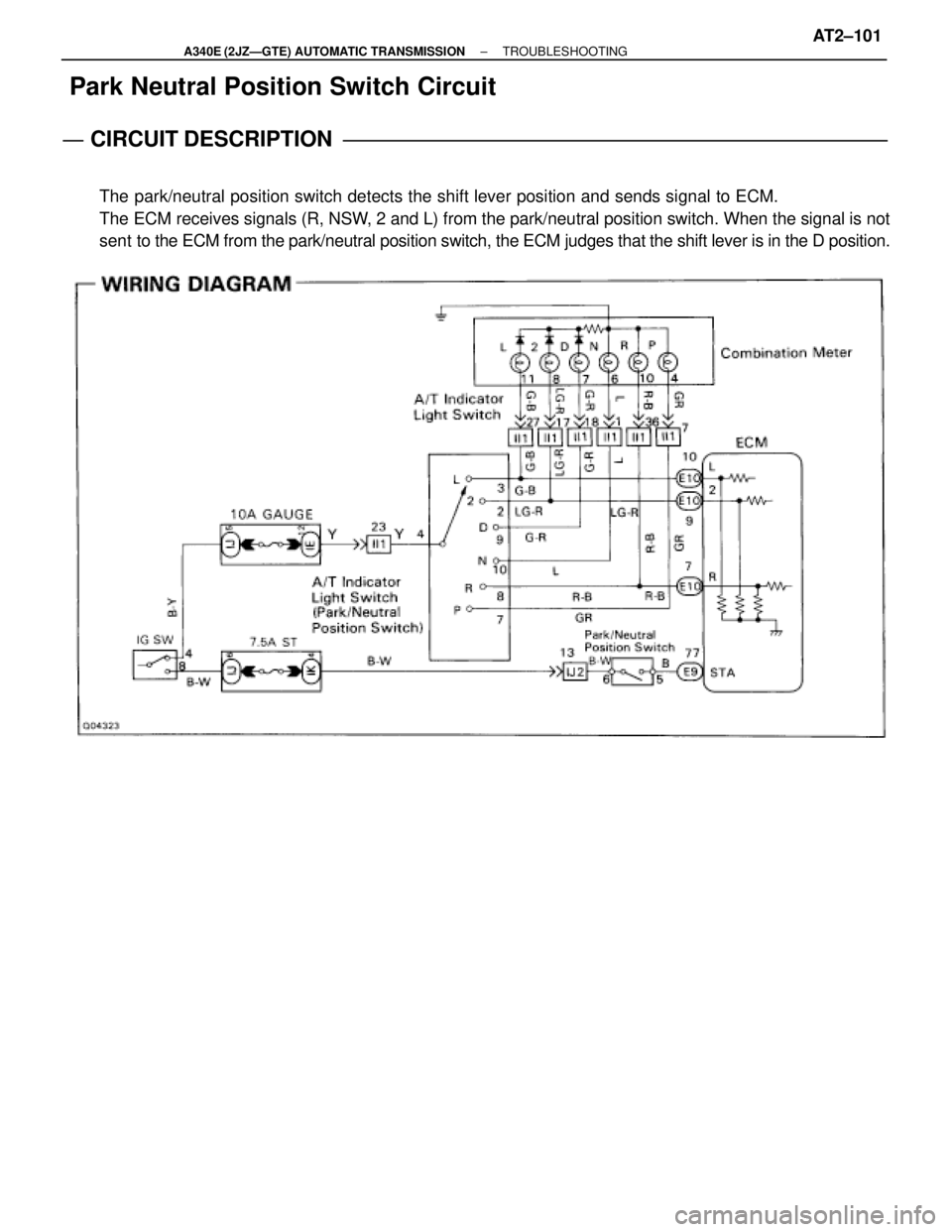

Park Neutral Position Switch Circuit

CIRCUIT DESCRIPTION

The park/neutral position switch detects the shift lever position and sends signal to ECM.

The ECM receives signals (R, NSW, 2 and L) from the park/neutral position switch. When the signal is not

sent to the ECM from the park/neutral position switch, the ECM judges that the shift lever is in the D position.

± A340E (2JZÐGTE) AUTOMATIC TRANSMISSIONTROUBLESHOOTINGAT2±101

Page 586 of 2543

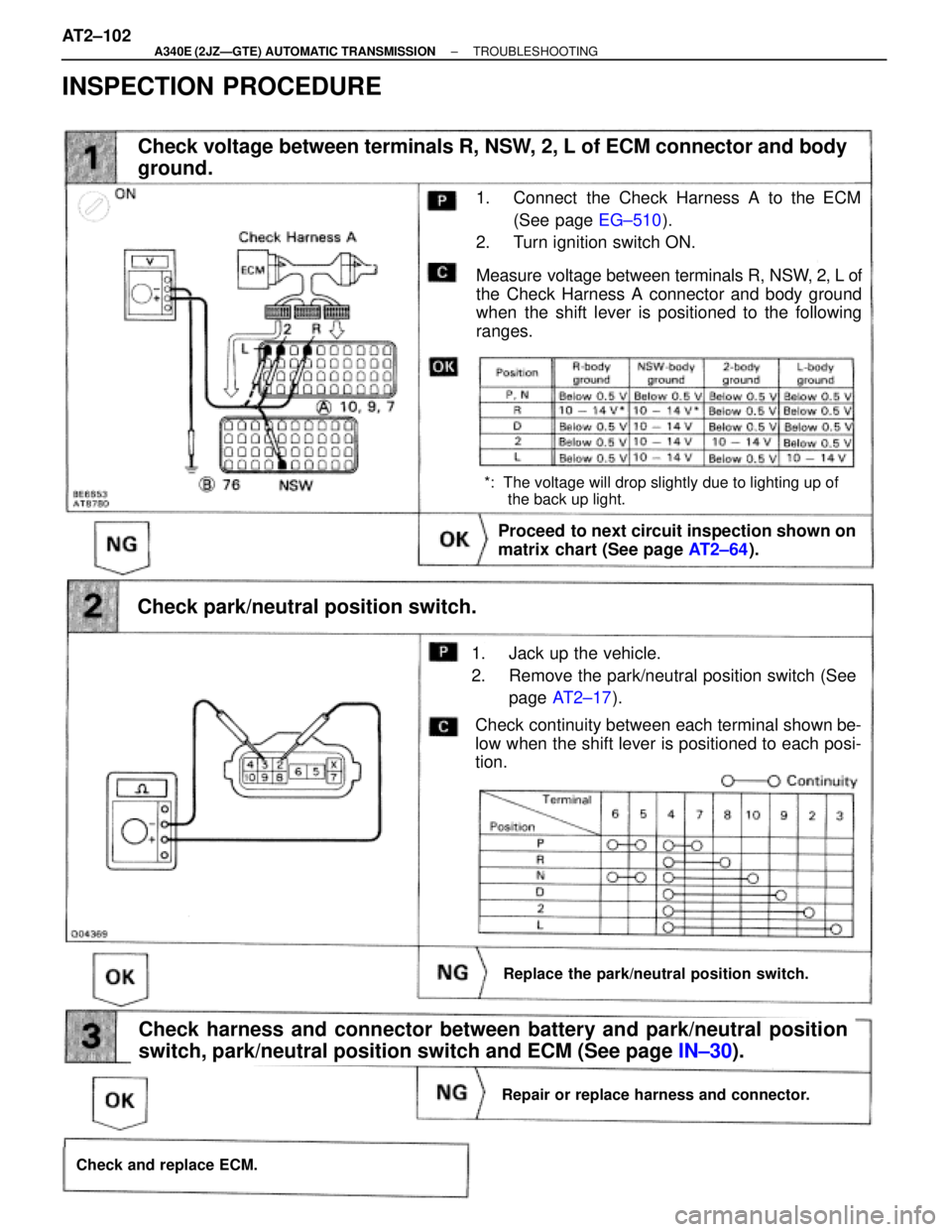

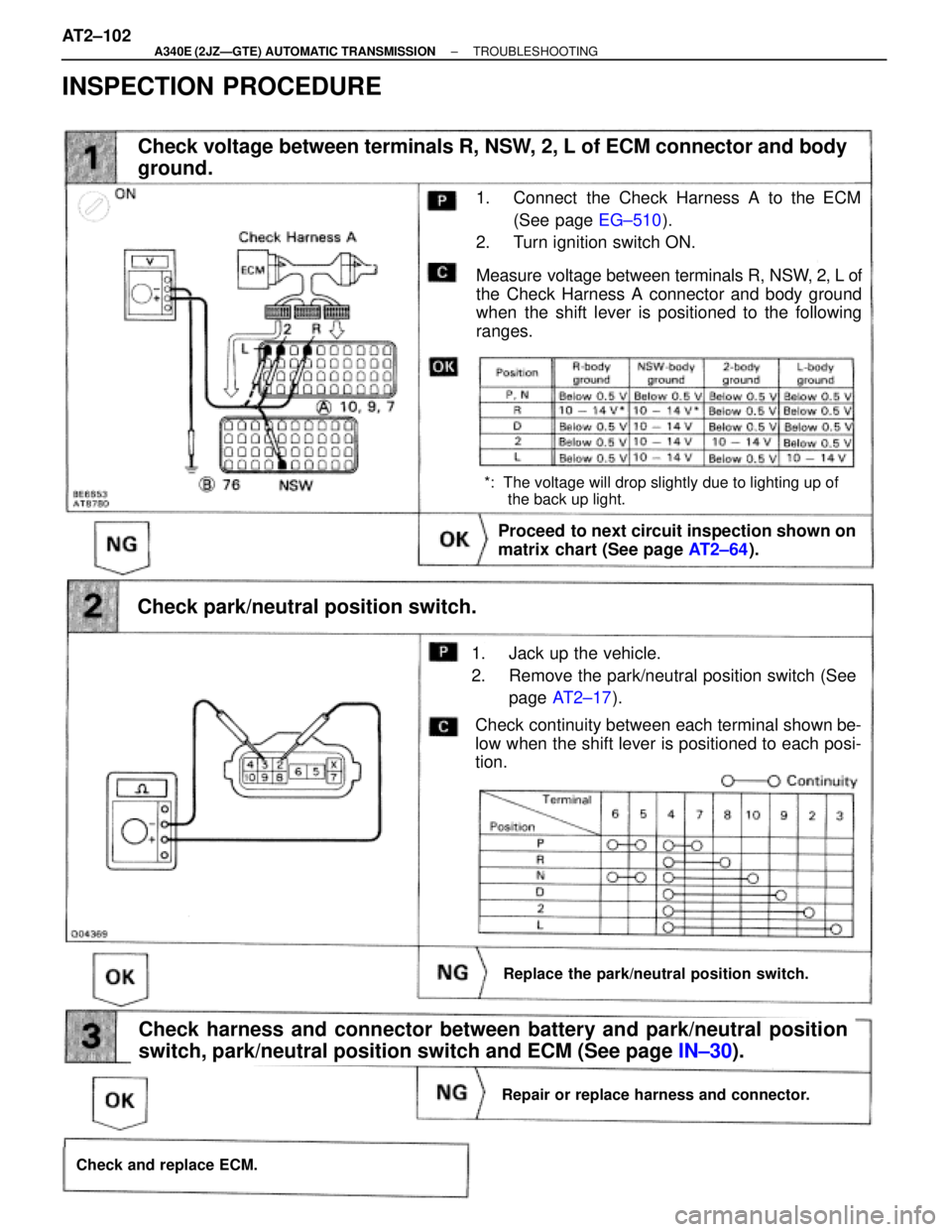

Check voltage between terminals R, NSW, 2, L of ECM connector and body

ground.

1. Connect the Check Harness A to the ECM

(See page EG±510).

2. Turn ignition switch ON.

Measure voltage between terminals R, NSW, 2, L of

the Check Harness A connector and body ground

when the shift lever is positioned to the following

ranges.

Proceed to next circuit inspection shown on

matrix chart (See page AT2±64).

*: The voltage will drop slightly due to lighting up of

the back up light.

Check harness and connector between battery and park/neutral position

switch, park/neutral position switch and ECM (See page IN±30).

Check park/neutral position switch.

Replace the park/neutral position switch.

Repair or replace harness and connector.

Check and replace ECM.

1. Jack up the vehicle.

2. Remove the park/neutral position switch (See

page AT2±17).

Check continuity between each terminal shown be-

low when the shift lever is positioned to each posi-

tion.

INSPECTION PROCEDURE

AT2±102± A340E (2JZÐGTE) AUTOMATIC TRANSMISSIONTROUBLESHOOTING

Page 587 of 2543

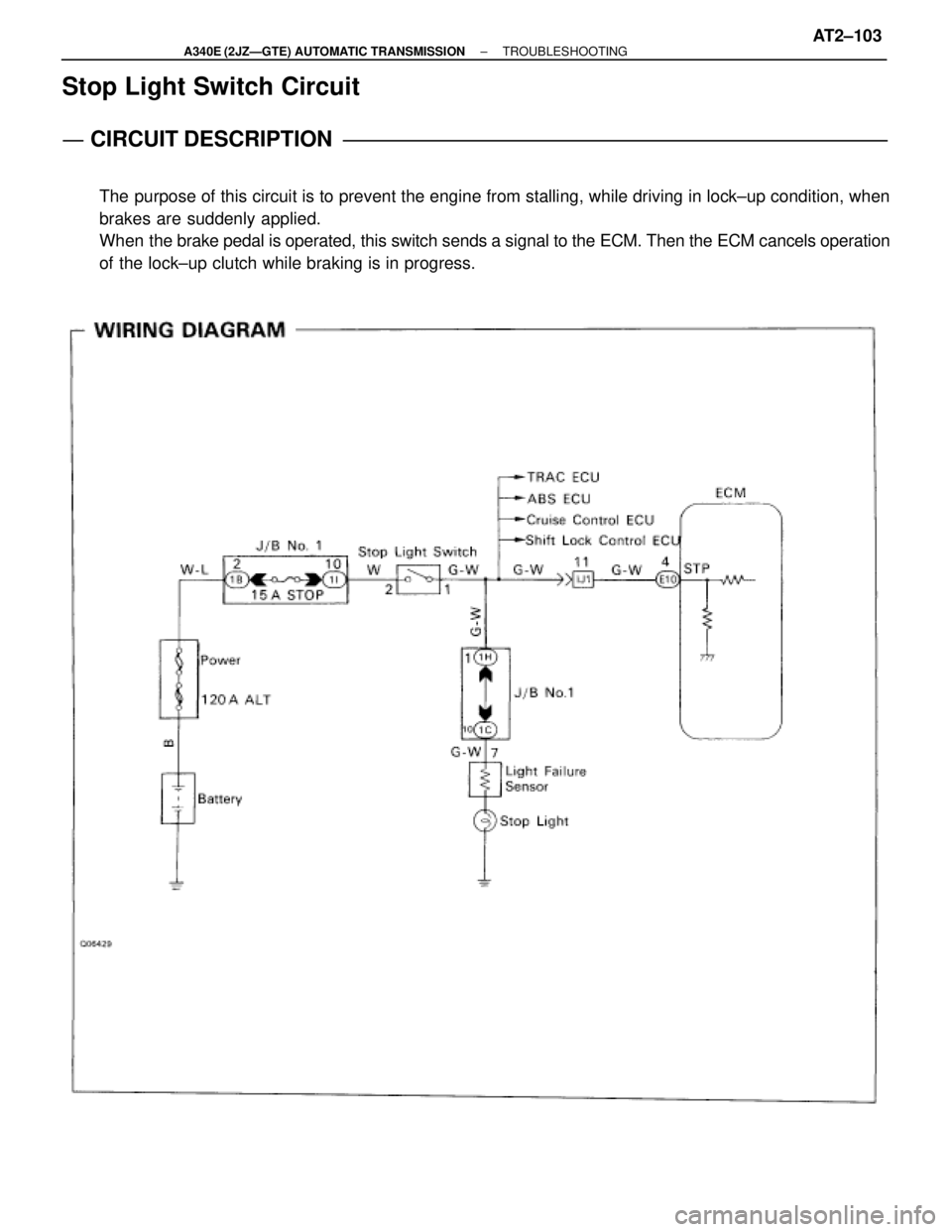

Stop Light Switch Circuit

CIRCUIT DESCRIPTION

The purpose of this circuit is to prevent the engine from stalling, while driving in lock±up condition, when

brakes are suddenly applied.

When the brake pedal is operated, this switch sends a signal to the ECM. Then the ECM cancels operation

of the lock±up clutch while braking is in progress.

± A340E (2JZÐGTE) AUTOMATIC TRANSMISSIONTROUBLESHOOTINGAT2±103

Page 588 of 2543

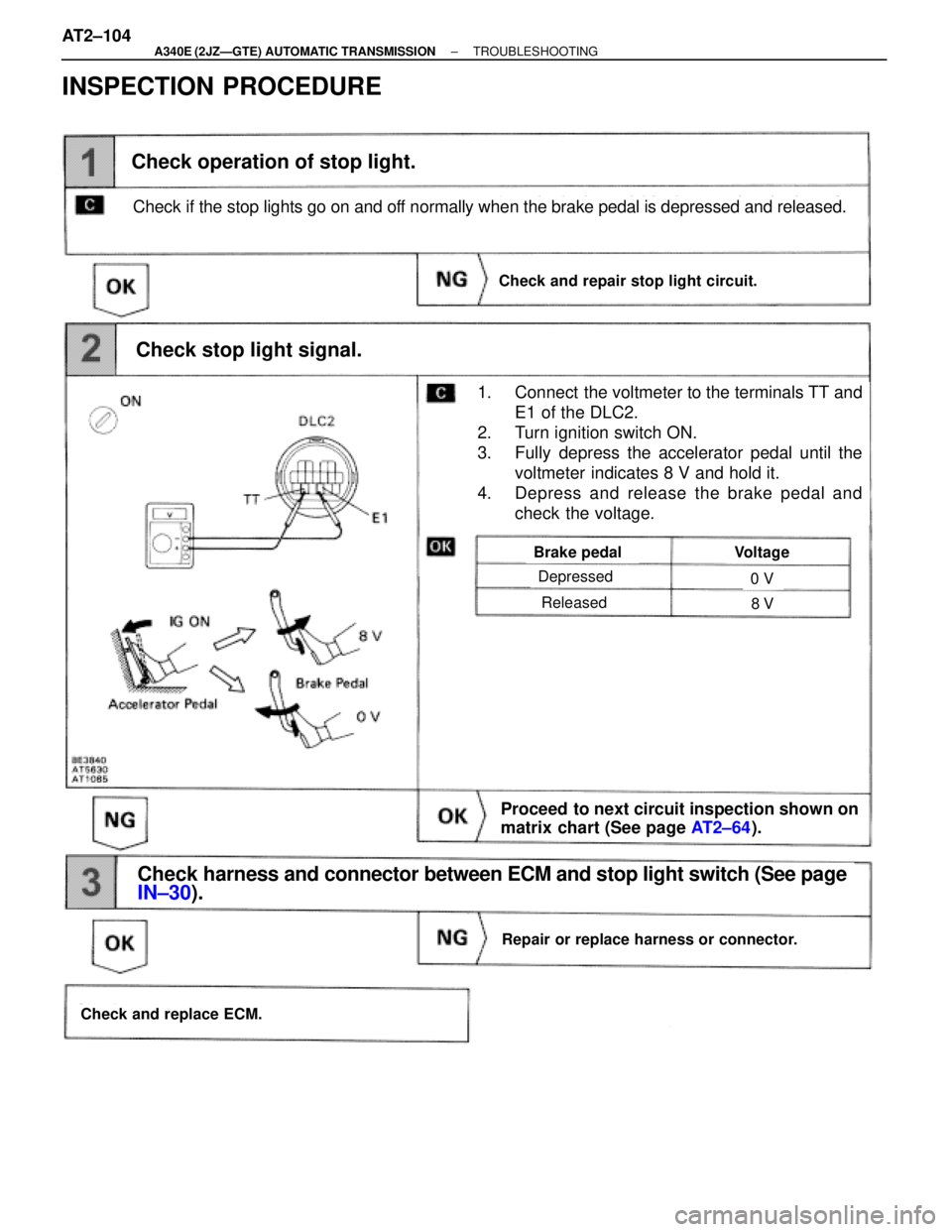

Depressed

Released

Brake pedalVoltage

0 V

8 V

Check stop light signal.

1. Connect the voltmeter to the terminals TT and

E1 of the DLC2.

2. Turn ignition switch ON.

3. Fully depress the accelerator pedal until the

voltmeter indicates 8 V and hold it.

4. Depress and release the brake pedal and

check the voltage.

Proceed to next circuit inspection shown on

matrix chart (See page AT2±64).

Check operation of stop light.

Repair or replace harness or connector.

Check and replace ECM.

Check harness and connector between ECM and stop light switch (See page

IN±30).

Check and repair stop light circuit.

Check if the stop lights go on and off normally when the brake pedal is depressed and released.

INSPECTION PROCEDURE

AT2±104± A340E (2JZÐGTE) AUTOMATIC TRANSMISSIONTROUBLESHOOTING

Page 589 of 2543

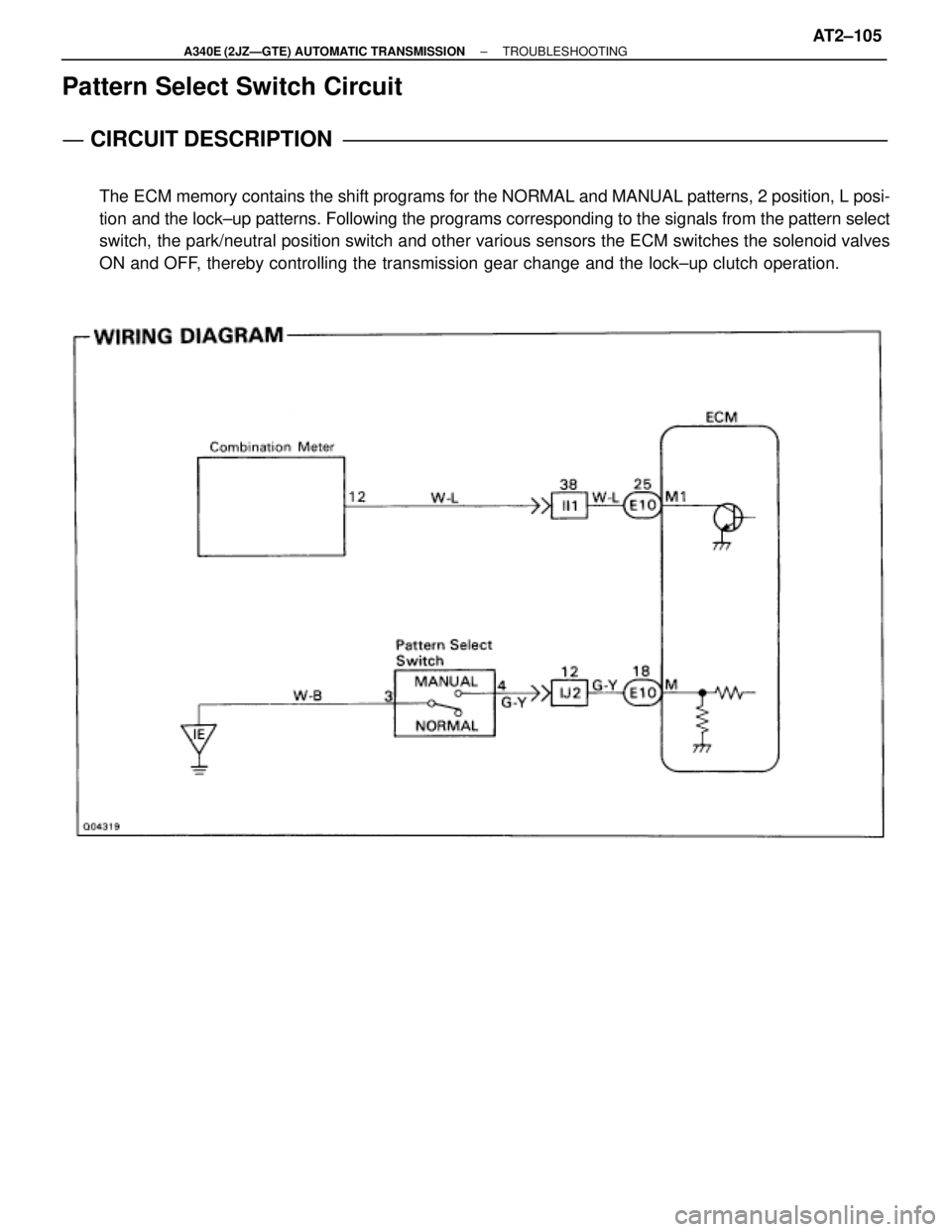

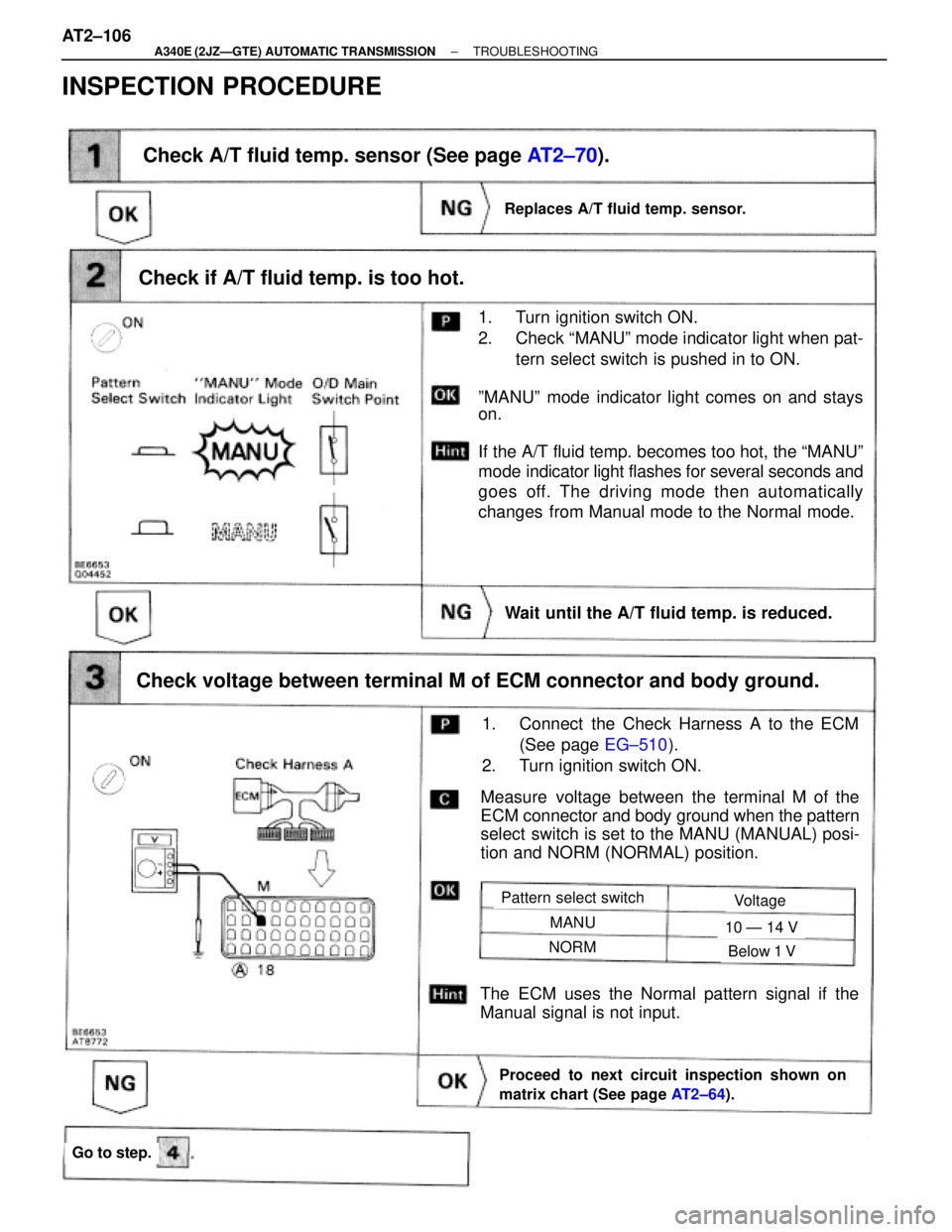

Pattern Select Switch Circuit

CIRCUIT DESCRIPTION

The ECM memory contains the shift programs for the NORMAL and MANUAL patterns, 2 position, L posi-

tion and the lock±up patterns. Following the programs corresponding to the signals from the pattern select

switch, the park/neutral position switch and other various sensors the ECM switches the solenoid valves

ON and OFF, thereby controlling the transmission gear change and the lock±up clutch operation.

± A340E (2JZÐGTE) AUTOMATIC TRANSMISSIONTROUBLESHOOTINGAT2±105

Page 590 of 2543

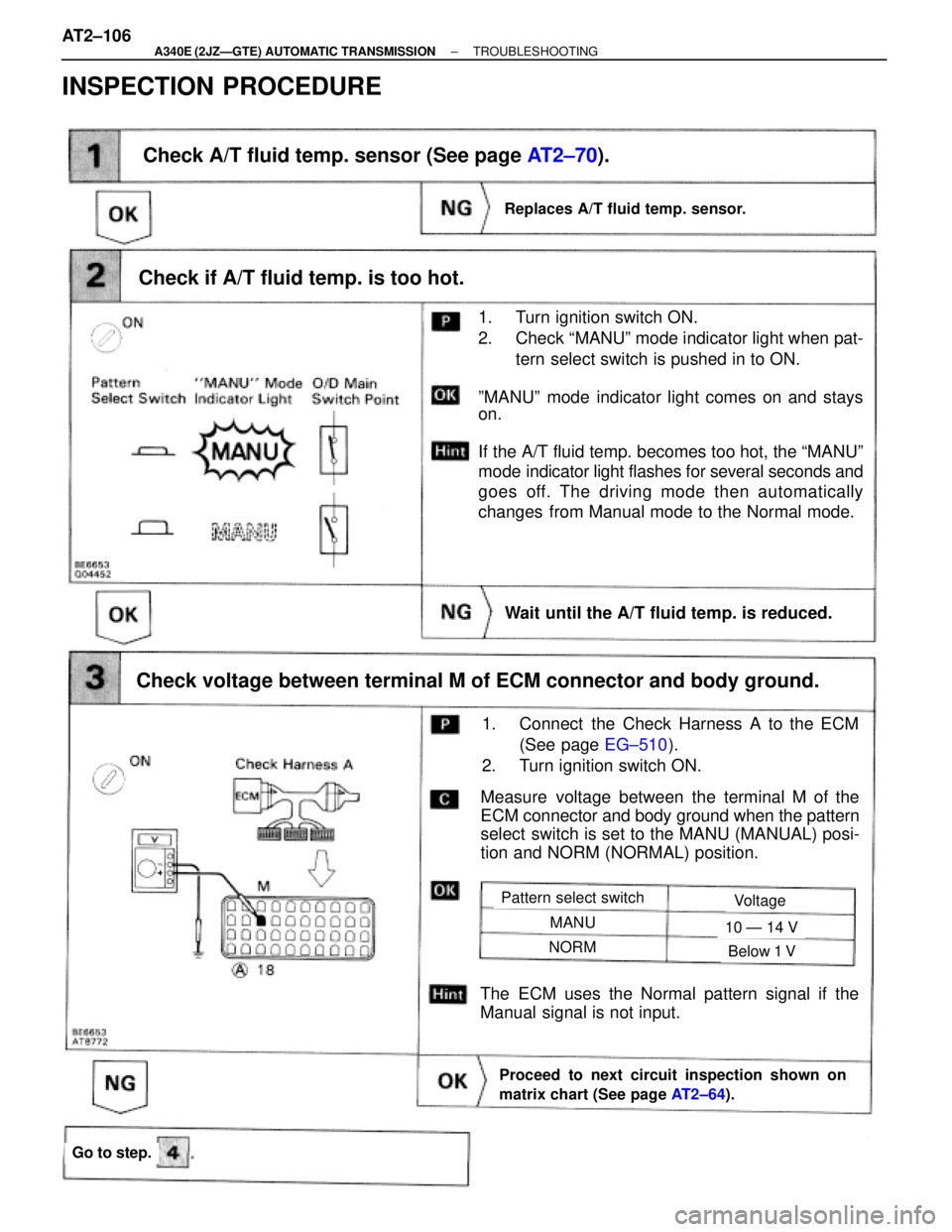

Check if A/T fluid temp. is too hot.

1. Turn ignition switch ON.

2. Check ªMANUº mode indicator light when pat-

tern select switch is pushed in to ON.

ºMANUº mode indicator light comes on and stays

on.

If the A/T fluid temp. becomes too hot, the ªMANUº

mode indicator light flashes for several seconds and

goes off. The driving mode then automatically

changes from Manual mode to the Normal mode.

Measure voltage between the terminal M of the

ECM connector and body ground when the pattern

select switch is set to the MANU (MANUAL) posi-

tion and NORM (NORMAL) position.

Check A/T fluid temp. sensor (See page AT2±70).

Check voltage between terminal M of ECM connector and body ground.

Replaces A/T fluid temp. sensor.

1. Connect the Check Harness A to the ECM

(See page EG±510).

2. Turn ignition switch ON.

Proceed to next circuit inspection shown on

matrix chart (See page AT2±64).

The ECM uses the Normal pattern signal if the

Manual signal is not input.

Pattern select switchVoltage

MANU

NORM

10 Ð 14 V

Below 1 V

Go to step.

Wait until the A/T fluid temp. is reduced.

INSPECTION PROCEDURE

AT2±106± A340E (2JZÐGTE) AUTOMATIC TRANSMISSIONTROUBLESHOOTING

Trending: fuel cap, alarm, remove seats, trunk, check engine, jacking, trunk release