lock TOYOTA TERCEL 1985 User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1985, Model line: TERCEL, Model: TOYOTA TERCEL 1985Pages: 885, PDF Size: 64.52 MB

Page 541 of 885

REAR AXLE AND SUSPENSION - Differential (4WD)RA-33

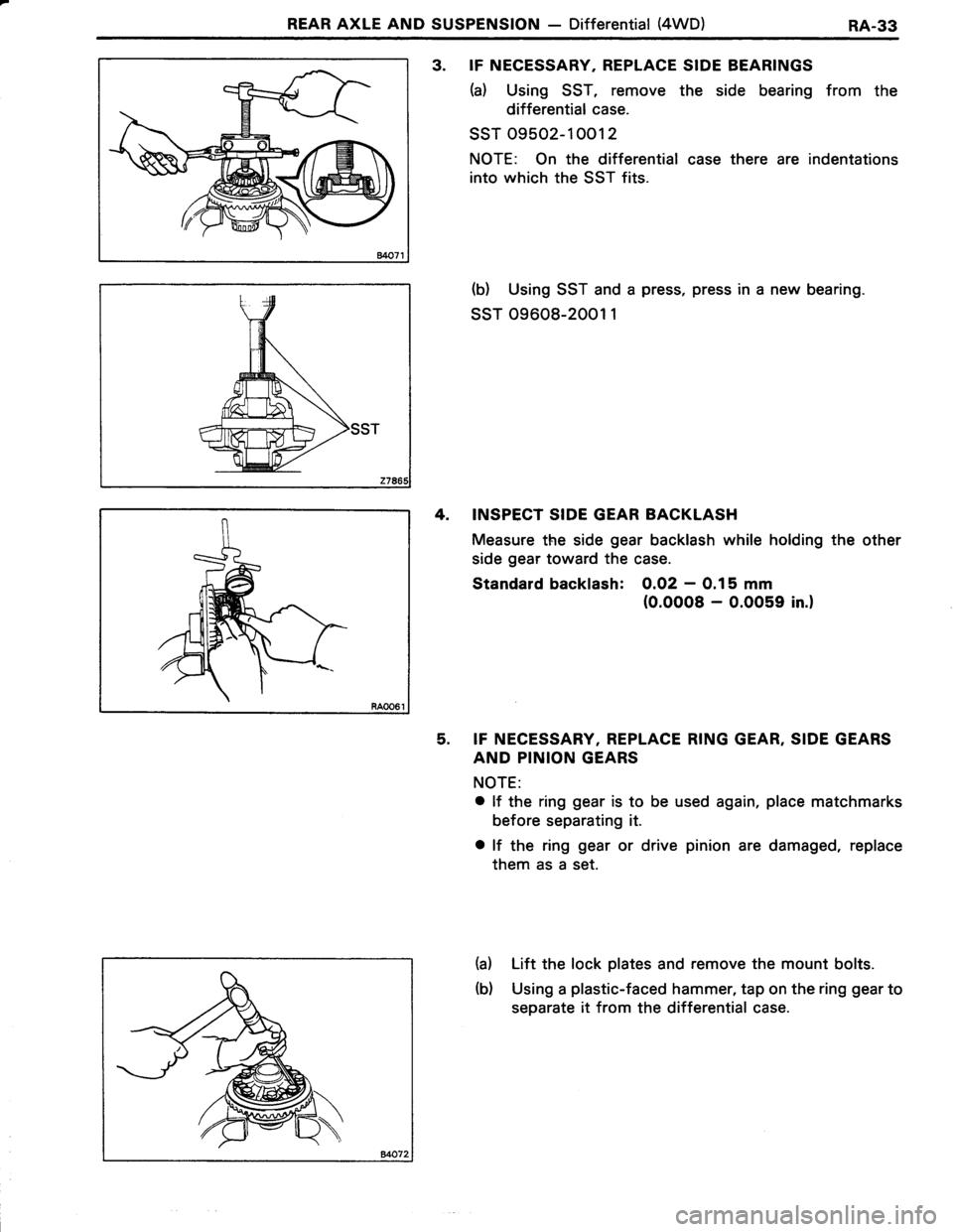

3. IF NECESSARY, REPLACE SIDE BEARINGS

(a) Using SST, remove the side bearing from the

differential case.

ssT 09502-10012

NOTE: On the differential case there are indentations

into which the ssT fits.

(b) Using SST and a press, press in a new bearing.

ssr 09608-2001 1

4. INSPECT SIDE GEAR BACKLASH

Measure the side gear backlash while holding the other

side gear toward the case.

Standard backlash: 0.02 - 0.15 mm

(0.0008 - 0.0059 in.)

5. IF NECESSARY, REPLACE RING GEAR, SIDE GEARS

AND PINION GEARS

NOTE:

o lf the ring gear is to be used again, place matchmarks

before separating it.

o lf the ring gear or drive pinion are damaged, replace

them as a set.

(a) Lift the lock plates and remove the mount bolts.

(b) Using a plastic-faced hammer, tap on the ring gear to

separate it from the differential case.

Page 543 of 885

REAR AXIE AND SUSPENSION - Differential (4WD)RA-35

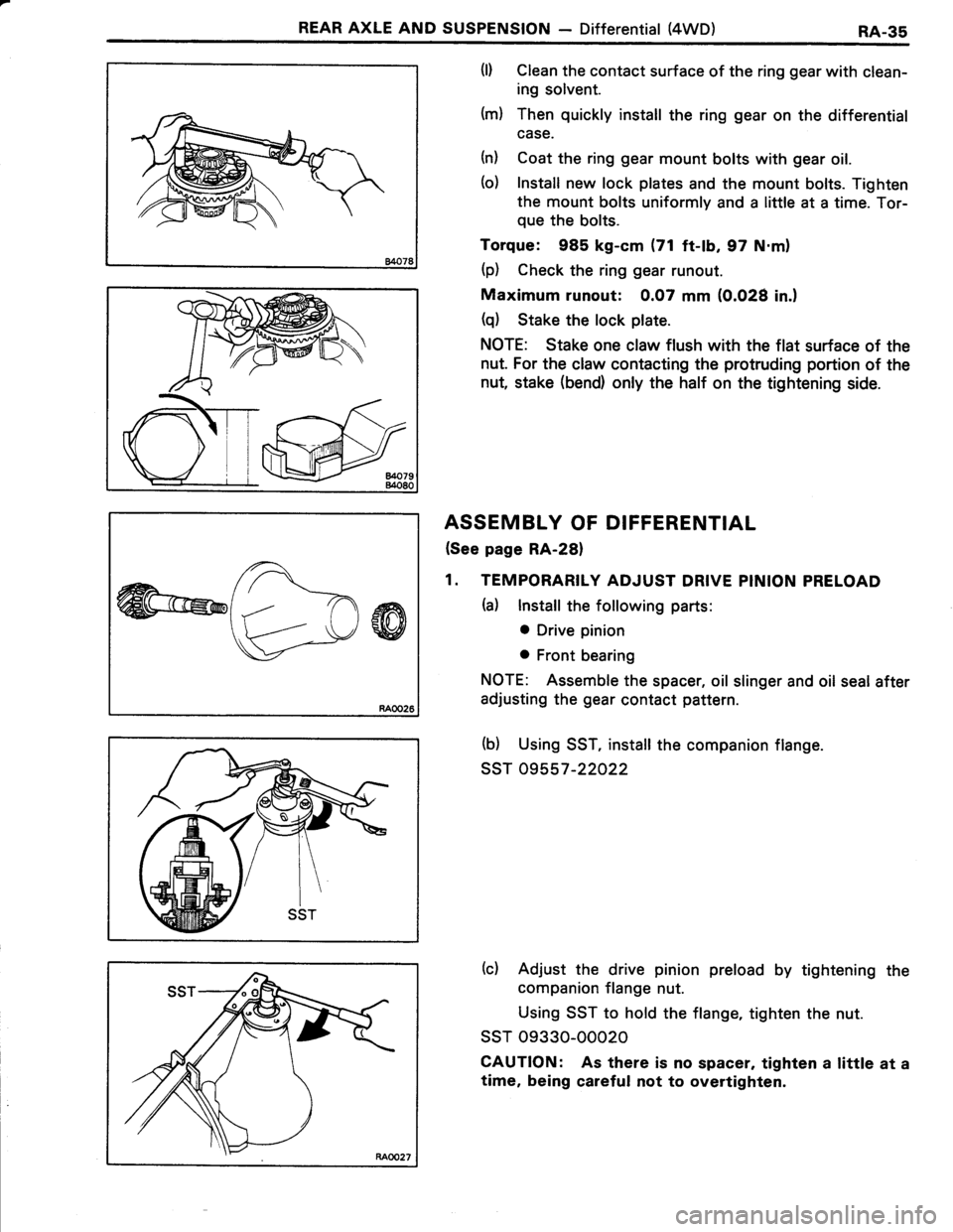

(l) Clean the contact surface of the ring gear with clean-

ing solvent.

(m) Then quickly install the ring gear on the differential

case.

(n) Coat the ring gear mount bolts with gear oil.

(o) Install new lock plates and the mount bolts. Tighten

the mount bolts uniformly and a little at a time. Tor-

que the bolts.

Torque: 985 kg-cm (71 ft-lb, 97 N.m)

(p) Check the ring gear runout.

Maximum runout: 0.07 mm (0.028 in.)

(q) Stake the lock plate.

NOTE: Stake one claw flush with the flat surface of the

nut. For the claw contacting the protruding portion of the

nut, stake (bend) only the half on the tightening side.

ASSEMBLY OF DIFFERENTIAL

(See page RA-28)

1. TEMPORARILY ADJUST DRIVE PINION PRELOAD

(a) lnstall the following parts:

o Drive pinion

o Front bearing

NOTE: Assemble the spacer, oil slinger and oil seal after

adjusting the gear contact pattern.

(b) Using SST, install the companion flange.

ssT 09557-22022

(c) Adjust the drive pinion preload by tightening the

companion flange nut.

Using SST to hold the flange, tighten the nut.

ssT 09330-00020

CAUTION: As there is no spacer, taghten a little at a

time, being careful not to overtighten.

Page 549 of 885

REAR AXLE AND SUSPENSION - Differential (4WD)RA.41

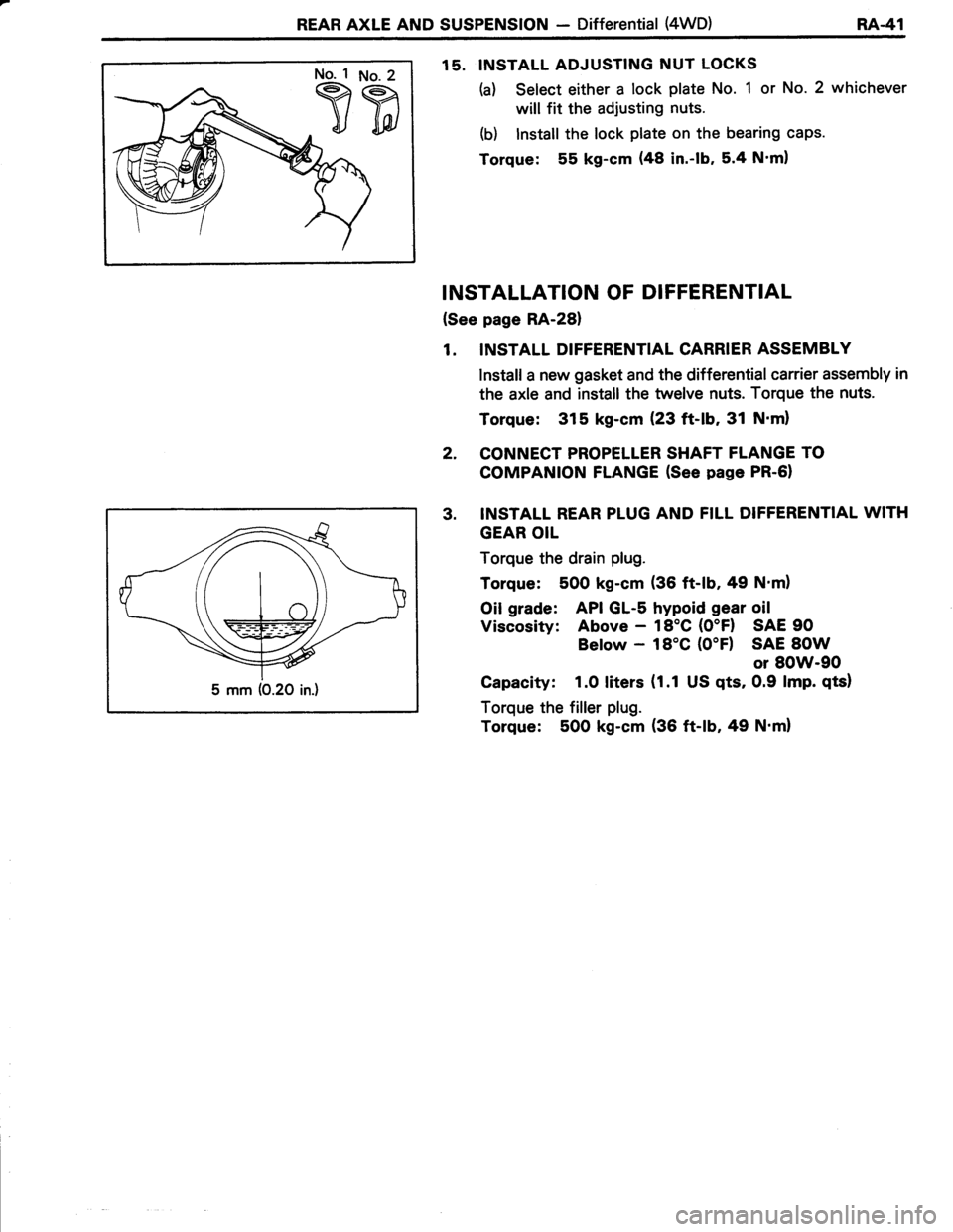

15. INSTALL ADJUSTING NUT LOCKS

(a) Select either a lock plate No. 1 or No. 2 whichever

will fit the adjusting nuts.

(b) lnstall the lock plate on the bearing caps.

Torque: 55 kg-cm (48 in.-lb, 5.4 N'ml

INSTALLATION OF DIFFERENTIAL

(See page RA-281

1. INSTALL DIFFERENTIAL CARRIER ASSEMBLY

Install a new gasket and the differentialcarrier assembly in

the axle and install the twelve nuts. Torque the nuts.

Torque: 315 kg-cm (23 ft-lb, 31 N'm)

2. CONNECT PROPELLER SHAFT FLANGE TO

COMPANION FLANGE (See page PR-61

3. INSTALL REAR PLUG AND FILL DIFFERENTIAL WITH

GEAR OIL

Torque the drain plug.

Torque: 500 kg-cm (36 ft-|b,49 N'm)

Oil grade: API GL-s hypoid gear oil

Viscosity: Above - 18"C (O'Fl SAE 90

Below - 18'C (0"F) SAE 8OW

or 80W-90

Capacity: 1.0 liters (1.1 US qts, 0.9 lmp. qts)

Torque the filler plug.

Torque: 500 kg-cm (36 ft-|b,49 N'ml

5 mm (0.2O in.)

Page 567 of 885

BR.8BRAKE SYSTEM - Checks and Adjustments

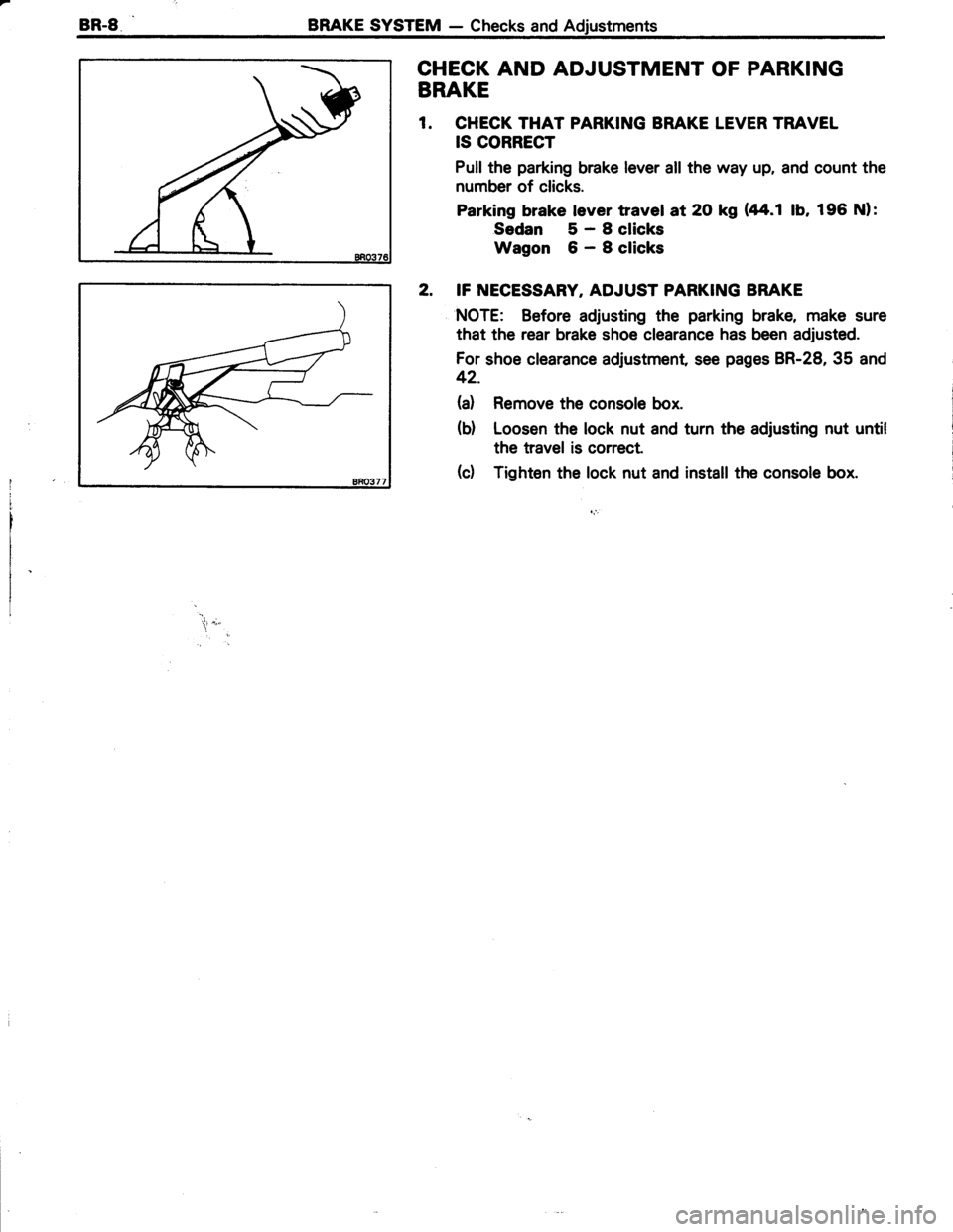

CHECK AND ADJUSTMENT OF PARKING

BRAKE

1. CHECK THAT PARKING BRAKE LEVER TRAVEL

IS CORRECT

Pull the parking brake lever all the way up, and count the

number of clicks.

Parking brake lever travel at 2O kg (44.1 lb, 196 Nl:

Sedan 5-Sclicks

Wagon 6-Sclicks

2. IF NECESSARY, ADJUST PARKING BRAKE

NOTE: Before adjusting the parking brake, make sure

that the rear brake shoe clearance has been adjusted.

For shoe clearance adjustment, see pages BR-28, 35 and

42.

(a) Remove the console box.

(d Loosen the lock nut and turn the adjusting nut until

the travel is correct.

(d Tighten the lock nut and install the console box.

*r .;"

Page 570 of 885

BRAKE SYSTEM - Master CylinderBR-11

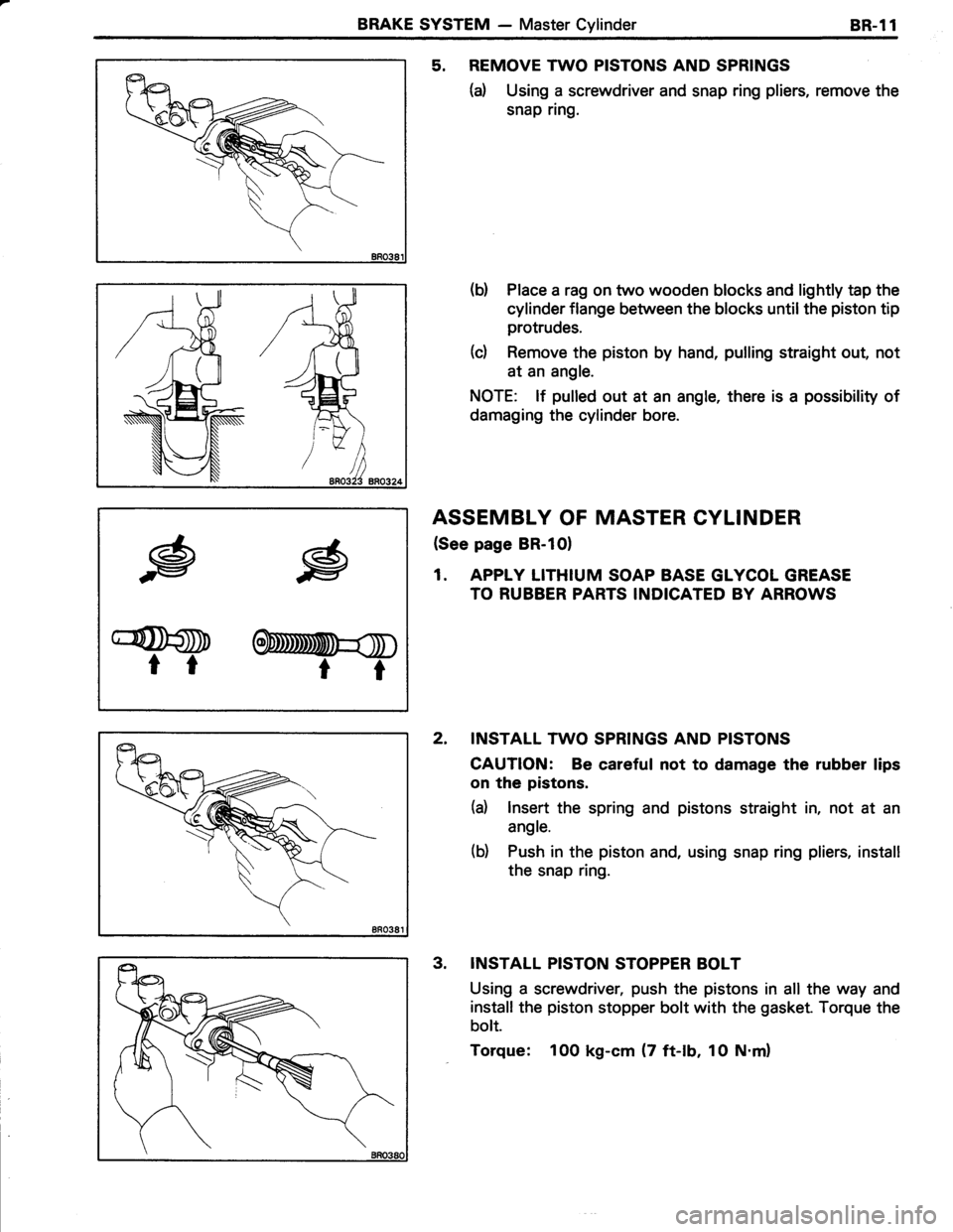

5. REMOVE TWO PISTONS AND SPRINGS

(d Using a screwdriver and snap ring pliers, remove the

snap ring.

(b) Place a rag on two wooden blocks and lightly tap the

cylinder flange between the blocks until the piston tip

protrudes.

(c) Remove the piston by hand, pulling straight out, not

at an angle.

NOTE: lf pulled out at an angle, there is a possibility of

damaging the cylinder bore.

ASSEMBLY OF MASTER CYLINDER

(See page BR-10)

1. APPLY LITHIUM SOAP BASE GLYCOL GREASE

TO RUBBER PARTS INDICATED BY ARROWS

2. INSTALL TWO SPRINGS AND PISTONS

CAUTION: Be careful not to damage the rubber lips

on the pistons.

(d lnsert the spring and pistons straight in, not at an

angle.

(b) Push in the piston and, using snap ring pliers, install

the snap ring.

INSTALL PISTON STOPPER BOLT

Using a screwdriver, push the pistons in all the way and

install the piston stopper bolt with the gasket. Torque the

bolt.

Torque: 100 kg-cm (7 ft-lb, 1O N.m)

.g

G@D

tr

.g

OnmmU=$

rt

3.