key VAUXHALL ANTARA 2015 Owner's Guide

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015, Model line: ANTARA, Model: VAUXHALL ANTARA 2015Pages: 223, PDF Size: 6.07 MB

Page 130 of 223

128Driving and operating■ Switch off the engine and turnthe ignition key to position

LOCK , push key into ignition

switch and remove.

Turn the steering wheel until the steering wheel lock is felt to

engage.

For vehicles with automatic

transmission, depress foot

brake and shift into P before

pushing key into ignition switch

and removing.

■ If the vehicle is on a level surface or uphill slope, engage

first gear or move the selector

lever to P before switching off

the ignition. On an uphill slope,

turn the front wheels away from

the kerb.

If the vehicle is on a downhill

slope, engage reverse gear or

move the selector lever to P

before switching off the ignition.

Turn the front wheels towards

the kerb.■ Close windows and sunroof.

■ Lock the vehicle with button p on

the radio remote control 3 21.

Activate the anti-theft alarm system

3 25.Engine exhaust9 Danger

Engine exhaust gases contain

poisonous carbon monoxide,

which is colourless and odourless and could be fatal if inhaled.

If exhaust gases enter the interior

of the vehicle, open the windows.

Have the cause of the fault

rectified by a workshop.

Avoid driving with an open load

compartment, otherwise exhaust

gases could enter the vehicle.

Malfunction indicator light 3 85.

Diesel particle filter

The diesel particle filter system filters

harmful soot particles out of the

exhaust gases. The system includes

a self-cleaning function that runs

automatically during driving without

any notification.

Page 133 of 223

Driving and operating131

The selector lever is locked in position

P and N and can only be moved when

the ignition is on and the foot brake is applied.

To engage P or R, push the release

button.

Never shift to P or R while the vehicle

is moving.

The engine can only be started with

lever in position P or N. Depress foot

brake or apply electrical parking

brake before starting.

Do not accelerate while engaging a

gear. Never depress the accelerator

pedal and brake pedal at the same

time.

When a gear is engaged, the vehicle

slowly begins to creep when the foot

brake is released.

Engine braking To utilise the engine braking effect,

select a lower gear in good time when

driving downhill - see Manual mode.

Use of the engine braking effect, as

opposed to the use of the foot brake

when driving downhill, can extend the

life of the brakes.Rocking the vehicle

Rocking the vehicle is only

permissible if the vehicle is stuck in

water, ice, sand, mud, snow or a dip.

Move the selector lever between D

and R in a repeat pattern while

applying light pressure to the

accelerator pedal when the vehicle is in gear. Do not race the engine and

avoid sudden acceleration.

If the vehicle cannot be released after

rocking the vehicle several times,

your vehicle may need to be towed

3 192.

Parking

Apply the electrical parking brake and engage P.

The ignition key can only be removed

when the selector lever is in position

P .Manual mode

Move selector lever out of position D

towards the left and then forwards or backwards.

<=Shift to a higher gear.]=Shift to a lower gear.

Tip selector lever in the appropriate

direction. It then returns to the centre

position.

Gearshifting in manual mode can be

achieved whilst accelerating. If the

engine speed is too low, the

Page 135 of 223

Driving and operating133

Deactivation

Fuel economy mode is switched off

by pressing button s again;

control indicator s extinguishes in

the instrument cluster.

Fault

In the event of a fault in the automatic

transmission, control indicator Z

illuminates in the instrument cluster 3 85 . Automatic shifting may be much

harsher than normal or, in the case of

a serious fault, cancelled altogether.

Have the cause of the fault remedied

by a workshop.

If control indicator g illuminates in

the instrument cluster when the

engine is running, this may indicate a

fault in the transmission electronics

3 85. The electronics switch to the

emergency running programme, fuel

consumption may increase and the

driveability of the vehicle may be

affected. Seek the assistance of a

workshop.Interruption of power

supply

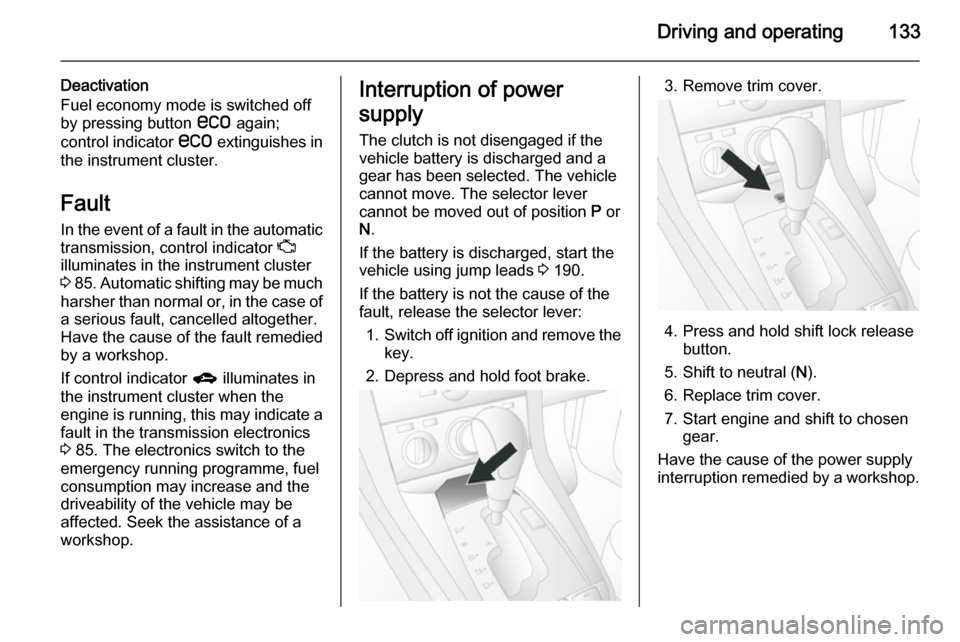

The clutch is not disengaged if the

vehicle battery is discharged and a

gear has been selected. The vehicle

cannot move. The selector lever

cannot be moved out of position P or

N .

If the battery is discharged, start the

vehicle using jump leads 3 190.

If the battery is not the cause of the

fault, release the selector lever:

1. Switch off ignition and remove the

key.

2. Depress and hold foot brake.3. Remove trim cover.

4. Press and hold shift lock release button.

5. Shift to neutral ( N).

6. Replace trim cover.

7. Start engine and shift to chosen gear.

Have the cause of the power supply

interruption remedied by a workshop.

Page 150 of 223

148Driving and operating

If no eye is available, loop cable

around coupling ball bar. Ensure

cable is crossed under the vertical

coupling socket to ensure the trailer

nose cannot drop to the ground if it

becomes separated from the trailer

hitch. Do not allow the cable to drag

along the ground and always allow

enough slack to permit full turning.

Follow the instructions supplied with

the towing equipment.

Before attaching a trailer, lubricate

the coupling ball. However, do not do

so if a stabiliser, which acts on the coupling ball, is being used to reduce snaking movements. For trailers with

low driving stability, the use of a

friction-type stabiliser is strongly

recommended.

Do not drive faster than 50 mph, even

in countries where higher speeds are

permitted. When driving uphill, do not drive faster than 20 mph in 1st gear,

or 30 mph in 2nd gear.

If the trailer starts snaking, drive more slowly, do not attempt to correct the

steering and brake sharply if

necessary.When driving downhill, drive in the

same gear as if driving uphill and

drive at a similar speed.

Adjust tyre pressure to the value

specified for full load 3 210.

Trailer towing Trailer loads

The permissible trailer loads are

vehicle-dependent and engine-

dependent maximum values which

must not be exceeded. The actual

trailer load is the difference between

the actual gross weight of the trailer

and the actual coupling socket load

with the trailer coupled.

When the trailer load is being

checked, therefore, only the trailer

wheels - and not the jockey wheel -

must be standing on the weighing

apparatus.

The permissible trailer loads are

specified in the vehicle documents. In general, they are valid for gradients

up to max. 12 %.The permitted trailer load applies up

to the specified incline and up to an

altitude of 1000 metres above sea

level. Since engine power decreases

as altitude increases due to the air

becoming thinner, therefore reducing

climbing ability, the permissible gross train weight also decreases by 10 %

for every 1000 metres of additional

altitude. The gross train weight does

not have to be reduced when driving

on roads with slight inclines (less than

8 %, e.g. motorways).

The permissible gross train weight

must not be exceeded. This weight is

specified on the identification plate

3 201.

Vertical coupling load

The vertical coupling load is the load

exerted by the trailer on the coupling

ball. It can be varied by changing the

weight distribution when loading the

trailer.

The maximum permissible vertical

coupling load (80 kg) is specified on

the towing equipment identification

plate and in the vehicle documents.

Always aim for the maximum load,

Page 152 of 223

150Driving and operating

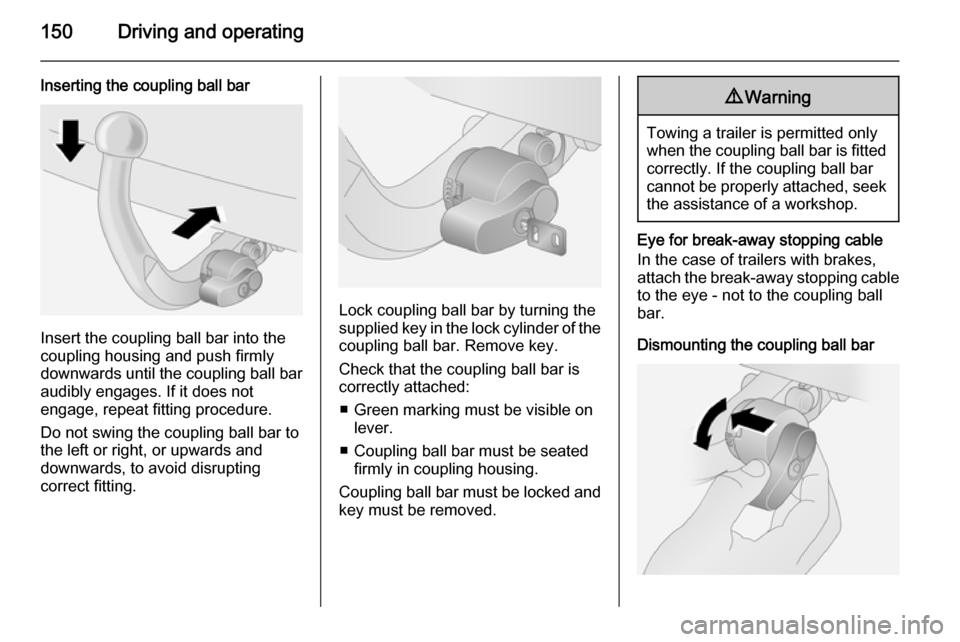

Inserting the coupling ball bar

Insert the coupling ball bar into the

coupling housing and push firmly

downwards until the coupling ball bar

audibly engages. If it does not

engage, repeat fitting procedure.

Do not swing the coupling ball bar to

the left or right, or upwards and

downwards, to avoid disrupting

correct fitting.

Lock coupling ball bar by turning the supplied key in the lock cylinder of the coupling ball bar. Remove key.

Check that the coupling ball bar is

correctly attached:

■ Green marking must be visible on lever.

■ Coupling ball bar must be seated firmly in coupling housing.

Coupling ball bar must be locked and key must be removed.

9 Warning

Towing a trailer is permitted only

when the coupling ball bar is fitted correctly. If the coupling ball bar

cannot be properly attached, seek the assistance of a workshop.

Eye for break-away stopping cable

In the case of trailers with brakes,

attach the break-away stopping cable

to the eye - not to the coupling ball

bar.

Dismounting the coupling ball bar

Page 153 of 223

Driving and operating151

Unlock coupling ball bar and remove

key. Push lever to the left, towards the

coupling ball bar and turn it

downwards. Pull coupling ball bar out of coupling housing.

Remove any rust or dirt from area

around the coupling housing and

coupling ball bar connection before

inserting sealing plug in the hole.

Place the coupling ball bar in the bag supplied, fasten it with the strap and

stow it below the floor cover in the

load compartment.

Do not use steam-jet cleaners or

other high-pressure cleaners to clean

the coupling ball bar.

Trailer stability assist If the system detects snaking

movements, engine power is reduced

and the vehicle/trailer combination is

selectively braked until the snaking ceases. While system is working keep steering wheel as still as possible.

Trailer stability assist (TSA) is a

function of the Electronic Stability

Control 3 139.

Page 162 of 223

160Vehicle care

Charging the vehicle battery9Warning

On vehicles with stop-start

system, ensure that the charging potential does not exceed

14.6 volts when using a battery

charger. Otherwise the vehicle

battery might be damaged.

Jump starting 3 190.

Warning label

Meaning of symbols: ■ No sparks, naked flames or smoking.

■ Always shield eyes. Explosive gases can cause blindness or

injury.

■ Keep the vehicle battery out of reach of children.

■ The vehicle battery contains sulfuric acid which could cause

blindness or serious burn injuries.

■ See the Owner's Manual for further

information.

■ Explosive gas may be present in the vicinity of the vehicle battery.Diesel fuel filter

Drain diesel fuel filter of residual

water at every engine oil change.

Place a container underneath the

filter housing. Turn drain plug

anticlockwise using a suitable

screwdriver, to drain off the water.

The filter is drained as soon as diesel fuel emerges from the port. Retighten

the drain plug by turning it clockwise.

With engine switched off, turn ignition

key to ON, wait approx. 5 seconds,

and turn key to LOCK to perform

priming operation. Perform this

Page 176 of 223

174Vehicle care

FuseCircuitAMPAmplifierAPO JACK

(CONSOLE)Power outlet

(centre console)APO JACK

(REAR CARGO)Power outlet

(load compart‐

ment)AWD/VENTAll-wheel drive,

ventilationBCM (CTSY)Courtesy lightsBCM (DIMMER)Instrument illu‐

minationBCM (INT LIGHT

TRLR FOG)Interior lights,

trailer fog lightBCM (PRK/TRN)Parking lights,

turn signalsBCM (STOP)Brake lightsBCM (TRN SIG)Turn signalsBCM (VBATT)Battery voltageFuseCircuitCIMCommunica‐

tions Integration

ModuleCLSTRInstrument

clusterDRLDaytime running

lightsDR/LCKDriver door lockDRVR PWR

SEATDriver power

seatDRV/PWR

WNDWDriver power

windowF/DOOR LOCKFuel filler flapFRT WSRFront washerFSCMFuel systemFSCM/VENT SOLFuel system,

vent solenoidHEATING MAT

SWHeating mat

switchHTD SEAT PWRSeat heatingFuseCircuitHVAC BLWRClimate control,

air conditioning

fanIPCInstrument panel clusterISRVM/RCMInterior mirror,

remote compass moduleKEY CAPTUREKey captureL/GATETailgateLOGISTIC MODELogistic modeOSRVMExterior mirrorsPASS PWR

WNDWPassenger

power windowPWR DIODEPower diodePWR MODINGPower modingRADIORadioRR FOGHeated rear

window

Page 177 of 223

Vehicle care175

FuseCircuitRUN 2Power battery

key on runRUN/CRNKRun crankSDM (BATT)Safety Diag‐

nosis Module

(Battery)SDM (IGN 1)Safety Diag‐

nosis Module

(Ignition)SPARE-S/ROOFSunroofS/ROOF BATTSunroof batterySSPSPower steeringSTR/WHL SWSteering wheelTRLRTrailerTRLR BATTTrailer batteryFuseCircuitXBCMExport Body

Control ModuleXM/HVAC/DLCXM satellite

radio, climate

control, data link

connection

After changing of defective fuses

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunctions may occur.

Vehicle tools

Tools

Vehicles with spare wheel

In vehicles with a spare wheel, a jack and vehicle tools kit are available.

The jack and vehicle tools have been

specially developed for your vehicle

and must only be used on that

vehicle. Only use jack for changing

wheels.

The jack and vehicle tools are in a

storage compartment below the floor

cover in the load compartment.

Page 180 of 223

178Vehicle care

V=up to 150 mphW=up to 168 mph

Tyre pressureCheck the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Use the valve cap key to make

unscrewing the valve caps easier.

The valve cap key is located on the

inside of the tank flap.

Tyre pressure 3 210.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 205.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 210.

For the tyres approved for your

vehicle, refer to the EEC Certificate of Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

If the tyre pressure must be reduced

or increased on a vehicle with tyre

pressure monitoring system, switch

off ignition.

Tyre pressure monitoring system The tyre pressure monitoring system

checks the pressure of all four wheels

once per minute when vehicle speed

exceeds a certain limit.Caution

Tyre pressure monitoring system

warns only about low tyre pressure

condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure. If

wheels without sensors are mounted,

the tyre pressure monitoring system

is not operational.