VAUXHALL MOVANO_B 2015 Owner's Manual

Manufacturer: VAUXHALL, Model Year: 2015, Model line: MOVANO_B, Model: VAUXHALL MOVANO_B 2015Pages: 209, PDF Size: 4.92 MB

Page 161 of 209

Vehicle care159

Relearn function

After changing the wheels, TPMS

needs to recalculate.

With the vehicle stationary, select the tyre pressure menu in the Driver

Information Centre by pressing button

on end of wiper lever. Press and hold button for approx. 3 seconds to

initialise recalculation. A

corresponding message appears in

the Driver Information Centre.

Several minutes of driving may be

required to complete the relearn

process.

If problems occur during the relearn

process, a warning message is

displayed in the Driver Information

Centre.

Driver Information Centre 3 84.

Vehicle messages 3 85.

General information The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory-

approved tyre repair kits can be used.

Tyre repair kit 3 161.

External high-power radio equipment

could disrupt the TPMS.

Each time the tyres are replaced,

TPMS sensors must be dismounted

and serviced by a workshop.

Fault The TPMS will not function properly if

one or more of the sensors are

missing or inoperable. When the

system detects a malfunction, w

flashes for several seconds and then

illuminates. Additionally a

corresponding message appears in

the Driver Information Centre.Control indicator w and the

corresponding message appear at

each ignition cycle until the problem

is corrected.

Some of the conditions that can

cause these to appear are:

■ One of the tyres has been replaced

with the spare tyre which does not

have a TPMS sensor.

■ The TPMS sensor relearn process was not completed successfully.

Control indicator w and the

corresponding message should

extinguish after successfully

completing the sensor relearn

process.

■ One or more TPMS sensors are missing or damaged. Control

indicator w and the corresponding

message should extinguish when the TPMS sensors are installed and

the sensor relearn process is

performed successfully. Consult a

workshop for service.

■ Replacement tyres or wheels do not match the original equipment

tyres or wheels. Tyres and wheels

Page 162 of 209

160Vehicle care

other than those recommended

could prevent the TPMS from

functioning properly.

■ Operating electronic devices or being near facilities using radio

wave frequencies similar to the

TPMS could cause the TPMS

sensors to malfunction.

If the TPMS is not functioning

properly, it cannot detect or signal

a low tyre condition. Consult a

workshop for service if control

indicator w illuminates and a

corresponding message appears in the Driver Information Centre.

Tread depth Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than

2 mm.

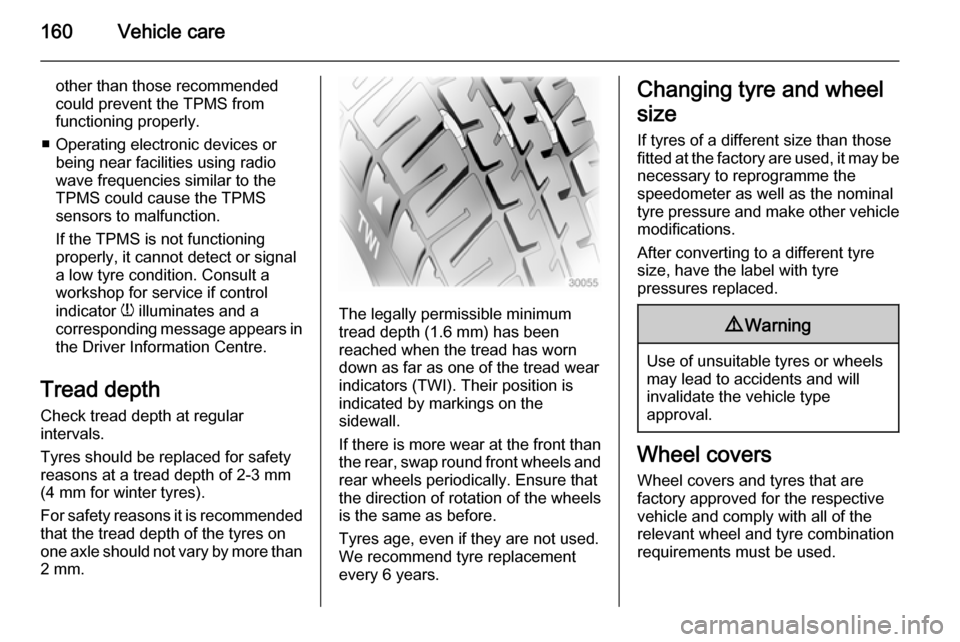

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels periodically. Ensure that

the direction of rotation of the wheels

is the same as before.

Tyres age, even if they are not used.

We recommend tyre replacement

every 6 years.

Changing tyre and wheel

size

If tyres of a different size than those

fitted at the factory are used, it may be necessary to reprogramme the

speedometer as well as the nominal tyre pressure and make other vehicle modifications.

After converting to a different tyre

size, have the label with tyre

pressures replaced.9 Warning

Use of unsuitable tyres or wheels

may lead to accidents and will

invalidate the vehicle type

approval.

Wheel covers

Wheel covers and tyres that are

factory approved for the respective

vehicle and comply with all of the

relevant wheel and tyre combination requirements must be used.

Page 163 of 209

Vehicle care161

If the wheel covers and tyres used are

not factory approved, the tyres must

not have a rim protection ridge.

Wheel covers must not impair brake

cooling.9 Warning

Use of unsuitable tyres or wheel

covers could lead to sudden

pressure loss and thereby

accidents.

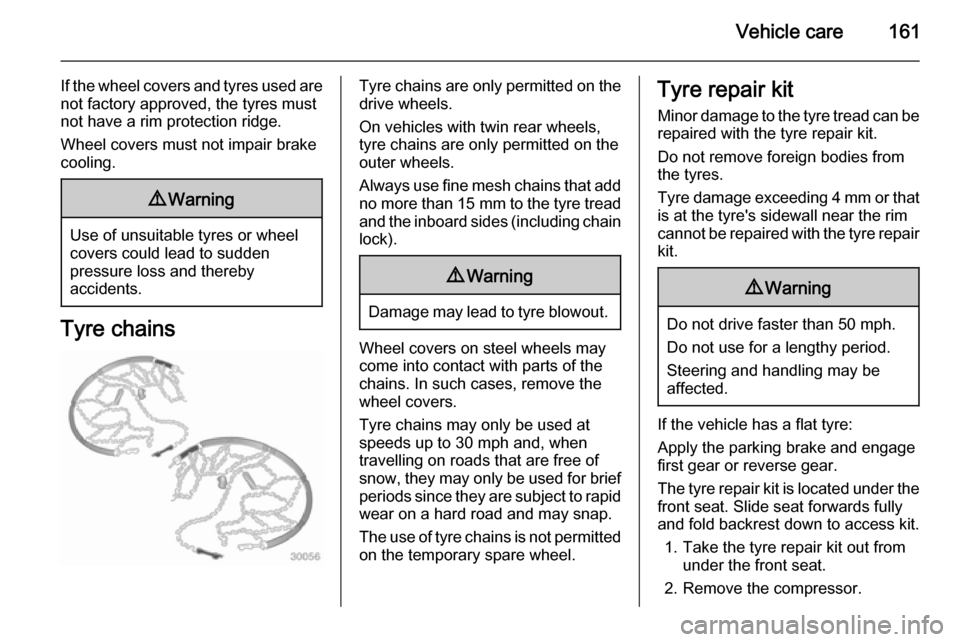

Tyre chains

Tyre chains are only permitted on the

drive wheels.

On vehicles with twin rear wheels,

tyre chains are only permitted on the

outer wheels.

Always use fine mesh chains that add no more than 15 mm to the tyre tread

and the inboard sides (including chain lock).9 Warning

Damage may lead to tyre blowout.

Wheel covers on steel wheels may

come into contact with parts of the

chains. In such cases, remove the

wheel covers.

Tyre chains may only be used at

speeds up to 30 mph and, when

travelling on roads that are free of

snow, they may only be used for brief

periods since they are subject to rapid wear on a hard road and may snap.

The use of tyre chains is not permitted on the temporary spare wheel.

Tyre repair kit

Minor damage to the tyre tread can be

repaired with the tyre repair kit.

Do not remove foreign bodies from

the tyres.

Tyre damage exceeding 4 mm or that

is at the tyre's sidewall near the rim

cannot be repaired with the tyre repair kit.9 Warning

Do not drive faster than 50 mph.

Do not use for a lengthy period.

Steering and handling may be

affected.

If the vehicle has a flat tyre:

Apply the parking brake and engage

first gear or reverse gear.

The tyre repair kit is located under the

front seat. Slide seat forwards fully

and fold backrest down to access kit.

1. Take the tyre repair kit out from under the front seat.

2. Remove the compressor.

Page 164 of 209

162Vehicle care

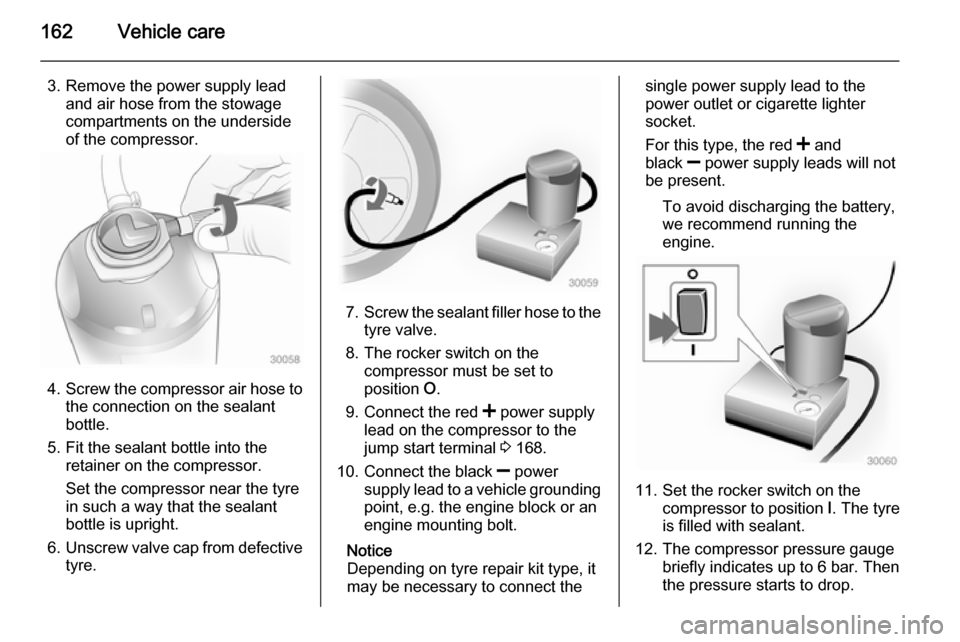

3. Remove the power supply leadand air hose from the stowage

compartments on the underside

of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.

6. Unscrew valve cap from defective

tyre.

7. Screw the sealant filler hose to the

tyre valve.

8. The rocker switch on the compressor must be set to

position O.

9. Connect the red < power supply

lead on the compressor to the

jump start terminal 3 168.

10. Connect the black ] power

supply lead to a vehicle grounding

point, e.g. the engine block or an

engine mounting bolt.

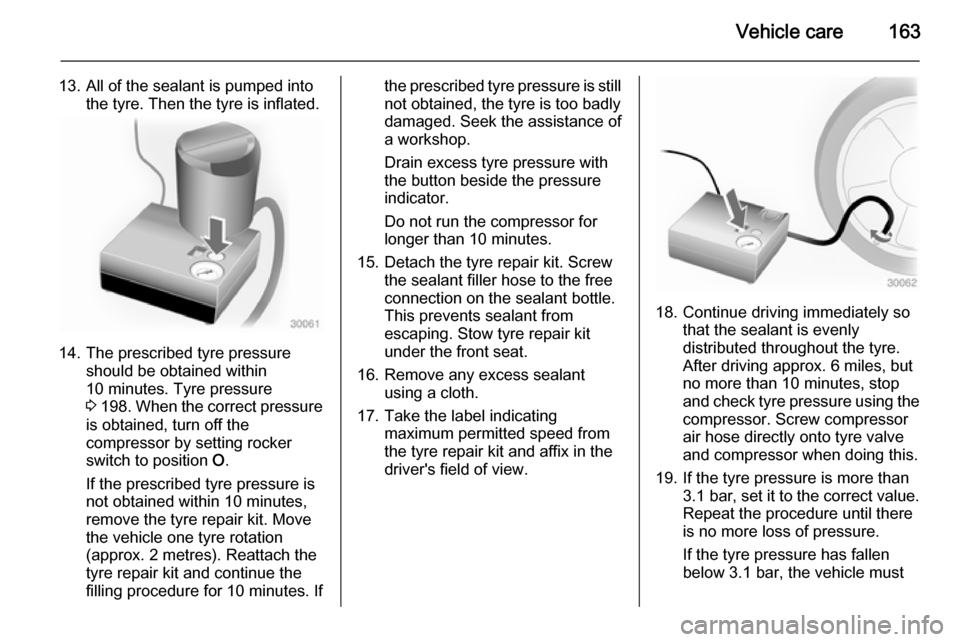

Notice

Depending on tyre repair kit type, it

may be necessary to connect the

single power supply lead to the

power outlet or cigarette lighter

socket.

For this type, the red < and

black ] power supply leads will not

be present.

To avoid discharging the battery,

we recommend running the

engine.

11. Set the rocker switch on the compressor to position I. The tyre

is filled with sealant.

12. The compressor pressure gauge briefly indicates up to 6 bar. Then

the pressure starts to drop.

Page 165 of 209

Vehicle care163

13. All of the sealant is pumped intothe tyre. Then the tyre is inflated.

14. The prescribed tyre pressure should be obtained within

10 minutes. Tyre pressure

3 198 . When the correct pressure

is obtained, turn off the

compressor by setting rocker

switch to position O.

If the prescribed tyre pressure is

not obtained within 10 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation

(approx. 2 metres). Reattach the

tyre repair kit and continue the

filling procedure for 10 minutes. If

the prescribed tyre pressure is still not obtained, the tyre is too badly

damaged. Seek the assistance of

a workshop.

Drain excess tyre pressure with

the button beside the pressure

indicator.

Do not run the compressor for

longer than 10 minutes.

15. Detach the tyre repair kit. Screw the sealant filler hose to the free

connection on the sealant bottle.

This prevents sealant from

escaping. Stow tyre repair kit

under the front seat.

16. Remove any excess sealant using a cloth.

17. Take the label indicating maximum permitted speed from

the tyre repair kit and affix in the

driver's field of view.

18. Continue driving immediately so that the sealant is evenly

distributed throughout the tyre.

After driving approx. 6 miles, but

no more than 10 minutes, stop

and check tyre pressure using the

compressor. Screw compressor

air hose directly onto tyre valve

and compressor when doing this.

19. If the tyre pressure is more than 3.1 bar , set it to the correct value.

Repeat the procedure until there

is no more loss of pressure.

If the tyre pressure has fallen

below 3.1 bar, the vehicle must

Page 166 of 209

164Vehicle care

not be driven. Seek the

assistance of a workshop.

20. Stow tyre repair kit under the front

seat.

Notice

The driving characteristics of the repaired tyre are severely affected,

therefore have this tyre replaced.

If unusual noise is heard or the

compressor becomes hot, turn

compressor off for at least

30 minutes.

The built-in safety valve opens at a

pressure of 7 bar (102 psi).

Note the expiry date of the kit. After

this date its sealing capability is no

longer guaranteed. Pay attention to

storage information on sealant

bottle.

Replace the used sealant bottle. Dispose of the bottle as prescribed

by applicable laws.

The compressor and sealant can be

used from approx. -30 °C.

The adapters supplied can be used

to pump up other items e.g.

footballs, air mattresses, inflatabledinghies etc. They are located on the underside of the compressor. To

remove, screw on compressor air

hose and withdraw adapter.

Wheel changing Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 161.

Make the following preparations and

observe the following information:

■ Park the vehicle on a level, firm and

non-slippery surface. The front wheels must be in the straight-ahead position.

■ Apply the parking brake and engage first gear or reverse gear.

■ Switch off the air suspension system 3 114.

■ Remove the spare wheel 3 166.

■ Never change more than one wheel

at a time.

■ Use the jack only to change wheels

in case of puncture, not for

seasonal winter or summer tyre

change.

■ The jack is maintenance-free.■ If the ground on which the vehicle is standing is soft, a solid board

(max. 1 cm thick) should be placed

under the jack.

■ No people or animals may be in the

vehicle when it is jacked-up.

■ Never crawl under a jacked-up vehicle.

■ Do not start the engine when the vehicle is raised on the jack.

■ Clean wheel bolts/nuts and their threads before mounting the wheel.9 Warning

Do not grease wheel bolt, wheel

nut and wheel nut cone.

1. Remove the wheel cover using the hook supplied. Vehicle tools

3 155.

2. Install the wheel wrench ensuring that it locates securely and loosen

each wheel bolt/nut by half a turn.

Page 167 of 209

Vehicle care165

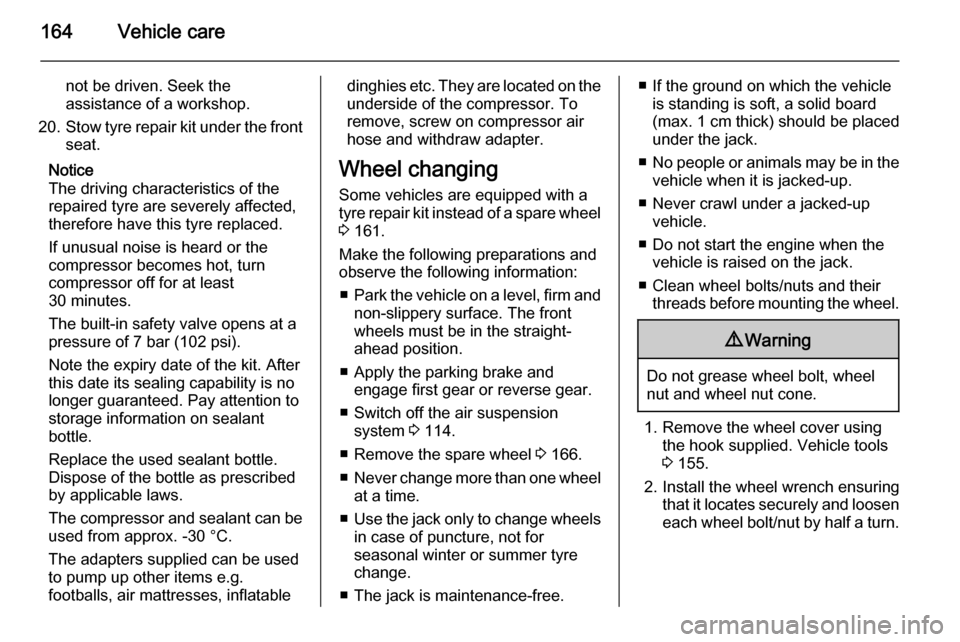

3. Vehicles with Front-wheel drive:Raise vehicle by placing lifting

pad spigot of the jack under the

jacking hole located nearest the

wheel concerned.

Ensure the jack is positioned

correctly. The jack base must be

on the ground directly below the

jacking hole in a manner that

prevents it from slipping.

Attach wheel wrench onto the jack

and raise the vehicle by turning

the wrench until the wheel is clear of the ground.

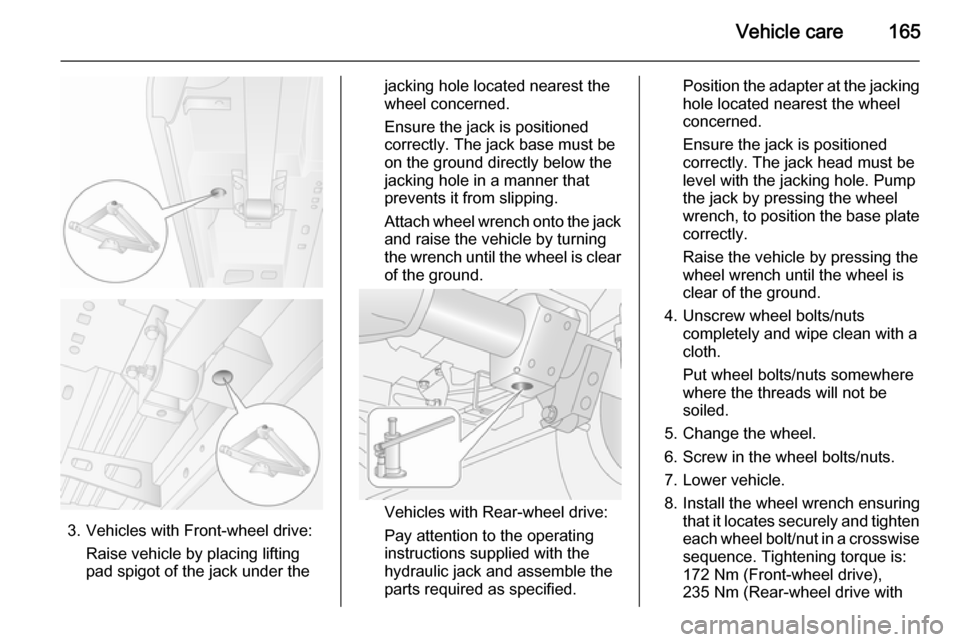

Vehicles with Rear-wheel drive:

Pay attention to the operating

instructions supplied with the

hydraulic jack and assemble the

parts required as specified.

Position the adapter at the jacking

hole located nearest the wheel

concerned.

Ensure the jack is positioned

correctly. The jack head must be

level with the jacking hole. Pump

the jack by pressing the wheel

wrench, to position the base plate

correctly.

Raise the vehicle by pressing the wheel wrench until the wheel is

clear of the ground.

4. Unscrew wheel bolts/nuts completely and wipe clean with a

cloth.

Put wheel bolts/nuts somewhere

where the threads will not be

soiled.

5. Change the wheel.

6. Screw in the wheel bolts/nuts.

7. Lower vehicle.

8. Install the wheel wrench ensuring that it locates securely and tighten

each wheel bolt/nut in a crosswise sequence. Tightening torque is:

172 Nm (Front-wheel drive),

235 Nm (Rear-wheel drive with

Page 168 of 209

166Vehicle care

twin rear wheels), 264 Nm (Rear-

wheel drive with single rear

wheels).

9. Refit wheel cover.

10. Stow the replaced wheel 3 166

and the vehicle tools 3 155.

11. Have the new wheel balanced on the vehicle. Check the tyre

pressure of the installed tyre

3 198 and also the wheel bolt/nut

torque as soon as possible.

Have the defective tyre renewed or

repaired.

Spare wheel Some vehicles are equipped with a

tyre repair kit instead of a spare wheel

3 161.

If mounting a spare wheel which is

different from the other wheels, this

wheel might be classified as a

temporary spare wheel and the

corresponding speed limits apply,

even though no label indicates this.

Seek the assistance of a workshop to

check the applicable speed limit.Caution

The use of a spare wheel that is smaller than the other wheels or in combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

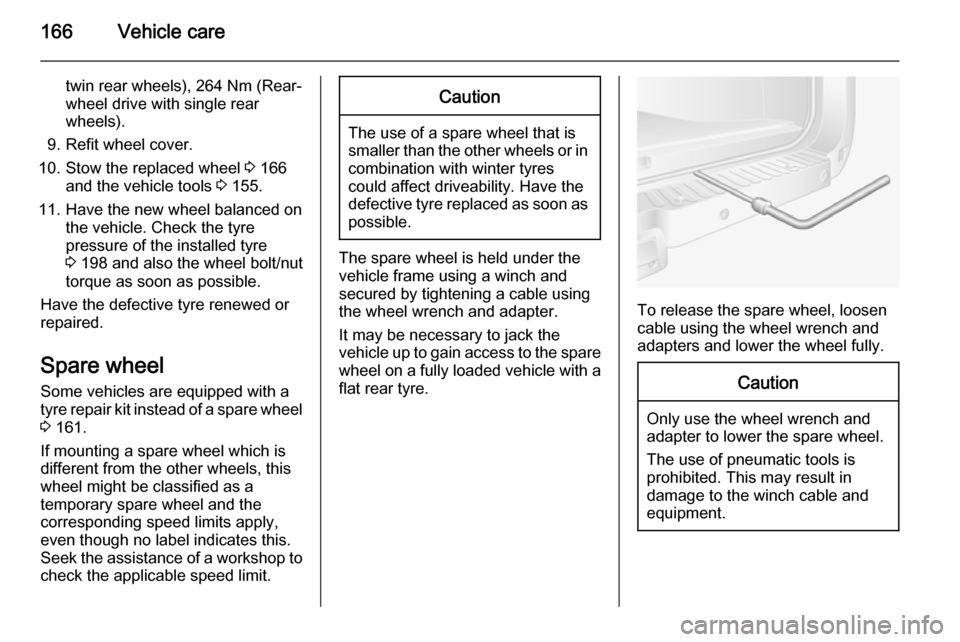

The spare wheel is held under the

vehicle frame using a winch and

secured by tightening a cable using

the wheel wrench and adapter.

It may be necessary to jack the

vehicle up to gain access to the spare

wheel on a fully loaded vehicle with a flat rear tyre.

To release the spare wheel, loosen

cable using the wheel wrench and

adapters and lower the wheel fully.

Caution

Only use the wheel wrench and

adapter to lower the spare wheel.

The use of pneumatic tools is

prohibited. This may result in

damage to the winch cable and

equipment.

Page 169 of 209

Vehicle care167

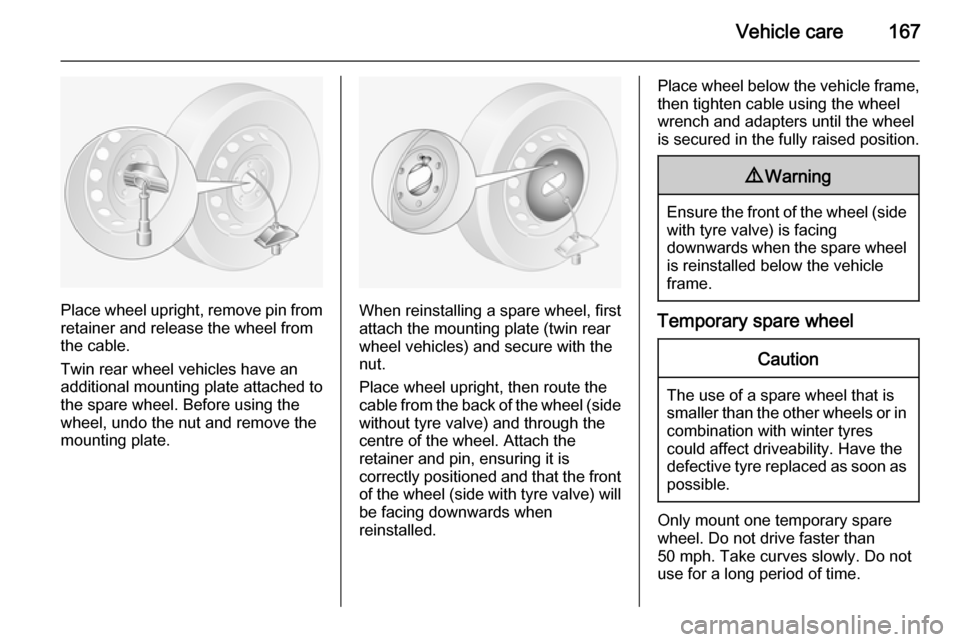

Place wheel upright, remove pin fromretainer and release the wheel from

the cable.

Twin rear wheel vehicles have an

additional mounting plate attached to

the spare wheel. Before using the

wheel, undo the nut and remove the

mounting plate.When reinstalling a spare wheel, first

attach the mounting plate (twin rear

wheel vehicles) and secure with the

nut.

Place wheel upright, then route the

cable from the back of the wheel (side

without tyre valve) and through the

centre of the wheel. Attach the

retainer and pin, ensuring it is

correctly positioned and that the front

of the wheel (side with tyre valve) will be facing downwards when

reinstalled.

Place wheel below the vehicle frame,

then tighten cable using the wheel

wrench and adapters until the wheel

is secured in the fully raised position.9 Warning

Ensure the front of the wheel (side

with tyre valve) is facing

downwards when the spare wheel is reinstalled below the vehicle

frame.

Temporary spare wheel

Caution

The use of a spare wheel that is smaller than the other wheels or in

combination with winter tyres

could affect driveability. Have the defective tyre replaced as soon as

possible.

Only mount one temporary spare

wheel. Do not drive faster than

50 mph. Take curves slowly. Do not

use for a long period of time.

Page 170 of 209

168Vehicle care

If your vehicle gets a flat tyre on therear while towing another vehicle,

mount the temporary spare wheel in the front and the full tyre in the rear.

Tyre chains 3 161.

Summer and winter tyres

If you use winter tyres, the spare

wheel may still be fitted with a

summer tyre.

If you use the spare wheel when it is

fitted with a summer tyre the vehicle's

driveability may be affected,

especially on slippery road surfaces.

Directional tyres Fit directional tyres such that they rollin the direction of travel. The rolling

direction is indicated by a symbol

(e.g. an arrow) on the sidewall.

The following applies to tyres fitted

opposing the rolling direction:

■ Driveability may be affected. Have the defective tyre renewed or

repaired as soon as possible.

■ Do not drive faster than 50 mph.

■ Drive particularly carefully on wet and snow-covered road surfaces.Jump starting

Do not start with a quick charger.

A vehicle with a discharged battery

can be started using jump leads and

the battery of another vehicle.9 Warning

Be extremely careful when starting

with jump leads. Any deviation

from the following instructions can

lead to injuries or damage caused

by battery explosion or damage to the electrical systems of both

vehicles.

9 Warning

Avoid contact with eyes, skin,

fabrics, and painted surfaces. The fluid contains sulphuric acid which can cause injuries and damage in

the event of direct contact.

Caution

The air suspension system must

be switched off prior to jump

starting.

9 Warning

Avoid contact of the battery with

eyes, skin, fabrics and painted

surfaces. The fluid contains

sulphuric acid which can cause

injuries and damage in the event

of direct contact.

■ Never expose the vehicle battery to

naked flames or sparks.

■ A discharged vehicle battery can already freeze at a temperature of

0 °C. Defrost the frozen vehicle

battery before connecting jump

leads.

■ Wear eye protection and protective

clothing when handling a vehicle

battery.