check engine light TOYOTA T100 1996 Factory Service Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: T100, Model: TOYOTA T100 1996Pages: 2062, PDF Size: 43.47 MB

Page 1877 of 2062

Downloaded from www.Manualslib.com manuals search engine Z09691

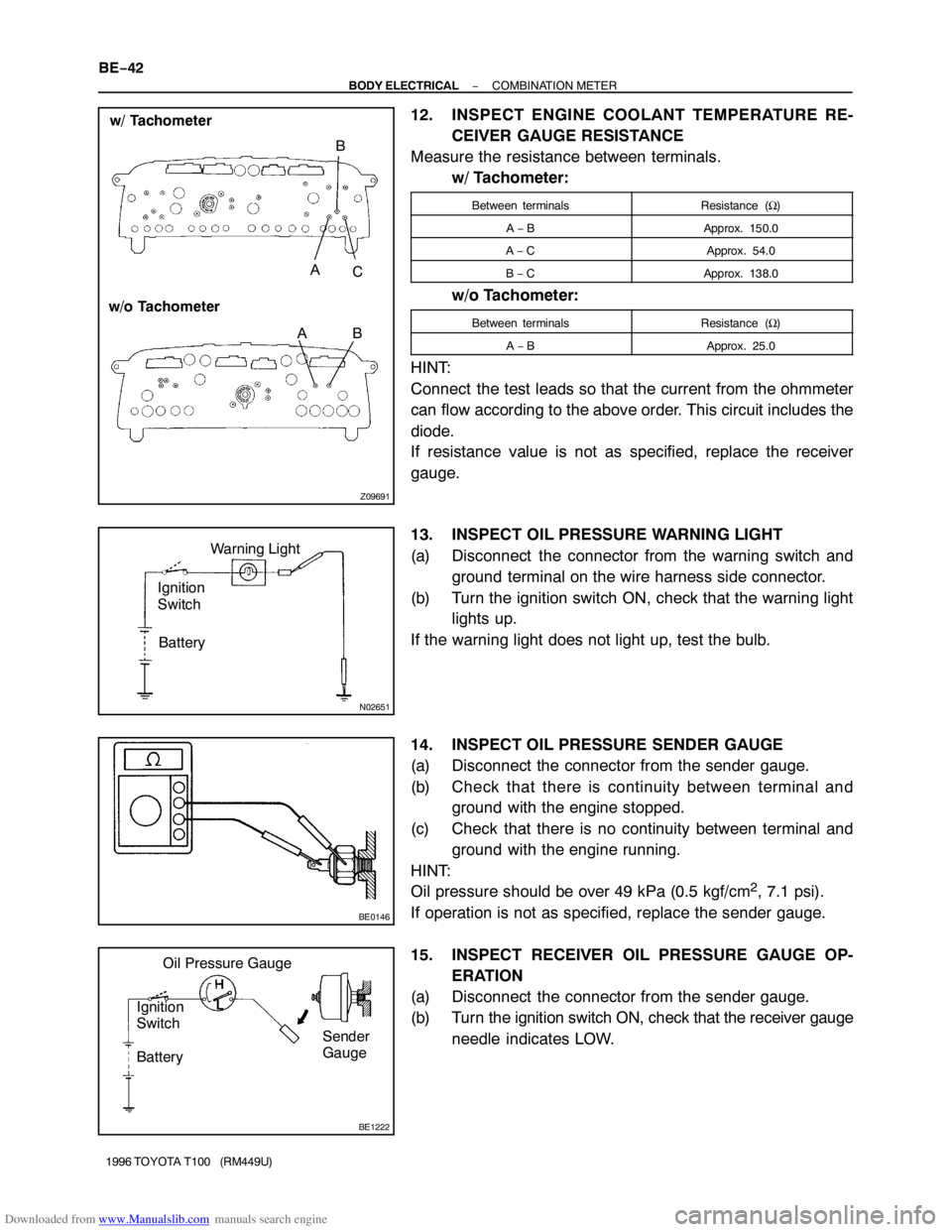

w/ Tachometer

w/o TachometerB

A

C

B A

N02651

Warning Light

Ignition

Switch

Battery

BE0146

BE1222

Oil Pressure Gauge

Ignition

Switch

BatterySender

Gauge BE−42

− BODY ELECTRICALCOMBINATION METER

1996 TOYOTA T100 (RM449U)

12. INSPECT ENGINE COOLANT TEMPERATURE RE-

CEIVER GAUGE RESISTANCE

Measure the resistance between terminals.

w/ Tachometer:

Between terminalsResistance (Ω)

A − BApprox. 150.0

A − CApprox. 54.0

B − CApprox. 138.0

w/o Tachometer:

Between terminalsResistance (Ω)

A − BApprox. 25.0

HINT:

Connect the test leads so that the current from the ohmmeter

can flow according to the above order. This circuit includes the

diode.

If resistance value is not as specified, replace the receiver

gauge.

13. INSPECT OIL PRESSURE WARNING LIGHT

(a) Disconnect the connector from the warning switch and

ground terminal on the wire harness side connector.

(b) Turn the ignition switch ON, check that the warning light

lights up.

If the warning light does not light up, test the bulb.

14. INSPECT OIL PRESSURE SENDER GAUGE

(a) Disconnect the connector from the sender gauge.

(b) Check that there is continuity between terminal and

ground with the engine stopped.

(c) Check that there is no continuity between terminal and

ground with the engine running.

HINT:

Oil pressure should be over 49 kPa (0.5 kgf/cm

2, 7.1 psi).

If operation is not as specified, replace the sender gauge.

15. INSPECT RECEIVER OIL PRESSURE GAUGE OP-

ERATION

(a) Disconnect the connector from the sender gauge.

(b) Turn the ignition switch ON, check that the receiver gauge

needle indicates LOW.

Page 1878 of 2062

Downloaded from www.Manualslib.com manuals search engine N06234

Oil Pressure Gauge

Ignition

Switch

BatteryTest Bulb

(3.4W)

Z09833

w/ TachometerAB

BE4917

Test LED

Battery

BE1217

Ignition

Switch

BatteryWarning Light

BE2570

ONOFF

− BODY ELECTRICALCOMBINATION METER

BE−43

1996 TOYOTA T100 (RM449U)

(c) Ground terminal on the wire harness side connector

through a 3.4 W test bulb.

(d) Turn the ignition ON, check that the bulb lights up and the

receiver gauge needle moves to the high side.

If resistance value is not as specified, replace the receiver

gauge.

16. INSPECT OIL PRESSURE RECEIVER GAUGE RESIS-

TANCE

Measure the resistance between terminals A and B.

Resistance: Approx. 25.0 Ω

If resistance value is not as specified, replace the receiver

gauge.

17. INSPECT OIL PRESSURE SENDER GAUGE OPERA-

TION

(a) Disconnect the connector from the sender gauge.

(b) Apply battery positive voltage to the sender gauge termi-

nal through a test LED.

(c) Check that the bulb does not light when the engine is

stopped.

(d) Check that the LED flashes when the engine is running.

The number of flashes should vary with the engine speed.

If operation is not as specified, replace the sender gauge.

18. INSPECT BRAKE WARNING LIGHT

(a) Disconnect the connectors from the level warning switch

and parking brake switch.

(b) Connect terminals on the wire harness side connector of

the level warning switch connector.

(c) Turn the ignition switch ON, check that the warning light

lights up.

If the warning light does not light up, test the bulb.

19. INSPECT BRAKE FLUID LEVEL WARNING SWITCH

(a) Check that there is no continuity between terminals with

the switch OFF (float up).

(b) Check that there is continuity between terminals with the

switch ON (float down).

If operation is not as specified, replace the switch.

Page 1879 of 2062

Downloaded from www.Manualslib.com manuals search engine N06136

ON

OFF

BE1217

Warning Light

Ignition

Switch

Battery

N07797

ONOFF

N13155

Warning Light

Ignition

Switch

Battery

N06137

ON

OFF BE−44

− BODY ELECTRICALCOMBINATION METER

1996 TOYOTA T100 (RM449U)

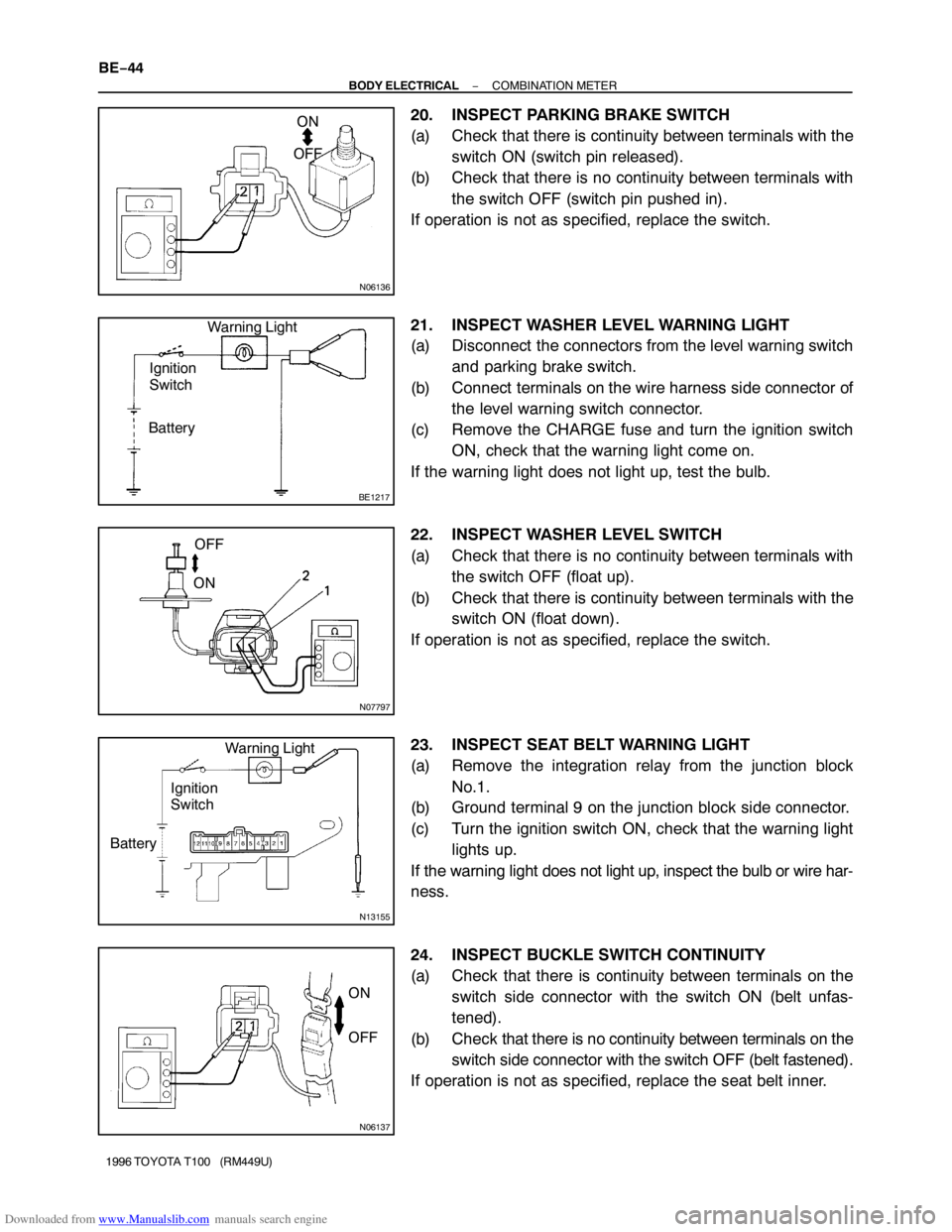

20. INSPECT PARKING BRAKE SWITCH

(a) Check that there is continuity between terminals with the

switch ON (switch pin released).

(b) Check that there is no continuity between terminals with

the switch OFF (switch pin pushed in).

If operation is not as specified, replace the switch.

21. INSPECT WASHER LEVEL WARNING LIGHT

(a) Disconnect the connectors from the level warning switch

and parking brake switch.

(b) Connect terminals on the wire harness side connector of

the level warning switch connector.

(c) Remove the CHARGE fuse and turn the ignition switch

ON, check that the warning light come on.

If the warning light does not light up, test the bulb.

22. INSPECT WASHER LEVEL SWITCH

(a) Check that there is no continuity between terminals with

the switch OFF (float up).

(b) Check that there is continuity between terminals with the

switch ON (float down).

If operation is not as specified, replace the switch.

23. INSPECT SEAT BELT WARNING LIGHT

(a) Remove the integration relay from the junction block

No.1.

(b) Ground terminal 9 on the junction block side connector.

(c) Turn the ignition switch ON, check that the warning light

lights up.

If the warning light does not light up, inspect the bulb or wire har-

ness.

24. INSPECT BUCKLE SWITCH CONTINUITY

(a) Check that there is continuity between terminals on the

switch side connector with the switch ON (belt unfas-

tened).

(b) Check that there is no continuity between terminals on the

switch side connector with the switch OFF (belt fastened).

If operation is not as specified, replace the seat belt inner.

Page 1880 of 2062

Downloaded from www.Manualslib.com manuals search engine N12611

N12612

Z04393

4WD Indicator Light

(Wire Harness Side) Ignition

Switch

Battery

BE3241

OFF

ON

Z04394

Test Bulb

(3.4W)

Bright

Extinguished

Dark

− BODY ELECTRICALCOMBINATION METER

BE−45

1996 TOYOTA T100 (RM449U)

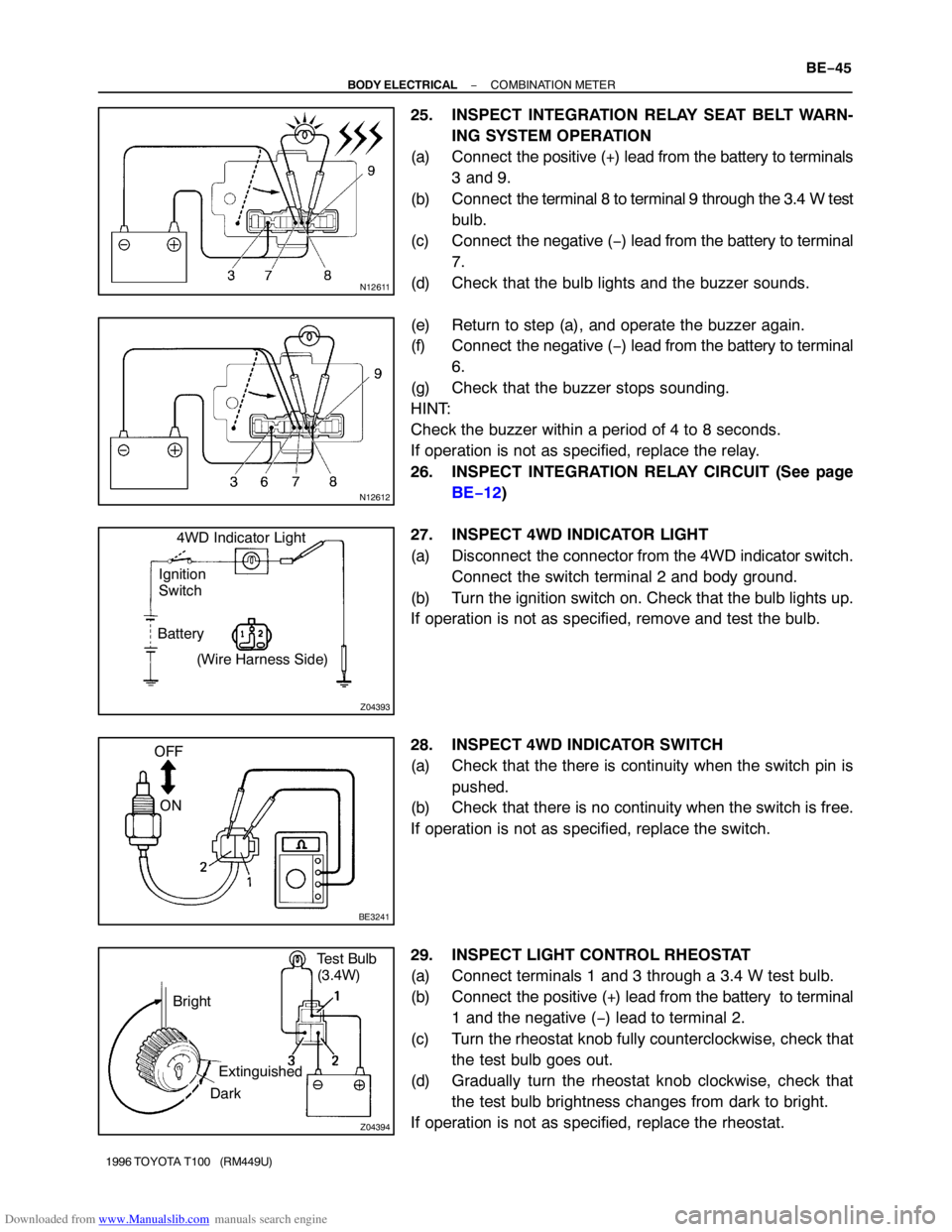

25. INSPECT INTEGRATION RELAY SEAT BELT WARN-

ING SYSTEM OPERATION

(a) Connect the positive (+) lead from the battery to terminals

3 and 9.

(b) Connect the terminal 8 to terminal 9 through the 3.4 W test

bulb.

(c) Connect the negative (−) lead from the battery to terminal

7.

(d) Check that the bulb lights and the buzzer sounds.

(e) Return to step (a), and operate the buzzer again.

(f) Connect the negative (−) lead from the battery to terminal

6.

(g) Check that the buzzer stops sounding.

HINT:

Check the buzzer within a period of 4 to 8 seconds.

If operation is not as specified, replace the relay.

26. INSPECT INTEGRATION RELAY CIRCUIT (See page

BE−12)

27. INSPECT 4WD INDICATOR LIGHT

(a) Disconnect the connector from the 4WD indicator switch.

Connect the switch terminal 2 and body ground.

(b) Turn the ignition switch on. Check that the bulb lights up.

If operation is not as specified, remove and test the bulb.

28. INSPECT 4WD INDICATOR SWITCH

(a) Check that the there is continuity when the switch pin is

pushed.

(b) Check that there is no continuity when the switch is free.

If operation is not as specified, replace the switch.

29. INSPECT LIGHT CONTROL RHEOSTAT

(a) Connect terminals 1 and 3 through a 3.4 W test bulb.

(b) Connect the positive (+) lead from the battery to terminal

1 and the negative (−) lead to terminal 2.

(c) Turn the rheostat knob fully counterclockwise, check that

the test bulb goes out.

(d) Gradually turn the rheostat knob clockwise, check that

the test bulb brightness changes from dark to bright.

If operation is not as specified, replace the rheostat.

Page 1892 of 2062

Downloaded from www.Manualslib.com manuals search engine BE03H−03

Z09299

Left/Light

Adjustment

Switch

Control Switch

Z04379

Z04380

− BODY ELECTRICALPOWER MIRROR CONTROL SYSTEM

BE−57

1996 TOYOTA T100 (RM449U)

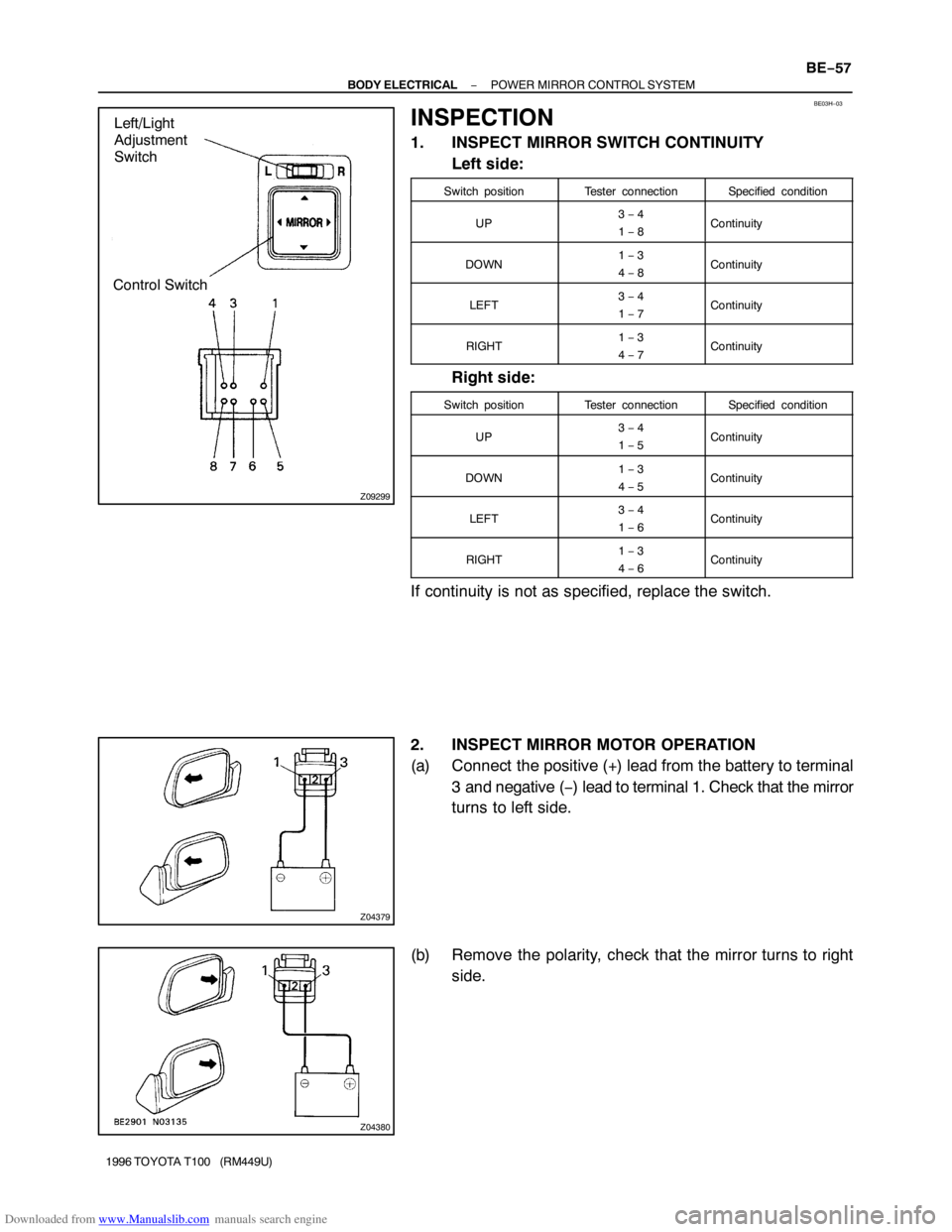

INSPECTION

1. INSPECT MIRROR SWITCH CONTINUITY

Left side:

Switch positionTester connectionSpecified condition

UP3 − 4

1 − 8Continuity

DOWN1 − 3

4 − 8Continuity

LEFT3 − 4

1 − 7Continuity

RIGHT1 − 3

4 − 7Continuity

Right side:

Switch positionTester connectionSpecified condition

UP3 − 4

1 − 5Continuity

DOWN1 − 3

4 − 5Continuity

LEFT3 − 4

1 − 6Continuity

RIGHT1 − 3

4 − 6Continuity

If continuity is not as specified, replace the switch.

2. INSPECT MIRROR MOTOR OPERATION

(a) Connect the positive (+) lead from the battery to terminal

3 and negative (−) lead to terminal 1. Check that the mirror

turns to left side.

(b) Remove the polarity, check that the mirror turns to right

side.

Page 1970 of 2062

Downloaded from www.Manualslib.com manuals search engine BO0FD−02

BO0632

BO0633

15°

45°

N15359

BO−50

− BODYSEAT BELT

1996 TOYOTA T100 (RM449U)

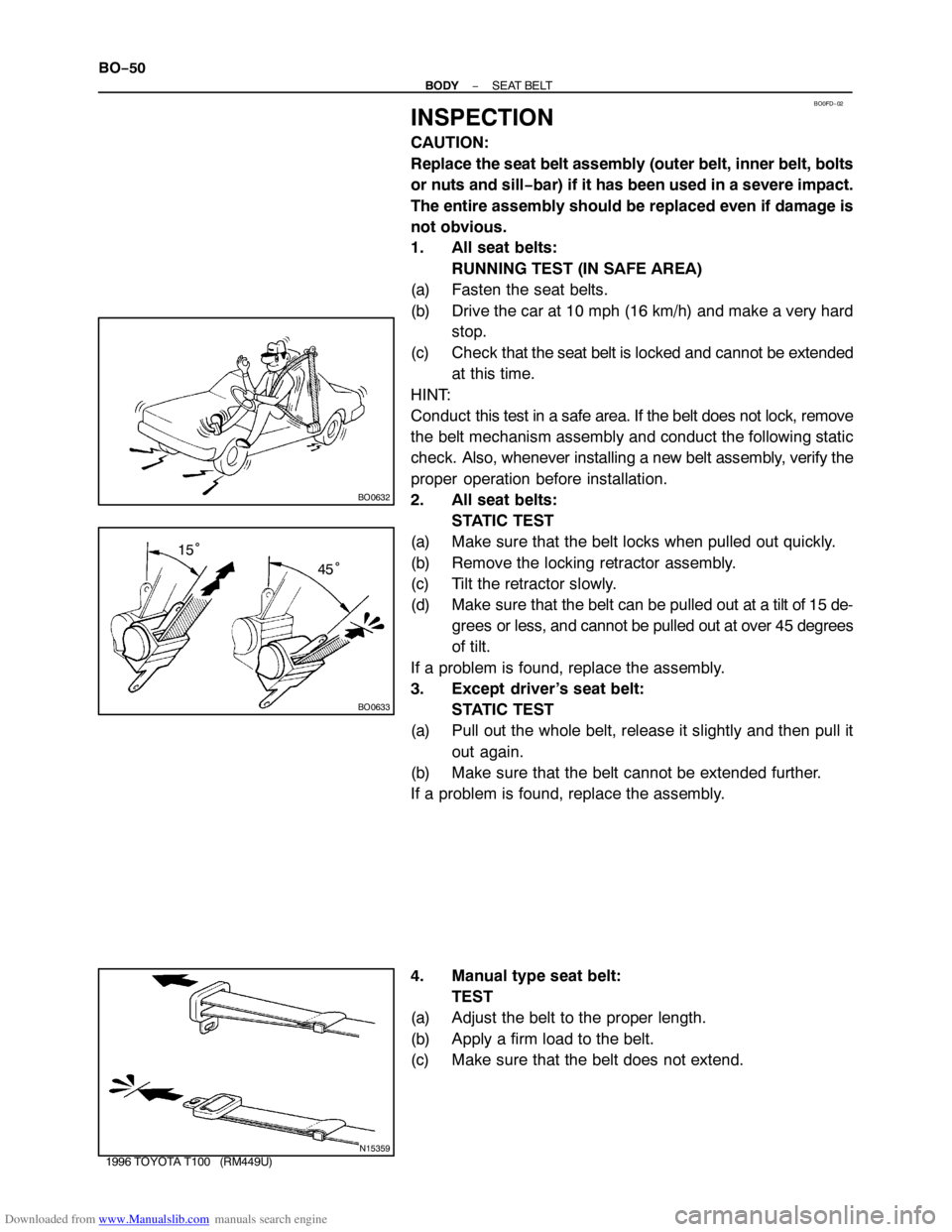

INSPECTION

CAUTION:

Replace the seat belt assembly (outer belt, inner belt, bolts

or nuts and sill−bar) if it has been used in a severe impact.

The entire assembly should be replaced even if damage is

not obvious.

1. All seat belts:

RUNNING TEST (IN SAFE AREA)

(a) Fasten the seat belts.

(b) Drive the car at 10 mph (16 km/h) and make a very hard

stop.

(c) Check that the seat belt is locked and cannot be extended

at this time.

HINT:

Conduct this test in a safe area. If the belt does not lock, remove

the belt mechanism assembly and conduct the following static

check. Also, whenever installing a new belt assembly, verify the

proper operation before installation.

2. All seat belts:

STATIC TEST

(a) Make sure that the belt locks when pulled out quickly.

(b) Remove the locking retractor assembly.

(c) Tilt the retractor slowly.

(d) Make sure that the belt can be pulled out at a tilt of 15 de-

grees or less, and cannot be pulled out at over 45 degrees

of tilt.

If a problem is found, replace the assembly.

3. Except driver’s seat belt:

STATIC TEST

(a) Pull out the whole belt, release it slightly and then pull it

out again.

(b) Make sure that the belt cannot be extended further.

If a problem is found, replace the assembly.

4. Manual type seat belt:

TEST

(a) Adjust the belt to the proper length.

(b) Apply a firm load to the belt.

(c) Make sure that the belt does not extend.

Page 2053 of 2062

Downloaded from www.Manualslib.com manuals search engine AC0GN−02

I02282

OFF ON

64

I02283

OFF ON

6 4

3

Z07777

1

3 4 65

− AIR CONDITIONINGAIR CONDITIONING SWITCH

AC−83

1996 TOYOTA T100 (RM449U)

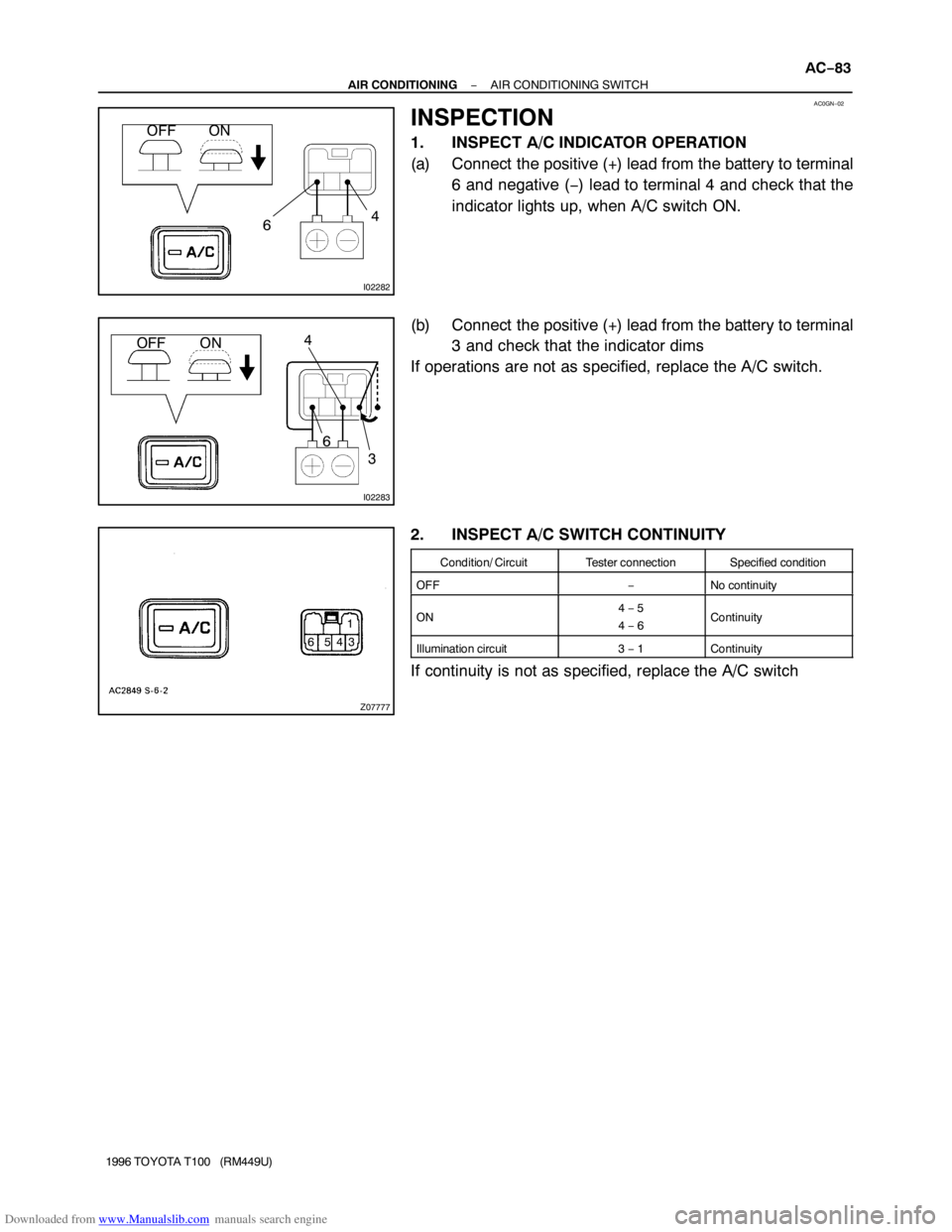

INSPECTION

1. INSPECT A/C INDICATOR OPERATION

(a) Connect the positive (+) lead from the battery to terminal

6 and negative (−) lead to terminal 4 and check that the

indicator lights up, when A/C switch ON.

(b) Connect the positive (+) lead from the battery to terminal

3 and check that the indicator dims

If operations are not as specified, replace the A/C switch.

2. INSPECT A/C SWITCH CONTINUITY

Condition/ CircuitTester connectionSpecified condition

OFF−No continuity

ON4 − 5

4 − 6Continuity

Illumination circuit3 − 1Continuity

If continuity is not as specified, replace the A/C switch

Page 2061 of 2062

Downloaded from www.Manualslib.com manuals search engine AC0GV−02

N05735

FRESH Clamp

RECIRC

N05736

Clamp

DEF

FACE

N05734

Clamp

COOL

WARM

− AIR CONDITIONINGHEATER CONTROL ASSEMBLY

AC−91

1996 TOYOTA T100 (RM449U)

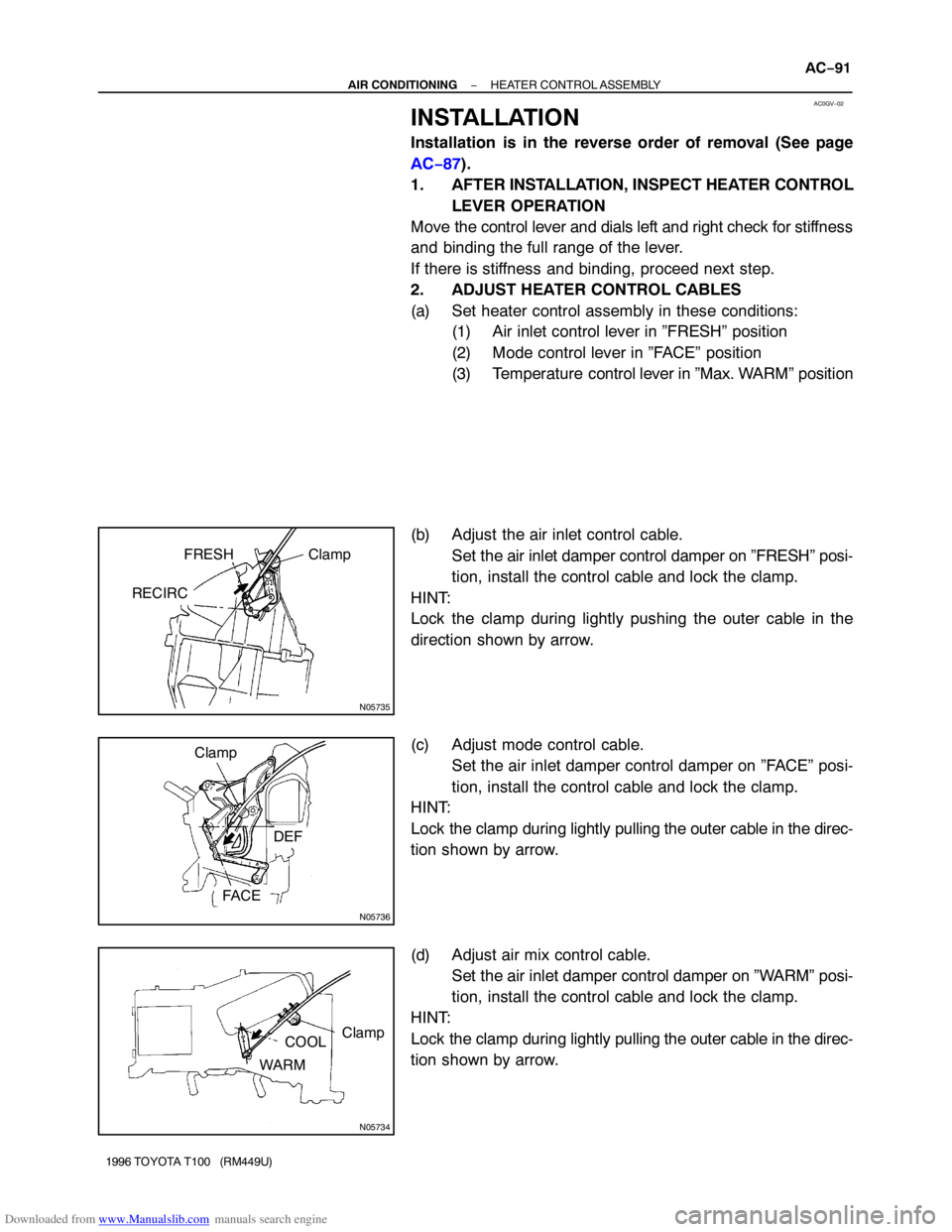

INSTALLATION

Installation is in the reverse order of removal (See page

AC−87).

1. AFTER INSTALLATION, INSPECT HEATER CONTROL

LEVER OPERATION

Move the control lever and dials left and right check for stiffness

and binding the full range of the lever.

If there is stiffness and binding, proceed next step.

2. ADJUST HEATER CONTROL CABLES

(a) Set heater control assembly in these conditions:

(1) Air inlet control lever in ”FRESH” position

(2) Mode control lever in ”FACE” position

(3) Temperature control lever in ”Max. WARM” position

(b) Adjust the air inlet control cable.

Set the air inlet damper control damper on ”FRESH” posi-

tion, install the control cable and lock the clamp.

HINT:

Lock the clamp during lightly pushing the outer cable in the

direction shown by arrow.

(c) Adjust mode control cable.

Set the air inlet damper control damper on ”FACE” posi-

tion, install the control cable and lock the clamp.

HINT:

Lock the clamp during lightly pulling the outer cable in the direc-

tion shown by arrow.

(d) Adjust air mix control cable.

Set the air inlet damper control damper on ”WARM” posi-

tion, install the control cable and lock the clamp.

HINT:

Lock the clamp during lightly pulling the outer cable in the direc-

tion shown by arrow.