oil VOLKSWAGEN CORRADO 1990 Owner's Guide

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1990, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1990Pages: 906, PDF Size: 6.56 MB

Page 303 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 12)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

2) Remove intake camshaft bearing cap Nos. 5, 7 and rear

evenly a little at a time. See Fig. 12. Loosen remaining intake

camshaft bearing caps evenly a little at a time. Remove exhaust

camshaft bearing cap Nos. 1, 3, front and rear evenly a little at a

time. Loosen remaining exhaust camshaft bearing caps evenly a little

at a time. Remove loosened caps. Lift camshafts out of cylinder head

together.

INSPECTION

1) Check camshaft bearing oil clearance. See ENGINE

SPECIFICATIONS at end of this article. If oil clearance is greater

than specifications, install new camshaft and recheck clearance.

2) If clearance is still greater than specifications, replace

cylinder head. If replacing camshaft(s), ensure identification number

between lobes of cylinder No. one, are the same.

INSTALLATION (16-VALVE)

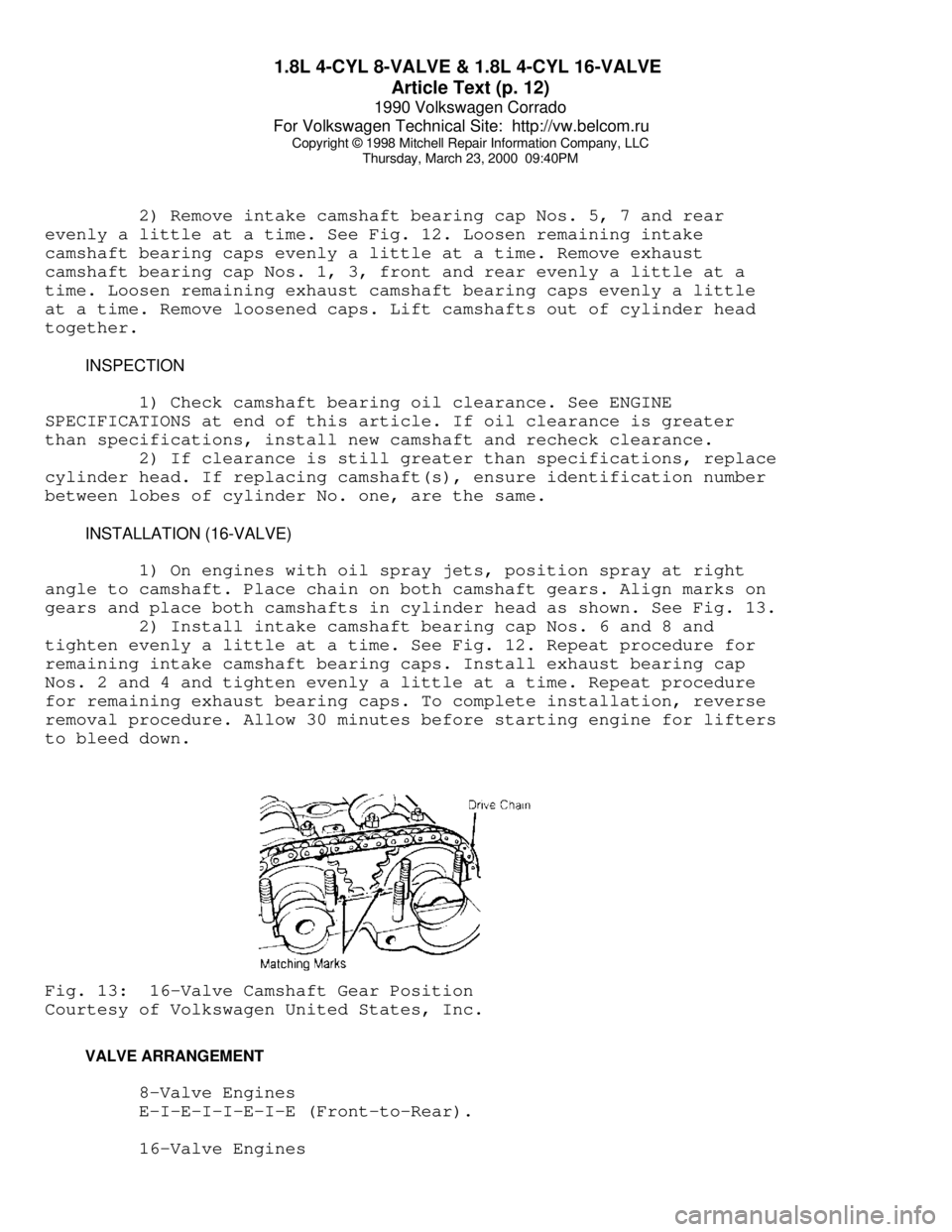

1) On engines with oil spray jets, position spray at right

angle to camshaft. Place chain on both camshaft gears. Align marks on

gears and place both camshafts in cylinder head as shown. See Fig. 13.

2) Install intake camshaft bearing cap Nos. 6 and 8 and

tighten evenly a little at a time. See Fig. 12. Repeat procedure for

remaining intake camshaft bearing caps. Install exhaust bearing cap

Nos. 2 and 4 and tighten evenly a little at a time. Repeat procedure

for remaining exhaust bearing caps. To complete installation, reverse

removal procedure. Allow 30 minutes before starting engine for lifters

to bleed down.Fig. 13: 16-Valve Camshaft Gear Position

Courtesy of Volkswagen United States, Inc.

VALVE ARRANGEMENT

8-Valve Engines

E-I-E-I-I-E-I-E (Front-to-Rear).

16-Valve Engines

Page 308 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 17)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

PISTON PIN REPLACEMENT R & I

Ensure piston and rod are properly marked. Remove both

circlips from pin bore groove. Use Piston Pin Replacer (VW 207C) to

remove and install the piston pin. If pin is too tight, heat piston to

140øF (60øC). To install, reverse removal procedure. Ensure rod is

properly positioned with piston. See Fig. 15.

CRANKSHAFT R & I

1) Using flywheel Holder (10-201), remove flywheel bolts.

Remove flywheel. Remove front and rear oil seals and covers. Remove

connecting rod bearing caps.

2) Measure crankshaft end play. See CRANKSHAFT END PLAY CHECK

in this article. Remove main bearing cap bolts. Remove main bearing

caps. Remove crankshaft. To install, reverse removal procedure.

MAIN BEARING INSTALLATION

Main bearing caps are marked with matching journal and must

be installed to original position. See Fig. 16. Thrust bearing is

located at No. 3 main bearing cap. Use Plastigage method to check

clearance. Machine or replace as necessary. See ENGINE SPECIFICATIONS

at end of this article. Tighten evenly to specifications in several

steps.

CONNECTING ROD BEARING INSTALLATION

Ensure rod caps are marked to ensure installation to original

position and location. Use Plastigage to measure bearing clearances.

Measure connecting rod side play. Replace or machine as necessary. See

ENGINE SPECIFICATIONS at end of this article. Tighten evenly to

specifications in several steps.

CRANKSHAFT END PLAY CHECK

Insert feeler gauge between No. 3 main bearing and crankshaft

thrust face to measure end play. See Fig. 16. Replace thrust bearing

as necessary. See ENGINE SPECIFICATIONS at end of this article.

Original thrust bearing uses plain shell with 4 separate washers and

replacements have attached collar.

REAR MAIN BEARING OIL SEAL R & I

Remove flywheel/flex plate and discard retaining bolts. Oil

seal may removed without removing retaining flange by prying seal out.

Remove retaining flange if gasket is leaking. See Fig. 16. If

installing without removing retaining flange, use Centering Tool

(2003/2A) to center seal and Installer (2003/1) to install seal.

Page 309 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 18)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

Install new flywheel bolts.

FRONT COVER OIL SEAL R & I

REMOVAL

Remove timing belt. See REMOVAL under TIMING BELT R & I in

this article. Rotate inner part of Oil Seal Extractor (2085) outward 2

turns and tighten set screw. See Fig. 11. Lubricate threaded area of

extractor and push in as far as possible. Loosen set screw and turn

inner part of extractor until oil seal is removed.

INSTALLATION

Lubricate outer edge and lip of new seal. Place guide sleeve

from Seal Installer (3083) onto crankshaft. Push oil seal over guide

sleeve. Press seal completely into position. To complete installation,

reverse removal procedure.

INTERMEDIATE SHAFT ASSEMBLY

Remove timing belt. See REMOVAL under TIMING BELT in this

article. Mark distributor assembly for installation reference and

remove distributor assembly. Check intermediate shaft end play. See

INTERMEDIATE SHAFT END PLAY SPECIFICATION table following this

paragraph. Remove intermediate shaft sprocket. Remove intermediate

shaft seal flange. Replace seal (if necessary). To install, reverse

removal procedure. See ENGINE SPECIFICATIONS at end of this article.

INTERMEDIATE SHAFT END PLAY SPECIFICATIONÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication In. (mm)

1.8L ........................... .010 (.25)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ CYLINDER BLOCK INSPECTION

DO NOT measure cylinder block while mounted on an engine

stand. Inaccurate measurements may be achieved. Check cylinder bore

for wear, out-of-round and taper. Pistons are available in oversize.

Cylinder block bore may be machined. Check cylinder block for warpage.

See ENGINE SPECIFICATIONS at end of this article.

ENGINE OILING SYSTEM SPECIFICATIONS

CRANKCASE CAPACITY

CRANKCASE CAPACITY TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ With Filter Without Filter

Page 310 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 19)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

Model Replacement Replacement

Fox ........... 3.7 Qts. (3.5L) . 3.2 Qts. (3.0L)

All Others .... 4.3 Qts. (4.1L) . 4.7 Qts. (4.5L)ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ OIL PRESSURE

Minimum oil pressure at idle is 4.3 psi (.3 kg/cm

ý). Oil

pressure at 2000 RPM is 29 psi (2.0 kg/cm

ý).

OIL PAN REMOVAL

REMOVAL

Oil pan can be removed and installed with engine in vehicle.

No further information available from manufacturer.

OIL PUMP R & I

REMOVAL & INSTALLATION

Remove oil pan. Remove oil pump attaching bolts and remove

oil pump assembly. To install, reverse removal procedure.

INSPECTION

Check oil pump backlash and oil pump axial play. If not

within specifications, replace oil pump assembly. See OIL PUMP

SPECIFICATIONS table in this article.

OIL PUMP SPECIFICATIONS

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication In. (mm)

Backlash

New .......................... .002 (.05)

Limit ........................ .008 (.20)

Axial Play Limit ............... .006 (.15)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ ENGINE COOLING SYSTEM

CAUTION: Coolant/water mixture should be used at all times. Only

ethylene glycol based (phosphate-free) antifreeze may be

used, as it protects aluminum/iron engines from corrosion.

BELT TENSION

Belt deflection with 22 lbs. (10 kg) pressure applied at

midpoint of longest belt run should be 3/8-9/16" (10-15mm).

Page 312 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 21)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

Engine Mounts (4)

A Bolt/Nut ..................................... 18 (24)

B Bolt ......................................... 22 (30)

C Bolt ......................................... 44 (60)

D Bolt ......................................... 53 (72)

E Bolt ......................................... 59 (80)

Engine-to-Transaxle Bolt

M10 ............................................ 33 (45)

M12 ............................................ 55 (75)

Exhaust Manifold Nut ............................. 18 (24)

Flywheel-to-Crankshaft Bolt (5) ................. 74 (100)

Intake Manifold Bolt ............................. 18 (24)

Intermediate Shaft Sprocket Bolt

8-Valve ........................................ 59 (80)

16-Valve ....................................... 48 (65)

Main Bearing Cap Bolt (6) ........................ 48 (65)

Oil Pan Bolt ..................................... 15 (20)

Oil Pump

Short Bolt ...................................... 7 (10)

Long Bolt ...................................... 15 (20)

Power Steering Pump-to-Bracket Nut ............... 14 (19)

Timing Belt Tensioner Pulley Nut ................. 33 (45)

Water Pump Housing-to-Block ...................... 15 (20)

Water Pump Pulley ................................ 15 (20)

INCH Lbs. (N.m)

Piston Oil Spray

Nozzle Bolt .................................... 84 (10)

Thermostat Housing-to-Water

Pump Housing ................................... 84 (10)

Upper & Lower Timing Belt Cover Bolt .............. 53 (6)

Water Pump-to-Housing ............................ 84 (10)

(1) - Tighten an additional 180 degrees. Ensure a new bolt

is used.

(2) - Tighten in sequence. See Fig. 5.

(3) - Turn bolts 180 degrees further in one continuous

movement. Two separate 90 degree turns may be used.

(4) - See Fig. 2.

(5) - Apply sealant to threads and tighten evenly and

diagonally.

(6) - Tighten in several steps evenly.ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ ENGINE SPECIFICATIONS

GENERAL ENGINE SPECIFICATIONS

GENERAL SPECIFICATIONS TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Specifications

Page 314 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 23)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

Oil Ring

End Gap ........................ .010-.018 (.25-.45).

Side Clearance .................. .001-.002 (.02-.05)

(1) - Wear limit is .04" (1.0mm).

(2) - Wear limit is .006" (.15mm).ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ CRANKSHAFT MAIN & CONNECTING

ROD BEARINGS SPECIFICATIONS

CRANKSHAFT MAIN & CONNECTING

ROD BEARINGS SPECIFICATIONS TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication In. (mm)

1.8L

Crankshaft

Crankshaft End Play (1) ............ .003-.007 (.07-.17)

Runout ........................................... .....

Journal Taper .................................... .....

Journal Out-Of-Round ........................ .001 (.03)

Main Bearings

Journal Diameter ............. 2.124-2.125 (53.96-53.98)

Oil Clearance (2) .................. .001-.003 (.02-.07)

Connecting Rod Bearings

Journal Diameter ............. 1.880-1.881 (47.76-47.78)

Oil Clearance (3) ......................... .0049 (.124)

(1) - Wear limit is .010" (.25mm).

(2) - Wear limit is .007" (.17mm).

(3) - Maximum allowable clearance.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ CONNECTING ROD SPECIFICATIONS

CONNECTING ROD SPECIFICATIONS TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication In. (mm)

1.8L

Side Play (1) ............................... .015 (.38)

Maximum Bend & Twist ............................. .....

Pin Bore Diameter ......................... .787 (19.98)

Large Bore Diameter ...................... 1.992 (50.59)

Center-to-Center Length ................. 5.669 (143.99)

(1) - Maximum allowable limit.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ CYLINDER HEAD SPECIFICATIONS

Page 316 of 906

1.8L 4-CYL 8-VALVE & 1.8L 4-CYL 16-VALVE

Article Text (p. 25)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:40PM

8-Valve Exhaust ...................... 1.300 (33.02)

8-Valve Intake (2) ................... 1.575 (40.00)

8-Valve Exhaust ...................... 1.229 (31.21)

16-Valve (3) ......................... 1.102 (27.99)

Stem Diameter

8-Valve ................................ .314 (7.97)

16-Valve ............................... .273 (6.93)

Face Angle ....................................... 45ø Maximum Refinish

8-Valve Intake (4) ................... 3.583 (91.00)

8-Valve Exhaust (4) .................. 3.574 (90.77)

8-Valve Intake (4) ................... 3.886 (98.70)

8-Valve Exhaust (4) .................. 3.878 (98.50)

16-Valve (4) ......................... 3.866 (98.19)

(1) - These specifications apply to engines with code

UM.

(2) - These specifications apply to engines with codes

GX, JH, PF and RV.

(3) - These specifications apply to engines with code

PL. Specifications apply to both intake and

exhaust valves.

(4) - Specification is standard valve length.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ CAMSHAFT SPECIFICATIONS

CAMSHAFT SPECIFICATIONS TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication In. (mm)

Oil Clearance ................................. .004 (.10)

End Play ...................................... .006 (.15)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEND OF ARTICLE

Page 319 of 906

A/C COMPRESSOR OIL CHECKING

Article Text

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

ARTICLE BEGINNING

1990 AIR CONDITIONING & HEAT

Compressor Oil Checking

ISOLATING COMPRESSOR

NOTE: Only compressors with stem-type service valves can be

isolated.

1) Connect service gauge set to the compressor service valves

and open compressor valves slightly (turn in clockwise). Start engine

and operate air conditioning. Slowly turn compressor suction valve

clockwise toward closed (front-seated) position.

2) When suction pressure is reduced to zero or less, turn off

engine and compressor and quickly turn suction valve stem in to full

front-seated position. Suction pressure should be slightly above zero.

Turn discharge valve into front-seated position.

3) To check oil level, slowly open compressor crankcase plug

to relieve any remaining pressure. After oil level is corrected, cap

service gauge ports on both valves. Back-seat suction service valve to

allow refrigerant to enter compressor. Open discharge valve halfway.

4) Loosen discharge service valve cap, allowing refrigerant

pressure to force air out of compressor. Back-seat service valve and

tighten cap. Compressor is now ready for operation.

REFRIGERANT OIL

Only new, pure, moisture-free refrigerant oil should be used

in the air conditioning system. This oil is highly refined and

dehydrated to a point where moisture content is less than 10 parts per

million. The oil container must be tightly closed at all times when

not in use, or moisture will be absorbed into the refrigerant oil from

the air.

SERVICING PRECAUTIONS

NOTE: Recent findings by the EPA indicate that refrigerant is

harmful to the earth's protective Ozone layer. When

discharging refrigerant, DO NOT allow refrigerant to enter

the atmosphere. If available, use refrigerant

recovery/recycle systems when discharging system. Always

follow manufacturer's instructions.

DISCHARGING SYSTEM PRECAUTIONS

If compressor has stem-type service valves, it can be

isolated and removed without discharging entire system. See ISOLATING

COMPRESSOR at the beginning of this article. Otherwise, discharge

system completely before loosening any fittings.

Page 320 of 906

A/C COMPRESSOR OIL CHECKING

Article Text (p. 2)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

DISCONNECTING LINES & FITTINGS TEST

After system is discharged, carefully clean area around all

fittings to be opened. Always use 2 wrenches when tightening or

loosening fittings to avoid twisting or distorting lines. Cap or plug

all openings as soon as lines are removed. DO NOT remove caps until

immediately before connections are made. This will keep entry of air

and moisture to a minimum.

CONNECTING LINES AND FITTINGS

A new gasket or "O" ring should be used in all instances when

connecting lines or fittings. Dip "O" ring in new refrigerant oil and

ensure it is not twisted during installation. Always use 2 wrenches to

prevent damage to lines and fittings.

PLACING SYSTEM IN OPERATION

After component service or replacement has been completed and

all connections have been made, evacuate system thoroughly with a

vacuum pump. Charge system with proper amount of refrigerant and

perform a leak test. See REFRIGERANT OIL & R-12 SPECIFICATIONS chart

in this section for system capacities. Be sure to check all fittings

that have been opened. After system has been leak tested, make a

system performance check.

NOTE: Air conditioning systems will not normally need addition of

refrigerant oil unless definite oil loss has occurred due to

ruptured lines, leaking compressor seals, compressor

overhaul or component replacement.

ATSUGI ROTARY VANE DRAIN & REFILL

1) Before checking and adjusting oil level, operate

compressor at engine idling speed, with controls set for maximum

cooling and high blower speed, for 20 to 30 minutes to return oil to

compressor.

2) Stop engine, discharge refrigerant and remove compressor

from vehicle. See SERVICING PRECAUTIONS at beginning of article. Drain

compressor oil from compressor discharge port and measure the amount.

Oil is sometimes hard to drain when compressor is cool. Remove oil

while compressor is warm.

3) If the amount drained is less than 3 ounces, conduct leak

tests at system connections, and if necessary, repair or replace

faulty parts. Check purity of oil and adjust oil level as follows.

4) If amount drained was above 3 ounces, oil level is right.

Pour in same amount as was drained. If amount drained was below 3

ounces, pour in 3 ounces of new refrigerant oil.

Page 321 of 906

A/C COMPRESSOR OIL CHECKING

Article Text (p. 3)

1990 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, March 23, 2000 09:41PM

BOSCH 6-CYL DRAIN & REFILL

1) Before checking and adjusting oil level, operate

compressor at engine idling speed, with controls set for maximum

cooling and high blower speed, for 20 to 30 minutes to return oil to

compressor.

2) Stop engine and discharge refrigerant. Remove refrigerant

oil level inspection plug on side of compressor. Oil should be at

lower lip of threaded hole. Add necessary new refrigerant oil (if

low). Replace inspection plug and tighten to 10-12 ft. lbs. (14-16 N.

m).

CALSONIC V5 5-CYLINDER

1) Before checking and adjusting oil level, operate

compressor at 1000-1500 engine RPM, and set controls at maximum

cooling and blowing speed for 20-30 minutes to return oil to

compressor.

2) Stop engine. Discharge refrigerant and remove compressor

from vehicle. See SERVICING PRECAUTIONS at the beginning of this

article. Drain compressor oil from compressor discharge port and

measure oil amount. Oil may be hard to drain if compressor is cool.

Drain oil while compressor is warm.

3) If amount drained is less than 3.2 ounces, conduct leak

tests at system connections. Repair or replace faulty parts as

necessary. Check purity of oil and oil level as follows.

4) If amount drained is more than 3.2 ounces, oil level is

okay; fill with same amount drained using new oil. If amount drained

is less than 3.2 ounces, pour in 3.2 ounces of new refrigerant oil.

DIESEL KIKI ROTARY VANE DRAIN & REFILL

1) Before checking and adjusting oil level, operate

compressor at engine idling speed, with controls set for maximum

cooling and high blower speed, for 20 to 30 minutes to return oil to

compressor.

2) Stop engine, discharge refrigerant and remove compressor

from vehicle. See SERVICING PRECAUTIONS at the beginning of this

article. Drain compressor oil from compressor discharge port and

measure the amount. Oil is sometimes hard to drain when compressor is

cool. Remove oil while compressor is warm.

3) If the amount is less than 2.4 ounces, conduct leak tests

at system connections, and if necessary, repair or replace faulty

parts. Check purity of oil and adjust oil level as follows.

4) If amount drained was above 2.4 ounces, oil level is

right. Pour in same amount as was drained. If amount drained was below

2.4 ounces, pour in 2.4 ounces of new refrigerant oil.

DIESEL KIKI 6-CYL DRAIN & REFILL

1) Before checking and adjusting oil level, operate