check engine TOYOTA SUPRA 1995 Service Manual Online

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1995, Model line: SUPRA, Model: TOYOTA SUPRA 1995Pages: 2543, PDF Size: 53.25 MB

Page 1043 of 2543

wConnect the positive (+) probe of the ammeter to

terminal B of the generator.

wConnect the positive (+) probe of the voltmeter to

terminal B of the generator.

wGround the negative (±) probe of the voltmeter.

(b) Check the charging circuit as follows:

With the engine running from idling to 2,000 rpm, check the

reading on the ammeter and voltmeter:

Standard amperage:

10 A or less

Standard voltage:

At 25°C (77°F)

13.6±14.8 V

At 115°C (239°F)

S13.2±14.0 V

If the voltmeter reading is more than standard voltage, re-

place the voltage regulator.

If the voltmeter reading is less than standard voltage, check

the voltage regulator and generator as follows:

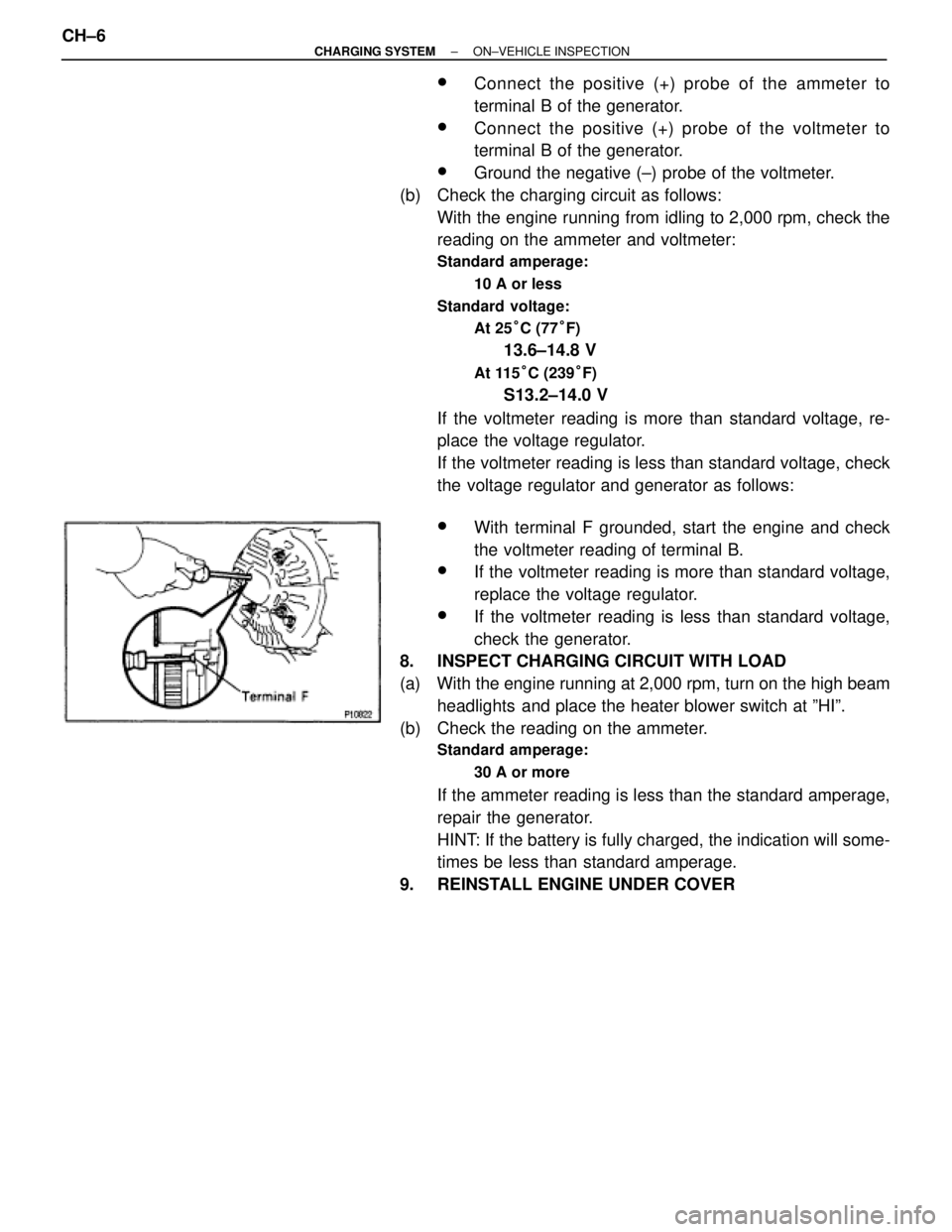

wWith terminal F grounded, start the engine and check

the voltmeter reading of terminal B.

wIf the voltmeter reading is more than standard voltage,

replace the voltage regulator.

wIf the voltmeter reading is less than standard voltage,

check the generator.

8. INSPECT CHARGING CIRCUIT WITH LOAD

(a) With the engine running at 2,000 rpm, turn on the high beam

headlights and place the heater blower switch at ºHIº.

(b) Check the reading on the ammeter.

Standard amperage:

30 A or more

If the ammeter reading is less than the standard amperage,

repair the generator.

HINT: If the battery is fully charged, the indication will some-

times be less than standard amperage.

9. REINSTALL ENGINE UNDER COVER CH±6

± CHARGING SYSTEMON±VEHICLE INSPECTION

Page 1060 of 2543

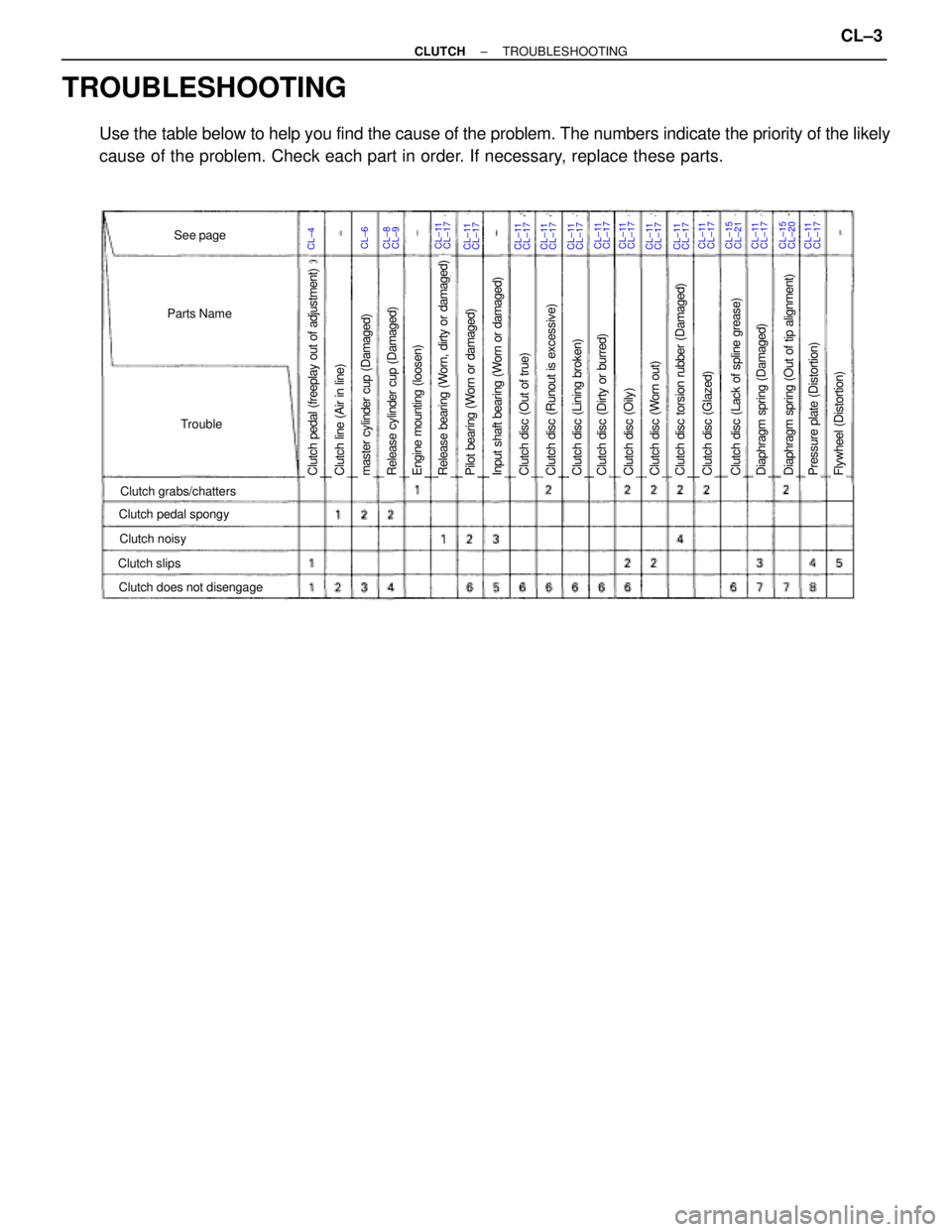

TROUBLESHOOTING

Use the table below to help you find the cause of the problem. The numbers indicate the priority of the likely

cause of the problem. Check each part in order. If necessary, replace these parts.

CL±4CL±6CL±11See page

Parts Name

Trouble

Clutch grabs/chatters

Clutch noisy

Clutch slips

Clutch pedal spongy

Clutch does not disengage

Clutch pedal (freeplay out of adjustment)Pilot bearing (Worn or damaged)Release bearing (Worn, dirty or damaged)Engine mounting (loosen)Release cylinder cup (Damaged)master cylinder cup (Damaged)Clutch line (Air in line)Clutch disc (Dirty or burred)Clutch disc (Oily)Clutch disc (Worn out)Clutch disc torsion rubber (Damaged)Clutch disc (Out of true)Input shaft bearing (Worn or damaged)Clutch disc (Lining broken)Clutch disc (Runout is excessive)Clutch disc (Lack of spline grease)Diaphragm spring (Damaged)Clutch disc (Glazed)Diaphragm spring (Out of tip alignment)Pressure plate (Distortion)Flywheel (Distortion)

CL±17CL±8CL±9CL±11CL±17CL±11CL±17CL±11CL±17CL±11CL±17CL±11CL±17CL±11CL±17CL±11CL±17CL±11CL±17CL±11CL±17CL±15CL±21CL±11CL±17CL±15CL±20CL±11CL±17

± CLUTCHTROUBLESHOOTINGCL±3

Page 1061 of 2543

CLUTCH PEDAL

CLUTCH PEDAL CHECK AND ADJUSTMENT

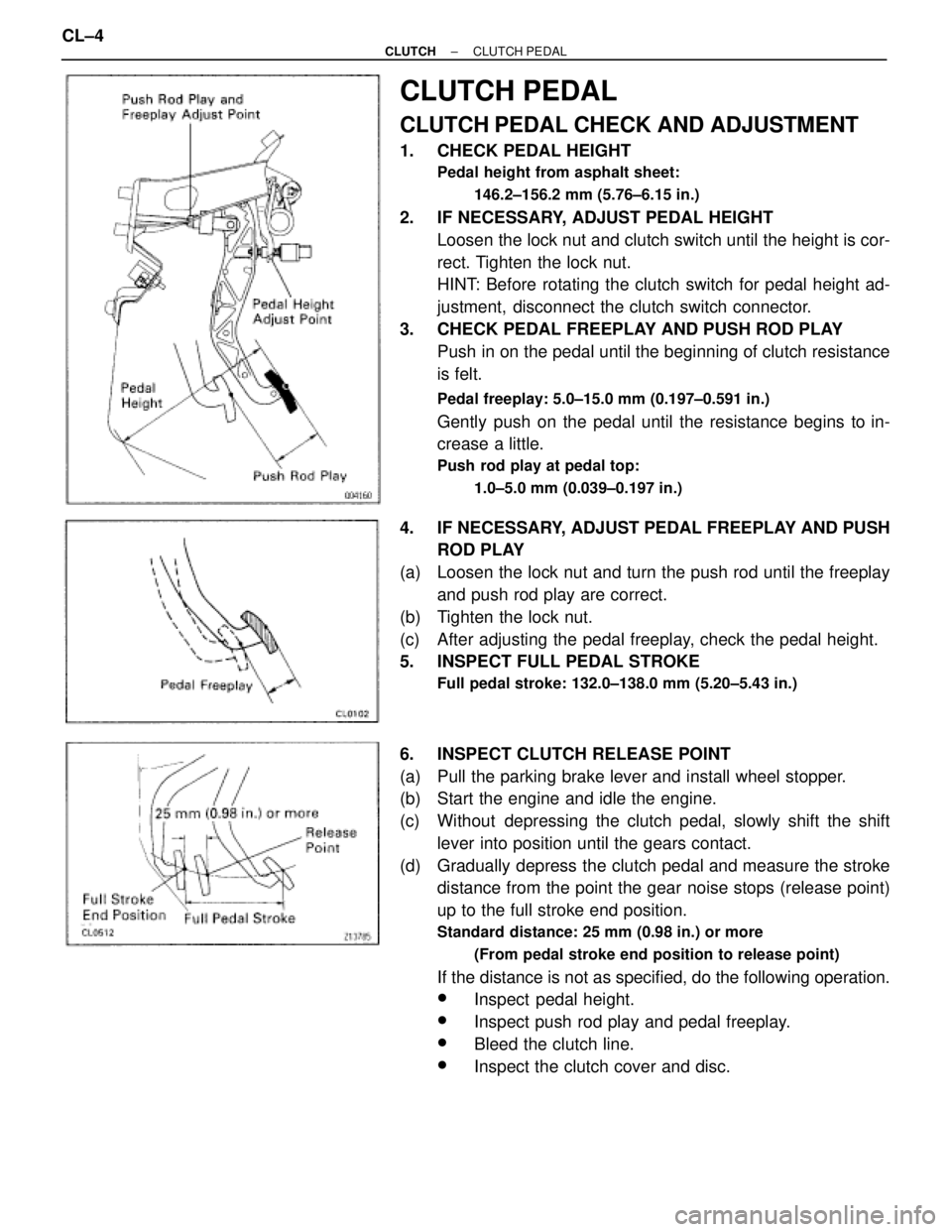

1. CHECK PEDAL HEIGHT

Pedal height from asphalt sheet:

146.2±156.2 mm (5.76±6.15 in.)

2. IF NECESSARY, ADJUST PEDAL HEIGHT

Loosen the lock nut and clutch switch until the height is cor-

rect. Tighten the lock nut.

HINT: Before rotating the clutch switch for pedal height ad-

justment, disconnect the clutch switch connector.

3. CHECK PEDAL FREEPLAY AND PUSH ROD PLAY

Push in on the pedal until the beginning of clutch resistance

is felt.

Pedal freeplay: 5.0±15.0 mm (0.197±0.591 in.)

Gently push on the pedal until the resistance begins to in-

crease a little.

Push rod play at pedal top:

1.0±5.0 mm (0.039±0.197 in.)

4. IF NECESSARY, ADJUST PEDAL FREEPLAY AND PUSH

ROD PLAY

(a) Loosen the lock nut and turn the push rod until the freeplay

and push rod play are correct.

(b) Tighten the lock nut.

(c) After adjusting the pedal freeplay, check the pedal height.

5. INSPECT FULL PEDAL STROKE

Full pedal stroke: 132.0±138.0 mm (5.20±5.43 in.)

6. INSPECT CLUTCH RELEASE POINT

(a) Pull the parking brake lever and install wheel stopper.

(b) Start the engine and idle the engine.

(c) Without depressing the clutch pedal, slowly shift the shift

lever into position until the gears contact.

(d) Gradually depress the clutch pedal and measure the stroke

distance from the point the gear noise stops (release point)

up to the full stroke end position.

Standard distance: 25 mm (0.98 in.) or more

(From pedal stroke end position to release point)

If the distance is not as specified, do the following operation.

wInspect pedal height.

wInspect push rod play and pedal freeplay.

wBleed the clutch line.

wInspect the clutch cover and disc. CL±4

± CLUTCHCLUTCH PEDAL

Page 1062 of 2543

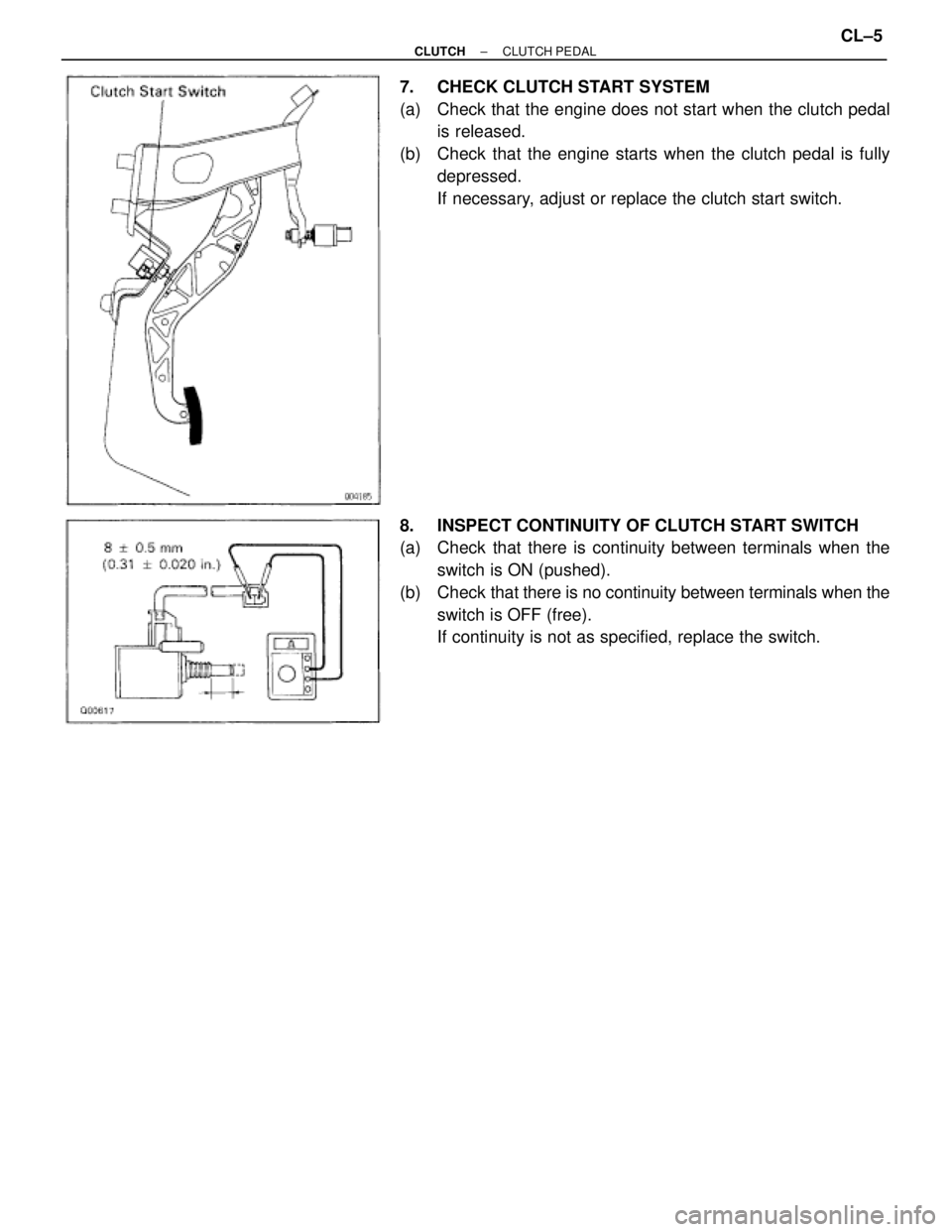

7. CHECK CLUTCH START SYSTEM

(a) Check that the engine does not start when the clutch pedal

is released.

(b) Check that the engine starts when the clutch pedal is fully

depressed.

If necessary, adjust or replace the clutch start switch.

8. INSPECT CONTINUITY OF CLUTCH START SWITCH

(a) Check that there is continuity between terminals when the

switch is ON (pushed).

(b) Check that there is no continuity between terminals when the

switch is OFF (free).

If continuity is not as specified, replace the switch.

± CLUTCHCLUTCH PEDALCL±5

Page 1075 of 2543

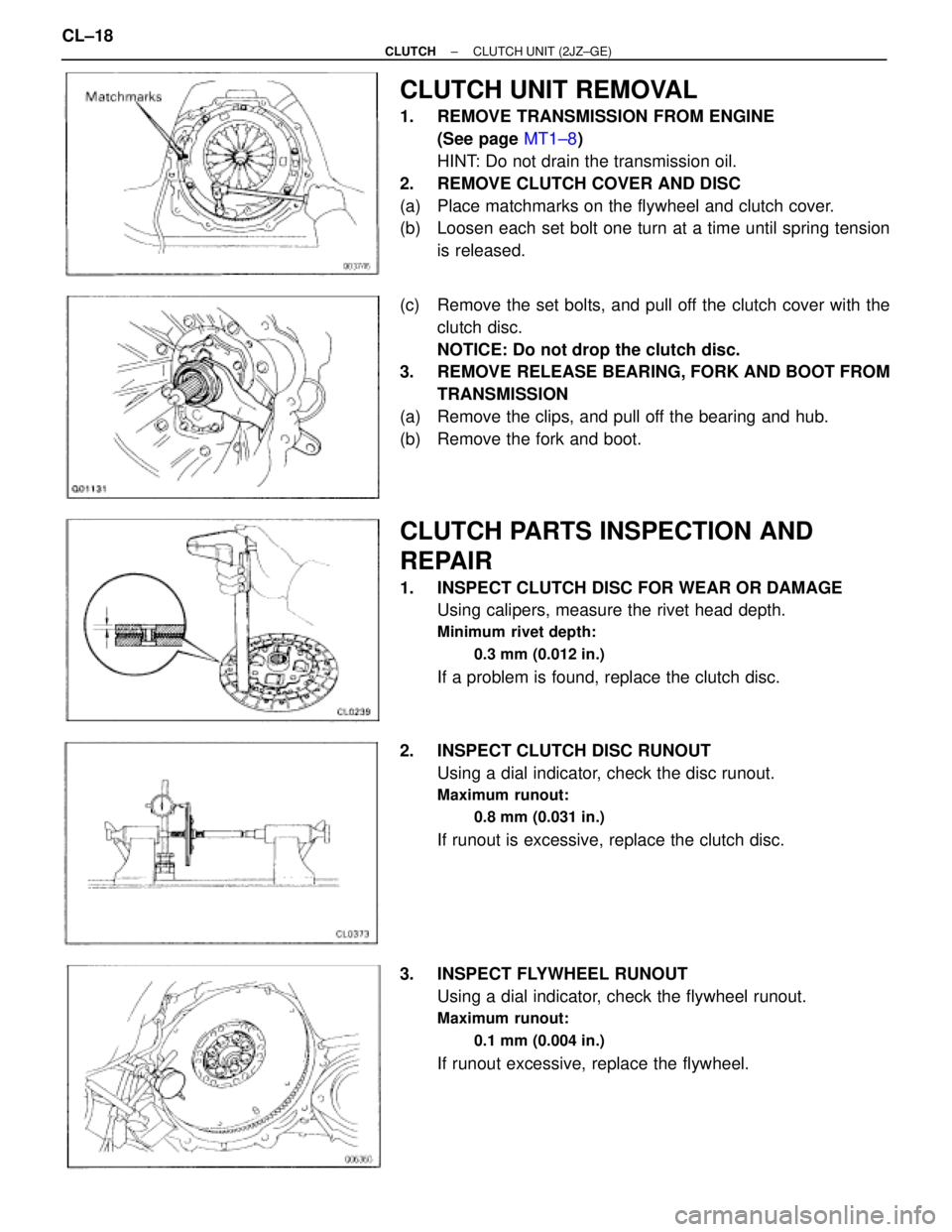

CLUTCH UNIT REMOVAL

1. REMOVE TRANSMISSION FROM ENGINE

(See page MT1±8)

HINT: Do not drain the transmission oil.

2. REMOVE CLUTCH COVER AND DISC

(a) Place matchmarks on the flywheel and clutch cover.

(b) Loosen each set bolt one turn at a time until spring tension

is released.

(c) Remove the set bolts, and pull off the clutch cover with the

clutch disc.

NOTICE: Do not drop the clutch disc.

3. REMOVE RELEASE BEARING, FORK AND BOOT FROM

TRANSMISSION

(a) Remove the clips, and pull off the bearing and hub.

(b) Remove the fork and boot.

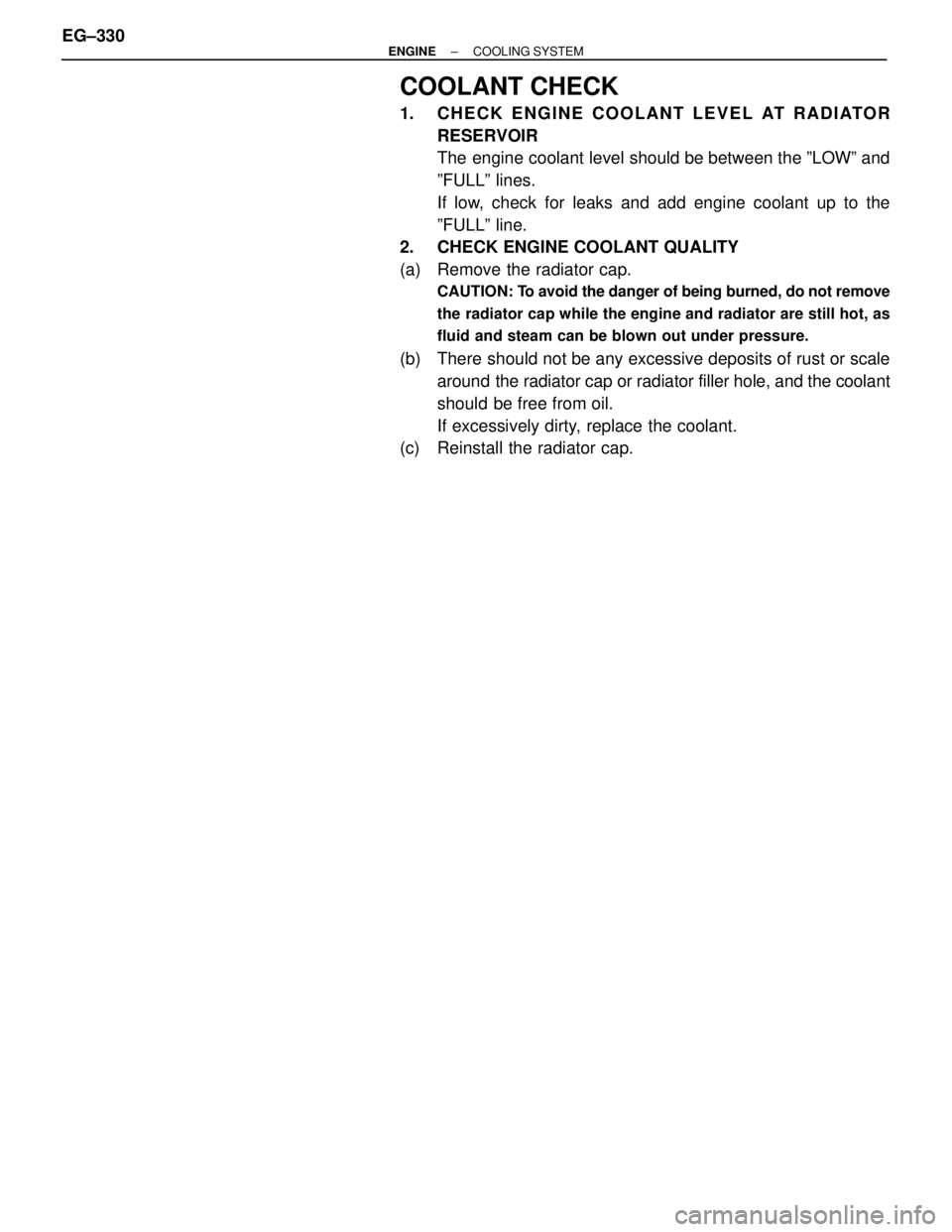

CLUTCH PARTS INSPECTION AND

REPAIR

1. INSPECT CLUTCH DISC FOR WEAR OR DAMAGE

Using calipers, measure the rivet head depth.

Minimum rivet depth:

0.3 mm (0.012 in.)

If a problem is found, replace the clutch disc.

2. INSPECT CLUTCH DISC RUNOUT

Using a dial indicator, check the disc runout.

Maximum runout:

0.8 mm (0.031 in.)

If runout is excessive, replace the clutch disc.

3. INSPECT FLYWHEEL RUNOUT

Using a dial indicator, check the flywheel runout.

Maximum runout:

0.1 mm (0.004 in.)

If runout excessive, replace the flywheel. CL±18

± CLUTCHCLUTCH UNIT (2JZ±GE)

Page 1081 of 2543

COOLANT CHECK

1. CHECK ENGINE COOLANT LEVEL AT RADIATOR

RESERVOIR

The engine coolant level should be between the ºLOWº and

ºFULLº lines.

If low, check for leaks and add engine coolant up to the

ºFULLº line.

2. CHECK ENGINE COOLANT QUALITY

(a) Remove the radiator cap.

CAUTION: To avoid the danger of being burned, do not remove

the radiator cap while the engine and radiator are still hot, as

fluid and steam can be blown out under pressure.

(b) There should not be any excessive deposits of rust or scale

around the radiator cap or radiator filler hole, and the coolant

should be free from oil.

If excessively dirty, replace the coolant.

(c) Reinstall the radiator cap. EG±330

± ENGINECOOLING SYSTEM

Page 1082 of 2543

COOLANT REPLACEMENT

1. DRAIN ENGINE COOLANT

(a) Remove the radiator cap.

CAUTION: To avoid the danger of being burned, do not remove

the radiator cap while the engine and radiator are still hot, as

fluid and steam can be blown out under pressure.

(b) Loosen the 2 drain plugs (for the engine and radiator), and

drain the coolant.

(c) Close the drain plugs.

Torque:

Engine drain plug

29 NVm (300 kgfVcm, 22 ftVlbf)

2. FILL ENGINE COOLANT

(a) Slowly fill the system with coolant.

wUse a good brand of ethylene±glycol base coolant and

mix it according to the manufacturer's directions.

wUsing coolant which includes more than 50 %

ethylene±glycol (but not more than 70 %) is

recommended.

NOTICE:

wDo not use an alcohol type coolant.

wThe coolant should be mixed with demineralized water or

distilled water.

Capacity (w/ Heater):

2JZ±GE

M/T

7.3 liters (7.7 US qts, 6.4 lmp. qts)

A/T

8.3 liters (8.8 US qts, 7.3 lmp. qts)

2JZ±GTE

M/T

9.5 liters (10.0 US qts, 8.4 lmp. qts)

A/T

9.4 liters (9.9 US qts, 8.3 lmp. qts)

(b) Install the radiator cap.

(c) Start the engine, and bleed the cooling system.

(d) Refill the reservoir with coolant until it reaches the ºFULLº

line.

3. CHECK ENGINE COOLANT FOR LEAKS

± ENGINECOOLING SYSTEMEG±331

Page 1087 of 2543

(d) Remove the 2 nuts, and disconnect the No.2 water bypass

pipe from the water pump.

(e) 2JZ±GTE:

Disconnect the No.3 turbo water hose from the water pump.

(f) Remove the 6 bolts, water pump and gasket.

(g) Remove the O±ring from the cylinder block.

WATER PUMP COMPONENTS

INSPECTION

1. INSPECT WATER PUMP

Turn the pulley seat, and check that the water pump bearing

is not rough or noisy.

If necessary, replace the water pump.

2. INSPECT FLUID COUPLING

(a) Remove the 4 nuts and fan from the fluid coupling. EG±336

± ENGINECOOLING SYSTEM

Page 1088 of 2543

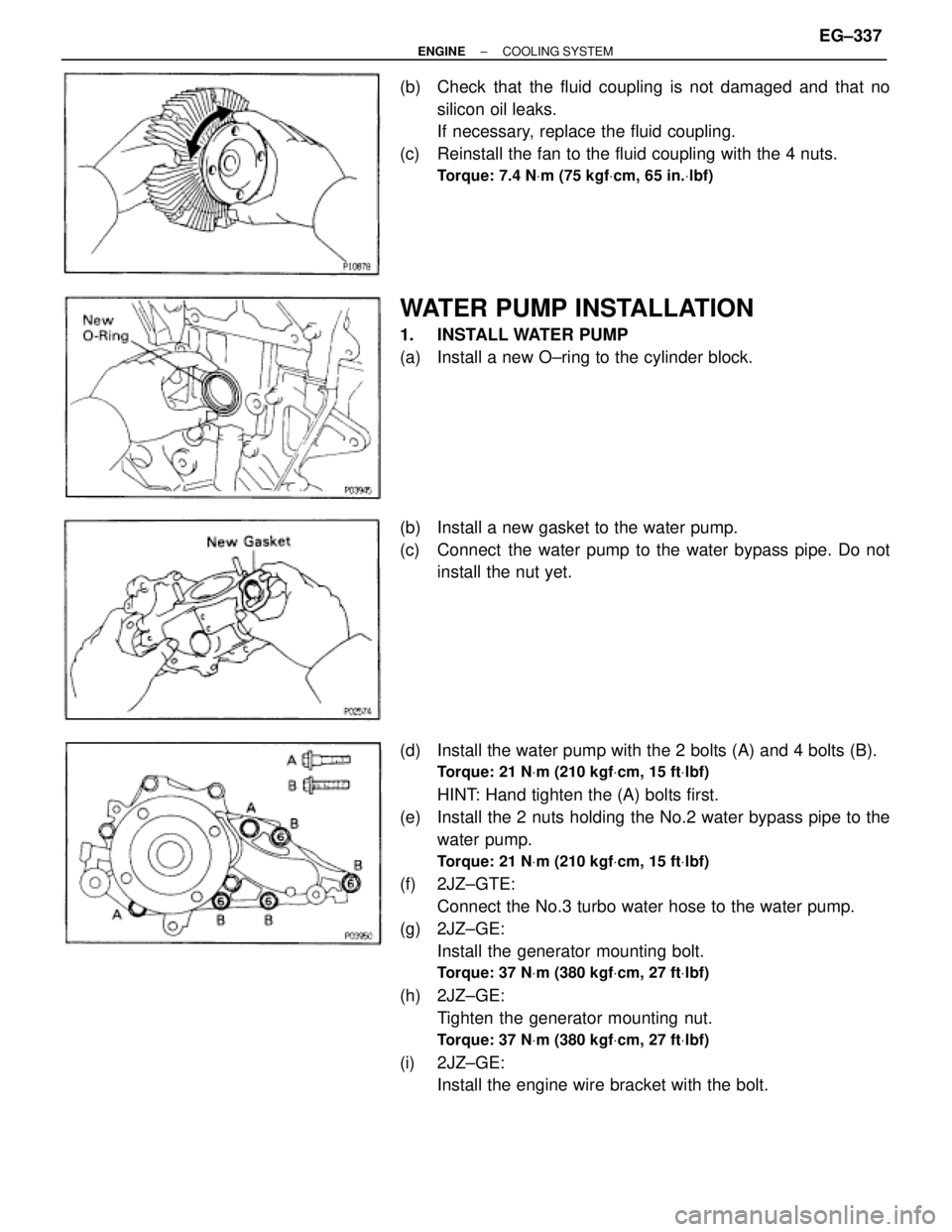

(b) Check that the fluid coupling is not damaged and that no

silicon oil leaks.

If necessary, replace the fluid coupling.

(c) Reinstall the fan to the fluid coupling with the 4 nuts.

Torque: 7.4 NVm (75 kgfVcm, 65 in.Vlbf)

WATER PUMP INSTALLATION

1. INSTALL WATER PUMP

(a) Install a new O±ring to the cylinder block.

(b) Install a new gasket to the water pump.

(c) Connect the water pump to the water bypass pipe. Do not

install the nut yet.

(d) Install the water pump with the 2 bolts (A) and 4 bolts (B).

Torque: 21 NVm (210 kgfVcm, 15 ftVlbf)

HINT: Hand tighten the (A) bolts first.

(e) Install the 2 nuts holding the No.2 water bypass pipe to the

water pump.

Torque: 21 NVm (210 kgfVcm, 15 ftVlbf)

(f) 2JZ±GTE:

Connect the No.3 turbo water hose to the water pump.

(g) 2JZ±GE:

Install the generator mounting bolt.

Torque: 37 NVm (380 kgfVcm, 27 ftVlbf)

(h) 2JZ±GE:

Tighten the generator mounting nut.

Torque: 37 NVm (380 kgfVcm, 27 ftVlbf)

(i) 2JZ±GE:

Install the engine wire bracket with the bolt.

± ENGINECOOLING SYSTEMEG±337

Page 1090 of 2543

11. 2JZ±GTE M/T:

INSTALL DRIVE BELT TENSIONER DAMPER

12. INSTALL RADIATOR ASSEMBLY

(See radiator installation)

13. 2JZ±GE:

INSTALL AIR CLEANER, VAF METER AND INTAKE AIR

CONNECTOR PIPE ASSEMBLY

14. 2JZ±GTE:

INSTALL AIR CLEANER AND MAF METER ASSEMBLY

15. 2JZ±GTE:

INSTALL NO.1 AIR HOSE

16. ROAD TEST VEHICLE

Check for abnormal noise, shock, slippage, correct shift

points and smooth operation.

± ENGINECOOLING SYSTEMEG±339