VAUXHALL GRANDLAND X 2018 Owner's Manual

Manufacturer: VAUXHALL, Model Year: 2018, Model line: GRANDLAND X, Model: VAUXHALL GRANDLAND X 2018Pages: 263, PDF Size: 7.41 MB

Page 211 of 263

Vehicle care209● See the Owner's Manual forfurther information.

● Explosive gas may be present in the vicinity of the vehicle battery.

Diesel fuel system bleeding If the tank has been run dry, the diesel

fuel system must be bled. Switch on the ignition three times for

15 seconds at a time. Then crank the

engine for a maximum of

40 seconds. Repeat this process after

no less than five seconds. If the

engine fails to start, seek the

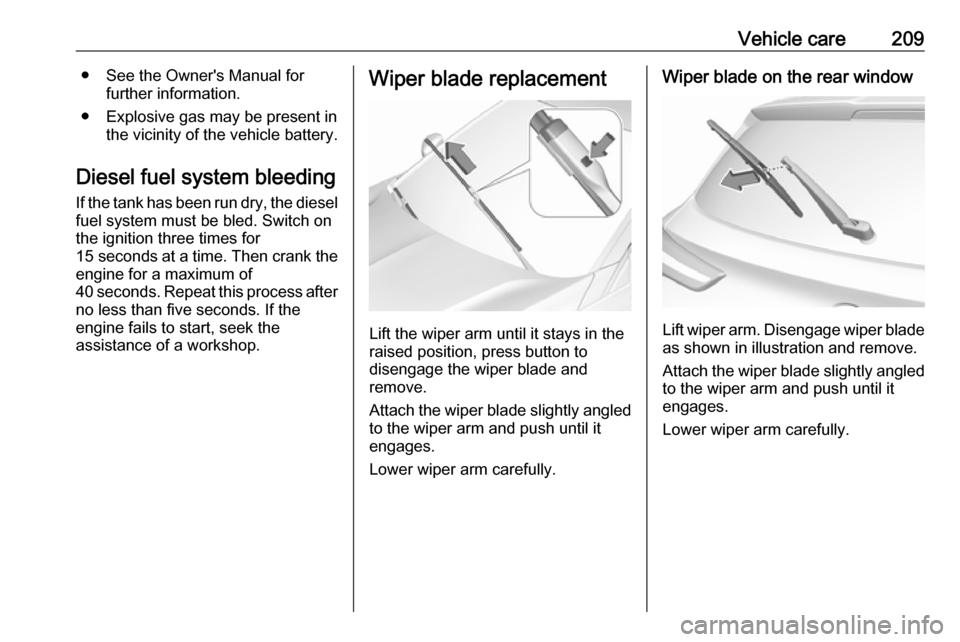

assistance of a workshop.Wiper blade replacement

Lift the wiper arm until it stays in the

raised position, press button to

disengage the wiper blade and

remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Wiper blade on the rear window

Lift wiper arm. Disengage wiper blade as shown in illustration and remove.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Page 212 of 263

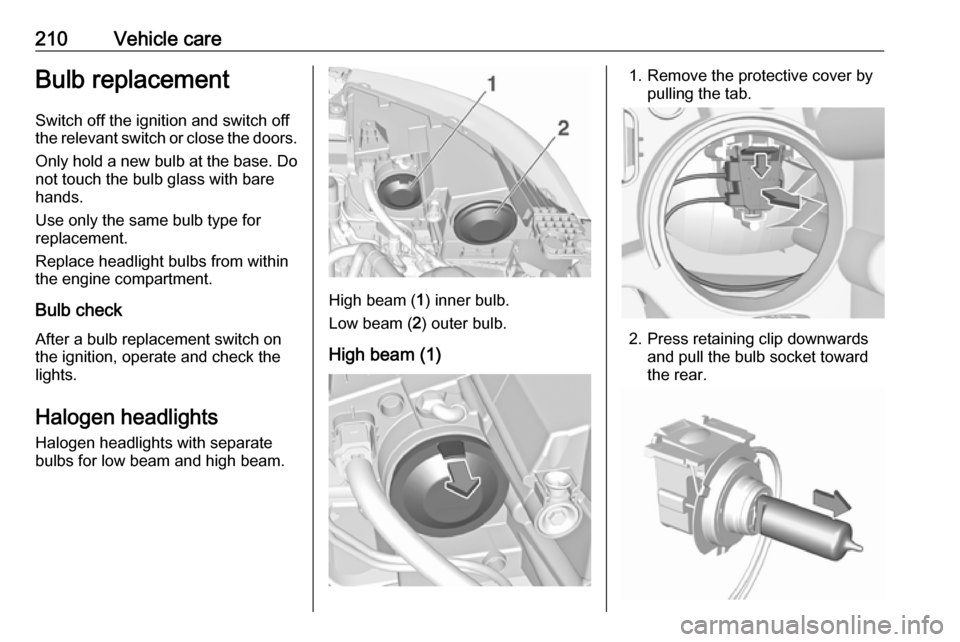

210Vehicle careBulb replacement

Switch off the ignition and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base. Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Bulb check After a bulb replacement switch on

the ignition, operate and check the

lights.

Halogen headlights

Halogen headlights with separate

bulbs for low beam and high beam.

High beam ( 1) inner bulb.

Low beam ( 2) outer bulb.

High beam (1)

1. Remove the protective cover by pulling the tab.

2. Press retaining clip downwardsand pull the bulb socket toward

the rear.

Page 213 of 263

Vehicle care2113. Detach the bulb from the bulbsocket and replace the bulb.

4. Insert the bulb socket into the reflector housing.

5. Fit the cap on.

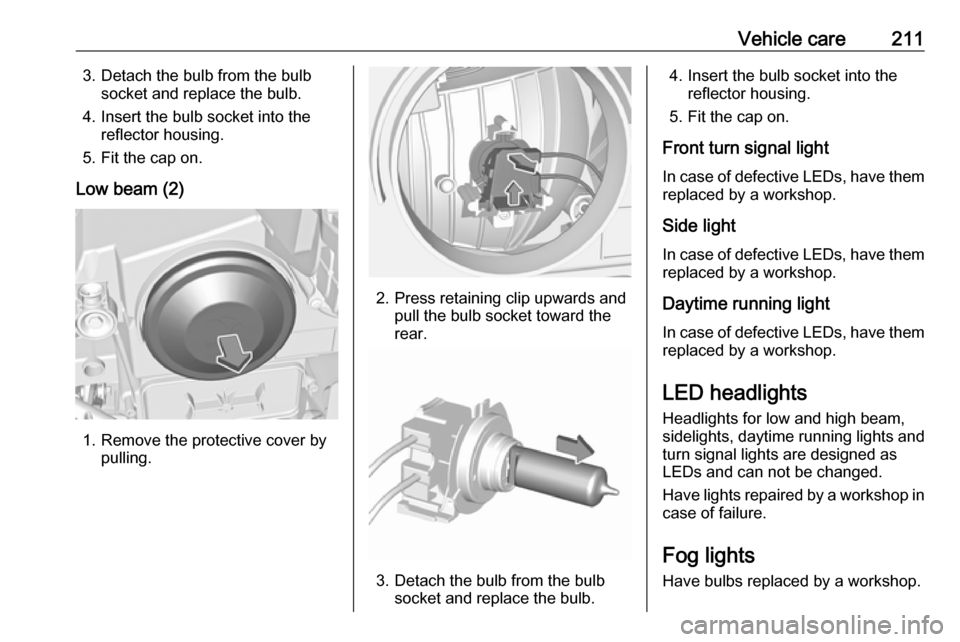

Low beam (2)

1. Remove the protective cover by pulling.

2. Press retaining clip upwards and pull the bulb socket toward the

rear.

3. Detach the bulb from the bulb socket and replace the bulb.

4. Insert the bulb socket into the reflector housing.

5. Fit the cap on.

Front turn signal light In case of defective LEDs, have them

replaced by a workshop.

Side light

In case of defective LEDs, have them replaced by a workshop.

Daytime running light In case of defective LEDs, have them

replaced by a workshop.

LED headlights

Headlights for low and high beam,

sidelights, daytime running lights and turn signal lights are designed as

LEDs and can not be changed.

Have lights repaired by a workshop in

case of failure.

Fog lights

Have bulbs replaced by a workshop.

Page 214 of 263

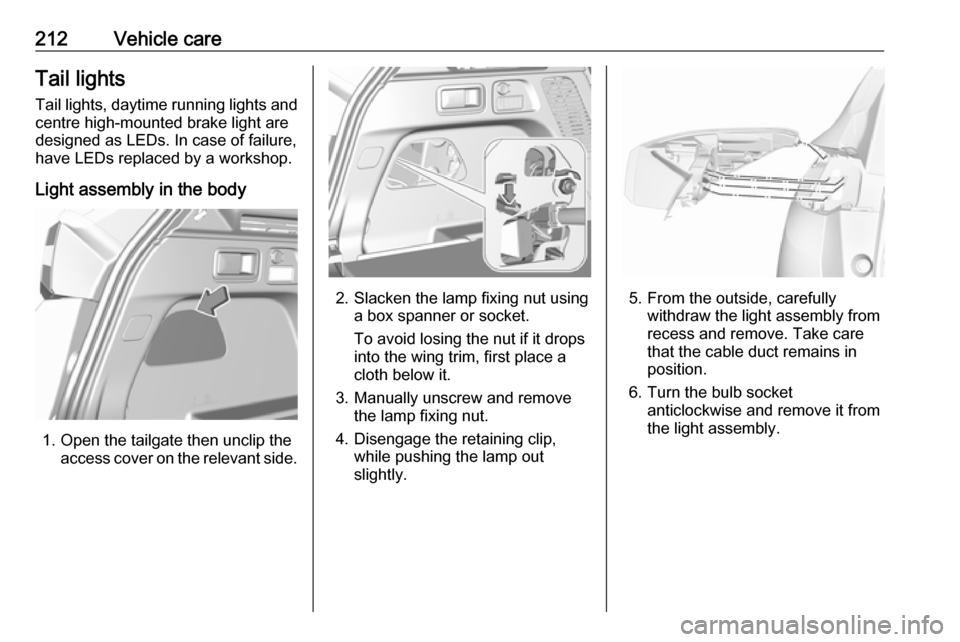

212Vehicle careTail lightsTail lights, daytime running lights and

centre high-mounted brake light are

designed as LEDs. In case of failure, have LEDs replaced by a workshop.

Light assembly in the body

1. Open the tailgate then unclip the access cover on the relevant side.

2. Slacken the lamp fixing nut usinga box spanner or socket.

To avoid losing the nut if it drops

into the wing trim, first place a

cloth below it.

3. Manually unscrew and remove the lamp fixing nut.

4. Disengage the retaining clip, while pushing the lamp out

slightly.5. From the outside, carefully withdraw the light assembly from

recess and remove. Take care

that the cable duct remains in

position.

6. Turn the bulb socket anticlockwise and remove it from

the light assembly.

Page 215 of 263

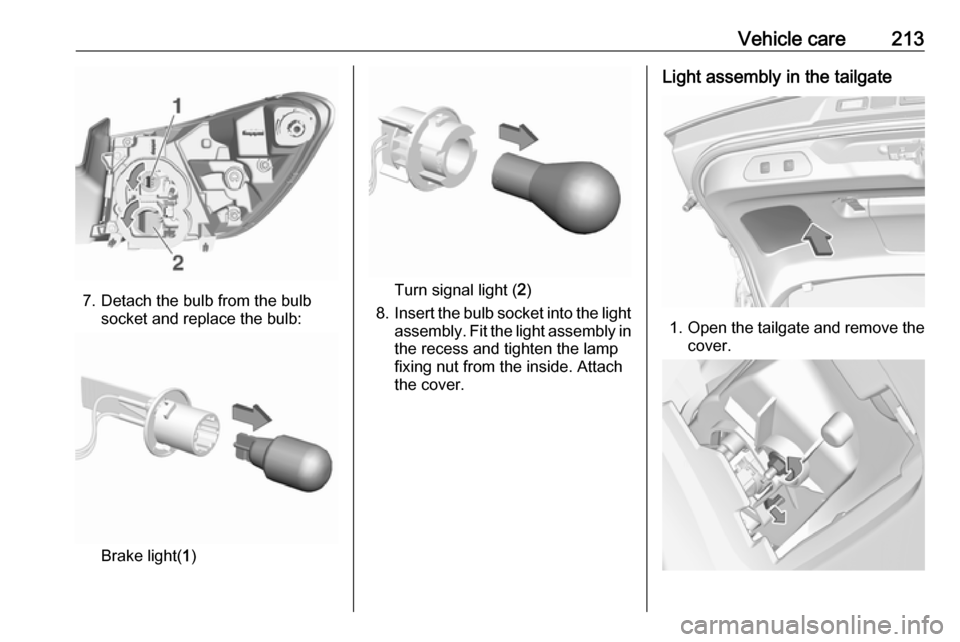

Vehicle care213

7. Detach the bulb from the bulbsocket and replace the bulb:

Brake light( 1)

Turn signal light ( 2)

8. Insert the bulb socket into the light

assembly. Fit the light assembly in the recess and tighten the lamp

fixing nut from the inside. Attach the cover.

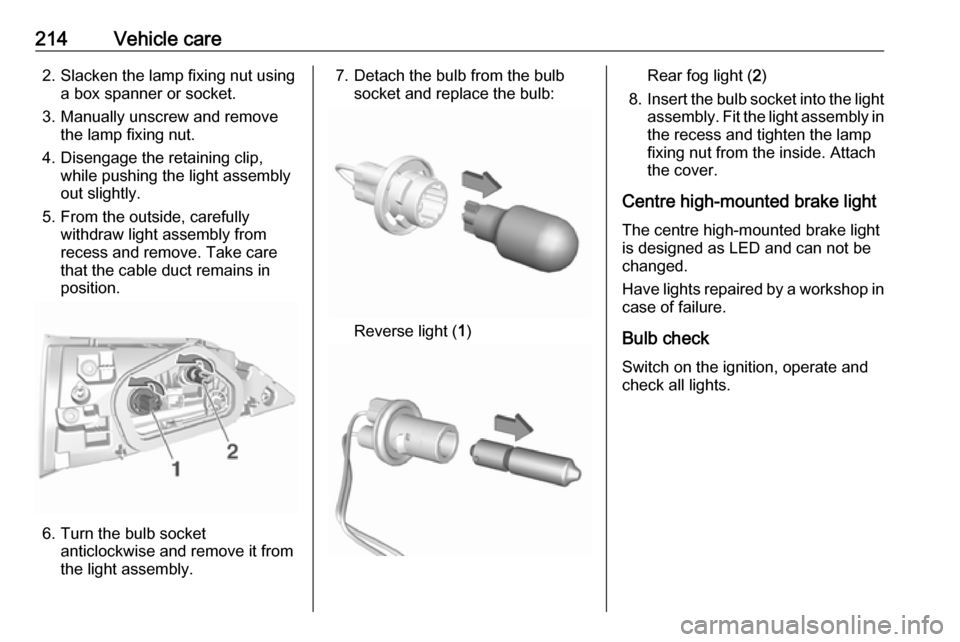

Light assembly in the tailgate

1. Open the tailgate and remove the

cover.

Page 216 of 263

214Vehicle care2. Slacken the lamp fixing nut usinga box spanner or socket.

3. Manually unscrew and remove the lamp fixing nut.

4. Disengage the retaining clip, while pushing the light assembly

out slightly.

5. From the outside, carefully withdraw light assembly from

recess and remove. Take care

that the cable duct remains in

position.

6. Turn the bulb socket anticlockwise and remove it from

the light assembly.

7. Detach the bulb from the bulb socket and replace the bulb:

Reverse light ( 1)

Rear fog light ( 2)

8. Insert the bulb socket into the light

assembly. Fit the light assembly in the recess and tighten the lamp

fixing nut from the inside. Attach

the cover.

Centre high-mounted brake light The centre high-mounted brake light

is designed as LED and can not be

changed.

Have lights repaired by a workshop in

case of failure.

Bulb check

Switch on the ignition, operate and

check all lights.

Page 217 of 263

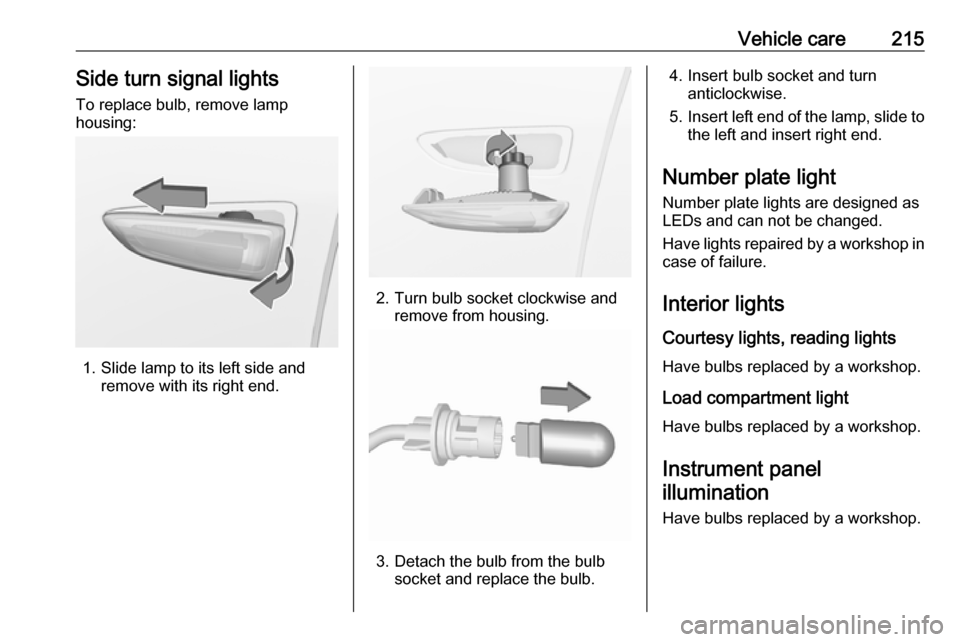

Vehicle care215Side turn signal lights

To replace bulb, remove lamp

housing:

1. Slide lamp to its left side and remove with its right end.

2. Turn bulb socket clockwise andremove from housing.

3. Detach the bulb from the bulb socket and replace the bulb.

4. Insert bulb socket and turnanticlockwise.

5. Insert left end of the lamp, slide to

the left and insert right end.

Number plate light Number plate lights are designed as

LEDs and can not be changed.

Have lights repaired by a workshop in

case of failure.

Interior lights

Courtesy lights, reading lights Have bulbs replaced by a workshop.

Load compartment light

Have bulbs replaced by a workshop.

Instrument panel illumination

Have bulbs replaced by a workshop.

Page 218 of 263

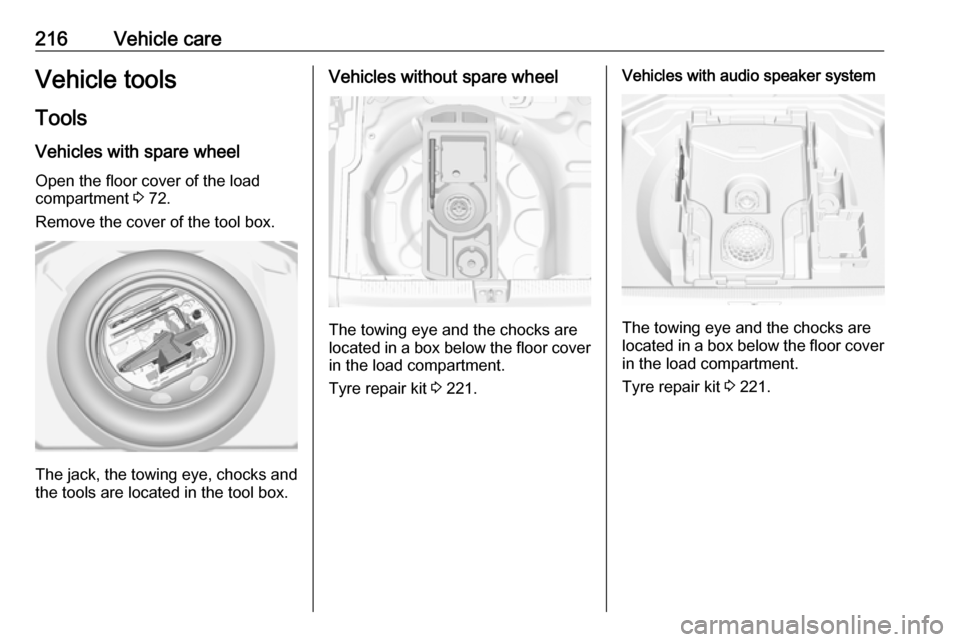

216Vehicle careVehicle tools

Tools

Vehicles with spare wheel Open the floor cover of the load

compartment 3 72.

Remove the cover of the tool box.

The jack, the towing eye, chocks and

the tools are located in the tool box.

Vehicles without spare wheel

The towing eye and the chocks are

located in a box below the floor cover in the load compartment.

Tyre repair kit 3 221.

Vehicles with audio speaker system

The towing eye and the chocks are

located in a box below the floor cover in the load compartment.

Tyre repair kit 3 221.

Page 219 of 263

Vehicle care217Wheels and tyres

Tyre condition, wheel condition

Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Winter tyres

Winter tyres improve driving safety at temperatures below 7 °C and should

therefore be fitted on all wheels.

In accordance with country-specific

regulations, affix the speed sticker in

the driver's field of view.

All tyre sizes are permitted as winter

tyres 3 247.Tyre designations

E.g. 225/55 R 18 98 V225:tyre width, mm55:cross-section ratio (tyre height

to tyre width), %R:belt type: RadialRF:type: RunFlat18:wheel diameter, inches98:load index e.g. 98 is equivalent

to 750 kgV:speed code letter

Speed code letter:

Q:up to 100 mphS:up to 112 mphT:up to 118 mphH:up to 130 mphV:up to 150 mphW:up to 168 mph

Choose a tyre appropriate for the

maximum speed of your vehicle.

The maximum speed is achievable at kerb weight with driver (75 kg) plus

125 kg payload. Optional equipment

could reduce the maximum speed of

the vehicle.

Performance 3 244.

Directional tyres

Directional tyres should be mounted

so that they rotate in the correct

direction. The proper rotation

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

Tyre pressure

Check the pressure of cold tyres at

least every 14 days and before any

long journey. Do not forget the spare

wheel. This also applies to vehicles

with tyre pressure monitoring system.

Tyre pressure 3 247.

Page 220 of 263

218Vehicle careThe tyre pressure information labelon the left door frame indicates the

original equipment tyres and the

correspondent tyre pressures.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

The ECO tyre pressure serves to

achieve the smallest amount of fuel

consumption possible.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 243.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 247.For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.

The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

9 Warning

For specific tyres the

recommended tyre pressure as

shown in the tyre pressure table may exceed the maximum tyre

pressure as indicated on the tyre.

Never exceed the maximum tyre

pressure as indicated on the tyre.

Temperature dependency

The tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase. Tyre pressure

values provided on the tyre

information label and tyre pressure

chart are valid for cold tyres, which means at 20 °C.

The pressure increases by nearly

1.5 psi for a 10 °C temperature

increase. This must be considered

when warm tyres are checked.

The tyre pressure value displayed in

the Driver Information Centre shows

the real tyre pressure. A cooled down

tyre will show a decreased value,

which does not indicate an air leak.

Tyre deflation detectionsystem

The tyre deflation detection system continually checks the rotation speed

of all four wheels and warns on low

tyre pressure condition once vehicle

is driving. This is achieved by

comparing tyre rolling circumference

with reference values.