engine VOLKSWAGEN CORRADO 1993 Repair Manual

[x] Cancel search | Manufacturer: VOLKSWAGEN, Model Year: 1993, Model line: CORRADO, Model: VOLKSWAGEN CORRADO 1993Pages: 920, PDF Size: 6.92 MB

Page 722 of 920

SCHEDULED SERVICES

Article Text (p. 40)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:22PM

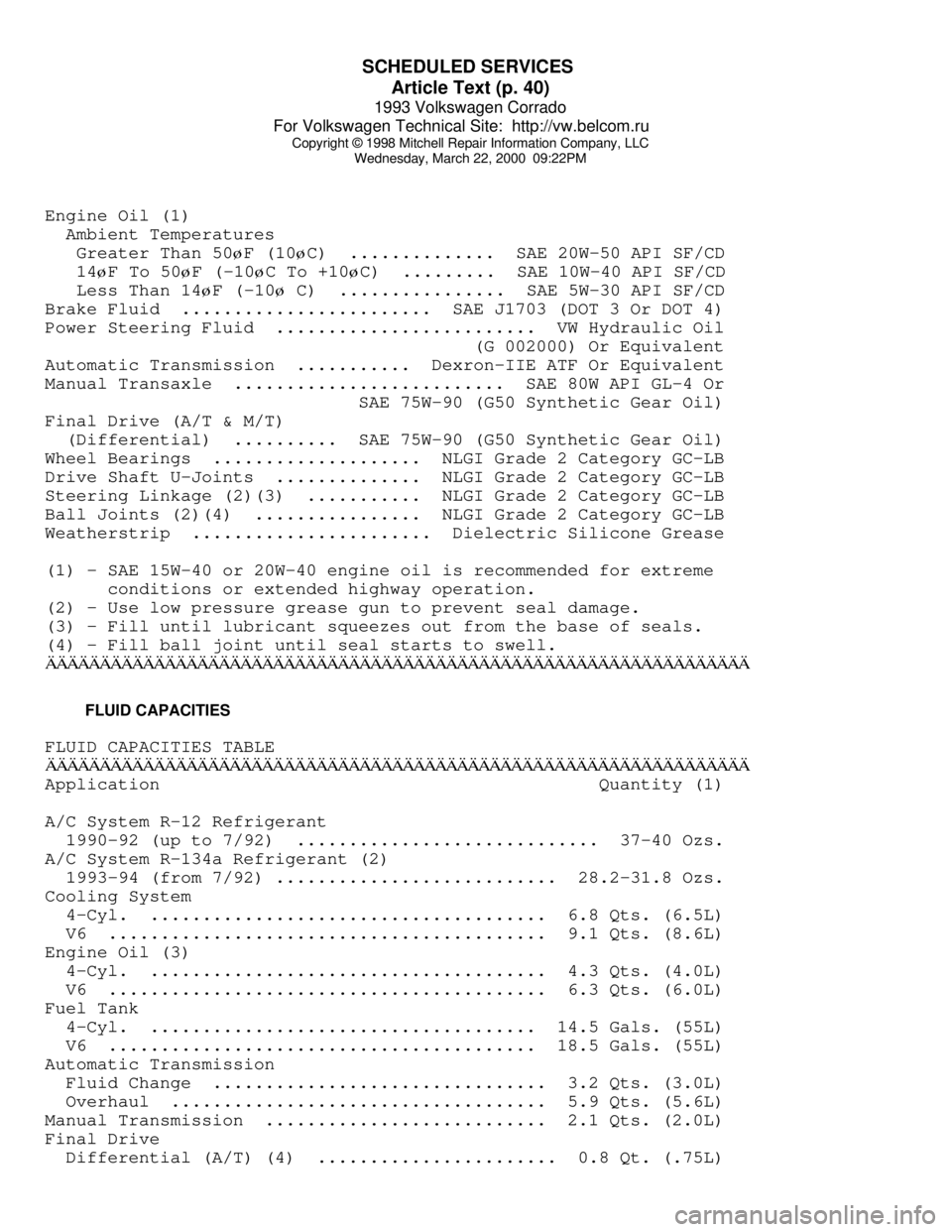

Engine Oil (1)

Ambient Temperatures

Greater Than 50øF (10øC) .............. SAE 20W-50 API SF/CD

14

øF To 50øF (-10øC To +10øC) ......... SAE 10W-40 API SF/CD

Less Than 14

øF (-10ø C) ................ SAE 5W-30 API SF/CD

Brake Fluid ........................ SAE J1703 (DOT 3 Or DOT 4)

Power Steering Fluid ......................... VW Hydraulic Oil

(G 002000) Or Equivalent

Automatic Transmission ........... Dexron-IIE ATF Or Equivalent

Manual Transaxle .......................... SAE 80W API GL-4 Or

SAE 75W-90 (G50 Synthetic Gear Oil)

Final Drive (A/T & M/T)

(Differential) .......... SAE 75W-90 (G50 Synthetic Gear Oil)

Wheel Bearings .................... NLGI Grade 2 Category GC-LB

Drive Shaft U-Joints .............. NLGI Grade 2 Category GC-LB

Steering Linkage (2)(3) ........... NLGI Grade 2 Category GC-LB

Ball Joints (2)(4) ................ NLGI Grade 2 Category GC-LB

Weatherstrip ....................... Dielectric Silicone Grease

(1) - SAE 15W-40 or 20W-40 engine oil is recommended for extreme

conditions or extended highway operation.

(2) - Use low pressure grease gun to prevent seal damage.

(3) - Fill until lubricant squeezes out from the base of seals.

(4) - Fill ball joint until seal starts to swell.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ FLUID CAPACITIES

FLUID CAPACITIES TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Quantity (1)

A/C System R-12 Refrigerant

1990-92 (up to 7/92) ............................. 37-40 Ozs.

A/C System R-134a Refrigerant (2)

1993-94 (from 7/92) ........................... 28.2-31.8 Ozs.

Cooling System

4-Cyl. ...................................... 6.8 Qts. (6.5L)

V6 .......................................... 9.1 Qts. (8.6L)

Engine Oil (3)

4-Cyl. ...................................... 4.3 Qts. (4.0L)

V6 .......................................... 6.3 Qts. (6.0L)

Fuel Tank

4-Cyl. ..................................... 14.5 Gals. (55L)

V6 ......................................... 18.5 Gals. (55L)

Automatic Transmission

Fluid Change ................................ 3.2 Qts. (3.0L)

Overhaul .................................... 5.9 Qts. (5.6L)

Manual Transmission ........................... 2.1 Qts. (2.0L)

Final Drive

Differential (A/T) (4) ....................... 0.8 Qt. (.75L)

Page 724 of 920

SPECIFICATIONS & ELECTRIC COOLING FANS

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:23PM

ARTICLE BEGINNING

1993 ENGINE COOLING

Volkswagen Specifications & Electric Cooling Fans

Volkswagen; Corrado SLC, Passat

SPECIFICATIONS

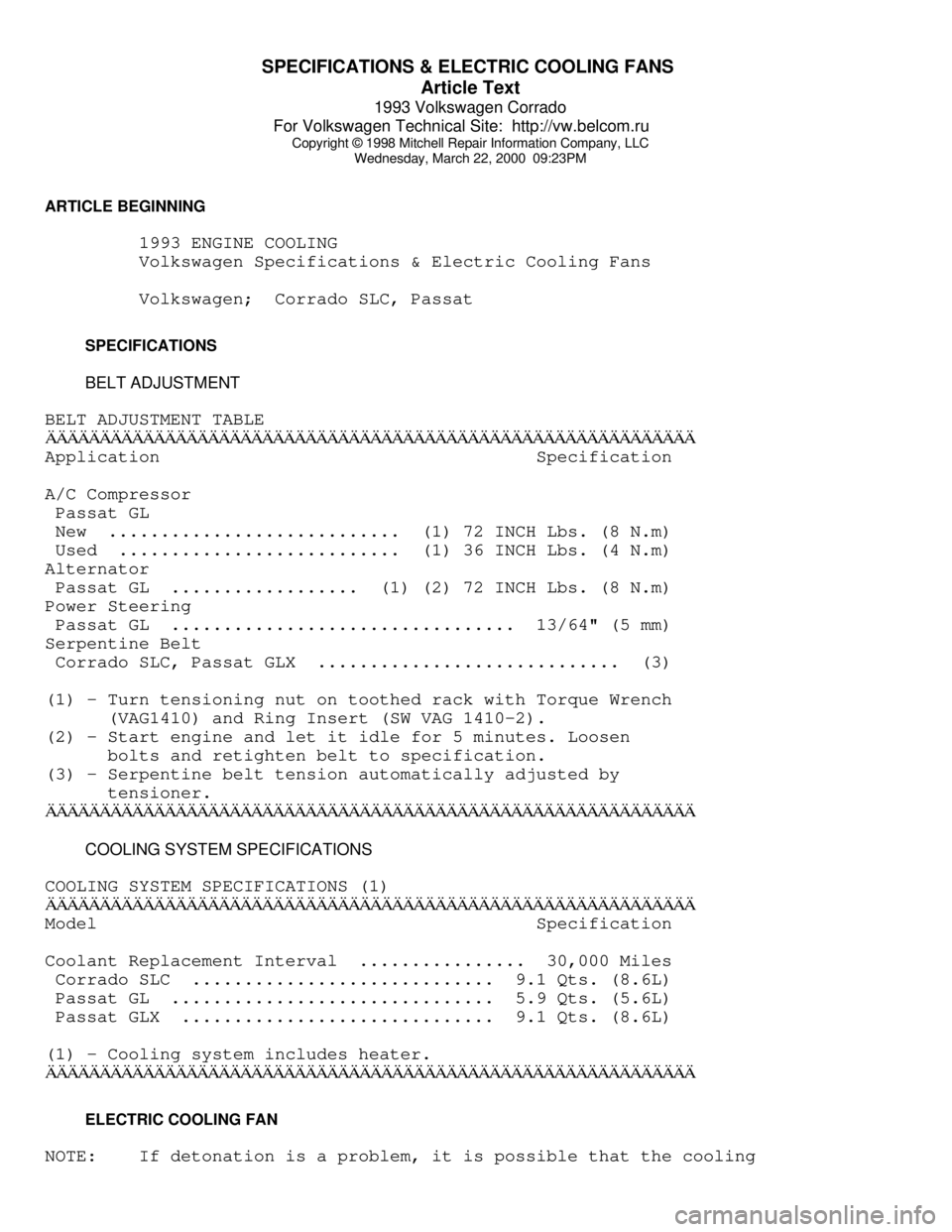

BELT ADJUSTMENT

BELT ADJUSTMENT TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄApplication Specification

A/C Compressor

Passat GL

New ............................ (1) 72 INCH Lbs. (8 N.m)

Used ........................... (1) 36 INCH Lbs. (4 N.m)

Alternator

Passat GL .................. (1) (2) 72 INCH Lbs. (8 N.m)

Power Steering

Passat GL ................................. 13/64" (5 mm)

Serpentine Belt

Corrado SLC, Passat GLX ............................. (3)

(1) - Turn tensioning nut on toothed rack with Torque Wrench

(VAG1410) and Ring Insert (SW VAG 1410-2).

(2) - Start engine and let it idle for 5 minutes. Loosen

bolts and retighten belt to specification.

(3) - Serpentine belt tension automatically adjusted by

tensioner.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ COOLING SYSTEM SPECIFICATIONS

COOLING SYSTEM SPECIFICATIONS (1)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄModel Specification

Coolant Replacement Interval ................ 30,000 Miles

Corrado SLC ............................. 9.1 Qts. (8.6L)

Passat GL ............................... 5.9 Qts. (5.6L)

Passat GLX .............................. 9.1 Qts. (8.6L)

(1) - Cooling system includes heater.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ ELECTRIC COOLING FAN

NOTE: If detonation is a problem, it is possible that the cooling

Page 725 of 920

SPECIFICATIONS & ELECTRIC COOLING FANS

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:23PM

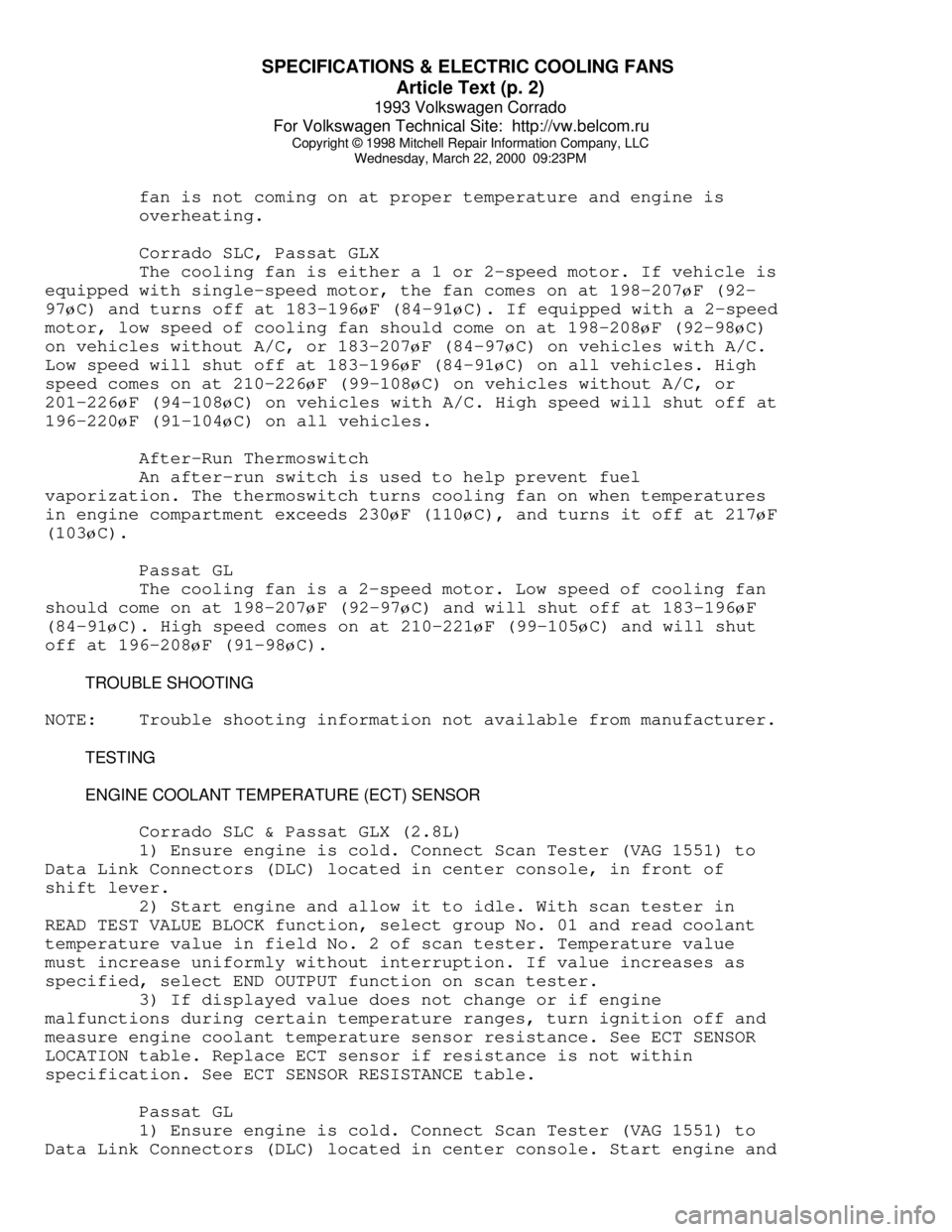

fan is not coming on at proper temperature and engine is

overheating.

Corrado SLC, Passat GLX

The cooling fan is either a 1 or 2-speed motor. If vehicle is

equipped with single-speed motor, the fan comes on at 198-207øF (92-

97

øC) and turns off at 183-196øF (84-91øC). If equipped with a 2-speed

motor, low speed of cooling fan should come on at 198-208

øF (92-98øC)

on vehicles without A/C, or 183-207

øF (84-97øC) on vehicles with A/C.

Low speed will shut off at 183-196

øF (84-91øC) on all vehicles. High

speed comes on at 210-226

øF (99-108øC) on vehicles without A/C, or

201-226

øF (94-108øC) on vehicles with A/C. High speed will shut off at

196-220

øF (91-104øC) on all vehicles.

After-Run Thermoswitch

An after-run switch is used to help prevent fuel

vaporization. The thermoswitch turns cooling fan on when temperatures

in engine compartment exceeds 230

øF (110øC), and turns it off at 217øF

(103

øC).

Passat GL

The cooling fan is a 2-speed motor. Low speed of cooling fan

should come on at 198-207

øF (92-97øC) and will shut off at 183-196øF

(84-91

øC). High speed comes on at 210-221øF (99-105øC) and will shut

off at 196-208

øF (91-98øC).

TROUBLE SHOOTING

NOTE: Trouble shooting information not available from manufacturer.

TESTING

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

Corrado SLC & Passat GLX (2.8L)

1) Ensure engine is cold. Connect Scan Tester (VAG 1551) to

Data Link Connectors (DLC) located in center console, in front of

shift lever.

2) Start engine and allow it to idle. With scan tester in

READ TEST VALUE BLOCK function, select group No. 01 and read coolant

temperature value in field No. 2 of scan tester. Temperature value

must increase uniformly without interruption. If value increases as

specified, select END OUTPUT function on scan tester.

3) If displayed value does not change or if engine

malfunctions during certain temperature ranges, turn ignition off and

measure engine coolant temperature sensor resistance. See ECT SENSOR

LOCATION table. Replace ECT sensor if resistance is not within

specification. See ECT SENSOR RESISTANCE table.

Passat GL

1) Ensure engine is cold. Connect Scan Tester (VAG 1551) to

Data Link Connectors (DLC) located in center console. Start engine and

Page 726 of 920

SPECIFICATIONS & ELECTRIC COOLING FANS

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:23PM

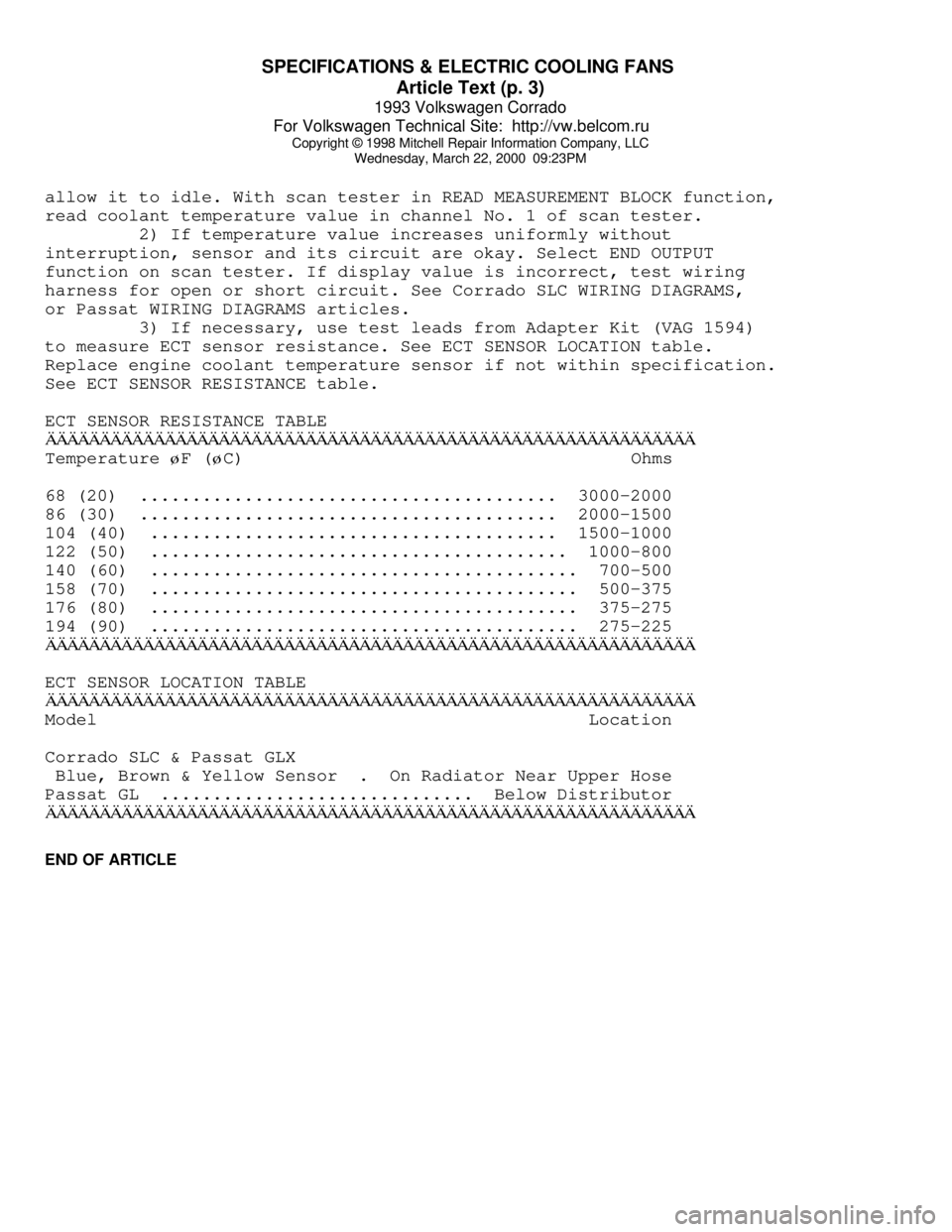

allow it to idle. With scan tester in READ MEASUREMENT BLOCK function,

read coolant temperature value in channel No. 1 of scan tester.

2) If temperature value increases uniformly without

interruption, sensor and its circuit are okay. Select END OUTPUT

function on scan tester. If display value is incorrect, test wiring

harness for open or short circuit. See Corrado SLC WIRING DIAGRAMS,

or Passat WIRING DIAGRAMS articles.

3) If necessary, use test leads from Adapter Kit (VAG 1594)

to measure ECT sensor resistance. See ECT SENSOR LOCATION table.

Replace engine coolant temperature sensor if not within specification.

See ECT SENSOR RESISTANCE table.

ECT SENSOR RESISTANCE TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄTemperature

øF (øC) Ohms

68 (20) ........................................ 3000-2000

86 (30) ........................................ 2000-1500

104 (40) ....................................... 1500-1000

122 (50) ........................................ 1000-800

140 (60) ......................................... 700-500

158 (70) ......................................... 500-375

176 (80) ......................................... 375-275

194 (90) ......................................... 275-225

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄECT SENSOR LOCATION TABLE

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄModel Location

Corrado SLC & Passat GLX

Blue, Brown & Yellow Sensor . On Radiator Near Upper Hose

Passat GL .............................. Below Distributor

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄEND OF ARTICLE

Page 727 of 920

STARTER

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:23PM

ARTICLE BEGINNING

1993 ELECTRICAL

Volkswagen Starters - Bosch

Volkswagen; Corrado SLC, Passat

DESCRIPTION

Starter is a brush type, series-wound electric motor with an

overrunning clutch. Field frame is enclosed by commutator end frame

and drive bushing, and carries pole shoes and field coils. A splined

armature shaft drive end carries drive assembly.

TROUBLE SHOOTING

NOTE: See TROUBLE SHOOTING - BASIC PROCEDURES article in

GENERAL INFORMATION.

ON-VEHICLE TESTING

STARTER DOES NOT CRANK ENGINE

1) Ensure battery is fully charged. Make sure electrical and

ground connections are clean and tight. With ignition switch in START

position, measure voltage at spade terminal of starter solenoid.

Reading should be at least 8 volts. If voltage is as specified, check

engine for mechanical problems. If voltage is not as specified, go to

next step.

2) Measure voltage at ignition switch. If reading is at least

8 volts, check wiring between ignition switch and starter solenoid. If

voltage is not as specified, replace ignition switch.

3) Measure voltage at field (starter) terminal of starter

solenoid. If reading is 8 volts or more, repair or replace starter. If

reading is less than 8 volts, replace starter solenoid.

NOTE: On vehicles with automatic transmission, also check

park/neutral switch.

STARTER CRANKS TOO SLOWLY

Ensure engine crankcase is filled with recommended viscosity

oil. Check charging system to ensure battery is fully charged. Make

sure electrical and ground connections are clean and tight. If starter

still turns slowly, repair or replace starter.

VOLTAGE DROP TEST

Starter Main Terminal

Connect a voltmeter between starter main terminal and starter

body. Disconnect ignition coil positive terminal and operate starter.

Page 729 of 920

STARTER

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:23PM

STARTER NO-LOAD TEST

With starter on test bench, operate starter and check

ammeter, voltage, and RPM. Readings should be within specification.

See STARTER NO-LOAD TEST SPECIFICATIONS table.

STARTER NO-LOAD TEST SPECIFICATIONS TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄVolts Amps RPM

11.5 ........... 65-95 .......... 6500

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ REMOVAL & INSTALLATION

CORRADO SLC & PASSAT

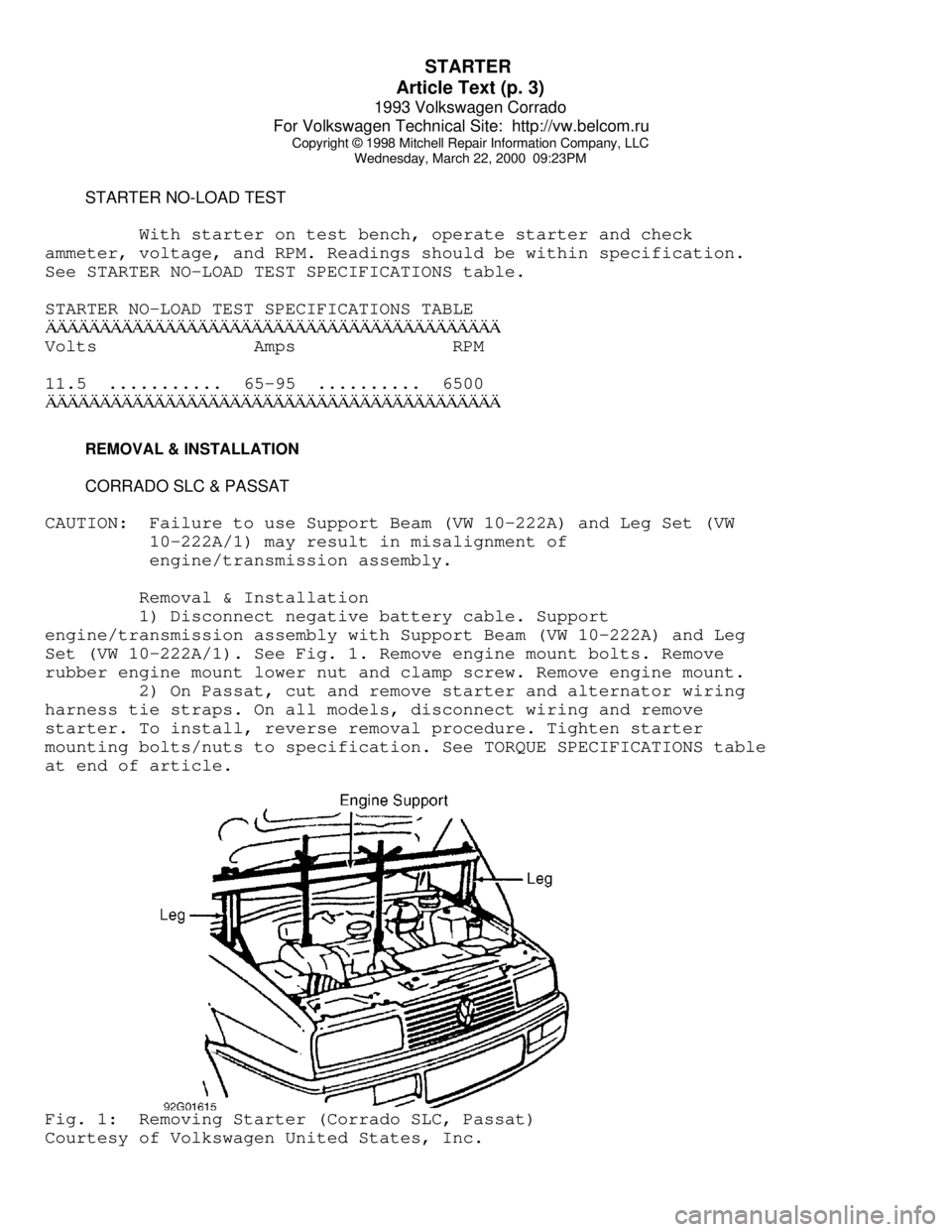

CAUTION: Failure to use Support Beam (VW 10-222A) and Leg Set (VW

10-222A/1) may result in misalignment of

engine/transmission assembly.

Removal & Installation

1) Disconnect negative battery cable. Support

engine/transmission assembly with Support Beam (VW 10-222A) and Leg

Set (VW 10-222A/1). See Fig. 1. Remove engine mount bolts. Remove

rubber engine mount lower nut and clamp screw. Remove engine mount.

2) On Passat, cut and remove starter and alternator wiring

harness tie straps. On all models, disconnect wiring and remove

starter. To install, reverse removal procedure. Tighten starter

mounting bolts/nuts to specification. See TORQUE SPECIFICATIONS table

at end of article.Fig. 1: Removing Starter (Corrado SLC, Passat)

Courtesy of Volkswagen United States, Inc.

Page 744 of 920

STEERING GEAR - POWER RACK & PINION

Article Text

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:23PM

ARTICLE BEGINNING

1993 STEERING

Volkswagen - Power Rack & Pinion

Corrado SLC

DESCRIPTION & OPERATION

System consists of a vane pump, rack and pinion steering

gear, and an oil reservoir. Vane pump draws fluid from reservoir and

supplies it to flow control valve. Control valve directs fluid to

appropriate side of rack piston.

LUBRICATION

CAPACITY

Fluid capacity is approximately 1 qt. (.95L).

FLUID TYPE

Recommended fluid type is VW Hydraulic Oil No. G 002 000.

FLUID LEVEL CHECK

Remove reservoir cover. Start engine and let idle. Fluid

level should be between MIN and MAX marks on reservoir.

HYDRAULIC SYSTEM BLEEDING

1) Start engine and let idle. Ensure fluid is at proper

level. Turn steering wheel from lock to lock several times quickly.

2) Continue until fluid level remains at reservoir mark.

Ensure no bubbles appear in reservoir when steering wheel is turned.

Shut off engine. Ensure oil level does not rise more than 3/8" (10

mm).

Page 745 of 920

STEERING GEAR - POWER RACK & PINION

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

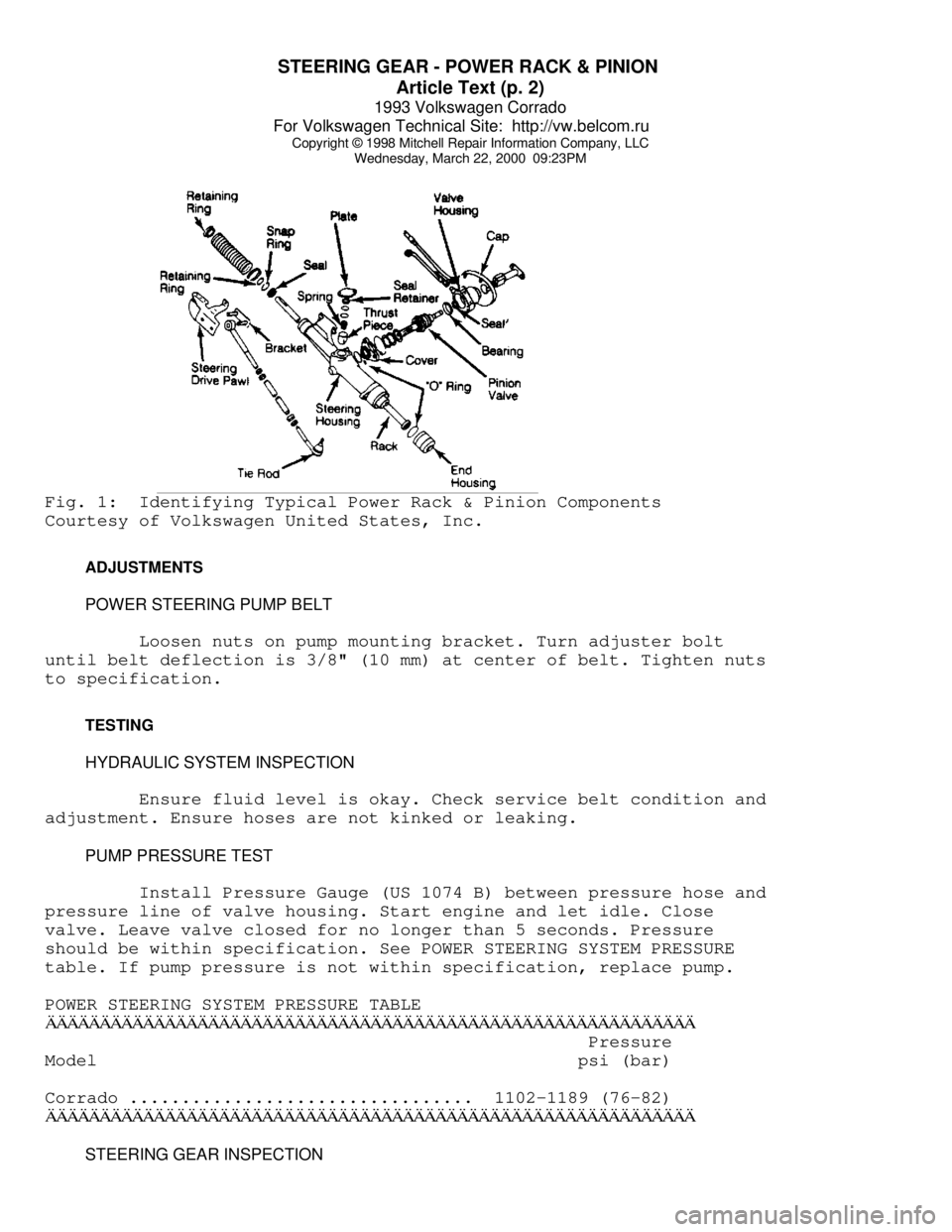

Wednesday, March 22, 2000 09:23PMFig. 1: Identifying Typical Power Rack & Pinion Components

Courtesy of Volkswagen United States, Inc.

ADJUSTMENTS

POWER STEERING PUMP BELT

Loosen nuts on pump mounting bracket. Turn adjuster bolt

until belt deflection is 3/8" (10 mm) at center of belt. Tighten nuts

to specification.

TESTING

HYDRAULIC SYSTEM INSPECTION

Ensure fluid level is okay. Check service belt condition and

adjustment. Ensure hoses are not kinked or leaking.

PUMP PRESSURE TEST

Install Pressure Gauge (US 1074 B) between pressure hose and

pressure line of valve housing. Start engine and let idle. Close

valve. Leave valve closed for no longer than 5 seconds. Pressure

should be within specification. See POWER STEERING SYSTEM PRESSURE

table. If pump pressure is not within specification, replace pump.

POWER STEERING SYSTEM PRESSURE TABLEÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ Pressure

Model psi (bar)

Corrado ................................. 1102-1189 (76-82)

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ STEERING GEAR INSPECTION

Page 746 of 920

STEERING GEAR - POWER RACK & PINION

Article Text (p. 3)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:23PM

Remove rack and pinion assembly. See POWER RACK & PINION

under REMOVAL & INSTALLATION. Loosen lock nut. Turn adjuster bolt

until pinion shaft can be turned by hand without binding. Hold

adjuster bolt in position while tightening lock nut.

REMOVAL & INSTALLATION

POWER STEERING PUMP

Removal

Remove alternator and pump belts. Disconnect hydraulic lines

from pump. Cap lines to prevent contamination. Remove bracket bolts.

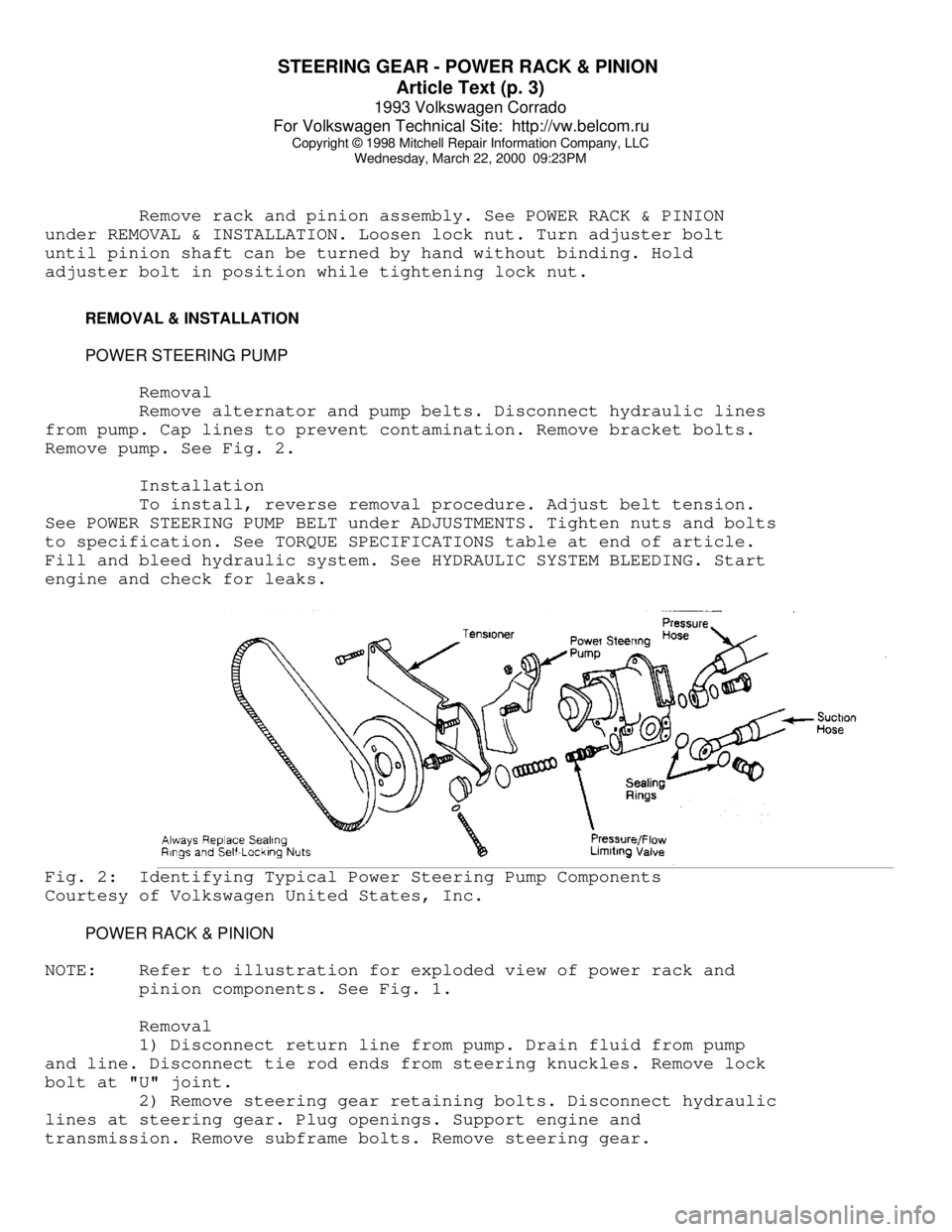

Remove pump. See Fig. 2.

Installation

To install, reverse removal procedure. Adjust belt tension.

See POWER STEERING PUMP BELT under ADJUSTMENTS. Tighten nuts and bolts

to specification. See TORQUE SPECIFICATIONS table at end of article.

Fill and bleed hydraulic system. See HYDRAULIC SYSTEM BLEEDING. Start

engine and check for leaks.Fig. 2: Identifying Typical Power Steering Pump Components

Courtesy of Volkswagen United States, Inc.

POWER RACK & PINION

NOTE: Refer to illustration for exploded view of power rack and

pinion components. See Fig. 1.

Removal

1) Disconnect return line from pump. Drain fluid from pump

and line. Disconnect tie rod ends from steering knuckles. Remove lock

bolt at "U" joint.

2) Remove steering gear retaining bolts. Disconnect hydraulic

lines at steering gear. Plug openings. Support engine and

transmission. Remove subframe bolts. Remove steering gear.

Page 756 of 920

SUSPENSION - FRONT

Article Text (p. 2)

1993 Volkswagen Corrado

For Volkswagen Technical Site: http://vw.belcom.ru

Copyright © 1998 Mitchell Repair Information Company, LLC

Wednesday, March 22, 2000 09:24PM

NOTE: See WHEEL ALIGNMENT SPECIFICATIONS & PROCEDURES article in

the WHEEL ALIGNMENT section.

WHEEL BEARING

No adjustment is required.

BALL JOINT CHECKING

Raise and support vehicle. Inspect ball joints for excessive

play and damaged rubber boots. There should be no vertical or

horizontal ball joint play. Replace ball joint if any play is present.

REMOVAL & INSTALLATION

HUB & KNUCKLE ASSEMBLY

Use exploded view illustration when removing or installing

hub and knuckle assembly. See Fig. 1.

LOWER CONTROL ARM & BALL JOINT

Removal

1) Raise and support vehicle. Remove bolt retaining ball

joint at steering knuckle. Separate ball joint from housing. Leave

control arm hanging in mounts at subframe.

2) If control arm is not to be removed and ball joint is

riveted to control arm, drill out ball joint rivets using a 9/32" (7

mm) drill. After drilling rivets, chisel off rivet heads (if

necessary). If ball joint is bolted to control arm, remove bolts.

Remove ball joint.

3) If control arm is to be removed from vehicle, remove

stabilizer bar link rod nut, washers, and bushings. Remove pivot bolt

and "U" bracket housing inner pivot pin. Slide out control arm.

NOTE: On vehicles with automatic transmission, engine may have to

be lifted slightly to gain access to pivot bolts.

Inspection

Check lower control arm bushings for excessive wear, cracks

or contamination. Replace bushings if necessary. To replace bushings,

press out worn bushing. Select new bushing and press into position.

Ensure bushing does not twist when seating into place.

Installation

Slide new ball joint into slot in control arm. Install and

tighten ball joint retaining bolts. Install lower control arm to

subframe. Install ball joint into steering knuckle. To complete

installation, reverse removal procedure. Tighten control arm bolts

with vehicle on ground. Tighten all bolts and nuts to specification.

See TORQUE SPECIFICATIONS table at end of article. Check wheel