torque TOYOTA TERCEL 1985 Service Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1985, Model line: TERCEL, Model: TOYOTA TERCEL 1985Pages: 885, PDF Size: 64.52 MB

Page 548 of 885

RA-/[()REAR AXLE AND SUSPENSION - Differential (4WD)

RAOO3

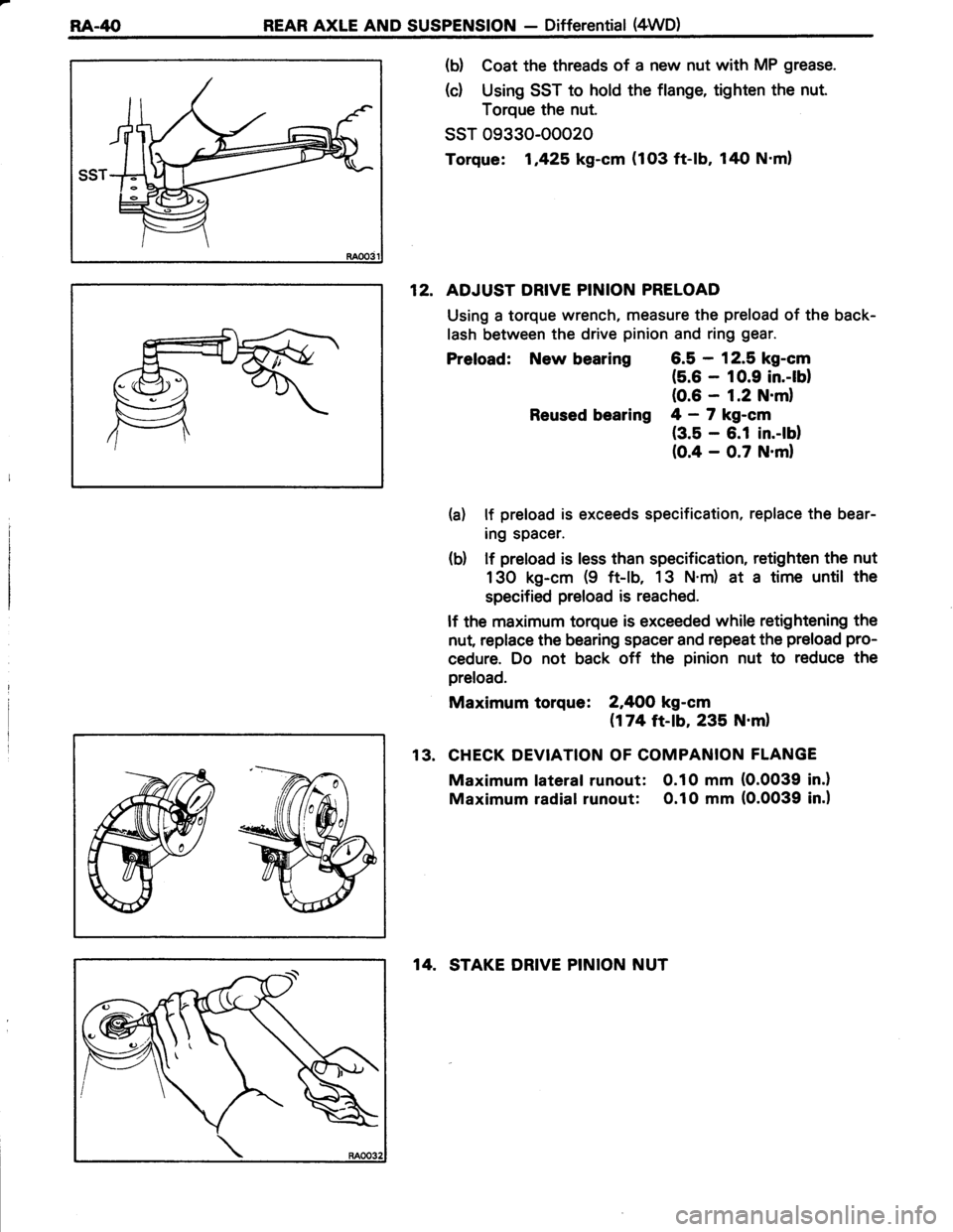

(b) Coat the threads of a new nut with MP grease.

(c) Using SST to hold the flange, tighten the nut.

Torque the nut.

ssr 09330-ooo20

Torque: 1,425 kg-cm (103 ft-lb, 140 N'ml

12. ADJUST DRIVE PINION PRELOAD

Using a torque wrench, measure the preload of the back-

lash between the drive pinion and ring gear.

Preload: New bearing 6.5 - 12.5 kg-cm

(5.6 - 10.9 in.-lbl

(0.6 - 1.2 N'ml

Reused bearing 4 - 7 kg-cm

(3.5 - 6.1 in.-lbl

(0.4 - 0.7 N'ml

lf preload is exceeds specification, replace the bear-

ing spacer.

lf preload is less than specification, retighten the nut

130 kg-cm (9 ft-lb, 13 N.m) at a time until the

specified preload is reached.

lf the maximum torque is exceeded while retightening the

nut, replace the bearing spacer and repeat the preload pro-

cedure. Do not back off the pinion nut to reduce the

preload.

Maximum torque: 2,4OO kg-cm

(174 ft-lb, 235 N'm)

CHECK DEVIATION OF COMPANION FLANGE

Maximum tateral runout: 0.10 mm (0.0039 in.l

Maximum radial runout: 0.10 mm (0.0039 in.l

14. STAKE DRIVE PINION NUT

(a)

(b)

13.

Page 549 of 885

REAR AXLE AND SUSPENSION - Differential (4WD)RA.41

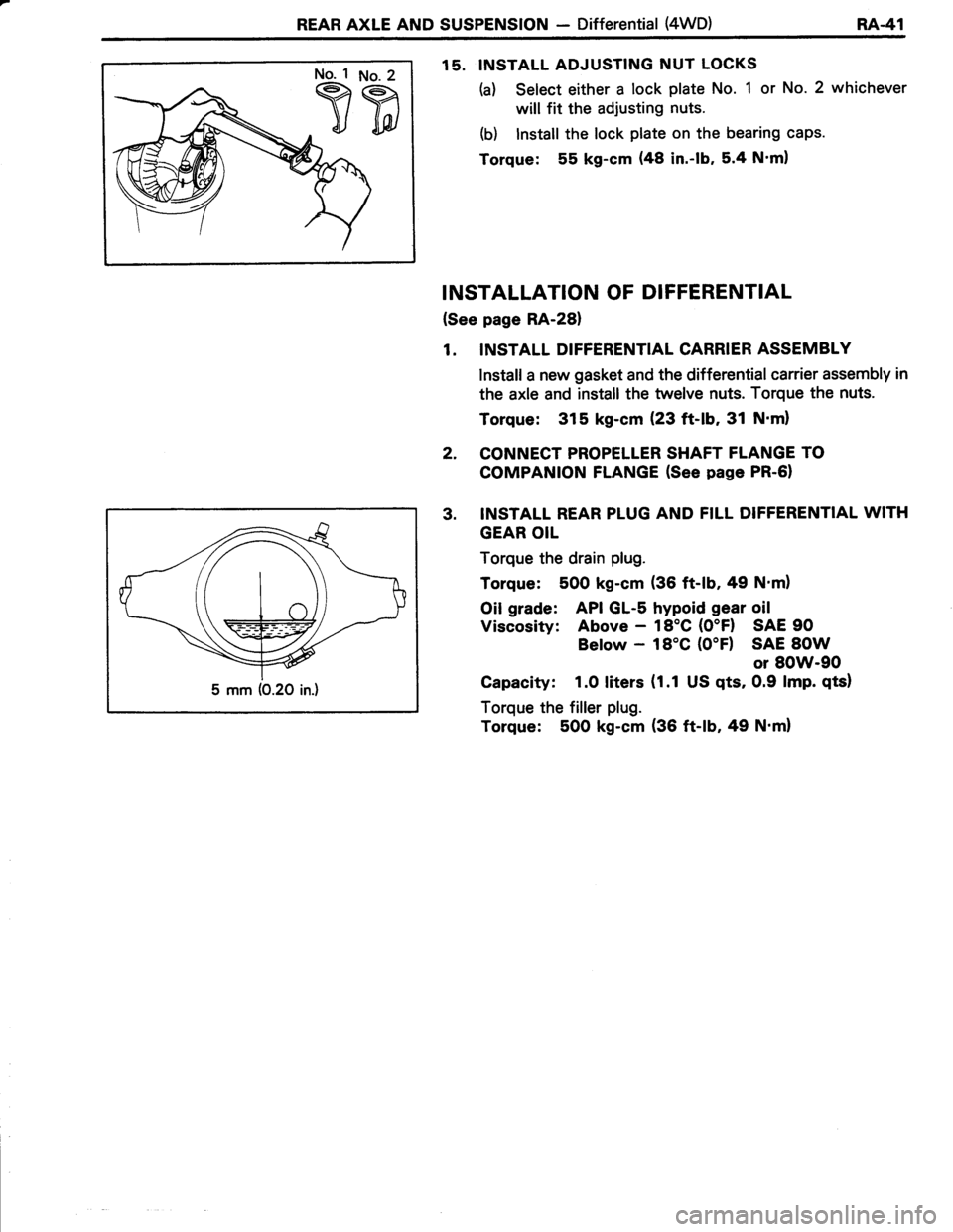

15. INSTALL ADJUSTING NUT LOCKS

(a) Select either a lock plate No. 1 or No. 2 whichever

will fit the adjusting nuts.

(b) lnstall the lock plate on the bearing caps.

Torque: 55 kg-cm (48 in.-lb, 5.4 N'ml

INSTALLATION OF DIFFERENTIAL

(See page RA-281

1. INSTALL DIFFERENTIAL CARRIER ASSEMBLY

Install a new gasket and the differentialcarrier assembly in

the axle and install the twelve nuts. Torque the nuts.

Torque: 315 kg-cm (23 ft-lb, 31 N'm)

2. CONNECT PROPELLER SHAFT FLANGE TO

COMPANION FLANGE (See page PR-61

3. INSTALL REAR PLUG AND FILL DIFFERENTIAL WITH

GEAR OIL

Torque the drain plug.

Torque: 500 kg-cm (36 ft-|b,49 N'm)

Oil grade: API GL-s hypoid gear oil

Viscosity: Above - 18"C (O'Fl SAE 90

Below - 18'C (0"F) SAE 8OW

or 80W-90

Capacity: 1.0 liters (1.1 US qts, 0.9 lmp. qts)

Torque the filler plug.

Torque: 500 kg-cm (36 ft-|b,49 N'ml

5 mm (0.2O in.)

Page 550 of 885

RA-42 REAR AXLE AND SUSPENSION - Four Link Type Rear Suspension (4WD)

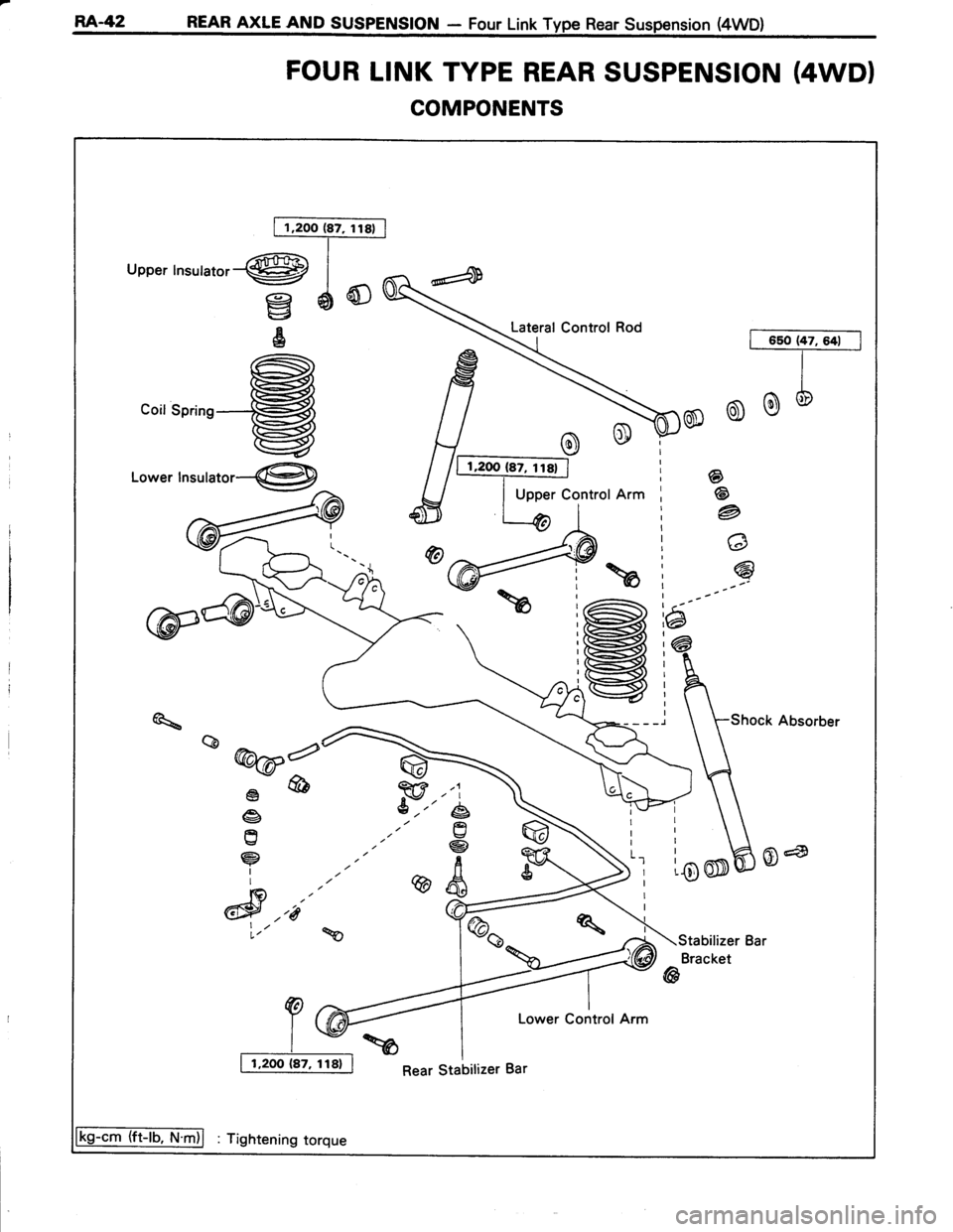

FOUR LINK TYPE REAR SUSPENSION (4WDI

COMPONENTS

fl,rooEz lrol

.ffi |Upper lnsutator-{sH9 I

€d@(

g\- Lateral Control Rod

\l l- 650 t+?,54l_l

€ ^T-

ll

ooo@

A/----_-9

a, r

f f I r,zoo raz, nat]. I a

g I uooe, Control Arm ', @

otr 11 " @

a",, ,0.,"n@

Lower tnrut.tor-@

D aia I i @v@

i o'wr=:i

b | .g

e€t,6

E i*u

,Wte

qShock Absorber

anv

%=

e@

e

Fv

? u.,r€

@.,a

i ,' a^@a

Lower Control Arm

-lb, N'm)l : Tightening torque

Rear Stabilizer Bar

Page 553 of 885

REAR AXLE AND SUSPENSION - Four Link Type Rear Suspension (4WD) Rl-+S

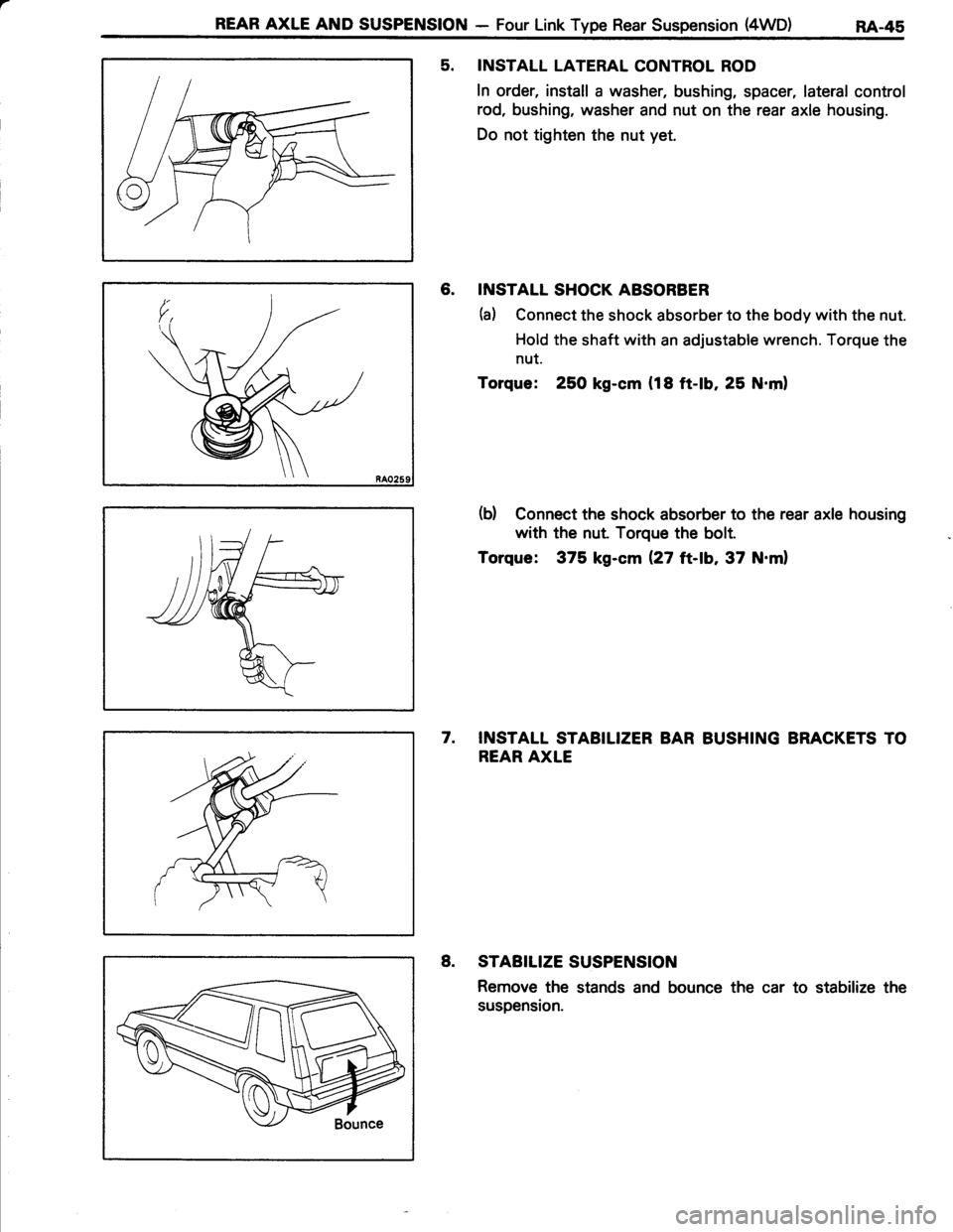

5. INSTALL LATERAL CONTROL ROD

In order, install a washer, bushing, spacer, lateral control

rod, bushing, washer and nut on the rear axle housing.

Do not tighten the nut yet.

6. INSTALL SHOCK ABSORBER

b) Connect the shock absorber to the body with the nut.

Hold the shaft with an adjustable wrench. Torque the

nut.

Torque: 250 kg-cm (18 ft-lb, 25 N.m)

(b) Connect the shock absorber to the rear axle housing

with the nut Torque the bolt.

Torque: 375 kg-cm (27 ft-\b,37 N.ml

7. INSTALL STABILIZER BAR BUSHING BRACKETS TO

REAR AXLE

8. STABILIZESUSPENSION

Remove the stands and bounce the car to stabilize the

suspension.

Page 554 of 885

RA-/t6 REAR AXLE AND SUSPENSION - Four Link Type Rear Suspension (4WD)

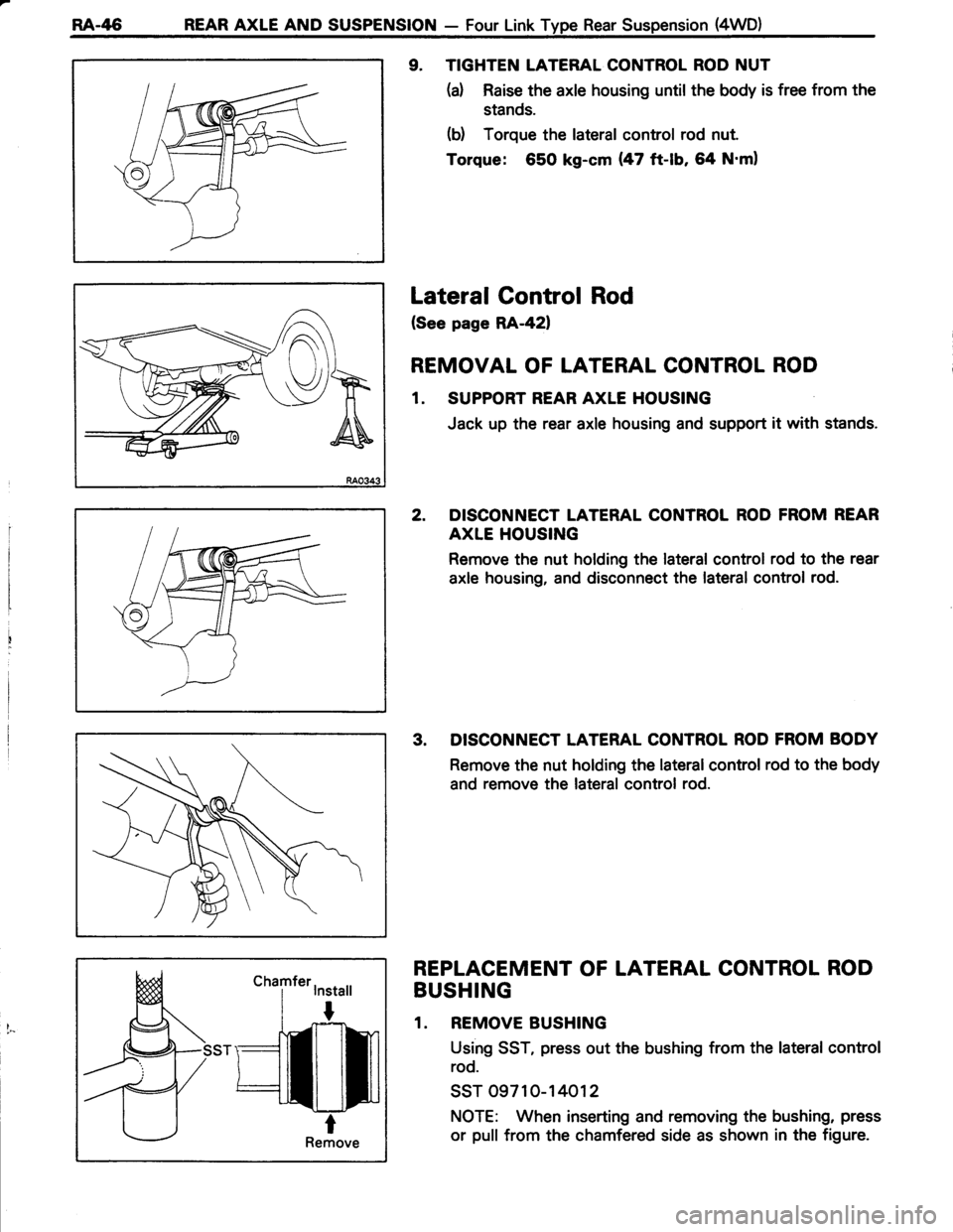

9. TIGHTEN LATERAL CONTROL ROD NUT

h) Raise the axle housing until the body is free from the

stands.

(b) Torque the lateral control rod nut.

Torque: 650 kg-cm (47 ft-lb, 64 N'm)

Lateral Control Rod

(See page RA-421

REMOVAL OF LATERAL CONTROL ROD

1. SUPPORT REAR AXLE HOUSING

Jack up the rear axle housing and support it with stands.

2. DISCONNECT LATERAL CONTROL ROD FROM REAR

AXLE HOUSING

Remove the nut holding the lateral control rod to the rear

axle housing, and disconnect the lateral control rod.

3. DISCONNECT LATERAL CONTROL ROD FROM BODY

Remove the nut holding the lateral control rod to the body

and remove the lateral control rod.

REPLACEMENT OF LATERAL CONTROL ROD

BUSHING

1. REMOVE BUSHING

Using SST, press out the bushing from the lateral control

rod.

ssT 0971 0-14012

NOTE: When inserting and removing the bushing, press

or pull from the chamfered side as shown in the figure.tRemove

Page 556 of 885

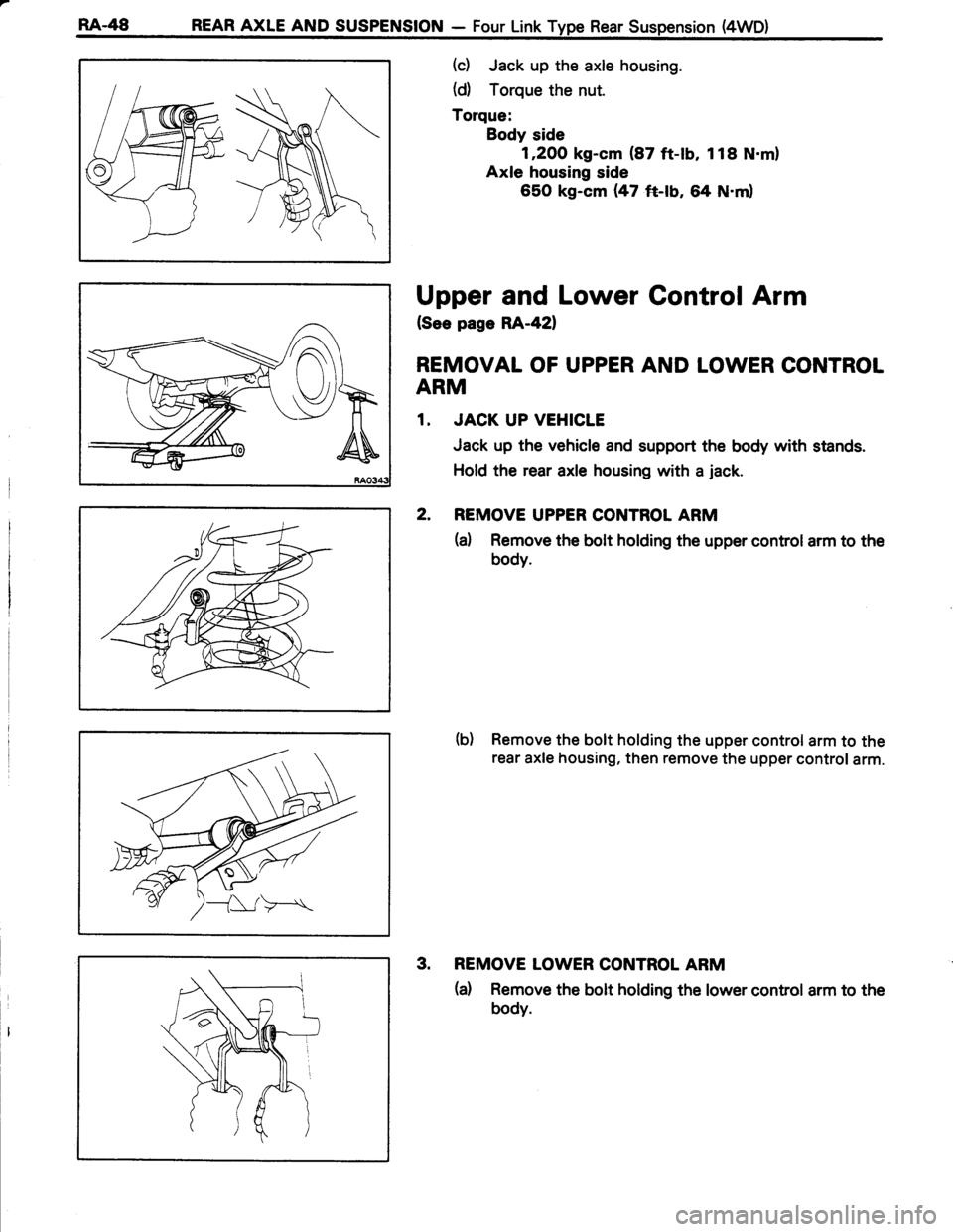

RA-48 REAR AXLE AND SUSPENSION - Four Link Type Rear Suspension (4WD)

(d Jack up the axle housing.

(d) Torque the nut.

Torque:

Body side

1,2OO kg-cm (87 ft-lb, 1 18 N.m)

Axle housing side

650 kg-cm {47 ft-lb, 64 N.ml

Upper and Lower Gontrol Arm

(See page RA-421

REMOVAL OF UPPER AND LOWER CONTROL

ARM

1. JACK UP VEHICLE

Jack up the vehicle and support the body with stands.

Hold the rear axle housing with a jack.

2. REMOVE UPPER CONTROL ARM

(a) Remove the bolt holding the upper controlarm to the

body.

(b) Remove the bolt holding the upper control arm to the

rear axle housing, then remove the upper control arm.

3. REMOVE LOWER CONTROL ARM

(a) Remove the bolt holding the lower control arm to the

body.

Page 558 of 885

RA-50 REAR AXLE AND SUSPENSION - Four Link Type Rear Suspension (4WD)

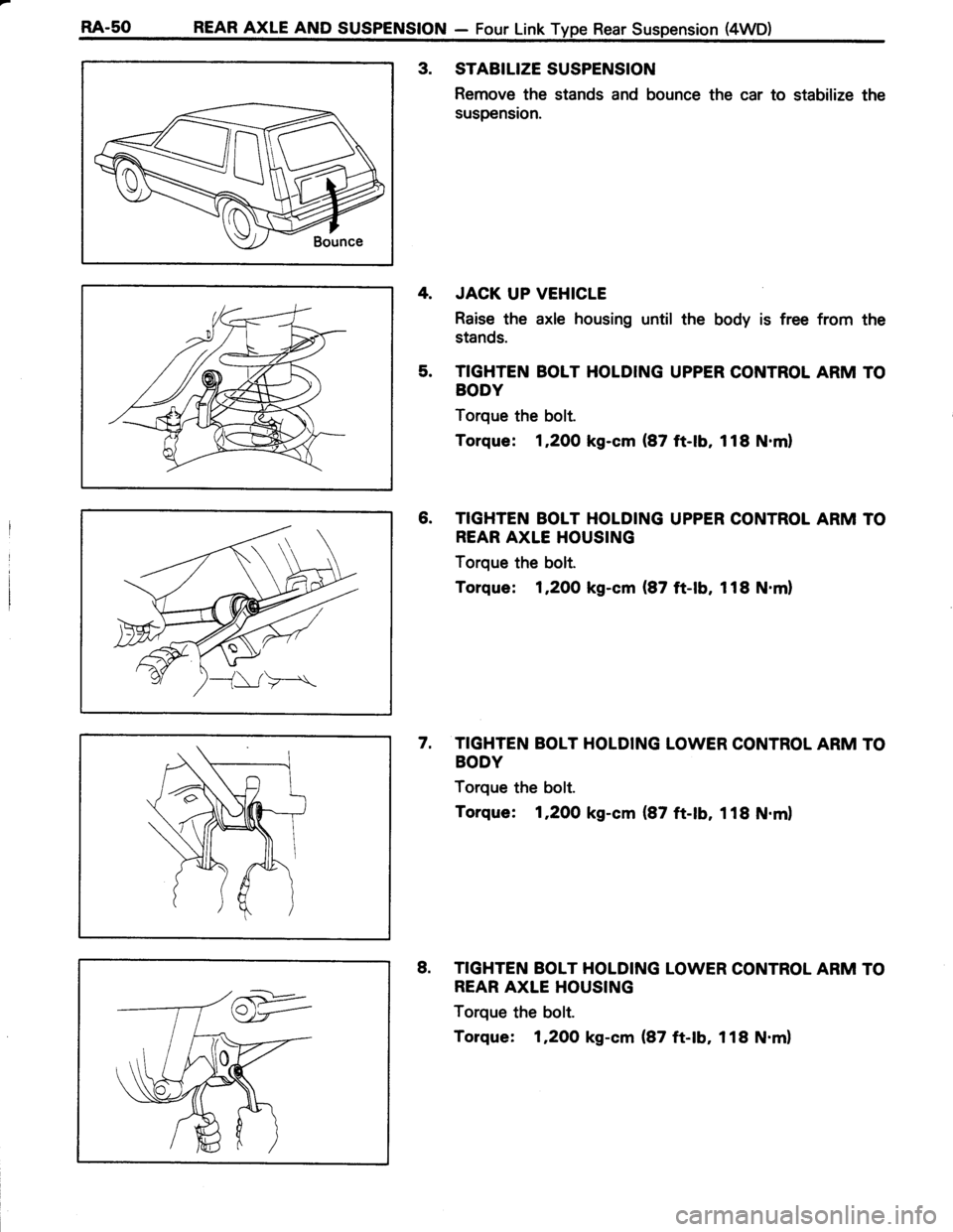

3. STABILIZESUSPENSION

Remove the stands and bounce the car to stabilize the

suspension.

4. JACK UP VEHICLE

Raise the axle housing until the body is free from the

stands.

5. TIGHTEN BOIT HOLDING UPPER CONTROL ARM TO

BODY

Torque the bolt.

Torque: 1,2OO kg-cm (87 ft-lb, 118 N.ml

6. TIGHTEN BOLT HOLDING UPPER CONTROT ARM TO

REAR AXLE HOUSING

Torque the bolt.

Torque: 1,2OO kg-cm (87 ft-lb, 1 18 N.ml

7, TIGHTEN BOLT HOLDING LOWER CONTROL ARM TO

BODY

Torque the bolt.

Torque: 1,2OO kg-cm (87 ft-lb, 118 N.ml

8. TIGHTEN BOLT HOLDING LOWER CONTROL ARM TO

REAR AXIE HOUSING

Torque the bolt.

Torque: 1,2OO kg-cm (87 ft-lb, 1 18 N.ml

Page 559 of 885

REAR AXLE AND SUSPENSION - Four Link Type Rear Suspension (4WD) ne-St

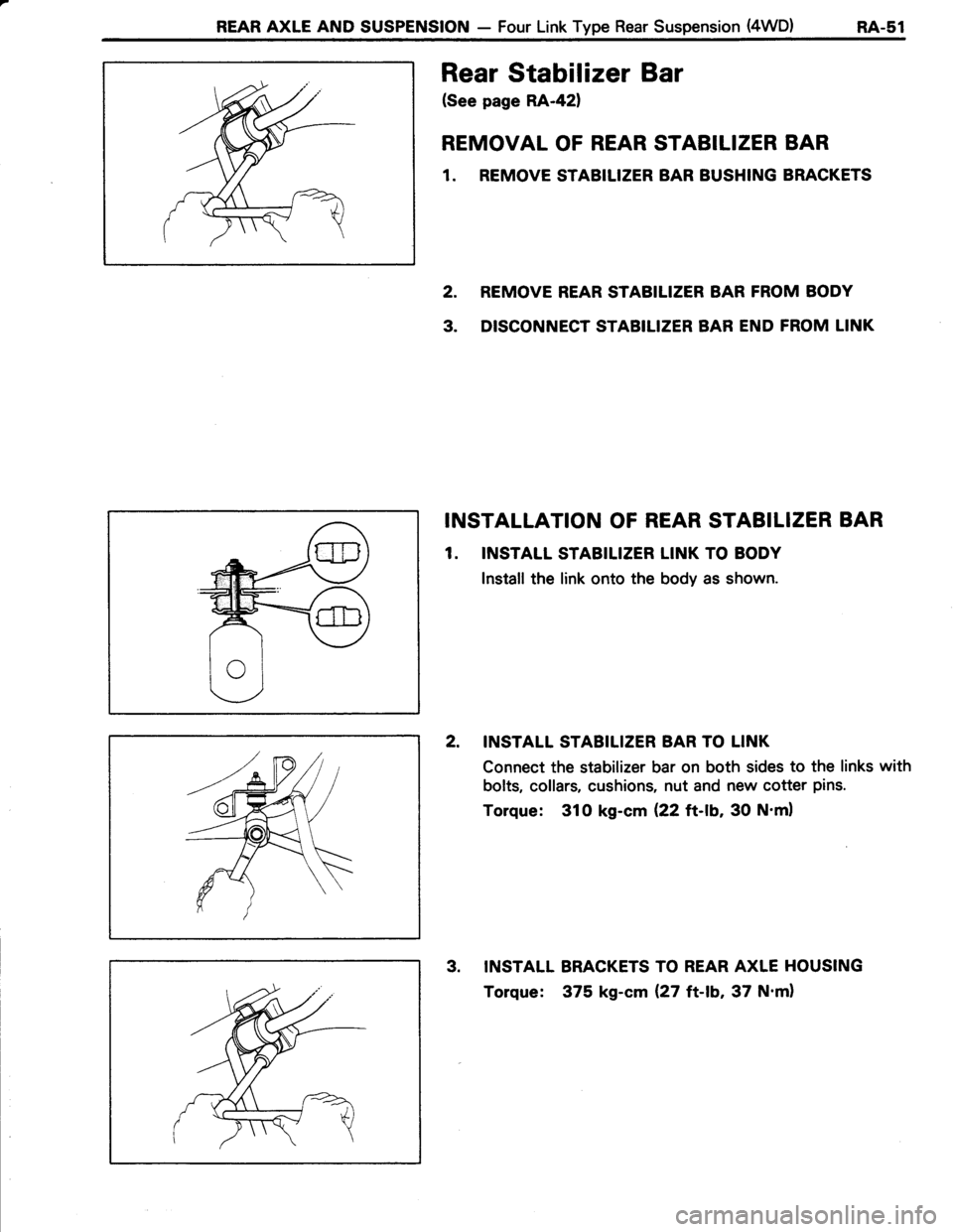

Rear Stabilizer Bar

(See page RA-421

REMOVAL OF REAR STABILIZER BAR

1. REMOVE STABILIZER BAR BUSHING BRACKETS

2. REMOVE REAR STABILIZER BAR FROM BODY

3. DISCONNECT STABILIZER BAR END FROM LINK

INSTALLATION OF REAR STABILIZER BAR

1. INSTATL STABILIZER LINK TO BODY

Install the link onto the body as shown.

2. INSTALL STABILIZER BAR TO LINK

Connect the stabilizer bar on both sides to the links with

bolts, collars, cushions, nut and new cotter pins.

Torque: 310 kg-cm (22 ft-\b,30 N'ml

3. INSTALL BRACKETS TO REAR AXLE HOUSING

Torque: 375 kg-cm 127 ft-1b,37 N'm)

Page 564 of 885

BRAKE SYSTEM - TroubleshootingBR-5

TROUBLESHOOTING (Cont'dl

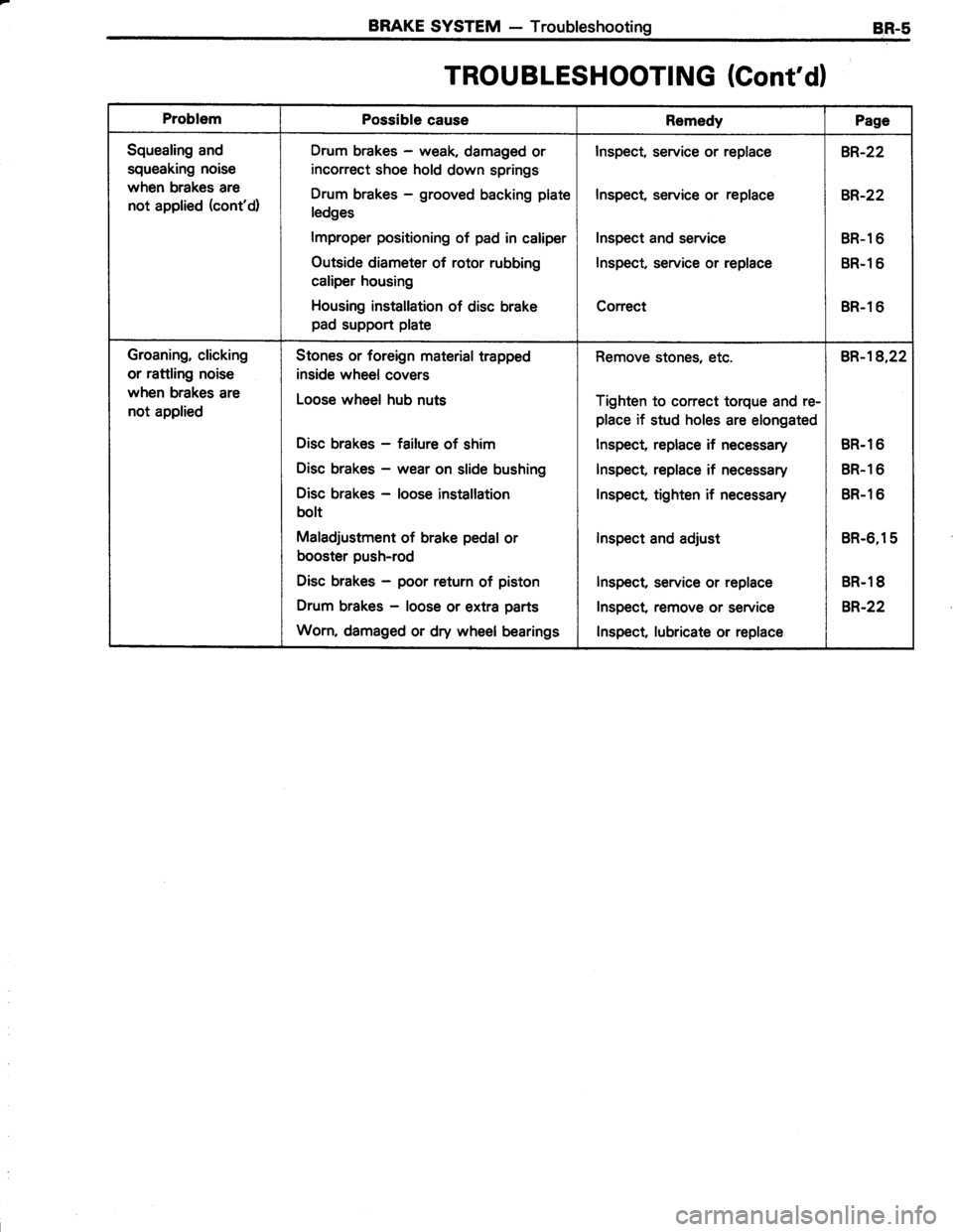

ProblemPossible causeRemedyPage

Squealing and

squeaking noise

when brakes are

not applied (cont'd)

Drum brakes - weak, damaged or

incorrect shoe hold down springs

Drum brakes - grooved backing plate

ledges

lmproper positioning of pad in caliper

Outside diameter of rotor rubbing

caliper housing

Housing installation of disc brake

pad support plate

Inspect, service or replace

Inspect, service or replace

Inspect and service

Inspect, service or replace

Correct

BR-22

BR-22

BR-l 6

BR-l 6

BR-1 6

Groaning, clicking

or rattling noise

when brakes are

not applied

Stones or foreign material trapped

inside wheel covers

Loose wheel hub nuts

Disc brakes - failure of shim

Disc brakes - wear on slide bushing

Disc brakes - loose installation

bolt

Maladjustment of brake pedal or

booster push-rod

Disc brakes - poor return of piston

Drum brakes - loose or extra parts

Worn, damaged or dry wheel bearings

Remove stones, etc.

Tighten to correct torque and re-

place if stud holes are elongated

lnspect, replace if necessary

Inspect, replace if necessary

Inspect, tighten if necessary

lnspect and adjust

Inspect, service or replace

Inspect remove or service

lnspect lubricate or replace

BR-18,22

BR.1 6

BR.1 6

BR-1 6

BR-6,15

BR.1 8

B,R.22

Page 566 of 885

BRAKE SYSTEM - Checks and AdjustmentsBR-7

@@

VV

1 st 2nd

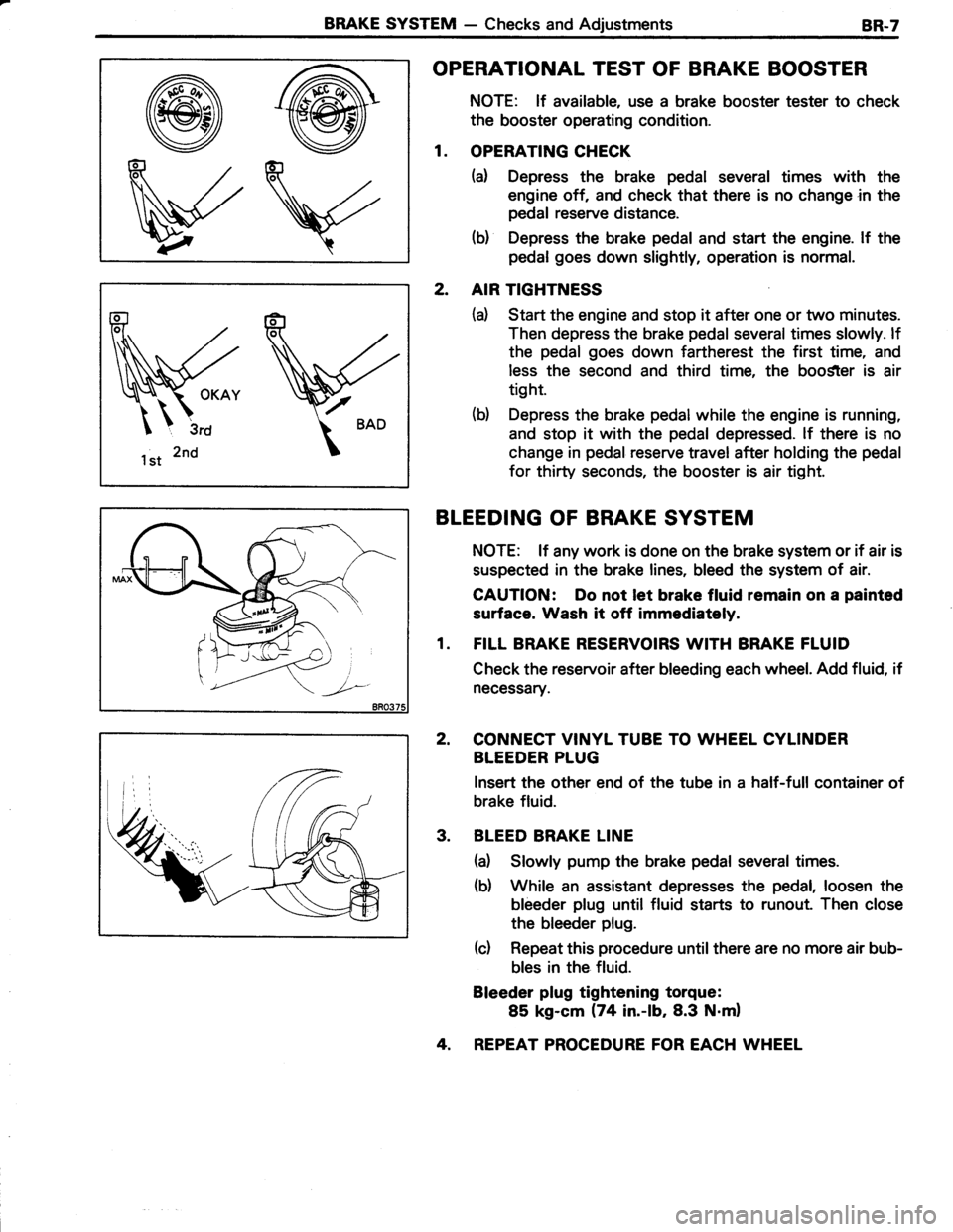

OPERATIONAL TEST OF BRAKE BOOSTER

NOTE: lf available, use a brake booster tester to check

the booster operating condition.

1. OPERATING CHECK

(a) Depress the brake pedal several times with the

engine off, and check that there is no change in the

pedal reserve distance.

(b) Depress the brake pedal and start the engine. lf the

pedal goes down slightly, operation is normal.

2. AIR TIGHTNESS

(d Start the engine and stop it after one or two minutes.

Then depress the brake pedal several times slowly. lf

the pedal goes down fartherest the first time, and

less the second and third time, the boo$ter is air

tight.

(b) Depress the brake pedal while the engine is running,

and stop it with the pedal depressed. lf there is no

change in pedal reserve travel after holding the pedal

for thirty seconds, the booster is air tight.

BLEEDING OF BRAKE SYSTEM

NOTE: lf any work is done on the brake system or if air is

suspected in the brake lines, bleed the system of air.

CAUTION: Do not let brake fluid remain on a painted

surface. Wash it off immediataly.

1. FILL BRAKE RESERVOIRS WITH BRAKE FLUID

Check the reservoir after bleeding each wheel. Add fluid, if

necessary.

2, CONNECT VINYL TUBE TO WHEEL CYLINDER

BLEEDER PLUG

lnsert the other end of the tube in a half-full container of

brake fluid.

3. BLEED BRAKE LINE

(a) Slowly pump the brake pedal several times.

(b) While an assistant depresses the pedal, loosen the

bleeder plug until fluid starts to runout. Then close

the bleeder plug.

(c) Repeat this procedure until there are no more air bub-

bles in the fluid.

Bleeder plug tightening torque:

85 kg-cm (74 in.-lb,8.3 N.m)

4. REPEAT PROCEDURE FOR EACH WHEEL