TOYOTA SUPRA 1995 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 1995, Model line: SUPRA, Model: TOYOTA SUPRA 1995Pages: 2543, PDF Size: 53.25 MB

Page 881 of 2543

4. REMOVE MASTER CYLINDER

(a) Remove the 2 nuts.

(b) Remove the master cylinder and gasket from the brake

booster.

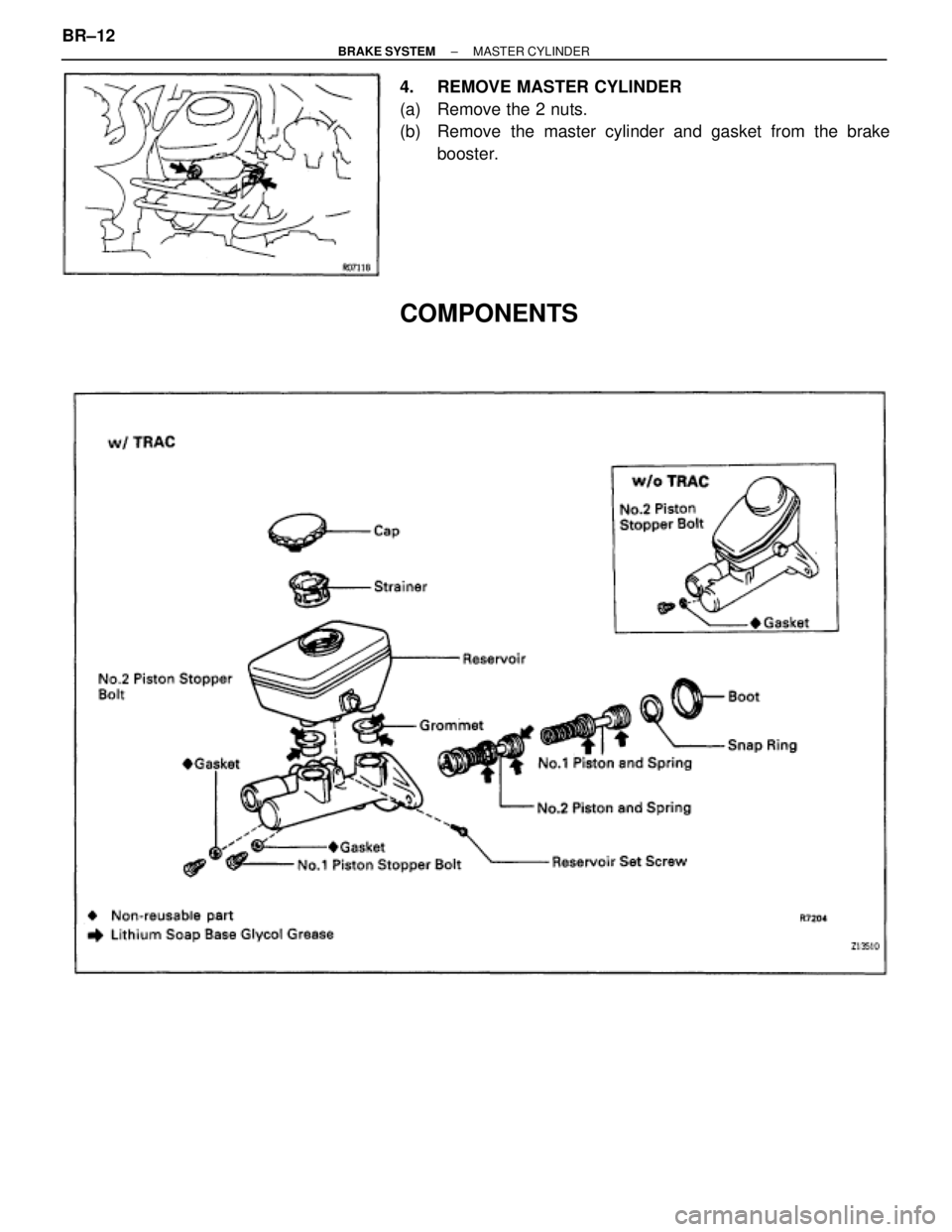

COMPONENTS

BR±12± BRAKE SYSTEMMASTER CYLINDER

Page 882 of 2543

MASTER CYLINDER DISASSEMBLY

Assembly is in the reverse order of disassembly.

ASSEMBLY NOTICE: Apply lithium soap base glycol

grease to the rubber parts indicated by the arrows (See

page BR±12).

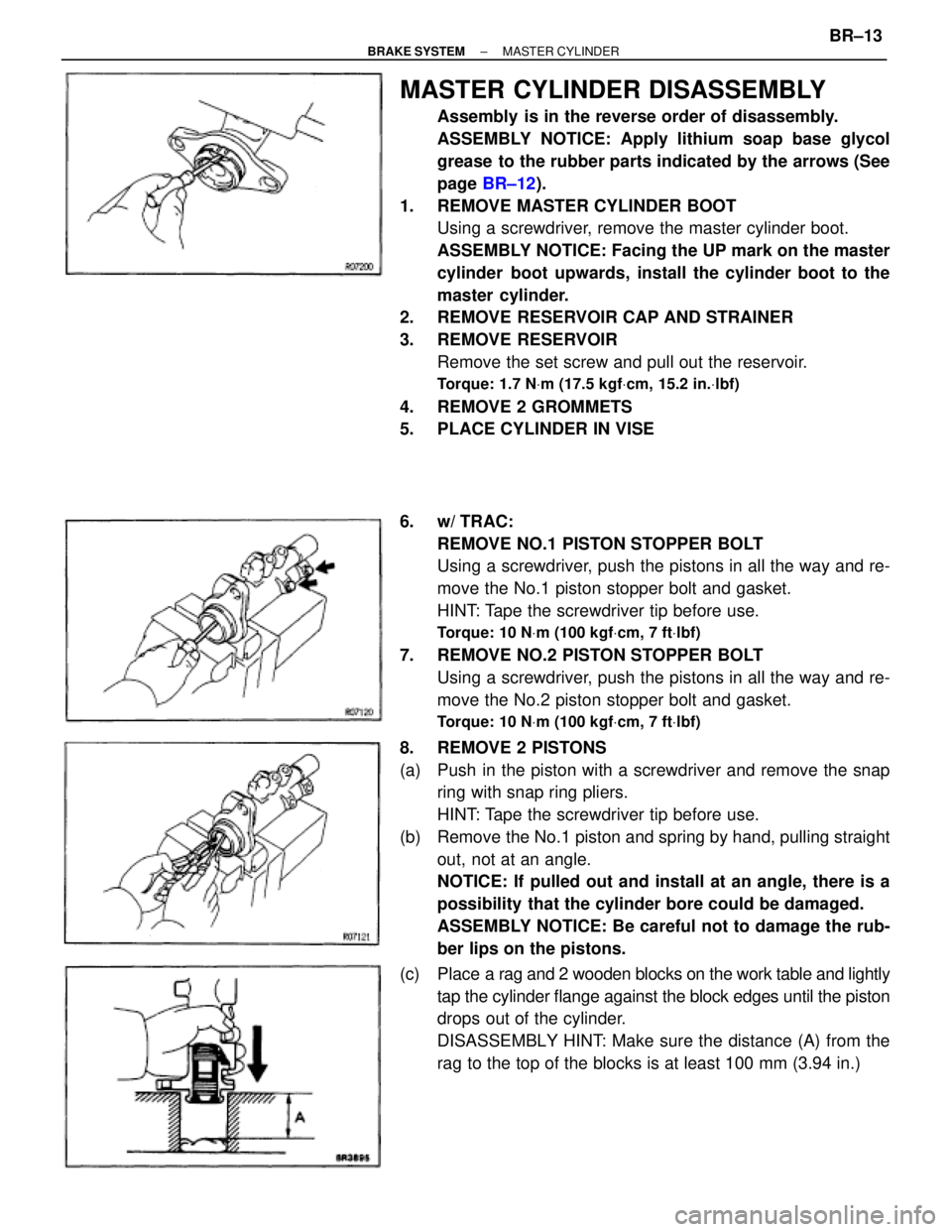

1. REMOVE MASTER CYLINDER BOOT

Using a screwdriver, remove the master cylinder boot.

ASSEMBLY NOTICE: Facing the UP mark on the master

cylinder boot upwards, install the cylinder boot to the

master cylinder.

2. REMOVE RESERVOIR CAP AND STRAINER

3. REMOVE RESERVOIR

Remove the set screw and pull out the reservoir.

Torque: 1.7 NVm (17.5 kgfVcm, 15.2 in.Vlbf)

4. REMOVE 2 GROMMETS

5. PLACE CYLINDER IN VISE

6. w/ TRAC:

REMOVE NO.1 PISTON STOPPER BOLT

Using a screwdriver, push the pistons in all the way and re-

move the No.1 piston stopper bolt and gasket.

HINT: Tape the screwdriver tip before use.

Torque: 10 NVm (100 kgfVcm, 7 ftVlbf)

7. REMOVE NO.2 PISTON STOPPER BOLT

Using a screwdriver, push the pistons in all the way and re-

move the No.2 piston stopper bolt and gasket.

Torque: 10 NVm (100 kgfVcm, 7 ftVlbf)

8. REMOVE 2 PISTONS

(a) Push in the piston with a screwdriver and remove the snap

ring with snap ring pliers.

HINT: Tape the screwdriver tip before use.

(b) Remove the No.1 piston and spring by hand, pulling straight

out, not at an angle.

NOTICE: If pulled out and install at an angle, there is a

possibility that the cylinder bore could be damaged.

ASSEMBLY NOTICE: Be careful not to damage the rub-

ber lips on the pistons.

(c) Place a rag and 2 wooden blocks on the work table and lightly

tap the cylinder flange against the block edges until the piston

drops out of the cylinder.

DISASSEMBLY HINT: Make sure the distance (A) from the

rag to the top of the blocks is at least 100 mm (3.94 in.)

± BRAKE SYSTEMMASTER CYLINDERBR±13

Page 883 of 2543

MASTER CYLINDER COMPONENTS

INSPECTION

HINT: Clean the disassembled parts with compressed air.

1. INSPECT CYLINDER BORE FOR RUST OR SCORING

2. INSPECT CYLINDER FOR WEAR OR DAMAGE

If necessary, clean or replace the cylinder.

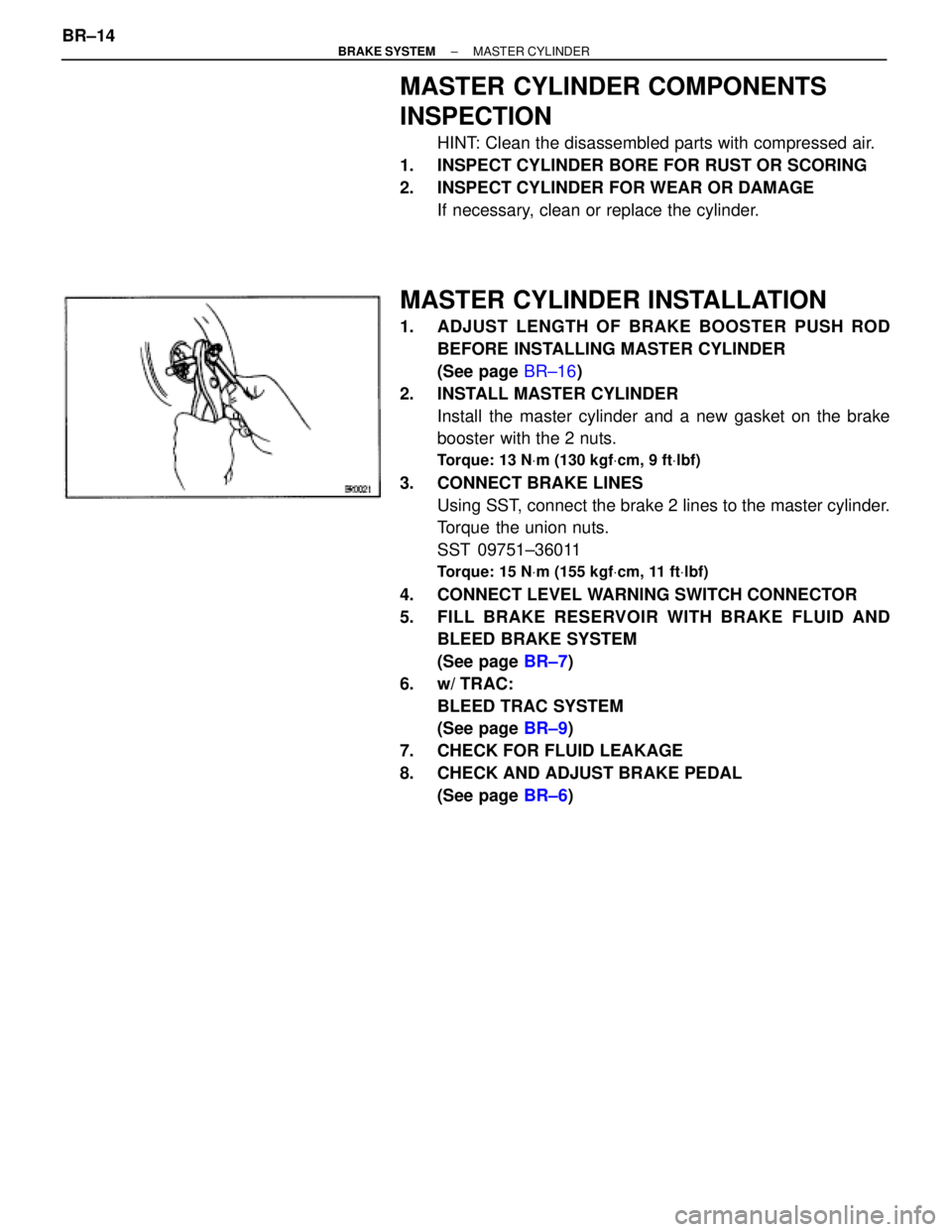

MASTER CYLINDER INSTALLATION

1. ADJUST LENGTH OF BRAKE BOOSTER PUSH ROD

BEFORE INSTALLING MASTER CYLINDER

(See page BR±16)

2. INSTALL MASTER CYLINDER

Install the master cylinder and a new gasket on the brake

booster with the 2 nuts.

Torque: 13 NVm (130 kgfVcm, 9 ftVlbf)

3. CONNECT BRAKE LINES

Using SST, connect the brake 2 lines to the master cylinder.

Torque the union nuts.

SST 09751±36011

Torque: 15 NVm (155 kgfVcm, 11 ftVlbf)

4. CONNECT LEVEL WARNING SWITCH CONNECTOR

5. FILL BRAKE RESERVOIR WITH BRAKE FLUID AND

BLEED BRAKE SYSTEM

(See page BR±7)

6. w/ TRAC:

BLEED TRAC SYSTEM

(See page BR±9)

7. CHECK FOR FLUID LEAKAGE

8. CHECK AND ADJUST BRAKE PEDAL

(See page BR±6) BR±14

± BRAKE SYSTEMMASTER CYLINDER

Page 884 of 2543

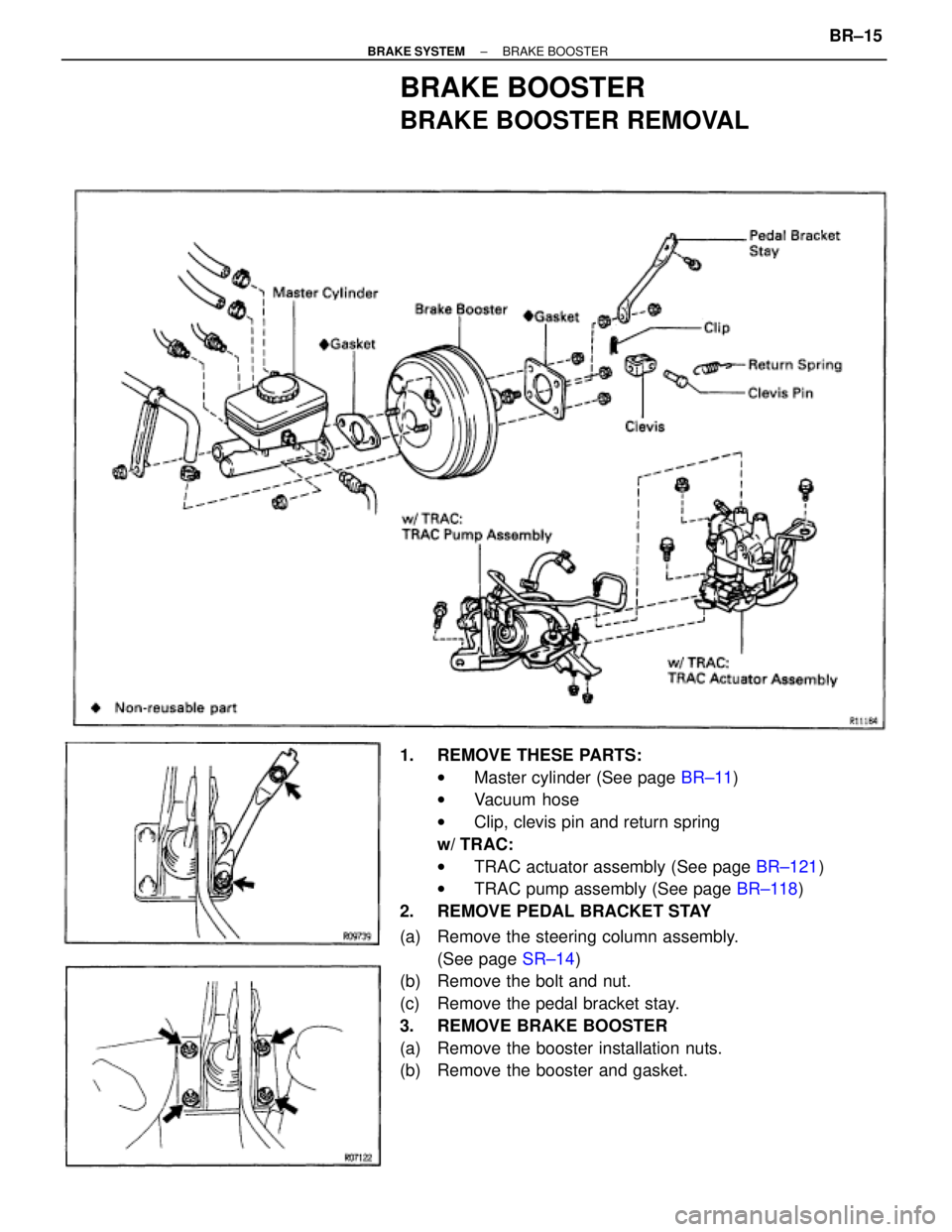

BRAKE BOOSTER

BRAKE BOOSTER REMOVAL

1. REMOVE THESE PARTS:

wMaster cylinder (See page BR±11)

wVacuum hose

wClip, clevis pin and return spring

w/ TRAC:

wTRAC actuator assembly (See page BR±121)

wTRAC pump assembly (See page BR±118)

2. REMOVE PEDAL BRACKET STAY

(a) Remove the steering column assembly.

(See page SR±14)

(b) Remove the bolt and nut.

(c) Remove the pedal bracket stay.

3. REMOVE BRAKE BOOSTER

(a) Remove the booster installation nuts.

(b) Remove the booster and gasket.

± BRAKE SYSTEMBRAKE BOOSTERBR±15

Page 885 of 2543

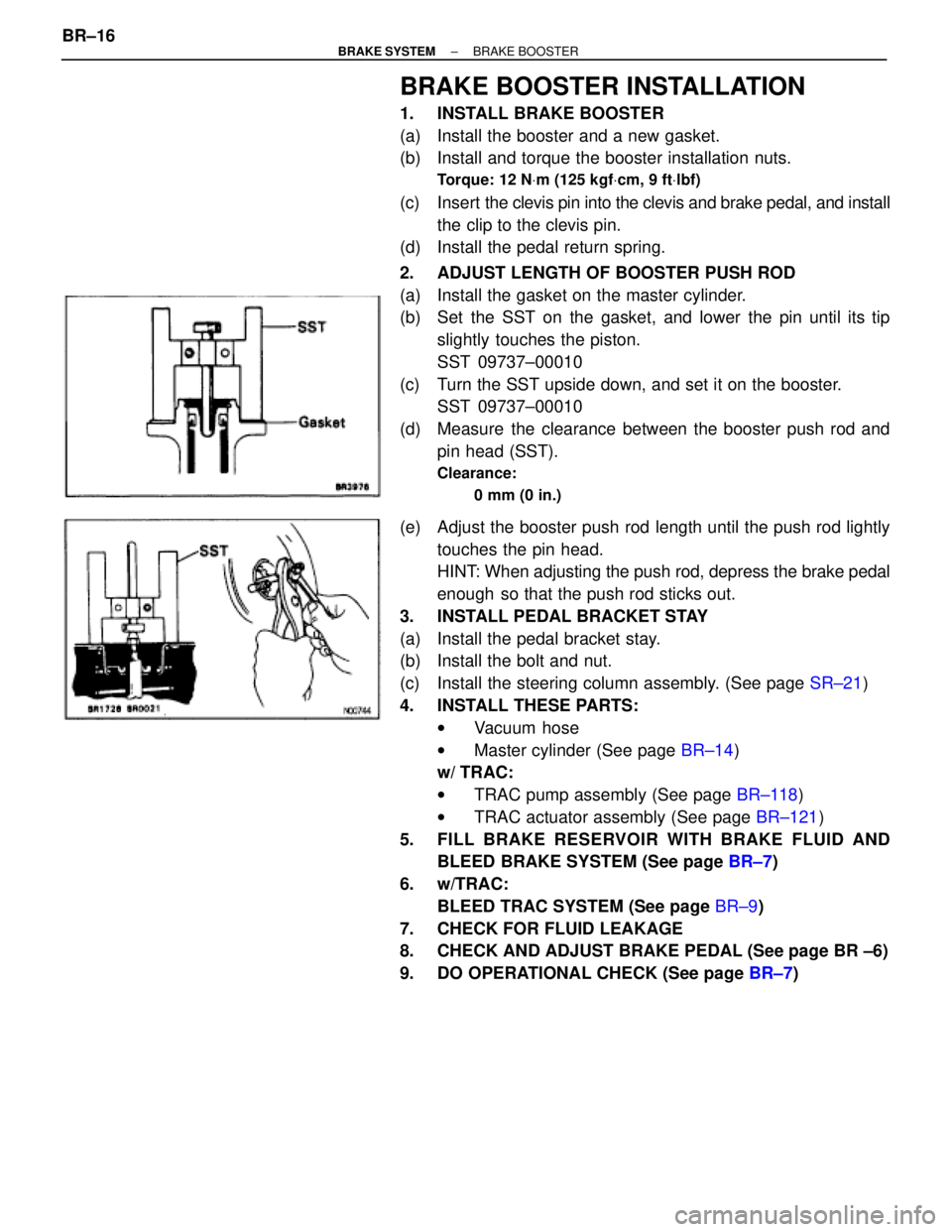

BRAKE BOOSTER INSTALLATION

1. INSTALL BRAKE BOOSTER

(a) Install the booster and a new gasket.

(b) Install and torque the booster installation nuts.

Torque: 12 NVm (125 kgfVcm, 9 ftVlbf)

(c) Insert the clevis pin into the clevis and brake pedal, and install

the clip to the clevis pin.

(d) Install the pedal return spring.

2. ADJUST LENGTH OF BOOSTER PUSH ROD

(a) Install the gasket on the master cylinder.

(b) Set the SST on the gasket, and lower the pin until its tip

slightly touches the piston.

SST 09737±00010

(c) Turn the SST upside down, and set it on the booster.

SST 09737±00010

(d) Measure the clearance between the booster push rod and

pin head (SST).

Clearance:

0 mm (0 in.)

(e) Adjust the booster push rod length until the push rod lightly

touches the pin head.

HINT: When adjusting the push rod, depress the brake pedal

enough so that the push rod sticks out.

3. INSTALL PEDAL BRACKET STAY

(a) Install the pedal bracket stay.

(b) Install the bolt and nut.

(c) Install the steering column assembly. (See page SR±21)

4. INSTALL THESE PARTS:

wVacuum hose

wMaster cylinder (See page BR±14)

w/ TRAC:

wTRAC pump assembly (See page BR±118)

wTRAC actuator assembly (See page BR±121)

5. FILL BRAKE RESERVOIR WITH BRAKE FLUID AND

BLEED BRAKE SYSTEM (See page BR±7)

6. w/TRAC:

BLEED TRAC SYSTEM (See page BR±9)

7. CHECK FOR FLUID LEAKAGE

8. CHECK AND ADJUST BRAKE PEDAL (See page BR ±6)

9. DO OPERATIONAL CHECK (See page BR±7) BR±16

± BRAKE SYSTEMBRAKE BOOSTER

Page 886 of 2543

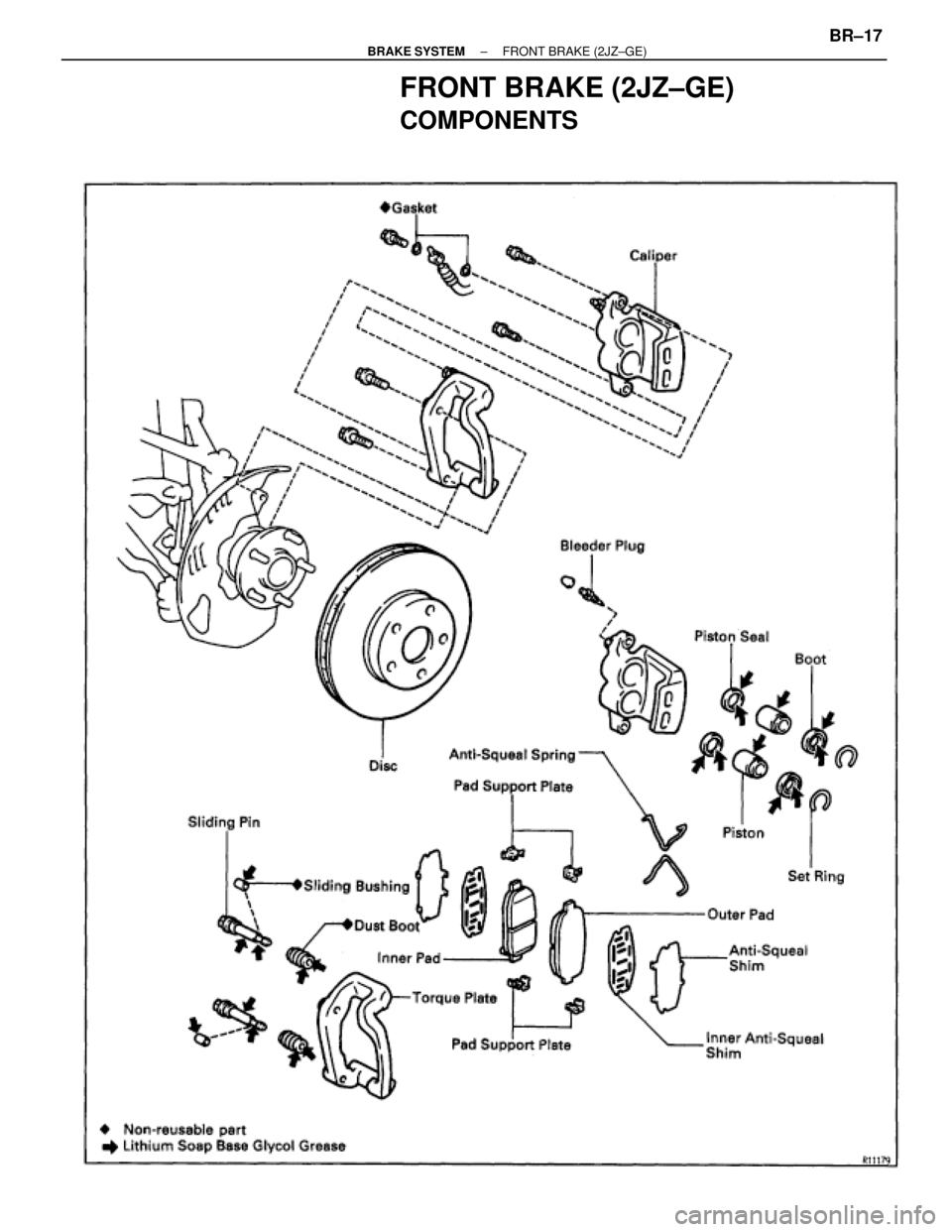

FRONT BRAKE (2JZ±GE)

COMPONENTS

± BRAKE SYSTEMFRONT BRAKE (2JZ±GE)BR±17

Page 887 of 2543

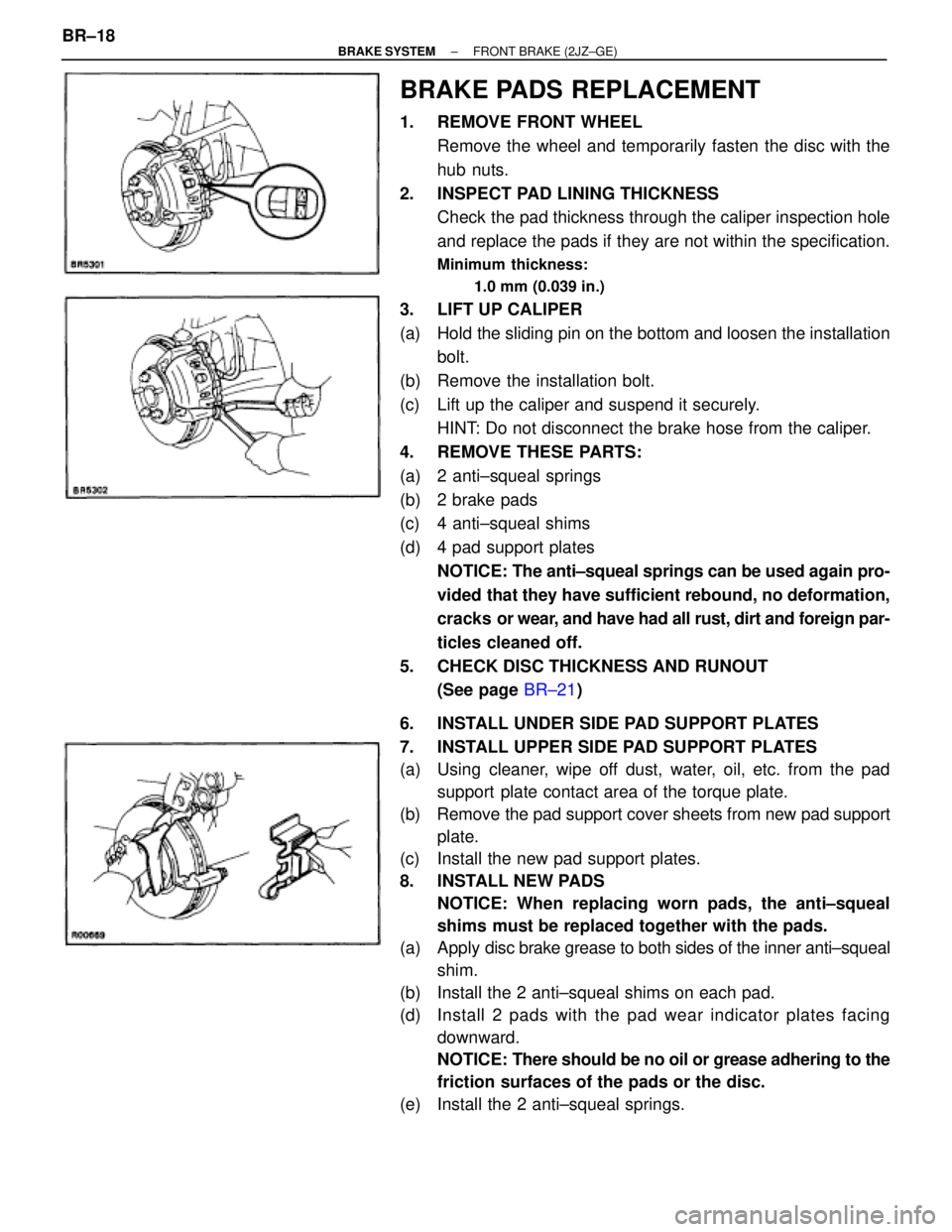

BRAKE PADS REPLACEMENT

1. REMOVE FRONT WHEEL

Remove the wheel and temporarily fasten the disc with the

hub nuts.

2. INSPECT PAD LINING THICKNESS

Check the pad thickness through the caliper inspection hole

and replace the pads if they are not within the specification.

Minimum thickness:

1.0 mm (0.039 in.)

3. LIFT UP CALIPER

(a) Hold the sliding pin on the bottom and loosen the installation

bolt.

(b) Remove the installation bolt.

(c) Lift up the caliper and suspend it securely.

HINT: Do not disconnect the brake hose from the caliper.

4. REMOVE THESE PARTS:

(a) 2 anti±squeal springs

(b) 2 brake pads

(c) 4 anti±squeal shims

(d) 4 pad support plates

NOTICE: The anti±squeal springs can be used again pro-

vided that they have sufficient rebound, no deformation,

cracks or wear, and have had all rust, dirt and foreign par-

ticles cleaned off.

5. CHECK DISC THICKNESS AND RUNOUT

(See page BR±21)

6. INSTALL UNDER SIDE PAD SUPPORT PLATES

7. INSTALL UPPER SIDE PAD SUPPORT PLATES

(a) Using cleaner, wipe off dust, water, oil, etc. from the pad

support plate contact area of the torque plate.

(b) Remove the pad support cover sheets from new pad support

plate.

(c) Install the new pad support plates.

8. INSTALL NEW PADS

NOTICE: When replacing worn pads, the anti±squeal

shims must be replaced together with the pads.

(a) Apply disc brake grease to both sides of the inner anti±squeal

shim.

(b) Install the 2 anti±squeal shims on each pad.

(d) Install 2 pads with the pad wear indicator plates facing

downward.

NOTICE: There should be no oil or grease adhering to the

friction surfaces of the pads or the disc.

(e) Install the 2 anti±squeal springs. BR±18

± BRAKE SYSTEMFRONT BRAKE (2JZ±GE)

Page 888 of 2543

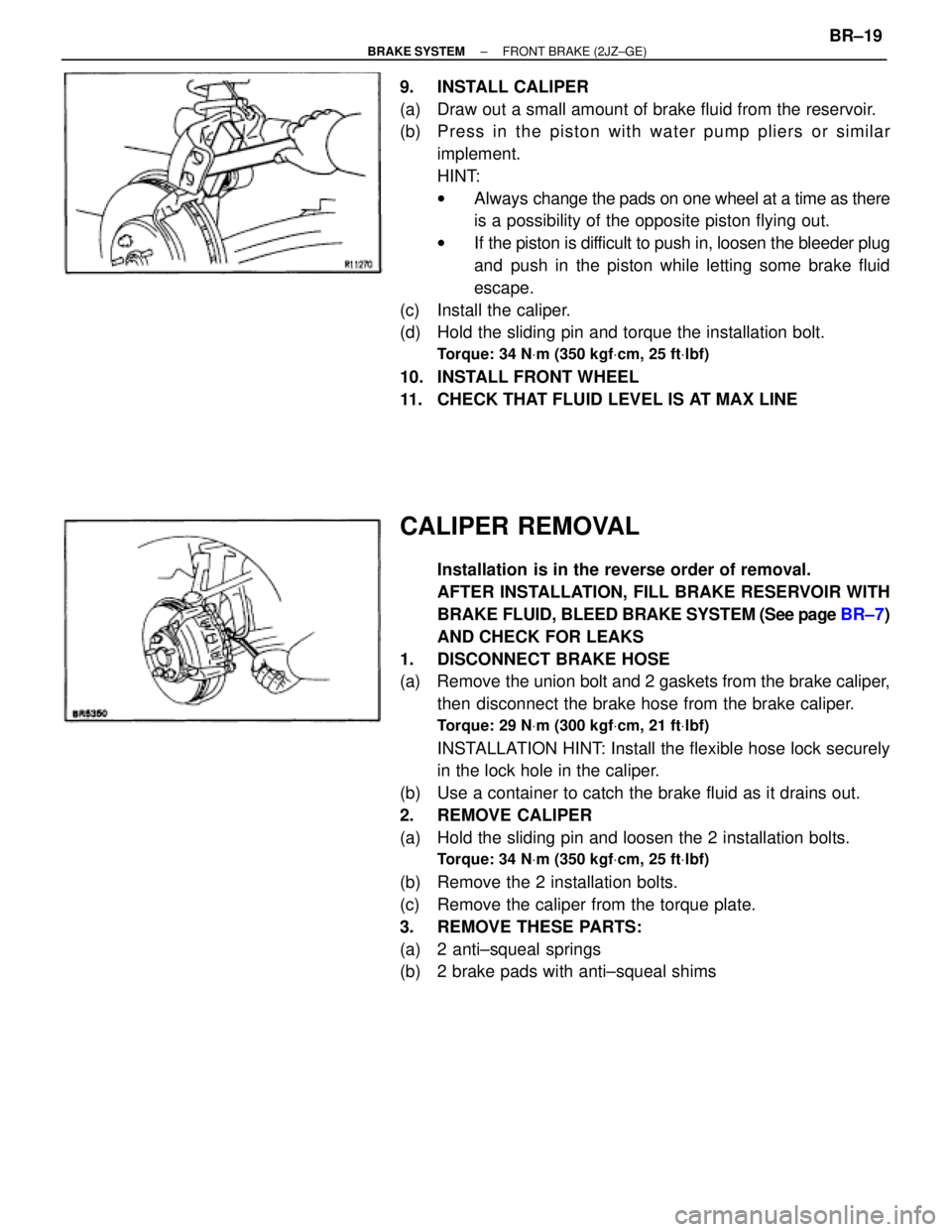

9. INSTALL CALIPER

(a) Draw out a small amount of brake fluid from the reservoir.

(b) P re ss in th e pisto n with wa te r pu mp plie rs or simila r

implement.

HINT:

wAlways change the pads on one wheel at a time as there

is a possibility of the opposite piston flying out.

wIf the piston is difficult to push in, loosen the bleeder plug

and push in the piston while letting some brake fluid

escape.

(c) Install the caliper.

(d) Hold the sliding pin and torque the installation bolt.

Torque: 34 NVm (350 kgfVcm, 25 ftVlbf)

10. INSTALL FRONT WHEEL

11. CHECK THAT FLUID LEVEL IS AT MAX LINE

CALIPER REMOVAL

Installation is in the reverse order of removal.

AFTER INSTALLATION, FILL BRAKE RESERVOIR WITH

BRAKE FLUID, BLEED BRAKE SYSTEM (See page BR±7)

AND CHECK FOR LEAKS

1. DISCONNECT BRAKE HOSE

(a) Remove the union bolt and 2 gaskets from the brake caliper,

then disconnect the brake hose from the brake caliper.

Torque: 29 NVm (300 kgfVcm, 21 ftVlbf)

INSTALLATION HINT: Install the flexible hose lock securely

in the lock hole in the caliper.

(b) Use a container to catch the brake fluid as it drains out.

2. REMOVE CALIPER

(a) Hold the sliding pin and loosen the 2 installation bolts.

Torque: 34 NVm (350 kgfVcm, 25 ftVlbf)

(b) Remove the 2 installation bolts.

(c) Remove the caliper from the torque plate.

3. REMOVE THESE PARTS:

(a) 2 anti±squeal springs

(b) 2 brake pads with anti±squeal shims

± BRAKE SYSTEMFRONT BRAKE (2JZ±GE)BR±19

Page 889 of 2543

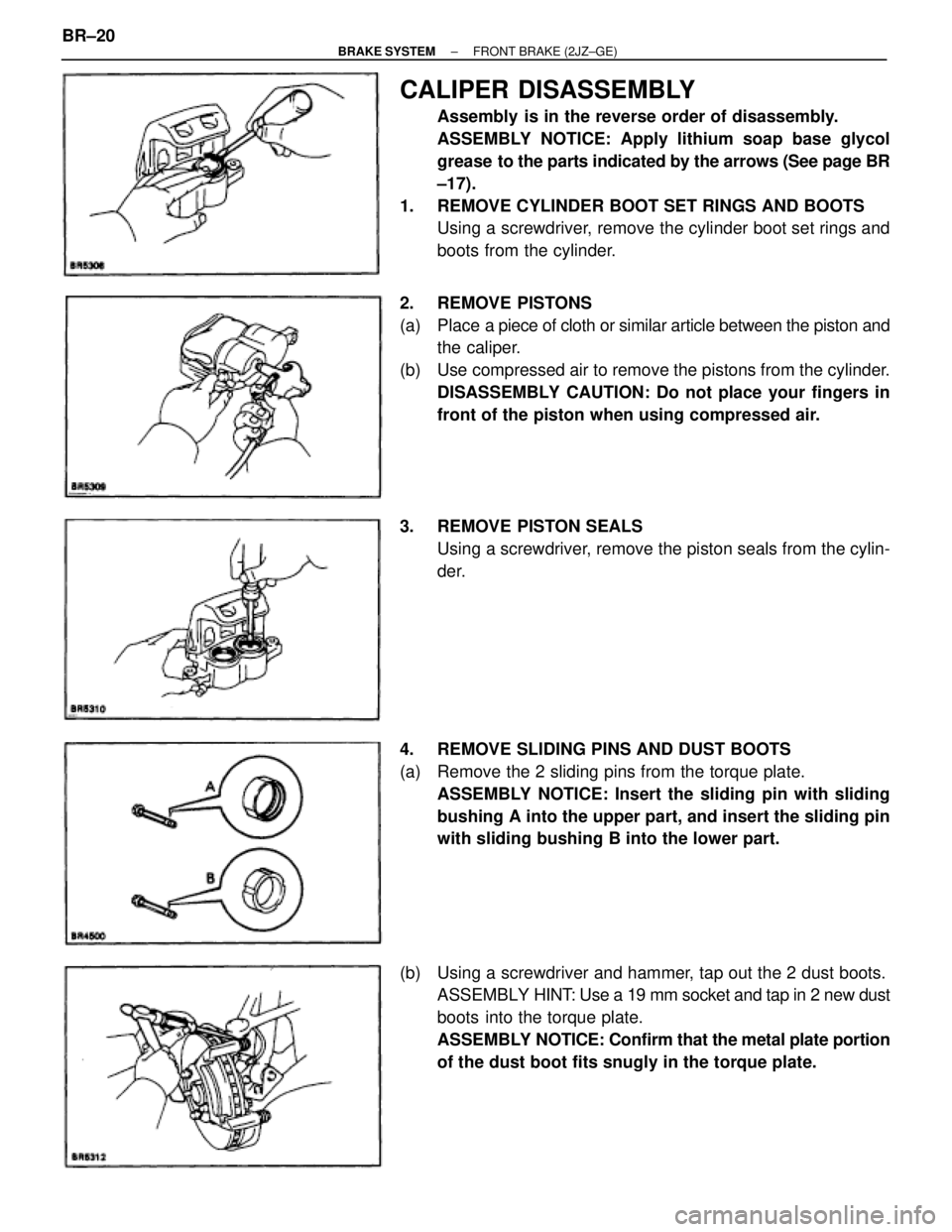

CALIPER DISASSEMBLY

Assembly is in the reverse order of disassembly.

ASSEMBLY NOTICE: Apply lithium soap base glycol

grease to the parts indicated by the arrows (See page BR

±17).

1. REMOVE CYLINDER BOOT SET RINGS AND BOOTS

Using a screwdriver, remove the cylinder boot set rings and

boots from the cylinder.

2. REMOVE PISTONS

(a) Place a piece of cloth or similar article between the piston and

the caliper.

(b) Use compressed air to remove the pistons from the cylinder.

DISASSEMBLY CAUTION: Do not place your fingers in

front of the piston when using compressed air.

3. REMOVE PISTON SEALS

Using a screwdriver, remove the piston seals from the cylin-

der.

4. REMOVE SLIDING PINS AND DUST BOOTS

(a) Remove the 2 sliding pins from the torque plate.

ASSEMBLY NOTICE: Insert the sliding pin with sliding

bushing A into the upper part, and insert the sliding pin

with sliding bushing B into the lower part.

(b) Using a screwdriver and hammer, tap out the 2 dust boots.

ASSEMBLY HINT: Use a 19 mm socket and tap in 2 new dust

boots into the torque plate.

ASSEMBLY NOTICE: Confirm that the metal plate portion

of the dust boot fits snugly in the torque plate. BR±20

± BRAKE SYSTEMFRONT BRAKE (2JZ±GE)

Page 890 of 2543

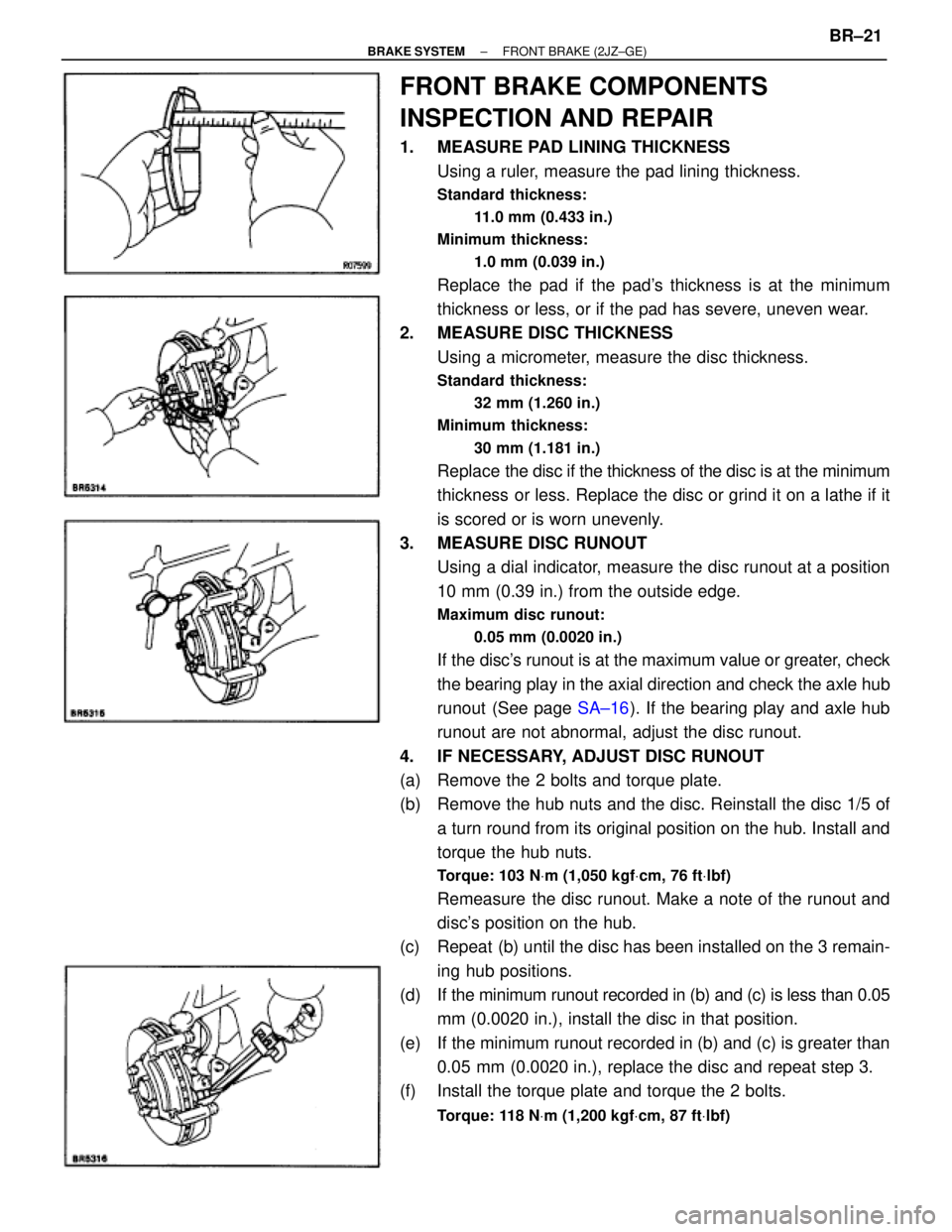

FRONT BRAKE COMPONENTS

INSPECTION AND REPAIR

1. MEASURE PAD LINING THICKNESS

Using a ruler, measure the pad lining thickness.

Standard thickness:

11.0 mm (0.433 in.)

Minimum thickness:

1.0 mm (0.039 in.)

Replace the pad if the pad's thickness is at the minimum

thickness or less, or if the pad has severe, uneven wear.

2. MEASURE DISC THICKNESS

Using a micrometer, measure the disc thickness.

Standard thickness:

32 mm (1.260 in.)

Minimum thickness:

30 mm (1.181 in.)

Replace the disc if the thickness of the disc is at the minimum

thickness or less. Replace the disc or grind it on a lathe if it

is scored or is worn unevenly.

3. MEASURE DISC RUNOUT

Using a dial indicator, measure the disc runout at a position

10 mm (0.39 in.) from the outside edge.

Maximum disc runout:

0.05 mm (0.0020 in.)

If the disc's runout is at the maximum value or greater, check

the bearing play in the axial direction and check the axle hub

runout (See page SA±16). If the bearing play and axle hub

runout are not abnormal, adjust the disc runout.

4. IF NECESSARY, ADJUST DISC RUNOUT

(a) Remove the 2 bolts and torque plate.

(b) Remove the hub nuts and the disc. Reinstall the disc 1/5 of

a turn round from its original position on the hub. Install and

torque the hub nuts.

Torque: 103 NVm (1,050 kgfVcm, 76 ftVlbf)

Remeasure the disc runout. Make a note of the runout and

disc's position on the hub.

(c) Repeat (b) until the disc has been installed on the 3 remain-

ing hub positions.

(d) If the minimum runout recorded in (b) and (c) is less than 0.05

mm (0.0020 in.), install the disc in that position.

(e) If the minimum runout recorded in (b) and (c) is greater than

0.05 mm (0.0020 in.), replace the disc and repeat step 3.

(f) Install the torque plate and torque the 2 bolts.

Torque: 118 NVm (1,200 kgfVcm, 87 ftVlbf)

± BRAKE SYSTEMFRONT BRAKE (2JZ±GE)BR±21