engine repair TOYOTA T100 1996 Factory Workshop Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1996, Model line: T100, Model: TOYOTA T100 1996Pages: 2062, PDF Size: 43.47 MB

Page 359 of 2062

Downloaded from www.Manualslib.com manuals search engine BE6653

P24207

P24208

A00083

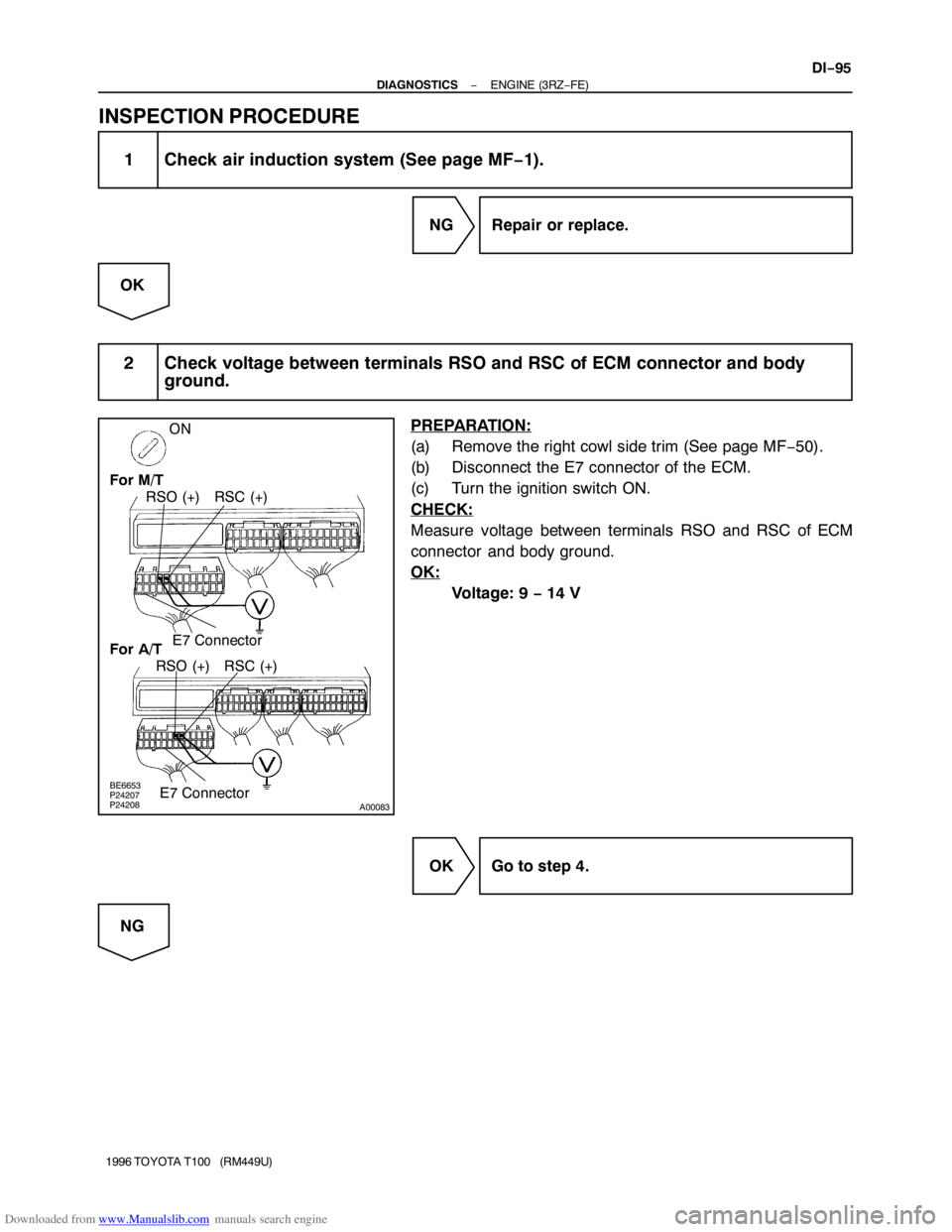

ON

For M/T

RSO (+) RSC (+)

For A/T

RSO (+) RSC (+)E7 Connector

E7 Connector

− DIAGNOSTICSENGINE (3RZ−FE)

DI−95

1996 TOYOTA T100 (RM449U)

INSPECTION PROCEDURE

1 Check air induction system (See page MF−1).

NG Repair or replace.

OK

2 Check voltage between terminals RSO and RSC of ECM connector and body

ground.

PREPARATION:

(a) Remove the right cowl side trim (See page MF−50).

(b) Disconnect the E7 connector of the ECM.

(c) Turn the ignition switch ON.

CHECK:

Measure voltage between terminals RSO and RSC of ECM

connector and body ground.

OK:

Voltage: 9 − 14 V

OK Go to step 4.

NG

Page 360 of 2062

Downloaded from www.Manualslib.com manuals search engine DI−96

− DIAGNOSTICSENGINE (3RZ−FE)

1996 TOYOTA T100 (RM449U)

3 Check IAC valve (See page MF−31).

NG Replace IAC valve.

OK

Check for open and short in harness and con-

nector between R/B No.2 and IAC valve, IAC

valve and ECM (See page IN−26).

4 Check operation of IAC valve (See page MF−31).

NG Repair or replace IAC valve.

OK

Check and replace ECM (See page IN−26).

Page 363 of 2062

Downloaded from www.Manualslib.com manuals search engine BE6653

P19556

P19711

P19687

A00085

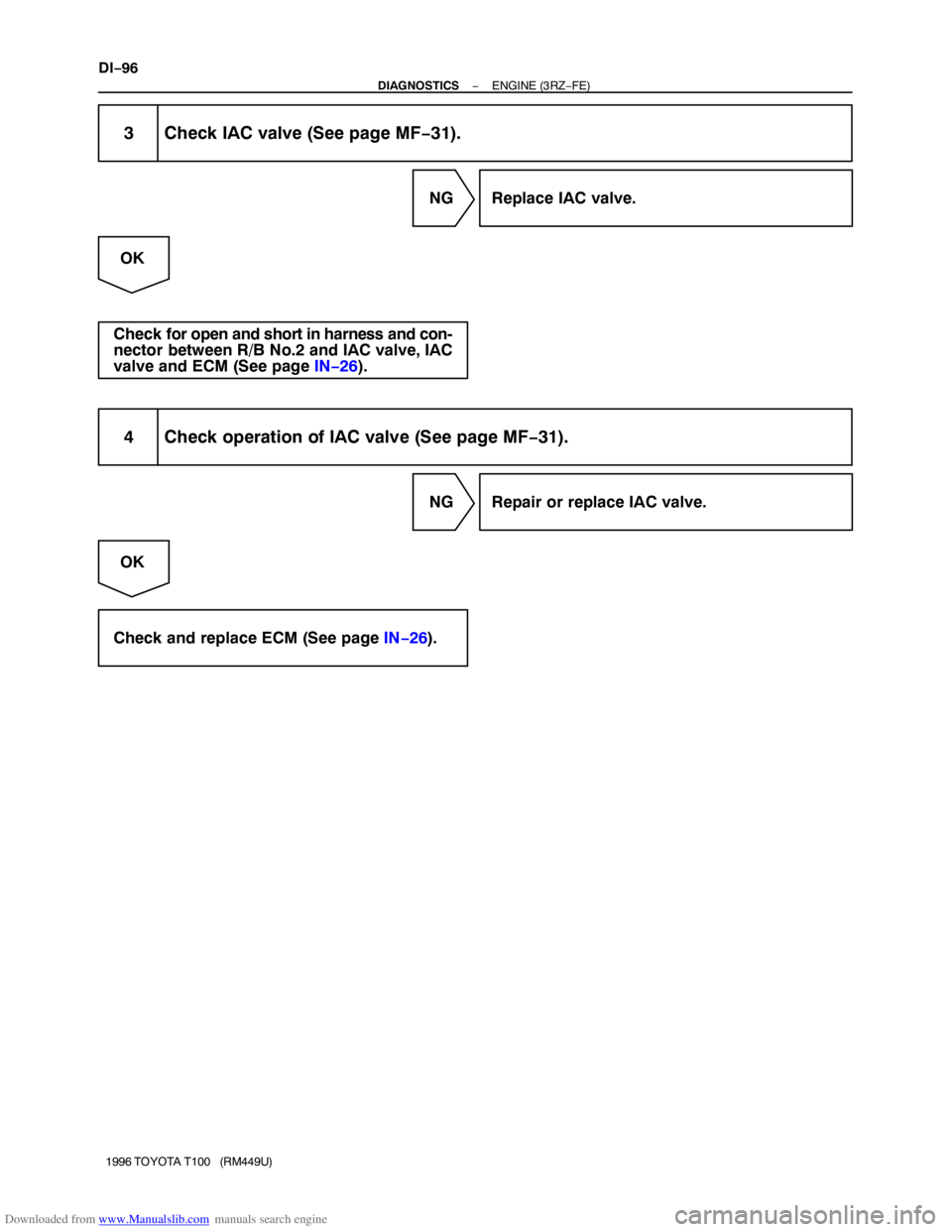

ON

ECM

1

2

3

411

11 1 0

11

99

Throttle Position

Sensor

E6 E6

(M/T)(A/T)5 V

VCC

VTA

IDL

E2B+

E1

12

For M/T

For A/TE2

E2

IDL (+)

IDL (+)

E6 E6

E6 E6

E6 E6

− DIAGNOSTICSENGINE (3RZ−FE)

DI−99

1996 TOYOTA T100 (RM449U)

3 Check for open in harness or ECM.

PREPARATION:

(a) Remove the right cowl side trim (See page MF−50).

(b) Connect between terminals IDL and E2 of the ECM con-

nector.

HINT:

Throttle position sensor connector is disconnected.

Before checking, do a visual check and contact pressure check

for the connector (See page IN−26).

(c) Turn the ignition switch ON.

CHECK:

Read CTP switch signal on the TOYOTA hand−held tester.

OK:

CTP switch signal: ON

OK Open in harness between ECM and throttle

position sensor, repair or replace harness.

NG

Confirm connection at ECM.

If OK, replace ECM.

Page 365 of 2062

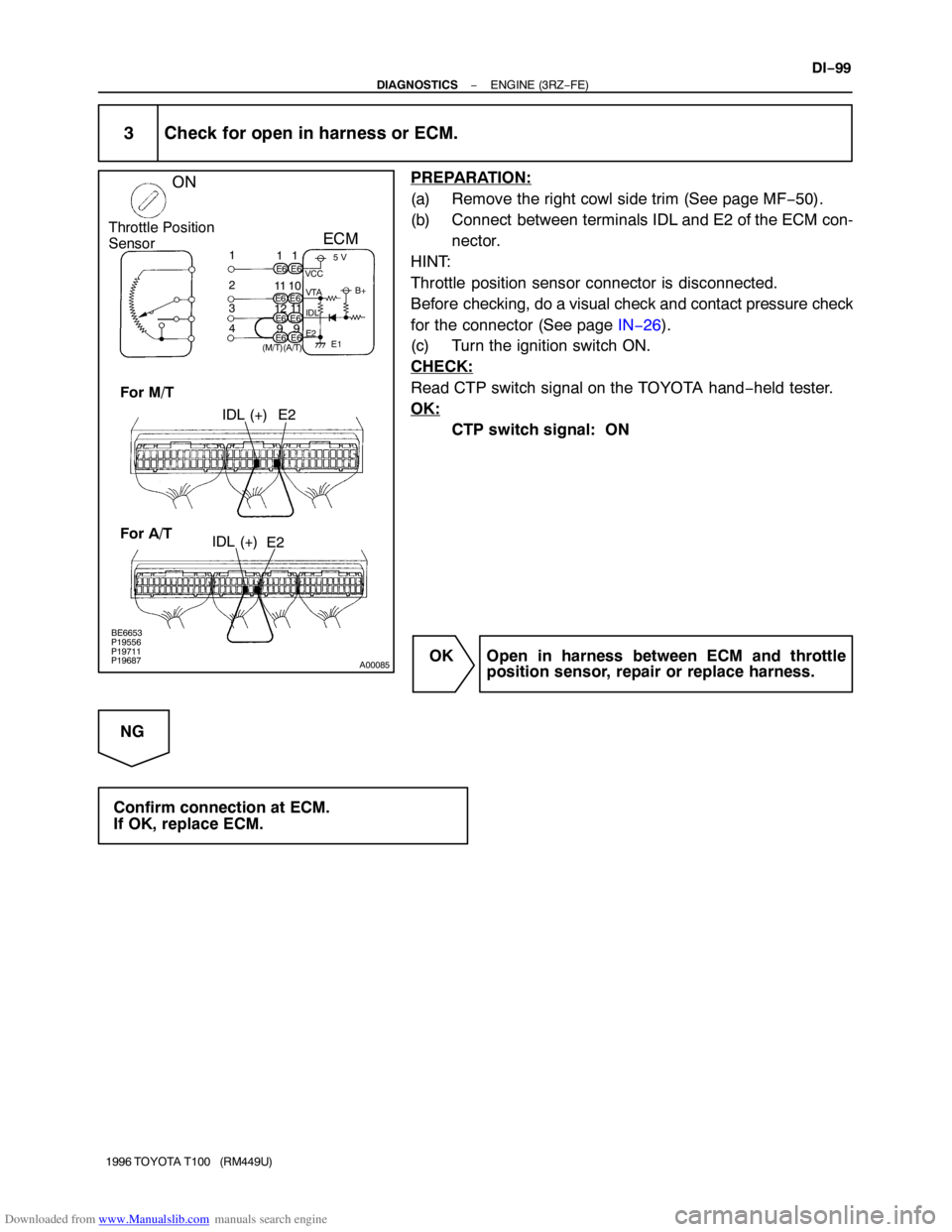

Downloaded from www.Manualslib.com manuals search engine A00683

1

2

3

411

11 1 0

12 11

99E6 E6

(M/T)(A/T)5 V

VCC

VTA

IDL

E2

B+

E1E6 E6

E6 E6

E6E6

ON

For M/T

For A/TE6 Connector

E6 Connector

− DIAGNOSTICSENGINE (3RZ−FE)

DI−101

1996 TOYOTA T100 (RM449U)

5 Check for short in harness or ECM.

PREPARATION:

(a) Remove right cowl side trim (See page MF−50).

(b) Disconnect the E6 connector of the ECM.

(c) Turn the ignition switch ON.

HINT:

Throttle position sensor connector is disconnected.

CHECK:

Read CTP switch signal on TOYOTA hand−held tester.

OK:

CTP switch signal: OFF

OK Short in harness between ECM and throttle

position sensor, repair or replace harness.

NG

Confirm connection at ECM.

If OK, replace ECM.

Page 368 of 2062

Downloaded from www.Manualslib.com manuals search engine DI−104

− DIAGNOSTICSENGINE (3RZ−FE)

1996 TOYOTA T100 (RM449U)

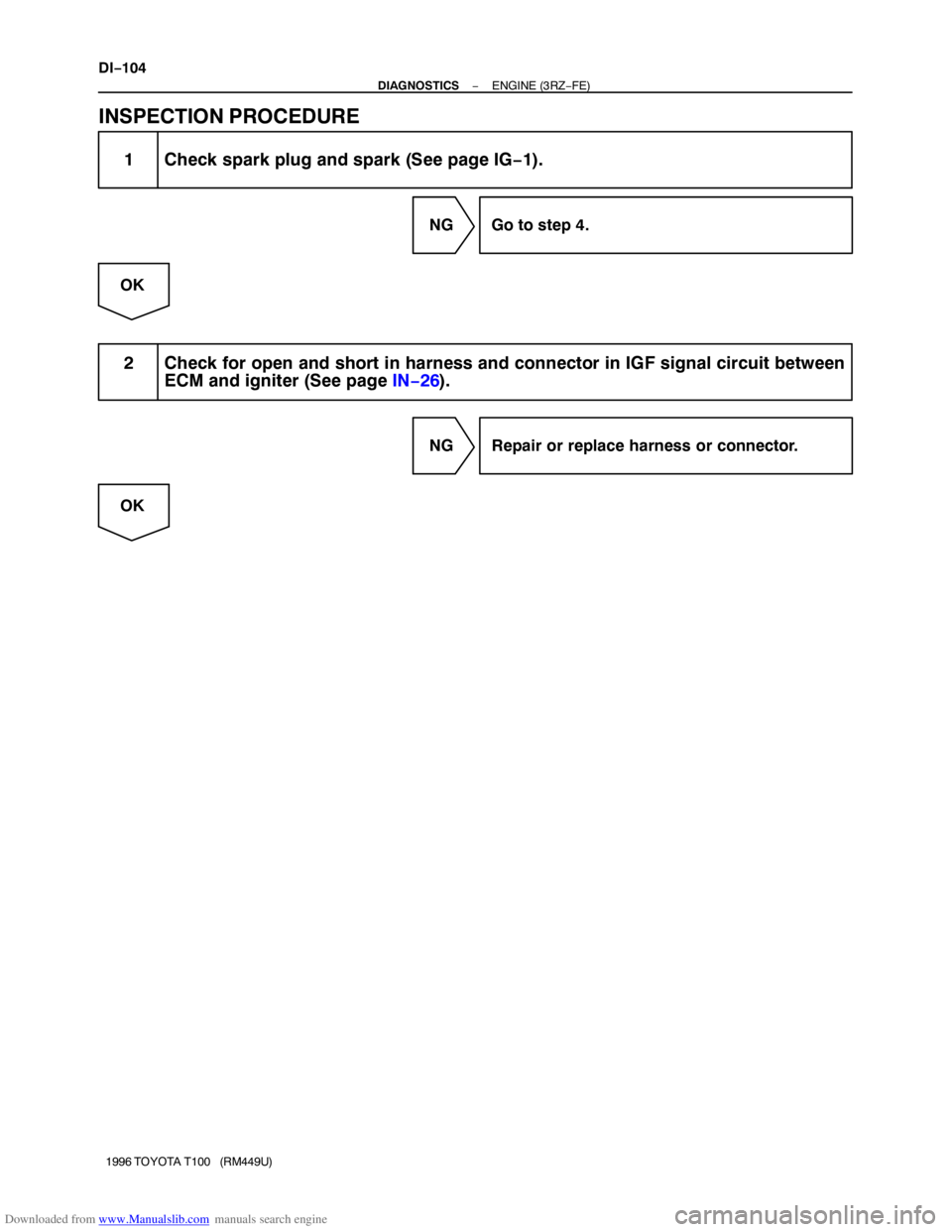

INSPECTION PROCEDURE

1 Check spark plug and spark (See page IG−1).

NG Go to step 4.

OK

2 Check for open and short in harness and connector in IGF signal circuit between

ECM and igniter (See page IN−26).

NG Repair or replace harness or connector.

OK

Page 369 of 2062

Downloaded from www.Manualslib.com manuals search engine BE6653

P24210

P24211

A00087

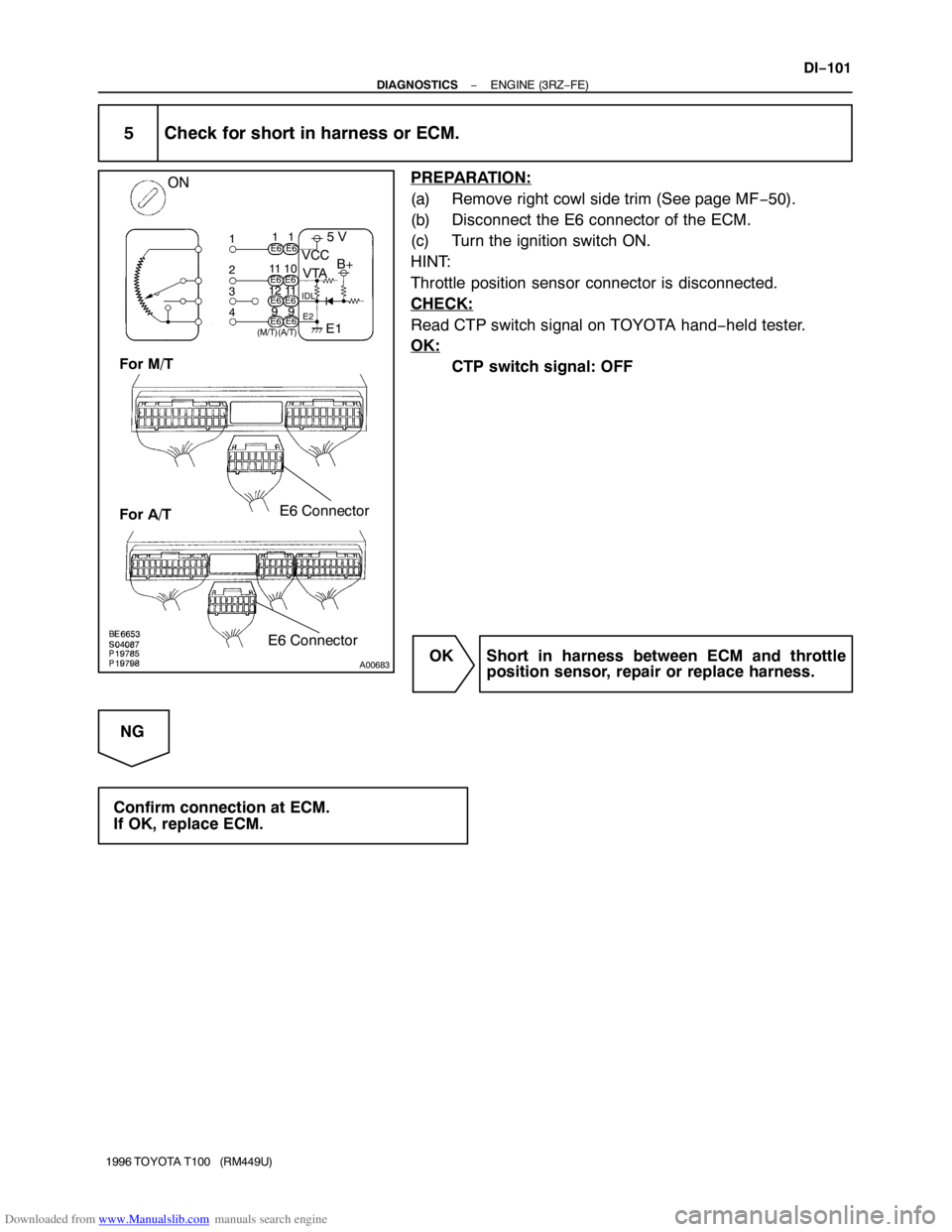

ON

IGF (+) For M/T

For A/T

IGF (+)

− DIAGNOSTICSENGINE (3RZ−FE)

DI−105

1996 TOYOTA T100 (RM449U)

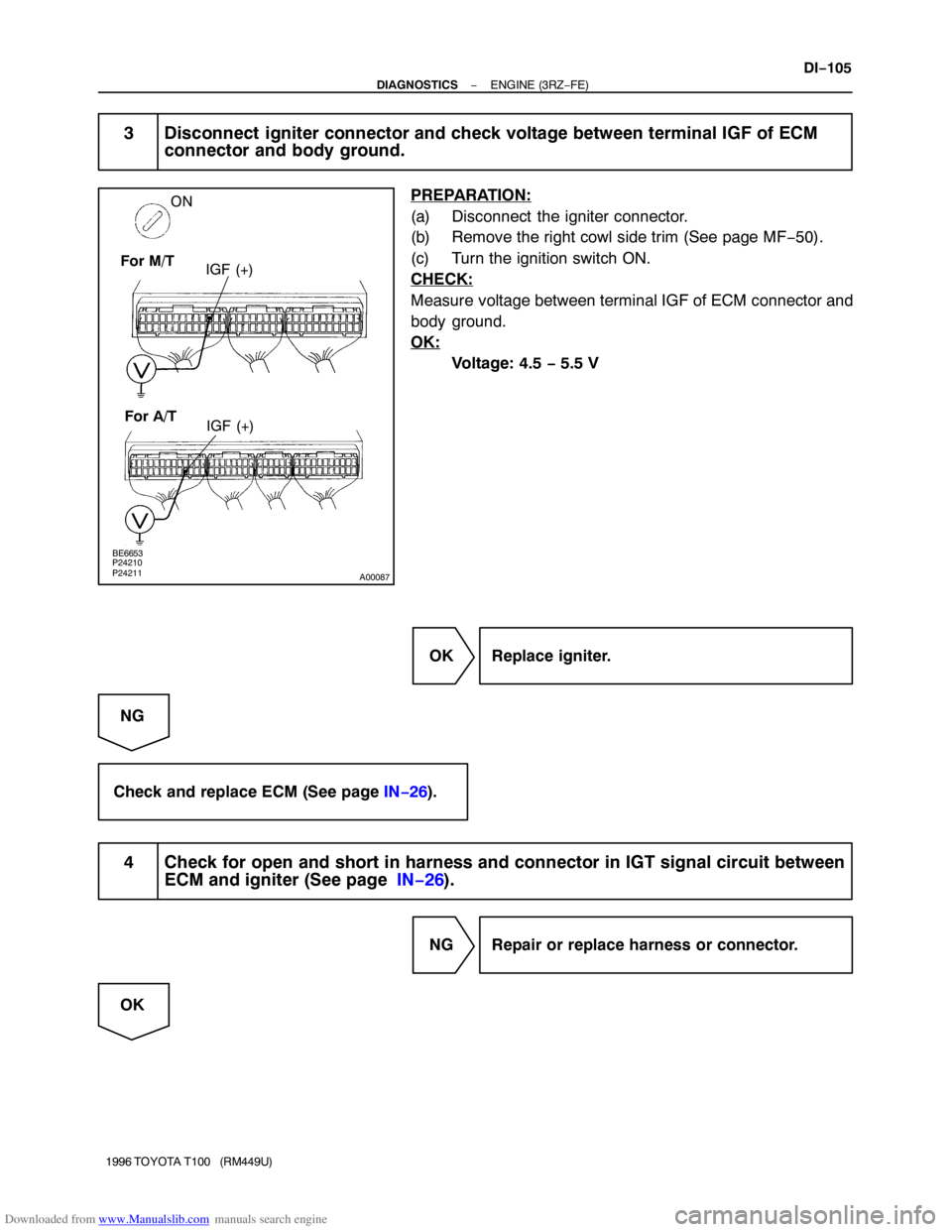

3 Disconnect igniter connector and check voltage between terminal IGF of ECM

connector and body ground.

PREPARATION:

(a) Disconnect the igniter connector.

(b) Remove the right cowl side trim (See page MF−50).

(c) Turn the ignition switch ON.

CHECK:

Measure voltage between terminal IGF of ECM connector and

body ground.

OK:

Voltage: 4.5 − 5.5 V

OK Replace igniter.

NG

Check and replace ECM (See page IN−26).

4 Check for open and short in harness and connector in IGT signal circuit between

ECM and igniter (See page

IN−26).

NG Repair or replace harness or connector.

OK

Page 371 of 2062

Downloaded from www.Manualslib.com manuals search engine BE6653

P24212

P24213

A00088

START

IGT (+) For M/T

For A/T

IGT (+)

BE6653

P24215

A00089

ON

START

3 (+)

− DIAGNOSTICSENGINE (3RZ−FE)

DI−107

1996 TOYOTA T100 (RM449U)

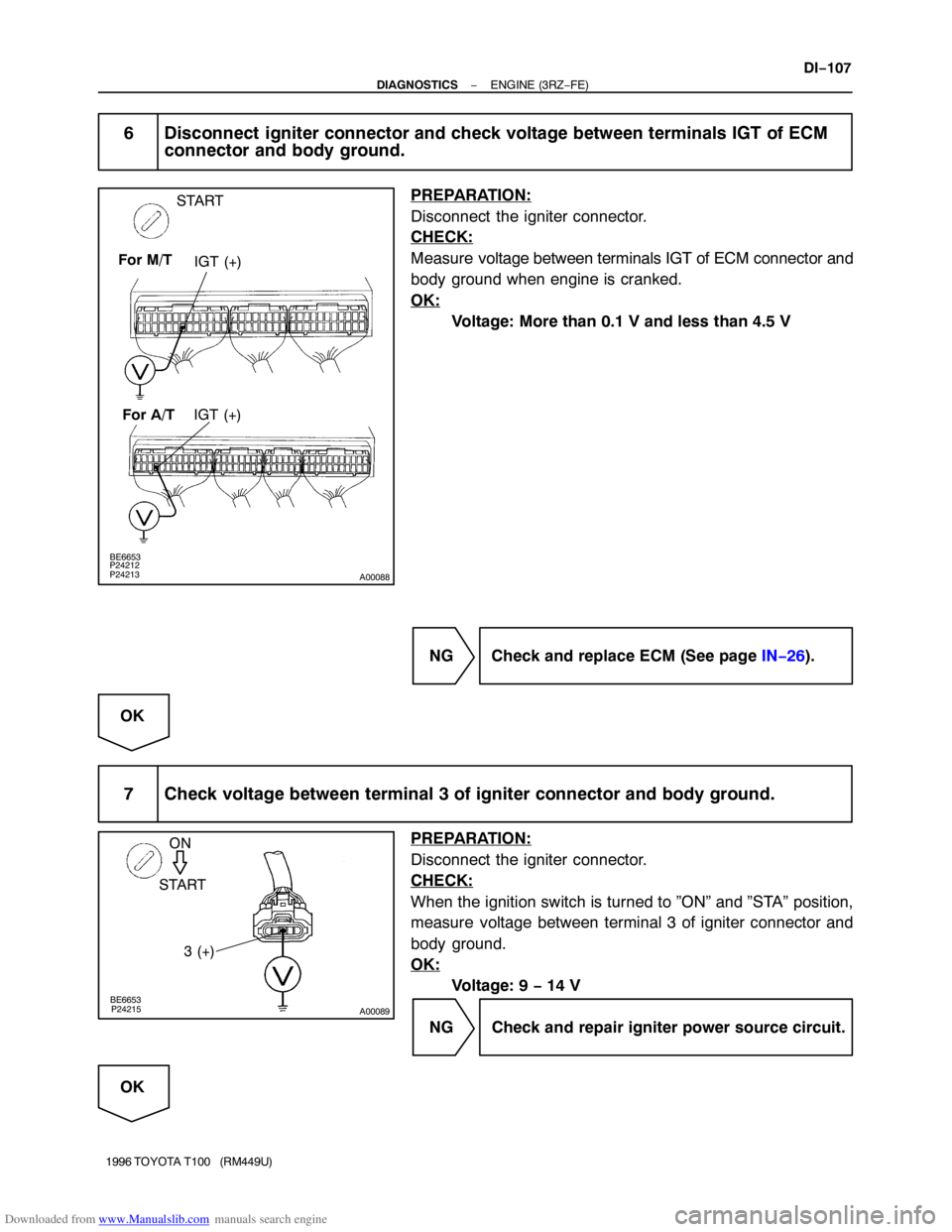

6 Disconnect igniter connector and check voltage between terminals IGT of ECM

connector and body ground.

PREPARATION:

Disconnect the igniter connector.

CHECK:

Measure voltage between terminals IGT of ECM connector and

body ground when engine is cranked.

OK:

Voltage: More than 0.1 V and less than 4.5 V

NG Check and replace ECM (See page IN−26).

OK

7 Check voltage between terminal 3 of igniter connector and body ground.

PREPARATION:

Disconnect the igniter connector.

CHECK:

When the ignition switch is turned to ”ON” and ”STA” position,

measure voltage between terminal 3 of igniter connector and

body ground.

OK:

Voltage: 9 − 14 V

NG Check and repair igniter power source circuit.

OK

Page 372 of 2062

Downloaded from www.Manualslib.com manuals search engine DI−108

− DIAGNOSTICSENGINE (3RZ−FE)

1996 TOYOTA T100 (RM449U)

8 Check for open and short in harness and connector between ignition switch and

ignition coil, ignition coil and igniter (See page IN−26).

NG Repair or replace harness or connector.

OK

9 Check ignition coil (See page IG−1).

NG Replace ignition coil.

OK

Replace igniter.

Page 375 of 2062

Downloaded from www.Manualslib.com manuals search engine − DIAGNOSTICSENGINE (3RZ−FE)

DI−111

1996 TOYOTA T100 (RM449U)

INSPECTION PROCEDURE

HINT:

This inspection procedure is based on the premise that the engine is cranked normally. If the engine is not

cranked, proceed to the matrix chart of problem symptoms on page DI−21.

1 Connect the TOYOTA hand−held tester and check STA signal.

PREPARATION:

(a) Connect the TOYOTA hand−held tester to the DLC3.

(b) Turn ignition switch ON and TOYOTA hand−held tester main switch ON.

CHECK:

Read STA signal on the TOYOTA hand−held tester while starter operates.

OK:

Ignition switch positionONSTART

STA signalOFFON

OK Proceed to next circuit inspection shown on

matrix chart (See page DI−21)

NG

2 Check for open in harness and connector between ECM and starter relay

(See page IN−26).

NG Repair or replace harness and sconnector.

OK

Check and replace ECM (See page IN−26).

Page 377 of 2062

Downloaded from www.Manualslib.com manuals search engine AB0117

P24216

P24217

A00090

LOCK

BATT (+)

BATT (+) For M/T

For A/T

FI7107

EFI Fuse

R/B No.2

− DIAGNOSTICSENGINE (3RZ−FE)

DI−11 3

1996 TOYOTA T100 (RM449U)

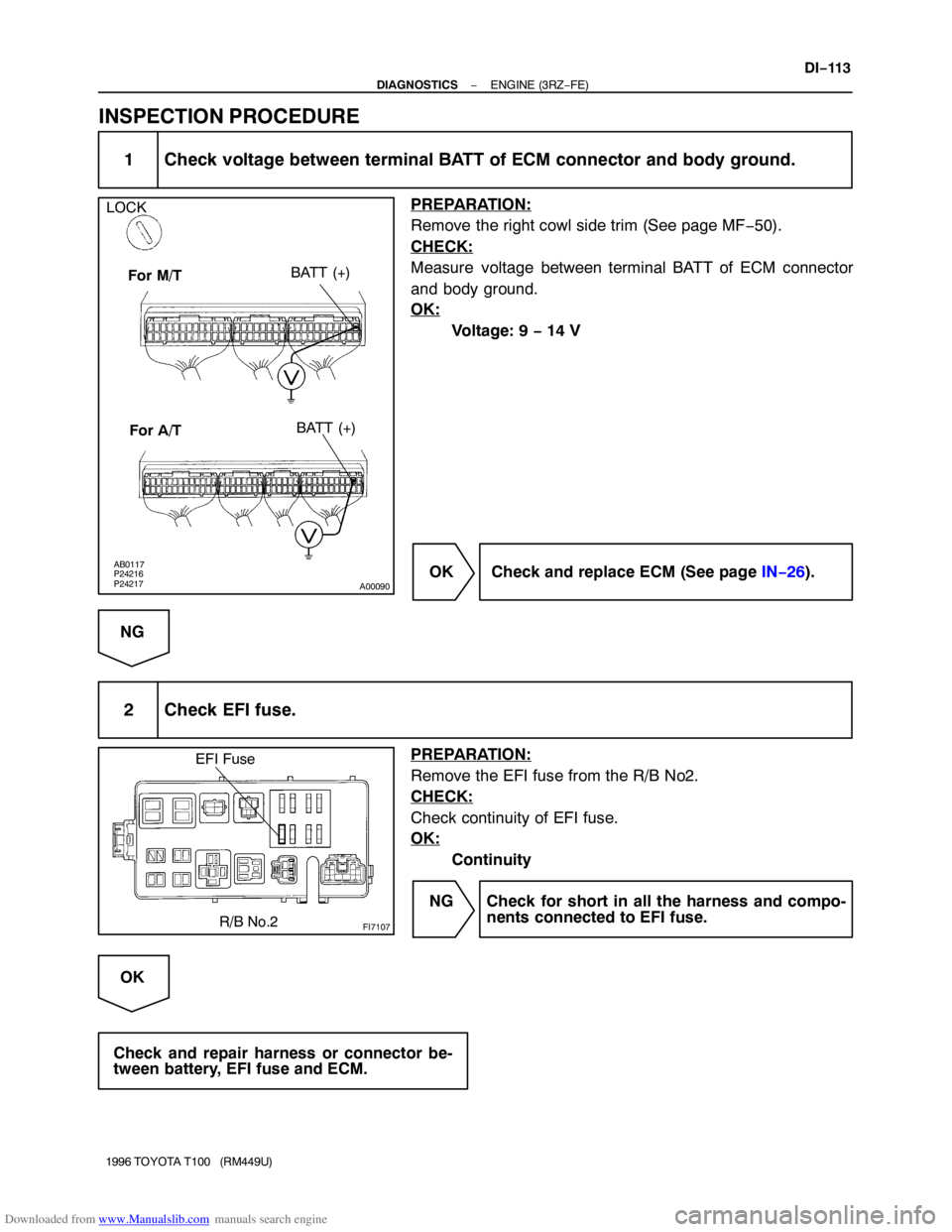

INSPECTION PROCEDURE

1 Check voltage between terminal BATT of ECM connector and body ground.

PREPARATION:

Remove the right cowl side trim (See page MF−50).

CHECK:

Measure voltage between terminal BATT of ECM connector

and body ground.

OK:

Voltage: 9 − 14 V

OK Check and replace ECM (See page IN−26).

NG

2 Check EFI fuse.

PREPARATION:

Remove the EFI fuse from the R/B No2.

CHECK:

Check continuity of EFI fuse.

OK:

Continuity

NG Check for short in all the harness and compo-

nents connected to EFI fuse.

OK

Check and repair harness or connector be-

tween battery, EFI fuse and ECM.