engine VAUXHALL VIVARO 2015.5 Workshop Manual

[x] Cancel search | Manufacturer: VAUXHALL, Model Year: 2015.5, Model line: VIVARO, Model: VAUXHALL VIVARO 2015.5Pages: 203, PDF Size: 4.54 MB

Page 140 of 203

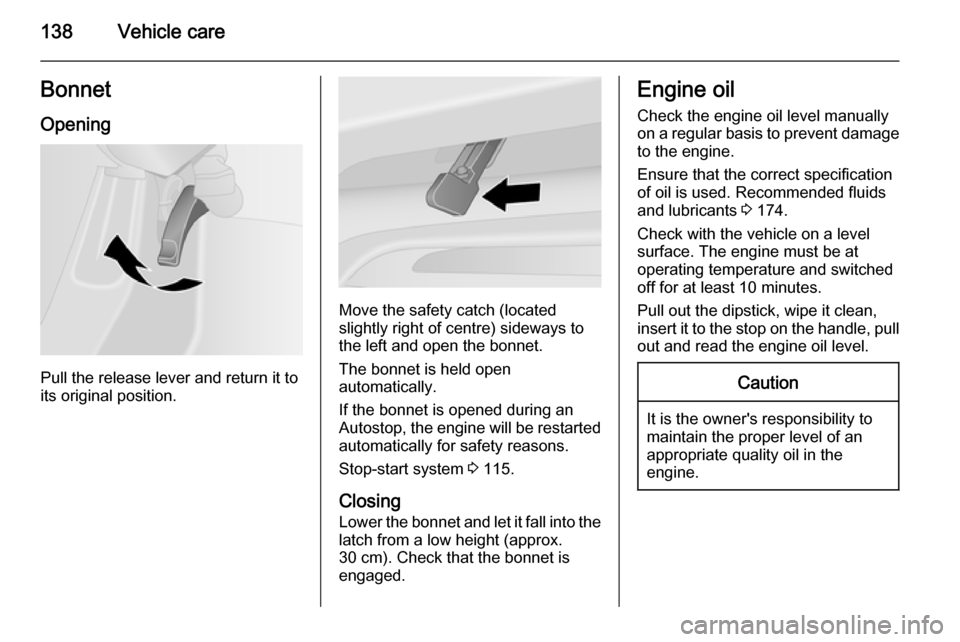

138Vehicle careBonnetOpening

Pull the release lever and return it to

its original position.

Move the safety catch (located

slightly right of centre) sideways to

the left and open the bonnet.

The bonnet is held open

automatically.

If the bonnet is opened during an

Autostop, the engine will be restarted automatically for safety reasons.

Stop-start system 3 115.

Closing Lower the bonnet and let it fall into the

latch from a low height (approx.

30 cm). Check that the bonnet is

engaged.

Engine oil

Check the engine oil level manually

on a regular basis to prevent damage

to the engine.

Ensure that the correct specification

of oil is used. Recommended fluids

and lubricants 3 174.

Check with the vehicle on a level

surface. The engine must be at

operating temperature and switched

off for at least 10 minutes.

Pull out the dipstick, wipe it clean,

insert it to the stop on the handle, pull

out and read the engine oil level.Caution

It is the owner's responsibility to

maintain the proper level of an

appropriate quality oil in the

engine.

Page 141 of 203

Vehicle care139

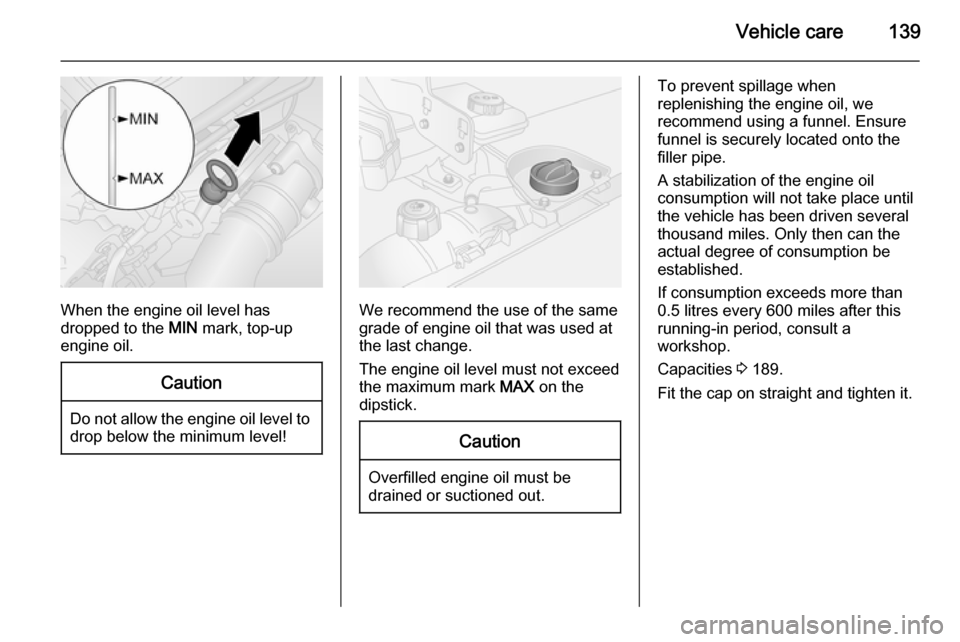

When the engine oil level has

dropped to the MIN mark, top-up

engine oil.

Caution

Do not allow the engine oil level to drop below the minimum level!

We recommend the use of the same

grade of engine oil that was used at

the last change.

The engine oil level must not exceed the maximum mark MAX on the

dipstick.

Caution

Overfilled engine oil must be

drained or suctioned out.

To prevent spillage when

replenishing the engine oil, we

recommend using a funnel. Ensure funnel is securely located onto the

filler pipe.

A stabilization of the engine oil

consumption will not take place until

the vehicle has been driven several

thousand miles. Only then can the

actual degree of consumption be

established.

If consumption exceeds more than

0.5 litres every 600 miles after this

running-in period, consult a

workshop.

Capacities 3 189.

Fit the cap on straight and tighten it.

Page 142 of 203

140Vehicle careEngine air filterEngine air flow indicator

On certain models, an indicator is

located in the engine induction

system and indicates if the air-intake

to the engine is restricted.

Clear=No restrictionRed tell-tale=Restricted

If the red tell-tale is displayed when

the engine is running, consult a

workshop.

Engine coolant

The coolant provides freeze

protection down to approx. -28 °C.Caution

Only use approved antifreeze.

Coolant level

Caution

Too low a coolant level can cause engine damage.

If the cooling system is cold, the

coolant level should be just above the

MINI mark. Top up if the level is low.9Warning

Allow the engine to cool before

opening the cap. Carefully open

the cap, relieving the pressure

slowly.

Top up with antifreeze. If no

antifreeze is available, use clean tap

water or distilled water. Install the cap

tightly. Have the antifreeze

concentration checked and have the

cause of the coolant loss remedied by a workshop.

If a substantial amount of coolant is

required, it will be necessary to bleed

any trapped air from the cooling

system. Seek the assistance of a

workshop.

If the coolant temperature is too high, control indicator W 3 86 illuminates

red in the instrument cluster, together

with C 3 84. Consult a workshop if

coolant level is sufficient.

Page 144 of 203

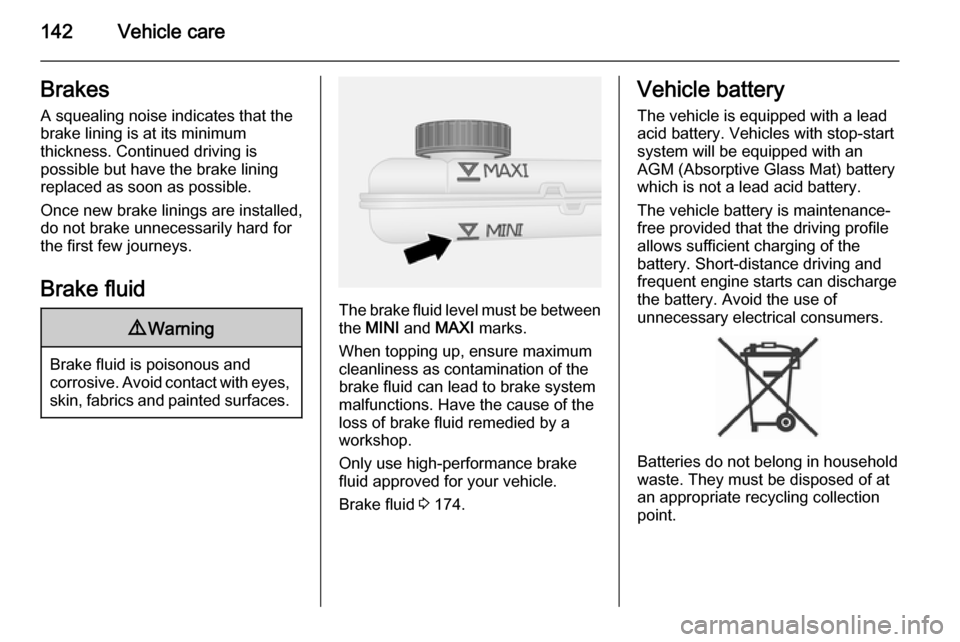

142Vehicle careBrakesA squealing noise indicates that the

brake lining is at its minimum

thickness. Continued driving is

possible but have the brake lining

replaced as soon as possible.

Once new brake linings are installed,

do not brake unnecessarily hard for

the first few journeys.

Brake fluid9 Warning

Brake fluid is poisonous and

corrosive. Avoid contact with eyes, skin, fabrics and painted surfaces.

The brake fluid level must be betweenthe MINI and MAXI marks.

When topping up, ensure maximum cleanliness as contamination of the

brake fluid can lead to brake system

malfunctions. Have the cause of the

loss of brake fluid remedied by a

workshop.

Only use high-performance brake

fluid approved for your vehicle.

Brake fluid 3 174.

Vehicle battery

The vehicle is equipped with a lead

acid battery. Vehicles with stop-start

system will be equipped with an

AGM (Absorptive Glass Mat) battery

which is not a lead acid battery.

The vehicle battery is maintenance-

free provided that the driving profile

allows sufficient charging of the

battery. Short-distance driving and

frequent engine starts can discharge

the battery. Avoid the use of

unnecessary electrical consumers.

Batteries do not belong in household

waste. They must be disposed of at

an appropriate recycling collection

point.

Page 146 of 203

144Vehicle care

Meaning of symbols:■ No sparks, naked flames or smoking.

■ Always shield eyes. Explosive gases can cause blindness or

injury.

■ Keep the vehicle battery out of reach of children.

■ The vehicle battery contains sulfuric acid which could cause

blindness or serious burn injuries.

■ See the Owner's Manual for further

information.

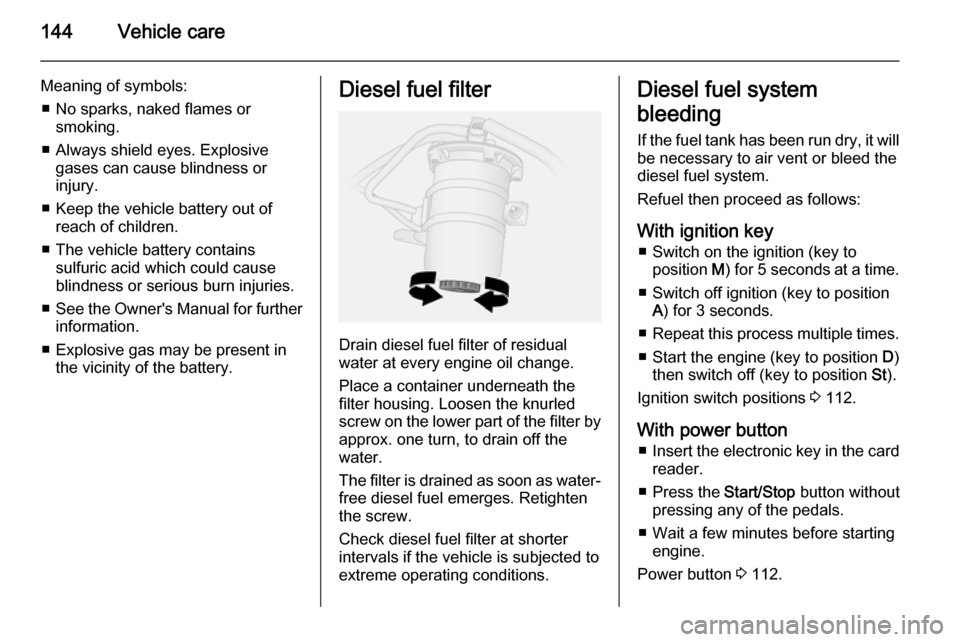

■ Explosive gas may be present in the vicinity of the battery.Diesel fuel filter

Drain diesel fuel filter of residual

water at every engine oil change.

Place a container underneath the

filter housing. Loosen the knurled

screw on the lower part of the filter by approx. one turn, to drain off the

water.

The filter is drained as soon as water-

free diesel fuel emerges. Retighten

the screw.

Check diesel fuel filter at shorter

intervals if the vehicle is subjected to

extreme operating conditions.

Diesel fuel system

bleeding

If the fuel tank has been run dry, it will

be necessary to air vent or bleed the

diesel fuel system.

Refuel then proceed as follows:

With ignition key ■ Switch on the ignition (key to position M) for 5 seconds at a time.

■ Switch off ignition (key to position A) for 3 seconds.

■ Repeat this process multiple times.

■ Start the engine (key to position D)

then switch off (key to position St).

Ignition switch positions 3 112.

With power button ■ Insert the electronic key in the card

reader.

■ Press the Start/Stop button without

pressing any of the pedals.

■ Wait a few minutes before starting engine.

Power button 3 112.

Page 147 of 203

Vehicle care145

If the engine fails to start, seek the

assistance of a workshop.

Starting the engine 3 114.

Wiper blade replacement Wiper blades on the windscreen

Lift the wiper arm, press button to

disengage the wiper blade and

remove.

Attach new wiper blade slightly

angled to the wiper arm and push until

it engages.

Lower wiper arm carefully.

Wiper blade on the rear window Lift wiper arm, rotate wiper blade and

detach.Bulb replacement

Switch off the ignition and turn off the

relevant switch or close the doors.

Only hold a new bulb at the base. Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Bulb check

After a bulb replacement, switch on

the ignition, operate and check the

lights.

Page 159 of 203

Vehicle care157

Tyre pressures 3 190. Always inflate

tyres to the pressures shown on the label on the driver's door frame.

The tyre pressure data refers to cold

tyres. It applies to summer and winter tyres.

Always inflate the spare tyre to the

pressure specified for full load.

Incorrect tyre pressures will impair

safety, vehicle handling, comfort and

fuel economy and will increase tyre

wear.

Tyre pressures differ depending on

various options. For the correct tyre

pressure value, follow the procedure

below:

1. Identify the engine identifier code.

Engine data 3 180.

2. Identify the respective tyre.

The tyre pressure tables show all

possible tyre combinations 3 190.

For the tyres approved for your

vehicle, refer to the EEC Certificate of

Conformity provided with your vehicle

or other national registration

documents.The driver is responsible for correct

adjustment of tyre pressure.9 Warning

If the pressure is too low, this can

result in considerable tyre warm-

up and internal damage, leading to tread separation and even to tyre

blow-out at high speeds.

Tyre pressure monitoring

system

The Tyre Pressure Monitoring

System (TPMS) uses radio and

sensor technology to check tyre

pressure levels.

Caution

Tyre pressure monitoring system

warns only about low tyre pressure condition and does not replace

regular tyre maintenance by the

driver.

All wheels must be equipped with pressure sensors and the tyres must

have the prescribed pressure.

Notice

In countries where the tyre pressure

monitoring system is legally

required, the use of wheels without

pressure sensors will invalidate the

vehicle type approval.

The TPMS sensors monitor the air

pressure in the tyres and transmit tyre pressure readings to a receiver

located in the vehicle.

Tyre pressures in display The current tyre pressures can be

shown in the Driver Information

Centre 3 88.

Page 161 of 203

Vehicle care159

Puncture

A puncture or severely under-inflated

tyre is indicated by illumination of

control indicator w together with C

3 84 and a corresponding message

appears in the Driver Information

Centre. Stop vehicle and switch off

engine.

Tyre pressure 3 190, Tyre repair kit

3 161, Spare wheel 3 165, Wheel

changing 3 164.

Temperature dependency Tyre pressure depends on the

temperature of the tyre. During

driving, tyre temperature and

pressure increase.

The tyre pressure value displayed in

the Driver Information Centre shows

the actual tyre pressure. Therefore it

is important to check tyre pressure

with cold tyres.Relearn function

After changing the wheels, TPMS

needs to recalculate.

With the vehicle stationary, select the tyre pressure menu in the Driver

Information Centre by pressing button

on end of wiper lever. Press and hold button for approx. 3 seconds to

initialise recalculation. A

corresponding message appears in

the Driver Information Centre.

Several minutes of driving may be

required to complete the relearn

process.

If problems occur during the relearn

process, control indicator w remains

illuminated and a warning message is displayed in the Driver Information

Centre.

Driver Information Centre 3 88.

Vehicle messages 3 89.

General information

The use of commercially available

liquid tyre repair kits can impair the

function of the system. Factory-

approved tyre repair kits can be used.

Tyre repair kit 3 161.

External high-power radio equipment

could disrupt the tyre pressure

monitoring system.

Each time the tyres are replaced,

TPMS sensors must be dismounted

and serviced by a workshop.

Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

Page 164 of 203

162Vehicle care

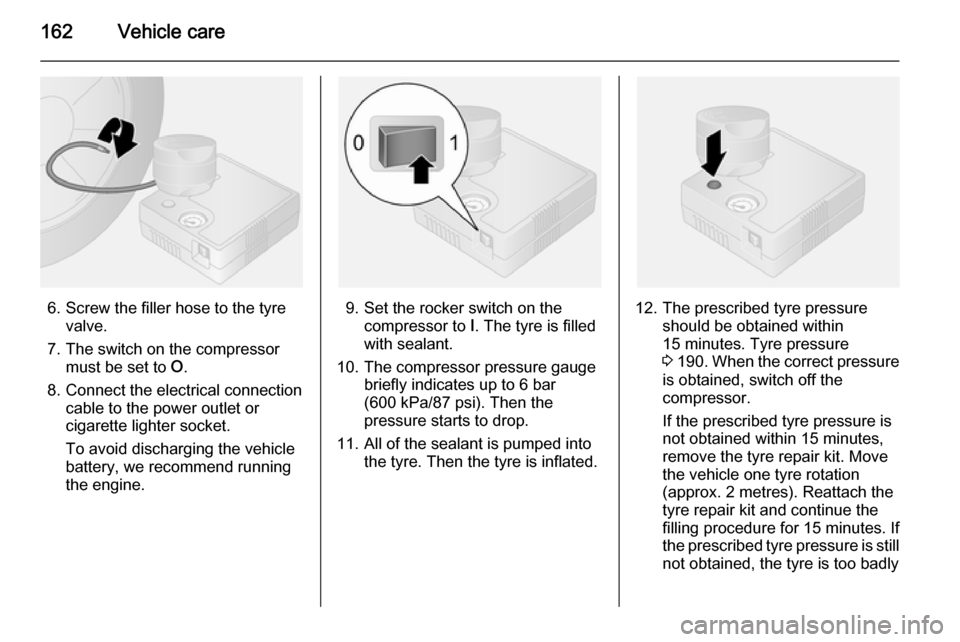

6. Screw the filler hose to the tyrevalve.

7. The switch on the compressor must be set to O.

8. Connect the electrical connection cable to the power outlet or

cigarette lighter socket.

To avoid discharging the vehicle

battery, we recommend running

the engine.9. Set the rocker switch on the compressor to I. The tyre is filled

with sealant.

10. The compressor pressure gauge briefly indicates up to 6 bar(600 kPa/87 psi). Then the

pressure starts to drop.

11. All of the sealant is pumped into the tyre. Then the tyre is inflated.12. The prescribed tyre pressureshould be obtained within

15 minutes. Tyre pressure

3 190 . When the correct pressure

is obtained, switch off the

compressor.

If the prescribed tyre pressure is

not obtained within 15 minutes,

remove the tyre repair kit. Move

the vehicle one tyre rotation

(approx. 2 metres). Reattach the

tyre repair kit and continue the

filling procedure for 15 minutes. If

the prescribed tyre pressure is still not obtained, the tyre is too badly

Page 166 of 203

164Vehicle care

Replace the used sealant bottle.Dispose of the sealant bottle as

prescribed by applicable laws.

Wheel changing

Some vehicles are equipped with a

tyre repair kit instead of a spare wheel 3 161.

Make the following preparations and

observe the following information:

■ Park the vehicle on a level, firm and

non-slippery surface. The front wheels must be in the straight-

ahead position.

■ Apply the parking brake and engage first gear or reverse gear.

■ Remove the spare wheel 3 165.

■ Never change more than one wheel

at a time.

■ Use the jack only to change wheels

in case of puncture, not for a

seasonal winter or summer tyre

change.

■ If the ground on which the vehicle is standing is soft, a solid board

(max. 1 cm thick) should be placed

under the jack.■ Take heavy objects out of the vehicle before jacking up.

■ No people or animals may be in the

vehicle when it is jacked-up.

■ Never crawl under a jacked-up vehicle.

■ Do not start the engine when the vehicle is raised on the jack.

1. Remove the wheel cover (using the hook supplied). Vehicle tools

3 155.

2. Loosen each of the wheel bolts by

half a turn using the wheel

wrench. Ensure the wrench

locates securely. The wrench

should turn anticlockwise to

loosen the bolts. Invert the wrench if necessary.

3. Place lifting pad spigot of the jack

under the jacking hole located

nearest the wheel concerned.

Ensure the jack is positioned

correctly. The jack base must be

on the ground directly below the

jacking hole in a manner that

prevents it from slipping.

4. Install wrench onto the jack and raise the vehicle by turning the

wrench until the wheel is clear of

the ground.